Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

10 x 14 Horizontal Mitering Band Saw

Model MBS-1014W

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414477

Ph.: 800-274-6848 Revision G2 05/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Warnings ........................................................................................................................................................ 4

4.0 About this manual .......................................................................................................................................... 5

5.0 Specifications ................................................................................................................................................. 5

6.0 Uncrating and Cleanup .................................................................................................................................. 6

7.0 Installation ...................................................................................................................................................... 6

8.0 Assembly ........................................................................................................................................................ 6

9.0 Electrical Connections .................................................................................................................................... 7

10.0 Controls ........................................................................................................................................................ 7

11.0 Prior to Operation ......................................................................................................................................... 7

12.0 Adjustments ................................................................................................................................................. 8

12.1 Adjusting vise square to blade ................................................................................................................. 8

12.2 Changing blade speeds ............................................................................................................................ 8

12.3 Adjusting feed rate ................................................................................................................................... 8

12.4 Changing blades ...................................................................................................................................... 8

12.5 Blade tracking adjustment ........................................................................................................................ 9

12.6 Automatic shut-off adjustment ................................................................................................................ 10

12.7 Thrust roller adjustment .......................................................................................................................... 10

12.8 Guide roller adjustment .......................................................................................................................... 10

12.9 Bow weight adjustment .......................................................................................................................... 10

12.10 Angle adjustment .................................................................................................................................. 11

12.11 Vise adjustment .................................................................................................................................... 11

13.0 Maintenance ............................................................................................................................................... 12

13.1 Lubrication .............................................................................................................................................. 12

14.0 Replacement Parts ..................................................................................................................................... 12

14.1.1 Base and Bed Assembly – Exploded View ......................................................................................... 13

14.1.2 Bow Assembly – Exploded View ......................................................................................................... 14

14.1.3 Parts List for MBS-1014W Band Saw ................................................................................................. 15

14.2.1 Gear Speed Reducer Assembly – Exploded View .............................................................................. 20

14.2.2 Gear Speed Reducer Assembly – Parts List ....................................................................................... 21

15.0 Electrical Connections ................................................................................................................................ 22

15.1.1 Electrical Connections – 1 Phase ........................................................................................................ 22

15.1.2 Electrical Panel Layout – 1 Phase ....................................................................................................... 22

15.2.1 Electrical Connections – 3 Phase ........................................................................................................ 23

15.2.2 Electrical Panel Layout – 3 Phase ....................................................................................................... 23

3

Page 4

3.0 Warnings

1. Read and understand the e ntire instruction

manual before attempting assembly or

operation.

2. All JET bandsaws are designed and

intended for use by properly trained and

experienced personnel only. If you are not

familiar with the proper and safe operation

of a bandsaw, do not use until proper

training and knowledge have been obtained

3. Always wear approved safety glasses/face

shields while using this machine. (Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.)

4. Make certain the machine is properly

grounded.

5. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll up

sleeves past the elbows. Remove all loose

clot hing and conf ine long hair. Do NOT wear

gloves.

6. Keep the floor around the machine clean and

free of scrap material, oil and grease.

7. Keep machine guards in place at all times

when the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

8. Do NOT over reach. Maintain a balanced

stance at all times so that you do not fall or

lean against blades or other moving parts.

9. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

10. Use the right tool. Do not force a tool or

attachment to do a job for which it was not

designed. The right tool will do the job better

and more safely.

11. Replace warning labels if they become

obscured or removed.

12. Make certain the switch is in t he OFF position

before connecting the machine to the power

supply.

13. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

14. Keep visitors a safe distance from the work

area.

15. Use recommended accessories; improper

accessories may be hazardous.

16. Form a habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

17. Always keep hands a nd fingers away from the

blade when the machine is running.

18. Never hand-hold the material. Always use the

vise and clamp it securely.

19. Keep belt guard, blade guards, and wheel

covers in place and in working order.

20. Always provide adequate support for lo ng and

heavy material.

21. Use a sharp blade and keep machine clean for

best and safest performance.

22. Failure to comply with all of these warnings

may ca use serio u s i njury.

23. WARNING: Some dust created by power

sanding, sawing, grinding, drilling and other

construction activities contain chemicals

known to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

•

Crystalline silica from bricks, cement and

other masonry products.

•

Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as face or dust masks

that are specifically designed to filter out

microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or even fatal, injury.

4

Page 5

4.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

MBS-1014W Horizontal Saw. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide years of trouble-free operation if used in accordance with t he instructions as set forth in

this document.

If there are questions or comments, please contact your local supp lier or JET. JE T can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

5.0 Specifications

Model number ...................................................... MBS-1014W-1....................................... MBS-1014W-3

Stock Number.................................................................. 414479.................................................. 414477

Capacity:

Round at 90° (in.) ................................................................. 10.......................................................... 10

Round at 45° (in.) ................................................................... 9............................................................ 9

Rectangle at 90° (in.) .................................................... 10 x 14................................................... 10 x 14

Rectangle at 45° (in.) .................................................. 9 x 8-1/2.................................................9 x 8-1/2

Blade Provided (i n.) .................................. 1 x 0. 035 x 130, 4/6VT........................... 1 x 0.035 x 130, 4/6VT

Blade Wheel Diameter (in.) ...................................................... 14.......................................................... 14

Blade Speeds (SFP M) ......................................82, 132, 210, 330................................... 82, 132, 210, 330

Motor .......................................................... 2HP, 1PH, 230V only.............................. 3HP, 3PH, 230/460V

(Prewired 230V)

Throat Depth (in.) .............................................................. 10-1/2.................................................... 1 0-1/2

Head Swivels......................................................................... 45°......................................................... 45°

Lowered Height (in.) ................................................................ 43.......................................................... 4 3

Raised Height (in.) ................................................................... 73.......................................................... 73

Bed Hei ght (in.) ....................................................................... 25.......................................................... 25

Floor Space Requi r ed (i n.) ............................................... 26 x 69................................................... 26 x 69

Net Weigh t (lb ) ...................................................................... 948........................................................ 948

Shipping Weigh t (lb) ............................................................ 1102...................................................... 1102

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

5

Page 6

6.0 Uncrating and Cleanup

NOTE: Read and understand the entire manual

before attempting setup or operation.

1. Finish uncrating the saw and inspect for

damage. Should any have occurred, contact

your loc a l d i st ribut o r.

2. Remove all bolts attaching machine to

shipping base.

3. Leave packing material between vice clamps

and saw head intact until bandsaw has been

lifted to its final position .

4. Clean all rust protected surfaces with kerosene

or diesel oil to remove protective coating. Do

not use gasoline, paint thinner, mineral spirit s,

etc. These may damage painted surfaces.

5. Lubricate all slideway s with SAE 10W oil.

7.0 Installation

For best performance, the bandsaw should be

located on a solid and level foundation. Allow room

for servicing and f or m oving large stock around the

bandsaw when deciding a location for the machine.

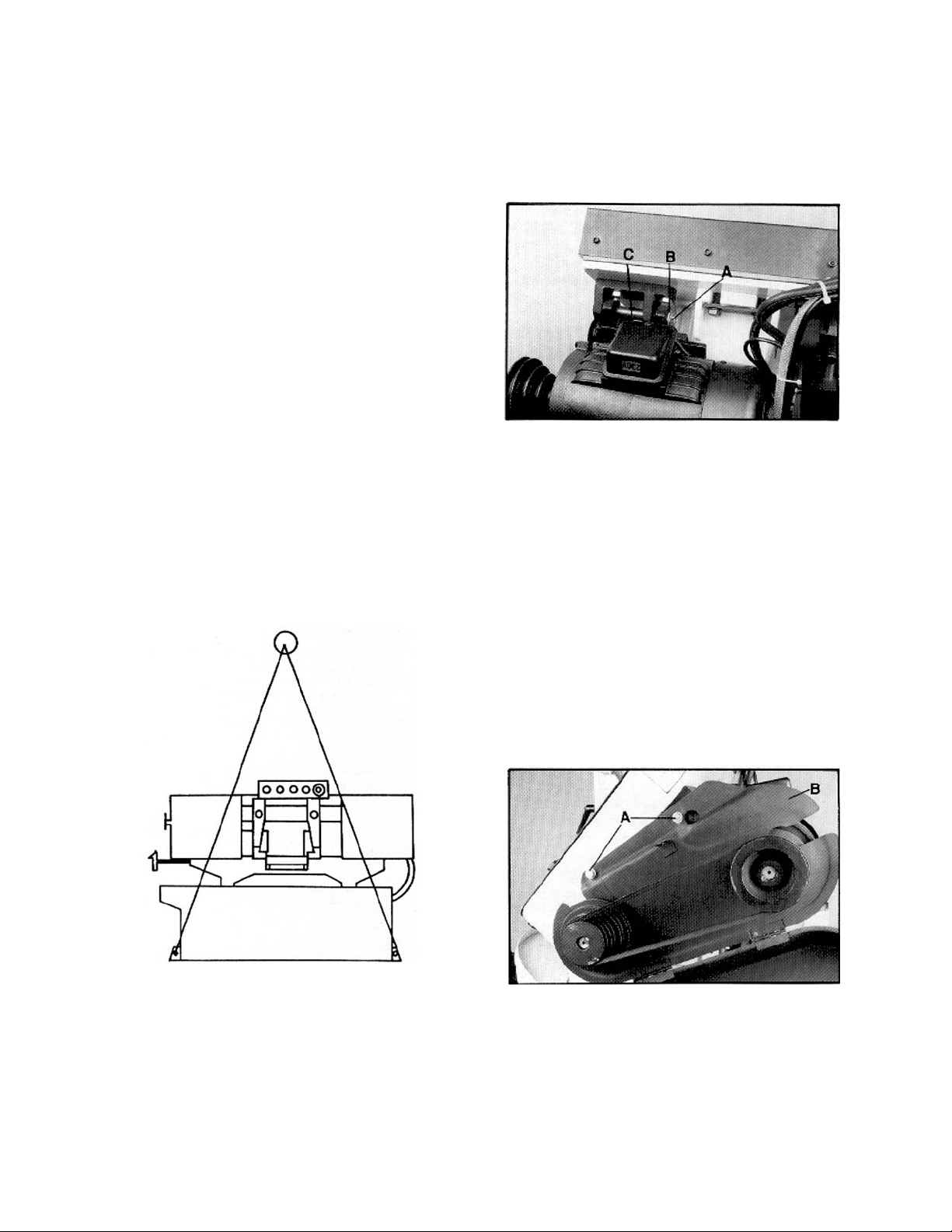

1. Using lifting straps that are isolated from the

bandsaw’s finished surfaces, place machine in

desired location. See Figure 1 for strap

placement.

8.0 Assembly

1. Unbolt the motor assembly from the shipping

crate bottom.

2. Remove nut (A, Figure 2) and washer (B,

Figure 2) from the motor support shaft. Note:

Picture shows motor already in place.

Figure 2

3. Remove shaft (C, Figure 2) from the motor

mount bracket.

4. Carefully lift motor and line up holes in the

motor mounting place and the motor bracket.

5. Slide motor support shaft into motor mount

bracket to hold the motor in place.

6. Fasten shaft with nut and washer.

7. Loosen strain relief nut on the motor junction

box. Remove the junction box cover. Insert

wire though strain relief and wire to the

terminal strip using the diagram on the junction

box cover. Tighten the strain relief nut and

replace the junction box cover.

8. Remove two hex cap bolts and washers (A,

Figure 3) from the right side of the saw arm.

Figure 1

2. Install f our leveling bo lts with lock nuts o n bot h

sides of the base as shown in the parts

breakdown in sect. 14.1.1, items #2 and #3.

3. Place a level on the table surface and check

side to side and front to back.

4. Adjust leveling screws until machine is level in

both directions and tighten locking nuts.

Figure 3

9. Slide belt cover (B, Figure 3) around pulley

shafts and attach to saw with two hex cap

bolts and two washers.

10. Lift motor and place v-belt around both pulleys.

Lower motor.

6

Page 7

11. Tension the v-belt by pushing down on the

motor and tightening the lock handle on the

motor tilt plate. Correct tension is achieved

when finger pressure between the two pulleys

causes approximately a 1/2” deflection.

12. Close pulley cover door and fasten with lock

knob.

• Control Transformer – Open electrical

panel on rear of base and switch primary

wire on transformer from 230V to 460V.

Machine must always be correctly grounded.

Note: the pow er co rd end w ill have to be chang ed

to one that is rated 460V when changing voltage.

13. Fasten work stop rod (#241, sect. 14.1.1) to

saw bed (#11A) by inserting into bed and

turning clockwise until tight. Place work stop

bracket (#16) onto stop rod (#241) and t ighten

lock handle (#20). Attach stop screw (#19) to

stop bracket (#16) with lock handle (#18) and

tighten.

9.0 Electrical Connections

All electrical connections

must be done by a qualified electrician. Failure

to comply may result in serious injury.

Disconnect machine from the

power source before changing any voltage

components. Failure to comply may cause

serious injury.

The MBS-1014W bandsaw is rated at 3HP, 3

phase 230/460V, prewired 230V; or 2HP, single

phase, 230V only. Confirm power available at t he

saw’s location is the same as the saw is wired. To

switch the MBS-1014W from 230V to 460V, the

following item s will have to be changed:

10.0 Controls

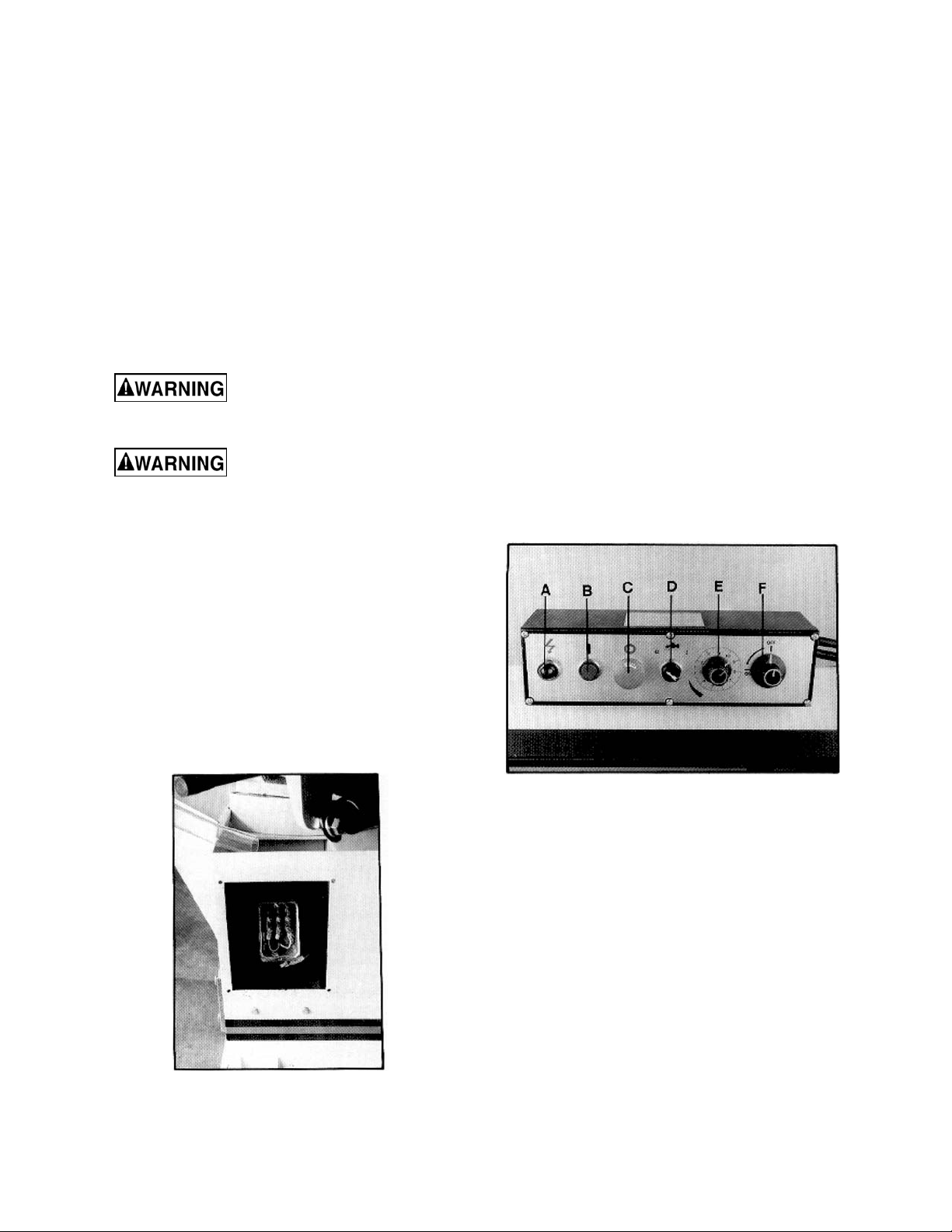

See Figure 5.

Power Indicator Light (A) – lit whenever machine

is running.

Start Button (B) – depress to start bandsaw.

Emergency Stop Button (C) – depress to

immediately stop all machine functions.

Coolant Switch (D) – turn arrow to “I” to turn on

flow of coolant. Turn arrow to “O” to stop flow of

coolant.

Cutting Pressur e Control (E) – t urn clockwise to

decrease cutting pressure. Turn counterclockwise

to increase cutting pressure.

Hydraulic On-Off Valve (F) – turns hydraulic

cylinder on and off.

• Main Motor – follow diagram inside

junction box cover.

• Coolant Pump – Remove access panel

on right side of saw, remove junction box

cover on pump, and follow diagram inside

junction box cover. See Figure 4.

Figure 4

Figure 5

11.0 Prior to Operation

1. Check that blade tooth direction matches

diagram on blade guides.

2. Check to see that b lade is properly seated on

wheels after applying correction tension

(approximately 25,000 lbs.)

3. Set blade holder guides for approximately

0.003” to 0.005” clearance between t he guides

and blade.

4. Check for slight clearance between back-up

rollers and back of blade.

5. Position blade guides as close to work piece

as possible.

7

Page 8

6. Select proper speed a nd feed rate f or material

being cut. Consult Machinery’s Handbook or

similar source for speed and feed charts.

7. Material to be cut must be securely held in

vise.

8. Check to see that coolant level is adequate

and turn on coolant pump if m aterial to be cut

requires it. Machine should be filled with four

gallons of the proper coolant mixture. Follow

the directions on the product maker’s label and

fill the coolant tank through the chip tray area.

9. Do not start cut on a sharp edge.

10. Keep machine lubricated. See “Lubrication”

section.

12.3 Adjusting feed rate

Rate of feed is adjusted by turning the cutting

pressure control knob on the control panel. Rate of

feed is important to bandsaw performance,

excessive pressure may break the blade or stall

the saw. Insufficient pressure rapidly dulls the

blade.

Material chips or shavings are the best indicator of

proper speed and pressure. The ideal chip is thin,

tightly curled, and warm to the touch. Chips that

range from golden brown to black indicate

excessive force. Blue chips indicate e xtreme heat

from too high a band speed which will shorten

blade life. Thin or powdered chips indicate

insufficient feed pressure.

12.0 Adjustments

12.1 Adjusting vise square to blade

1. Disconnect machine from power source.

2. Place a machinist’s square on the table

against the blade and the vise. The square

should lie along the entire length of the vise

and blade without a gap.

3. If adjustment is necessary, loosen bolts

holding the vise and adjust vise so square

lines up p roper ly. Tighten bolts.

4. Connect machine to the power source.

12.2 Changing blade sp eeds

Disconnect the machine from

the power source before making any repair or

adjustment. Failure to comply may cause

serious injury.

1. Disconnect machine from power source.

2. Open pulley cover b y supporti ng the belt co ver

with one hand while removing the belt cover

lock knob with the other. Lower guard gently to

its full open position.

12.4 Changing blades

Disconnect the machine from

the power source before making any repair or

adjustment (with the exception of blade

tracking). Failure to comply may cause serious

injury.

1. Disconnect machine from power source.

2. Raise saw arm approximately 6”. Hold saw

arm in place by closing cutting pressure

control valve.

3. Open both wheel covers and clean chips out of

both wheel housings. Loosen two lock knobs

below the control panel and remove upper

blade guard.

4. Loose n set screw (A, Figure 6) and lower the

blade cleaning brush.

3. Support motor with one hand while loosening

lock handle. Lower motor gently.

4. Position belt in grooves according to the speed

selection chart.

5. Tension the v-belt by pushing down on the

motor and tightening the lock handle on the

motor tilt plate. Correct tension is achieved

when finger pressure on the belt between the

two pulleys causes approximately 1/2"

deflection.

6. Close pulley cover and fasten.

7. Connect machine to the power source.

Figure 6

5. Release blade tension by turning blade

tensioning handwheel (A, Figure 7)

counterclockwise until blade is f ree.

8

Page 9

Figure 7

6. Loosen lock knob (A, Figure 8) and slide left

blade guide arm (B, Figure 8) to the right as far

as possible.

Figure 8

7. Rem ove old blade from both wheels and out of

each blade guide.

Even dull blades are sharp

to the skin. Use extra caution handling

bandsaw blades.

8. Install new blade making sure teeth are

pointed downward in the proper cutting

direction. If necessary, turn blade inside out.

13. Turn power off and recheck blade tension and

wire brush adjustment. If further adjustment is

necessary, disconnect saw from power source,

make adjustments, and reconnect to power.

12.5 Blade tracking adjustment

Blade tracking has been set at the factory and

should require no adjustment. If a track ing problem

occ urs, adjust the mac hine as foll ows:

Tracking adjustment is done

with the wheel covers open to observe the

blade. Use extreme caution so as not to come

into contact with the blade.

Since tracking can only be adjusted while machi ne

is running, it is suggested that this adjustment be

accomplished by qualified personnel that are

familiar with this type of adjustment and the

dangers associated with it.

1. Disconnect machine from power source.

2. Raise saw arm to its highest position and close

cutting pressure control valve to hold saw arm

in place.

3. Locate tracking adjustment plate on the back

side of the driven blade wheel.

4. Loosen the three bolts (A, F ig ure 9) located on

the top of the tracking nuts.

5. Tracking adjustment is accomplished by either

loosening or tightening three adjusting nuts (B,

Figure 9).

6. Tracking is set properly when the back of the

blade lightly touches the wheel flange. Note:

Over-tracking (allowing blade back to rub hard

against wheel flange) will damage the blade

wheels and blade.

7. Tighten locking bolts (A, Figure 9) once proper

tracking is completed.

8. Connect machine to the power source.

9. Position blade on band wheel s and tighten j ust

enough to hold blade on wheels. Make sure

back of blade rests lightly against the wheel

flange of both wheels. Twist blade slightly to

allow it to slip into guides.

10. Tension blade to appro ximately 25,000 lbs., as

indicated on the blade tension indicator found

on the tension wheel shaft housing.

11. Raise wire brush and tighten set screw to hold

brush in place.

12. Close all covers and guards and fasten

securely. Connect machine to power and run

freely for approximately two minutes.

Figure 9

9

Page 10

12.6 Automatic shut-off adjustment

The motor should shut off immediately after the

blade has cut through the material and just before

the head comes to rest on the horizontal stop bolt.

If the machine continues to run after the work piece

has been fully cut, locate and adjust the micro

switch mounting plate down. If the machine s hut s

off before the work piece has been completely cut,

move the micro switch mounting plate up.

12.7 Thrust roller a djustment

1. Disconnect machine from power source.

2. Loosen two hex socket cap screws (A, Figure

10).

3. Move guide seat (B, Figure 10) up or down

until a clearance of 0.003” to 0.005” between

back of blade and thrust roller is obtained.

4. Tighten two he x socket cap screws (A , Figure

10).

5. Repeat for other blade guide assembly.

6. Connect machine to power source.

Figure 10

12.8 Guide roller adjustment

1. Disconnect machine from power source.

Figure 11

12.9 Bow weight adjustment

Bow weight is one of the most important

adjustments of the saw. If the bow weight is not set

properly, one can expect poor performance,

crooked cuts, tooth stripping, stalling, and the

blade popping off the blade wheels. They hydraulic

feed rate unit will not com pensate for improper bow

weight. Bow weight has been set at the factory and

should not need any adjustment. If adjustment is

necessary:

1. Disconnect machine from power source.

2. Turn on hydraulic valve (F, Figure 5).

3. Tur n cutting pressure contro l valve (E, Figure

5) counterclockwise until it stops.

4. Place one end of a fish-type scale under the

blade tension handle and lift the saw with t he

other end. Scale should indicate approximately

22-24 lbs.

5. Adjust tension to approximately 22-24 lbs. by

turning the adjustable C-bolt found at the end

of the coil spring on the rear of the bandsaw.

See Figure 12.

6. Connect the machine to the power source.

2. Loosen blade guides (A, Figure 11) by

loosening screws (B, Figure 10). Slide blade

guides away from blade.

3. Loosen locking screws (C, Figure 11) by using

a hex wrench.

4. Adjust the eccentric bushings with a

combination wrench until the ball beari ngs are

snug to the blade. Note: Blade should travel

freely up and down between the ba ll bearings.

Do not pinch the blade.

5. Tighte n locking screws (C, Figure 11).

6. Slide blade guides back into contact with blade

and tighten screws (B, Figure 11).

7. Connect machine to the power source.

Figure 12

10

Page 11

12.10 Angle adjustment

To swivel the saw arm up to a 45° angle:

1. Disconnect machine from power source.

2. Pull the handle (A, Figure 13) toward the front

of the saw.

3. Rotate the upper assembly to the desired

angle.

4. Push the handle back toward the rear of the

saw to lock the upper assembly.

Figure 13

To adjust the 45° stop:

1. Disconnect machine from power source.

2. Lower saw arm completely.

3. Pull the lock lever toward the front of the saw

and push the saw arm assembly against the

45° stop.

4. Place a 45° angle sq uare on t he blade and the

fixed vise jaw.

5. Loosen the lock nut (A, Figure 15).

6. Adjust the hex cap screw (B, Figure 15) until

the blade is at a 90° angle to the fixed vise

jaw.

7. Tighten the lock nut (A, Figure 15).

To adjust the 90° stop:

1. Disconnect machine from power source.

2. Lower saw arm completely.

3. Pull the lock lever toward the front of the saw

and pull the saw arm assembly against the 90°

stop.

4. Place a 90° square on the blade a nd the fixed

vise jaw.

5. Loosen the lock nut (A, Figure 14).

6. Adjust the hex cap screw (B, Figure 14) until

the blade is at a 90° angle to the fixed vise

jaw.

7. Tighten the lock nut (A, Figure 14).

Figure 15

12.11 Vise adjustment

To position the movable vise jaw:

1. Turn vise handwheel 1/2 turn counter

clockwise.

2. Move rack block (B, Figure 16) to desired

location by sliding along the bed. Place the

rack block onto the rack.

3. Tur n the handwheel to tighten th e vise.

Figure 14

Figure 16

11

Page 12

To adjust the vise for angle cutting:

To change gear box lubricant:

1. Loosen adjustable handle (index #219,221) to

desired location.

2. Set the vise to desired angle, reinstall nuts and

tighten the nut and bolt assemblies.

3. Adjust the movable vise parallel to the fixed

vise by loosening bolt (A, Figure 17), adjusting

to parallel, and tightening bolt.

Figure 17

13.0 Maintenance

1. Disconnect machine from power source.

2. Open drain plug and allow lubricant to drain

completely. Drain plug may be found on lower

rear of gear case. Remove drain plug with a

hex wrench.

3. Replace drain plug.

4. Remove filler cap (A, F igure 18) and fill gear

box wit h 50 we ight gea r oil u ntil le vel rea ches

dot in middle of sight glass.

5. Replace filler cap.

6. Connect machine to the power source.

Use a light machine oil to lubricate all other moving

parts as needed.

Keep bandsaw and motor clean.

13.1 Lubrication

All ball bearings are permanently lubricated and

sealed. They require no further lubrication.

The gear box lubricant should be changed after the

first 50 hours of operation. Change lubricant from

then on every 250 hours of operation.

To check level of gear box lubricant, place saw arm

in down position and allow a few minutes to pass

so that oil drains down. Check level in sight glass

on side of gear casing. Correct level is the dot in

the middle of sight glass.

14.0 Replacement Parts

Figure 18

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

12

Page 13

14.1.1 MBS-1014W – Base and Bed Assembly – Exploded View

13

Page 14

14.1.2 MBS-1014W – Bow Assembly – Exploded View

14

Page 15

14.1.3 Parts List for MBS-1014W Band Saw

Index No Part No Description Size Qty

1A .............. MBS1014W-1A ......... Base......................................................................... ...................................... 1

2 ................ Ts-1492071 ............... Hex Cap Bolt............................................................ M12x 70 ......................... 4

3 ................ TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 4

4 ................ HBS916W-CP ........... Coolant Pump (1PH)................................................ ...................................... 1

.................. MBS1014W-CP ......... Coolant Pump (3PH)................................................ ...................................... 1

5 ................ TS-15311051 ............ Pan Head Screw ...................................................... M6x16 ........................... 2

8 ................ HBS916W-08 ............ Hose ........................................................................ ...................................... 1

9 ................ HBS916W-09 ............ Coolant Gauge......................................................... ...................................... 1

9-1 ............. TS-1491041 .............. Hex Cap Bolt............................................................ M10x30 ......................... 2

11A ............ MBS1014W-11A ....... Bed .......................................................................... ...................................... 1

11B ............ MBS1014W-11B ....... Bed (s/n 01021646 and lower)................................. ...................................... 1

11BN ......... MBS1014W-11BN ..... Bed (s/n 01021647 and higher) ............................... ...................................... 1

15 .............. HBS916 W-16 ............ Stop Bracket ............................................................ ...................................... 1

18 .............. HBS916 W-18 ............ Lock Handle ............................................................. ...................................... 1

19 .............. HBS916W-19 ............ Work Stop ................................................................ ...................................... 1

20 .............. HBS916 W-20 ............ Lock Knob ................................................................ ...................................... 1

21 .............. HBS1018 W-21 .......... Handwheel Assembly .............................................. ...................................... 1

22 .............. HBS1018W-22 .......... Lead Screw Seat ..................................................... ...................................... 1

23 .............. TS-1490051 .............. Hex Cap Bolt............................................................ M8x30 ........................... 4

23-1 ........... TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 2

24A ............ MBS1014W-24A ....... Lead Screw (s/n 01021646 and lower) .................... 780mm .......................... 1

24AN ......... MBS1014W-24AN ..... Lead Screw (s/n 01021647 and higher)................... 530mm .......................... 1

25 .............. HBS916W-25 ............ Lead Screw Bracket (s/n 903358 and lower) ........... ...................................... 1

26 .............. HBS916W-26 ............ Acme Nut (Re:HBS916W-26A)(s/n 903358 and lower) .................................. 1

.................. HBS916W-26A .......... Acme Nut Assembly (inc. 26,27,28,29)(s/n 903358 and lower)...................... 1

27 .............. HBS916W-27 ............ Button (Re:HBS916W-26A)(s/n 903358 and lower) ...................................... 1

28 .............. HBS916W-28 ............ Retain er (Re:HBS916W-26A)(s/n 903358 and lower) .................................... 2

29 .............. HBS916W-29 ............ Pan Head Screw (Re:HBS916W-26A)(s/n 903358 and low er)....................... 1

30 .............. HK-2516-2RS ............ Needle Bearing ........................................................ ...................................... 2

31 .............. HBS1018W-31 .......... Torsion Spring ......................................................... ...................................... 1

32 .............. HBS916W-32 ............ Pivo t Shaft ............................................................... ...................................... 1

32-1 ........... TS-1550041 .............. Washer .................................................................... M12 ............................... 2

32-2 ........... HBS916 W-32-2 ......... Bolt w/ Zerk Fitting ................................................... ...................................... 2

33 .............. HBS1018 W-33 .......... Pivot Bracket............................................................ ...................................... 1

34 .............. TS-1540081 .............. Nut ........................................................................... M12 ............................... 1

35 .............. TS-1550081 .............. Washer .................................................................... 12mm ............................ 1

36 .............. TS-1492041 .............. Hex Cap Bolt............................................................ M12x40 ......................... 1

37 .............. HBS916W-37 ............ Torsion Spring Shaft ................................................ ...................................... 1

38 .............. HBS916W-38 ............ C-Ri ng...................................................................... S-22 .............................. 1

39 .............. TS-1490041 .............. Hex Cap Bolt............................................................ M8x25 ........................... 1

40 .............. HBS1018W-40 .......... Motor Tilt Plate......................................................... ...................................... 1

41 .............. HBS916W-41 ............ Limit Switch Plate .................................................... ...................................... 1

42 .............. TS-1550061 .............. Washer .................................................................... 8mm .............................. 2

43 .............. TS-1490031 .............. Hex Cap Bolt............................................................ M8x20 ........................... 2

44 .............. TS-1482021 .............. Hex Cap Screw ........................................................ M6x12 ........................... 6

45 .............. HBS916 W-45 ............ Limit Switch.............................................................. ...................................... 1

47 .............. HBS1018W-47A ........ Cylinder Pin ............................................................. ...................................... 1

48 .............. HBS916W-48 ............ C-Ri ng...................................................................... S-20 .............................. 1

49 .............. HBS916W-49 ............ C-Ri ng...................................................................... S-25 .............................. 2

51 .............. HBS1018W-51 .......... Hydraulic Cylinder Assembly ................................... ...................................... 1

52 .............. HBS916W-52 ............ Cylin der Pin ............................................................. ...................................... 1

53 .............. HBS1018W-53 .......... Hydrauli c Mounting Plate - Top ............................... ...................................... 1

53-1 ........... TS-1551071 .............. Lock Washer ............................................................ 10mm ............................ 4

53-2 ........... TS-1491041 .............. Hex Cap Bolt............................................................ M10x30 ......................... 2

54 .............. TS-1492051 .............. Hex Cap Bolt............................................................ M12x50 ......................... 2

55 .............. TS-1550081 .............. Washer .................................................................... 12mm ............................ 2

56 .............. HBS916W-56 ............ Plate......................................................................... ...................................... 1

15

Page 16

Index No Part No Description Size Qty

57 .............. TS-0561051 .............. Hex Nut .................................................................... 1/2" ................................ 2

58 .............. HBS916 W-58 ............ Spring Bracket ......................................................... ...................................... 1

59 .............. HBS916W-59 ............ Adjustable C-Bolt ..................................................... ...................................... 1

60 .............. HBS1018W-60 .......... Spri ng ...................................................................... ...................................... 1

62 .............. TS-1492041 .............. Hex Cap Bolt............................................................ M12x40 ......................... 2

63-1 ........... TS-1551081 .............. Lock Washer (s/n 0202755 and lower) .................... 12mm ............................ 6

.................. TS-1551081 .............. Lock Washer (s/n 0202756 and higher)................... 12mm ............................ 2

65 .............. HBS916W-64 ............ Vise Jaw – left.......................................................... ...................................... 1

65-1 ........... MBS1014 W-65-1....... Extension Plate ........................................................ ...................................... 1

65-2 ........... MBS1014 W-65-2....... Hex Socket Cap Screw ............................................ ...................................... 2

65-3 ........... MBS1014 W-65-3....... Lock Washer ............................................................ ...................................... 2

69 .............. TS-1503011 .............. Hex Socket Cap Bolt ............................................... M6x8 ............................. 8

70 .............. HBS916W-70 ............ Electrical Panel Cover ............................................. ...................................... 1

71 .............. HBS916W-71 ............ Fuse Block ............................................................... ...................................... 2

72 .............. HBS1018W-72 .......... Magnetic Switch (1PH) ............................................ ...................................... 1

.................. MBS1014W-72 .......... Magnetic Switch (3PH) ............................................ ...................................... 1

73 .............. HBS1018W-73 .......... Transformer (1PH) ................................................... ...................................... 1

.................. MBS1014W-73 .......... Transformer (3PH) ................................................... ...................................... 1

74 .............. HBS916W-74 ............ Transformer Strip ..................................................... ...................................... 1

75 .............. HBS916W-75 ............ Handl e ..................................................................... ...................................... 1

76 .............. TS-1534051 .............. Pan Head Screw ...................................................... M6x16 ........................... 4

77 .............. TS-1482021 .............. Hex Cap Bolt............................................................ M6x12 ........................... 2

77-1 ........... TS-1551041 .............. Lock Washer ............................................................ M6 ................................. 2

77-2 ........... TS-1550041 .............. Washer .................................................................... M6 ................................. 2

78 .............. HBS916W-78 ............ Wire Brush Guard .................................................... ...................................... 1

79 .............. TS-1503011 .............. Hex Socket Cap Screw ............................................ M6x8 ........................... 12

.................. HBS1018W-79A ........ Adjustable Bracket Mount - rear (HBS-1018W only; not shown) .................... 1

80 .............. HBS1018W-80A ........ Blade Wheel Cover - right........................................ ...................................... 1

81 .............. TS-1550041 .............. Washer .................................................................... M6 ................................. 4

82 .............. HBS916 W-82 ............ Bushing .................................................................... ...................................... 1

83 .............. HBS916W-83 ............ Wash er .................................................................... ...................................... 1

84 .............. MBS1018W-84 .......... Drive Wheel ............................................................. ...................................... 1

85 .............. .................................. Blade (local purchase) ............................................. ...................................... 1

86 .............. HBS916W-86 ............ Hose ........................................................................ ...................................... 1

87 .............. TS-1533031 .............. Pan Head Screw ...................................................... M5x10 ........................... 2

88 .............. HBS916W-88 ............ Filter Screen ............................................................ ...................................... 1

89 .............. TS-1492031 .............. Hex Cap Bolt............................................................ M12x35 ......................... 5

89-1 ........... TS-1551081 .............. Lock Washer ............................................................ 12mm ............................ 4

90 .............. HBS916 W-90 ............ Lock Knob ................................................................ ...................................... 4

92 .............. HBS1018W-92 .......... Blade Wheel Box - right ........................................... ...................................... 1

93 .............. HBS1018W-93 .......... Connector ................................................................ .......... ............................ 1

94 .............. HBS1018W-94 .......... Gear Box Assembly (can only order entire assembly).................................... 1

95 .............. HBS916W-95 ............ Key ........................................................................... 7mm .............................. 1

96 .............. HBS1018W-96 .......... Pulley Cover ............................................................ ...................................... 1

96-1 ........... HBS916 W-96-1 ......... Lock Knob ................................................................ ...................................... 1

97 .............. HBS1018W-97 .......... Gear Box Pulley ....................................................... ...................................... 1

98 .............. VB-A37 ...................... V-Belt ....................................................................... ...................................... 1

99 .............. HBS1018W-99 .......... Motor Pulley ............................................................. ...................................... 1

100 ............ TS-1482031 .............. Hex Cap Bolt............................................................ M8x16 ........................... 4

100-1 ......... TS-1550061 .............. Washer .................................................................... M8 ................................. 2

100-2 ......... TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 2

101 ............ HBS916W-101 .......... Hos e ........................................................................ ...................................... 1

101-1 ......... HBS916W-101-1 ....... Hose ........................................................................ ...................................... 1

102 ............ HBS916W-102 .......... Support Shaft ........................................................... ...................................... 1

102-1 ......... TS-1550081 .............. Washer .................................................................... M12 ............................... 1

102-2 ......... TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 1

103 ............ TS-1492021 .............. Hex Cap Bolt (S/N 0202755 and lower)................... M12 x30 ......................... 5

.................. TS-1492021 .............. Hex Cap Bolt (S/N 0202756 and higher) ................. M12x30 ......................... 1

104 ............ HBS916W-104 .......... Motor Moun t Bracket ............................................... ...................................... 1

105 ............ HBS1018W-105A ...... Column .................................................................... ...................................... 1

16

Page 17

Index No Part No Description Size Qty

106 ............ TS-1506011 .............. Hex Socket Cap Screw ............................................ M12x 20 ......................... 6

107 ............ HBS916W-107 .......... Locking Handle ........................................................ ...................................... 1

108 ............ TS-1550061 .............. Washer .................................................................... 8mm .............................. 1

109 ............ TS-1490081 .............. Hex Cap Bolt............................................................ M8x45 ........................... 4

109-1 ......... TS-1550061 .............. Washer .................................................................... M8 ................................. 4

110 ............ HBS916W-110 .......... Motor Mount Pl ate ................................................... ...................................... 1

111 ............ HBS1018W-111 ........ Motor........................................................................ 2HP, 1PH, 230V only .... 1

.................. MBS1014W-111 ........ Motor........................................................................ 3HP, 3PH, 230/460V..... 1

.................. HBS1018W-111A ...... Capacitor (not shown).............................................. 400MFD, 125VAC ......... 1

.................. HBS1018W-111B ...... Capacitor Cover (not shown) ................................... ...................................... 1

112 ............ TS-1550061 .............. Washer .................................................................... M8 ................................. 4

112-1 ......... TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 4

113 ............ TS-1540061 .............. Hex Nut .................................................................... M8 ................................. 4

114 ............ HBS916W-114 .......... Key ........................................................................... 7mm .............................. 1

115 ............ TS-1550081 .............. Washer .................................................................... M12 ............................... 1

116 ............ TS-1504041 .............. Hex Socket Cap Screw ............................................ M8x20 ........................... 1

117 ............ HBS1018W-117A ...... Blade Wheel Cover - left .......................................... ...................................... 1

118 ............ BB-608VV ................. Ball Bearing ............................................................. ...................................... 2

119 ............ TS-1492011 .............. Hex Cap Bolt............................................................ M12x25 ......................... 2

120 ............ TS-1550081 .............. Washer .................................................................... M12 ............................... 1

121 ............ BB-6205Z .................. Ball Bearing ............................................................. ...................................... 3

122 ............ MBS1014W-122 ........ Idler Wheel............................................................... ...................................... 1

123 ............ HBS1018W-123A ...... Blade Guard............................................................. ...................................... 1

123-1 ......... TS-1550061 .............. Washer .................................................................... M8 ................................. 1

123-2 ......... TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 1

123-3 ......... TS-1490021 .............. Hex Cap Bolt............................................................ M8x16 ........................... 1

124 ............ HBS916W-124 .......... Guide Bracket - left .................................................. ...................................... 1

.................. HBS916W-124A ........ Guide Bracket Assembly - left ................................. ...................................... 1

124-1 ......... TS-1504031 .............. Hex Socket Cap Screw ............................................ M8x16 ........................... 6

125 ............ TS-1540061 .............. Washer .................................................................... M8 ................................. 4

126 ............ BB-6201VV ............... Ball Bearin g ............................................................. ...................................... 8

127 ............ HBS916W-127 .......... Eccentric Sleeve (outside) ....................................... ...................................... 2

127-1 ......... HBS1018W-127-1 ..... Sleeve ( inside, not shown)....................................... ...................................... 2

128 ............ TS-1551061 .............. Lock Washer ............................................................ M8 ................................. 4

129 ............ TS-1504091 .............. Hex Socket Cap Screw ............................................ M8x45 ........................... 4

130 ............ TS-1503071 .............. Hex Socket Cap Screw ............................................ M6x30 ........................... 4

130-1 ......... TS-1550041 .............. Washer .................................................................... M6 ................................. 8

131 ............ HBS916W-131 .......... Blade Guide ............................................................. ...................................... 4

132 ............ TS-1504081 .............. Hex Socket Cap Screw ............................................ M8x40 ........................... 4

133 ............ TS-1551081 .............. Lock Washer ............................................................ M8 ................................. 4

133-1 ......... TS-1550081 .............. Washer (HBS-916W) ............................................... M8 ................................. 4

134 ............ HBS1018W-134A ...... Adjustable Bracket ................................................... ...................................... 1

135 ............ HBS1018W-135 ........ Scale ........................................................................ ...................................... 1

136 ............ TS-1505031 .............. Hex Socket Cap Screw ............................................ M10x 25 ......................... 2

137 ............ HBS1018W-137 ........ Slide ......................................................................... ...................................... 1

138 ............ HBS1018W-138 ........ Blade Bracket - left .................................................. ...................................... 1

139 ............ TS-1492021 .............. Hex Cap Bolt............................................................ M12x30 ......................... 4

139-1 ......... TS-1551081 .............. Lock Washer ............................................................ M12 ............................... 4

141 ............ MBS1014W-141 ........ Knob ........................................................................ ...................................... 2

143 ............ TS-1524021 .............. Set Screw ................................................................ M8x10 ........................... 4

144 ............ HBS1018W-144 ........ Blade Bracket - right ................................................ ...................................... 1

145 ............ TS-1482011 .............. Hex Cap Bolt............................................................ M6x10 ........................... 1

146 ............ TS-1550041 .............. Washer .................................................................... M6 ................................. 1

147 ............ HBS916W-147 .......... Wire Brush ............................................................... ...................................... 1

148 ............ HBS916W-148 .......... Wire Brush Rod ....................................................... ...................................... 1

149 ............ HBS1018W-149 ........ Guide Bracket - right ................................................ ...................................... 1

.................. HBS1018W-149A ...... Guide Bracket Assembly - right ............................... ...................................... 1

150 ............ HBS916W-150 .......... Spri ng ...................................................................... ...................................... 1

152 ............ TS-1540071 .............. Hex Nut .................................................................... M10 ............................... 2

154 ............ HBS1018W-154A ...... Adjustable Bracket - right......................................... ...................................... 1

155 ............ TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 1

17

Page 18

Index No Part No Description Size Qty

156 ............ MBS1014W-156 ........ Hex Cap Bolt with Rubber Stopper .......................... M12x60 ......................... 1

157 ............ HBS1018W-157A ...... Blade Guard............................................................. ...................................... 1

157-1 ......... HBS1018W-157-1 ..... Blade Guard - down ................................................. ...................................... 1

158 ............ HBS916W-158 .......... Lock Knob ................................................................ ...................................... 2

159 ............ TS-1523021 .............. Set Screw ................................................................ M6x8 ............................. 1

160 ............ HBS916W-160 .......... Adjusting Valve ........................................................ ...................................... 2

160-1 ......... HBS916W-160-1 ....... Clamp ...................................................................... ...................................... 2

160-2 ......... TS-1551041 .............. Lock Washer ............................................................ M6 ................................. 4

160-3 ......... TS-1482021 .............. Hex Cap Bolt............................................................ M6x12 ........................... 4

161 ............ HBS916W-161 .......... Power Indicator Light ............................................... ...................................... 1

162 ............ HBS916 W-162 .......... Start Switch.............................................................. ...................................... 1

163 ............ HBS916W-163 .......... Stop Switch .............................................................. ...................................... 1

164 ............ HBS916 W-164 .......... Pump Switch ............................................................ ...................................... 1

165 ............ HBS916W-165S ........ Feed Control – On/Off Valve (S/N 912484 and l ower 1014W) ....................... 1

.................. HBS916W-165S-1..... Speed Control – On/Off Valve (S/N 912484 and lower 1014W) ..................... 1

.................. HBS916W-165SP ..... Plate (n ot shown)(S/N 912484 and low er 1014W) .. ...................................... 1

165N .......... HBS916W-165N........ Feed Con trol - On/Off Valve (S/N 912485 and higher 1014W) ..................... 1

.................. HBS916W-165N-1 .... Plate (not shown)(S/N 912485 and higher 1014W) . ...................................... 1

166 ............ HBS916W-166 .......... Connecting Tube ..................................................... ...................................... 1

166-1 ......... HBS916 W-166-1 ....... Hose Clamp ............................................................. ...................................... 3

168 ............ HBS916W-168 .......... Control Box .............................................................. ...................................... 1

169 ............ HBS916W-169 .......... Control Panel ........................................................... ...................................... 1

170 ............ TS-1533031 .............. Pan Head Screw ...................................................... M5x10 ........................... 6

171 ............ HBS1018W-171 ........ Wheel Box - left ....................................................... ...................................... 1

172 ............ HBS916W-172 .......... Han dle ..................................................................... ...................................... 1

173 ............ TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 2

175 ............ TS-1533031 .............. Pan Head Screw ...................................................... M5x10 ........................... 2

176 ............ HBS916W-176 .......... Indicator Scale ......................................................... ...................................... 1

177 ............ HBS916W-177 .......... Slide Bracket............................................................ ...................................... 1

178 ............ HBS916W-178 .......... Tension Shaft........................................................... ...................................... 1

179 ............ HBS916W-179 .......... Key ........................................................................... 5mm .............................. 1

180 ............ HBS916W-180 .......... Handwheel ............................................................... ...................................... 1

181 ............ HBS916W-181 .......... Lock Washer ............................................................ M22 ............................. 13

182 ............ HBS916W-182 .......... Flat Steel Washer .................................................... ...................................... 1

183 ............ HBS916W-183 .......... Tension Ind icator ..................................................... ...................................... 1

184 ............ BB-51104 .................. Thrus t Bearing ......................................................... ...................................... 1

187 ............ HBS916W-187 .......... Sli de ......................................................................... ...................................... 1

188 ............ TS-1524021 .............. Set Screw ................................................................ M8x10 ........................... 2

189 ............ HBS916W-189 .......... Ex tension Bar .......................................................... ...................................... 1

190 ............ HBS916W-190 .......... Wheel Sh aft ............................................................. ...................................... 1

191 ............ TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 1

191-1 ......... TS-1523021 .............. Set Screw ................................................................ M6x8 ............................. 3

192 ............ TS-1504051 .............. Hex Socket Cap Screw ............................................ M8x25 ........................... 4

192N .......... TS-1503021 .............. Hex Socket Cap Screw ............................................ M6x12 ........................... 2

193 ............ TS-1492011 .............. Hex Socket Cap Screw ............................................ M12x 25 ......................... 1

194 ............ HBS916W-194 .......... Gib ........................................................................... ...................................... 2

195 ............ HBS916W-195 .......... Hex Cap Screw (re: HBS916W-196) ....................... ...................................... 3

196 ............ HBS916W-196 .......... Screw Assembly ...................................................... ................ ...................... 3

196-1 ......... HBS916 W-196-1 ....... Lock Washer (re: HBS916W-196) ........................... ...................................... 3

197 ............ HBS916 W-197 .......... Hose Fitting.............................................................. ...................................... 1

198 ............ HBS916W-198 .......... Hose Clamp ............................................................. ...................................... 1

199 ............ HBS916W-199 .......... Hose Clamp ............................................................. ...................................... 1

202 ............ HBS916W-202 .......... Power Cord .............................................................. 1 PH .............................. 1

.................. MBS1014W-202 ........ Power Cord .............................................................. 3 PH .............................. 1

206 ............ HBS916W-206 .......... Speed Chart Label ................................................... ...................................... 1

207 ............ HBS916W-207 .......... Hos e ........................................................................ ...................................... 1

208 ............ HBS916W-208 .......... Hos e ........................................................................ ...................................... 1

213 ............ TS-1550071 .............. Washer .................................................................... M10 ............................... 5

214 ............ HBS1018W-214 ........ Clamp ...................................................................... ...................................... 2

215 ............ HBS1018W-215 ........ Connector ................................................................ ............ .......................... 2

216 ............ MBS1014W-216 ........ Fixed Vise Jaw......................................................... ...................................... 1

18

Page 19

Index No Part No Description Size Qty

217 ............ MBS1014W-217 ........ Cotter Pin ................................................................. ...................................... 1

218 ............ MBS1014W-218 ........ Spring Cover ............................................................ ...................................... 1

219 ............ MBS1014W-219 ........ Adjustable Handle.................................................... ...................................... 1

220 ............ MBS1014W-220 ........ Support (S/N 0202755 and lower) ........................... ...................................... 1

220A .......... MBS1014W-220A ..... Support (S/N 0202756 and higher) .......................... ...................................... 1

221 ............ MBS1014W-221 ........ Adjustable Handle.................................................... ...................................... 1

222 ............ MBS1014W-222 ........ Bracket..................................................................... ...................................... 1

223 ............ MBS1014W-223 ........ Bracket..................................................................... ...................................... 1

224 ............ MBS1014W-224 ........ Slide ......................................................................... ...................................... 1

225 ............ MBS1014W-225 ........ Guide Plate .............................................................. ...................................... 1

226 ............ MBS1014W-226 ........ Turning Slide............................................................ ...................................... 1

226A .......... MBS1014W-226A ..... Scale ........................................................................ ...................................... 1

227 ............ MBS1014W-227 ........ Bracket..................................................................... ...................................... 1

228 ............ BB-51106 .................. Thrust Bearing (S/N 0202755 and lower) ................ ...................................... 1

229 ............ MBS1014W-229 ........ Center Fixed Bracket (S/N 0202755 and lower) ...... ...................................... 1

230 ............ MBS1014W-230 ........ Turning Slide Bracket (S/N 0202755 and lo wer) ..... ...................................... 1

231 ............ MBS1014W-231 ........ Turning Slide (S/N 0202755 and lower)................... ...................................... 1

231A .......... MBS1014W-231A ..... Turning Slide (S/N 0202756 and higher) ................. ...................................... 1

232 ............ MBS1014W-232 ........ Turn Plate ................................................................ ...................................... 1

233 ............ MBS1014W-233 ........ Coolant Pump Bracket ............................................. ...................................... 1

234 ............ TS-1491061 .............. Hex Cap Bolt............................................................ M10x40 ......................... 3

235 ............ TS-1482041 .............. Hex Socket Cap Screw ............................................ M6x20 ........................... 6

236 ............ MBS1014W-236 ........ Washer .................................................................... ...................................... 1

237 ............ MBS1014W-237 ........ Lock Knob ................................................................ ...................................... 1

238 ............ MBS1014W-238 ........ Brass Fitting ............................................................. ...................................... 2

239 ............ TS-1524041 .............. Set Screw ................................................................ M8x16 ........................... 1

240 ............ TS-1550101 .............. Washer .................................................................... M16 ............................... 2

241 ............ MBS1014W-241 ........ Stop Rod .................................................................. ...................................... 1