Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Geared Head Horizontal Band Saw

Model HBS-814GH

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414466

Ph.: 800-274-6848 Revision B3 02/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to pro vi d e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Unpac king ............................................................................................................................................... 7

Contents of the Shipping Container ...................................................................................................... 7

Installation and Assembly ........................................................................................................................ 8

Installing Motor..................................................................................................................................... 8

Wheels and Leveling S tands ................................................................................................................ 8

Stock Stop ........................................................................................................................................... 8

Shut-O ff Switch .................................................................................................................................... 9

Coolant Hose ....................................................................................................................................... 9

Grounding Inst r uc tions ......................................................................................................................... 9

Extension cords ................................................................................................................................. 10

Adjustments ................................................................................................................... ....................... 1 1

Vise .......................................................................................................................... ......................... 11

Squaring Vise to Blade ....................................................................................................................... 11

Positioning the Vise............................................................................................................................ 11

Miter Cuts .......................................................................................................................................... 12

Setting Downfeed Rate ...................................................................................................................... 1 2

Blade Tension .................................................................................................................................... 12

Blade Tracking ................................................................................................................................... 12

Setting Blade Speed .......................................................................................................................... 13

Blade Guides ..................................................................................................................................... 14

Blade Replacement ............................................................................................................................ 15

Bow Stop ........................................................................................................................................... 15

Operation .............................................................................................................................................. 1 6

Troubleshooting ..................................................................................................................................... 18

Replacement Parts ................................................................................................................................ 19

Base Assembly .................................................................................................................................. 20

Bow Assembly ................................................................................................................................... 21

Parts List: HBS-814GH Band Saw...................................................................................................... 22

Gear Box Assembly ........................................................................................................................... 26

Parts List: Gear Box Assembly ........................................................................................................... 27

Electrical Control Box Assembly ......................................................................................................... 28

Parts List: Electrical Control Box Assembly ........................................................................................ 29

Electri c al Connec tions ........................................................................................................................... 30

3

Page 4

Warning

1. Read and understand the ent ire owner’s manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw is designed and i ntended for use by pr operl y tr ained and ex peri enced personnel only .

If you are not familiar with the proper and safe operation of a band saw, do not use until proper

training and knowledge have been obtai ned.

5. Do not use this b and saw for ot her than its int ended use. If used for other pur poses, JET discl aims

any real or implied warrant y and holds itself harmless f rom any injury that may result fr om that use.

6. Always wear approved safet y glasses/face shields while using this band saw. Ev eryday eyeglasses

only have impact resi stant lenses; they are not saf ety glasses.

7. Before operating this band saw, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Non- sl ip footwear or anti-ski d floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of operati on.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any m edic ation.

11. Make certain t he switc h is i n the OFF position before connect ing the machine to the power supply .

12. Make certain t he machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turni ng it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

17. Provide f or adequate space surrounding work area and non- glare, overhead lighting.

18. Keep the floor around the machine clean and free of scrap material, oil and grease.

19. Keep visit or s a safe di stanc e from the work area. Keep children away.

4

Page 5

20. Make your workshop chil d pr oof with padlocks, master switc hes or by removing starter k ey s.

21. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

22. Maintain a balanced stance at all times so that you do not f all or lean against the blade or other

moving part s. Do not over r eac h or use excessive force to perform any m ac hine operation.

23. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use recommended accessories; improper accessories may be hazardous.

25. Mai ntain tools with care. Keep bl ades sharp and clean for the best and saf est performance. Follow

instructions for lubricating and c hanging accessories.

26. Make sure the work piece is securely clamped in the vise. Never use your hand to hold the work

piece.

27. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

28. Check coolant l ev el daily. Replace dirty or weak coolant.

29. Do not stand on the machine. S eri ous i njur y c oul d oc c ur if the mac hine tips over.

30. Never leave t he m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

31. Remove loose it em s and unnecessary work pieces from the ar ea before starting the machine.

Familiariz e you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for a JET

Model HBS-814GH Horizontal Band Saw. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordanc e with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local suppli er or JET. JET can also be reached at our web site: www.jettools.com.

Specifications

Model Number ........................................................................................................................ HBS-814GH

Stock Number................................................................................................................................ 414466

Round Capacity at 90° (i n.) ...................................................................................................................... 8

Round Capacity at 45° (i n.) ................................................................................................................ 6-1/2

Rectangle Capacit y at 90° (W x H) (i n.) ................................................................................. 14 x 8; 2 x 14

Rectangle Capacit y at 45° (W x H) (i n.) ............................................................................... 6-1/2 x 6; 2 x 7

Throat Depth (in.) .................................................................................................................................... 8

Vise Swivel (deg.) .................................................................................................................................. 45

Blade Wheel Diameter (in.) .................................................................................................................... 12

Blade Speeds (SFP M) .......................................................................................................... 135, 197, 256

Bed Height (in.) ..................................................................................................................................... 26

Motor ...............................................................................................1HP, 1Ph, 110/220V (pre- wir ed 110V )

Overall Dimensions (L x W x H)(in.) ...................................................................... 51-1/2 x 18-1/8 x 44-7/8

Net Weigh t (lb s.) .................................................................................................................................. 287

Shipping Weigh t (lbs.) .......................................................................................................................... 34 2

The above specifications were current at the time this manual was published, but bec ause of our policy of

continuous impr ovement , JET reserves the r ight to change specifications at any t ime and without prior

notice, without incurring obligations.

6

Page 7

Unpacking

Open shipping container and accessory boxes,

and check for shipping damage. Report any

damage immediately to your distributor and

shipping agent. Do not discard any shipping

material until the Band Saw is assembled and

running properly.

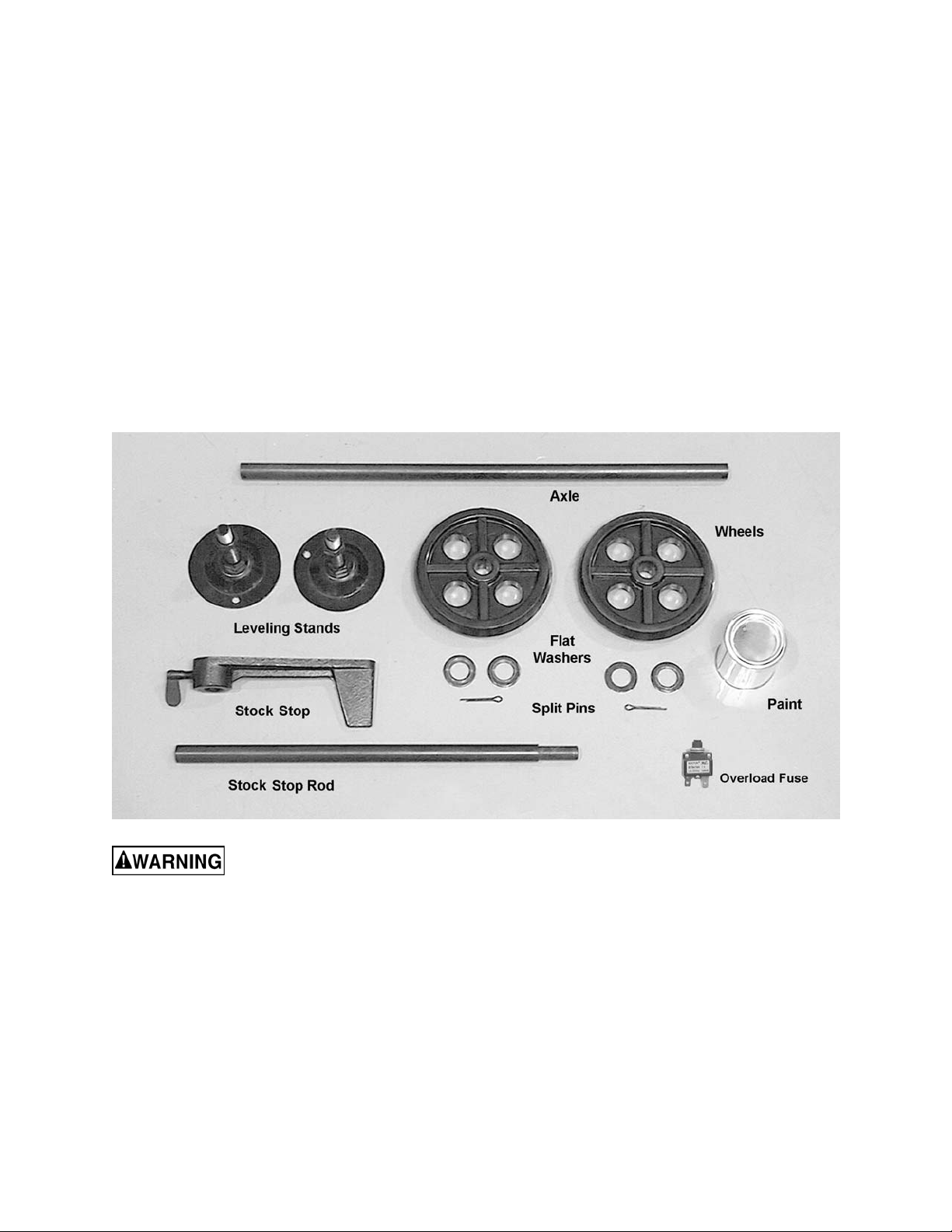

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, i f any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Band Saw

2 Leveling Stands (wit h hex nuts)

2 Wheels

1 Axle

4 Flat Washers

2 Split Pins

1 Stock Stop

1 Stock Stop Rod

1 Can White Touch-Up Paint

1 Overload Fuse 10A

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

7

Page 8

Installation and Assembly

Remove all crati ng and plastic from around the

band saw. Remove any lag screws or holding

straps which secure t he band saw to the wood

pallet.

Unpainted areas of the machine have been

treated with a r ust prevent ative. This should be

removed wit h a soft clot h and a mil d solvent . Do

not use paint thinner, lacquer thinner, gasoline

or mineral spirits; these will damage painted and

plastic surf ac es. Do not use an abrasive pad.

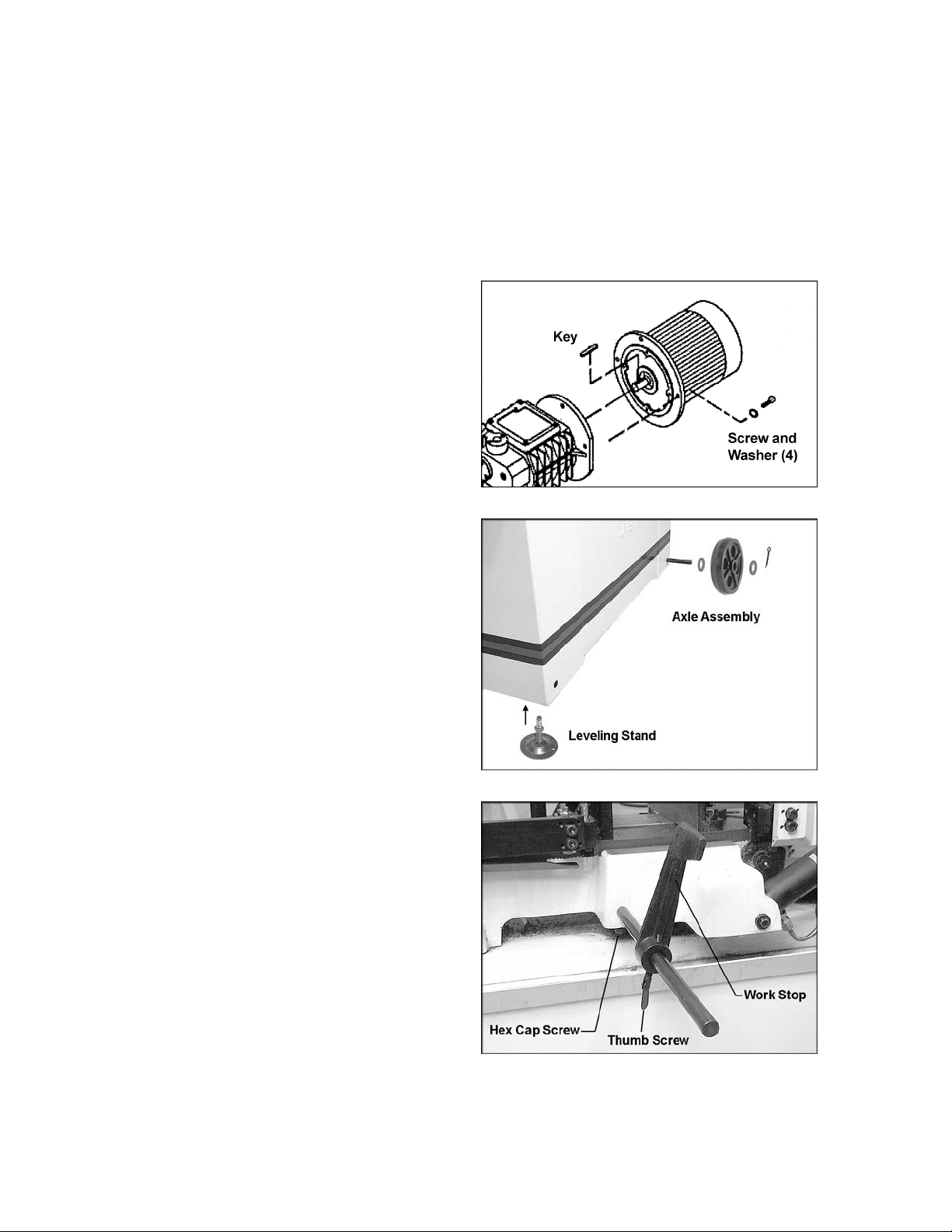

Installing Motor

Mount the motor to the gearbox using the four

M10 x 30 socket head c ap screws and f our M 10

lock washers, through the holes in the motor’s

flange. See F i gure 1. The key in t he m otor shaf t

must line up with the keyway in the gearbox

opening.

Wheels and Leveling Stands

1. Slide the band saw at an angle so that the

edges hang over the sides of the pallet.

2. Insert t he axle thr ough the holes at t he right

end of the band saw cabinet (opposite the

end where the lifting handle is mounted).

See Figure 2.

3. Install a wheel and two f lat washers on eac h

end of the axle. Insert a spli t pi n through the

hole in the axle and bend the ends of the

split pin to secure the wheel on the axle.

4. Install t he two leveling stands at t he left end

of the band saw (the end where the lifting

handle is mounted). See Figure 2. Screw

the leveling stand i nto the hole beneath the

band saw cabinet, and tighten the top hex

nut against the bott om of t he cabi net.

5. The leveli ng st ands can be later adjusted for

level by r otating the stand and re-tighteni ng

the hex nut against the c abinet.

6. Roll the band saw off the pallet.

Figure 1

Figure 2

Stock Stop

1. Insert t he stock stop rod i nto the hol e at t he

front of the base (Figur e 3) .

2. Secure the rod by tightening the hex cap

screw below the casting.

3. Slide the stock stop onto the rod, and

tighten the t humb screw. The stock stop can

be mounted so it faces either direction.

Figure 3

8

Page 9

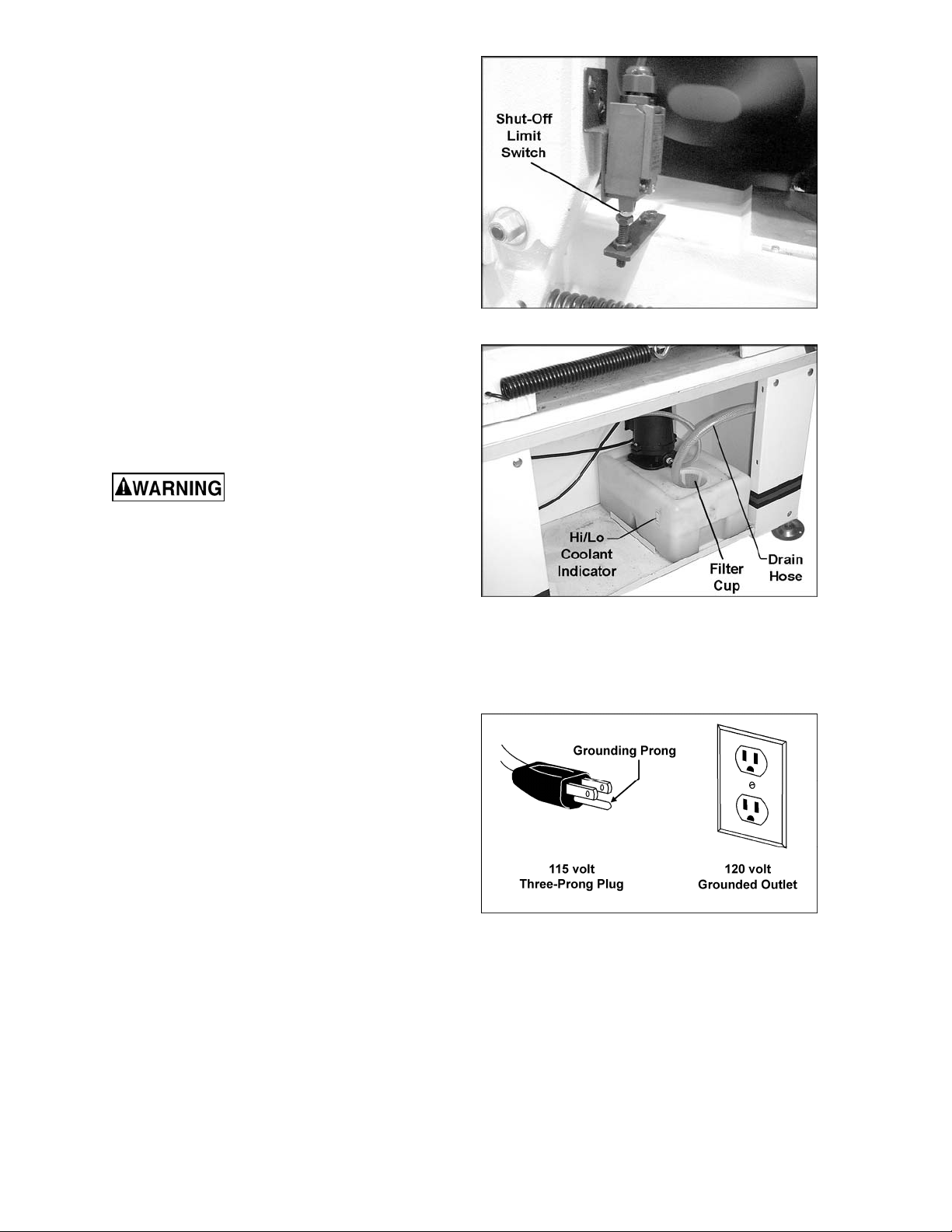

Shut-Off Switch

Remove the screw and hex nuts which hel d the

bow to the base during shipm ent. These should

be retained in case of future transportation of

the Band Saw.

The screw below the limit switch, shown in

Figure 4, has been pre-set at the factor y so that

the switch will contact the screw and stop the

blade after each cutting operation.

Coolant Hose

Before operati ng, the coolant dr ain hose (Figure

5) must be connected to the coolant pan and the

other end of the hose placed into the filter c up in

the tank as shown.

The hose from the coolant pump i s attached to a

valve which should be i nserted into the hole on

the guide assembl y (see Fi gur e 17) .

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least r esistance f or electric current to

reduce the ri sk of el ectri c shock .

This band saw is pre-wired f or 115 volt and is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug si mil ar to that shown in Fi gure 6.

The plug must be inserted int o a matching outl et

that is properly installed and grounded in

accordance with all local codes and ordinances.

Figure 4

Figure 5

Do not modify the plug provided. If it will not fi t

the outlet, have the proper outlet installed by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the machine is properly grounded.

Figure 6

9

Page 10

115 Volt Operation

As received fr om the f actory, your band saw is

ready to operate at 115 volt power, using an

outlet and a plug that look similar to those

illustrated in Figure 6.

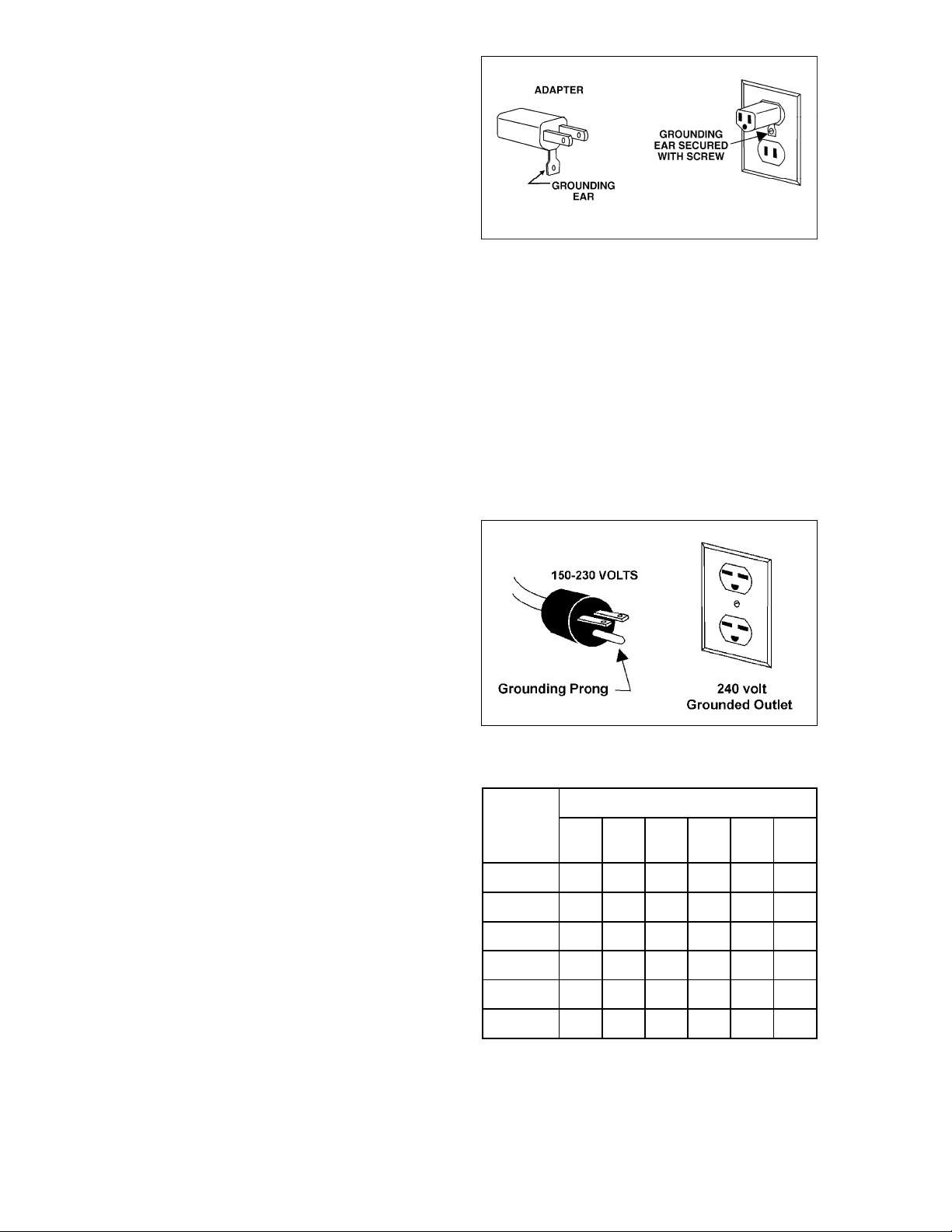

A temporary adapter, which looks like the

adapter illustrated in Figure 7, may be used to

connect this plug to a two-pole receptacle as

shown, if a properly grounded outlet is not

immediately available. The temporary adapter

should only be used until a properly

grounded outlet can be installed by a

qualifi ed el ect rician.

The green colored rigid ear, lug or tab,

extending f rom the adapter must be connec ted

to a permanent ground such as a properly

grounded outlet box, as shown in Figure 7.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the Band Saw.

Conversion to 220 Volt

If 220 volt, single phase operation is desired, t he

following inst r uc tions must be followed:

Figure 7

1. Disconnect machine from power source.

2. Open the electrical box and change the

position of the fuse from the 115V slot to the

220V slot. An el ectrical drawing is included

inside the elect rical box, and is also shown

on page 31 of this manual.

3. The 115V att achm ent plug suppl ied wit h the

band saw must be repl aced with a UL-li sted

plug suitable for 220 volt operation. The

band saw must comply with all local and

national codes after the 220 volt plug is

install ed. The band saw with a 220 volt plug

should only be connected to an outlet

having the same configuration (Figure 8).

No adapter is available or should be used

with the 220 volt plug.

Extens ion cords

If an extensi on c or d is necessary, m ak e sure t he

cord rating i s suitable for the am perage listed on

the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

of power and ov erheating. Use only three wire

extension cords that have three-prong

grounding plugs and three- pole recept acles that

accept the mac hine’s pl ug.

Use the chart in Fi gure 9 as a general guide in

choosing the c orrect size cord. If in doubt, use

the next heavi er gauge. The small er the gauge

number, the heavier the cord.

Figure 8

Recomm end ed Ga ug es (A WG ) of Extensi on Co rd s

Extension Cord Length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting th e lin e voltag e drop to 5V at 150% of th e

rated amp eres.

NR: Not Recommended.

feet

feet

feet

feet

feet

feet

Figure 9

10

Page 11

Adjustments

Vise

There are two set s of hol es in the bed to m ount

the right j aw. The inner hole and slot (A, Figure

10) are used for mit er cuts. The outer hole and

slot (B, Figure 10) are used for square, or 90°

cuts. Figure 10 shows the v ise l ocated i n the “A”

position for miter cuts.

Use only position “A” for miter cuts. If the “A”

position is used for square cuts, it leav es more

blade exposed to the right of the jaw.

Squaring Vise to Blade

1. To set up for square cutting, m ove the right

jaw to “B” position (Figure 10). Place a

machinist’s square on the bed against the

blade and the right vise jaw. The square

should lie along t he entire length of the jaw

and blade without a gap.

2. If adjustment is necessary, slightly loosen

the front screw on the ri ght jaw. Loosen the

hex nut at the center of the right jaw and

adjust jaw so the square li nes up properly.

Figure 10

(fixed jaw shown in “A” posit ion for mitering)

3. Re-tighten the hex nut and the front screw.

4. Loosen the handl e (C, Figure 10) on the l eft

jaw. Move t he left jaw until it c ontacts flush

with the right jaw.

5. Tighten t he handle (C, Figure 10). T he vise

is now set for square cuts.

Positioning the Vise

Keep hands away f rom blade

while adjusting the vise.

1. The workpiece is placed against the fixed

jaw, which has already been squared (see

“Squaring Vise to Blade”), or has been

locked at the appropriate angl e (see “Miter

Cuts”).

2. The vise has a quick-release f eature which

allows fast positioning of the movable jaw

against the workpiece and then a final

tightening with the handle. Lift up on the

quick release lever (D, Figure 11), then

push the movable jaw by hand until it

contacts the workpi ec e.

3. Push down the quick release lever (D,

Figure 11).

4. Turn the lead screw handle (E, Figure 11)

clockwise to cont i nue the t ight eni ng proces s

of the movable jaw until the workpiece is

securely cl am ped.

Figure 11

11

Page 12

5. The qui ck release f uncti on can al so be used

to back off the movabl e jaw when the cut is

finished.

Miter Cuts

1. For miter cuts, move the fixed jaw to the

inner holes, or “A” position, as shown in

Figure 10.

2. Rotate the fixed jaw to the desired angle,

and tighten the center hex nut.

NOTE: There is an angl e scale on the back

side of the bed. This is for reference only.

Check angles with a protractor if greater

precision is needed.

3. Adjust the movable jaw in the manner

described abov e, and tight en the handle (C,

Figure 10).

Setting Downfeed Rate

The downfeed r ate of the blade is i mportant to

band saw performance. Excessive pressure of

blade against the workpiece may break the

blade or stall the saw. In contrast, insufficient

pressure rapidl y dulls the blade.

Turn the valve lever (Figure 12)

countercl ockwise to l ower the bo w. The rat e of

downfeed is cont rolled by the dial setting (Figure

12).

Blade Tension

Blade tension has been set at t he fact ory. W hen

installing a new blade, use the tension handle

(Figure 13) to adjust blade tension (cl ockwise to

tighten). Tension is set properly when the

indicator moves into the “green” area on the

scale.

Figure 12

Blade Tracking

Tracking the blade requires

that the band saw be operating while the

back cover is removed. Use extreme caution.

Blade tracking has been tested at the factory.

Adjustment i s rarely required when the blade i s

used properly and if the blade is correctly

welded. If a tracking problem should occur,

adjust the machine as follows:

1. Raise the bow to its hi ghest position. Make

sure the hydraulic cylinder valve is closed

so the bow remains in place.

2. The blade should be properly tensioned.

NOTE: Keep proper tension on t he blade at

all times using the blade tension adjustment .

3. Open the back wheel cov er.

Figure 13

12

Page 13

While performing the

following steps, keep th e bl ade fro m rubbing

excessively on the shoulder of the wheel.

Excessive rubbing will damage the wheel

and/or the blade.

4. Start the saw. Turn the set screw (Figure

14) to tilt the idler wheel until the blade is

touching the shoulder of the idler wheel.

5. Turn the set screw (Fi gure 14) so the blade

starts to move away from the shoulder of

the wheel; then immediately turn the set

screw in the other direction so the blade

stops; then moves slowly towards the

shoulder. NOTE: This adjustment is

sensitive; do it gradually and in small

increment s all owing the wheel to r espo nd to

the changes.

Keep your fingers clear of

the blade and wheel to avoid injury.

6. Tur n the set scre w to stop the shif ti ng of the

blade on the wheel as it gets closer to the

wheel shoulder. Put a six-inch length of

paper between the blade and the wheel.

See Figure 15. The paper should not be cut

as it passes between the wheel shoulder

and the blade.

7. Turn the set screw a small amount. Repeat

the insertion of the paper between the wheel

shoulder and the bl ade u nti l the paper is cut

into two pieces.

NOTE: You may have to repeat the check

with the paper several times before the

blade and the shoulder cut the paper into

two pieces. Do not hurry the adjustment.

Patience and acc uracy here will pay off wit h

better, more accurate, quieter cutting and

longer machine and blade life.

8. When the paper is cut, back off the set

screw slightl y. This assure s that t he bl ade is

not touching the shoul der of the wheel.

Figure 14

Figure 15

IMPORTANT: If the blade is al lowed to run

against the shoulder of the wheel, it will

wear off the shoulder.

Setting Blade Speed

Rotate the dial (see Figure 16) to the desired

setting – 135, 197 or 256 feet per minute.

Do not change blade speed

during a cutting operat ion.

Figure 16

13

Page 14

Material c hips or shavings are the best i ndicator

of proper bl ade speed and downfeed rate. The

ideal chi p is thin, tightl y curled and warm to the

touch. Chips that range from golden brown to

black indicate excessive force. Blue chips

indicate extreme heat from too high a blade

speed, which will shorten blade life. Thin or

powdered chips indicate insufficient downfeed

rate.

Blade Guides

Loosen the handle (Figure 17) and slide the

guide assembly as close to the workpiece as

possible. This will prevent excessive exposure

of the blade duri ng oper ation.

[NOTE: The handl e (Figure 17) can be adj usted

out of the way. Lift up on the handle and rotate it

on the pin. Release the handle, making sure it

seats itself proper ly on the pin.]

The guide bearings and carbide guide blocks

come pre-adj usted from the fact ory, but should

be inspected frequently and adj ustments made

as needed. For most efficient operation and

maximum accuracy, provide 0.001” clearance

between the blade a nd the gui de bearings. The

bearings will still turn freely with this clearance.

If the clear ance i s incorr ect, the bl ade m ay track

off the drive wheel.

1. Disconnect machine from power source.

Figure 17

2. Loosen the t wo socket head cap scre ws (A,

Figure 18) and move the guide seat (B,

Figure 18) up or down unt i l t he gui de bloc ks

(D, Figure 18) are positioned adequately

across the width of the blade.

3. Loosen the socket head cap screws (C,

Figure 18) on the carbide guide blocks (D,

Figure 18) and shi ft both guide bloc ks until

they place a light pressure on the blade. Retighten the socket head cap screws (C,

Figure 18).

4. The outer guide bearing (E, Figure 18) is

mounted to an eccentric bushing and is

adjustable. Loosen the hex nut (F, Figure

18) and rotate the bearing shaft (G, Figure

18) with a wrench until the bearing (E,

Figure 18) clears the blade by

approxim ately .001”. Do not pinch the blade.

5. Re-tighten hex nut (F, Figure 18).

6. Repeat these steps for the other blade

guide assembly.

Figure 18

14

Page 15

Blade Replacement

A general-use variable-tooth blade is provided

with this metal cutting band saw. Additional

blades can be used and are av ail able from y our

JET distri butor.

The choice of blade pitch is governed by the

thickness of the work to be cut: the thinner the

workpiece, the m ore teeth advised. A minimum

of 3 teeth should engage the workpiece at all

times. If t he teeth of the blade are so far apar t

that they straddle the work, severe damage to

the workpiece and to the blade can result.

1. Disconnect machine from power source.

2. Loosen the handle (Figure 17) and move

the blade guides away from the wheel, as

shown in Figure 19.

3. Raise the bow, making sure the hydraulic

cylinder is closed so the bow will remain

stationary.

4. Open t he back cover, by looseni ng the two

knobs and the four screws on the brackets.

5. Loosen tension on the blade.

Figure 19

6. Remove t he blade f rom between the gui des

and from around the wheels. (Use gloves

when handling sharp bl ades!).

7. Install new blade on wheels, making sure

the teeth point downward in the proper

cutting di rection. See Fi gure 20; also noti ce

the blade dir ection arrow on the f ront of the

bow.

8. Increase blade tension just enough to hold

the blade on the wheels. M ake sure back of

blade rests lightly against the shoulder of

both wheels.

9. Twist bl ade slightly to allow it to slip into the

guides.

10. T he blade should be t ensioned and t racked

properly before use. See “Blade Tension”

and “Blade Tracking” above.

Bow Stop

The stop screw (Fi gure 21) cont rol s the dept h of

fall of t he bow to prevent the bl ade from hitti ng

the bed casting. The stop scre w has been set at

the factory. If future adjustment is needed,

loosen the hex nut and rotate the screw, then retighten the hex nut.

Figure 20

Figure 21

15

Page 16

Operation

Figure 22 shows the contr ol panel functions.

The Emergency Stop shuts do wn all f unctions

on the band saw. The machine will not start if

the emergenc y stop is still engaged. T o start the

machine, twist t he emergency stop butt on until it

pops back out.

IMPORTANT: When cutting magnesium, never

use soluble oils or em ulsions (oil-water mix) as

water will greatly intensify any accidental

magnesium chi p fi re. S ee your i ndustri al cool ant

supplier for specific coolant recommendations

when cutti ng magnesium.

General Operating Procedure:

1. Give machine an overall inspection. Verify

that all guards, cov ers, etc. are in plac e and

in working order, the blade is tensioned

properly and t he toot h dir ection m atches t he

arrow on the bow. Check that the blade

guides are set correctly, and also the wire

brush.

2. Place workpiece in vise and tighten vise.

The workpiece should be fitted directly

between the jaws without adding other

objects.

Figure 22

When the workpiece to be cut is a profiled

section, fl at piece or special shape, ref er to

the examples sho wn in Figur e 23 for pr oper

clamping positions. The top row shows

acceptable clamping positions, the bottom

row sho w s unacceptabl e posit ions.

If the thic kness of the profiled section i s very

thin, a piece which duplicates the profile

should be fitted inside the workpiece itself,

to prevent the workpiece being crushed

between the jaws.

Never hold a workpiece by

hand when cu tting it – t he workp iece should

be firmly secured in the vise. Do not reach

into the cutting area during cutting

operations.

3. Rotate t he speed dial to the desir ed setti ng.

Do not rotate the speed dial during a

cutting operati on .

4. Set a suitable downfeed rate for that

operation on the cylinder dial.

5. Push the start button to start the blade

circulating.

6. Turn on the coolant flow.

Figure 23

16

Page 17

7. Open t he valve on the hydrauli c cylinder to

allow the bow to desce nd in a gradual and

controlled manner.

8. The m achine will shut off at the completi on

of the cut. Turn off the coolant flow, and

remove the workpiec e.

9. Return the bow to vertical position for the

next c u t.

Maintenance

Before doing maintenance

on the machine, disconnect it from the

electrical supply by pulling out the plug or

switching off the main switch. Failure to

comply may cause seriou s injury.

Clean the band saw regularly after each day’s

work. Clear metal shavings with the provided

brush, do not use your hands. Do not use

compressed air.

To prevent corrosion of machined surfaces

when a soluble oil is used as coolant, pay

particular attention to wiping dry the surfaces

where fluid acc um ulates and does not evaporate

quickly, such as between the machi ne bed and

vise.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

All ball bearings are perm anentl y lubri cated and

sealed. They require no further lubric ation.

Grease the vise l ead screw as needed.

Place a thin coat of oil on the bed surface on

which the vise jaw slides.

Maintain coolant level. Low coolant level can

cause foaming and high blade temperatures.

Replace dirt y coolant; dirty or weak coolant can

clog the pump, cause crooked cuts, a low

cutting rat e and/or permanent blade damage. To

fill the tank, remove the filter cup and pour

coolant i nto the hol e. A “Hi/Lo” mark on t he tank

indicates proper level (see Figure 5).

Maintain oil level in the gear box, using SAE No.

10. To check level of the gear box oil, place bow

in down posit ion so that oil drains do wn. Check

level in sight glass on side of gear casing.

Correct l ev el is the dot in t he mi ddl e of t he si ght

glass. Figure 24 shows the locations of the fill

hole, sight gl ass and drain plug for the gear box.

Completely drai n and refill the gear box oil once

a year.

Figure 24

17

Page 18

Troubleshooting

Trouble Probable Cause Remedy

Motor will not start. No incoming power. Check plug connection.

Blown electri c al panel fuses. Replace fuses.

Overload trips

frequently.

Band Saw vibrates

excessively.

Miter cuts not

accurate.

Thermal overload has tripped.

Defective motor, switch, power cable,

or plug.

Motor is overheating. Check that motor air intakes are clear.

Downfeed rate too f ast . Reduce downfeed rat e.

Motor is faulty.

Base on uneven surfac e. Adjust base for even support.

Saw blade has cracks. Replace blade immediately.

Too heavy a cut.

Setting of the miter stops is not

correct.

Blade is worn, cutting crooked. Replace blade.

Wait several minutes for overload to

reset itself.

Qualified electrician/service personnel

should inspect these i tems.

Motor should be i nspect ed by

qualified elec trician/service personnel.

Reduce downfeed rate and blade

speed.

Loosen the screws and adjust the

stops to correct positions. Use an

adjustable square or protractor t o

check angle setti ngs.

Cuts not square. Feed pressure too great . Decrease feed pressure.

Adjust stop until blade is square with

vise.

Check Machinist’s Handbook for

recommended blade type.

Re-adjust these. See page 14.

Check positi oning and clamping in the

vise.

Check Machinist’s Handbook for

blade recommendations.

Finished surfac e of

workpiece is rough,

unsatisfactory.

90° angle stop is not set c orrec tly.

Incorrect blade toothing in relation t o

workpiece.

Blade is worn, cutting crooked. Replace blade.

Incorrect adjustment of bearing

guides and guide assembly.

Workpiec e inc or r ectly posi tioned in

vise.

Poor blade tensi on. Check and correct if needed.

Blade is dull. Replace blade.

Improper bl ade for cutting operation.

Downfeed rate too f ast . Reduce downfeed rat e.

Blade tension too low. Increase blade tensi on.

18

Page 19

Trouble Probable Cause Remedy

Excessive blade

breakage.

Premature Blade

Dulling.

Incorrect blade tension. Adjust accordingly (see page 12).

Incorrect blade speed or downf eed

rate.

Workpiec e loose i n vi se. Clamp workpiece securely.

Blade rubs on wheel shoulder. Adjust blade trac ki ng.

Teeth too coarse f or mat eri al.

Teeth in contact with workpiece

before saw is started.

Blade guides are misal igned. Adjust as needed. See page 14.

Blade too thick for wheel diameter. Use thinner blade.

Cracking at weld; poor annealing of

blade.

Teeth too coarse. Use finer toot h blade.

Blade speed too fast. Reduce speed.

Inadequate downf eed rate. Adjust cylinder dial setting as needed.

Adjust acccordingly.

Use appropriate bl ade for material

being cut.

Start motor before blade contacts

workpiece.

Replace blade.

Scale: Reduce speed and incr ease

Hard spots or scale on mat eri al.

Work hardeni ng of material

(especially stainless steel)

Blade installed backwards.

Insuffici ent blade tension. Adjust as needed.

downfeed rate. Hard S pots: Increase

downfeed rate.

Increase downfeed r ate.

Remove blade, twist inside-out and

re-install.

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848 Monday through F riday ( see our websit e f or business hours, www.jett ools.com). Hav ing

the Model Num ber and S eri al Num ber of y our machi ne avail abl e when you cal l will allow us to serve you

quickly and acc ur ately.

19

Page 20

Base Assembly

20

Page 21

Bow Assembly

202

21

Page 22

Parts List: HBS-814GH Band Saw

Index No. P art No. Description Size Qty

1 ............... HBS814GH-001 ............. Base ............................................................................................... 1

2 ............... HBS814GH-002 ............. Stand Complete Assembl y .............................................................. 1

2-1............ HBS 814GH-002-1 .......... Coolant Pan .................................................................................... 1

2-2............ HBS 814GH-002-2 .......... Leg ( Right) ...................................................................................... 1

2-3............ HBS 814GH-002-3 .......... Leg ( Left) ........................................................................................ 1

2-4............ HBS 814GH-002-4 .......... Panel .............................................................................................. 1

3 ............... HBS814GH-003 ............. Vise Jaw Bracket (Front) ................................................................. 1

4 ............... HBS814GH-4 ................. Washer ........................................................10 x 25 x 2.................. 2

5 ............... HBS814GH-005 ............. Carriage Bolt ................................................1/2"-12 x 2” ................. 1

6 ............... TS-0209071 ................... Socket Head Cap Screw ..............................3/8"-1 6 x 1-1/2 "L ......... 1

7 ............... 6290483......................... Hex Nut ........................................................1/2”-12........................ 1

8 ............... HBS814GH-063 ............. Washer ........................................................12 x 28 x 2.................. 2

9 ............... HBS814GH-009 ............. Hex Cap Scre w ............................................1/2"-12 x 2"L ............... 1

10 ............. HBS814GH-010 ............. Vise Jaw Bracket (Rear) .................................................................. 1

11 ............. HBS814GH-011 ............. Miter Clamp Bolt .............................................................................. 1

13 ............. HBS814GH-013 ............. Handle ............................................................................................ 1

14 ............. HBS814GH-014 ............. Crank .............................................................................................. 1

15 ............. HBS814GH-015 ............. Washer ........................................................12 x 23 x 2.................. 1

16 ............. HBS814GH-016 ............. Thrust Flange .................................................................................. 1

17 ............. TS-0267051 ................... Socket Set Screw .........................................1/4"-20 x 1/2"L ............ 1

18 ............. HBS814GH-018 ............. Acme Nut ..................................................... .................................. 1

19 ............. HBS814GH-019 ............. Acme Screw .................................................................................... 1

20 ............. HBS814GH-020 ............. Pin ...............................................................5 x 34L ....................... 2

21 ............. HBS814GH-021 ............. Vise Cam ........................................................................................ 1

22 ............. TS-

23 ............. HBS814GH-023 ............. Washer ........................................................8 x 25 x 3 ................... 2

24 ............. HBS814GH-024 ............. Shipping Bracket ............................................................................. 1

25 ............. TS-0060081 ................... Hex Cap Screw ............................................3 /8 "- 1 6 x 1-3/4 " ........... 1

26 ............. TS-0060091 ................... Hex Cap Screw ............................................3 /8 "- 1 6 x 2" ................. 1

27 ............. HBS814GH-285 ............. Washer ........................................................10 x 20 x 2.................. 1

28 ............. TS-0561031 ................... Hex Nut ........................................................3/8”-16........................ 2

29 ............. HBS814GH-029 ............. Knob ............................................................................................... 1

30 ............. HBS814GH-030 ............. Shaft ............................................................................................... 1

37 ............. HBS814GH-037 ............. Fiber washer ................................................................................... 8

40 ............. HBS814GH-040 ............. Cover .............................................................................................. 1

41 ............. TS-081C022 .................. Phillips Pan Head Machine Screw ................#10-24 x 3/8"L ............ 2

50 ............. HBS814GH-050 ............. Stop Block ....................................................................................... 1

51 ............. HBS814GH-051 ............. Thumb Screw .................................................................................. 1

52 ............. HBS814GH-052 ............. Stock Stop Rod ............................................................................... 1

53 ............. TS-0051031 ................... Hex Cap Screw ............................................5 /1 6 "- 1 8 x 3/4"L .......... 1

54 ............. TS-0267061 ................... Socket Set Screw .........................................1/4"-20 x 5/8"L ............ 1

55 ............. HBS814GH-055 ............. Cylinder Lower Support ................................................................... 1

56 ............. TS-0060061 ................... Hex Cap Screw ............................................3 /8 "- 1 6 x 1-1/4 "L ......... 2

57 ............. HBS814GH-285 ............. Washer ........................................................10 x 20 x 2.................. 2

58 ............. HBS814GH-058 ............. Bearing ........................................................................................... 1

59 ............. HBS814GH-059 ............. Washer ........................................................................................... 1

60 ............. HBS814GH-060 ............. Spring ............................................................................................. 1

61 ............. HBS814GH-061 ............. Pivot Shaft....................................................................................... 1

62 ............. HBS814GH-062 ............. Bushing ........................................................................................... 1

63 ............. HBS814GH-063 ............. Washer ........................................................12 x 28 x 2.................. 2

64 ............. 6290483......................... Hex Nut ........................................................1/2"-12 ....................... 2

69 ............. HBS814GH-069 ............. Bracket............................................................................................ 1

70 ............. TS-0060031 ................... Hex Cap Screw ............................................3 /8 "- 1 6 x 3/4"L ............ 1

71 ............. HBS814GH-071 ............. Washer ........................................................10 x 25 x 3.................. 1

76 ............. HBS814GH-076

77 ............. TS-0050011 ................... Hex Cap Screw ............................................1 /4 "- 2 0 x 1/2"L ............ 1

81 ............. TS-081C022 .................. Phillips Pan Head Machine Screw ................#10-24 x 3/8"L ............ 2

0051021 ................... Hex Cap Scre w ............................................5 /1 6 " -1 8 x 5/8"L .......... 2

............. Screen ............................................................................................ 1

22

Page 23

Index No. P art No. Description Size Qty

82 ............. TS-069204 ..................... Flat Washer..................................................#10 ............................. 2

83 ............. HBS814GH-083 ............. Scale ............................................................................................... 1

84 ............. HBS814GH-084 ............. Spring ............................................................................................. 1

85 ............. HBS814GH-085 ............. Spring Adjusting Screw ................................................................... 1

86 ............. TS-0051031 ................... Hex Cap Screw ............................................5 /1 6 "- 1 8 x 3/4"L .......... 1

87 ............. HBS814GH-087 ............. Washer ........................................................8 x 23 x 2 ................... 1

88 ............. HBS814GH-088 ............. Spring Handle Bracket..................................................................... 1

89 ............. HBS814GH-092 ............. Washer ........................................................10 x 23 x 2.................. 1

90 ............. TS-0561031 ................... Hex Nut ........................................................3/8-16 ......................... 1

92 ............. HBS814GH-092 ............. Washer ........................................................10 x 23 x 2.................. 3

93 ............. TS-0209061 ................... Socket Head Cap Screw ..............................3/8" -1 6 x 1-1/4 " L ......... 3

96 ............. HBS814GH-096 ............. Rear Pivot Bracket .......................................................................... 1

98 ............. TS-0267051 ................... Socket Set Screw .........................................1/4"-20 x 1/2"L ............ 1

99 ............. HBS814GH-099 ............. Cylinder Upper Support ................................................................... 1

100 ........... HBS814GH-100 ............. Shaft .............................................................................................. 1

101 ........... TS-0060051 ................... Hex Cap Scre w ............................................3/8"-1 6 x 1"L ............... 2

102 ........... HBS814GH-4 ................. Washer ........................................................10 x 25 x 2.................. 2

103 ........... HBS814GH-103 ............. Cylinder Complete Set..................................................................... 1

105 ........... HBS814GH-105 ............. Cross Round Head Screw ............................1/4"-20 x 5/8"L ............ 4

106 ........... HBS814GH-106 ............. Washer ........................................................6.3 x 19 x 1.5 .............. 4

107 ........... HBS814GH-107 ............. Pump ...........................................................1/8HP,110/220V,1PH . 1

108 ........... HBS814GH-108 ............. Close Nipple .................................................3/8"PT ........................ 1

109 ........... HBS814GH-109 ............. Hose ............................................................OD12 x ID8 x 2000 ..... 1

110 ........... HBS814GH-110 ............. Hose Clip .....................................................5/8" ............................ 3

111 ........... TS-081C022 .................. Phillips Pan Head Machine Screw ................#10-24 x 3/8"L ............ 3

113 ........... HBS814GH-092 ............. Washer ........................................................10 x 23 x 2.................. 2

114 ........... TS-0209031 ................... Socket Head Cap Screw

118 ........... HBS814GH-118 ............. Hose ............................................................OD16 x ID13 x 260 ..... 1

................. HBS814GH-118N .......... Hose ............................................................OD24 x ID1 8 .5 x 650 .. 1

119 ........... HBS814GH-119 ............. Coolant Tank ................................................................................... 1

126 ........... HBS814GH-126 ............. Washer ........................................................5/8" x 40 x 3" .............. 4

127 ........... HBS814GH-127 ............. Wheel ............................................................................................. 2

128 ........... 5519932......................... Cotter Pin .....................................................3 x 25L ....................... 2

129 ........... HBS814GH-129 ............. Wheel Rod ...................................................................................... 1

133 ........... 6290483......................... Hex Nut ........................................................1/”2-12........................ 2

134 ........... HBS814GH-134 ............. Coaster of Stand ..........................................1 /2 " ............................ 2

137 ........... TS-0680041 ................... Washer ........................................................3/8" ............................ 8

138 ........... TS-0060051 ................... Hex Cap Scre w ............................................3/8"-1 6 x 1"L ............... 8

139 ........... HBS814GH-139 ............. Handle ............................................................................................ 1

140 ........... HBS814GH-140 ............. Flat Cross Head Screw .................................M5-0.8 x 12L .............. 1

141 ........... TS-1523051 ................... Socket Set Screw .........................................M6-1 x 15L ................. 4

142 ........... HBS814GH-142 ............. Door Clip Lower .............................................................................. 2

143 ........... HBS814GH-143 ............. Washer ........................................................6.3 x 16 x 1.5 .............. 4

144 ........... TS-0050011 ................... Hex Cap Scre w ............................................1/4"-2 0 x 1/2"L ............ 4

146 ........... HBS814GH-146 ............. Body Frame .................................................................................... 1

147 ........... TS-0720091 ................... Lock Was h e r ................................................3/8" ............................ 4

148 ........... TS-0060061 ................... Hex Cap Scre w ............................................3/8"-1 6 x 1-1/4 "L ......... 4

152 ........... HBS814GH-152 ............. Upper Bracket hold down ................................................................ 1

153 ........... HBS814GH-285 ............. Washer ........................................................10 x 20 x 2.................. 2

154 ........... TS-0060051 ................... Hex Cap Scre w ............................................3/8"-1 6 x 1" ................. 2

155 ........... HBS814GH-155 ............. Blade.............................................0.032" x 3/4" x 2464L x 5-8T" ...... 1

156 ........... HBS814GH-156 ............. Drive Wheel .................................................................................... 1

157 ........... TS-0267051 ................... Socket Set Screw .........................................1/4"-20 x 1/2"L ............ 1

158 ........... 5519933......................... C-Retainer Ring ...........................................S2 5 ............................ 1

159 ........... HBS814GH-159 ............. Bl

160 ........... HBS814GH-143 ............. Washer ........................................................6.3 x 16 x 1.5 .............. 4

161 ........... HBS814GH-161 ............. Knob ............................................................................................... 4

163 ........... HBS814GH-163 ............. Clamp Block Guide Arm .................................................................. 1

164 ........... TS-1550071 ................... Flat Washer..................................................M10 ............................ 1

ade Back Cover............................................................................ 1

..............................3/8"-16 x 3/4"L ............ 2

23

Page 24

Index No. P art No. Description Size Qty

165 ........... HBS814GH-165 ............. Grip ..............................................................M10-1.5 x 52L ............ 1

166 ........... HBS814GH-166 ............. Idler Wheel Assembly ...................................................................... 1

166-1 ........ HBS814GH-166-1 .......... Idler Wheel ...................................................................................... 1

166-2 ........ HBS814GH-166-2 .......... Be aring Cover ................................................................................. 1

166-3 ........ HBS814GH-211 ............. Washer ........................................................8 x 18 x 1.5 ................. 1

166-4 ........ TS-0051031 ................... Hex Cap Screw ............................................5 /1 6 " -1 8 x 3/4"L .......... 1

166-5 ........ HBS814GH-166-5 .......... Cross Round Head Scre w ............................#10-24 x 3/8"L ............ 3

166-6 ........ HBS814GH-166-6 .......... Bushing ........................................................................................... 1

166-8 ........ BB-6202ZZ .................... Bearing ........................................................6202ZZ....................... 2

166-9 ........ HBS814GH-166-9 .......... Bushing ........................................................................................... 1

173 ........... HBS814GH-173 ............. Shaft Assembly ............................................................................... 1

173-1 ........ HBS814GH-173-1 .......... Sliding Plate Draw Block ................................................................. 1

173-2 ........ HBS814GH-173-2 .......... Blade Wheel Shaft........................................................................... 1

173-3 ........ HBS814GH-173-3 .......... Pin ...............................................................4 x 22L ....................... 1

174 ........... HBS814GH-174 ............. Control Box Assembly ..................................................................... 1

174-1 ........ HBS814GH-174-1 .......... C ontrol Box ..................................................................................... 1

174-2 ........ HBS814GH-174-2 .......... Control Plate ................................................................................... 1

174-3 ........ HBS814GH-174-3 .......... Label for Name Plate ....................................................................... 1

174-4 ........ TS-1533042 ................... Phillips Pan Head Machine Screw ................M5-0.8P*12L .............. 4

174-5 ........ TS-1550041 ................... Flat Washer..................................................M6 .............................. 2

174-6 ........ TS-1482031 ................... Hex Cap Screw ............................................M 6 -1 .0 x 15L .............. 2

175 ........... TS-0561031 ................... Hex Nut ........................................................3/8-16 ......................... 1

176 ........... HBS814GH-176 ............. Sliding Plate .................................................................................... 2

177 ........... HBS814GH-177 ............. Blade Tension Slide Bloc k ............................................................... 1

178 ........... TS-0270071 ................... Socket Set Screw .........................................5/16"-18 x 3/4"L .......... 1

179 ........... TS-0051071 ................... Hex Cap Scre w ............................................5/16"- 1 8 x 1-1/2 "L ....... 2

180 ........... HBS814GH-180 ............. Washer ........................................................8 x 12 x 2 ................... 2

181 ........... TS-0051031 ................... Hex Cap Screw ............................................5/16"-18 × 3/4"L .......... 4

182 ........... TS-0720081 ................... Lock Washer ................................................5/16"........................... 4

186 ........... HBS814GH-200 ............. Phillips Pan Head Machine Screw ................1/4"-20 x 3/8"L ............ 1

187 ........... HBS814GH-187 ............. Blade Guard .................................................................................... 1

190 ........... HBS814GH-190 ............. Blade Guide Assembly .................................................................... 1

190-1 ........ HBS814GH-190-1 .......... Blade Guide .................................................................................... 1

190-2 ........ HBS814GH-190-2 .......... Adjustable Bracket (Front) ............................................................... 1

190-3 ........ HBS814GH-211 ............. Washer ........................................................8 x 18 x 1.5 ................. 2

190-4 ........ TS-0720081 ................... Lock Washer ................................................5/16"........................... 2

190-5 ........ TS-0208071 ................... Socket Head Cap Screw ..............................5/16"-18 x 1-1/4 ” L ....... 2

190-6 ........ TS-1523031 ................... Socket Set Screw .........................................M6-1P*10L ................. 2

190-7 ........ TS-1503041 ................... Socket Head Cap Screw ..............................M6 -1 x 15L ................. 2

190-8 ........ TS-1540071 ................... Hex Nut ........................................................M10-1.5 x P1 .............. 2

190-9 ........ TS-2361101 ................... Lock Washer ................................................M10 ............................ 2

190-10 ...... HBS814GH-190-10 ........ Carbide Guide ................................................................................. 2

190-11 ...... TS-0207041 ................... Socket Head Cap Screw ..............................1/4" -2 0 x 3/4"L ............ 2

190-12 ...... HBS814GH-190-12 ........ Top Guide Left ................................................................................ 1

190-13 ...... TS-1503021 ................... Socket Head Cap Screw ..............................M6-1 x 10 ................... 1

191 ........... HBS814GH-191 ............. Eccentric shaft Assembly................................................................. 2

191-1 ........ HBS814GH-191-1 .......... Eccentric shaft................................................................................. 2

191-2 ........ BB-608ZZ ...................... Bearing ........................................................608ZZ......................... 2

191-3 ........ 5515607......................... C-Retaining Ring ..........................................S10 ............................ 2

192 ........... HBS814GH-192 ............. Bearing Shaft Assembly .................................................................. 2

192-1 ........ HBS814GH-192-1 .......... Bearing Shaft .................................................................................. 2

192-2 ........ BB-608ZZ ...................... Bearing ........................................................608ZZ......................... 2

192-3 ........ 5515607......................... C-Retaining Ring ..........................................S10 ............................ 2

198 ........... HBS814GH-198 ............. Brush Assembly .............................................................................. 1

198-1 ........ HBS814GH-198-1 .......... Brush Support ................................................................................. 1

198-2 ........ HBS814GH-198-2 .......... Brush .............................................................................................. 1

198-3 ........ HBS814GH-198-3 .......... Bushing ........................................................................................... 1

198-4 ........ HBS814GH-285 ............. Washer ........................................................10 x 20 x 2.................. 1

198-5 ........ TS-1523031 ................... Socket Set Screw .........................................M6-1 x 10L ................. 1

24

Page 25

Index No. P art No. Description Size Qty

198-6 ........ HBS814GH-198-6 .......... Bushing ........................................................................................... 1

200 ........... HBS814GH-200 ............. Phillips Pan Head Machine Screw ................1/4"-20 x 3/8"L ............ 2

201 ........... TS-0680021 ................... Flat Washer..................................................1/4" ............................ 2

202 ........... HBS814GH-202 ............. Blade Guide Assembly .................................................................... 1

202-1 ........ HBS814GH-202-1 .......... Blade Adjustabl e ............................................................................. 1

202-5 ........ TS-1540071 ................... Hex Nut ........................................................M10-1.5 x P1 .............. 2

202-6 ........ TS-2361101 ................... Lock Washer ................................................M10 ............................ 2

202-13 ...... HBS814GH-202-13 ........ Carbide Guide ................................................................................. 2

202-14 ...... TS-0207041 ................... Socket Head Cap Screw ..............................1/4" -2 0 x 3/4"L ............ 2

202-15 ...... HBS814GH-202-15 ........ Top Guide Right .............................................................................. 1

211 ........... HBS814GH-211 ............. Washer ........................................................8 x 18 x 1.5 ................. 2

212 ........... TS-0720081 ................... Lock Washer ................................................5/16"........................... 2

213 ........... TS-0208121 ................... Socket Head Cap Screw ..............................5/16"- 1 8 x 2-1/2 "L ....... 2

231 ........... HBS814GH-231 ............. Handle Body ................................................................................... 1

232 ........... HBS814GH-232 ............. Blade Tension Bar ........................................................................... 1

233 ........... HBS814GH-233 ............. Knob ............................................................................................... 2

234 ........... HBS814GH-234 ............. Indicator plate ................................................................................. 1

235 ........... HBS814GH-235 ............. Thrust Rearing .............................................10 x 25 x 2.................. 2

238 ........... HBS814GH-238 ............. Sleeve ............................................................................................. 1

239 ........... HBS814GH-239 ............. Spring ..........................................................23 x 12.2 x 1.5t ........... 8

240 ........... HBS814GH-240 ............. Scale ............................................................................................... 1

241 ........... HBS814GH-241 ............. Rivet ............................................................Ø2 x 6 ........................ 2

249 ........... HBS814GH-249 ............. Spring ............................................................................................. 1

271A ........ HBS814GH-271A ........... Electrical Control Box ..................................................................... 1

272 ........... HBS814GH-272 ............. Cable Clamp ................................................................................... 2

281 ........... TS-081F052 ................... Pan Head Phillips Screw ..............................1 /4 "- 2 0 x 3/4"L ............ 8

282 ........... HBS814GH-143 ............. Washer ........................................................6.3 x 16 x 1.5 ............ 16

283 ........... TS-0570011 ................... Hex Nut ........................................................1/4-20 ......................... 8

284 ........... TS-0060051 ................... Hex Cap Scre w ............................................3/8"-1 6 x 1"L ............... 8

285 ........... HBS814GH-285 ............. Washer ........................................................10 x 20 x 2................ 16

286 ........... TS-0561031 ................... Hex Nut ........................................................3/8-16 ......................... 8

287 ........... HBS814GH-287 ............. Valve Assembly ............................................................................... 1

287-1 ........ HBS814GH-287-1 .......... Micro Control Block ......................................PT1/8" x 1/4" .............. 1

287-2 ........ HBS814GH-287-2 .......... Valve ............................................................PT1/8" x 1/8" .............. 1

287-3 ........ HBS814GH-287-3 .......... Jet Pipe ........................................................................................... 1

287-4 ........ HBS814GH-287-4 .......... O-Ring .........................................................8 x 4.5 x 1.9 ................ 1

290 ........... HBS814GH-105 ............. Cross Socket Head Screw ............................1/4"-20 x 5/8"L ............ 2

291 ........... HBS814GH-143 ............. Washer ........................................................6.3 x 16 x 1.5 .............. 2

292 ........... HBS814GH-292 ............. Support Pl ate .................................................................................. 1

400 ........... HBS814GH-400 ............. Limit Plate ....................................................................................... 1

401 ........... HBS814GH-143 ............. Washer ........................................................6 x 16 x 1.5mm ........... 2

402 ........... TS-0207031 ................... Socket Head Cap Screw ..............................1/4”-2 0 x 5/8” .............. 2