Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Horizontal/Vertical Bandsaw

Model: HVBS-56M

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414458

Ph.: 800-274-6848 Revision G3 02/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrant s every prod uct i t sell s against m anuf acturers ’ def ects. If o ne of o ur tools need s servi ce or r epair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This war ranty covers any defects in workmanship or materi als subject to t he limit ations stated below. This wa r ranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspecti o n, the Techn ic a l Servi c e r epr esent a tive will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informat io n

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents..................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Minimum gage for cor d ............................................................................................................................ 5

Grounding Inst r uc tions ............................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 7

Unpacking and Clean- Up ......................................................................................................................... 8

Tools Supplied for Assembly.................................................................................................................... 8

Tools Required for Assembly ................................................................................................................... 8

Assembly ................................................................................................................................................ 8

Vertical Cutting Plate Assembly ............................................................................................................. 10

Electri c al Connec tions ........................................................................................................................... 11

Changing Blade Speed .......................................................................................................................... 12

Adjusting Bl ade Guides ......................................................................................................................... 12

Adjusting Bl ade Tension ........................................................................................................................ 1 2

Changing Blades ................................................................................................................................... 13

Adjusting Bl ade Guide Bearings............................................................................................................. 13

Adjusting Bl ade Trac ki ng ....................................................................................................................... 1 4

Adjusting Feed Pressure........................................................................................................................ 14

Blade-Table S quar eness ....................................................................................................................... 14

Adjusting Automatic Shut-Off ................................................................................................................. 15

Adjusting the Vise .................................................................................................................................. 15

Lubrication............................................................................................................................................. 15

Breakdown for Bow Assembly ............................................................................................................... 17

Parts List for the HV BS-56M B andsaw ................................................................................................... 19

Wiring Diagram ...................................................................................................................................... 22

3

Page 4

Warning

Read and understand the entire instruction manual before operating machine.

This bandsaw is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper and safe use of a bandsaw, do not use until proper

training and knowl edge have been obtained.

“Warning: F or you own safet y r ead i nstr uc tion manual before operati ng saw.”

a) Wear eye protection.

b) Do not remove jammed cut off piec es until blade has stopped.

c) Maintain proper adjustment of blade tension, blade guides, and thrust bearing.

d) Adjust upper gui de to just clear workpiece.

e) Hold workpiece fi rmly against table.

1. Keep guar ds i n place and in working order.

2. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

3. Keep work ar ea c lean. Clutter ed ar eas and benches i nvite accidents.

4. Don’t use in dangerous envi ronm ent. Don’t use power tools in damp or wet locations, or ex pose them

to rain. Keep work area well lighted.

5. Keep c hildren away. All vi sitor s should be k ept a safe distance from the work area.

6. Mak e y our workshop child proof wi th padlocks, master switches or by rem ov ing starter keys.

7. Don’t force tool. It will do the job bett er and m or e safely at the rate for which it was designed.

8. Use the right t ool at the corr ect speed and f eed rat e. Do not forc e a tool or att achment to do a job for

which it was not designed.

9. Use proper extension cord. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in voltage resulting in loss of power and overheating. Table 1

shows the correct size t o use depending on cord lengt h and nameplate ampere rating. If in double,

use the next heavier gage. The smaller the gage number, t he heav ier the cor d.

10. W ear proper apparel. Do not wear loose clothi ng, gloves, neckties, r ings, bracelet s, or other jewelry

which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair

covering t o contain long hair.

11. Always wear approv ed safety glasses/f ace shields while using thi s bandsaw. Also use face or dust

mask if cutting oper ation is dusty. Everyday eyeglasses only have impact resi stant lenses; they are

NOT safe ty glasses.

12. Secure work. Use clamp or vise to hold work when practi cal. It is safer than using your hand and it

frees both hands to operate t ool.

13. Don’t overreac h. Keep pr oper footing and balance at all times.

14. Maintain tools with care. Keep tools sharp and clean for the best and safest performance. Follow

instructions for lubricating and c hanging accessories.

15. Di sconnect tool s before servicing; when changing ac cessories such as blades, bi ts, cutter s, and the

like.

16. Reduc e the risk of unint entional starting. Mak e sure switc h is i n off posi tion before plugging in.

17. Use recomm ended acc essories. Consul t t he owner’s m anual for recomm ended accessories. T he use

of improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

4

Page 5

19. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lum ber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

20. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repair ed or r eplac ed.

21. Feed work into a blade or cutt er only against the direction of r otation of the blade or cutter.

22. Never leav e tool running unattended. Turn power off . Don’t leave tool until it comes to a c ompl ete

stop.

23. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

24. Do not operate this machine while tired or under the influence of drugs, alcohol or any medic ation.

25. Never leave the m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

26. Tur n off the machine bef ore cleaning. Use a brush or compressed air t o remove chips or debris — do

not use your hands.

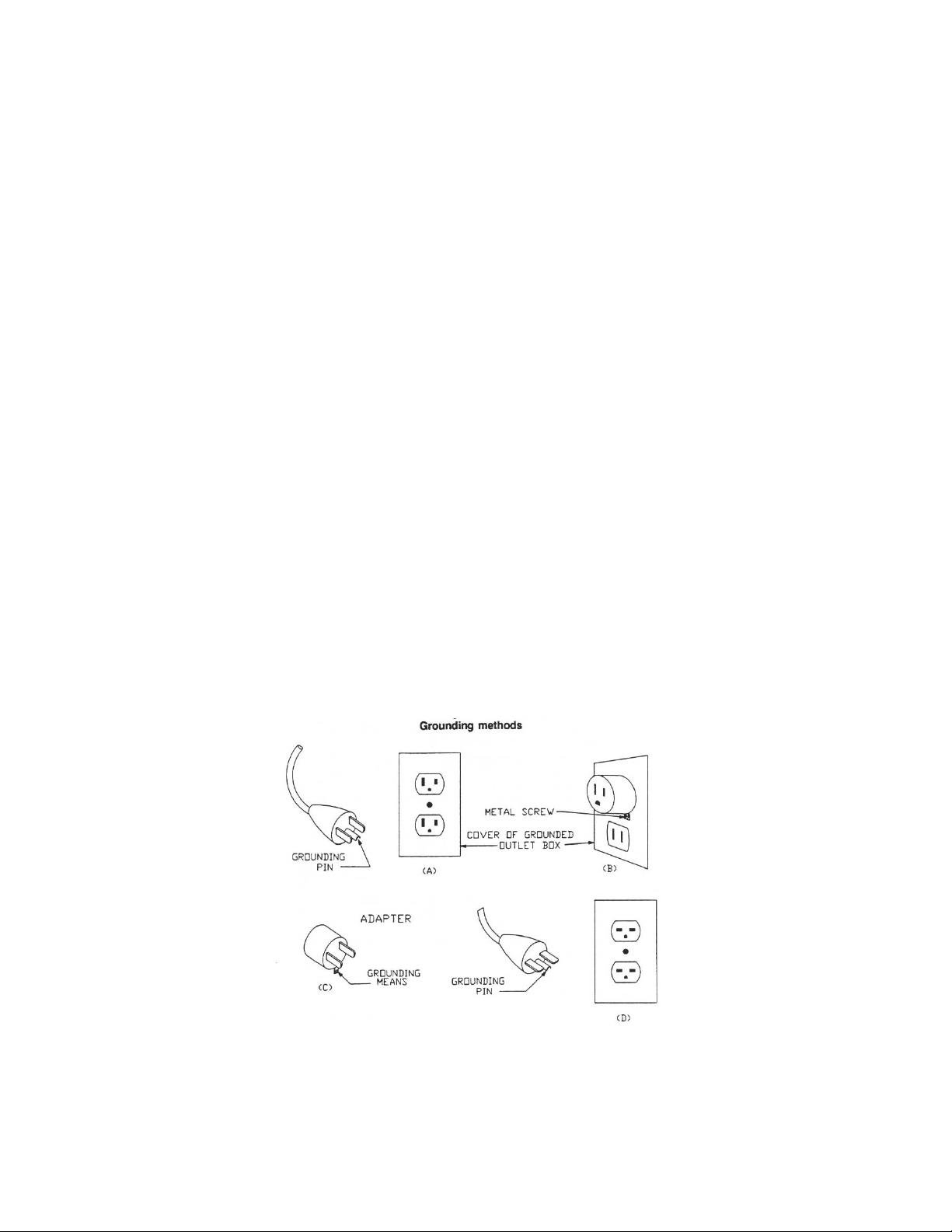

Minimum gage for cord

Volts

Total length of cord in feet

120V 25 ft. 50ft. 100ft. 150ft.

Ampere Rating

240V 50ft. 100ft. 200ft. 300ft.

Not

More More

Than Than

0 6 16 16 14

6 10 161412

10 12 16 14 12

12 16 12

18

18

16

14

AWG

Not Recommended

Only the applicable parts o the Table need to be included, For instance, a

120-volt product need not include the 240-volt heading

Table 1

5

Page 6

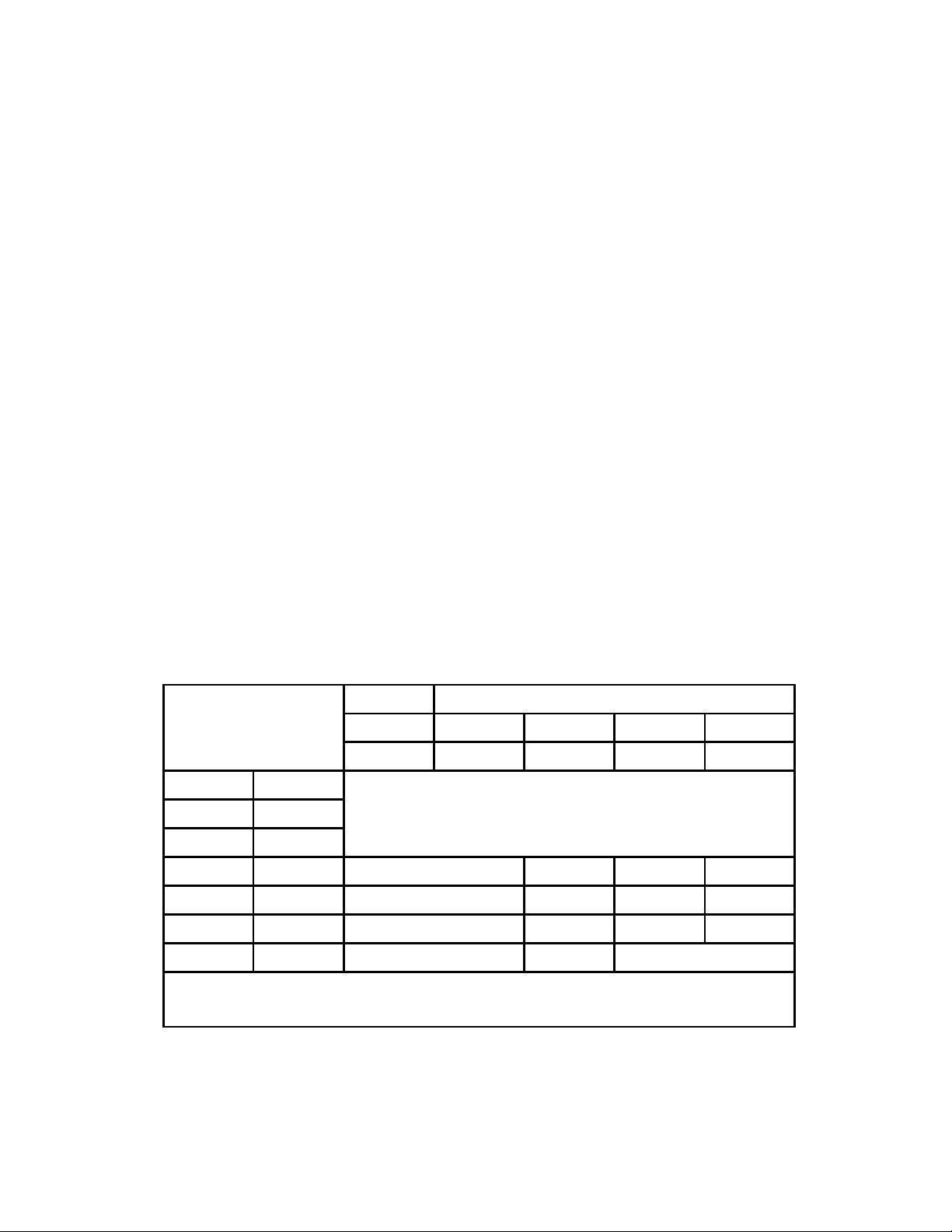

Grounding Instructions

Caution: This tool must be grounded while in use to protect the operator from electric shock.

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-gr ounding conduct or and a grounding pl ug. The plug m ust be plugged into a mat ching outl et

that is properly installed and grounded in acc or danc e with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

equipment-gr ounding c onductor . If r epair or repl acement of the elec tri c cord or pl ug is necessary , do not

connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded. Use only three wire extension

cords that hav e three- pr ong gr ounding plugs and three-pole r ec eptacles that accept the tool’s plug.

Repair or replace a dam aged or worn cord im mediately.

This tool is int ended for use on a circuit that has an outl et that looks like the one illustr ated in sketch A.

The tool has a groundi ng that looks li ke the pl ug ill ustrated i n sketch A. A temporary adapter, which looks

like the adapter illustrat ed in sketches B and C, may be used to connect this plug to a 2-pole receptacle

as show in sketch B if a properly until a properly grounded outlet can be installed by a qualified

electrici an. (This adapter is not permitted in Canada) The green-color ed rigid ear, lug, the like, extendi ng

from the adapter must be c onnec ted to a permanent ground such as a properly gr ounded outlet box.

This tool is int ended for use on a circuit that has an outlet that l ooks like the one illustrated in sketch D.

The tool has a grounding t hat looks like the plug illustrated in sketch D. Make sure the tool is connected to

an outlet havi ng the same configuration as the pl ug. No adapter is available or should be used wit h this

tool. If the tool must be reconnected for use on a different type of electric circuit, the reconnect ion should

be made by qualified service personnel; and after reconnection, the tool should comply with all local

codes and ordinances.

6

Page 7

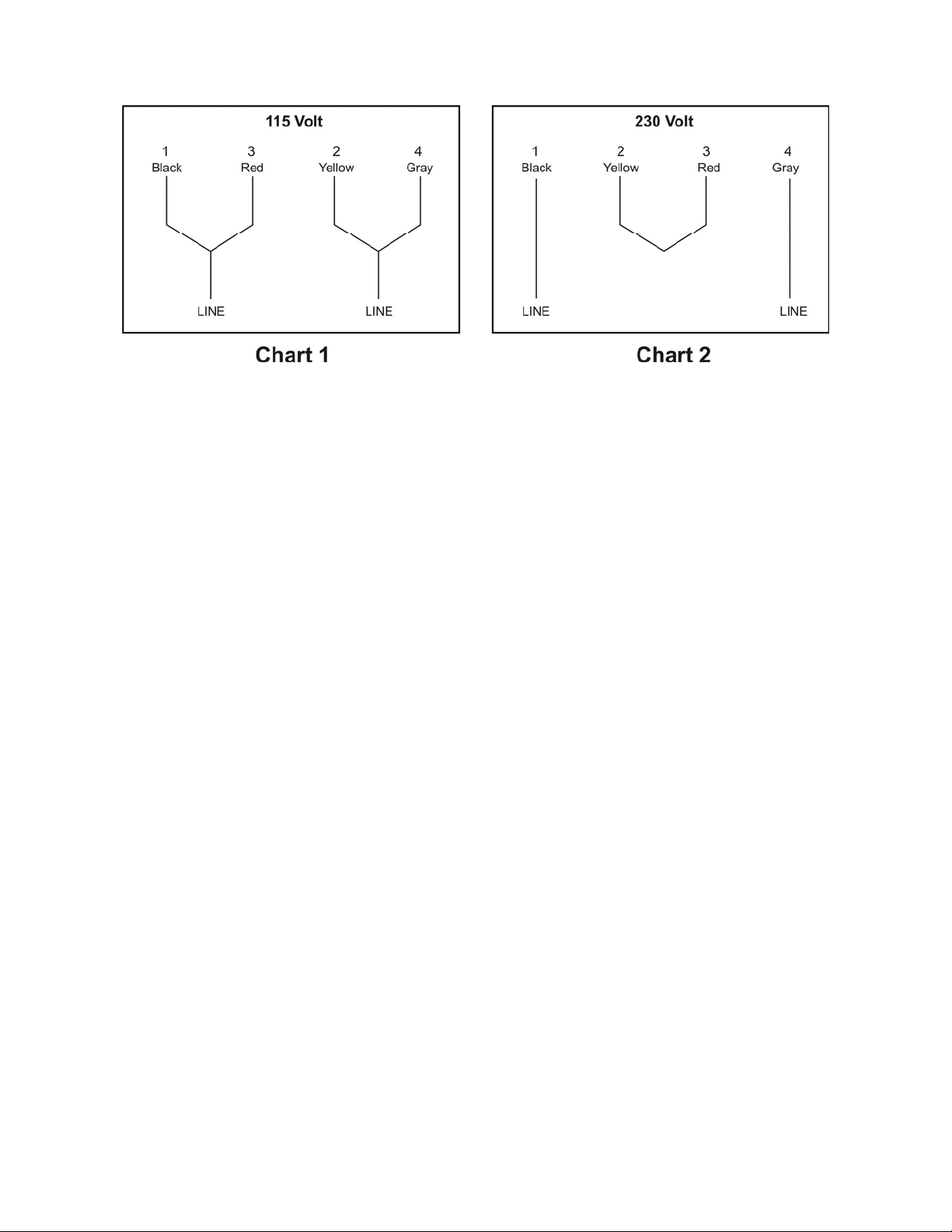

The conversion fro m 115V to 230V op erat ion must be done by a qualified elect rician.

Specifications

Model Number .......................................................................................................................... HVBS-56M

Stock Number................................................................................................................................ 414458

Horizontal Capacity:

Round @ 90° .................................................................................................................................... 5”

Round @ 45° .................................................................................................................................... 3”

Rectangle @ 90° .......................................................................... 5”(H) x 5-3/4”(W), and 2”(H) x 6”(W)

Rectangle @ 45° ....................................................................................................... 4-1/2”(H ) x 3”(W)

Throat Depth .......................................................................................................................................... 5”

Vertical Work Table Size...................................................................................................... 9-5/8” x 9-1/2”

Vise Swivels ......................................................................................................................................... 45°

Blade Size ............................................................................................................... 1/2” x 0.025” x 64-1/2”

Blade Wheel Diameter ...................................................................................................................... 7-3/8”

Speeds ........................................................................................................................ 80, 120, 200 SFPM

Bed Height ..................................................................................................................................... 25-1/2 ”

Floor Space Requi r ed ...................................................................................................... 16-1/4 ” x 42-1/2”

Motor (UL listed) ........................................................................... 1/2 HP, 1 Ph, 115/230V, prewired 115V

Net Weight (approx.)...................................................................................................................... 115 lbs.

The specifi cati ons in this m anual are giv en as general i nform ation and are not bi nding. J ET reserv es the

right to eff ect, at any tim e and wit hout pri or notic e, changes or alt erat ions to par ts, fi tti ngs, and accessory

equipment deemed nec essary for any reason whatsoever.

7

Page 8

Unpacking and Clean-Up

Note: Read and understand the entire manual

before attem pting setup or operation.

1. Remove all content s form the shipping

carton.

2. I nspect c ontents for shippi ng dam age and

report any damage t o your distributor.

3. Wipe bed and vise assembly wit h cl ean

cloth to remov e excess oil used to pr event

rust.

4. Do not discard any packing material until

saw has been assembl ed and is running

properly.

Tools Supplied for Assembly

Wrench 12/14mm

4mm Angle Hex Wrench

Tools Required for Assembly

• #2 Cross Point Screwdriver

• 6-8" Adjustable Wrench or Wrench Set

• Pliers - Regular or Needl e Nose

• Ratchet and Sockets will Speed Assembly

Assembly

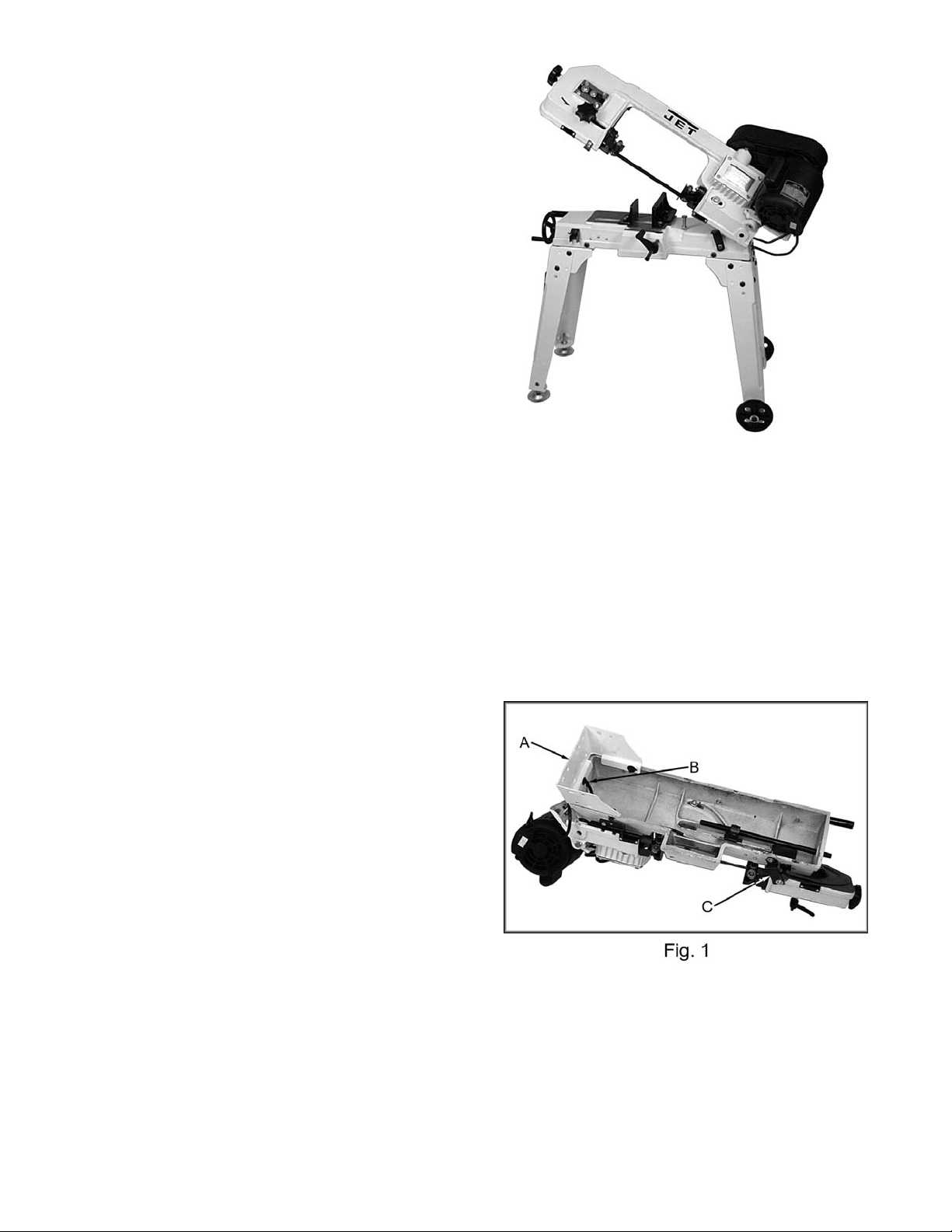

1. With the help of another person tur n the saw

over so that it rests on the m otor and saw

bow, Figure 1. Place it on a piece of

cardboard, or a surface that will not damage

the saw.

2. Attach a cross brace (A, Fig. 1) to t he motor

side of the bed using t hr ee 5/16”x 1” hex cap

bolts, six 5/16” flat washers, and secure with

three 5/16” hex nuts. Hint: Tighten the nut

(B, Fig. 1) on the end of the bed first

followed by the nuts on the si des.

3. Attach a leg to the cross brace using f our

5/16”x3/ 4” car ri age bolts, four 5/16” flat

washers and four 5/ 16” hex nuts. Use a

12mm wrench to tighten. Repeat for other

leg.

4. Remove the brace (C, Fig. 1) on the

opposite end of the bed and bow using a

10mm wrench.

8

Page 9

5. Attach a cross brace to the opposit e end of

the bed using three 5/ 16”x1” hex cap bolts,

six 5/16” flat washers, and secur e wi th three

5/16” hex nuts. Tighten the nut on the end

of the bed first followed by the nuts on the

sides.

6. Attach a leg to the cross brace using f our

5/16”x3/ 4” car ri age bolts, four 5/16” flat

washers and four 5/ 16” hex nuts. Use a

12mm wrench to tighten. Repeat for other

leg.

7. Attach the adjustable feet (A, Fig. 2) to the

legs opposite of t he m otor, using the

provided hardware.

8. Slide the axle (A, Fig. 3) thr ough the legs.

Place a large fl at washer (B, Fi g. 3) on both

sides of the wheels and plac e on the axle.

Secure wheels with t wo spli t pins (C, Fig. 3).

9. Carefully tur n the saw onto it s stand and

adjust the feet so the bed is level.

10. P ut the handle (A, Fig. 4) through holes in

the stand legs opposite of the wheel

assembly and secure with split pins.

9

Page 10

11. S lide pulley cov er (A, Fi g. 5) around motor

shaft and worm gear shaf t. Secure with two

hex cap screws and washers (B, Fig. 5).

12. Lift motor with one hand while the other

hand places V-belt (C, Fig.5) on both pulleys.

13. A ttach the tension brac k et (D , Fi g. 5) to the

saw bow with one 5/16”x3/4” hex head bolt

and flat washer (E, Fig. 5).

14. Connec t the two tension brack ets with one

5/16”x3/ 4” car ri age bolt, one 5/16” flat

washers and one 5/16” hex nut (F, Fig. 5).

Hint: Insert the carri age bolt from the inside

so the hex nut is easy to access with a

wrench.

15. Tension belt by pressing down on the m otor

while tightening hex nut (F, Fig. 5) until

finger pressure on the belt between the two

pulleys causes approxim ately 1/2" deflecti on.

Close pulley cover . Don’t ov er tighten the

belt.

16. Insert stop rod (A, Fig. 6) into bed and

tighten set screw (B, Fig. 6). Slide stock

stop (C, Fig. 6) onto r od and tight en set

screw (D, Fig. 6) to hold in plac e.

17. S lide handwheel (E, Fi g. 6) onto shaft and

secure by tight ening set screw (F, Fig. 6).

Make sure set screw seats on flat portion of

shaft.

Vertical Cutting Plate Assembly

Note: These steps are only nec essary when

using the bandsaw in the ver tical mode.

Disconnect the b and saw

from the power source before making any

repairs or adjustments. Failure to comply

may cause serious injury!

1. Disconnect the b and saw from the power

source.

2. Raise the arm to the vertical position and

lock in place wit h lev er (A, Fi g. 7) .

3. Loosen bolt (B, Fig. 7) and insert br acket (C,

Fig. 7). Tighten bolt just enough to hold the

bracket in place.

10

Page 11

4. Remove two screws (D, Fig. 7) and plate ( E,

Fig. 7).

5. G uide blade through slot i n table (A, Fig. 8)

and fasten table with two screws (B, Fig. 8).

6. F asten support bracket to under si de of table

using screw (C, Fig. 8) and hex nut .

7. T ighten bolt (B, Fig 7).

Electrical Connections

All electrical connect ions

must be completed by a qualified electrician.

Failure to compl y may cause seri ou s in ju ry!

The HVBS-56M band saw is rated at 115/230V

and comes from the fact or y prewir ed 115V .

To switch to 230V operation, follow the wiri ng

diagram found on the inside of the motor

junction box. The pl ug on the end will have to

be replaced with a plug that is rated at 230V.

This bandsaw is designed f or use on a circ uit

with an outlet t hat looks li k e ( A, Fig. 9). The

bandsaw has a grounding prong as i llustrated in

(B, Fig. 9). A temporary adapt er (C, Fig. 9) may

be used to connect the plug t o a two pole

receptacl e ( D, Fi g. 9) if a properly grounded

outlet is not av ailable. The temporary adapter

should only be used until a pr operl y gr ounded

outlet can be instal led by a qualified electrician.

The green color ed lug m ust be securely

fastened to the cov er plate screw.

Before hooki ng up to t he power source, be sure

the switch is in the off posi tion.

11

Page 12

Changing Blade Speed

1. Disconnect the mach in e f rom the power

source.

2. Place saw arm in the horizontal position.

3. Loosen tensioning pl ate hex nut (A, Fig.10).

4. O pen pulley cover (B, Fig. 10). Lift mot or

with one hand while pl aci ng the belt (C, Fig.

10) on the desired pull ey c om bination.

5. T ensi on belt by pressing down on the motor

while tightening hex nut (A, Fig. 10) until

finger pressure on the belt between the two

pulleys causes approxim ately 1/2" deflecti on.

Close pulley cover . Don’t ov er tighten the

belt.

6. Close pulley cover and connec t t o power

source.

The general rule for band saw blade speed is

the harder the material being cut, the slower the

blade speed. Reference Figure 11 for a guide to

blade speed for a type of material being cut.

Adjusting Blade Guides

1. Disconnect mach in e f rom the power

source.

2. Loosen k nob ( A , Fig. 12) and slide blade

guide assembly ( B, Fig. 12), as close as,

possible without interference to the material

being cut. Tighten knob.

3. Loosen bolt (C, Fig. 12) and slide blade

guide assembly ( D, Fi g. 12), as close as,

possible without interference to the material

being cut. Tighten bolt

Adjusting Blade Tension

1. Disconnect mach in e f rom the power

source.

2. O pen blade cover and observe the posi tion

of the blade on the wheel. If the blade is not

next to the wheel flange, adjust blade

tracki ng following the steps under "Adjusting

Blade Tracking".

3. If the blade is next to the wheel fl ange,

loosen the blade guide assembly lock knob

and hex head bolt (A & C, Fig. 12) and sli de

the blade guide assembl ies as far apart as

possible. Loc k in pl ac e.

4. Depres s bl ade. Finger pressure should

cause approxim ately .004" deflection. T ur n

blade tension knob ( B , Fi g. 12) until the

proper tension i s achieved. Re-position

guides for cutting material.

12

Page 13

Changing Blades

1. Disconnect mach in e f rom the power

source.

2. Raise the saw arm to the vertical position

and lock in place wit h loc k lever.

3. O pen blade cover by removing the small

knob found on the topsi de of t he bow.

4. Remove red blade guards by removing two

screws.

It is essential these two

guards be installed after the new blade has

been fitted. Fai lu re to comply may cause

serious injury!

5. Release tension on the blade by turning

tensioning knob ( B , Fi g. 12), and remove the

blade.

6. Place new blade between the blade guide

assemblies and around each wheel. Make

sure blade teeth are pointing in the proper

direction, Figure 13. Tension enough to

hold in place.

7. I nstall red blade guards with two screws.

8. T ensi on blade fully, see “Adjusting Blade

Tension”.

9. Place two to three drops of li ghtweight oil on

the blade.

10. Connec t machine to the power source.

11. Run sa w and make sure blade is tracking

properly, see "Adjusting Blade Tracki ng".

As a general rule, t he thinner the material to be

cut, the more teeth per inch on the blade. A

minimum of three teeth should be in contact with

the material at all times during the cut. If the

teeth straddl e the material, severe damage can

result to the mat eri al and the blade.

Adjusting Blade Guide Bearings

1. Disconnect mach in e f rom the power

source.

2. Loosen bolt (A, Fig. 14) and adjust assem bly

so that back roll er bearing is

approximat ely .002" - .003" from the back of

the blade. Tight en bolt.

3. Loosen nut (B, Fig. 14) and turn nut (C, Fig.

14) to adjust ecc entric bearing to a

clearance of .001" . Tighten nut (B, Fig. 14)

to lock.

4. Connect machine to power source.

13

Page 14

Adjusting Blade Tracking

Blade tracking adjustment

requires runni ng the saw with th e back co ver

open. This adjustment must be completed by

qualified persons only. Failure to comply

may cause serious injury!

Blade tracking has been set at the factory and

should not need imm ediate adjustment. If blade

tracki ng should ever require adjustment:

1. Conf irm that blade tensi on is set proper ly.

To adjust, see section titled "Adjusting Bl ade

Tension".

2. Mak e sure the saw is in its slowest speed,

see “Changing Blade Speeds”.

3. Move saw arm to the vertical posi tion and

lock in place with the lock lever.

4. Conf irm that blade tensi on is set proper ly.

To adjust, see section titled " Adjusting

Blade Tension" .

5. O pen blade cover by removing the knob

found on the top side of t he bow.

6. Run saw and observe blade. Blade should

run next to but not tightl y against wheel

flange.

7. Loosen bolts (A, Fig. 15).

8. T ur n set scr ew (B, Fig. 15) while observing

blade tracki ng on wheel. Turn set screw

clockwise to t r ack closer t o wheel flange.

Turn set screw counter-clockwise to track

away from the wheel flange. Hint: start

with ¼ turns on the set screw. The tracking

is sensitive.

9. O nc e tracking is set, tight en bolts (A, Fig.

15).

Adjusting Feed Pressure

1. T ur n handle (A, Fig. 16) clockwise to

decrease cutti ng pr essure and counter clockwise to incr ease cut ting pressure.

A good indication of proper feed pressure is the

color and shape of the c utti ng c hips. If the chips

are thin or powdered, increase the f eed pr essure.

If the chips are burned and heav y , decr ease the

feed pressure. If they are still burned and heav y,

reduce the blade speed. Optimum feed

pressure has been set when the chips are curled,

silvery, and warm .

14

Page 15

Blade-Table Squareness

1. The band saw blade must be perpendicul ar

to the table to ensure a straight cut. This

setting should be checked. Special blade

setting gauges can be purchased for this

type of inspection; however, it can also be

done using more common shop items, as

follows.

2. First “extend” the surface of the blade by

clamping a straight , flat object to the blade.

(Figure 16a uses a small, lightweight

aluminum ruler.) Use a lightweight clamp.

3. Place a square on the table and against the

ruler. The square should l ie flat against the

ruler without a gap.

4. If there i s a gap, loosen the bolt (Figure 16b)

on each blade guide assembly and rotate

the blade guide assembly until there is no

more gap between the square and the r uler.

5. Re-tighten the bolts.

3. Adjust the blade guides so they are as close

as possible t o the material without int erfer ing.

4. T her e is a scale on the back side of the bed

to aid in setting up the vise for 90° cuts or a

particular miter. Hint: Always check the

vise setup with a combination square,

against the bl ade and v ise, so that you can

verify the vise setting is correct.

6. After making this adjustment, be sure to recheck other blade adjustments as noted in

your manual.

Adjusting Automatic Shut-Off

The saw should stop aft er the cut has been

completed:

• If the saw complet es the c ut and continues

to run, adjust the stop tip (A, Fig. 17) down.

• If the saw shuts off bef or e the cut is

complete, adjust the stop tip (A, Fig. 17) up.

• If the saw stops cutting but continues to run,

adjust the stop bol t (B , fi g. 17) down.

The saw is properly adjusted when the saw

shuts off just after the blade has finished the cut.

Adjusting the Vise

1. T o open and c lose the vise use the

handwheel (C, Fi g. 17).

2. T he v ise can be adjusted for square and

miter cuts. Loosen the hex c ap bolts and

adjust the vise for the cut.

Fig. 16a

Fig. 16b

15

Page 16

Lubrication

Ball bearings on t he blade guide assemblies and

the blade wheels are permanently sealed and

require no lubrication.

Lubricate the vise lead screw as needed with #2

tube grease.

Gear box oil will hav e to be changed aft er 90

days of operation. Thereafter, change ever y six

months.

To change the gear box oil:

1. Disconnect mach in e f rom the power

source.

2. Place saw arm in the horizontal position.

3. Remove screws (A, Fig. 18) fr om the gear

box and remove cover plate and gasket.

4. Hold a container under t he lower right corner

of the gear box with one hand whil e sl owly

raising the saw arm with the other. Drain

completely.

5. Place arm in the horizont al posi tion. Wipe

out remaining oil with a rag.

6. F ill gear box with approximately 1/2 pint of

MOBIL SHC 634.

7. Replace gasket and cov er. Fasten cov er

with bolts.

16

Page 17

Breakdown for Bow Assembly

17

Page 18

Breakdown for Base Assembly

18

Page 19

Parts List for the HVBS-56M Bandsaw

Index Part

No. No. Description Size Qty.

1 .......... TS-0051031 .............................. Hex Cap Bolt ..........................................5/16”x3/4” ................... 4

2 .......... TS-0561011 .............................. Hex Nut..................................................1/4”............................. 1

3 .......... TS-0680021 .............................. Flat Washer ...........................................1/4”............................. 4

4 .......... HVBS56M-04 ............................ Stand Leg ................................................................................. 4

4-1....... HVBS56 M-04-1 ......................... Cross Brace .............................................................................. 2

5 .......... HVBS56M-05 ............................ Washer ..................................................................................... 6

6 .......... HVBS462-006 ........................... Cotter Pin ...............................................1/8”x1” ........................ 4

7 .......... HVBS56M-07 ............................ Axle .......................................................................................... 1

8 .......... TS-0680031 .............................. Flat Washer ...........................................5/16” ......................... 38

9 .......... HVBS56M-09 ............................ Wheel ....................................................................................... 2

10 ........ HVBS56M-010 .......................... Washer ..................................................1/4 ”x5/8” ..................... 1

11 ........ TS-0051051 .............................. Hex Cap Bolt ..........................................5/16”x1” ...................... 4

11-1 ..... HVBS56M-11-1 ......................... Ca rriage Bolt ..........................................5/16”x3/4” ................. 16

11-2 ..... TS-0051051 .............................. Hex Cap Bolt ..........................................5/16”x1” ...................... 6

12 ........ TS-0561021 .............................. Hex Nut..................................................5/1 6” ......................... 22

13 ........ HVBS56M-013 .......................... Adjustab le Foot ......................................................................... 2

14 ........ HVBS462-014 ........................... Floor Stand Handle ................................................................... 1

15 ........ HVBS462-015 ........................... Adjusting Rod ........................................................................... 1

16 ........ HVBS462-016 ........................... Electric Cord ............................................................................. 1

17 ........ HVBS462-017 ........................... Pivoting Rod ............................................................................. 1

18 ........ HVBS462-018 ........................... Support P late ............................................................................ 1

19 ........ HVBS462-019 ........................... Stock Stop ................................................................................ 1

20 ........ TS-0270021 .............................. Socket Set Screw ...................................5/16”x5/16” ................. 4

21 ........ HVBS

22 ........ HVBS462-022 ........................... Wire Relief Retainer .................................................................. 2

25 ........ TS-0051031 .............................. Hex Cap Bolt ..........................................5/16”x3/4” ................... 1

27 ........ HVBS462-027 ........................... Wheel Handle ........................................................................... 1

28 ........ HVBS462-028 ........................... Hand Wheel .............................................................................. 1

29 ........ HVBS56M-029 .......................... Toggle Switch Assem bly ........................................................... 1

29-1 ..... HVBS56M-029-1 ....................... Plastic Cover ............................................................................. 1

30 ........ HVBS462-030 ........................... E-Ring ...................................................E10 ............................ 1

31 ........ HVBS462-031 ........................... Screw ....................................................5/16”x1” ...................... 3

32 ........ HVBS462-032 ........................... Lead Screw ............................................................................... 1

33 ........ HVBS462-033 ........................... Vise Nut .................................................................................... 1

34 ........ HVBS462-034 ........................... Moveable Vise Plate ................................................................. 1

35 ........ TS-0680041 .............................. Flat Washer ...........................................3/8”x1” ........................ 4

36 ........ TS-0090061 .............................. Hex Cap Bolt ..........................................3/8”x1-1/4” .................. 1

37 ........ HVBS462-037 ........................... Bed ........................................................................................... 1

38 ........ HVBS462-038 ........................... Cross Round Head Screw ......................3/16”x3/8” ................... 2

39 ........ HVBS462-039 ........................... Scale ........................................................................................ 1

40 ........ HVBS462-040 ........................... Electric Cord Clip ...................................................................... 1

42 ........ HVBS56M-042 .......................... Screw ....................................................M4x16 ........................ 2

43 ........ HVBS462-043 ........................... Rubber Ring.............................................................................. 1

44 ........ HVBS462-044 ........................... Electric Cable ............................................................................ 1

45 ........ HVBS462-045 ........................... Nut Plate ................................................................................... 1

45-1 ..... HVBS56M-045-1 ....................... Spring Handle Bracket .............................................................. 1

46 ........ HVBS462-046 ........................... Spring Adjusting Screw ............................................................. 1

47 ........ HVBS462-047 ........................... Spring ....................................................................................... 1

48 ........ HVBS462-048 ........................... Cross Round Head Screw ......................3/16”x3/8” ................... 4

49 ........ HVBS462-049 ........................... Mitering Vise Plate .................................................................... 1

50 ........ TS-0081031 .............................. Hex Cap Bolt ..........................................5/16”x3/4” ................... 6

462-021 ........................... Stock Stop Rod ......................................................................... 1

19

Page 20

Index Part

No. No. Description Size Qty.

49 ........ HVBS462-049 ........................... Mitering Vise Plate .................................................................... 1

50 ........ TS-0081031 .............................. Hex Cap Bolt ..........................................5/16”x3/4” ................... 6

51 ........ TS-0680031 .............................. Flat Washer ...........................................5/16” ........................... 3

52 ........ TS-0081071 .............................. Hex Cap Bolt ..........................................5/16”x1-1/2” ................ 1

53 ........ TS-0091071 .............................. Hex Cap Screw ......................................7/16”x2” ...................... 1

54 ........ HVBS56M-054 .......................... Pivot Bracket ............................................................................. 1

55 ........ HVBS462-055 ........................... Vertical Cutting Plate ................................................................. 1

56 ........ HVBS462-056 ........................... Stand for Vertical Cutting Plate.................................................. 1

57 ........ HVBS56M-057 .......................... Adjustable Bracket LH ............................................................... 1

57A ..... HVBS56M-057A........................ Adjustable Bracket Assembly LH ............................................... 1

58 ........ HVBS462-058 ........................... Knob ......................................................1/4”............................. 1

59 ........ HVBS56M-380 .......................... Blade Back Safety Cover .......................................................... 1

60 ........ HVBS462-060 ........................... C-C lip ....................................................S1 0 ............................ 4

61 ........ BB-6000ZZ ............................... Ball Bearing ...........................................6000ZZ....................... 6

62 ........ HVBS462-062 ........................... Guide Pivot ............................................................................... 2

62A ..... HVBS462-062A......................... Center Shaft Assembly (Includes: #60-62) ................................. 1

62-1 ..... HVBS462-062-1 ........................ Centrifugal Guide Pivot ............................................................. 2

62-1A .. HVBS462-062-1A ..................... Eccentric Shaft Assembly (Includes: #60,61,62-1) ..................... 1

63 ........ HVBS462-063 ........................... Bearing Shaft Pin ...................................................................... 2

64-1 ..... HVBS462-064-1 ........................ Blade S eat Lef t ......................................................................... 1

64-2 ..... HVBS462-064-2 ........................ Blade S eat Right ....................................................................... 1

65 ........ HVBS56M-065 .......................... Adjustab le Bracket-RH .............................................................. 1

65A ..... HVBS56M-065A........................ Adjustable Bracket-Assembly RH .............................................. 1

66 ........ HVBS56M-066 .......................... Lock Knob ................................................................................. 1

67 ........ TS-0720081 .............................. Lock Washe r ..........................................5/16 ” ........................... 3

68 ........ TS-0813051 .............................. Flat Head Machine Screw ......................1/4 ”X3/4 ” .................... 3

69 ........ HVBS462-069 ........................... Bearing Guard .......................................................................... 1

70 ........ TS-0561031 .............................. Hex Nut..................................................3/8 ”............................. 4

71 ........ HVBS462-071 ........................... Blade Wheel Drive .................................................................... 1

72 ........ HVBS462-072 ........................... Bearing Cover ........................................................................... 2

73 ........ HVBS462-073 ........................... Key ........................................................5x5x25 ....................... 2

74 ........ HVBS56M-060 .......................... C-C lip ....................................................S1 5 ............................ 1

75 ........ HVBS462-075 ........................... Hex Cap Bolt (w/Washer) .......................1/4”x1/2” ..................... 8

76 ........ HVBS462-076 ........................... Switch Cut Off Trip .................................................................... 1

77 ........ HVBS462-077 ........................... Idle Blade Wheel ....................................................................... 1

78 ........ TS-0680031 .............................. Flat Washer ...........................................5/16” ........................... 2

79 ........ HVBS462-079 ........................... Blade T ension Knob ...............................3/8”............................. 1

80 ........ HVBS462-080 ........................... Spring ....................................................................................... 1

81 ........ HVBS56M-081 .......................... Saw Bow................................................................................... 1

82 ........ HVBS56M-082 .......................... Washer ..................................................................................... 1

83 ........ TS-0070031 .............................. Cap Screw .............................................1 /2”x1-1/2” .................. 2

84 ........ HVBS56M-084 .......................... Motor Mount Plate ..................................................................... 1

84-1 ..... HVBS56M-084-1 ....................... Tension Bracket ........................................................................ 1

85 ........ HVBS463-085 ........................... Motor .....................................................1/2 HP, 1Ph ................ 1

............ HVBS463-085-01 ...................... Capacitor Cover (not shown) ..................................................... 1

............ HVBS462-085-02 ...................... Capacitor (not shown) ............................................................... 1

86 ........ HVBS462-086 ........................... Motor Pulle y .............................................................................. 1

87 ........ BB-6202ZZ

88 ........ HVBS462-088 ........................... Bearing Bushing........................................................................ 1

89 ........ OS-15375 ................................. Oil Seal ..................................................................................... 2

90 ........ HVBS462-090 ........................... Transmiss ion Wheel Sha ft......................................................... 1

91 ........ HVBS462-091 ........................... Worm Gear ............................................................................... 1

92 ........ HVBS462-092 ........................... Gear Box Gasket ...................................................................... 1

93 ........ HVBS462-093 ........................... Gear Box Cover ........................................................................ 1

............................... Ball Bearing ...........................................6202ZZ....................... 6

20

Page 21

Index Part

No. No. Description Size Qty.

94 ........ HVBS462-094 ........................... Worm Gear (w/Sha ft) ................................................................ 1

95 ........ HVBS462-095 ........................... Spring Pin ................................................................................. 1

96 ........ HVBS462-096 ........................... Bearing Bushing........................................................................ 1

97 ........ TS-0050011 .............................. Hex Cap Bolt ..........................................1/4”x1/2” ..................... 3

98 ........ HVBS56M-098 .......................... Clamp ....................................................................................... 2

99 ........ HVBS462-099 ........................... Spacer ...................................................................................... 1

100 ...... HVBS462-100 ........................... Flat Cross Head Screw ..........................5/32”x3/8” ................... 8

101 ...... HVBS462-101 ........................... Worm Gear Pulle y ..................................................................... 1

102 ...... TS-0720081 .............................. Lock Washe r ..........................................5/16” ........................... 2

103 ...... HVBS462-103 ........................... Blade Tension Sli ding Plate ....................................................... 1

104 ...... TS-0270051 .............................. Socket Set Screw ...................................5/16”x1/2” ................... 3

105 ...... HVBS462-105 ........................... Spring Pin ................................................................................. 1

106 ...... HVBS462-106 ........................... Sliding Plate Draw Block ........................................................... 1

107 ...... HVBS462-107 ........................... Blade Wheel Shaft .................................................................... 1

108 ...... HVBS462-108 ........................... Shaft Block ............................................................................... 1

109 ...... HVBS462-109 ........................... Blade Tension Sli ding Guide ..................................................... 2

110 ...... HVBS462-110 ........................... Motor Pul l ey Cover Assembly.................................................... 1

111 ...... TS-0680031 .............................. Flat Washer ...........................................5/16” ........................... 1

112 ...... VB-A22 ..................................... V-Bel t .....................................................A22 ............................ 1

113 ...... 414301 ..................................... Blade ........................................................................................ 1

114 ...... TS-0680041 .............................. Flat Washer ...........................................3/8”............................. 4

115 ...... TS-0561011 .............................. Hex Nut..................................................1 /4”............................. 1

116 ...... HVBS

117 ...... HVBS463-171 ........................... Hex Screw .............................................3/8”x1-1/4” .................. 1

120 ...... HVBS462-120 ........................... Bushing .................................................................................... 1

122 ...... TS-0561041 .............................. Hex Nut..................................................7 /16” ........................... 1

123 ...... TS-0050031 .............................. Cap Screw .............................................1 /4”x3/4” ..................... 1

124 ...... HVBS463-124 ........................... Machine Screw ......................................3/16”x3/4” ................... 2

126 ...... HVBS462-126 ........................... Bushing .................................................................................... 1

132 ...... HVBS462-132 ........................... Blade Guard- Right .................................................................... 1

132-1 ... HVBS462-132A......................... Blade Guard- Left ....................................................................... 1

156 ...... HVBS462-156 ........................... Round Head Screw ................................3/16”x3/4” ................... 1

157 ...... HVBS462-157 ........................... Star Washer ...........................................3/16” ........................... 3

158 ...... HVBS463-158 ........................... Hex Nut ..................................................3/16” ........................... 2

159 ...... HVBS463-159 ........................... Round Cross Head Scre w ......................3/16”x1/2” ................... 1

............ HVBS56M-BS ........................... Blade Speed Label (not shown) ................................................. 1

............ HVBS56M-ID ............................ I.D. Label (not shown) ............................................................... 1

............ HVBS56M-WL .......................... Warning Label (not shown)........................................................ 1

............ JM-56M..................................... Stripe Decal (not shown) ........................................................... 1

463-170 ........................... Wire Plug .................................................................................. 3

21

Page 22

Wiring Diagram

22

Page 23

Notes

23

Page 24

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

24

Loading...

Loading...