Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Drill Press

Models: J-2500, J-2530, J-2550

J-2530 J-2500 J-2550

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-354400

Ph.: 800-274-6848 Revision B3 11/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact

Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official JET

branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not

cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair,

alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood. Use of these machines in

the processing of metal, plastics, or other materials may void the warranty. The exceptions are acrylics and other natural items

that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a Two Year

Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pr o of of ini tial

purchase when calling. If a product requires further inspection, the Technical Service representative will explain and assist

with any additional action needed. JET has Authorized Service Centers located throughout the United States. For the name of

an Authorized Service Center in your area call 1-800-274-6846 or use the Service Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor or visit

the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are given as

general information and are not binding. JET reserves the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

are not sold in Canada by JPW Industries, Inc.

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries, Inc., or any

of its successors in interest to the JET brand.

®

branded products

2

Page 3

Table of Contents

Table of Contents ................................................................................................................................................ 3

Warnings ............................................................................................................................................................. 4

Introduction .......................................................................................................................................................... 6

Specifications ...................................................................................................................................................... 6

Shipping Contents ............................................................................................................................................... 7

Required Tools .................................................................................................................................................... 7

Assembly ............................................................................................................................................................. 8

Before Assembly .............................................................................................................................................. 8

Column Assembly ............................................................................................................................................ 8

Table Bracket ................................................................................................................................................... 8

Crank Handle and Table Lock Handle .............................................................................................................. 8

Column Lock Handle ........................................................................................................................................ 9

Table Installation .............................................................................................................................................. 9

Head Assembly ................................................................................................................................................ 9

Chuck and Arbor Installation ............................................................................................................................. 9

Chuck and Arbor Removal.............................................................................................................................. 10

Adjustment ........................................................................................................................................................ 10

Depth Stop Adjustment ................................................................................................................................... 10

Changing Spindle Speeds .............................................................................................................................. 11

Return Spring Adjustment............................................................................................................................... 11

Work Light (J-2500 and J-2530 only) .............................................................................................................. 11

Table Tilt Adjustment ...................................................................................................................................... 12

Operation........................................................................................................................................................... 12

Installing Drills ................................................................................................................................................ 12

Positioning the Workpiece .............................................................................................................................. 12

Using the Vise ................................................................................................................................................ 12

Basic Operation .............................................................................................................................................. 12

Maintenance ...................................................................................................................................................... 12

Lubrication ......................................................................................................................................................... 12

Electrical ............................................................................................................................................................ 13

Grounding Instructions ................................................................................................................................... 13

115 Volt Operation ......................................................................................................................................... 13

230 Volt Operation ......................................................................................................................................... 13

Extension Cords ............................................................................................................................................. 13

Troubleshooting ................................................................................................................................................. 14

Replacement Parts ......................................................................................................................................... 15

Parts List – J-2500, J-2530 ............................................................................................................................. 15

Exploded View – J-2500, J-2530 .................................................................................................................... 18

Parts List – J-2550 ......................................................................................................................................... 19

Exploded View – J-2550 ................................................................................................................................. 22

Wiring Diagram .................................................................................................................................................. 23

J-2500/J-2530 – 115V .................................................................................................................................... 23

J-2500/J-2530 – 230V .................................................................................................................................... 23

J-2550 – 115V ................................................................................................................................................ 24

J-2550 – 230V ................................................................................................................................................ 24

The specifications in this manual are given as general information and are not binding. JET reserves the right to

effect, at any time and without prior notice, changes or alterations to parts, fittings, and accessory equipment

deemed necessary for any reason whatsoever.

3

Page 4

Warnings

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with all of

these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This drill press is designed and intended for use by properly trained and experienced personnel only. If you

are not familiar with the proper and safe operation of a drill press, do not use until proper training and

knowledge have been obtained.

5. Do not use this drill press for other than its intended use. If used for other purposes, JET disclaims any real or

implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approved safety glasses/face shields while using this drill press. Everyday eyeglasses only have

impact resistant lenses; they are not safety glasses.

7. Before operating this drill press, remove tie, rings, watches and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out microscopic particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting wrenches are

removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance purposes,

use extreme caution and replace the guards immediately.

16. Make sure the drill press is firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that

may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep child ren aw ay.

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

4

Page 5

22. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are careless

acts that can result in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against the spindle or other moving

parts. Do not overreach or use excessive force to perform any machine operation.

24. Use the right tool at the correct speed and feed ra

was not designed. The right tool will do the job better and safer.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep drill bits sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

27. Make sure the work piece is securely attached or clamped to the table. Never use your hand to hold the work

piece.

28. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do not use

your hands.

29. Do not stand on the machine. Serious injury could occur if the machine tips over.

30. Never leave the machine running unattended. Turn the power off and do not leave the machine until it comes

to a complete stop.

31. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no ti ces used in this manual:

e. Do not force a tool or attachment to do a job for which it

t

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

The JET 15-Inch 16-Speed Drill Presses and 20-Inch 12-Speed Drill Presses, Models J-2500, J-2530 and J-2550,

feature rugged cast iron design with ground-steel columns for drilling accuracy in metal, wood, and plastic. The

head casting features a ball bearing spindle assembly, supported by four permanently-lubricated, heavy duty ball

bearings that are mounted in an enclosed quill for extended life.

Specifications

Model J-2500 J-2530 J-2550

Stock Number ............................................. 354400 ............................. 354401 ............................. 354402

Model Type ................................................. 15-Inch Floor .................... 15-Inch Bench .................. 20-Inch Floor

Drilling Capacity

Cast Iron ................................................. Up to 5/8 In. ...................... Up to 5/8 In. ..................... Up to 3/4 In.

Steel ....................................................... Up to 1/2 In. ...................... Up to 1/2 In. ..................... Up to 5/8 In.

Drill to Center .............................................. 15 Inches ......................... 15 Inches ......................... 20 Inches

Motor

Rating ..................................................... 3/4 hp, 1-Phase ................ 3/4 hp, 1-Phase ................ 1 hp, 1-Phase

RPM ....................................................... 1725 ................................. 1725 ................................ 1725

Full Load Amperage ................................ 9.0/4.5 .............................. 9.0/4.5.............................. 14/7

Voltage............................................115/230V (prewired 115V).......115/230V (prewired 115V) ..... 115/230V (prewired 115V)

Column Diameter......................................... 2-7/8 In. ............................ 2-7/8 In. ........................... 3-5/8 In.

Quill

Diameter ................................................. 1-7/8 In. ............................ 1-7/8 In ............................ 2-1/4 In.

Travel ..................................................... 3-1/8 In. ............................ 3-1/8 In. ........................... 4-3/4 In.

Table

Overall .................................................... 11-1/2 x 11-1/2 In. ............. 11-1/2 x 11-1/2 In. ............ 18-1/2 x 16-1/2 In.

Working Surface ..................................... 9-1/2 x 9-1/2 In. ................ 9-1/2 x 9-1/2 In. ................ 15-1/2 x 13-1/2

Travel ..................................................... 24 In. ................................ 15-1/2 In. .......................... 21-1/2 In.

Base

Size ........................................................ 11 x 19-1/2 In. .................. 10-1/2 x 18 In. .................. 22-3/4 x 17-3/4 In.

Working Surface ..................................... 7 x 7-1/2 .......................... 8 x 8 ................................. 13 x 14-1/2

Chuck Size .................................................. 5/8-In., Key Chuck ............ 5/8-In., Key Chuck ............ 5/8-In, Key Chuck

Overall Dimensions

Length .................................................... 31 In. ................................ 31 In. ............................... 33-1/2 In.

Width ...................................................... 13 In. ................................ 13 In. ............................... 18-1/2 In.

Height ..................................................... 63 In. ................................ 39-1/2 In. .......................... 67 In.

Spindle to Table (Max.) ................................ 24 In. ................................ 15-1/2 In. .......................... 24 In.

Spindle to Column (Max.) ............................. 7-1/2 In. ............................ 7-1/2 In. ........................... 10-1/2 In.

Spindle

To Base .................................................. 48 .................................... 24 .................................... 43-1/2

Taper ...................................................... MT-2 ................................ MT-2 ................................ MT-3

Number of speeds .................................. 16 ..................................... 16 .................................... 12

RPM ...................................................... 200, 290, 350, 430............. 200, 290, 350, 430............ 150, 260, 300,

500, 580, 640, 720 500, 580, 640, 720 440, 490, 540,

800, 870, 1440, 1630 800, 870, 1440, 1630 1150, 1550, 1840,

1820, 2380, 2540, 3630 1820, 2380, 2540, 3630 2220, 2950, 4200

Shipping Weight .......................................... 185 pounds ...................... 157 pounds ...................... 321 pounds

6

Page 7

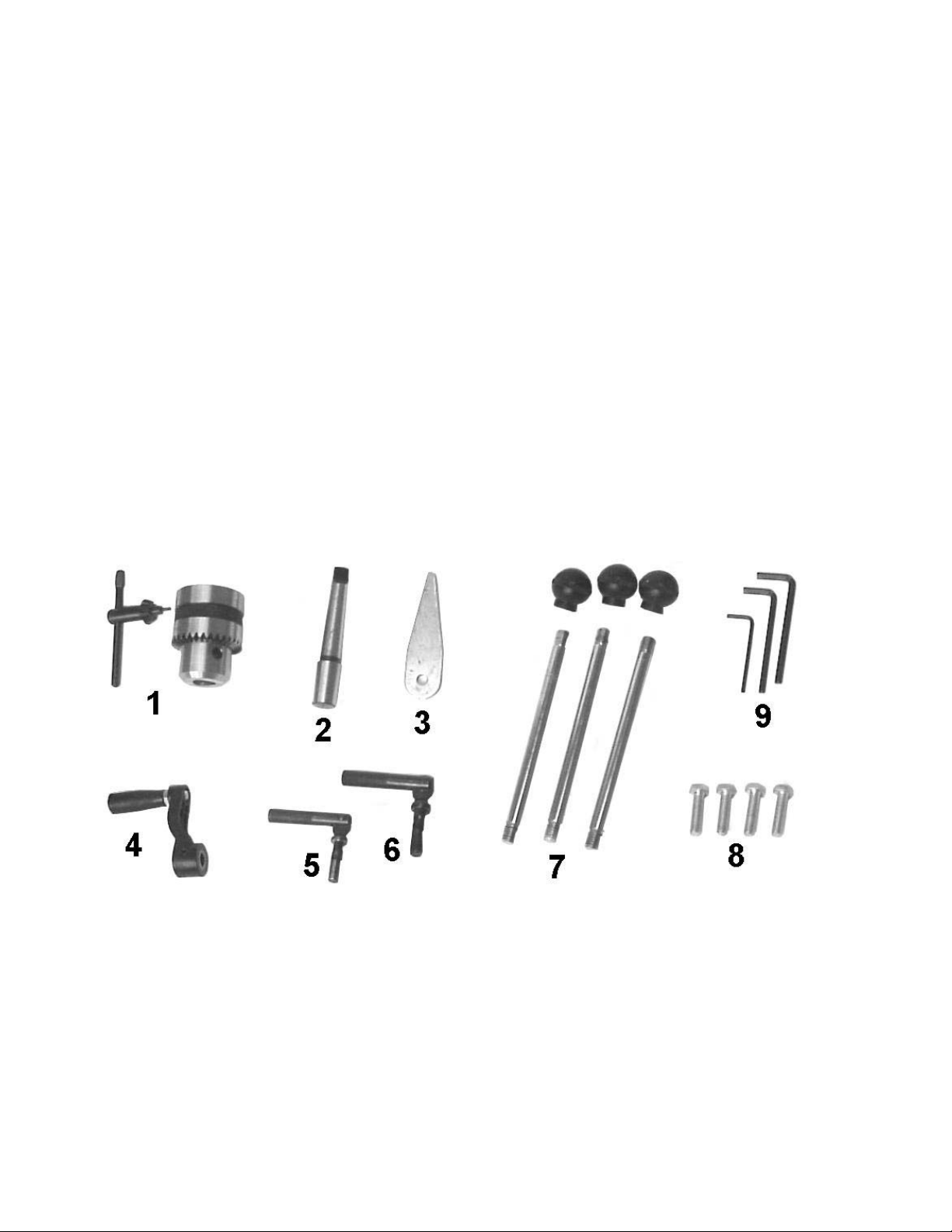

Shipping Contents

Unpack the carton and verify that all parts listed

below are included.

Main Parts

Other Material

1 ea Head Assembly

1 ea Table

1 set Column and Table Bracket Assembly

1 ea Base

Additional Parts

1. 1 set Chuck and Chuck Key

2. 1 pc Arbor

3. 1 pc Drift Key

4. 1 pc Table Crank Handle

5. 1 pc Table Lock Handle

6. 1 pc Column Lock Handle

7. 3 pcs Downfeed Handles and Knobs

8. 4 pcs M10 x 40 Hex Cap Screws

9. 1 set Hex Wrenches (3mm, 5mm, 6mm)

1 ea Owner’s Manual

1 ea Warranty Registration Card

Required Tools

1. 17mm Box Wrench or a 6” – 8” Adjustable

Wrench

2. 15/16" wrench

Additional Parts

7

Page 8

Assembly

Read and understand all assembly instructions

before attempting assembly! Failure to comply

may cause serious injury!

Before Assembly

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping container

with the list found above. Report any shortages

or damage to your JET distributor.

3. Clean all rust protected surfaces with kerosene

or a light solvent. Do not use lacquer thinner,

paint thinner, or gasoline. These will damage

plastic components and painted surfaces.

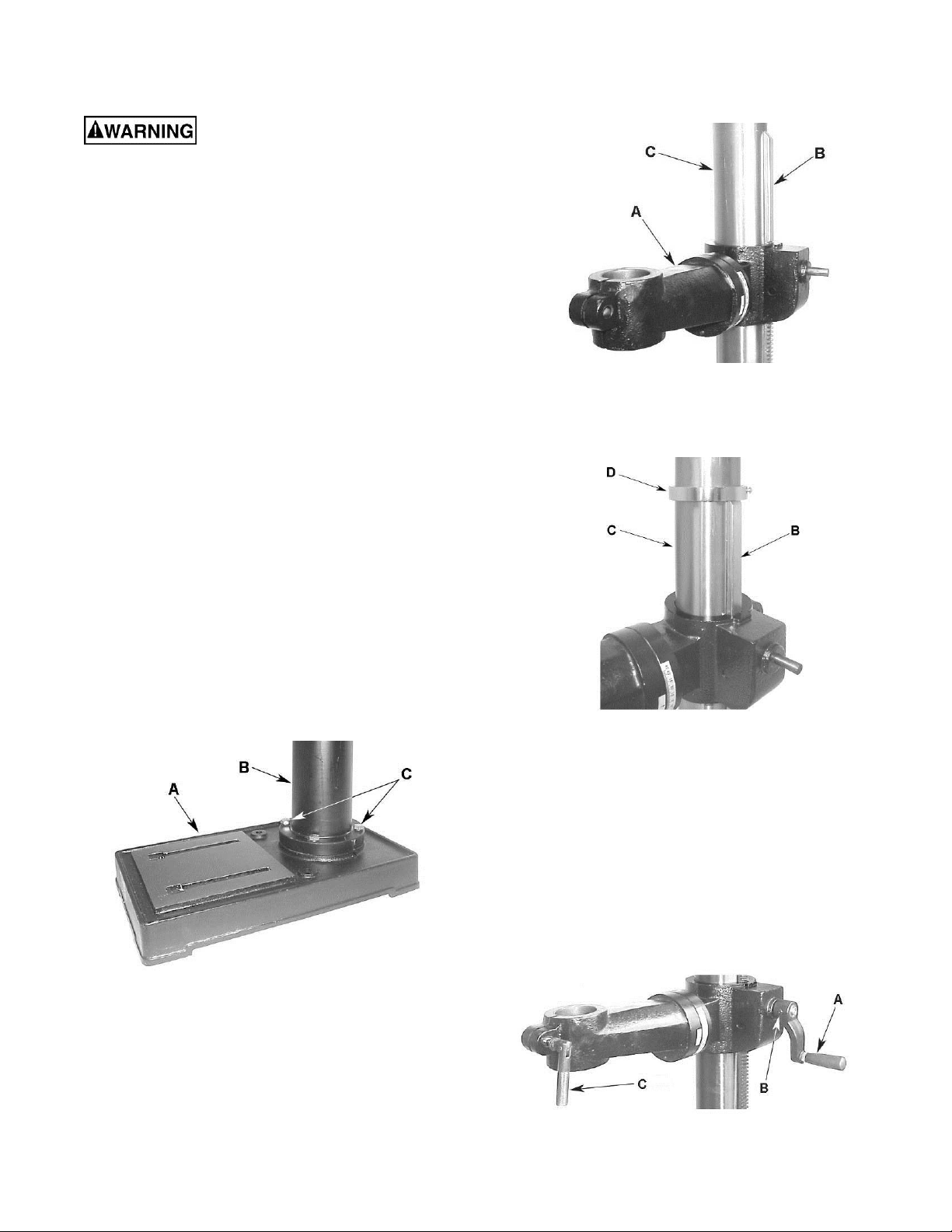

Column Assembly

Referring to Figure 1:

1. Place the base (A) on a level floor.

2. Install the table bracket (A) together with the

rack (B) as shown in Figure 2.

Figure 2

3. Slide the rack ring (D) over the column (C),

placing it so it rests against the rack (B) as

shown in Figure 3 and tighten firmly.

2. Place the column assembly (B) on the base (A)

and align the holes in the column support with

the holes in the base.

3. Note: The column shown in Figure 1 is for the

JDP-15MF. While the JDP-15M column is

slightly different in appearance, the assembly

procedure is the same.

4. Using a 17mm wrench, secure the column (B)

with four M10 x 40 hex cap screws (C) to the

base.

Figure 1

Figure 3

Crank Handle and Table Lock Handle

Referring to Figure 4 (shown already assembled):

1. Loosen the setscrew (B) on the table crank

handle (A).

2. Slide the handle (A) onto the table bracket shaft.

3. Turn the handle until the setscrew is opposite

the flat section on the shaft, and tighten the

setscrew to secure the handle.

4. Install the table lock handle (C), but do not tighten.

Table Bracket

When shipped, the rack ring and rack are bundled

together with the column in plastic wrap.

Referring to Figures 2 and 3:

1. Remove the wrap and take the rack ring (D) and

rack (B) off the column (C).

Figure 4

8

Page 9

Column Lock Handle

Referring to Figure 5:

Thread the column lock handle (D) into the table

bracket (E).

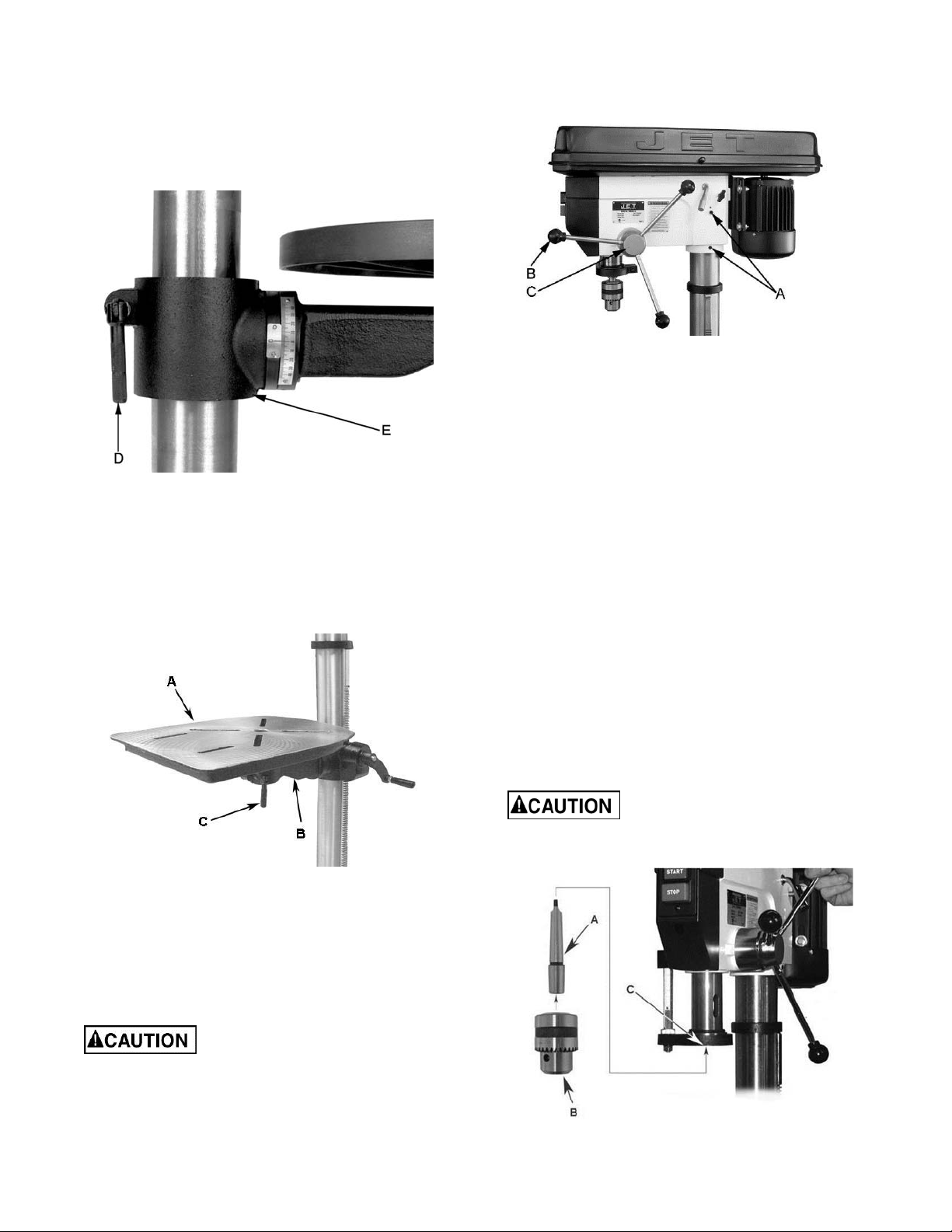

3. Tighten two setscrews (A) with a 5mm hex

wrench (provided) until they are snug.

Figure 7

4. Install three downfeed handles (B) into the

downfeed hub (C).

Chuck and Arbor Installation

Figure 5

Table Installation

Referring to Figure 6:

1. Place the table (A) on the bracket (B).

2. Tighten the table lock handle (C).

Figure 6

Referring to Figure 8:

1. Thoroughly clean arbor (A), chuck (B) and

spindle (C). Any grease or residue in these

areas can cause the pieces to separate and

create a safety hazard as well as damage to the

tool.

2. Twist the chuck (B) to retract the chuck jaws if

they are exposed.

3. Push chuck (B) by hand onto the arbor (A), and

slide assembly firmly up into the spindle (C).

4. Turn the arbor and chuck assembly until the

tang (B) on the arbor (C) engages the slot at the

end of the spindle.

Use a single tap from a rubber mallet, or a hammer

and a block of wood, against the bottom of the chuck

to seat the chuck securely onto the arbor.

Do not use a steel hammer

directly against the chuck, as this may damage

the chuck.

Head Assembly

Referring to Figure 7:

1. With the aid of a second person, carefully lift the

head onto the column top and slide it down into

position

The head assembly is heavy!

Use care when lifting onto th e col umn!

2. Rotate head assembly until sides of the pulley

cover are parallel with the sides of the base.

Figure 8

9

Page 10

Adjustment

Chuck and Arbor Removal

Referring to Figure 9:

1. Unplug machine from the power source.

2. Raise the table until it is about seven inches

below the chuck.

3. Place a piece of scrap wood on the table, and

lower quill (A) using the downfeed handle.

4. Rotate spindle to align the keyhole in the spindle

with the keyhole in the quill.

5. Insert the drift key (B) into the aligned slots and

tap lightly. The chuck and arbor assembly

should fall from the spindle.

Depth Stop Adjustment

Referring to Figure 10:

To drill multiple holes at the same preset depth, use

the depth stop:

1. Use a pencil to mark the depth the bit will drill

into the workpiece.

2. With the drill bit in the chuck, lower downfeed

handle to advance bit to your mark (A).

3. With your other hand, advance the lock nuts (B)

on the depth stop rod until they are snug to the

seat (C).

4. The drill bit will now advance to this point.

5. To release, advance the nuts counter-clockwise

to the top of the depth stop.

Figure 9

Figure 10

10

Page 11

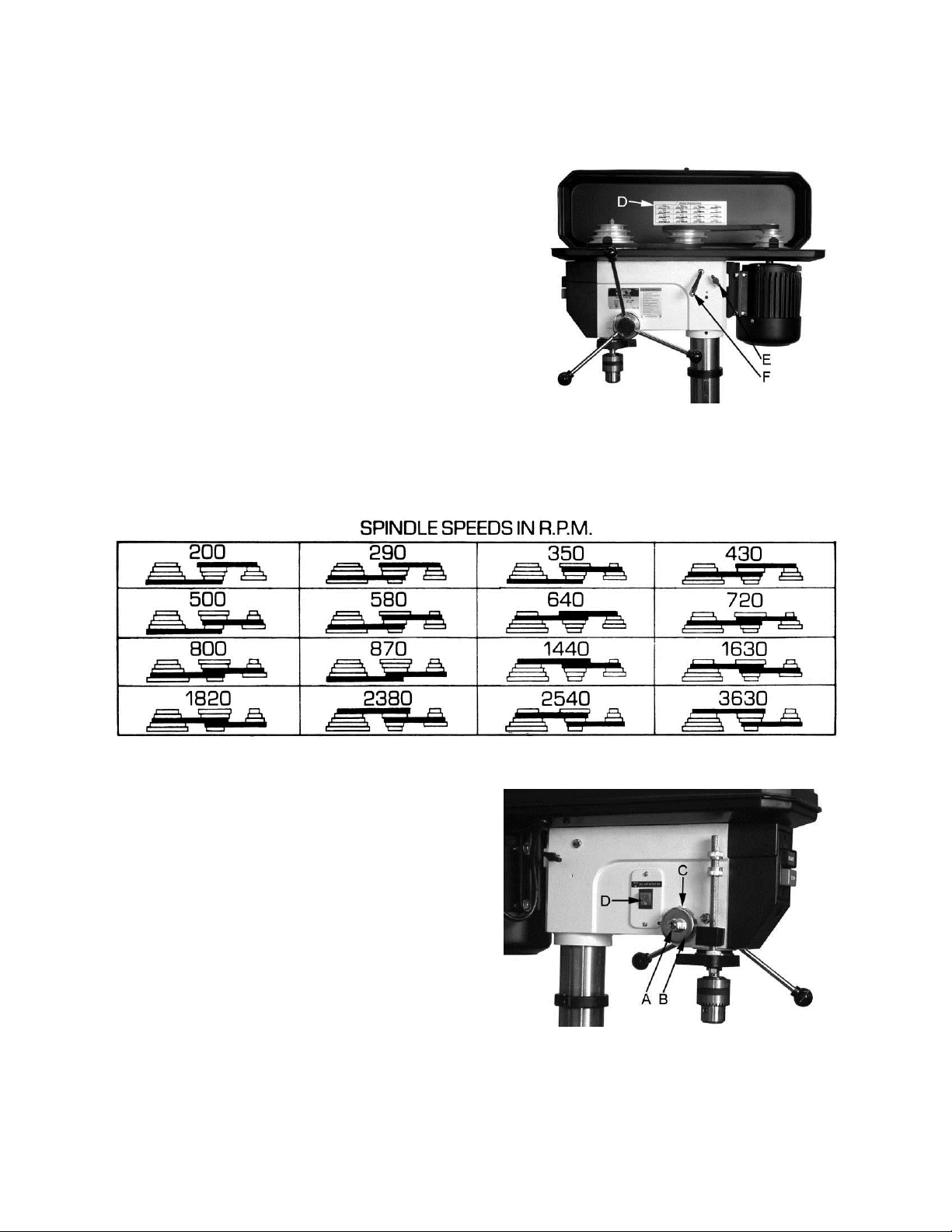

Changing Spindle Speeds

A spindle speed and pulley/belt arrangement chart

for all models is found on the inside of the pulley

cover (D, Fig. 11). Refer to this chart whenever

changing speeds.

Note: The chart in Figure 12 is for models J-2500

and J-2530 only.

To change spindle speeds:

1. Unplug the machine from the power source.

2. Loosen two bar knobs (E, Fig. 11) found on

each side of the head assembly.

3. Rotate the tension adjuster (F, Fig. 11)

clockwise to bring the motor base as close to the

head as possible.

4. For desired speed, change the location of belts

per pulley/belt arrangement chart.

5. Rotate the tension adjuster (F. Fig. 11)

counterclockwise to tension the belts.

6. Tighten two bar knobs (E, Fig. 11). Belts are

properly tensioned when finger and thumb

pressure midway between the two pulleys

causes approximately ½” deflection.

Figure 11

Figure 12 – Spindle Speed Chart for J-2500, J-2530

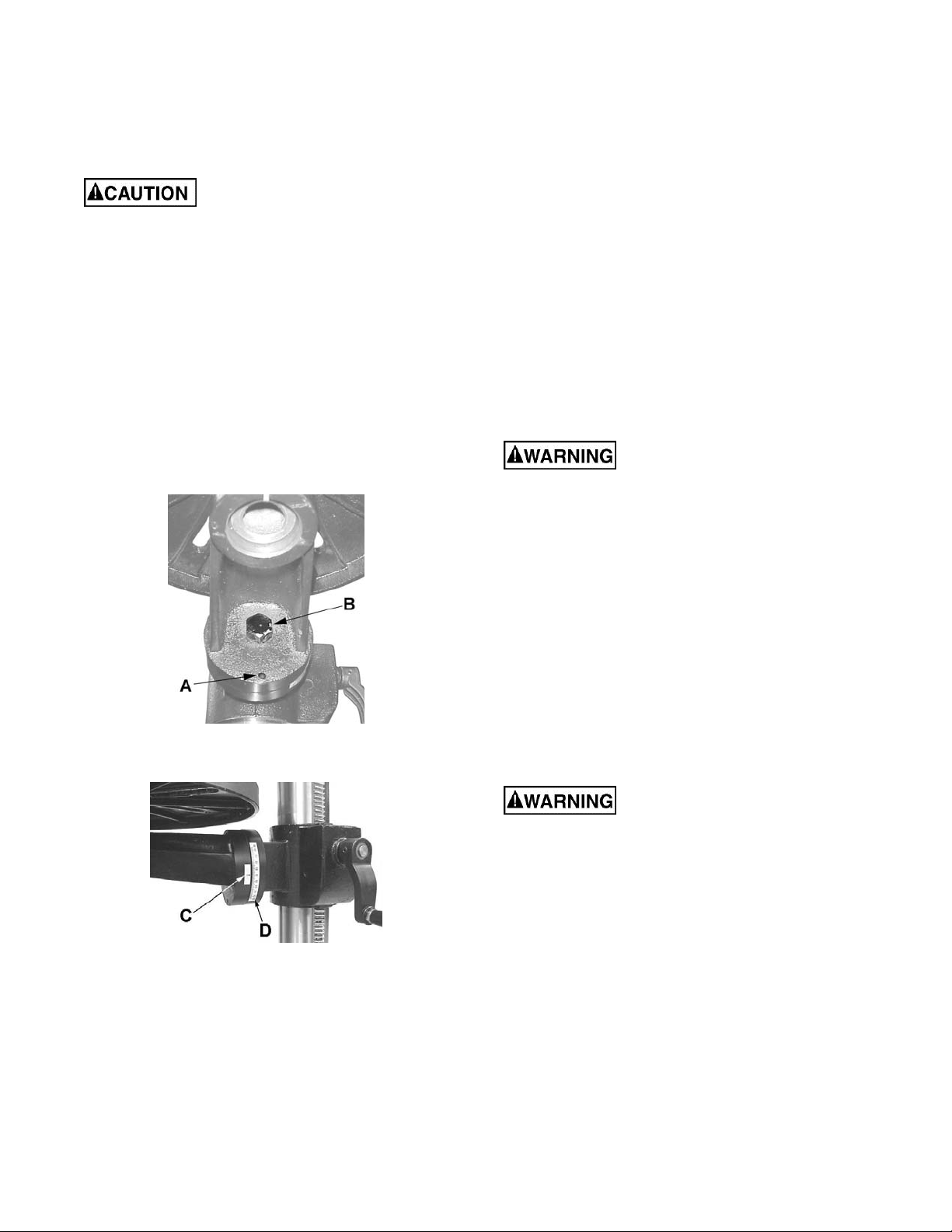

Return Spring Adjustment

The return spring is adjusted at the factory and

should not need further adjustment. If adjustment is

deemed necessary, follow the steps below while

referring to Figure 13:

1. Unplug the machine from the power source.

2. Loosen two hex nuts (A). Do not remove.

3. Firmly hold the coil spring cover (B).

4. Pull out the cover and rotate until the pin (C) on

the return spring plate engages the next notch in

the coil spring cover. Turn the cover clockwise to

decrease tension and counter-clockwise to

increase tension.

5. Tighten two hex nuts (A). Do not over-tighten. Nuts

should not contact the housing when tight. The hex

nuts should be tightened against each other.

Figure 13

Work Light (J-2500 and J-2530 only)

Install a light bulb, no larger than 60 watts into the

socket accessed from beneath the head. The rocker

switch controls the light switch (D, Fig. 13).

11

Page 12

Table Tilt A djustmen t

Positioning the Workpiece

The table tilt adjustments are made on the table

bracket under the table.

To tilt the table (refer to Figures 14 and 15):

In the following steps do not over loosen. This

could result in the table assembly to separate

from the column, fall and cause injury.

1. Loosen the socket head set screw (A) with a

3mm hex wrench.

2. Using a 15/16" wrench, loosen the hex cap

screw (B), and tilt the table to the desired angle

by aligning the arrow (C, Fig. 15) on the rotating

part of the bracket to the desired angle (in

degrees) displayed on the scale (D, Fig 15) at

the base of the bracket.

3. Tighten the hex cap screw (B).

4. Tighten the socket head set screw (A).

Always place a piece of wood (or plywood) on the

table. This will prevent "splintering" or making heavy

burrs on the underside of the workpiece as the drill

breaks through. The wood should contact the left

side of the column.

Using the Vise

For the small workpiece that cannot be clamped to

the table, use a drill press vise. The vise must be

clamped or bolted to the table. Always use a backup piece of scrap wood to cover the table. This

protects both the table and the drill bit.

Basic Operation

Place material to be drilled in such as way as to

come into contact with the left side of the column.

This prevents the material from spinning.

If the work piece is not large enough to come

into contact with the column , use a clamp or drill

press vise that is securely fastened to th e table!

Failure to compl y may cause seri ou s injury!

Operation

Figure 14

Figure 15

Feed the bit into the material with only enough force to

allow the drill bit to work. Feeding too slowly may cause

burning of the workpiece. Feeding too quickly may

cause the motor to stop and/or the drill bit to break.

Generally speaking, the smaller the drill bit, the greater

the RPM required. Wood requires higher speeds than

metal. Metal is usually drilled at slower speeds.

In dusty environments, frequently blow out any dust

that accumulates inside the motor.

Maintenance

Before any intervention on the machine,

disconnect it from the electrical supply by

pulling out the plug or switching off the main

switch! Failure to comply may cause serious

injury.

A coat of automobile-type wax applied to the table

and column will help to keep the surfaces clean.

If the power cord is worn, cut, or damaged in any

way, have it replaced immediately.

Installing Drills

Insert the drill into the chuck jaws about 1" (25.4mm)

long. When using a small drill do not insert it so far

that the jaws touch the flutes of the drill. Make sure

that the drill is centered in the chuck before

tightening the chuck with the key.

Lubrication

All of the ball bearings are packed with grease at the

factory. They require no further lubrication.

Periodically lubricate the gear, rack, table elevation

mechanism, the splines (grooves) in the spindle, and

the teeth of the quill with a #2 tube grease.

12

Page 13

Electrical

230 Volt Operation

Grounding Instructions

This tool must be grounded while in use to protect

the operator from electric shock.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is

green with or without yellow stripes, is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded. Use only three wire extension cords

that have three-prong grounding plugs and three-pole

receptacles that accept the tool’s plug.

Referring to Figure 17:

If 230V, single-phase operation is desired, the following

instructions must be followed:

Disconnect the machine from the power source.

The JET drill press motor has four numbered leads that

are factory connected for 115V operation, as shown in (A).

For 230V operation reconnect the leads as shown in (B).

The 115V attachment plug (C), supplied with the drill

press, must be replaced with a UL/CSA listed plug

suitable for 230V operation (D). Contact your local

Authorized JET Service Center or qualified electrician

for proper procedures to install the plug. The drill press

must comply with all local and national codes after the

230-volt plug is installed.

The drill press with a 230-volt plug should only be

connected to an outlet having the same configuration as

shown in (D). No adapter is available nor should be used

with the 230-volt plug.

Repair or replace a damaged or worn cord immediately.

115 Volt Operation

Referring to Figure 16:

As received from the factory, your drill press is ready to

run at 115-volt operation. This drill press, when wired for

115 volt, is intended for use on a circuit that has an

outlet and a plug that looks like the one illustrated in (A).

A temporary adapter, which looks like the adapter shown

in (B), may be used to connect this plug to a two-pole

receptacle if a properly grounded outlet is not available.

The temporary adapter should only be used until a

properly grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in Canada. The

green colored rigid ear, lug, or tab, extending from the

adapter, must be connected to a permanent ground such

as a properly grounded outlet box.

Figure 16

Figure 17

Extens ion Cords

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your machine will

draw. An undersized cord will cause a drop in the line

voltage resulting in power loss and overheating. The

table following shows the correct size to use depending

on the cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. Remember, the

smaller the gauge number, the heavier the cord.

Length of Cord AWG

000 – 25 Feet 16

025 – 50 Feet 14

The drill press with a 230-volt plug should only be

connected to an outlet having the same configuration

(D, Fig. 17). No adapter is available or should be used

with the 230-volt plug.

Important: In all cases (115 or 230 volts), make certain the

receptacle in question is properly grounded. If you are not

sure, have a registered electrician check the receptacle.

13

Page 14

Troubleshooting

Trouble Probable Cause Remedy

Drill press unplugged from wall, or motor. Check all plug connections.

Drill press will not start.

Drill press does not

come up to speed.

Drill Press vibrates

excessively.

Noisy Operation.

Workpiece Burns.

Fuse blown, or circuit breaker tripped. Replace fuse, or reset circuit breaker.

Cord damaged. Replace cord.

Starting capacitor bad. Replace starting capacitor.

Extension cord too light or too long. Replace with adequate size and length cord.

Low current. Contact a qualified electrician.

Stand on uneven surface. Adjust stand so that it rests evenly on the floor.

Bad belt(s). Replace belts.

Incorrect belt tension.

Dry spindle. Lubricate spindle. See the Lubrication section.

Loose spindle pulley.

Loose motor pulley. Tighten setscrews in pulleys.

Incorrect Speed.

Chips not clearing from hole or bit. Retract drill bit frequently to remove chips.

Dull drill bit. Resharpen, or replace drill bit.

Adjust belt tension. See the Changing Spindle

Speeds section.

Check tightness of retaining nut on pulley, and tighten

if necessary.

Change to appropriate speed; see the Changing

Spindle Speeds section.

Drill bit wanders.

Wood splinters on the

underside.

Drill bit binds in

workpiece.

Excessive drill bit

runout, or wobble.

Quill returns too slow, or

too fast.

Chuck or arbor does not

stay in place.

Feeding too slowly. Increase feed rate.

Bit sharpened incorrectly. Resharpen bit correctly.

Bent drill bit. Replace drill bit.

Bit, or chuck not installed properly. Reinstall the chuck, or bit properly.

No backing board used.

Workpiece pinching the bit. Support or clamp workpiece.

Excessive feed rate. Decrease feed rate.

Chuck jaws not tight. Tighten chuck jaws.

Improper belt tension. Adjust belt tension (Changing Spindle Speeds )

Bent drill bit. Replace drill bit.

Worn spindle bearings. Replace spindle bearings.

Bit, or chuck not properly installed. Reinstall the bit, or chuck properly.

Spring has improper tension.

Dirt, grease, etc on arbor, chuck, or

spindle.

Place a scrap board underneath the workpiece to

prevent splintering.

Adjust spring tension. See the Return Spring

Adjustment section.

Clean all mating surfaces thoroughly with a cleaner

degreaser.

14

Page 15

Parts

Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 Monday through Friday (see our website for

business hours, www.jettools.com). Having the Model Number and Serial Number of your machine available

when you call will allow us to serve you quickly and accurately.

Parts List – J-2500, J-2530

Index No. Part No. Description Size Qty

1A............. 10600110 ................ Base for J-2530 / JDP-15M ................................ ................................... 1

1B............. 10800101 ................ Base for J-2500 / JDP-15MF (not shown) ........... ................................... 1

2A............. JDP15-1002A .......... Column Holder for J-2530 / JDP-15M ................. ................................... 1

2B............. 10600204 ................ Column Holder for J-2500 / JDP-15MF............... ................................... 1

3 ............... TS-2279121 ............ Hex Socket Set Screw ....................................... M10-12 ....................... 3

4A............. JDP15-1004A .......... Body Column for J-2530 / JDP-15M ................... ................................... 1

4B............. JDP15-1004B .......... Body Column for J-2500 / JDP-15MF ................. ................................... 1

................. 10600404A1 ............ Column Assy for J-2530 / JDP-15M (includes #2A and #4A) .................. 1

................. 10400401A1 ............ Column Assy for J-2500 / JDP-15MF (includes #2B, #3 and #4B) .......... 1

5 ............... TS-2229403 ............ Hex Head Bolt ................................................... M10x40 ...................... 4

6 ............... 10600604 ................ Table Bracket .................................................... ................................... 1

................. JDP15-1006 ............ Table Bracket Assy (includes #6 thru #18) ......... ................................... 1

7 ............... 10600702 ................ Gear .................................................................. ................................... 1

8 ............... 10600802 ................ Gear Shaft ......................................................... ................................... 1

9 ............... 10600902 ................ Worm................................................................. ................................... 1

10A ........... 10601009A1 ............ Crank Handle Assy ............................................ ................................... 1

12 ............. JDP15-1012 ............ Table Bracket .................................................... ................................... 1

13 ............. TS-0071011 ............ Hex Head Bolt ................................................... 5/8-11 x 1-1/2 ............. 1

14 ............. TS-2276101 ............ Hex Socket Set Screw ....................................... M6-10 ......................... 1

16 ............. 10601601 ................ Tilting Scale ....................................................... ................................... 1

17 ............. JDP15-1017 ............ Centering Scale ................................................. ................................... 1

18 ............. JDP15-1018 ............ Drive Screw ....................................................... Φ 2.3-5 ....................... 2

19 ............. 10601901 ................ Column Lock Handle.......................................... M12 x 1.75-35 ............ 1

20 .............

21 ............. J-5625221 ............... Table ................................................................. ................................... 1

22A ........... 10602204 ................ Rack for J-2530 / JDP-15M ................................ ................................... 1

22B ........... 10602205 ................ Rack for J-2500 / JDP-15MF .............................. ................................... 1

23 ............. 10602304 ................ Rack Ring .......................................................... Φ 73.5 ........................ 1

24 ............. TS-2276081 ............ Hex Socket Set Screw ....................................... M6-8 ........................... 1

25 ............. JDP15-1025 ............ Head ................................................................. ................................... 1

26 ............. TS-2279121 ............ Hex Socket Set Screw ....................................... M10-12 ....................... 2

27 ............. JDP15-1027 ............ Lamp Socket...................................................... ................................... 1

28 ............. TS-1534042 ............ Cr. Re. Pan Head Screw .................................... M6-12 ......................... 2

29 ............. 10602901 ................ Handle Shifter .................................................... ................................... 1

30 ............. 10603002 ................ Motor Bar Shifter................................................ ................................... 1

31 ............. TS-2228161 ............ Hex Head Bolt ................................................... M8-16 ......................... 1

32 ............. 10603206 ................ Motor Rod .......................................................... ................................... 1

33 ............. 10603301 ................ Shifter Bolt ......................................................... M10-33 ....................... 2

34 ............. 10603416 ................ Motor Base ........................................................ 75 x 125mm ................ 1

35 ............. 2502NBC412 .......... Spring Washer ................................................... Φ1/2" .......................... 1

36 ............. TS-1540081 ............ Hex Nut ............................................................. M12 ............................ 2

37 ............. 10603704 ................ Hub ................................................................... ................................... 1

38 ............. 10603807 ................ Feed Shaft ......................................................... ................................... 1

................. JDP15-1038 ............ Feed Shaft Assy (includes #37 thru #39) ............ ................................... 1

39 ............. JDP12-55 ................ Roll Pin .............................................................. M5x16 ........................ 1

43A ........... JDP15-1043 ............ Handle Bar ........................................................ ................................... 1

10602001 ................ Table Lock Handle ............................................. M10 x 1.5 ................... 1

15

Page 16

Parts List – J-2500, J-2530

Index No. Part No. Description Size Qty

45 ............. 10604505 ................ Scale Ring ......................................................... ................................... 1

50A ........... JDP15-1050 ............ Spring Cap ........................................................ ................................... 1

51 ............. 10605115 ................ Shaft Seat.......................................................... ................................... 1

53 ............. TS-0561052 ............ Hex Nut ............................................................. 1/2"-20 ........................ 1

54 ............. 10605403 ................ Quill Set Screw .................................................. M10-28 ....................... 1

55 ............. TS-1540071 ............ Hex Nut ............................................................. M10 ............................ 1

56 ............. 10605608 ................ Quill ................................................................... MT2 ............................ 1

................. JDP15-1056 ............ Quill and Spindle Assy (includes #56 thru # 64) .. ................................... 1

57 ............. 10605702 ................ Rubber Washer ................................................. ................................... 1

58 ............. 10605822 ................ Spindle .............................................................. MT2 ............................ 1

59 ............. 2001ZZ6204 ............ Ball Bearing ....................................................... ................................... 1

61 ............. 2001ZZ6203 ............ Ball Bearing ....................................................... ................................... 1

62 ............. TS-2360161 ............ Washer .............................................................. M16 ............................ 1

63 ............. 10606301 ................ Nut Lock ............................................................ ................................... 1

64 ............. 10606401 ................ Spindle Nut ........................................................ ................................... 1

65 ............. 10606505 ................ Driving Sleeve ................................................... ................................... 1

................. JDP15-1065 ............ Driving Sleeve Assy (includes #65 thru #67) ...... ................................... 1

66 ............. 2001ZZ6204 ............ Ball Bearing ....................................................... ................................... 2

67 ............. 10606703 ................ Rack ring ........................................................... Φ 45 T=4 .................... 1

68 ............. 10606801 ................ Retaining Ring ................................................... ................................... 2

69 ............. 10606904 ................ Pulley Set Nut .................................................... ................................... 1

70 ............. JDP15-1070 ............ Spindle Pulley .................................................... ................................... 1

71 ............. 21015M2J30 ........... Drilling Arbor ...................................................... MT2*JT3 ..................... 1

72A ........... JDP15-1072 ............ Chuck Assy ....................................................... ................................... 1

73 ............. 10607303 ................ Wedge Shifter .................................................... ................................... 1

74 ............. JDP15-1074 ............ Motor ................................................................. ................................... 1

................. JDP15-1074A .......... Centrifugal Switch (not shown) ........................... ................................... 1

................. JDP15-1074B .......... Start Capacitor (not shown)................................

75 ............. JDP15-1075 ............ Motor Wire ......................................................... ................................... 1

76 ............. TS-2208201 ............ Hex. Hd. Screw .................................................. M8-20 ......................... 4

77 ............. TS-1550061 ............ Flat Washer ....................................................... M8 .............................. 8

78 ............. TS-1540061 ............ Hex Nut ............................................................. M8 .............................. 4

79 ............. JDP15-1079 ............ Motor Pulley ...................................................... ................................... 1

80 ............. 2571MNC307 .......... Parallel Key ....................................................... 5 x 5-20 ...................... 1

81 ............. TS-1504021 ............ Hex Socket Set Screw ....................................... M8-12 ......................... 1

83 ............. JDP15-1083 ............ Strain Relief ....................................................... ................................... 1

84 ............. TS-1534042 ............ Cr. Re. Pan Head Screw .................................... M6-12 ......................... 1

85 ............. JDP15-1085 ............ Power Cable ...................................................... ................................... 1

87 ............. JDP15-1087 ............ Rocker Switch .................................................... ................................... 1

88 ............. JDP15-1088 ............ Switch Box ......................................................... ................................... 1

89 ............. TS-1533042 ............ Cr. Re. Pan Head Screw .................................... M5-12 ......................... 3

90A ........... JDP15-1090 ............ Pulley Cover Assy .............................................. ................................... 1

................. JDP15-1090A .......... U Shaped Protecting Rubber (not shown) .......... ................................... 1

92 ............. JDP15-1092 ............ Cr. Re. Round Washer Hd. Screw ...................... M6 x 1.0-12 ................ 4

95 ............. JDP15-1095 ............ Center Pulley ..................................................... ................................... 1

................. JDP15-1095A .......... Center Pulley Assy (includes #95 thru #98) ........ ................................... 1

96 ............. JDP15-1096 ............ Ball Bearing ....................................................... ................................... 2

98 ............. 10609801 ................ Center Pulley Shaft ............................................ ................................... 1

99 ............. VB-A28 ................... V-Belt ................................................................ A-28 ........................... 1

101 ........... TS-0680021 ............ Flat Washer ....................................................... 1/4" ............................. 4

106 ........... TS-0561052 ............ Hex Nut ............................................................. ½”-20 .......................... 1

109 ........... JDP15-1109 ............ Clamp-Cord ....................................................... ................................... 3

110 ........... 2668BBDA23 .......... Cr. Re. Pan Head Screw ................................... M5-8 ........................... 3

112 ........... 10611201 ................ Chuck Key Holder .............................................. ................................... 1

113 ........... TS-2286122 ............ Cr. Re. Round Washer Hd. Screw ...................... M6-12 ......................... 1

119 ........... VB-A26 ................... V-Belt ................................................................ A-26 .......

200MFD 125VAC ........ 1

.................... 1

16

Page 17

Parts List – J-2500, J-2530

Index No. Part No. Description Size Qty

128 ........... TS-2285162 ............ Cr. Re. Truss Hd. Tapping Screw ....................... M5-16 ........................ 2

137 ........... JDP15-1137 ............ Switch Cover ..................................................... ................................... 1

138 ........... TS-1533042 ............ Cr. Re. Pan Head Screw .................................... M5-12 ........................ 2

139 ........... JDP15-1139 ............ Rocker Switch .................................................... ................................... 1

140 ........... 10614001 ................ Motor Rod .......................................................... ................................... 1

149 ........... 2536MBE616 .......... Roll Pin .............................................................. 6-25 ............................ 2

162 ........... 10916202 ................ Warning Label ................................................... ................................... 1

166 ........... JDP15-1166 ............ Speed Diagram .................................................. ................................... 1

169 ........... JDP15-1169 ............ Trade-Mark Label .............................................. ................................... 1

170 ........... 2658MZDU36 .......... Drive Screw ....................................................... Φ 2.3-5 ....................... 6

601 ........... TS-2245082 ............ Cr. Re. Pan Head Screw .................................... M5-8 ........................... 4

602 ........... TS-0733031 ............ External Tooth Lock Washer .............................. No 10.......................... 2

610 ........... TS-1534692 ............ Cr. Re. Pan Head Screw .................................... M6-35 ........................ 2

611 ........... JDP15-1611 ............ Cr. Re. Pan Head Screw .................................... ................................... 1

612 ........... TS-1540071 ............ Hex Nut ............................................................. M10 ............................ 1

613 ........... 10661301 ................ Set Bolt .............................................................. ................................... 1

................. JDP15-1613 ............ Set Bolt Assy (includes #613, 848, 849) ............. ................................... 1

614 ........... 13005701 ................ Nut………………………………………….M16 ..... ................................... 2

615 ........... 13005601 ................ Washer .............................................................. Φ24 ............................ 1

616 ........... TS-1502081 ............ Hex. Soc. Hd. Cap Blot ...................................... M5-35 ........................ 1

617 ........... JDP15-1617 ............ Set Ring ............................................................ ................................... 1

618 ........... 10661801 ................ Circular Nut ....................................................... ................................... 1

634 ........... 2502ABC410 ........... Spring Washer ................................................... Φ10 ............................ 1

700 ........... TS-152704 .............. Wrench Hex ....................................................... ................................... 1

701 ........... TS-

702 ........... TS-152707 .............. Wrench Hex ....................................................... ................................... 1

801 ........... JDP15-1801 ............ Lead Wire Assembly .......................................... ................................... 1

848 ........... JDP15-1848 ............ Drive Screw ....................................................... Φ 2.3-5 ....................... 2

849 ........... JDP15-1849 ............ Scale ................................................................. ................................... 1

922 ........... 2801ABRF04 .......... Strain Relief ....................................................... Φ 20 ........................... 2

999 ........... TS-1540081 ............ Hex Nut ............................................................. M12x10 ...................... 3

1000 ......... 100633Y8 ............... Plastic Sleeve ........................................................................................ 1

1001 ......... 10810401A1 ............ Chuck Guard Assembly ......................................................................... 1

152706 .............. Wrench Hex ....................................................... ................................... 1

17

Page 18

Exploded View – J-2500, J-2530

18

Page 19

Parts List – J-2550

Index No. Part No. Description Size Qty

1 ............... J-5627751 ............... Base .................................................................. ................................... 1

2 ............... J-5627761 ............... Collar, Column ................................................... ................................... 1

3 ............... 5626231 .................. Set Screw .......................................................... M10 x 40 mm .............. 1

4 ............... 5627771 .................. Column .............................................................. ................................... 1

5 ............... 5627781 .................. Screw, Hex Head ............................................... M12 x 40 mm .............. 4

6 ............... J-5627791 ............... Bracket, Table ................................................... ................................... 1

7 ............... 5625071 .................. Gear, Pinion ...................................................... ................................... 1

8 ............... 5625081 .................. Shaft, Gear ........................................................ ................................... 1

9 ............... 5625091 .................. Worm................................................................. ................................... 1

10 ............. 5627811 .................. Handle, Lowering/Raising .................................. ................................... 1

11 ............. 5626251 .................. Screw, Hex Head ............................................... M6 x 12 mm ................ 1

13 ............. 5627821 .................. Screw, Hex Head ............................................... 5/8” x 2” ...................... 1

14 ............. 5627831 .................. Pin, Location ...................................................... ................................... 1

15 ............. 5627841 .................. Nut, Hex ............................................................ 1/4" x 20” .................... 1

16 ............. 5627851 .................. Scale, Tilting ...................................................... ................................... 1

17 ............. 5625181 .................. Scale, Angle ...................................................... ................................... 1

18 ............. 5625191 .................. Set Screw .......................................................... Ø2.3x 5 mm ................ 3

19 ............. 5625211 .................. Handle, Lock...................................................... M12 x 180 mm ............ 1

21 ............. J-5627861 ............... Table ................................................................. 18-3/4” x 16-3/4” ......... 1

22 ............. 5627871 .................. Rack .................................................................. ................................... 1

23 ............. J-5627881 ............... Retainer, Rack ................................................... ................................... 1

24 ............. 5627061 .................. Screw Set, Hex Socket ...................................... M6 x 10mm ................. 1

25 ............. J-5627891 ............... Head ................................................................. ................................... 1

26 ............. 5627021 .................. Screw Set, Hex Socket ..................................... M10 x 12mm ............... 2

28 ............. 5627911 .................. Screw, Pan Head, Cr.-Re. .................................. M6 x 12mm ................. 2

29 ............. 5627121 .................. Lever, Tension Adjustment ................................ ................................... 1

30 ............. 5627131 .................. Cam .................................................................. ................................... 1

31 ............. 5627141 .................. Screw, Hex Head ............................................... M8 x 16 mm ................ 1

32 ............. 5627921

33 ............. 5627931 .................. Lock, Motor Bar ................................................. ................................... 2

34 ............. J-5627941 ............... Base, Motor ....................................................... ................................... 1

35 ............. 5627181 .................. Washer, Spring .................................................. Ø1/2” .......................... 2

36 ............. 5627191 .................. Nut, Hex ............................................................ M12 ............................ 2

37 ............. 5627211 .................. Hub ................................................................... ................................... 1

38 ............. 5627951 .................. Shaft, Feed Pinion ............................................. ................................... 1

38A ........... 5627961 .................. Shaft Assembly, Feed Pinion ............................. ................................... 1

39 ............. 5627971 .................. Pin, Roll ............................................................. ................................... 1

40 ............. 5627241 .................. Pin, Scale Set .................................................... ................................... 1

41 ............. 5627981 .................. Wedge, Scale Locking ....................................... ................................... 1

42 ............. 5627991 .................. Screw, Depth Lock ............................................. M8 x 17 mm ................ 1

43 ............. 5629011 .................. Handle ............................................................... ................................... 3

43A ........... 5629021 .................. Bar Assembly, Handle ....................................... ................................... 3

44 ............. 5627271 .................. Grip ................................................................... ................................... 3

45 ............. 5629031 .................. Housing, Spindle Depth ..................................... ................................... 1

46 ............. 5629041 .................. Scale ................................................................. ................................... 1

47 ............. 5625481 .................. Pointer ............................................................... ................................... 1

48 ............. 5626551 .................. Screw, Drive ...................................................... ................................... 3

49 ............. 5629051 .................. Coil .................................................................... ................................... 1

50 ............. 5629061 .................. Housing, Spring ................................................. ................................... 1

50A ........... 5629071 .................. Housing Assembly, Spring ................................. ................................... 1

51 ............. 5629081 .................. Seat, Spring ....................................................... ................................... 1

53 ............. 5629091 .................. Nut, Hex ............................................................ 1/2"-20 ........................ 2

54 ............. 5627321 .................. Screw, Set, Quill ................................................ M10 x 27mm ............... 1

55 ............. 5627331 .................. Nut, Hex ............................................................ M10 ............................ 1

56 ............. 5629111 .................. Quill ................................................................... ................................... 1

56A ........... 5629121 .................. Quill Assembly (includes #56 thru 64) ................ ................................... 1

.................. Shaft, Motor Base .............................................. ................................... 1

19

Page 20

Parts List – J-2550

Index No. Part No. Description Size Qty

57 ............. 5629131 .................. Washe r, Rubber................................................. ................................... 1

58 ............. 5629141 .................. Spindle .............................................................. MT3 , Ø34 ................... 1

59 ............. 5629151 .................. Bearin g, Ball ...................................................... 6206ZZ ....................... 1

60 ............. 5629161 .................. Bearing, Ball, Thrust .......................................... 2906 .............................

61 ............. 5635271 .................. Bearin g, Ball ...................................................... 6204Z ......................... 1

62 ............. 5629171 .................. Washe r .............................................................. ................................... 1

63 ............. 5629181 .................. Lock, Washe r..................................................... ................................... 1

64 ............. 5629191 .................. Lock, Nut ........................................................... ................................... 1

65 ............. 5629211 .................. Lock, Driving ...................................................... ................................... 1

66 ............. 5629221 .................. Bearin g, Ball ...................................................... 6206Z ......................... 2

67 ............. 5629231 .................. Collar ................................................................. ................................... 1

68 ............. 5629241 .................. Ring, Retainin g .................................................. ................................... 2

69 ............. 5629251 .................. Nut, Pulley Lock ................................................. ................................... 1

70 ............. 5629261 .................. Pulley , Spindle ................................................... ................................... 1

71 ............. 5624641 .................. Arbor ................................................................. MT3 x JT3 .................. 1

72 ............. 5628931 .................. Chuc k ................................................................ RJ 3 - 16L ................... 1

72A ........... 5627401 .................. Chuck and Key .................................................. ................................... 1

73 ............. 5624671 .................. Wedge, Taper .................................................... ................................... 1

74 ............. J-5629271 ............... Motor ................................................................. ................................... 1

76 ............. 5629291 .................. Screw, Hex Head ............................................... M8 x 25 mm ................ 4

77 ............. 5627511 .................. Washer, F lat ..................................................... 5/1 6 ” ........................... 4

78 ............. 5625821 .................. Nut, Hex ............................................................ M8 .............................. 4

79 ............. 5629311 .................. Pulley , Motor...................................................... ................................... 1

80 ............. 5629321 .................. Key .................................................................... ................................... 1

81 ............. 5629331 .................. Screw , Set ......................................................... M8 x 8 mm .................. 1

83 ............. 5627551 .................. Clamp ................................................................ ................................... 2

84 ............. 5626841 .................. Screw, Pan Head ............................................... M5 x 8 mm .................. 2

85 ............. 5629341 .................. Cord , Power ...................................................... ................................... 1

87 ............. JDP15-1087 ............ Push-Butto n Switch ........................................... ................................... 1

88 ............. 5629361 .................. Co ver, Switch .................................................... ................................... 1

89 ............. 5626871 .................. Screw, Pan Head ............................................... M5 x 12 mm ................ 2

92 ............. 5627591 .................. Washe r, Round Head Screw .............................. M6 x 12 mm ................ 4

93 ............. 5629381 .................. Screw, Truss Head Tapping ............................... M4 x 12 mm ................ 1

94 ............. 5627611 .................. Knob .................................................................. ................................... 1

95 ............. 5629391 .................. Pulley , Center .................................................... ................................... 1

96 ............. 5621681 .................. Bearin g, Ball ...................................................... 6202Z ......................... 2

98 ............. 5629411 .................. Shaft, Pulley ...................................................... ................................... 1

99 ............. 5624701 .................. V-Bel t ................................................................ A-30 ........................... 1

101 ........... 5627641 .................. Washer , Flat ...................................................... 1 /4" ............................. 4

102 ........... J2550-102 ............... Cover Plate ........................................................ ................................... 1

103 ........... 5712561 .................. Phillips Pan Head Machine Screw ...................... M5-0.8 x 8 .................. 2

119 ........... 5637541 .................. V-Belt ................................................................ A-32 ........................... 1

128 ........... TS-2285162 ............ Screw , Machine ................................................. M5 x 16 mm ................ 2

129 ........... 5629421 .................. Screw, Socket Head Cap ................................... M8 x 30 mm ................ 2

130 ........... 5629431 .................. Screw, Socket Head Cap ................................... M8 x 25 mm ................ 1

131 ........... 5629441 .................. Key, Chuck ........................................................ ................................... 1

140 ........... 5629451 .................. Shaft, Motor Base .............................................. ................................... 1

149 ........... 5629461 .................. Pin, Roll ............................................................. ................................... 2

601 ........... 5629471 .................. Screw, Pan Head ............................................... M4 x 12 mm ................ 1

602 ........... 5629481 .................. Washer, External Tooth Lock ............................. Ø4 .............................. 2

605 ........... 5629491 .................. Pin, Roll ............................................................. ................................... 1

606 ........... 5629511

610 ........... 5513738 .................. Screw ................................................................ ................................... 2

611 ........... 5513739 .................. Block, Depth Stop .............................................. ................................... 1

612 ........... 5513740 .................. Nut .................................................................... ................................... 1

613 ........... 5513741 .................. Rod, Depth Stop Adjustment .............................. 2550 Only ................... 1

.................. Pin, Roll ............................................................. Ø2.5 x 10 mm ............. 1

20

Page 21

Parts List – J-2550

Index No. Part No. Description Size Qty