Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

20-inch Drill Press

Model: JDP -2 0MF

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-354170

Ph.: 800-274-6848 Revision H4 03/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provi d e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Specifica tions ................................................................................................................ .......................... 6

Shipping Contents ................................................................................................................................... 7

Required Tools (not included) .................................................................................................................. 7

Assembly ................................................................................................................................................ 8

Before Assembly .................................................................................................................................. 8

Column Assembly ................................................................................................................................ 8

Table Bracket ....................................................................................................................................... 8

Crank Handle ....................................................................................................................................... 9

Column Lock Handl e ............................................................................................................................ 9

Table Installation .................................................................................................................................. 9

Head Assembly .................................................................................................................................. 10

Chuck and Arbor Installation .............................................................................................................. 10

Chuck and Arbor Removal ................................................................................................................. 10

Chuck Guard ...................................................................................................................................... 11

Adjust ment ............................................................................................................................................ 1 1

Depth Stop Adjustment ...................................................................................................................... 11

Changing Spindle Speeds .................................................................................................................. 11

Return Spring Adjustment .................................................................................................................. 12

Work Light ......................................................................................................................................... 12

Table Til t Ad ju stment ......................................................................................................................... 12

Operation .............................................................................................................................................. 1 3

Installing Dril ls .................................................................................................................................... 13

Positioning the Workpiece .................................................................................................................. 13

Using the Vise .................................................................................................................................... 13

Basic Operation ................................................................................................................................. 13

Maintenance .......................................................................................................................................... 13

Lubrication............................................................................................................................................. 13

Electrical ............................................................................................................................................... 13

115 Volt Operati on ............................................................................................................................. 13

230 Volt Operati on ............................................................................................................................. 14

Grounding Inst r uc tions ....................................................................................................................... 14

Extension Cords................................................................................................................................. 14

Troubleshooting ..................................................................................................................................... 1 5

Replacement Parts............................................................................................................................. 16

Exploded View Drawing JDP-20M F .................................................................................................... 17

Parts List JDP-20MF .......................................................................................................................... 18

Wiring Diagram ...................................................................................................................................... 21

JDP-20MF Electri c al S c hem atic – 115V ............................................................................................. 21

JDP-20MF Electri c al S c hem atic – 230V ............................................................................................. 21

The specificati ons in thi s manual are given as general inf ormation and ar e not binding. JET reserv es the

right to eff ect, at any tim e and wit hout pri or notic e, changes or alt erat ions to par ts, fi tti ngs, and accessory

equipment deemed nec essary for any reason whatsoev er.

3

Page 4

Warnings

1. Read and understand the ent ire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This drill pr ess is designed and i ntended f or use by pr operl y tr ained and ex peri enced personnel only .

If you are not familiar with the proper and safe operation of a drill press, do not use until proper

training and knowledge have been obtained.

5. Do not use this drill press for other than its int ended use. If used for other pur poses, JET discl aims

any real or implied warrant y and holds itself harmless from any injury that may result from that use.

6. Always wear approv ed safety glasses/face shiel ds whil e using this drill press. Everyday eyegl asses

only have impact resi stant lenses; they are not safet y glasses.

7. Before operating this drill press, remov e tie, rings, watches and other jewelry, and roll sl eev es up past

the elbows. Remove all l oose clothing and confine long hair. Non-slip footwear or anti-skid f loor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tired or under the influence of drugs, alcohol or any m edi c ation.

11. Make c ertain the switch is in the OFF position before connecti ng the machine to the power supply.

12. Make c ertain the machine is properly grounded.

13. Make all machine adjustment s or maintenanc e with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure the drill press is firml y secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Prov ide for adequate space surrounding work ar ea and non-glare, over head lighting.

19. Keep t he floor around the machine clean and free of scrap mat er ial, oil and grease.

4

Page 5

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make y our workshop child proof with padlocks, master switches or by removing starter keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintai n a bal anced stance at all times so that you do not f al l or lean against the spindle or other

moving part s. Do not over r eac h or use excessive force to perform any machine oper ation.

24. Use the right tool at the correc t speed and f eed rat e. Do not force a t ool or attac hment to do a job for

which it was not designed. T he ri ght tool will do the job better and saf er.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maint ain tool s with care. Keep drill bit s sharp and clea n for t he best and safest perf ormance. Foll ow

instructions for lubricating and changing accessories.

27. Make sure the work pi ece is securel y attached or clamped to the table. Never use your hand to hol d

the work piece.

28. Tur n off the machi ne before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

29. Do not stand on the machine. Serious injury c ould occur if the machine tips over.

30. Never leave the machine running unattended. Turn the power off and do not leave the machi ne until it

comes to a complete stop.

31. Remove loose items and unnecessary work piec es from the area before starti ng the mac hine.

Familiariz e you rself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Specifications

Model Number .......................................................................................................................... JDP-20MF

Stock Num ber................................................................................................................................ 354170

Type .................................................................................................................................................. Flo or

Motor:

Horsepower................................................................................................................................. 1 -1/2

Phase ........................................................................................................................................ single

Voltage........................................................................................................115/230V ( prewired 115V)

Frequency .................................................................................................................................. 60 Hz

FLA (Full Load Amperage) ........................................................................................................ 18/9 A

Capacities:

Drills to Center Circl e ..................................................................................................................... 20”

Distance Column to Spi ndle ........................................................................................................... 10 ”

Drilling Capacity – Cast Iron ............................................................................................................. 1”

Drilling Capacity – Mild Steel ......................................................................................................... 3/4"

Chuck Size .................................................................................................................................... 3/4”

Speeds:

Number of Spindl e Speeds .............................................................................................................. 12

Range of Spindle Speeds (RPM ) ........................................................................................ 150 – 4200

Spindle:

Spindle Taper .............................................................................................................................. MT-3

Spindle Travel ............................................................................................................................ 4-5/8”

Spindle Distance to Base.......................................................................................................... 46-3/4 ”

Spindle Distance to Table (max.) .............................................................................................. 29-1/8”

Table and Column:

Table Size (Length x Widt h) ............................................................................................ 18-1/2" x 16"

Table Weight Capacity .................................................................................................................80 lb

Table T-Slots, Number ...................................................................................................................... 6

Table T-Slots, Size ........................................................................................................................ 1/2"

Table T-Slots, Centers................................................................................................................ 3-1/2”

Table Tilt ................................................................................................................................. 45 deg.

Column Diameter ....................................................................................................................... 3-3/8”

Base:

Base Size .................................................................................................................. 13-3/4” x 22-3/4”

Base Working Surface ....................................................................................................... 13” x 8-1/2”

Base Slots, Num ber .......................................................................................................................... 2

Base Slots, Size ............................................................................................................................ 5/8”

Dimensions:

Overall Dimensions (H x W x D) ....................................................................... 66" x 18-1/2" x 31-1/2"

Carton Size (L x W x H) : ............................................................................................... 26" x 13" x 58"

Weights:

Net Weight (approx.) ............................................................................................................... 282 lbs.

Gross Weigh t ......................................................................................................................... 293 l bs.

6

Page 7

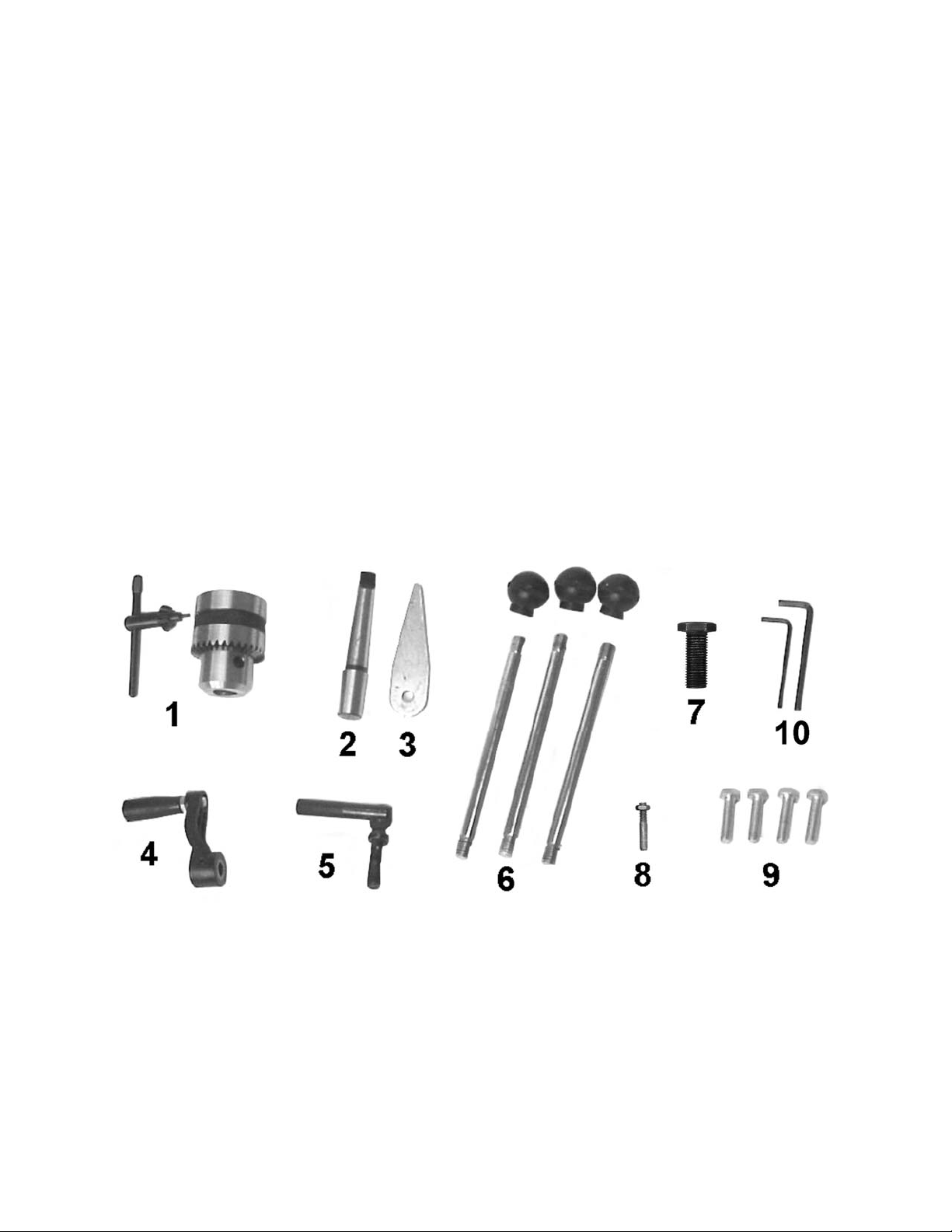

Shipping Contents

Unpack the cart on and v erify that all part s listed

below are incl uded.

Main Parts

1 ea Head Assembly

1 ea Table

1 set Colum n and Table Bracket Assembly

1 ea Base

Additional Parts

1. 1 set Chuck and Chuck K ey

2. 1 pc Arbor

3. 1 pc Drift Key

4. 1 pc T able Crank Handle

5. 1 pc Column Lock Handle

6. 3 pcs Downfeed Handles and Knobs

7. 1 pc 5/ 8"-11x2" Hex Cap Screw

8. 1 set Locator P in and Hex Nut

9. 4 pcs M10 x 40 Hex Cap Screws

10. 2 pc Hex Wrenches (3mm, 5mm)

11. 1 pc Chuck Guard (not shown)

Other Material

1 ea Owner’s Manual

1 ea Warranty Registr ation Card

Required Tools (not included)

1. 17mm Box Wrench or a 6” – 8” Adjustable

Wrench

2. 15/16" wrench

Additional Parts

7

Page 8

Assembly

Read and understand all

assembly instructions before attempting

assembly! Failure to comply may cause

serious injury!

Do not attempt to turn on

power before this machine is completely

assembled.

Before Assembly

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping

container wit h the list on page 7. Report any

shortages or damage to your JET distributor.

3. Clean all rust protected surfaces with

kerosene or a light solvent. Do not use

lacquer thinner, paint thinner, or gasoline.

These will damage plastic components and

painted surfaces.

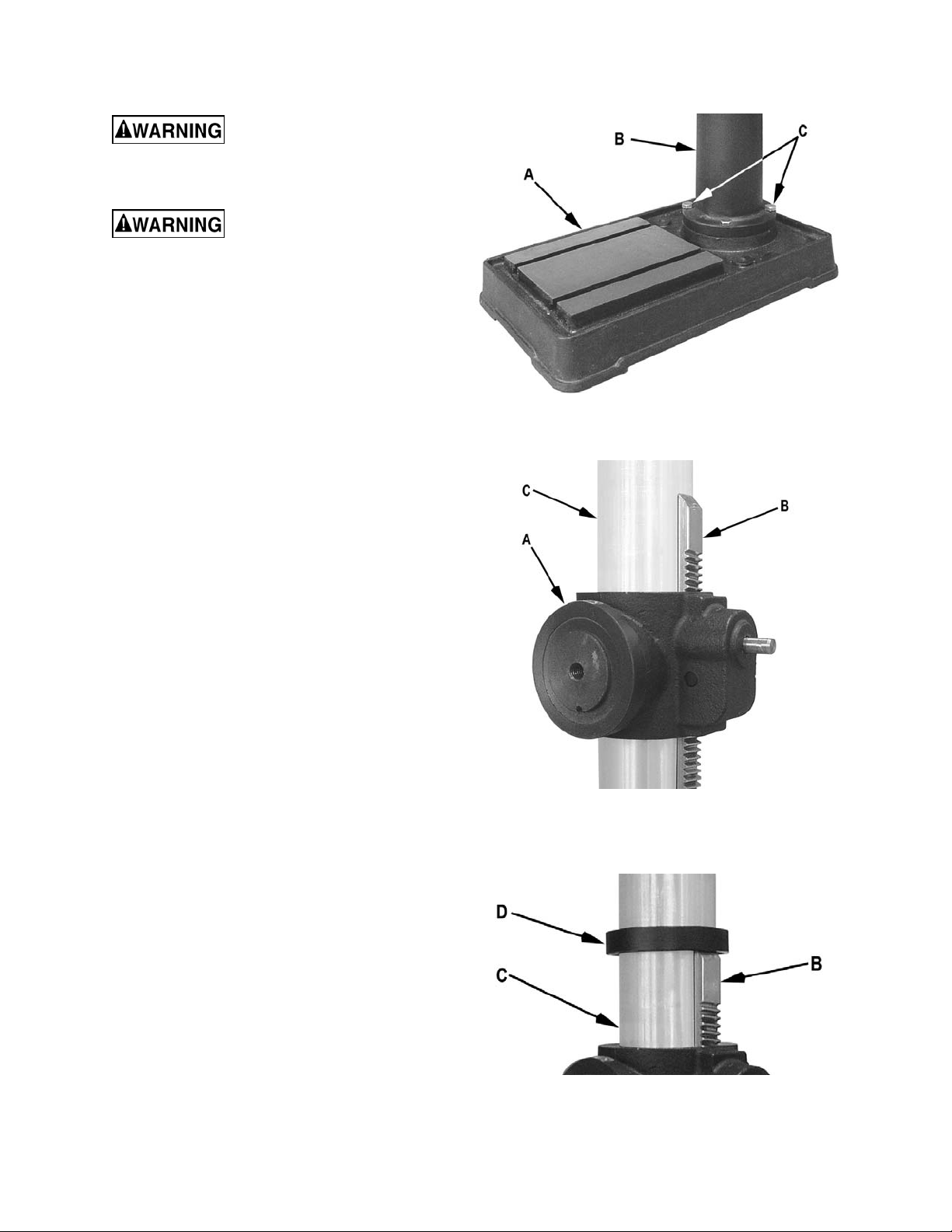

Column Assembly

Referring to Fi gur e 1:

1. Place the base (A) on a level floor.

2. Place the column assembly (B) on the base

(A) and ali gn the holes in the c olumn support

with the holes i n the base.

3. Using a 17mm wrench, secure the col um n (B)

with four M10 x 40 hex cap screws (C) to t he

base.

Table Bracket

When shipped, the rack ring and rack are bundled

together with the column in plastic wrap.

Figure 1

Figure 2

Referring to Fi gur es 2 and 3:

1. Remove the wrap and take the rack ring ( D)

and rack (B) off the colum n ( C).

2. Install the table bracket (A) toget her with t he

rack (B) on the column (C) as shown in

Figure 2.

3. Slide the rack ring (D) over the column (C),

placing it so it rests against the rack (B) as

shown in Figure 3 and tighten firmly with a

3mm hex wrench (provi ded) .

Figure 3

8

Page 9

Crank Handle

Referring to Fi gur e 4:

1. Loosen the setscrew (B) on the table crank

handle (A).

2. Slide the handle (A) onto the table bracket

shaft.

3. Turn the handle until the setscrew i s opposite

the flat section on the shaft, and tighten the

setscrew to secure the handle.

Column Lock Handle

Referring to Fi gur e 5:

Thread the column loc k handle (A) into the table

bracket (B).

Table Installation

Figure 4

The table is heavy! This

installatio n is a two person operation to avoid

injury fro m accid ental d ropp ing.

Referring to Fi gur e 6:

1. Have one person hold the table (A) against

the bracket (B), aligning the hole in the

mounting pl ate of the table with t he threaded

hole in bracket .

2. Have the second person ins ert the 5/8"-11x2

hex head screw (C) through the opening on

the bottom side of the table (A) and start

threading the scr ew into the bracket by hand.

3. Finish ti ghtening the screw (C) with a 15/16"

or wrench (wrench provided) , but leave l oose

enough so the table can be til ted by hand.

4. Using the scale on the bracket as a guide, set

the table angle to 0 degrees (level).

5. Take the locator pin (D) and adjust the hex

nut towards the end of t he thread as shown in

the close up view (D).

6. Insert the non-threaded end of the l ocator pin

(D) into t he hol e on the t able found just belo w

the mounting screw. Press al l the way in.

Note: The tabl e m ay have t o be til ted sli ghtly

back and forth if t he holes do not quite align.

7. Tighten the screw (C) with a 15/16" wrench.

Figure 5

Figure 6

9

Page 10

Head Assembly

Referring to Fi gur e 7:

1. With t he aid of a second person, c arefully lift

the head onto the column top and slide it

down into position

The head assembly is heavy!

Use care when lifting onto th e col umn!

2. Rotate head assembly until si des of the pulley

cover are parall el with the sides of the base.

3. Tighten two setscrews (A) with a 5mm hex

wrench (provi ded) until they are snug.

4. Install three downfeed handles (B) into the

downfeed hub (C).

Chuck and Arbor Installation

Referring to Fi gur e 8:

1. Thoroughly clean the internal and external

taper of the arbor (A), and chuck (B) and

spindle (C).

Important: These three pieces must be f ree

of any rust pr otect i on, or l ubric ant. If they are

not clean, the ar bor and c huc k m ay fail to seat

in the spindle.

2. Place arbor (A) into the chuck (B).

3. Twist the chuck to f ully r etrac t t he c huc k jaws.

4. Place arbor and chuck assembly into the

spindle (C).

5. Turn the arbor and chuck assembl y until the

tang on the arbor en gages the slot at t he end

of the spindl e.

6. Use a few taps from a rubber mallet, or a

hammer and a block of wood, against the

bottom of the chuck to seat the chuck

securely onto t he arbor. Do not use a steel-

faced hammer directly against the chuck.

Figure 7

Figure 8

Chuck and Arbor Removal

1. Unplug machine from the power source.

2. Raise the tabl e until it is about seven inc hes

below the chuck.

3. Place a piece of scrap wood on the t abl e, and

lower quill (A, Fig. 9) using the downfeed

handle.

4. Rotate spindle to align the keyhole in the

spindle with t he k ey hole in the quill.

5. Insert the drift key (B, Fi g. 9) into t he aligned

slots and tap lightly. The chuck and arbor

assembly should fall from the spindle.

Figure 9

10

Page 11

Chuck Guard

1. Unplug machine fr om power source.

2. Attach chuck guard to spindle collar and

tighten screw (Fi gure 9a). The guard can be

flipped up for chuck ac c ess.

Adjustment

Depth Stop Adjustment

To drill multiple holes at the same preset depth,

use the depth stop:

1. Use a pencil to mark the dept h the bit will dri ll

into the workpiece.

2. With the drill bit in the chuck, lower downfeed

handle to advance bit to your mark (A, Fig.

10).

3. With your other hand, adv anc e the lock nuts

(B, Fig. 10) on the depth stop r od until they

are snug to the seat (C, Fi g. 10).

4. The drill bit will now adv anc e to t his poi nt.

5. To release, advanc e the nuts counter-

clockwise to t he top of the depth stop.

Figure 9a

Changing Spindle Speeds

A spindle speed and pulley/belt arrangement c hart

is found on the inside of the pulley cover (D,

Fig. 11), also shown in Figure 12. Refer to this

chart whenev er changing speeds.

To change spindle speeds:

1. Unplug the machine from the power source.

2. Loosen two bar knobs (E, Fig. 11) found on

each side of the head assembly.

3. Rotate the tension adjuster clockwise

(F, Fig. 11) to bring the motor base as close

to the head as possible.

4. For desired speed, change t he location of

belts per pulley /belt arrangement chart.

5. Rotate the tension adjuster counterclockwise

(F. Fig. 11) to tension t he belts.

6. Tighten two bar knobs (E, Fig. 11). Belts are

properly t ensi oned when finger and thumb

pressure mi dway between the t wo pulleys

causes approximately ½” deflection.

Figure 10

Figure 11

11

Page 12

Return Spring Adjustment

The return spring is adjusted at the factory and

should not need furt her adjustment. If adjustment

is deemed necessary, follow the steps below

while referri ng to Figure 12:

1. Unplug the machine from the power source.

2. Loosen two hex nuts (A). Do not remove.

Do not remove th e co il spring

cover (Step 3). The torsion spring will uncoil

and can cause seriou s injury.

3. Firmly hol d the coil spring cover (B).

4. Pull out the cover and rotate until the pin (C)

on the return spring plate engages the next

notch in the c oil spring c over. Tur n the cov er

clockwise to decrease tension and counterclockwise to incr ease tensi on.

5. Tighten two hex nuts (A). Do not over-tighten.

Nuts should not contact the housing when

tight. The hex nuts should be tightened

against each other.

Figure 12

Work Light

Install a light bulb, no larger t han 60 watts int o the

socket accessed from beneath the head. The

rocker switc h contr ols the li ght switch (D, Fi g. 12).

NOTE: If using 230 volt power, use a light bulb

rated accordingly.

Table Tilt A djustment

To tilt the table ( r efer to Figures 13 and 14):

In the fo llowing step s, DO NOT

OVER LOOSEN. This could resu lt in the table

assembly to separate from the column, fall

and cause injury.

1. Using a 15/16" wrench, loosen the hex cap

screw (A, Fi gure 13) located under the t able,

about one turn.

2. Pull the locator pin out with a pliers placed

over the hex nut. The pin may be seated

tightly, requiring a twisting motion as it is

extracted.

Note: When the t abl e i s in any po siti on ot her

than level (0 degr ees), the locat or pin is not

used.

Figure 13

3. Til t the table to t he desired angle by ali gning

the scale (i n degrees) on the table (C) to t he

marker at the base of the br ac k et (D).

4. Tighten the hex c ap screw (A).

Figure 14

12

Page 13

Operation

Installing Drills

Insert the drill into the chuck jaws with about

1" insertion. When using a small drill do not

insert it so far that the jaws touch the flutes of

the drill. Make sure that the drill is centered in

the chuck before tightening the chuck with the

key.

A coat of automobile-type wax applied to the

table and col umn will help to keep t he surfaces

clean.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

Lubrication

All of the ball beari ngs are pack ed with grease at

the factory. They require no further lubrication.

Positioning the Workpiece

Always place a piece of wood (or plywood) on

the table. This will prevent "splintering" or

making heavy burrs on the underside of the

workpiece as the dril l breaks through. The wood

should contact the left side of the column.

Using the Vise

For the small workpi ece that cannot be cl amped

to the table, use a drill press vise. T he vi se must

be clamped or bolted t o the tabl e. Always use a

back-up piece of scrap wood to cover t he table.

This protects both the table and the drill bit.

Basic Operation

Place materi al to be drilled i n such as way as to

come into contact with the left side of the

column. This prevents the material from

spinning.

If the work pi ece is not large

enough to come into contact with the

column, use a cl amp or drill press vise th at

is securely fastened to the table! Failure to

comply may cause seriou s injury!

Periodically lubricate the gear, rack, table

elevation mechanism, the splines (grooves) in

the spindle, and the teeth of the quill with a #2

tube grease.

Electrical

115 Volt Operation

Referring to Fi gur e 15:

As received f rom the factory, your drill press is

ready to run at 115-volt operation. This drill

press, when wired for 115 volt, is intended for

use on a circuit t hat has an outlet and a plug that

looks li ke the one illustrated in ( A). A temporary

adapter, which looks like the adapter shown in

(B), may be used to connect this plug to a twopole receptacle if a properly grounded outlet is

not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicable i n Canada. The green

colored rigi d ear, lug, or tab, extending from the

adapter, must be connected to a permanent

ground such as a properly gr ounded outlet box.

Feed the bit into the material with only enough

force to all ow the drill bit to work. Feedi ng too

slowly may cause burning of the workpiece.

Feeding too quickly may cause the mot or to stop

and/or the drill bit to break.

Generally speaki ng, the small er the drill bit, the

greater the RPM requi red. Wood requi res hi gher

speeds than metal. Metal is usually drilled at

slower speeds.

In dusty environments, frequently blow out any

dust that accumulates inside the motor.

Maintenance

Before any intervention on

the machine, disco nnect it f rom the electri cal

supply by pulling out the plug or switching

off the main switch! Failure to co mply may

cause serious inj ury.

Figure 15

13

Page 14

230 Volt Operation

Referring to Fi gur e 16:

If 230V, single-phase operation is desired, the

following inst r uc tions must be followed:

1. Disconnect the machine from the power

source.

2. The JET drill press motor has four

numbered leads that are factory connected

for 115V operation, as shown in (A). For

230V operation reconnect the leads as

shown in (B).

3. The 115V attac hm ent plug (C), supplied wit h

the drill press, must be replaced with a

UL/CSA listed plug suitable for 230V

operation (D) . Contact your local Authorized

JET Service Center or qualified electrician

for proper procedures to install the plug.

The drill press must c om ply with all local and

national codes after the 230-volt plug is

installed.

4. The drill press with a 230-volt plug should

only be connected to an outlet having the

same configuration as shown in (D). No

adapter is av ailable nor should be used with

the 230-volt plug.

5. The light bulb must be replaced with a bulb

rated for 230 volt operation.

installed and grounded in accordance with all

local codes and ordinanc es.

Do not modify the plug provided. If it will not fi t

the outlet , have the proper outlet i nstalled by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s proper ly grounded. U se onl y

three wire ex tension cords that have three-prong

grounding plugs and t hree-pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

Extens ion Cords

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your m achine will draw. A n undersized

cord will cause a drop in the line voltage

resulting in power loss and overheating. The

table following shows the correct size to use

depending on the cord length and nameplate

ampere rati ng. If in doubt, use the next heavier

gauge. Remember, the smaller the gauge

number, the heavier the cord.

Figure 16

Grounding Instructions

This tool must be grounded

while in use to protect the operator from

electric shock.

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric

cord having an equipment-grounding conductor

and a grounding plug. The plug must be

plugged into a matching outlet that is properly

Length of

Cord

0–25 16

The drill press with a 230-v olt plug should only

be connected to an outlet having the same

configuration (D, Fig. 16). No adapter is

available or should be used with the 230-volt

plug.

Important : In all cases (115 or 230 v olts), make

certain the receptacle in question is properly

grounded. If you are not sure, have a registered

electrici an c hec k the rec eptacle.

25-50 14

51-100 12

AWG

14

Page 15

Troubleshooting

Trouble Probable Cause Remedy

Drill press will not

start.

Drill press does not

come up to speed.

Drill Press vibrates

excessively.

Noisy Operation.

Drill press unplugged from wall, or

motor.

Fuse blown, or cir c uit break er tr ipped. Repl ac e fuse, or reset circuit breaker.

Cord damaged. Replace cord.

Starting capac itor bad. Replace starting capacitor.

Extension cord too light or too long.

Low current. Contact a qualified electrician.

Stand on uneven surf ac e.

Bad belt(s). Replace belt s.

Incorrect belt t ensi on.

Dry spindle.

Loose spindle pul ley.

Check all plug connections.

Replace with adequat e si z e and

length cord.

Adjust stand so that it r ests evenly on

the floor.

Adjust belt t ensi on. See the

Changing Spindle Speeds section.

Lubricate spi ndle. See the

Lubrication secti on.

Check tightness of r etaining nut on

pulley, and ti ghten if necessary.

Workpiec e Burns.

Drill bit wanders.

Wood splint er s on the

underside.

Drill bit binds in

workpiece.

Loose motor pull ey . Tighten setscrews i n pulleys.

Incorrect Speed.

Chips not cleari ng from hole or bit.

Dull drill bit. Resharpen, or replace drill bit.

Feeding too sl owly . Increase feed r ate.

Bit sharpened incorr ec tly. Resharpen bit correctly.

Bent drill bit. Replace drill bit.

Bit, or chuck not i nstalled properly. Reinstall the chuck, or bit properly.

No backing board used.

Workpiec e pinc hing the bit. Support or clamp workpiece.

Excessive f eed r ate. Decrease feed rat e.

Chuck jaws not tight. Tighten chuck jaws.

Improper belt tension.

Change to appropriate speed; see the

Changing Spindle Speeds section.

Retract drill bit frequently to remove

chips.

Place a scrap board underneath the

workpiece to prevent splintering.

Adjust belt t ensi on. See the Changing

Spindle Speeds section.

15

Page 16

Troubleshooting (cont.)

Trouble Probable Cause Remedy

Bent drill bit. Replace drill bit.

Excessive drill bit

runout, or wobble.

Worn spindle beari ngs. Replace spindl e bear ings.

Bit, or chuck not properly installed. Reinstall t he bit, or chuck properly.

Quill returns too slow,

or too fast.

Chuck or arbor does

not stay in place.

Spring has impr oper tension.

Dirt, grease, et c on ar bor, c huc k, or

spindle.

Adjust spring t ensi on. See the Return

Spring Adjustment section.

Clean all mating surfaces thoroughly

with a cleaner degreaser.

Parts

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Mon day t hrough Fr iday (see our web sit e f or busi ness hours, www.j ett ool s.com). Havi ng

the Model Num ber and S eri al Num ber of y our machi ne avail abl e when you cal l will allow us to serve you

quickly and acc ur ately.

16

Page 17

Exploded View Drawing JDP-20MF

17

Page 18

Parts List JDP-20MF

Index No. Part No. Description Size Qty

1 ............... 11300117 .................Base JDP-20MF .................................................................................... 1

................. 11400401A1 ............Column & Holder Assembly (Index 2A, 2B) .........Ø85m m ...................... 1

2A ............ JDP2 0-102A ............C olumn.................................................................................................. 1

2B ............ JDP2 0-102B ............H older ................................................................................................... 1

3 ............... TS-1525021 .............Socket Set Screw ...............................................M10x12 ...................... 1

4 ............... TS-1523041 .............Socket Set Screw ...............................................M6x12 ........................ 1

5 ............... TS-1492041 .............Hex Cap Screw ..................................................M 1 2 x40 ...................... 4

6 ............... 11400607 .................Bracket .................................................................................................. 1

7 ............... 10600702 .................Pinion Gear ........................................................................................... 1

8 ............... 10600802 .................Gear Shaft ............................................................................................. 1

9 ............... 10600902 .................Wor m Pin io n ............................................................................................

10A .......... 11501003 .................Crank Handle ........................................................................................ 1

11 ............. JDP20-111 ...............Pan Head Screw ................................................M5x6 .......................... 2

13 ............. TS-0071031 .............Hex Cap Screw ..................................................5 /8 ” -1 1 x2” ................... 1

14 ............. 10901402 .................Locator Pin ............................................................................................ 1

15 ............. TS-0561011 .............Hex Nut ..............................................................1/4”-20........................ 1

16 ............. 11401601 .................Angle Scale ........................................................................................... 1

17 ............. 10601702 .................Centering Scale ..................................................................................... 1

18 ............. 2658MZDU36 ..........Drive Screw ........................................................Ø2.3x5 mm ................. 8

19 ............. 10601901 .................Column Lock Handle ............................................................................. 1

21 ............. 11302119 .................Work Ta b le ............................................................................................ 1

22 ............. 11402207 .................Rack ...................................................................................................... 1

23 ............. 11402311 .................Rack Ring.............................................................................................. 1

24 ............. TS-2276081 .............Socket Set Screw ...............................................M6x8 .......................... 1

25 ............. 11302522 .................Hea d ..................................................................................................... 1

26 ............. TS-1525021 .............Socket Set Screw ...............................................M10x12 ...................... 2

27 ............. 10602701 .................Lamp Socket ......................................................................................... 1

28 ............. TS-1534042

29 ............. 11502901 .................Handle Shifter........................................................................................ 1

30 ............. 10603002 .................Cam ...................................................................................................... 1

31 ............. TS-1490021 .............Hex Cap Screw ..................................................M 8 x16 ........................ 1

32 ............. 11503212 .................Slide Bar ( rig h t ) ..................................................................................... 1

33 ............. 10903302 .................Slide Bar Bolt......................................................M10x40 ...................... 2

34 ............. 11403437 .................Motor Base ............................................................................................ 1

35 ............. TS-0720111 .............Lock Washer ......................................................1/2”............................. 2

36 ............. TS-1540081 .............Hex Nut ..............................................................M12 ............................ 2

37 ............. 10603704 .................Hub ....................................................................................................... 1

38 ............. 11303812 .................Feed Shaft............................................................................................. 1

39 ............. 2536MBE611 ...........Spring Pin...........................................................Ø5x16 mm.................. 1

43A .......... 10604303A1 ............Handle Bar Assembl y ............................................................................ 3

45 ............. 10604505 .................Shaft Collar ........................................................................................... 1

................. JDP20MF-SA ...........Scale Assembly (includes #18, 46, 613)................................................. 1

46 ............. 13105102 .................Scale ..................................................................................................... 1

49 ............. 11404903A2 ............Coil Spring & Cover ............................................................................... 1

51 ............. 11305107 .................Spring Seat ........................................................................................... 1

53 ............. TS-0561052 .............Hex Nut ..............................................................1/2”-20 UNF ............. 12

54 ............. 10605403 .................Quill Set Screw ...................................................................................... 1

55 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

56 ............. 11305616 .................Quill ....................................................................................................... 1

57 ............. 11405704 .................Rubber Washer ..................................................................................... 1

58 ............. 11305801 .................Spindle .................................................................................................. 1

59 ............. BB-6206ZZ ..............Ball Bearing ........................................................6206ZZ....................... 1

60 ............. 2003A02906 ............Thrust Bearing ....................................................................................... 1

61 ............. BB-6204Z ................Ball Beari ng ........................................................6204Z ......................... 1

62 ............. 11406202 .................Washe r.................................................................................................. 1

63 ............. 11406302 .................Lock Nut ................................................................................................ 1

.............Pan Head Screw ................................................M6 x12 ........................ 2

18

Page 19

Index No. Part No. Description Size Qty

64 ............. 11406403 .................Spindle Nut ............................................................................................ 1

65 ............. 11406508 .................Drive Sleeve .......................................................................................... 1

66 ............. BB-6206Z ................Ball Beari ng ........................................................6206Z ........................ 2

67 ............. 11406706 .................Collar .................................................................................................... 1

68 ............. 11406803 .................Retaining Ring ....................................................................................... 2

69 ............. 10606902 .................Pulley Set Nut........................................................................................ 1

70 ............. 11407019 .................Spind le Pulley.....................................................12 S,A ......................... 1

71 ............. 21015M3J40 ............Arbor ..................................................................MT3 xJT4 .................... 1

72A .......... 561709 ....................Chuck & Chuck Key ............................................................................... 1

73 ............. 10607303 .................Wedge................................................................................................... 1

74 ............. 8211422651 .............Motor ..................................................................................................... 1

75 ............. C0014170122 ..........Motor Cable ........................................................................................... 1

76 ............. TS-1490041 .............Hex Cap Screw ..................................................M 8 x25 ........................ 4

77 ............. TS-1550061 .............Flat Washer ........................................................M8 .............................. 4

78 ............. TS-1540061 .............Hex Nut ..............................................................M8 .............................. 4

79 ............. 11037972 .................Motor Pulley .......................................................19mm ......................... 1

80 ............. 2571MNC109 ...........Key.....................................................................5x6x27 mm ................. 1

81 ............. TS-1524031 .............Socket Set Screw ...............................................M8x12 ........................ 1

83 ............. 10608301 .................Wire Clip ............................................................................................... 1

84 ............. TS-1533032 .............Pan Head Screw ................................................M5x10 ........................ 1

85 ............. 2807AB08B3............Power Cord ........................................................................................... 1

87 ............. 2850AG5A14 ...........S witch ................................................................................................... 1

88 ............. 11308801 .................Switch Box ............................................................................................ 1

89 ............. TS-1534042 .............Pan Head Screw ................................................M6x12 ........................ 2

90A .......... 11309014A1 ............Pulley Cover Assembly .......................................................................... 1

92 ............. TS-1534052 .............Pan Head Screw ................................................M6x16 ........................ 4

95 ............. 11409511 .................Center Pulley Assembly ......................................................................... 1

96 ............. BB-6202Z ................Ball Beari ng ........................................................6202Z

98 ............. 11409803 .................Center Pulley Shaft ................................................................................ 1

99 ............. VB-A32 ....................Belt.....................................................................A-32 ........................... 2

101 ........... 2501MNVN11 ..........Rubber Washer ..................................................................................... 4

121 ........... TS-2286302 .............Pan Head Screw ................................................M6x30 ........................ 2

128 ........... 2653MBDE15 ..........Tapping Screw ...................................................M4x20 ........................ 2

129 ........... TS-1504051 .............Socket Head Cap Screw .....................................M8 x25 ........................ 1

130 ........... TS-1504061 .............Socket Head Cap Screw .....................................M8 x30 ........................ 2

137 ........... 10308846 .................Switch Cover ......................................................................................... 1

138 ........... TS-1533042 .............Pan Head Screw ................................................M5x12 ........................ 2

139 ........... 2852U55702 ............Bulb Switch ........................................................................................... 1

140 ........... 11514001 .................Motor Bar (left) ...................................................................................... 1

147 ........... JDP20-1147 .............Cover Edge Strip ................................................................................... 1

149 ........... 2536MBE619 ...........Spring Pin...........................................................Ø8x25 mm.................. 2

160 ........... 11316902 .................Nameplate ............................................................................................. 1

162 ........... 10216210 .................Warning Label ....................................................................................... 1

163 ........... JDP20-1163 .............Motor Label ........................................................................................... 1

165 ........... 11316501 .................Speed Chart .......................................................................................... 1

601 ........... TS-1533032 .............Pan Head Screw ................................................M5x10 ........................ 2

602 ........... TS-0733041 .............Lock Washer External Tooth ...............................1/4" ............................ 2

605 ........... 2536MBE623 ...........Spring Pin...........................................................Ø6x16 mm.................. 1

606 ........... 2536MBE625 ...........Spring Pin...........................................................Ø2.5x10 mm ............... 1

607 ........... TS-0720091 .............Lock Washer ......................................................3/8”............................. 2

610 ........... TS-2286202 .............Pan Head Screw ................................................M6x20 ........................ 2

611 ........... 11361101 .................Seat ...................................................................................................... 1

612 ........... TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

613 ...........

614 ........... 13005701 .................Nut .....................................................................M1 6-2.0P ................... 2

615 ........... 13005601 .................Washe r.................................................................................................. 1

616 ........... TS-1504051 .............Socket Head Cap Screw .....................................M8 x25 ........................ 1

617 ........... 11361701 .................Set Ring ................................................................................................ 1

11361301 .................Scale Bol t .............................................................................................. 1

......................... 2

19

Page 20

Index No. Part No. Description Size Qty

618 ........... 10604505 .................Round Nut ............................................................................................. 1

619 ........... TS-0720091 .............Lock Washer ......................................................3/8”............................. 1

700 ........... TS-152704 ...............Hex Wrench .......................................................3 mm .......................... 1

701 ........... TS-152706 ...............Hex Wrench .......................................................5 mm .......................... 1

801 ........... 28065558B3 ............Bulb Wire .............................................................................................. 1

805 ........... 10280501 .................Bulb Sticker ........................................................................................... 1

903 ........... 2801ABRF04 ...........Strain Relief ........................................................................................... 2

817 ........... 28065558B3 ............Bulb Wire .............................................................................................. 1

904 ........... JDP20-1904 .............Strain Relief ........................................................................................... 1

905 ........... 10810402A1 ............Chuck Guard Assembly ......................................................................... 1

20

Page 21

Wiring Diagram

JDP-20MF Electrical Schematic – 115V

ON / OFF SWITCH

BLACK

WHITE

GREEN

GROUND

BLACK

WHITE

GREEN

STARTING CAPACITOR

400MFD 125 VAC

3

2

1

4

BLACK

JDP-20MF Electrical Schematic – 230V

ON / OFF SWITCH

BLACK

WHITE

GREEN

BLACK

GROUND

LAMP SWITCH

BLACK

WHITE

GREEN

BLACK

WHITE

LAMP

WHITE

STARTING CAPACITOR

400MFD 125 VAC

3 2

1

4

BLACK

GREEN

BLACK

BLACK

WHITE

LAMP SWITCH

BLACK

WHITE

LAMP

GREEN

BLACK

21

Page 22

NOTES

22

Page 23

NOTES

23

Page 24

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

24

Loading...

Loading...