Jenn-Air WW27210P Installation Instructions

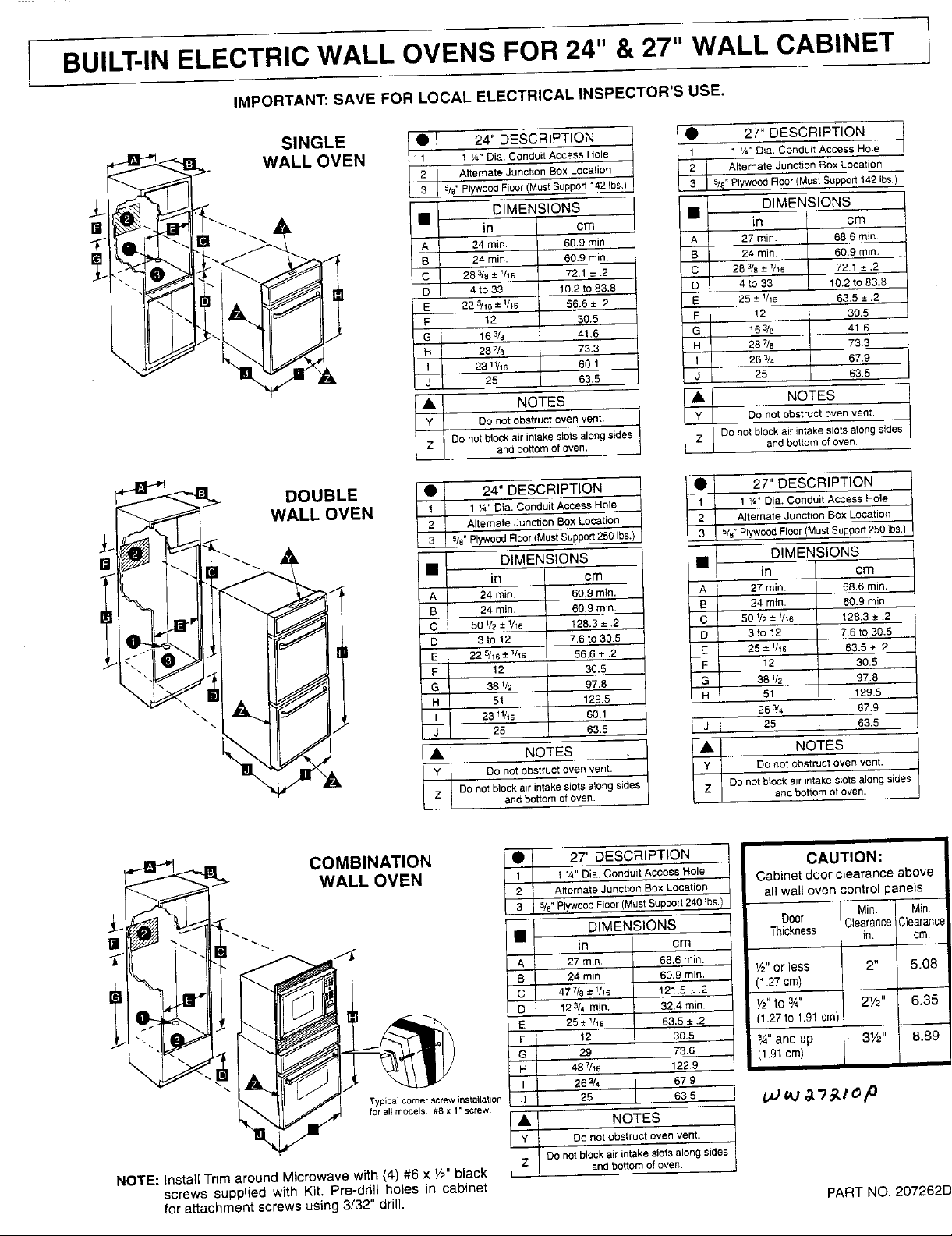

BUILT-INELECTRIC WALL OVENS FOR 24" & 27" WALL CABINET

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

SINGLE • 24"DESCRIPTION • 27" DESCRIPTION

2 Alternate Junction Box Location 2 Alternate Junction Box Location

3 s/8"PlywoodFloor(MustSupport142 Ibs.) 3 5/8 PlywoodF oor Mus Support142 Ibs)

jL _I_--..__91..__ WALL OVEN _ t '4"Die.ConduitAccessHole _ 1'_"DieConduitAccessHe_e

• in cm in cm

A 24 rain. 60.9 rain'. A ' 27 min. 68.6 min.

_ L _q_'_[ll _._ _ _J_ B 24 min. 60.9 min. B 24min 60.9 m,n.

DOUBLE • 24" DESCRIPTION • 27" DESCRIPTION

WALLOVEN 1 1 w, Die. Conduit Access Hole 1 1 _/_"Die. Conduit Access Hole

._ 3 _/e_ PlywoodFbor (Must Support250 tbs.} 3 5/e"PlywoodFreer(Must SUbbert250 Ib&/

r"-J "_" "- DIMENSIONS • DIMEN_SlONS

/ "A I 24 rain. 60.9 min. A 27 rain. 68.6 min.

C 283/a+-1/I_ 72.1 __.2 C 263/a-+1/_6 72 1 _+.2 .

D 4 to 33 10.2 to 83.8 D 4 to 33 10.2 to 83.8

E 22 s/_6± V_e 56.6 ± .2 E 25 -+Vls 635 ± .2

F 12 30.5 F 12 30.5

G 163/8 41.6 G 163/8 41.6

H 287/8 73.3 H' 28 7/8 73.3

I 231 _/16 60.1 I 263/4 67.9

J 25 63.5 25 63.5

Do not obstruct oven vent. , Do not obstruct oven vent.

Do not block air intake s_otsalong sides Do not block air intake slots along sides

_ NOTES _ NOTES

2 Alternate Junction Box Location 2 Alternate Junction Box Location

I

and bottom of oven. and bottom of oven.

C 50 V2 ± Vie 128.3 ± .2 C 50 V2± _A6 128.3 ± .2 ,

i'_ /I I E 22 s/_e± _/_6 56.6 ± .2 E 25 +-11_6 63.5 ± .2/

\ H 51 129.5 H 51 129.5

_" / J 25 63.5 J 25 63.5

/ D 3to12 7.6 to 30.5 D 3to12 7.6 to 30.5

B I 24 rain. 60.9 min, B 24 rain. 60.9 rain.

G 381/2 97.8 G 38 V2 97.8

i• NOTES • NOTES

_ I 2311/_6 60.1 I 263/4 67.9

Y Do not obstruct oven vent. Y Do not obstruct oven vent.

Z Do not block air intake slots along sides Z Do not b_ockair intake slots along sides

and bottom o1 oven. and bottom of o,/en.

COMBINATION • 27" DESCRIPTION, CAUTION:

WALL OVEN t 1 w' Die. Conduit Access Hole Cabinet door clearance above

2 Alternate Junction Box Location allwall oven control panels.

j_ 3 s/s"Plywood Floor(Must Support240 _bs.) Min. Min.

[] " • in cm Thickness in. cm.

/ A 27 rain. 88.6 m'_n. 2"

I D 123/4 rain. 32.4rain.,_ ½"to3_,, 2Ys" 6.35

B 24 min. 60.9 min. Y2" or less 5.08

I E 25±V_ 63.5±.2 (.__1.27tO1.91cm)

F t2 30.5 3A"andup 3W' 8.89

G 29 73.6 (1.91 cm)

H 487/16 122.9

"- I 263f,_ 67.9

Typical cornerscrewinstaltation J 25 63.5 _1,) t._ _'_ _ I (_ _

for allmOdels. #8 x 1"screw

• NOTES

l C 47718± V16 121.5 --..2 (127 cm)

Y Do not obstruct oven vent.

Z Do not block air intake slots along sides

NOTE:Install TrimaroundMicrowavewith (4) #6 x 1/2"black and bottom of oven.

screws supplied with Kit. Pre-drillholes in cabinet

forattachment screwsusing3/32" drill. PARTNO.207262l

DIMENSIONS Doer ClearanceClearanc_

CAUTION: For European style cabinets (flush front) the required clearance for operation of the oven door is a minimum

spacingof 7/8" betweenthe cutoutand the door,hingeor drawerof the cabinet.

Somebuilt-incabinets may not be wide enough, dueto theirconstruction,to allow this installation.

1. Cut hole in cabinet to mount oven. Cutout in cabinet should be level and straight. NOTE: There are no I

provisionsto levelthe unitafter it is installed.An oven thatis not levelcould cause poor baking results.

2. Installplywoodfloor asshownabove.

3. Attach unitto the cabinet with four No. 8 x 1" screws supplied with unit inside of envelope containingthese

instructions.Pre-drill holes in cabinet for attachmentscrews using 1/8"drill. Oven mountingholes are in each

corner of front panel For combination units, install trim around microwave with four No. 6 x 1/2" screws

suppliedwithunit. Pre-drillholes in cabinetfor attachmentscrewsusing3/32" drill.

4. See instructionsbelowfor electrical hook-up.

5. See User'sManualfor operatinginstructions.

6. SingleWall Ovensare also U.L. Listed to be installedas a combinationunit using MicrowaveModelsM166or

M167with TrimKits A526,A530or A424. Installperinstructionspackedwith TrimKits.

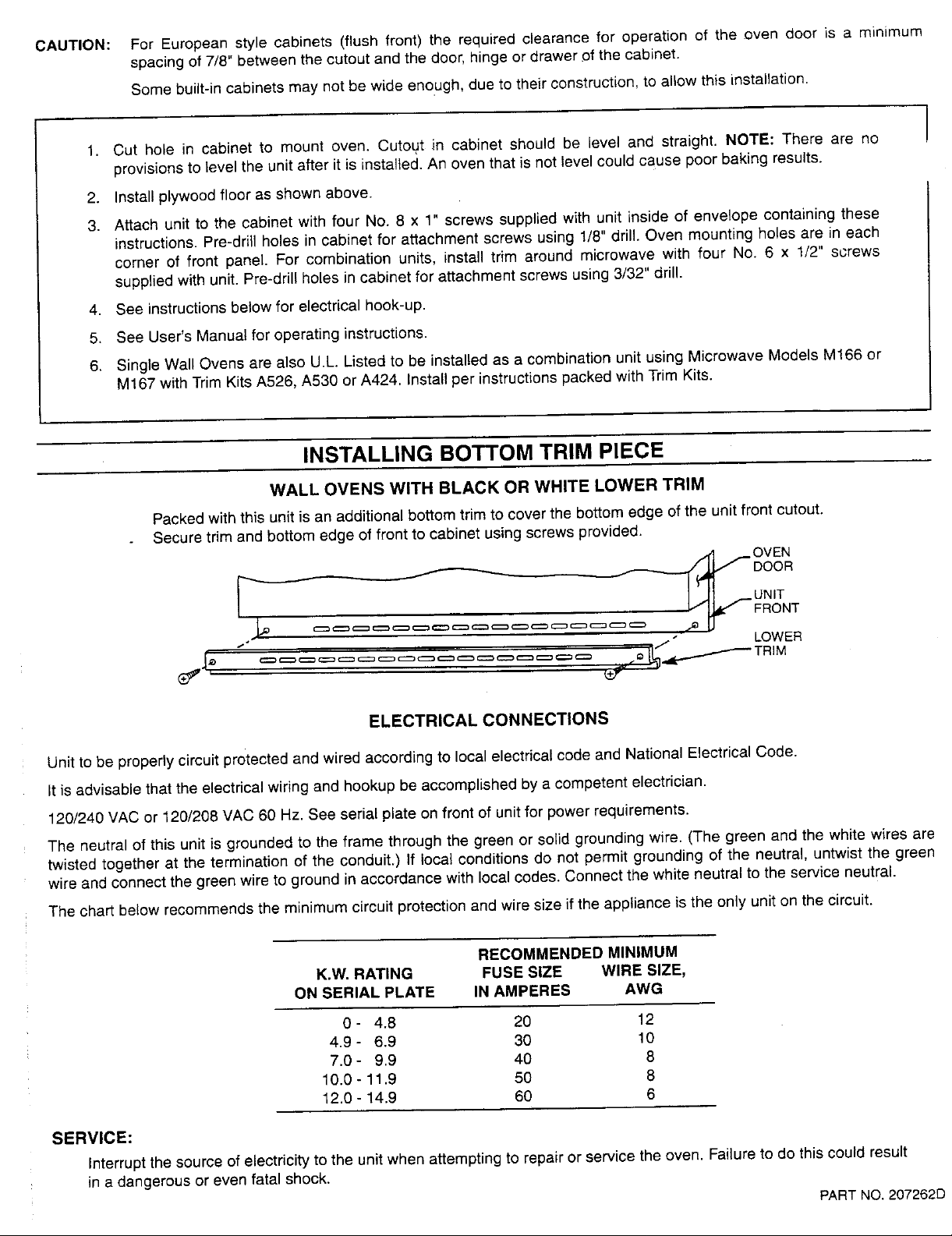

INSTALLING BOTTOM TRIM PIECE

WALL OVENS WITH BLACK OR WHITE LOWER TRIM

I

Packedwith this unitis an additionalbottomtrim to coverthebottomedge ofthe unit front cutout.

Securetrim and bottomedge offront to cabinet usingscrewsprovided.

......T.,M

ELECTRICAL CONNECTIONS

Unit to be properlycircuit protectedand wiredaccordingto localelectricalcode andNational ElectricalCode.

Itis advisablethatthe electricalwiringand hookup be accomplishedby a competentelectrician.

120/240VAC or 120/208VAC60 Hz. See serial plate onfront of unitfor powerrequirements.

The neutralof this unitis groundedto the frame through the green or solid groundingwire. (The green andthe white wires are

twistedtogether at the termination of the conduit.) If local conditionsdo not permit grounding of the neutral, untwist the green

wireand connectthe greenwire to ground in accordancewith localcodes.Connectthe white neutralto the service neutral.

Thechartbelowrecommendsthe minimumcircuit protectionandwire sizeif theapplianceis the only uniton the circuit.

RECOMMENDEDMINIMUM

K.W,RATING FUSESIZE WIRE SIZE,

ON SERIAL PLATE IN AMPERES AWG

0- 4.8 20 12

4.9- 6.9 30 10

7.O- 9.9 40 8

10.0- 11.9 50 8

12.0- 14.9 60 6

SERVICE:

Interruptthesourceof electricityto the unit whenattemptingto repairor service theoven. Failureto dothis could result

in a dangerousor even fatal shock.

PARTNO.207262r

Loading...

Loading...