Jenn-Air W10436037B User Manual

30" (76.2 CM) AND 36" (91.4 CM) ELECTRIC

IMPORTANT:

Save for local electrical inspector's use.

IMPORTANT :

À conserver pour consultation par l'inspecteur local des installations électriques.

DOWNDRAFT COOKTOP INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION DE LA TABLE DE

CUISSON ÉLECTRIQUE AVEC ASPIRATION PAR LE BAS DE

30" (76,2 CM) ET 36" (91,4 CM)

Table of Contents/Table des matières

COOKTOP SAFETY..................................................................... 2

INSTALLATION REQUIREMENTS............................................. 2

Tools and Parts......................................................................... 2

Location Requirements............................................................. 3

Venting Requirements............................................................... 4

Venting Methods....................................................................... 5

Electrical Requirements............................................................ 7

INSTALLATION INSTRUCTIONS............................................... 7

Prepare Cooktop....................................................................... 7

Install Foam Strip ...................................................................... 8

Rotate Blower - Optional .......................................................... 8

Install Cooktop.......................................................................... 8

Make Electrical Connection...................................................... 9

Complete Installation .............................................................. 10

SÉCURITÉ DE LA TABLE DE CUISSON................................. 11

EXIGENCES D'INSTALLATION ............................................... 11

Outillage et pièces .................................................................. 11

Exigences d'emplacement ..................................................... 12

Exigences concernant l'évacuation........................................ 14

Méthodes d'évacuation.......................................................... 15

Spécifications électriques....................................................... 16

INSTRUCTIONS D’INSTALLATION......................................... 17

Préparation de la table de cuisson......................................... 17

Installation de la bande de mousse........................................ 17

Rotation du ventilateur - Facultative ...................................... 18

Installation de la table de cuisson .......................................... 18

Raccordement électrique ....................................................... 19

Achever l'installation............................................................... 20

W10436037B

COOKTOP SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Tap e me asu re

■ Flat-blade screwdriver

■ Phillips head screwdriver

■ Drill

■ Level

■ 6" socket extension

■ Marker or pencil

■ Pliers

■ ¼" drill bit

■ Jigsaw

■ Ratchet with ³⁄₈" socket

Parts supplied

■ Vent grille

■ Pre-filter

Parts needed

■ A UL listed or CSA approved strain relief for ⁷⁄₈" (2.2 cm)

knockout.

■ A UL listed or CSA approved conduit connector for

¹⁄₂" (1.3 cm) trade-size metal-clad conduit

■ UL listed wire connectors

■ Metal ducting

■ Jenn-Air

Jenn-Air

Order Part Number A406

Jenn-Air

Order Part Number A403

To order, see the “Assistance or Service” section of the Use

and Care Guide.

■ Vent clamps

Check local codes. Check existing electrical supply. See

“Electrical Requirements” section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

®

wall cap

®

6" (15.2 cm) Round Surface Wall Cap Damper

®

3¼" x 10" (8.3 x 25.4 cm) Surface Wall Cap Damper

2

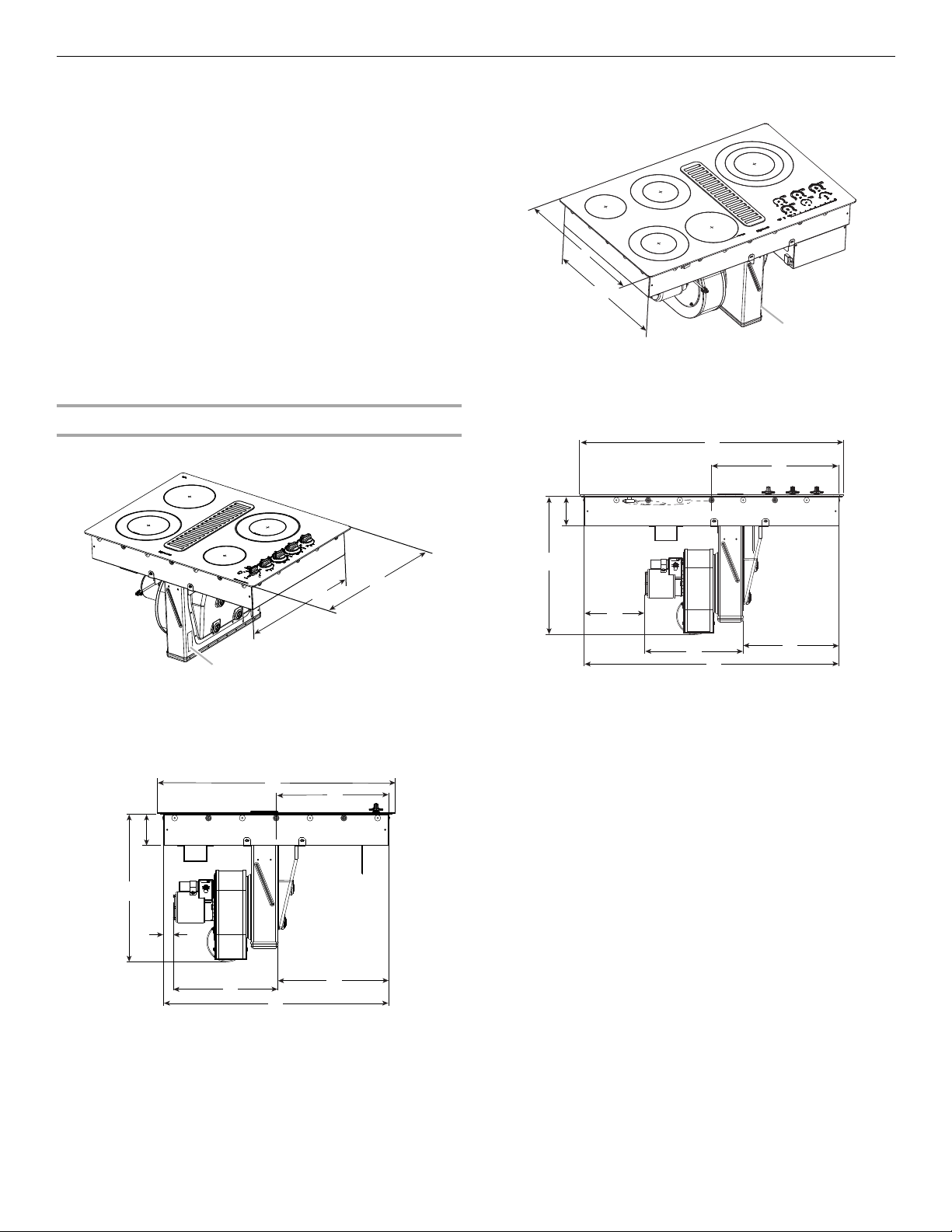

Location Requirements

A

B

C

A

B

C

D

F

E

G

H

B

C

A

A

B

C

E

D

F

G

H

IMPORTANT: Observe all governing codes and ordinances.

When installing cooktop, use minimum dimensions given.

■ To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to

be provided, the risk can be reduced by installing a range

hood that projects horizontally a minimum of 5" (12.7 cm)

beyond the bottom of the cabinets.

■ Use the countertop opening dimensions that are given with

these Installation Instructions. Given dimensions are

minimum clearances and provide 0" (0 cm) clearance.

■ Grounded electrical supply is required. See “Electrical

Requirements” section.

■ If cabinet has drawers, drawers will need to be removed and

drawer fronts installed on front of cabinet.

IMPORTANT: An under-counter built-in oven cannot be installed

under this product.

36" (91.4 cm) Cooktop - for standard and electric models

A. Model/serial rating plate location

B. 20

⁹⁄₁₆

" (52.3 cm)

C. 22" (55.9 cm)

Product Dimensions

30" (76.2 cm) Cooktop - for standard and electric models

A. Model/serial rating plate location

B. 20

⁹⁄₁₆

" (52.3 cm)

C. 22" (55.9 cm)

A. 35

¹¹⁄₃₂

" (89.8 cm)

B. 16

¹⁵⁄₆₄

" (41.2 cm) centerline of

product to edge of burner box

C. 12

⁷⁄₈

" (32.8 cm)

D. 34

¹⁄₈

" (86.7 cm)

E. 12

¹⁄₂

" (31.8 cm)

F. 8

¹⁷⁄₆₄

" (20.9 cm)

recommended minimum

cabinet to motor clearance

G. 18" (45.7 cm)

H. 4

⁵⁄₈

" (11.8 cm)

A. 29

³⁄₄

" (75.6 cm)

B. 12

¹⁄₂

" (31.8 cm)

centerline of product to

edge of burner box

C. 12

¹⁄₂

" (31.8 cm)

D. 28

³⁄₈

" (72.1 cm)

¹⁄₂

" (31.8 cm)

E. 12

F. 2" (5.1 cm) recommended minimum

cabinet to motor clearance

G. 18" (45.7 cm)

H. 4

⁵⁄₈

" (11.8 cm)

3

Cabinet Dimensions

D

A

E

I

J

K

G

H

L

C

F

B

A

B

C

D

E

F

G

H

I

J

A. 30" (76.2 cm) on 30" (76.2 cm) models

36" (91.4 cm) on 36" (91.4 cm) models

B. Combustible area above countertop (shown by dashed box above)

C. 30" (76.2 cm) minimum clearance between top of cooktop platform

and bottom of uncovered wood or metal cabinet (24" [61 cm]

minimum clearance if bottom of wood or metal cabinet is covered

by not less than

not less than No. 28 MSG sheet steel, 0.015" [0.04 cm] stainless

steel, or 0.024" [0.06 cm] aluminum or 0.020" [0.05 cm] copper)

D. 13" (33 cm) recommended upper cabinet depth

E. 2" (5.1 cm)

F. 2 1

¹⁄₈

" (73.4 cm)

G. 18" (45.7 cm) minimum clearance from upper cabinet to countertop

within minimum horizontal clearances to cooktop

H. Junction box or outlet; 12" (30.5 cm) minimum from bottom of

countertop

I. Junction box or outlet; 10" (25.4 cm) from right-hand side of

cabinet

J. 28

⁷⁄₈

" (73.4 cm) on 30" (76.2 cm) models

34½" (87.6 cm) on 36" (91.4 cm) models

K. 2½" (6.4 cm) minimum distance to nearest left and right side

combustible surface above cooktop

L. 1½" (3.8 cm) minimum clearance between back wall and

countertop

NOTES: After making the countertop cutout, some installations

may require notching down the base cabinet side walls to clear

the cooktop base. To avoid this modification, use a base cabinet

with sidewalls wider than the cutout.

■ A minimum side clearance of 6" (15.2 cm) is recommended

between side of cooktop and side wall for maximum

ventilation performance.

■ A minimum clearance of 2" (5.1 cm) is recommended

between the motor/blower and cabinet for proper cooling. A

6" (15.2 cm) clearance is recommended for servicing access.

¹⁄₄

" [0.6 cm] flame retardant millboard covered with

Cutout Dimensions

A. 28

⁷⁄₈

" (73.4 cm) maximum on 30" (76.2 cm) models

34½" (87.6 cm) maximum on 36" (91.4 cm) models

B. 21

¹⁄₈

" (53.7 cm) maximum on both 30" (76.2 cm) and 36" (91.4 cm)

models

C. 8

⁵⁄₈

" (21.9 cm) on 30" (76.2 cm) models

15

⁷⁄₁₆

" (39.2 cm) on 36" (91.4 cm) models

D. 6

⁵⁄₁₆

" (16.0 cm) on both 30" (76.2 cm) and 36" (91.4 cm) models

E. 2" (5.1 cm) minimum space to front edge of cooktop

F. Floor exhaust option

G. 6

¹⁄₈

" (15.6 cm) for 6" (15.2 cm) vent system

H. 8

⁵⁄₈

" (21.9 cm) on 30" (76.2 cm) models

15

⁷⁄₁₆

" (39.2 cm) on 36" (91.4 cm) models

I. 16" (40.6 cm) on both 30" (76.2 cm) and 36" (91.4 cm) models

J. Wall exhaust option

Venting Requirements

IMPORTANT: This cooktop must be exhausted outdoors unless

using the Jenn-Air

Methods” section.

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Use a Jenn-Air

■ Vent system must terminate to the outside.

■ Use only a 6" (15.2 cm) round metal vent. Rigid metal vent is

recommended. For best performance, do not use plastic or

metal foil vent.

■ Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

■ Do not cut a joist or stud unless absolutely necessary. If a

joist or stud must be cut, then a supporting frame must be

constructed.

■ The size of the vent should be uniform.

■ The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

■ Use vent clamps to seal all joints in the vent system.

■ Use caulking to seal exterior wall or roof opening around the

cap.

■ Determine which venting method is best for your application.

®

Duct Free Filter Accessory Kit. See “Venting

®

vent cap.

4

For Best Performance:

A

B

A

B

A

B

A

B

■ Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

■ Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

■ Do not install 2 elbows together.

■ Use no more than three 90° elbows.

■ If an elbow is used, install it as far away as possible from the

hood’s vent motor exhaust opening.

■ Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

■ Elbows too close together can cause excess turbulence that

reduces airflow.

■ Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or 3¹⁄₄" x 10"

(8.3 x 25.4 cm) system.

■ Do not reduce to a 5" (12.7 cm) system after using

6" (15.2 cm) or 3¹⁄₄" x 10" (8.3 x 25.4 cm) fittings.

■ Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

■ Use a Jenn-Air

®

vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is

not reduced and that it has a backdraft damper.

■ Use vent clamps to seal all joints in the vent system.

■ Use caulking to seal exterior wall or roof opening around the

cap.

The length of vent system and number of elbows should be kept

to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is 60 ft

(18.3 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

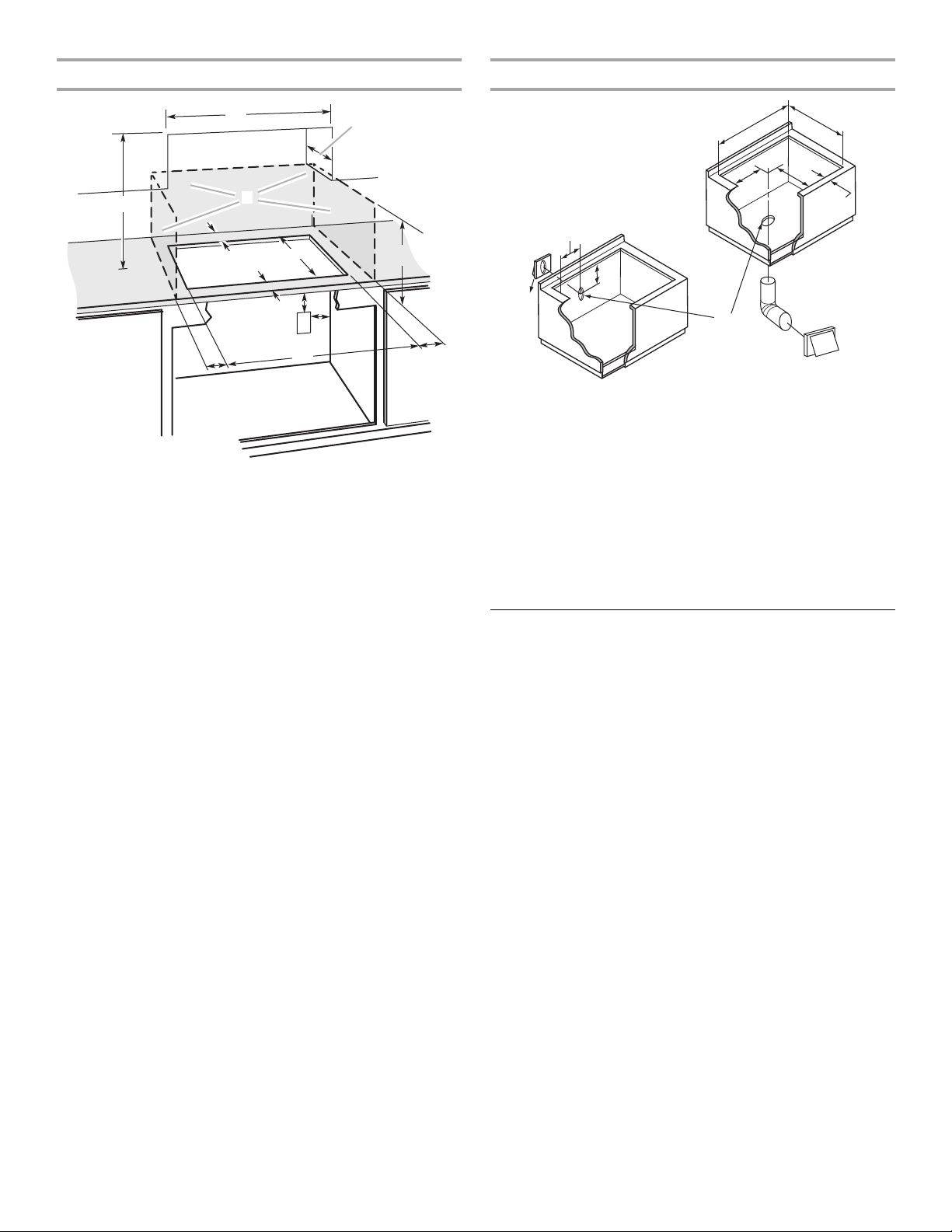

Ven ting Methods

Common venting methods are shown for a counter-mounted

downdraft cooktop. The cooktop may be vented through the wall

or floor.

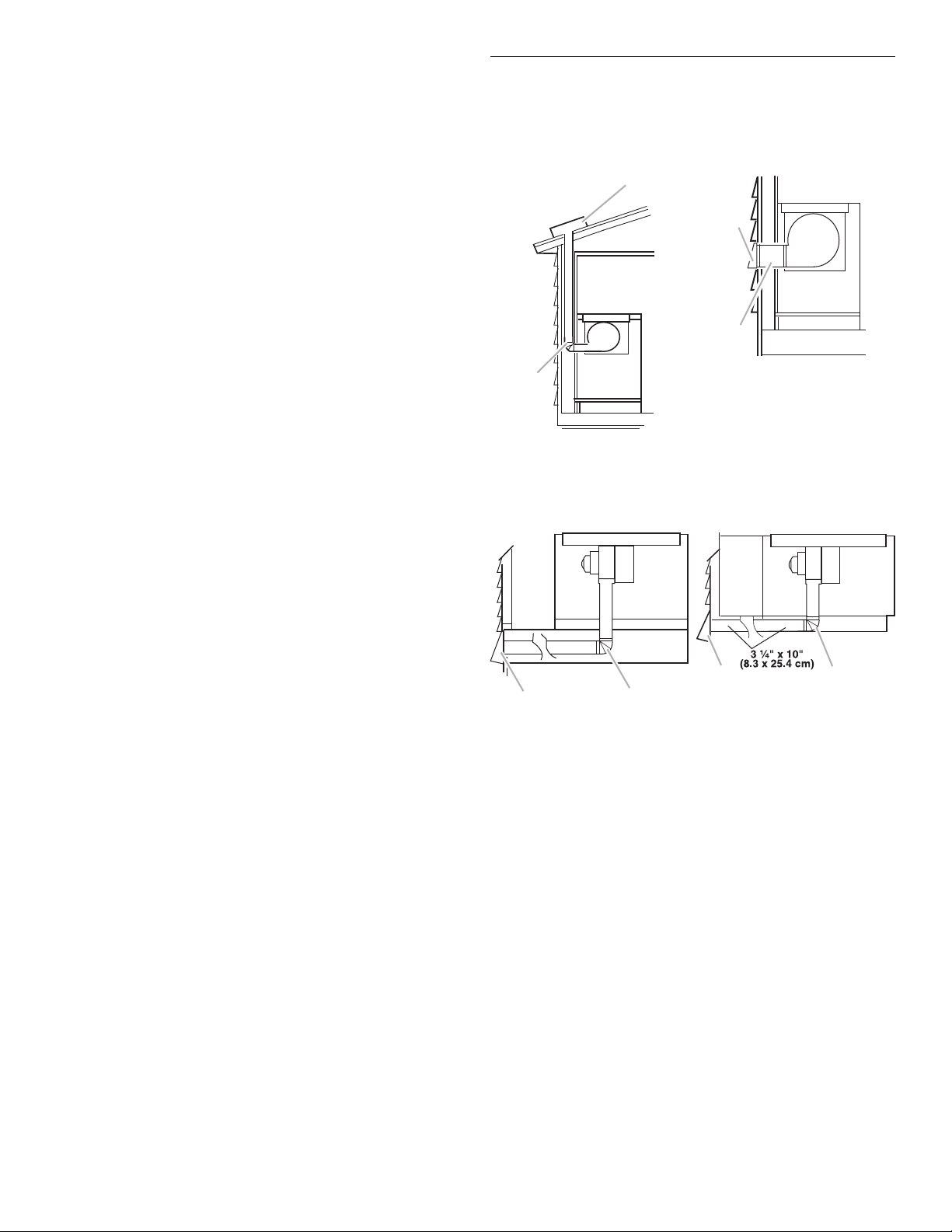

Option 1 - Roof Venting Option 2 - Wall Venting

A. Roof cap

B. 6" (15.2 cm) round roof venting

Option 3 - Venting Between

Floor Joist

A. Wall cap

B. 6" (15.2 cm) round wall venting

A. 6" (15.2 cm) round wall venting

B. Wall cap

Option 4 - Venting behind

Cabinet Kick Plate

A. Wall cap

B. 6" (15.2 cm) round wall venting

5

Concrete Slab Installations - Exhaust Through Wall

A

B

C

D

E

F

G

H

I

J

L

M

K

N

90˚ elbow

2 ft

(0.6 m)

6 ft (1.8 m)

wall cap

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) transition

1 ft

(0.3 m)

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round metal vent

F. 6" (15.2 cm) round PVC coupling

G. Concrete slab

H. 6" (15.2 cm) round PVC sewer pipe

I. 6" (15.2 cm) round 90° PVC sewer pipe elbow

J. Tightly pack gravel or sand completely around pipe.

K. 30 ft (9.1 m) max.

L. 6" (15.2 cm) round 90° PVC sewer pipe elbow

M. 6" (15.2 cm) round PVC coupling

N. 12" (30.5 cm) minimum

Jenn-Air

®

Duct Free Filter Accessory Kit

(For model numbers JED3430, JED3536, JED4430, JED4536,

JGD3430 and JGD3536)

On select downdraft models, the Jenn-Air

Accessory Kit Part Number JDA7000WX is now available. The

Jenn-Air

®

Duct Free Filter Accessory Kit is ideal for both new

®

Duct Free Filter

construction and kitchen renovation projects because it provides

an easy alternative to the installation of metal ducting and venting

in the downdraft system outside the home. The kit includes all

required hardware, one filter and complete installation

instructions. For more information on the Jenn-Air

®

Duct Free

Filter Accessory Kit, contact your Jenn-Air dealer or call

1-800-JENNAIR (1-800-536-6247).

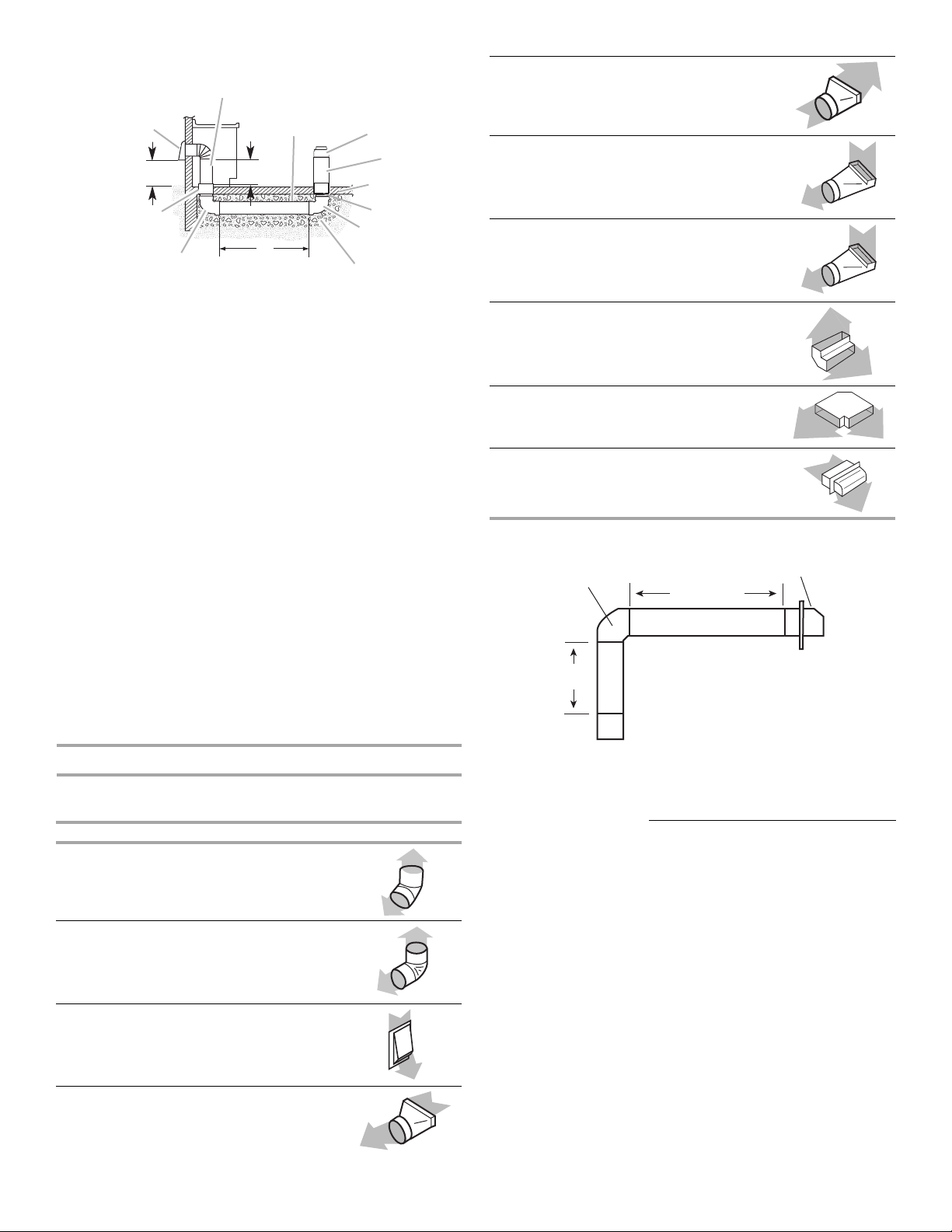

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) 90° elbow

transition

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) 90° elbow

transition

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

90° elbow

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

flat elbow

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

wall cap

Example vent system

5.0 ft

(1.5 m)

5.0 ft

(1.5 m)

5.0 ft

(1.5 m)

12.0 ft

(3.7 m)

0.0 ft

(0.0 m)

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8 m)

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm)

wall cap

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) transition

6

0.0 ft

(0.0 m)

4.5 ft

(1.4 m)

1- 90° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

NOTE: Flexible vent is not recommended. Flexible vent creates

back pressure and air turbulence that greatly reduce

performance.

Loading...

Loading...