Page 1

INSTALLATION INSTRUCTIONS

ELECTRIC DOWNDRAFT SLIDE-IN RANGES

INSTRUCTIONS D’INSTALLATION

DES CUISINIÈRES ÉLECTRIQUE À ÉVACUATION

DESCENDANTE ENCASTRABLE

Table of Contents/Table des matières

RANGE SAFETY .............................................................................2

INSTALLATION REQUIREMENTS................................................3

Tools and Parts ............................................................................3

Location Requirements................................................................3

Venting Requirements..................................................................5

Venting Methods..........................................................................5

Calculating Vent System Length..................................................6

Electrical Requirements - U.S.A. Only.........................................7

Electrical Requirements - Canada Only.......................................8

Countertop Preparation ...............................................................8

INSTALLATION INSTRUCTIONS..................................................9

Unpack Range..............................................................................9

Adjust Leveling Legs.................................................................... 9

Install Anti-Tip Bracket.................................................................9

Install Downdraft System...........................................................10

Electrical Connection - U.S.A. Only...........................................14

Connect Range to Downdraft System.......................................19

Complete Installation .................................................................21

Moving the Range......................................................................21

SÉCURITÉ DE LA CUISINIÈRE ...................................................23

EXIGENCES D’INSTALLATION...................................................24

Outils et pièces...........................................................................24

Exigences d’emplacement.........................................................24

Exigences concernant l’évacuation ...........................................26

Méthodes d’évacuation..............................................................27

Calcul de la longueur effective du circuit d’évacuation.............28

Spécifications électriques ..........................................................29

Préparation du plan de travail....................................................29

INSTRUCTIONS D’INSTALLATION.............................................30

Déballage de la cuisinière ..........................................................30

Réglage des pieds de nivellement.............................................30

Installation de la bride antibasculement ....................................31

Installation du circuit d’évacuation par le bas ...........................31

Raccordement de la cuisinière au circuit d’évacuation

par le bas....................................................................................35

Achever l’installation ..................................................................37

Déplacement de la cuisinière.....................................................38

IMPORTANT:

Save for local electrical inspector's use.

IMPORTANT :

À conserver pour consultation par l'inspecteur local des installations électriques.

W10253462A

Page 2

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

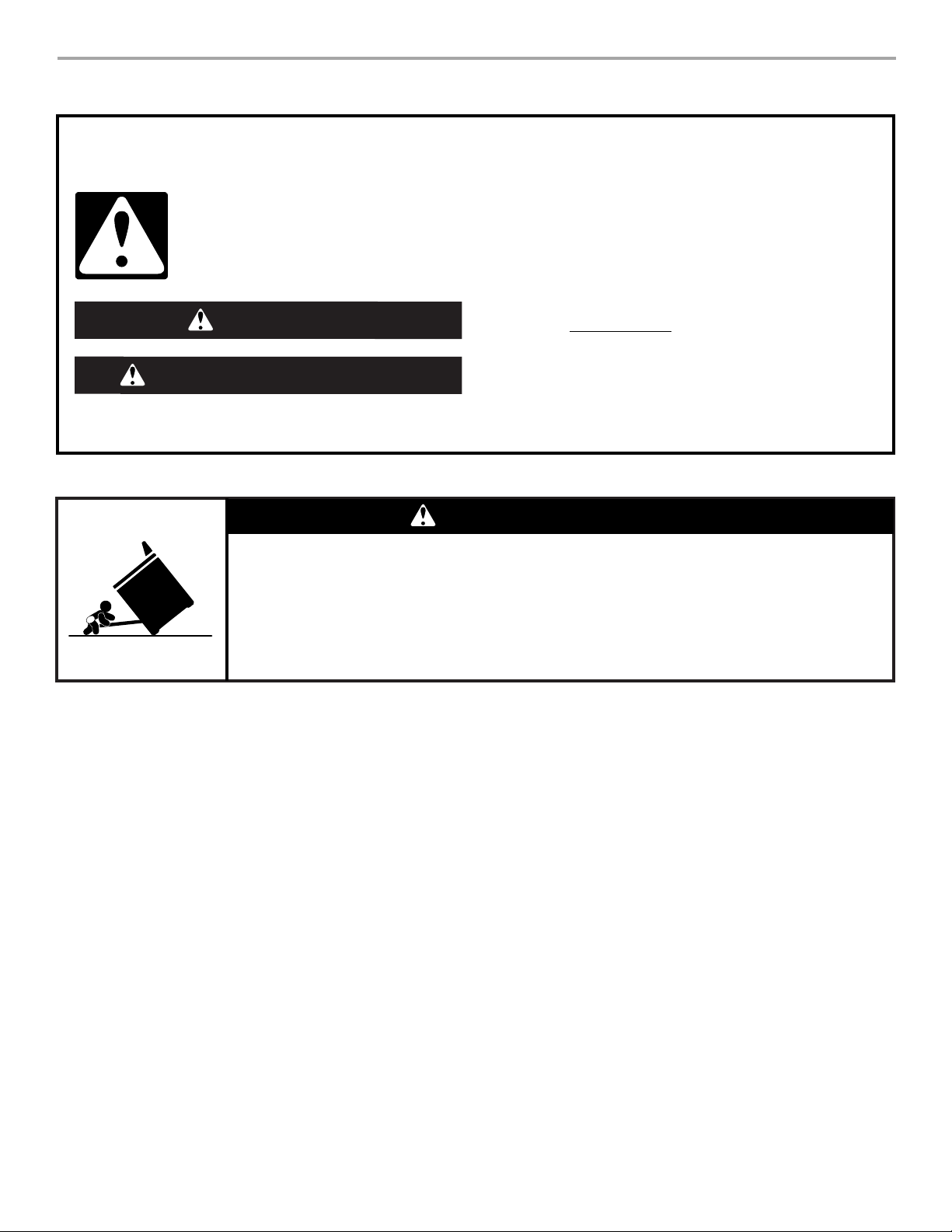

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

WARNING

Tip Over Hazard

follow

2

Page 3

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tool s ne e de d

■ Tape measure

■ Level

■ Phillips screwdriver

■ Flat-blade screwdriver

■ Saber or keyhole saw

■ Marker or pencil

Parts supplied

Check that all parts are included.

■ 3 - #10-32 hex nuts (attached to terminal block)

■ 3 - Terminal lugs

■ 2 or 3 - Oven racks (depending on your model)

■ Blower motor

■ 2 - vent clamps

■ Flexible vent

■ Flow tester card

■ Blower location template

■ 4 - #8 x ¾" screws (for mounting blower motor bracket)

■ 2 - #12 x 1⁵⁄₈" screws (for mounting anti-tip bracket)

■ Anti-tip bracket (taped to package containing literature in

oven cavity)

Anti-tip bracket must be securely mounted to back wall or

floor. Thickness of floor may require longer screws to anchor

bracket to subfloor. Longer screws are available from your

local hardware store.

Parts needed

■ One of the following Jenn-Air wall caps:

®

Jenn-Air

Order Part Number A405.

Jenn-Air

Order Part Number A406.

Jenn-Air

Damper. Order Part Number A403.

To order, see the “Assistance or Service” section of the Use

and Care Guide.

■ Metal ducting

■ Vent clamps

■ Concrete anchors (for concrete floor mounting)

■ 2 - 2" x 4" x 8¾" (5.0 x 10.2 x 22.2 cm) wood spacers (for left

or right side venting)

5" (12.7 cm) Round Surface Wall Cap Damper.

®

6" (15.2 cm) Round Surface Wall Cap Damper.

®

3¼" x 10" (8.3 x 25.4 cm) Surface Wall Cap

■ Wrench or pliers

■ ⁵⁄₁₆" nut driver

■ ¼" nut driver

■ Drill

■ ¹⁄₈" (3.2 mm) drill bit

■ ³⁄₁₆" (4.8 mm) carbide-tipped

masonry drill bit (for concrete/

ceramic floors)

If using a power supply cord:

■ A UL listed power supply cord kit marked for use with ranges.

The cord should be rated at 250 volts minimum, 40 amps or

50 amps that is marked for use with nominal 1³⁄₈" (3.5 cm)

diameter connection opening and must end in ring terminals

or open-end spade terminals with upturned ends.

■ A UL listed strain relief.

Check local codes. Check existing electrical supply. See

“Electrical Requirements” section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ It is the installer’s responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the right-hand side of

the oven frame behind the storage drawer panel.

■ The range should be located for convenient use in the

kitchen.

■ To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See “Electrical

Requirements” section.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, the Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

■ When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need to be

revised. See “Electrical Connection” section.

3

Page 4

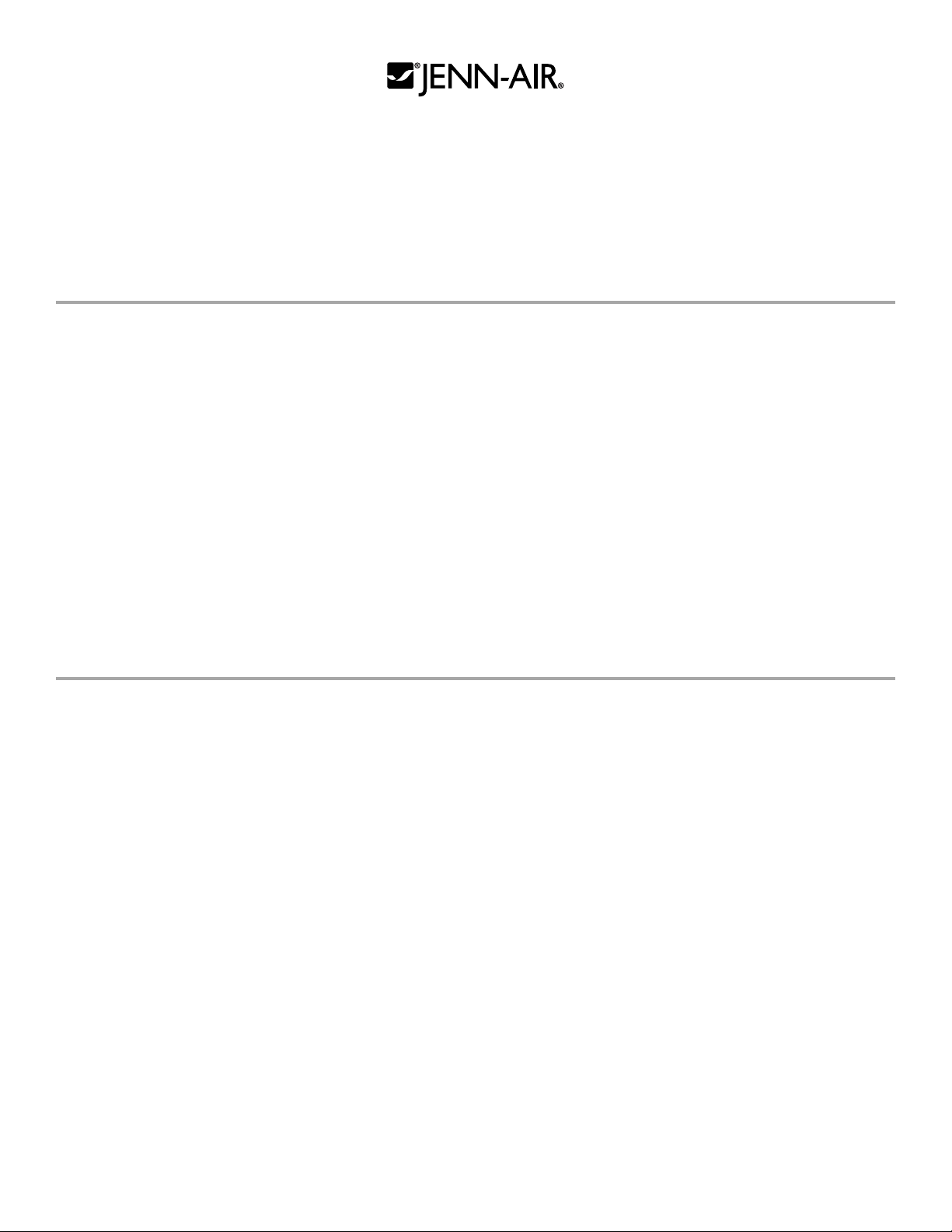

Product Dimensions

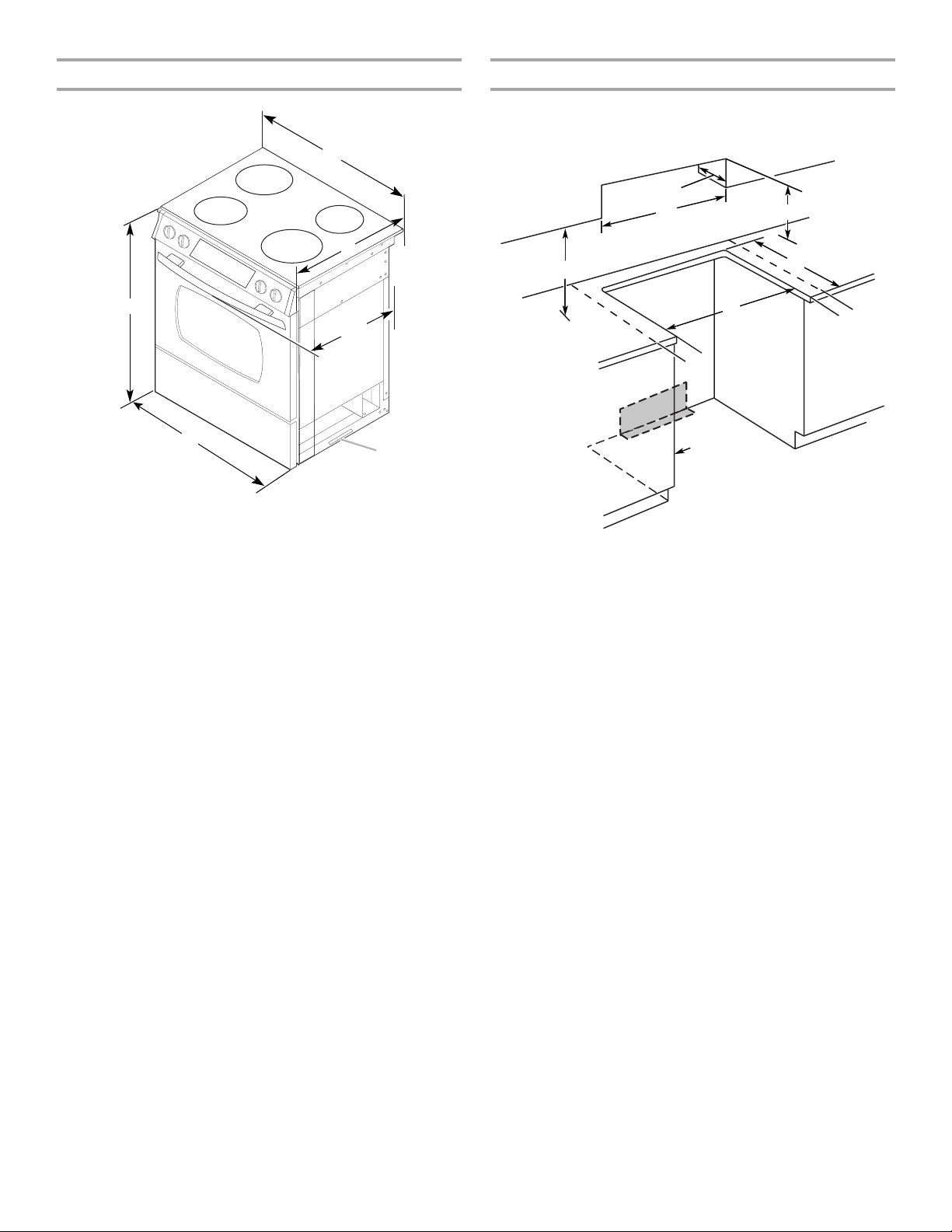

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

A

36" (91.4 cm) countertop height.

A

B

C

F

B*

E**

D

A. 30³⁄₄" (78.1 cm)

B. 35³⁄₄" (90.8 cm) height to underside

of cooktop edge with leveling legs

screwed all the way in*

C. Model/serial number plate (located

on the right-hand side of the

bottom oven frame)

D. 29⁷⁄₈" (75.9 cm)

E. 29¹⁄₁₆" (73.8 cm) from

handle to standoff at back

of range**

F. 23½" (59.7 cm)

countertop notch to rear

of cooktop

C

*Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

**When installed in a 24" (61 cm) base cabinet with 25" (63.5 cm)

countertop; front of oven door protrudes 2¹⁄₂" (6.4 cm) beyond

24" (61.0 cm) base cabinet.

H

F

A. 13" (33.0 cm) upper cabinet

depth

B. 30" (76.2 cm) min. opening

width

C. For minimum clearance to the

top of the cooktop,

see NOTE*.

D. 23¹⁄₄" (59.1 cm) opening

depth

E. 30" (76.2 cm) min. opening

width

D

E

I

I

G

F. Junction box - 5.5" (14.0 cm)

min. from either cabinet,

10" (25.4 cm) max. from floor

Outlet must be flush.

Nothing located in shaded

area can extend more than

2" (5.1 cm) from wall or range

will not slide all the way back.

G. Cabinet door or hinge should

not extend into cutout.

H. 18" (45.7 cm)

I. 3" (7.6 cm) min. clearance from

both sides of the range to the

side wall or other combustible

material.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than ¹⁄₄" (0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

4

Page 5

Venting Requirements

A

IMPORTANT: This range must be exhausted outdoors. See

“Venting Methods” section.

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Use a Jenn-Air wall cap.

■ Vent system must terminate to the outside.

■ Use only a 6" (15.2 cm) round metal vent or a 3¼ x 10"

(8.3 cm x 25.4 cm) rectangular vent, except as follows:

5" (12.7 cm) round metal vent may be used for venting

straight out the back of the range and directly through the

wall for vent lengths of 10 ft (3.0 m) or less.

■ Rigid metal vent is recommended. For best performance, do

not use plastic or metal foil vent.

■ Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

■ Do not cut a joist or stud unless absolutely necessary. If a

joist or stud must be cut, then a supporting frame must be

constructed.

■ The size of the vent should be uniform.

■ The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

■ Use vent clamps to seal all joints in the vent system.

■ Use caulking to seal exterior wall or roof opening around the

cap.

■ Determine which venting method is best for your application.

For Best Performance:

■ Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

■ Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

■ Do not install 2 elbows together.

■ Use no more than three 90° elbows.

■ If an elbow is used, install it as far away as possible from the

hood’s vent motor exhaust opening.

■ Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

■ Elbows too close together can cause excess turbulence that

reduces airflow.

■ Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or 3¹⁄₄" x 10"

(8.3 x 25.4 cm) system.

■ Do not reduce to a 5" (12.7 cm) system after using a

6" (15.2 cm) or 3¹⁄₄" x 10" (8.3 x 25.4 cm) fittings.

■ Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

■ Use a Jenn-Air vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is

not reduced and that it has a backdraft damper.

■ Use vent clamps to seal all joints in the vent system.

■ Use caulking to seal exterior wall or roof opening around the

cap.

The length of vent system and number of elbows should be kept

to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is

60 ft (18.3 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

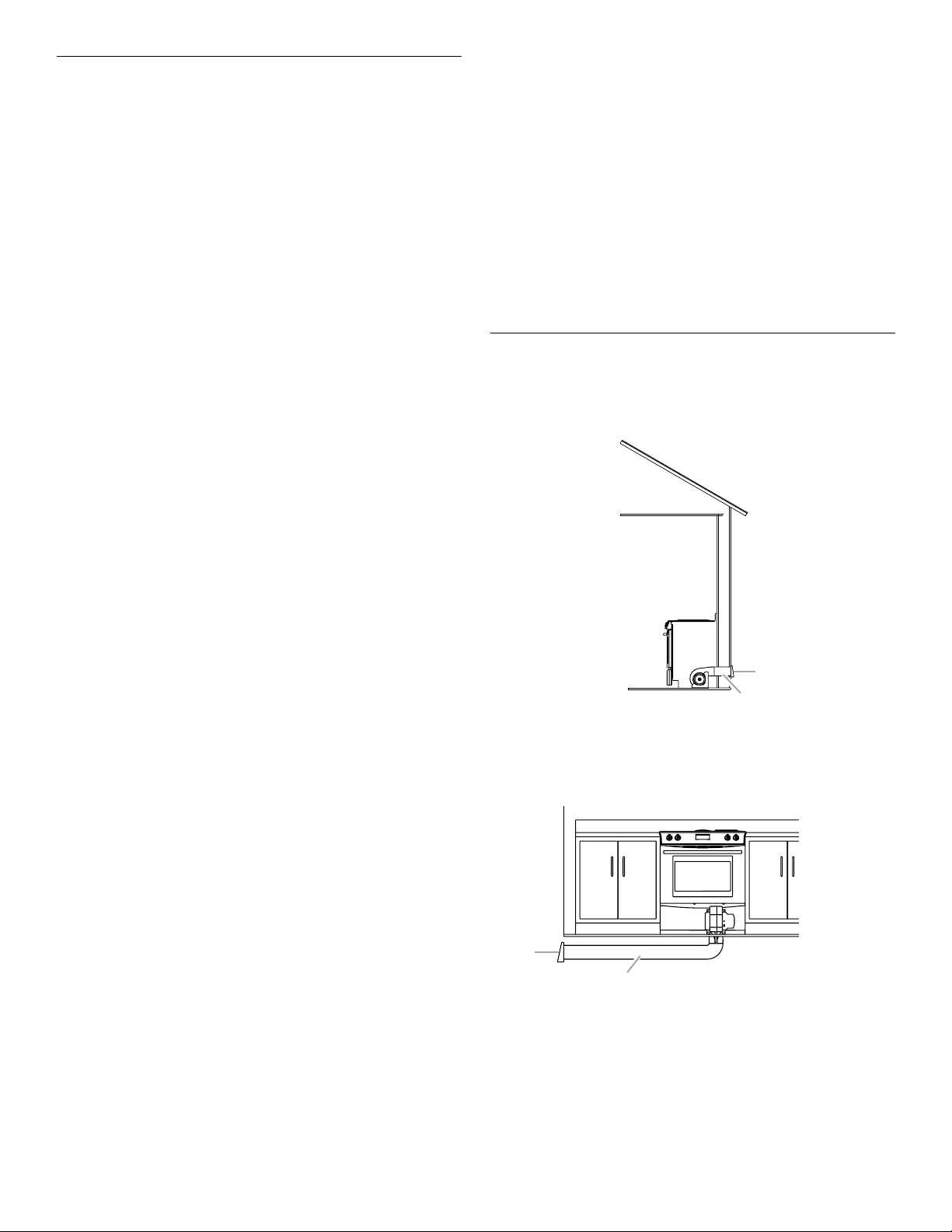

Ventin g Meth ods

Common venting methods are shown for a downdraft range. The

downdraft range may be vented through the wall or floor.

Wall Venting

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

Floor Venting

Venting Between Floor Joists

A

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

5

Page 6

Left or Right Side Venting

A

F

Venting Behind Cabinet Kickplate

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

Concrete Slab Installations - Exhaust Through Wall

B

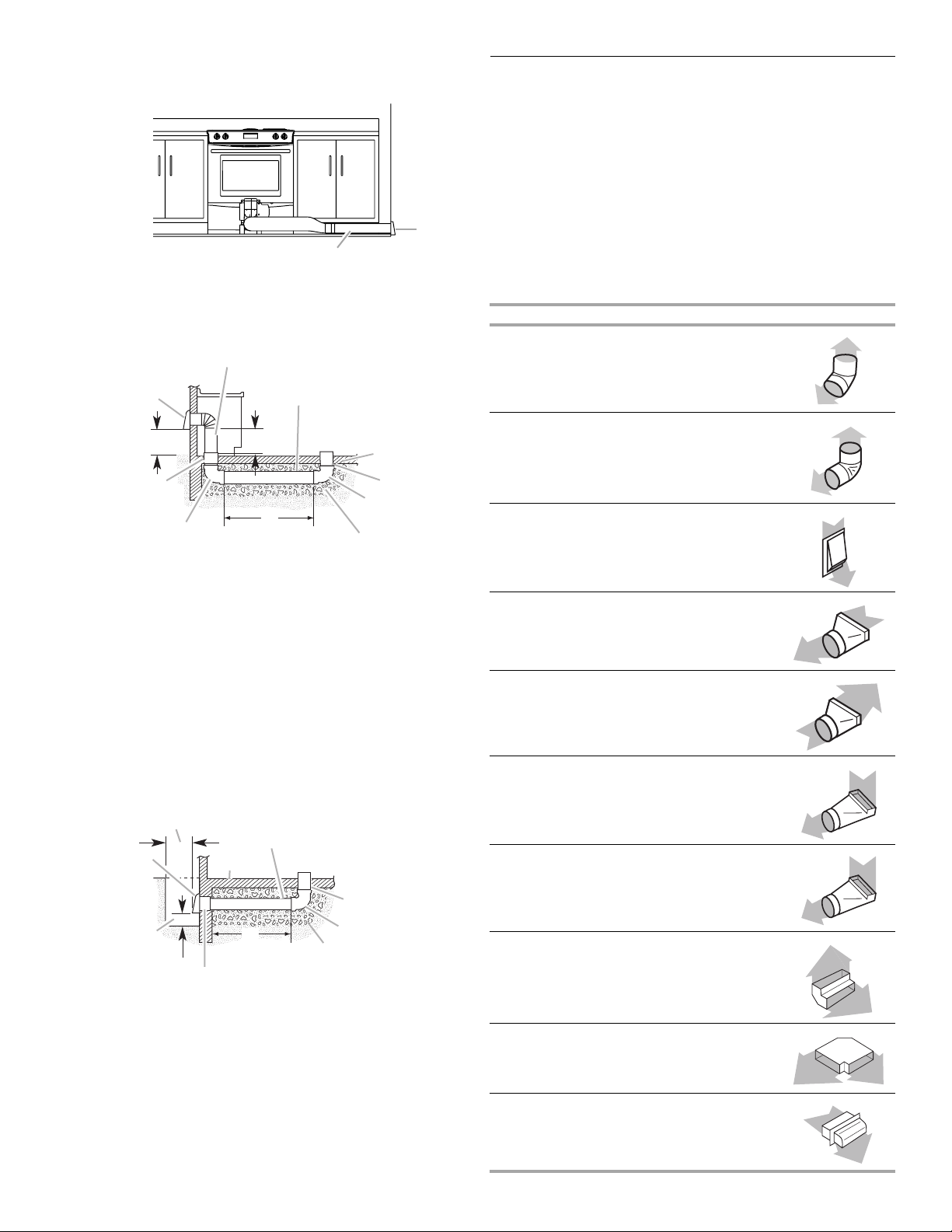

Calculating Vent System Length

IMPORTANT: This range is rated at 60 ft (18.3 m) of straight duct.

Low range is up to 30 ft (9.1 m); high range is 31 ft (9.4 m) to

60 ft (18.3 m).

If equivalent duct length exceeds 30 ft (18.3 m), the blower must

be converted to high range.

■ Do not convert to high range for shorter lengths. This will

cause excessive noise, conditioned air loss and affect the

flame pattern on gas ranges.

■ To convert blower for high range installations, see the

“Install Downdraft System” section.

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8 m)

A

L

K

J

C

I

D

E

G

H

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. Concrete slab

F. 6" (15.2 cm) round PVC sewer pipe

G. 6" (15.2 cm) round 90° PVC sewer pipe elbow

H. Tightly pack gravel or sand completely around pipe.

I. 30 ft (9.1 m) max.

J. 6" (15.2 cm) round 90° PVC sewer pipe elbow

K. 6" (15.2 cm) round PVC coupling

L. 12" (30.5 cm) minimum

Concrete Slab Installations Exhaust Through Window Well

IMPORTANT: Window well installation for electric models only.

B

D

A

K

J

C

E

H

F

G

I

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm)

wall cap

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) transition

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) transition

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) 90° elbow

0.0 ft

(0.0 m)

4.5 ft

(1.4 m)

1 ft

(0.3 m)

5.0 ft

(1.5 m)

transition

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) 90° elbow

5.0 ft

(1.5 m)

transition

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

90° elbow

5.0 ft

(1.5 m)

A. Wall cap

B. 12" (30.5 cm) minimum

C. Concrete slab

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round PVC sewer pipe

F. 6" (15.2 cm) round 90° PVC sewer pipe elbow

G. Tightly pack gravel or sand completely around pipe.

H. 42 ft (12.8 m) max.

I. 6" (15.2 cm) round PVC coupling

J. 6" (15.2 cm) minimum

K. Window well

6

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

flat elbow

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

wall cap

12.0 ft

(3.7 m)

0.0 ft

(0.0 m)

Page 7

Example vent system

90˚ elbow

6 ft (1.8 m)

wall cap

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

2 ft

(0.6 m)

Maximum length = 60 ft (18.3 m)

1- 90° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

NOTE: For external venting, flexible vent is not recommended.

Flexible vent creates back pressure and air turbulence that

greatly reduce performance.

Electrical Requirements - U.S.A. Only

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial number rating

plate. The model/serial number rating plate is located behind

the control panel or on the oven frame behind the storage

drawer panel. Refer to the figures in the “Product

Dimensions” section of the “Location Requirements” section.

■ This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40- or

50-amp power supply cord (pigtail) (see following Range

Rating chart). If local codes do not permit ground through the

neutral, use a 4-wire power supply cord rated at 250 volts,

40 or 50 amps and investigated for use with ranges.

8.8 - 16.5 KW

16.6 - 22.5 KW

7.8 - 12.5 KW

12.6 - 18.5 KW

40 or 50**

50

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a 50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 1³⁄₈" (34.9 mm) diameter connection opening.

■ A circuit breaker is recommended.

■ The range can be connected directly to the circuit breaker

box (or fused disconnect) through flexible or nonmetallic

sheathed, copper or aluminum cable. See “Electrical

Connection.”

■ Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack in the line so that

the range can be moved if servicing is ever necessary.

■ A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

■ Wire sizes and connections must conform with the rating of

the range.

■ The wiring diagram is located on the back of the access

panel in a plastic bag.

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green

ground wire of the 4-wire power supply cord is connected to the

cabinet. See “Electrical Connection.”

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

7

Page 8

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). This cord

contains 3 copper conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance end

must be provided at the point the power supply cord enters the

appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range’s final location.

■ Do not use an extension cord.

3-wire receptacle (10-50R)

Electrical Requirements - Canada Only

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualified electrical installer if you are not sure

the range is properly grounded.

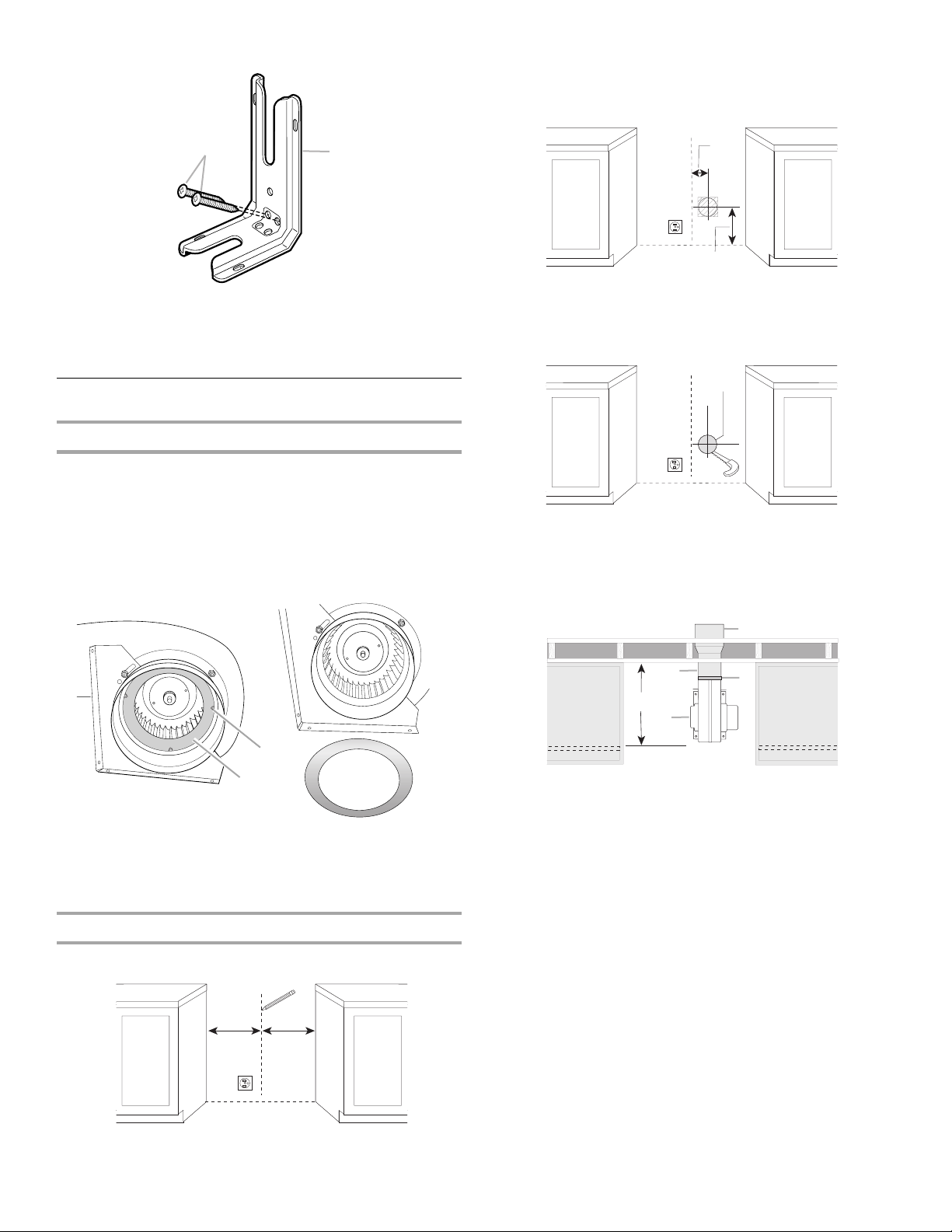

Countertop Preparation

(for Slide-in Ranges Only)

The cooktop sides of the slide-in range fit over the cutout edge of

your countertop.

If you have a square finish (flat) countertop and the opening width

is 30" (76.2 cm), no countertop preparation is required.

Formed front-edged countertops must have molded edge

shaved flat ³⁄₈" (1.0 cm) from each front corner of opening.

Tile countertops may need trim cut back ³⁄₈" (1.0 cm) from each

front corner and/or rounded edge flattened.

30"

(76.2 cm)

30 ¾"

(78.1 cm)

If countertop opening width is greater than 30" (76.2 cm), adjust

the ³⁄₈" (1.0 cm) dimension.

Countertop must be level. Place level on countertop, first side to

side, then front to back. If countertop is not level, range will not

be level. Range must be level for satisfactory baking conditions.

³⁄₈"

(1.0 cm)

Range Rating* Rating of

120/240 Volts 120/208 Volts Amps Amps

8.8 - 16.5 KW

16.6 - 22.5 KW

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

7.8 - 12.5 KW

12.6 - 18.5 KW4050

Power

Supply Cord

Circuit

Protection

40 or 50

50

8

Page 9

INSTALLATION INSTRUCTIONS

Unpack Range

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To remove cardboard bottom, place range on its back, take

4 cardboard corners from the carton. Stack one cardboard

corner on top of another. Repeat with the other 2 corners.

Place them lengthwise on the floor behind the range to

support the range when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the antitip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

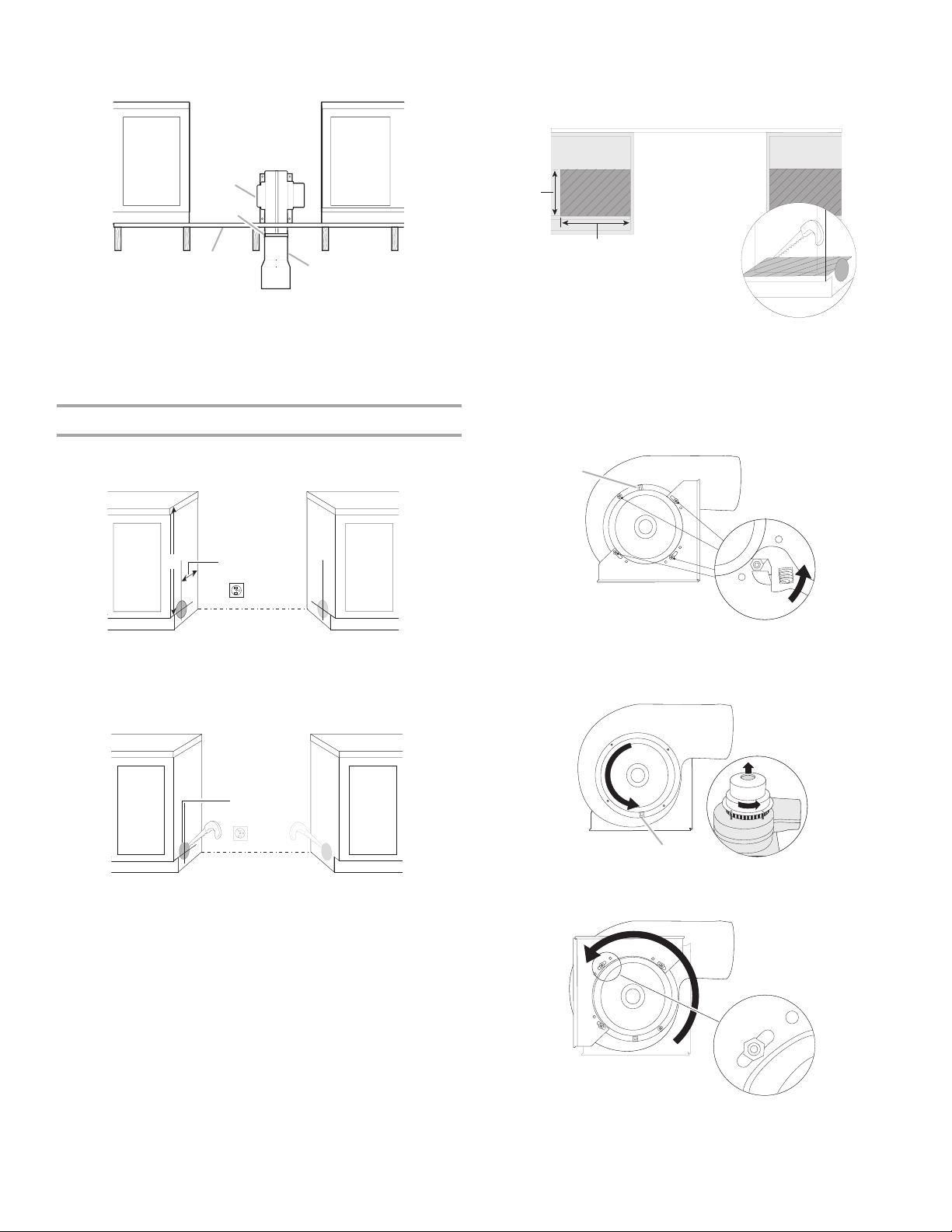

Install Anti-Tip Bracket

1. Remove the anti-tip bracket that is taped to the package

containing literature.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor you can use the wall

mounting method.

3. Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is 14¹⁄₄" (36.2 cm)

from centerline, as shown.

A

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

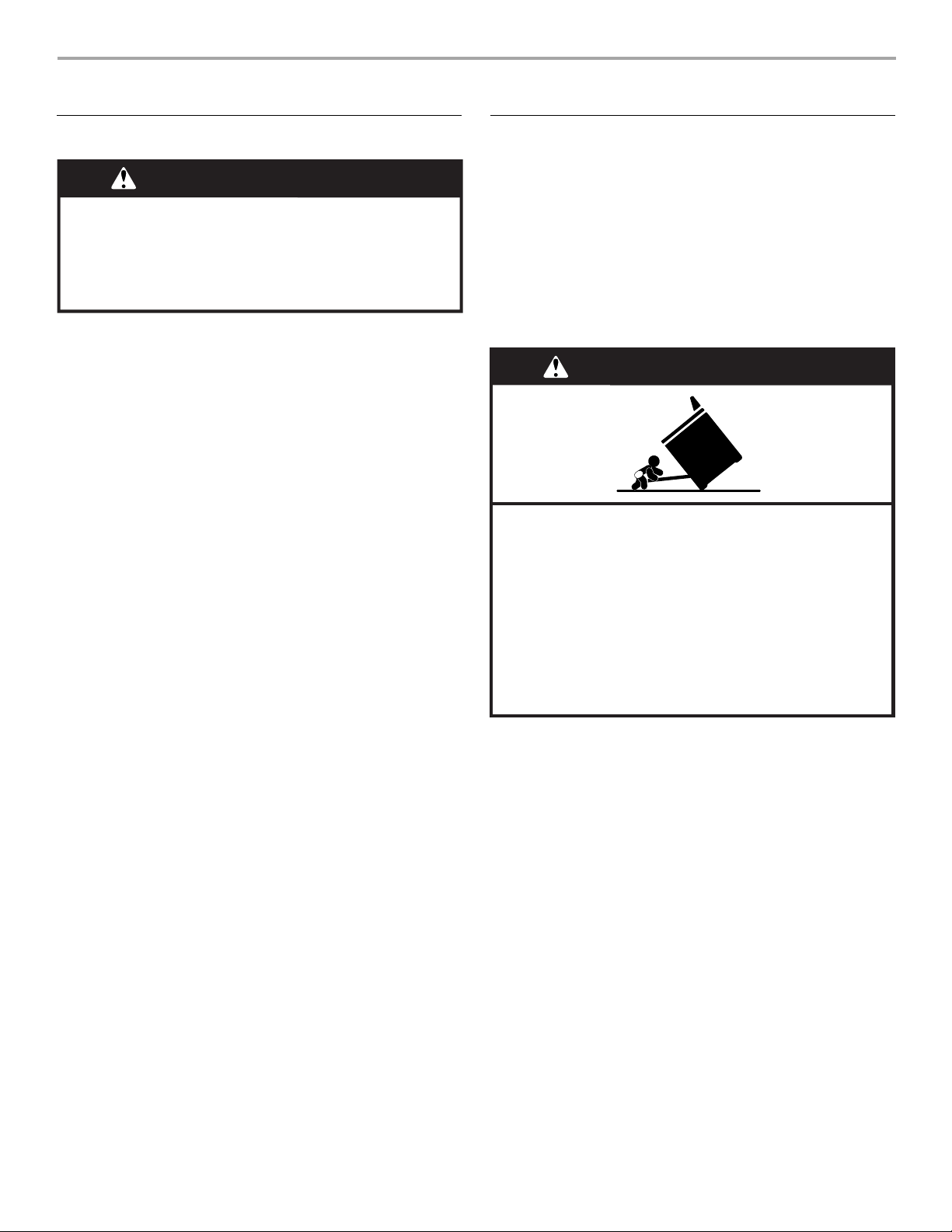

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

B

A. Centerline

B. 14¹⁄₄" (36.2 cm)

4. Drill two ¹⁄₈" (3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See below.

Floor Mounting

A

A. #12 x 1⁵⁄₈" screws

B. Anti-tip bracket

B

2. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of ³⁄₁₆" (5 mm) is needed to engage the anti-tip

bracket.

9

Page 10

Wall Mounting

B

2. Check for obstructions before marking the vent hole location.

Mark a horizontal line 8³⁄₁₆" (20.8 cm) from the floor. Mark a

vertical line up to a maximum of 2¼" (7.9 cm) from the righthand side of the cabinet centerline.

A

A. #12 x 1⁵⁄₈" screws

B. Anti-tip bracket

5. Using the Phillips screwdriver, mount anti-tip bracket to the

wall or floor with the two #12 x 1⁵⁄₈" screws provided.

Install Downdraft System

Determine Equivalent Length of Vent System

This range is equipped with a dual range blower. It is shipped

from the factory for Low Range installations. If vent system

equivalent length exceeds 30 ft (9.1 m), the downdraft blower

motor must be converted to High Range for best performance.

See “Calculating Vent System Length.”

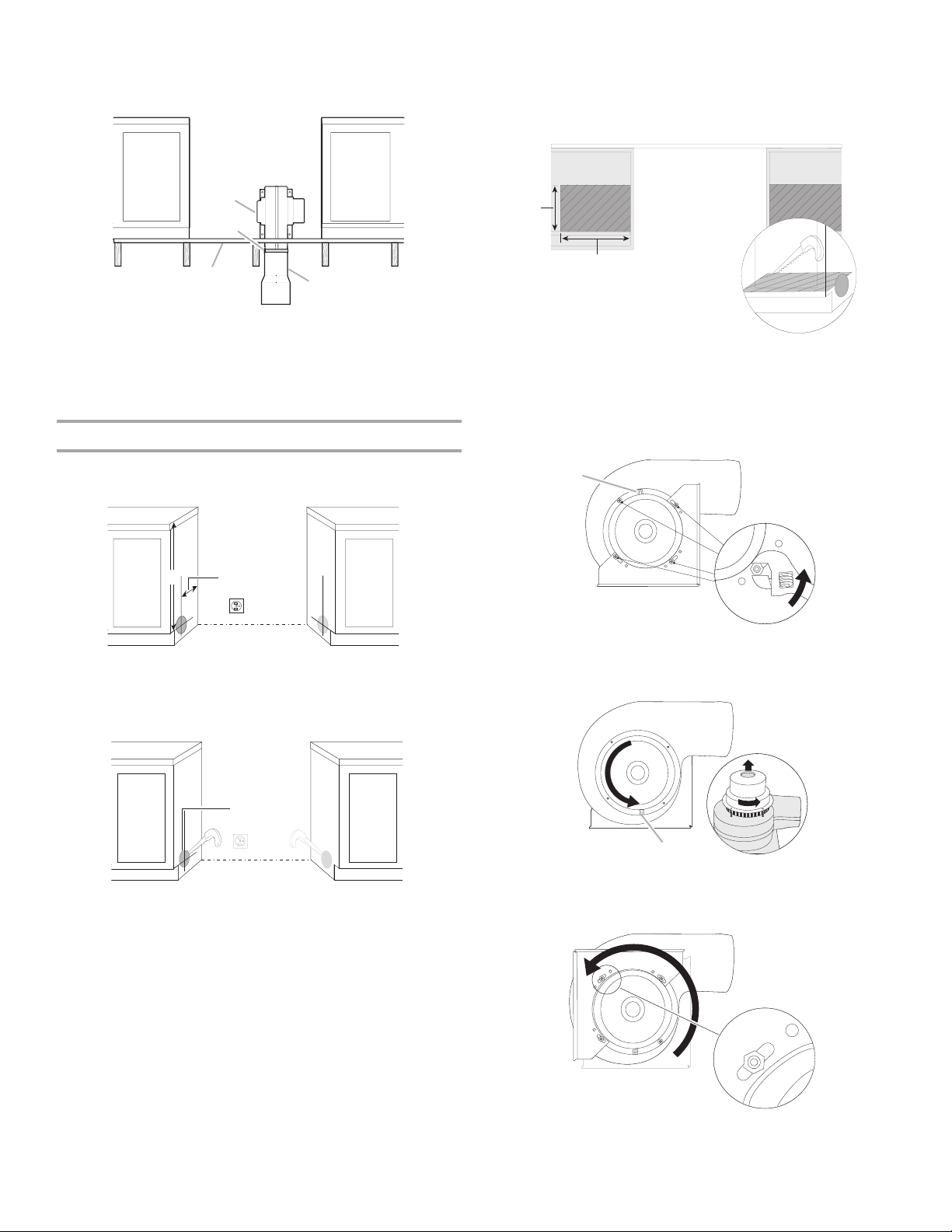

To Con v ert :

Gently remove the spring loaded Restricter Ring from the blower

inlet by pressing one of the 3 springs.

A

B

A. Maximum 2¼" (7.9 cm) from

the right of center

B. 8

³⁄₁₆

" (20.8 cm) from floor

3. Draw and cut a 6¼" (15.8 cm) diameter hole.

A

A. 6¼" (15.8 cm)

4. Position blower motor in cabinet opening. Connect vent

system to blower motor outlet using a vent clamp.

Top View

B

A

A. Restricter ring

B. Spring

Determine which venting method to use: floor, rear wall, or left or

right side venting. Go to the section for your type of venting.

Rear Wall Venting

1. Mark the wall at the center of the cabinet opening.

E

C

D

A

B

A. 18¾" (47.6 cm) maximum from back

wall forward into cabinet opening

B. Inlet

C. Vent system

D. Vent clamp

E. Wall vent

10

Page 11

5. Mount blower motor to the floor with 4 - #8 x ¾" hex head

screws provided.

Top View

NOTE: If the template is misplaced, the following

measurements can be used to determine the vent hole

location.

Top View

6. Go to the “Electrical Connection” section.

Floor Venting

1. Mark the floor at the center of the cabinet opening.

B

C

D

A

E

F

G

I

H

A. 9" (22.8 cm)

B. 3

¹⁄₈

" (7.9 cm)

³⁄₈

" (21.3 cm)

C. 8

³⁄₈

" (16.2 cm)

D. 6

E. 2¼" (5.7 cm)

F. 12½" (31.7 cm)

G. 18¾" (47.6 cm)

H. 1½" (3.8 cm)

I. 3½" (8.9 cm)

4. Draw and cut a 6¼" (15.8 cm) diameter hole (option 1 shown).

2. Position template on floor by matching the centerline of the

template to the centerline drawn on the floor and place

template 2¼" (5.7 cm) from the back wall.

3. Determine the correct position for the vent hole, depending

on obstructions (joists) in the floor.

The hole can be cut anywhere within the boundaries of either

hatched area.

Option 1: If using the back hatched area (bigger one), the

blower inlet must face the left side as shown on the template

Option 2: If using the front hatched area (smaller one), the

blower inlet must face the back.

Top View

Option 1 Option 2

B

A

A

B

A

A. Option 1

B. Option 2

5. Position blower motor in cabinet opening and mount blower

motor to the floor.

Top View

Option 1 Option 2

B

A

A

B

A. Inlet from range

B. Exhaust outlet

B

A. Inlet from range

B. Exhaust outlet

11

Page 12

6. Connect vent system to blower motor outlet (option 1 shown)

with 4 - #8 x ¾" hex head screws provided.

3. Mark and cut a 14" x 11" (35.6 x 27.9 cm) opening in the floor

of the same cabinet as the vent hole opening.

Top View

A

B

C

A. Inlet

B. Vent clamp

C. Floor

D. Vent system

D

7. Go to the “Electrical Connection” section.

Left or Right Side Venting

1. Mark cabinet side for either a left or right side vent hole

location.

A

B

A

B

A. 11" (27.9 cm) from front of cabinet

B. 14" (35.6 cm) from left side of cabinet

4. Remove 4 locknuts on the motor side of the blower and

remove the bracket.

View from Motor Side of Blower

A

³⁄₁₆

" (79.2 cm) to top of cabinet

A. 31

B. 18" (45.7 cm) from back wall

2. Mark and cut a 5½" (13.9 cm) diameter hole in the desired

cabinet side.

A

A. 5½" (13.9 cm) diameter hole

A.Electrical connector

5. Lift and rotate the motor 180° to reposition the electrical

connection.

A

A. Electrical connector

6. Rotate bracket 180° and secure with 4 locknuts.

12

Page 13

7. Remove the bracket from the other side of the blower motor,

rotate 180° and secure with 4 locknuts.

8. Position 2 wood spacers and mount them to the floor.

Top View

B

C

A

D

D

9. Mount blower motor to wood spacers using 4 - #8 x ¾" hex

head screws provided.

NOTE: Vent system will be connected after range has been

moved into it’s final location. “See Connect Range to

Downdraft System” section.

Top View

B

C

A

A. Wood spacers

B. Mounting bracket

C. Blower

10. Go to the “Electrical Connection” section.

A. 2" x 4" (5.0 x 10.2 cm) wood spacers

⁷⁄₉

" (7.3 cm) from back wall to edge of wood spacer

B. 2

C. 8¾" (22.2 cm)

D. 2

⁵⁄₁₆

" (5.8 cm) centerline of opening to wood spacer

13

Page 14

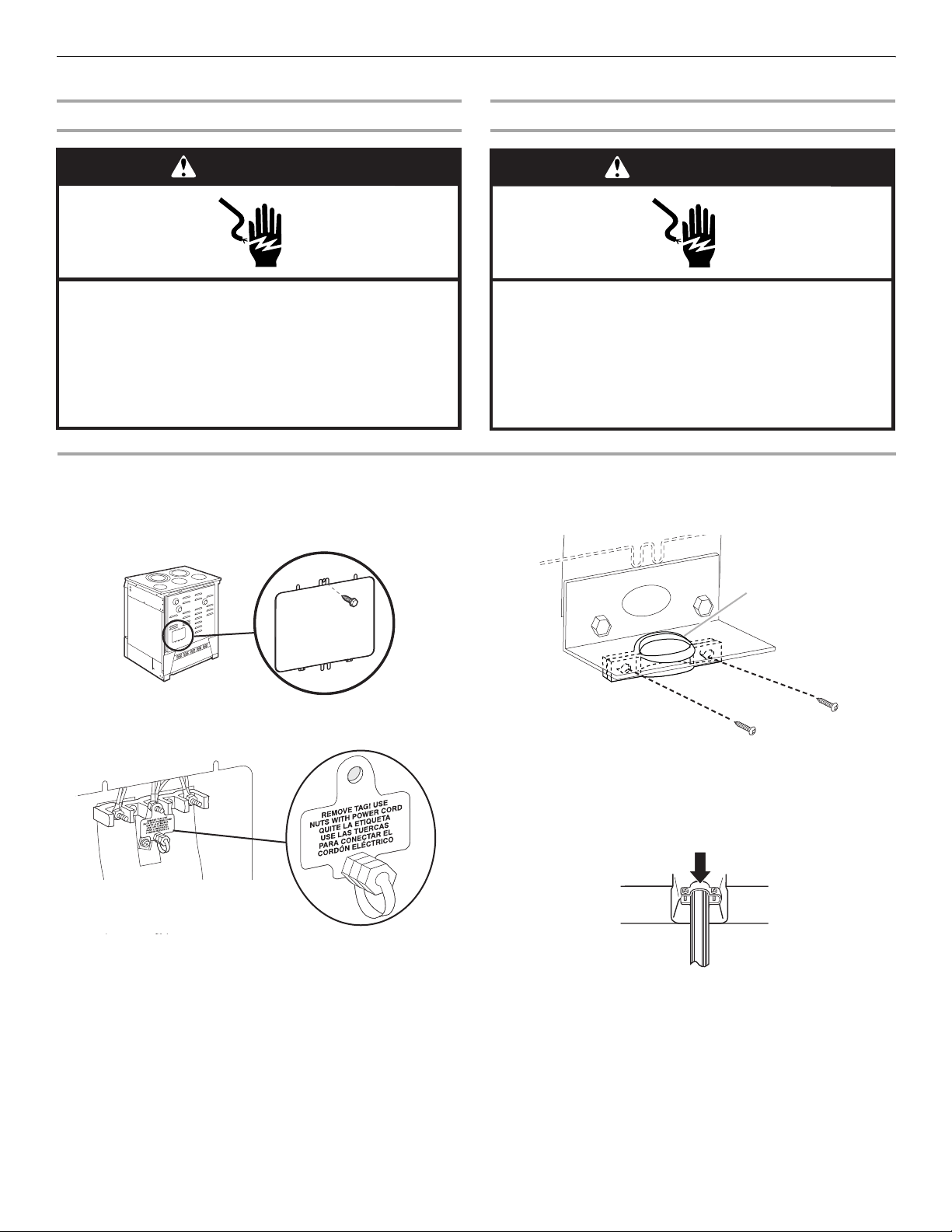

Electrical Connection - U.S.A. Only

Power Supply Cord Direct Wire

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Disconnect power.

2. Use Phillips screwdriver to remove the terminal block cover

screw located on the back of the range. Pull cover down and

toward you to remove cover.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Style 1: Power supply cord strain relief

■ Assemble a UL listed strain relief in the opening.

A

3. Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

4. Add strain relief.

A. UL listed strain relief

■ Feed the power supply cord through the opening in the

cord/conduit plate on bottom of range. Allow enough

slack to easily attach the wiring to the terminal block.

■ Tighten strain relief screw against the power supply cord.

14

Page 15

Style 2: Direct wire strain relief

N

U

TS

W

IT

H

P

O

W

E

R

C

O

R

D

N

U

T

S

W

I

T

H

P

O

W

E

R

C

O

RD

■ Use Phillips screwdriver to remove screws from panel on

back of range.

E

E

S

S

D

D

U

U

R

R

!

!

O

O

G

G

C

C

A

A

T

T

R

R

E

E

E

E

A

A

V

V

W

W

T

T

O

O

O

O

E

E

M

M

P

P

U

U

E

E

Q

Q

H

H

I

I

R

R

S

T

T

T

T

I

I

A

E

E

C

W

W

A

A

R

L

L

L

L

E

TS

TS

E

E

U

U

U

E

E

R

R

T

T

T

N

N

I

I

A

A

S

O

O

T

T

U

U

A

C

C

C

C

Q

Q

I

I

L

E

E

R

R

E

N

N

T

T

S

O

O

C

C

U

C

C

É

É

L

L

A

A

E

E

R

R

N

N

A

A

P

P

Ó

Ó

D

D

R

R

O

O

C

C

■ Lift range back panel up and off.

■ Replace cord/conduit plate and insert screws.

■ Assemble a UL listed conduit connector in the opening.

A

E

E

S

S

D

D

U

U

R

R

!

!

O

O

G

G

C

C

A

A

T

T

R

R

E

E

E

E

A

A

V

V

W

W

T

T

O

O

O

O

E

E

M

M

P

P

U

U

E

E

Q

Q

H

H

I

I

R

R

S

T

T

T

T

I

I

A

E

E

C

W

W

R

A

A

L

L

S

S

L

L

E

T

T

E

E

U

E

E

U

U

R

R

T

T

T

N

N

I

I

A

A

S

O

O

T

T

U

U

A

C

C

C

C

Q

Q

I

I

L

E

E

R

R

E

N

N

T

T

S

O

O

C

C

U

C

C

É

É

L

L

A

A

E

E

R

R

N

N

A

A

P

P

Ó

Ó

D

D

R

R

O

O

C

C

■ Use Phillips screwdriver to remove screws and slide

cord/conduit plate down and out.

■ Position cord/conduit plate as shown in the following

illustration.

B

A. Removable retaining nut

B. Strain relief

■ Feed the flexible conduit through the strain relief, allowing

enough slack to easily attach wiring to the terminal block.

■ Tighten strain relief screw against the flexible conduit.

5. Replace back panel and screws on rear of range.

6. Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

15

Page 16

Electrical Connection Options

A

B

C

B

If your home has: And you will be

connecting to:

Go to Section:

3. Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250-volt

4-wire connection:

Power supply cord

minimum,

40-amp, range

power supply

cord

4-wire direct A fused

disconnect or

4-wire connection:

Direct wire

circuit breaker

5"

(12.7 cm)

3-wire receptacle

(NEMA type 10-50R)

box

A UL listed,

250-volt

3-wire connection:

Power supply cord

minimum,

40-amp, range

power supply

cord

3-wire direct A fused

1"

(2.5 cm)

disconnect or

circuit breaker

3-wire connection:

Direct wire

box

3"

(7.6 cm)

4-wire connection: Power Supply Cord

Use this method for:

■ New branch-circuit installations (1996 NEC)

■ Mobile homes

■ Recreational vehicles

■ In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A

C

D

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

4. Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

5. Use ³⁄₈" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10–32 hex nuts.

A

F

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground-link under the screw.

16

B

C

E

D

A. 10–32 hex nut

B. Ground-link screw

C. Line 1 (black)

D. Green ground wire

E. Neutral (center) wire

F. Line 2 (red)

6. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

7. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 1³⁄₈" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

8. Replace terminal block access cover.

Page 17

3-wire connection: Power Supply Cord

B

A

B

C

Direct Wire Installation: Copper or Aluminum Wire

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

A

C

D

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

This range may be connected directly to the fuse disconnect or

circuit breaker box. Depending on your electrical supply, make

the required 3-wire or 4-wire connection.

1. Strip outer covering back 3" (7.6 cm) to expose wires. Strip

the insulation back 1" (2.5 cm) from the end of each wire.

1"

(2.5 cm)

3"

(7.6 cm)

2. Allow enough slack in the wire to easily attach the wiring

terminal block.

3. Complete electrical connection according to your type of

electrical supply (4-wire or 3-wire connection).

4-wire Connection: Direct Wire

Use this method for:

■ New branch-circuit installations (1996 NEC)

■ Mobile homes

■ Recreational vehicles

■ In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

2. Use ³⁄₈" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10–32 hex nuts.

A

B

D

E

C

A. 10–32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Neutral (white) wire

E. Line 2 (red)

3. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

4. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 1³⁄₈" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

5. Replace terminal block access cover.

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground-link under the screw.

17

Page 18

3. Pull the conduit through the strain relief on cord/conduit plate

B

C

on bottom of range. Allow enough slack to easily attach

wiring to the terminal block.

A

5. Use Phillips screwdriver to connect the bare (green) ground

wire to the range with the ground-link screw. The ground wire

must be attached first and must not contact any other

terminal.

6. Use ³⁄₈" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10–32 hex nuts.

B

C

G

F

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Line 2 (red) wire

E

E. Neutral (white) wire

F. Line 1 (black) wire

G. Bare (green) ground wire

D

4. Attach terminal lugs to line 1 (black), neutral (white), and line 2

(red) wires. Loosen (do not remove) the set screw on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to torque

as shown in the following Bare Wire Torque Specifications

chart.

A

A

G

B

F

D

E

C

A. 10–32 hex nut

B. Line 1 (black)

C. Bare (green) ground wire

D. Ground-link screw

E. Neutral (white) wire

F. Line 2 (red)

G. Terminal lug

7. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover.

3-wire connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the conduit through the hole and conduit plate on bottom

of range. Allow enough slack to easily attach the wiring to the

terminal block.

C

DE

A. Terminal lug

B. Set screw

C. Line 1 (black) wire

D. Neutral (white) wire

E. Line 2 (red) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 lbs-in. (2.8 N-m)

6 gauge aluminum 35 lbs-in. (4.0 N-m)

A

F

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

B

D

E

D. Line 2 (red) wire

E. Bare (green) ground wire

F. Line 1 (black) wire

18

Page 19

2. Attach terminal lugs to line 1 (black), bare (green) ground, and

B

B

line 2 (red) wires. Loosen (do not remove) the set screw on the

front of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to torque

as shown in the following Bare Wire Torque Specifications

chart.

A

Connect Range to Downdraft System

1. Attach flexible vent (provided) to the blower motor inlet using

a vent clamp.

C

DE

A. Terminal lug

B. Set screw

C. Line 1 (black) wire

D. Bare (green) ground wire

E. Line 2 (red) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 lbs-in. (2.8 N-m)

6 gauge aluminum 35 lbs-in. (4.0 N-m)

3. Use ³⁄₈" nut driver to connect the bare (green) ground wire to

the center terminal block post with one of the 10–32 hex nuts.

1

2

1

A

B

A. Inlet flexible vent

B. Vent clamp

2. Check countertop height to allow range top to clear

countertop. Adjusting leveling legs if necessary.

3. Remove access panel by grasping both sides, pulling

upward, and lifting out.

4. Move range close to cabinet opening.

5. Plug range into grounded outlet (if using a power supply

cord).

6. Plug range electrical connector into the downdraft blower

motor.

A

F

E

B

D

C

A. 10–32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Bare (green) ground wire

E. Line 2 (red)

F. Te r mi na l lu g

4. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

5. Securely tighten hex nuts.

6. Replace terminal block access cover.

A

A. Power supply cord (on some installations)

B. Range electrical connector to blower motor

7. Remove cardboard or hardboard from under the range. Using

2 or more people, gently move range into its final location.

19

Page 20

8. Check that the anti-tip bracket is installed and that electrical

cords are not kinked. Use a flashlight to look underneath the

bottom of the range.

■ Look for the anti-tip bracket securely attached to floor or

wall.

■ Slide range back so rear range foot is under anti-tip

bracket.

Floor Venting

Top View

B

A

9. Level the range.

a.) Place rack in oven.

b.) Place level on rack and check levelness of the range, first

side to side; then front to back.

c.) If range is not level, pull range forward until rear leveling

leg is removed from the anti-tip bracket.

d.) Use a wrench or pliers to adjust leveling legs up or down

until range is level.

e.) Push range back into position.

f.) Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

10. Depending on your installation, connect the flexible vent from

the blower motor inlet to the range using a vent clamp.

Wall Venting

Top View

B

C

A. Range

B. Floor venting outlet

C. Vent clamp

Side Venting (left side venting shown)

Connect flexible vent duct to range and connect vent system

to blower motor outlet.

Top View

A

E

BLOWER

D

C

B

A. Flexible vent duct to range

B. Vent clamp

C. Range

D. Vent system

E. Side venting outlet

20

11. Replace access panel.

A

C

A. Range

B. Wall venting outlet

C. Vent clamp

Page 21

12. Insert downdraft vent filter and place vent cover over

opening.

B

If you need Assistance or Service:

Please reference the “Assistance or Service” section of the Use

and Care Guide or contact the dealer from whom you purchased

your range.

A

A. Filter

B. Grate

13. Reconnect power.

Complete Installation

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See “Connect Range to

Downdraft System.”

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, read

the “Range Care” section of the Use and Care Guide.

6. Read “Range Use” in the range Use and Care Guide.

7. Turn on surface burners and oven. See the Use and Care

Guide for specific instruction on range operation.

If range does not operate, check the following:

■ Household fuse is intact and tight; or circuit breaker has not

tripped.

■ Range is plugged into an outlet.

■ Electrical supply is connected.

■ See “Troubleshooting” in the Use and Care Guide.

When the range has been on for 5 minutes, check for heat. If

range is cold, turn off the range and contact a qualified

technician.

8. Use the Flow Tester Card provided with your range to check

the airflow (see card for step-by-step instructions).

Moving the Range

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

When moving range, slide range onto cardboard or hardboard to

avoid damaging the floor covering.

If removing the range is necessary for cleaning or maintenance:

For power supply cord-connected ranges:

1. Disconnect range from downdraft vent system.

2. Slide range forward.

3. Unplug the power supply cord.

4. Complete cleaning or maintenance.

5. Plug in power supply cord

6. Check that anti-tip bracket is installed, remove access panel

and use a flashlight to look underneath the bottom of the

range:

■ Look for the anti-tip bracket securely attached to floor or

wall.

■ Slide range back so rear range foot is under anti-tip

bracket.

If there is not sufficient airflow, review the “Venting

Requirements” and “Venting Methods” sections.

7. Check that range is level.

8. Reconnect range to downdraft vent system.

21

Page 22

For direct-wired ranges:

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

4. Complete cleaning or maintenance.

5. To check that anti-tip bracket is installed, remove access

panel and use a flashlight and look underneath the bottom of

the range:

■ Look for the anti-tip bracket securely attached to floor or

wall.

■ Slide range back so rear range foot is under anti-tip

bracket.

1. Disconnect power.

2. Disconnect range from downdraft vent system.

3. Slide range forward.

6. Check that range is level.

7. Reconnect range to the downdraft vent system.

8. Reconnect power.

22

Page 23

SÉCURITÉ DE LA CUISINIÈRE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière ce qui peut causer un décès.

Joindre la bride antibasculement au pied arrière de la cuisinière.

Joindre de nouveau la bride antibasculement si la cuisinière est déplacée.

Le non-respect de ces instructions peut causer un décès ou des brûlures graves aux enfants et

aux adultes.

23

Page 24

EXIGENCES D’INSTALLATION

Outils et pièces

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils nécessaires

■ Mètre-ruban

■ Niveau

■ Tournevis Phillips

■ Tournevis à lame plate

■ Scie sauteuse ou scie à

guichet

■ Marqueur ou crayon

Pièces fournies

Vérifier que toutes les pièces sont présentes.

■ 3 écrous hexagonaux de #10-32 (vissés au boîtier de

connexion)

■ 3 attaches de bornes

■ 2 ou 3 grilles de four (en fonction du modèle)

■ Moteur du ventilateur

■ 2 brides pour conduit

■ Conduit flexible

■ Fiche de test du débit

■ Gabarit pour l’emplacement du ventilateur

■ 4 vis n° 8 x ¾" (pour le montage de la bride du ventilateur)

■ 2 vis n° 12 x 1⁵⁄₈" (pour le montage de la bride

antibasculement)

■ Bride antibasculement (fixée par du ruban adhésif à la

pochette contenant la documentation dans la cavité du four)

La bride antibasculement doit être bien fixée à la cloison

arrière ou au plancher. La profondeur du plancher peut

nécessiter des vis plus longues pour l’ancrage de la bride

dans le sous-plancher. Des vis plus longues sont disponibles

auprès de votre quincaillerie locale.

Pièces nécessaires

■ L’une des bouches de décharge murales Jenn-Air suivantes :

Clapet de décharge mural en surface rond Jenn-Air

5" (12,7 cm). Commander la pièce n° A405.

Clapet de décharge mural en surface rond Jenn-Air

6" (15,2 cm). Commander la pièce n° A406.

Clapet de décharge mural en surface Jenn-Air

(8,3 x 25,4 cm). Commander la pièce n° A403.

Pour commander, voir la section “Assistance ou service” du

Guide d’utilisation et d’entretien.

■ Conduit métallique

■ Brides pour conduit

■ Chevilles à béton (pour montage sur sol en béton)

■ 2 cales en bois 2" x 4" x 8¾" (5 x 10,2 x 22,2 cm) (pour

évacuation par la gauche ou par la droite)

■ Clé ou pince

■ Tourne-é c r ou d e ⁵⁄₁₆"

■ Tourne-é c r ou d e ¼ "

■ Perceuse

■ Foret de ¹⁄₈" (3,2 mm)

■ Foret à maçonnerie à pointe

carburée de ³⁄₁₆" (4,8 mm)

(pour planchers en béton/

céramique)

®

de

®

de

®

3¼" x 10"

En cas d’utilisation d’un cordon d’alimentation électrique :

■ Cordon d’alimentation (homologation UL) conçu pour

l’utilisation avec une cuisinière. Pour service 250 volts

minimum, 40 A ou 50 A, compatible avec une ouverture de

diamètre nominal 1³⁄₈" (3,5 cm) pour le raccordement, et avec

cosses rondes ou en fourche à pointes relevées à l’extrémité

de chaque conducteur.

■ Un serre-câble (homologation UL).

Consulter les codes locaux. Vérifier l’alimentation électrique

existante. Voir la section “Spécifications électriques”.

Il est recommandé de faire réaliser tous les raccordements

électriques par un électricien qualifié agréé.

Exigences d’emplacement

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur.

■ C’est à l’installateur qu’incombe la responsabilité de

respecter les distances de séparation exigées, spécifiées sur

la plaque signalétique de l’appareil. La plaque signalétique

est située sur le côté droit du châssis du four, derrière le

panneau du tiroir de remisage.

■ La cuisinière doit être installée à un endroit pratique dans la

cuisine.

■ Afin de supprimer le risque de brûlures ou d’incendie lié au

fait de se pencher au-dessus des plaques de cuisson

chaudes, les meubles de rangement au-dessus des plaques

doivent être évités. Si des placards de rangement sont

envisagés, le risque peut être réduit par l’installation d’une

hotte de cuisine dépassant le bas des placards d’au moins 5"

(12,7 cm) horizontalement.

■ Respecter les dimensions indiquées pour les ouvertures à

découper dans les placards. Ces dimensions constituent les

valeurs minimales des dégagements.

■ La bride antibasculement de plancher doit être installée. Pour

l’installation de la bride antibasculement fournie avec la

cuisinière, voir la section “Installation de la bride

antibasculement”.

■ Une source d’électricité avec liaison à la terre est nécessaire.

Voir la section “Spécifications électriques”.

IMPORTANT : Afin d’éviter d’endommager les placards,

consulter le constructeur de la maison ou le fabricant des

placards pour déterminer si les matériaux utilisés peuvent subir

un changement de couleur, une déstratification ou d’autres

dommages. Ce four a été conçu conformément aux exigences

des normes UL et CSA International et respecte les températures

maximales permises de 194°F (90°C) pour les placards en bois.

Résidence mobile – Spécifications additionnelles à

respecter lors de l’installation

L’installation de cette cuisinière doit être conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD Part 280). Lorsque cette norme n’est pas applicable,

l’installation doit satisfaire aux critères de la norme Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A ou

aux dispositions des codes locaux.

24

Page 25

Autres critères à respecter pour une installation en résidence

mobile :

■ Dans le cas de l’installation de cette cuisinière dans une

résidence mobile, la cuisinière doit être fixée au plancher

durant tout déplacement du véhicule. Toute méthode de

fixation de la cuisinière est adéquate dans la mesure où elle

satisfait aux critères des normes mentionnées ci-dessus.

■ Pour une installation en résidence mobile, un câble ou cordon

d’alimentation à quatre fils doit être utilisé. Le câblage de

l’appareil devra être révisé. Voir la section “Raccordement

électrique”.

Dimensions du placard

Les dimensions de l’espace entre les placards correspondent à

une installation entre des placards de 24" (61,0 cm) de

profondeur, avec plan de travail de 25" (64 cm) de profondeur et

de 36" (91,4 cm) de hauteur.

A

B

C

Dimensions du produit

A

F

B*

E**

D

A. 30³⁄₄" (78,1 cm)

B. Hauteur jusqu’à la partie

inférieure du bord de la

table de cuisson avec les

pieds de nivellement

complètement rétractés :

35³⁄₄" (90,8 cm)*

C. Plaque signalétique (située

en bas à droite du châssis

du four)

D. 29⁷⁄₈" (75,9 cm)

E. 29¹⁄₁₆" (73,8 cm) de la

poignée au support à

l’arrière de la cuisinière**

F. 23½" (59,7 cm) du coin du

plan de travail à l’arrière

de la table de cuisson

*La cuisinière peut être surélevée d’environ 1" (2,5 cm) en

ajustant les pieds de nivellement.

**Dans le cas d’une installation entre des placards de

24" (61 cm) avec plan de travail de 25" (63,5 cm), l’avant

de la porte du four dépassera les placards inférieurs de

24" (61 cm) d'une distance de 2¹⁄₂" (6,4 cm).

C

H

E

D

I

I

F

G

A. Profondeur des placards

supérieurs : 13" (33 cm)

B. Largeur de l’ouverture

30" (76,2 cm) min.

C. Pour le dégagement vertical

minimal de la table de

cuisson, voir la REMARQUE*.

D. Profondeur d'ouverture de

¹⁄₄" (59,1 cm)

E. Largeur de l’ouverture

30" (76,2 cm) min.

F. Boîtier de connexion :

5,5" (14 cm) min. de l’un des

deux placards, 10" (25,4 cm)

max. du plancher. La prise

doit être en affleurement.

Aucun élément situé dans la

zone ombrée ne doit

dépasser de plus de

2" (5,1 cm) du mur, sinon il

sera impossible de glisser la

cuisinière jusqu’au fond.

G. La porte ou charnière du

placard ne doit pas dépasser

à l’intérieur de l’ouverture.

H. 18" (45,7 cm)

I. Dégagement de 3" (7,6 cm)

min. entre les deux côtés de

la cuisinière et les parois

latérales ou d’autres

matériaux combustibles.

REMARQUE : Distance de séparation minimale de 24" (61 cm)

lorsque le fond d’un placard de bois ou de métal est protégé par

une planche ignifugée d’au moins ¹⁄₄" (0,64 cm) recouverte d’une

feuille métallique d’épaisseur égale ou supérieure à : acier calibre

28 MSG, acier inoxydable 0,015" (0,4 mm), aluminium

0,024" (0,6 mm), ou cuivre 0,020" (0,5 mm).

Distance de séparation minimale de 30" (76,2 cm) ou plus entre le

dessus de la table de cuisson et le fond d’un placard de bois ou

de métal non protégé.

25

Page 26

Exigences concernant l’évacuation

IMPORTANT : Cette cuisinière doit être ventilée vers l’extérieur.

Voir la section “Méthodes d’évacuation”.

■ Ne pas terminer le circuit d’évacuation dans un grenier ou

dans un autre espace fermé.

■ Utiliser une bouche de décharge murale Jenn-Air.

■ Le circuit doit évacuer l’air à l’extérieur.

■ Utiliser uniquement un conduit métallique rond de

6" (15,2 cm) ou un conduit rectangulaire de 3¼ x 10"

(8,3 cm x 25,4 cm), sauf dans les cas suivants :

Un conduit métallique rond de 5" (12,7 cm) peut être utilisé

pour une évacuation directement depuis l’arrière de la

cuisinière à travers le mur sur une longueur de 10 pi (3,0 m)

au maximum.

■ Un conduit en métal rigide est recommandé. Pour des

performances optimales, ne pas utiliser de conduit de

plastique ou d’aluminium.

■ Avant d’effectuer des découpes, s’assurer que l’espace est

suffisant sur le mur ou le plancher pour le conduit

d’évacuation.

■ On ne doit couper un poteau de colombage ou une solive

que si c’est absolument nécessaire. Dans ce cas, on devra

construire une structure de support appropriée.

■ La taille du conduit doit être uniforme.

■ Le circuit d’évacuation doit comporter un clapet anti-retour.

Si la bouche de décharge murale ou par le toit comporte un

clapet, ne pas utiliser le clapet fourni avec la hotte de

cuisinière.

■ Pour assurer l’étanchéité de toutes les jonctions du circuit

d’évacuation, utiliser des brides pour conduit.

■ À l’aide d’un produit de calfeutrage, assurer l’étanchéité

autour de la bouche de décharge à l’extérieur (à travers le

mur ou le toit).

■ Déterminer la méthode d’évacuation la plus appropriée.

Pour obtenir des performances optimales :

■ Utiliser un conduit métallique en acier galvanisé de calibre

26 minimum ou en aluminium de calibre 25 minimum. Des

raccords de tube de qualité médiocre peuvent réduire la

circulation d’air. On déconseille l’emploi d’un conduit en

métal flexible.

REMARQUE : Les codes locaux peuvent imposer un

matériau d’épaisseur supérieure.

■ Les conduits métalliques peuvent être réduits à de l’acier

galvanisé de calibre 30 ou de l’acier aluminisé de calibre 26 si

les codes locaux l’autorisent. Cette réduction repose sur les

informations du document International Residential Codes

Section M1601.1 (édition 2006).

■ Ne pas installer 2 coudes successifs.

■ Ne pas utiliser plus de trois coudes à 90°.

■ Si un coude est utilisé, on doit le placer le plus loin possible

de l’ouverture de décharge du ventilateur de la hotte.

■ Veiller à incorporer une section de conduit rectiligne d’au

moins 18" (45,7 cm) entre deux raccords coudés adjacents.

■ Des coudes trop rapprochés peuvent occasionner une

turbulence excessive qui réduit la circulation de l’air.

■ Ne pas utiliser de coude de 5" (12,7 cm) dans un circuit de

6" (15,2 cm) ou 3¹⁄₄" x 10" (8,3 x 25,4 cm).

■ Ne pas effectuer de réduction en un circuit de 5" (12,7 cm)

après avoir utilisé des raccords de 6" (15,2 cm) ou 3¼" x 10"

(8,3 x 25,4 cm).

■ Éviter les assemblages par sertissage à la main. Les

sertissages à la main peuvent réduire la circulation d’air.

■ Utiliser une bouche de décharge Jenn-Air. Si une autre

bouche de décharge de toit ou murale est utilisée, s’assurer

que ses dimensions ne sont pas plus petites et qu’elle est

équipée d’un clapet anti-retour.

■ Pour assurer l’étanchéité de toutes les jonctions du circuit

d’évacuation, utiliser des brides pour conduit.

■ À l’aide d’un produit de calfeutrage, assurer l’étanchéité

autour de la bouche de décharge à l’extérieur (à travers le

mur ou le toit).

La longueur du système d’évacuation et le nombre de coudes

doit être réduit au minimum pour une performance optimale.

La longueur équivalente maximale du circuit d’évacuation est de

60 pi (18,3 m). À une altitude supérieure à 4500 pi (1272 m),

réduire la longueur de 20 % pour une meilleure performance.

Installations dans les régions au climat froid

On devrait installer un clapet anti-retour additionnel pour

minimiser le reflux d’air froid et installer une barrière thermique

pour minimiser la conduction des températures extérieures par

l’intermédiaire du conduit d’évacuation. Le clapet anti-retour être

placé du côté air froid de la barrière thermique.

Air d’appoint

Les codes locaux en bâtiment peuvent imposer l’emploi d’un

circuit de renouvellement de l’air/introduction d’air d’appoint, lors

de l’utilisation d’un circuit d’aspiration de débit supérieur à une

valeur spécifiée en pieds cubes par minute. Le débit spécifié en

pieds cubes par minute varie d’une juridiction à l’autre. Consulter

un professionnel des installations de chauffage/ventilation/

climatisation au sujet des exigences spécifiques applicables

dans la juridiction locale.

26

Page 27

Méthodes d’évacuation

A

A

F

Les méthodes communes d’évacuation sont illustrées pour une

cuisinière à aspiration par le bas. L’évacuation de la cuisinière à

aspiration par le bas peut se faire par le mur ou le plancher.

Installations sur dalle de béton - Évacuation par le mur

B

Évacuation par le mur

A. Bouche de décharge murale

B. Conduit de dia. 6" (15,2 cm) –

sortie à travers le toit

Évacuation par le plancher

Évacuation entre solives de plancher

A

L

K

J

C

I

D

E

G

H

A. Bouche de décharge murale

B. Conduit métallique rond de dia. 6" (15,2 cm)

C. 16" (40,6 cm) maximum

D. Conduit PVC dia. 6" (15,2 cm) (pour égout)

E. Dalle de béton

F. Conduit PVC dia. 6" (15,2 cm) (pour égout)

G. Coudé à 90° PVC dia. 6" (15,2 cm) (pour égout)

B

H. Gravier ou sable compacté tout autour du tuyau

I. 30 pi (9,1 m) max.

J. Coudé à 90° PVC dia. 6" (15,2 cm) (pour égout)

K. Raccord PVC dia. 6" (15,2 cm)

L. 12" (30,5 cm) minimum

Installations sur dalle de béton

- Évacuation par un puits de fenêtre

IMPORTANT : Installation à travers un puits de fenêtre pour

modèles électriques uniquement.

B

D

A

C

A

B

A. Bouche de décharge murale

B. Conduit de dia. 6" (15,2 cm) – sortie à travers le toit

Évacuation par la gauche ou par la droite

Évacuation derrière les garde-pieds des placards

B

A. Bouche de décharge murale

B. Conduit de dia. 6" (15,2 cm) – sortie à travers le toit

E

K

J

A. Bouche de décharge murale

B. 12" (30,5 cm) minimum

C. Dalle de béton

D. Conduit PVC dia. 6" (15,2 cm) (pour égout)

E. Conduit PVC dia. 6" (15,2 cm) (pour égout)

F. Coudé à 90° PVC dia. 6" (15,2 cm) (pour égout)

G. Gravier ou sable compacté tout autour du tuyau

H. 42 pi (12,8 m) max.

I. Raccord PVC dia. 6" (15,2 cm)

J. 6" (15,2 cm) minimum

K. Puits de fenêtre

H

I

F

G

27

Page 28

Calcul de la longueur effective du circuit d’évacuation

IMPORTANT : Cette cuisinière accepte jusqu’à 60 pi (18,3 m)

de conduit droit. Le mode à faible aspiration admet jusqu’à

30 pi (9,1 m); le mode à forte aspiration admet de 31 pi (9,4 m) à

60 pi (18,3 m).

Si la longueur équivalente de conduit dépasse 30 pi (18,3 m), le

ventilateur doit être converti au mode à forte aspiration.

■ Ne pas convertir au mode à forte aspiration pour les

longueurs plus courtes. Il en résulterait un bruit excessif,

une perte d’air conditionné et une déformation des

flammes sur les cuisinières à gaz.

■ Pour convertir le ventilateur dans le cas d’une installation

dans le mode à forte aspiration, voir la section

“Installation du circuit d’évacuation par le bas”.

Pour calculer la longueur effective du circuit d’évacuation

nécessaire, additionner les longueurs équivalentes (en pieds ou

mètres) de tous les composants utilisés dans le système.

Composant Conduit de diamètre de 6"

(15,2 cm)

Coude à 45° 2,5 pi

(0,8 m)

Coudé à 90° de

6" (15,2 cm) vers 3¹⁄₄" x 10"

5 pi

(1,5 m)

(8,3 cm x 25,4 cm)

Coude à 90° de 3¹⁄₄" x

10" (8,3 cm x 25,4 cm) 5 pi

(1,5 m)

Coude plat de 3¹⁄₄" x

10" (8,3 cm x 25,4 cm) 12 pi

(3,7 m)

Bouche de décharge murale de

3¹⁄₄" x 10" (8,3 cm x 25,4 cm) 0 pi

(0 m)

Exemple de circuit d’évacuation

Coude à 90° 5 pi

(1,5 m)

Bouche de décharge murale

de 6" (15,2 cm)

Raccord de 3¹⁄₄" x 10" (8,3 cm

x 25,4 cm) vers 6" (15,2 cm)

Raccord de 6" (15,2 cm) vers

3¹⁄₄" x 10" (8,3 cm x 25,4 cm)

Coudé à 90° de 3¹⁄₄" x 10"

(8,3 cm x 25,4 cm) vers

0 pi

(0 m)

4,5 pi

(1,4 m)

1 pi

(0,3 m)

5 pi

(1,5 m)

6" (15,2 cm)

coude à 90˚

2 pi

(0,6 m)

bouche de décharge murale

6 pi (1,8 m)

Longueur maximum = 60 pi (18,3 m)

1 coude à 90° = 5 pi (1,5 m)

Section droite de 8 pi

= 8 pi (2,4 m)

(2,4 m)

1 bouche de décharge

= 0 pi (0 m)

murale

Longueur totale = 13 pi (3,9 m)

REMARQUE : On déconseille l’emploi d’un conduit flexible pour

une évacuation vers l’extérieur. Un conduit flexible peut causer

une contre-pression et des turbulences d’air, qui réduisent

considérablement la performance.

28

Page 29

Spécifications électriques

AVERTISSEMENT

Risque de choc électrique

Relier la cuisinière à la terre.

Le non-respect de cette instruction peut causer

un décès, un incendie ou un choc électrique.

Si l’on utilise un conducteur distinct de liaison à la terre lorsque

les codes le permettent, il est recommandé qu’un électricien

qualifié vérifie que la liaison à la terre est adéquate et la section