Jenn-Air JMW8527DA Series, JMW8530DA Series, JMW9527DA Series, JMW9530DA Series, MMW5530DA Series Service Manual

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

This Base Manual covers general information

Combination

Electric Wall Ovens

and Microwaves

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

JMW8527DA*

JMW8530DA*

JMW9527DA*

JMW9530DA*

MMW5530DA*

16022821

Revision 0

January 2004

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that during

its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBLITY TO REVIEW ALL

APPROPRIATE SER VICE INFORMATION BEFORE BEGINNING REP AIRS.

!

T o avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

T o locate an authorized servicer , please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM ................................................ 1-800-843-0304

WWW.JENNAIR.COM ............................................. 1-800-536-6247

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Amana Canada Product ........................................... 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16022821 Rev. 0 ©2004 Maytag Appliances Company

Table of Contents

Important Information .................................................. 2

Important Safety Information

ALL APPLIANCES................................................. 4

SELF-CLEANING OVEN........................................ 4

OVEN .................................................................... 4

In Case of Fire........................................................ 4

Precautions............................................................ 4

Microwave Leakage Testing ........................................ 6

General Information

Cooking Nomenclature ........................................... 7

Rating Label........................................................... 8

Functional Operation .............................................. 8

Cooking Guide ....................................................... 8

Specifications ........................................................ 9

Model Identification ................................................ 9

Service ................................................................... 9

Parts and Accessories........................................... 9

Extended Service Plan ........................................... 9

Wall Oven Troubleshooting Procedures..................... 10

Microwave Troubleshooting Procedures .................... 11

Wall Oven Testing Procedures.................................. 13

H1 Control............................................................ 15

“Quick Test” Mode for Electronic Range Control .. 18

Description of Error Codes ................................... 18

UH1/2 Control ...................................................... 21

Test Mode............................................................ 22

Description of Error Codes ................................... 23

Microwave Testing procedures .................................. 26

Wall Oven Disassembly Procedures

Removing and Replacing Unit............................... 27

Control Panel Assembly....................................... 27

Control Board Assembly ...................................... 27

Touch Panel......................................................... 27

Side Trim(s) ......................................................... 2 7

Stepdown Transformer(s) ..................................... 27

Oven High Limit.................................................... 27

Oven Sensor (some models)................................ 28

Oven Sensor (some models)................................ 28

Broil Element / Broil Element Reflector ................ 28

Convection Fan Assembly.................................... 2 8

Oven Bake Element ............................................. 28

Door Latch / Door Light Switch Assembly............ 28

Oven Light Assembly ........................................... 29

Oven Door Removal.............................................. 30

Blower Motor........................................................ 30

Vent Assembly / Smoke Eliminator ..................... 30

Oven Door Hinge .................................................. 30

Frameless Door Disassembly.............................. 30

Microwave Disassembly Procedures

Removing and Replacing Unit............................... 32

Side Trim(s) ......................................................... 3 2

Control Panel Assembly ....................................... 32

Control Board Assembly ...................................... 32

Touch Panel ......................................................... 33

Control Power Board ............................................ 33

Filter Assembly Board ......................................... 33

TCO Limit Switches (Oven and Magnetron).......... 34

Oven Sensor ........................................................ 34

Oven Light Assembly ........................................... 34

Magnetron............................................................ 35

Transformer .......................................................... 35

Blower Motor........................................................ 35

Turntable Motor .................................................... 36

Oven Door Removal.............................................. 36

Door Disassembly................................................ 37

Appendix A

Installation Instructions .......................................A- 2

©2004 Maytag Appliances Company 16022821 Rev. 0 3

Important Safety Information

CAUTION

!

To avoid personal injury, do not sit, st and or lean on

oven door .

WA RNING

!

To avoid risk of electrical shock, personal injury, or

death, make sure your oven has been properly

grounded and always disconnect it from main power

supply before any servicing.

CAUTION

!

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to cause

cancer , birth defects or other reproductive harm. T o

reduce the risk from substances in the fuel or from fuel

combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this booklet.

ALL APPLIANCES

1. Proper Installation—Be sure your appliance is properly

installed and grounded by a qualified technician.

2. Never Use Appliance for Warming or Heating the

Room.

3. Do Not Leave Children Alone—Children should not be

alone or unattended in the area where the appliance is

in use. They should never be allowed to sit or stand on

any part of the appliance.

4. Wear Proper Apparel—Loose fitting or hanging

garments should never be worn while using appliance.

5. User Servicing—Do not repair or replace any part of

the appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

6. Storage in or on Appliance—Flammable materials

should not be stored in oven.

7. Do Not Use Water on Grease Fires—Smother fire or

flame, or use dry chemical or foam-type extinguisher .

8. Use Only Dry Potholders—Moist or damp potholders

on hot surfaces may result in burns from steam. Do

not let potholder touch burners. Do not use a towel or

other bulky cloth.

SELF-CLEANING OVEN

1. Do Not Clean Door Gasket—The door gasket is

essential for a good seal. Care should be taken not to

rub, damage, or move the gasket.

2. Do Not Use Oven Cleaners—No commercial oven

cleaner or oven liner protective coating of any kind

should be used in or around any part of the liner.

3. Clean Only Parts Listed in Manual. See Cleaning

section.

4. Before Self-Cleaning the Oven—Remove broiler pan,

oven racks, and other utensils.

OVEN

1. Use Care When Opening Door—Let hot air or steam

escape before removing or replacing food.

2. Do Not Heat Unopened Food Containers—Build-up of

pressure may cause container to burst and result in

injury.

3. Keep Oven V ents Ducts Unobstructed.

4. Placement of Oven Racks—Always place oven racks

in desired location while oven is cool. If rack is

removed while oven is hot, do not let potholder contact

hot oven.

In Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely , if one occurs, proceed

as follows:

Oven Fires

1. If you see smoke from oven, do not open oven door .

2. Turn oven control to OFF.

3. As an added precaution, turn off power at main circuit

breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call repair

service before using oven.

Precautions

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas. They

may stick and melt.

• Do not use damp sponge or dishcloth to clean oven

when oven is hot. Steam from sponge or dishcloth can

burn.

• Do not leave fat heating unless you remain nearby. Fat

can ignite if overheated by spilling onto hot surfaces.

4 16022821 Rev. 0 ©2004 Maytag Appliances Company

Important Safety Information

CAUTION

!

Read the following information to avoid possible

exposure to microwave radiation:

The basic design of the Amana microwave oven makes it

an inherently safe device to both use and service.

However, there are some precautions which should be

followed when servicing the microwave oven to maintain

this safety . These are as follows:

1. Always operate the unit from an adequately grounded

outlet. Do not operate on a two-wire extension cord.

2. Before servicing the unit (if unit is operable) perform

the microwave leakage test.

3. The oven should never be operated if the door does not

fit properly against the seal; the hinges or hinge

bearings are damaged or broken; the choke is

damaged, (pieces missing, etc.); or any other visible

damage can be noted. Check the choke area to

ensure that this area is clean and free of all foreign

matter.

4. If the oven operates with the door open and produces

microwave energy , take the following steps.

A. T ell the user not to operate the oven.

B. Contact Maytag Appliances, Inc.

immediately.

5. Always have the oven disconnected when the outer

case is removed except when making the "live" tests

called for in the Service Manual. Do not reach into the

equipment area while the unit is energized. Make all

connections for the test and check them for tightness

before plugging the cord into the outlet.

6. Always ground the capacitors on the magnetron filter

box and H. V . Capacitor with an insulated-handle

screwdriver before working in the high voltage area of

the equipment compartment. Some types of failures

will leave a charge in these capacitors and the

discharge could cause a reflex action which could

make you injure yourself.

7. In the area of the transformer, cap acitor, diode, and

magnetron there is HIGH VOL T AGE. When the unit is

operating - keep this area clean and free of anything

which could possibly cause an arc or ground, etc.

8. Do not for any reason defeat the interlock switches–

there is no valid reason for this action at any time; nor

will it be condoned by Maytag.

9. IMPORT ANT : Before returning a microwave to a

customer, check for proper switch interlock action.

The primary and secondary switches MUST open

when the door is actuated. The monitor switch MUST

close at a 1/4 inch when the door is opened.

10.Before returning a microwave to a customer , verify the

door spacing is reasonably uniform along the top,

bottom, and sides and that it measures 1/8 inch or

less.

1 1.The Maytag microwave oven should never be operated

with:

• Any components removed and/or bypassed.

• Any of the safety interlocks are found to be failed.

• Any of the seal surfaces are defective, missing,

or damaged.

12.To ensure that the unit does not emit excessive

microwave leakage and to meet the Department of

Health Human Service guidelines, check the oven for

microwave leakage using Narda Model 8100, 8200,

Holaday HI1500, HI1501 or Simpson 380M leakage

monitor as outlined in the instructions. The maximum

leakage level allowed is 4mW/cm2.

13.If servicer encounters an emission reading over

4mw/cm2 the servicer is to cease repair and contact

the Amana Service Dep artment immediately for further

direction. Amana Appliances, Inc. will cont act the

proper Government Agency upon verification of the test

results.

©2004 Maytag Appliances Company 16022821 Rev. 0 5

Microwave Leakage Testing

!

WARNING

Check for radiation leakage after servicing. Should the

leakage be more than 4mW/cm2 inform Amana

Appliances, Inc. immediately . After rep airing or

replacing any radiation safety device, keep a written

record for future reference, as required by DHHS and

HEW regulations. This requirement must be strictly

observed. In addition, the leakage reading must be

recorded on the service repair ticket while in the

customer’s home.

Equipment

• Electromagnetic radiation monitor

• 600 cc glass beaker

Procedure For Measuring Radiation

Leakage

Note before measuring -

• Do not exceed meter full scale deflection. Leak monitor

should initially be set to the highest scale.

• T o prevent false readings, the test probe should be held

by the grip portion of the handle only .

• The scan speed is equal to one inch per antenna

revolution or one inch per second if antenna speed is

unknown.

• Areas to be checked are all door seal areas and any

venting parts.

• Leakage with the outer panel removed ...4mW/cm2 or

less.

• Leakage for fully assembled oven with door normally

closed ...4mW/cm2 or less.

• Leakage for a fully assembled oven (before the latch

switch (primary) is interrupted) while pulling the door ...

4mW/cm2 or less.

Measurement With the Outer Panel

Removed

DANGER

!

Avoid contacting any high voltage components.

Whenever you replace the magnetron, measure for

radiation leakage before the outer panel is installed and

after all necessary components are replaced or adjusted.

Special care should be t aken in measuring around the

magnetron.

Measurement With a Fully Assembled Oven

After all components, including the outer panel are fully

assembled, measure for radiation leakage around the

door periphery, the door viewing window , the exhaust

opening, and air inlet openings.

Record Keeping and Notification Af ter

Measurement

1. After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

2. A copy of the repair ticket and the microwave leakage

reading should be kept by the repair facility .

1. Pour 275 ±15 cc (9 oz ±1/2 oz) of 20 ±5°C (68 ±9°F)

water in a beaker which is graduated to 600 cc and

place the beaker in the center of oven.

2. Set the radiation monitor to 2450 MHz and use it

following the manufacturer’s recommended test

procedure to assure correct results.

3. While measuring the leakage, always use the 2–inch

(5 cm) spacer supplied with the probe.

4. Press the start pad or turn on the timer and with the

magnetron oscillating, measure the leakage by

holding the probe perpendicular to the surface being

measured.

6 16022821 Rev. 0 ©2004 Maytag Appliances Company

General Information

Cooking N o menclature

W

8

5

2

7

D

A

W

Feature Content

Color

)

This manual provides basic instructions and suggestions

for handling, installing , and servicing electric

combination microwave/wallovens.

The directions, information, and warnings in this manual

are developed from experience with, and careful testing

of the product. If the unit is installed according to the

Installation Instructions, it will operate properly and will

require minimal servicing. A unit in proper operating

order ensures the consumer all the benefits provided by

efficient electric cooking.

J M

Brand

A Amana

C Magic Chief

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Crosley

This manual contains information needed by authorized

service technicians to install and service electric

combination microwave/wallovens pertaining to this

manual. There maybe, however some information which

needs further explanation. Refer to individual Installation

Instructions, Use and Care, Technical Sheets, or toll free

technical support line to answer questions from

authorized service technicians.

A Almond on Almond

B Black

Brushed Chrome

C

Traditional White

H

L Traditional Almond

P Prostyle

Monochromatic Bisque

Q

S Stainless

T Traditional Bisque

Whi te on Whit e

W

F Frost White (True Colo r White)

Natural Bisque (True Color Bisque

N

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Produc t Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

Z RV Top

Listing

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

(Singapore)

X Expor t 120 V / 60 Hz

Production Code

This ident ifi es wh ic h

version of production the

unit is.

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn-Air

©2004 Maytag Appliances Company 16022821 Rev. 0 7

General Information

Rating Label

Model numbers are recorded on the rating label. Rating

label is located on under the control panel on the right

hand side. It can be seen by opening the oven door.

Before ordering parts, write down the correct model and

serial number from rating label. This avoids incorrect

shipments and delays. Please refer to parts reference

material when ordering replacement parts.

Functional Operation

Bake

Top and bottom elements operate during bake. Bake

can be used to cook foods which are normally baked.

Oven must be preheated.

Convection Broil (some models)

Top element and fan operate when using convection

broil. Convection broil can be used to cook foods that

are normally broiled. Oven does not require preheating

when using convection broil. Food does not need to be

turned during cooking.

Broil

Top element operates during broil. Broil can be used to

cook foods which are normally broiled. Preheating is not

required when using broil. All foods should be turned at

least once except fish, which does not need to be

turned.

Convection Bake (some models)

Upper element, lower element, and fan operate during

convection bake. Convection bake should be used for

cooking casseroles and roasting meats. Oven should be

preheated for best results when using convection bake.

Pans do not need to be staggered.

Convection (some models)

Rear element and fan operate during convection.

Convection should be used for cooking pastries,

souffles, yeast bread, cakes and cookies. Oven should

be preheated for best results when using convection.

Pans do not need to be staggered.

Cooking Guide

Refer to owners manual, for following recommendations

only as a guide for times and temperature. T imes, rack

position, and temperatures may vary depending on

conditions and food type. For best results, always check

food at minimum time. When roasting, choose rack

position based on size of food item.

8 16022821 Rev. 0 ©2004 Maytag Appliances Company

General Information

Specifications

Refer to individual Technial Sheet for information

regarding specifications.

Model Identification

Complete registration card and promptly return. If

registration card is missing:

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www .mayt ag.com

• For Jenn-Air product call 1-800-536-6247 or visit the

Web Site at www.jennair.com

• For product inCanada call 1-866-587-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an

authorized servicer:

• For Maytag/Jenn-Air product call 1-800-462-9824 or

visit the Web Site at www.maytag.com or

www.jennair.com

• For product inCanada call 1-866-587-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Maytag/Jenn-Air product call 1-800-462-9824 or

visit the Web Site at www.maytag.com or

www.jennair.com

• For product inCanada call 1-866-587-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Asure™ Extended Service Plan is specially designed

to supplement Amana’ s strong warranty. This plan

covers parts, labor, and travel charges.

Call 1-866-232-6244 for information.

• Dependability Plus

specially designed to supplement Maytag’s and

Jenn-Air’s strong warranty. This plan covers parts,

labor, and travel charges.

Call 1-800-925-2020 for information.

SM

Extended Service Plan is

©2004 Maytag Appliances Company 16022821 Rev. 0 9

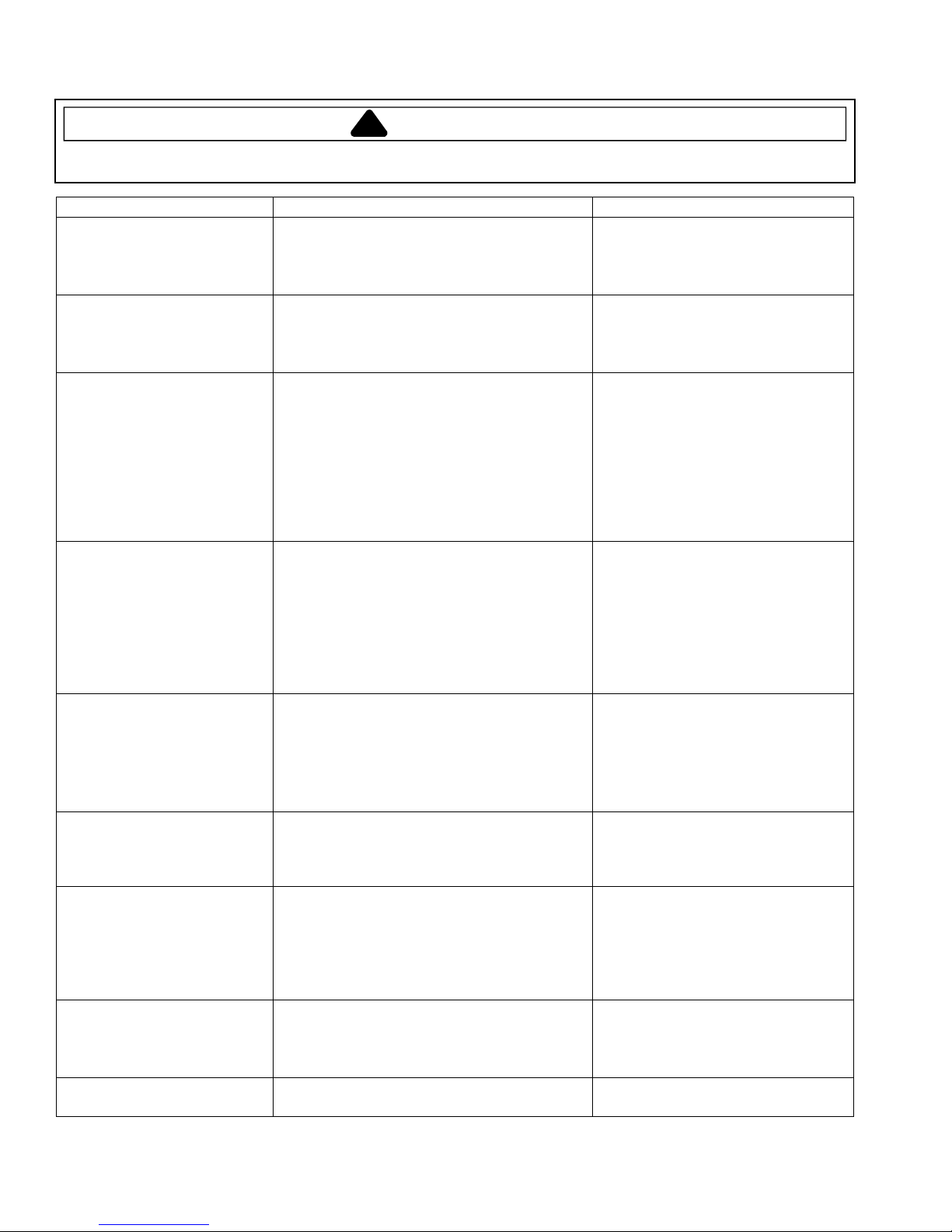

Wall Oven Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

Problem Possible Cause Correction

Open bake element.....................................

No bake element operation

No broil element operation

Oven not operating

Clock and timer not working

Oven light does not operate

Self-clean cycle not working

Oven door will not unlock

Oven smokes/order first few

times of usage

Failure Codes

Loose wire connection or broken wire.........

Open broil element......................................

Loose wire connection or broken wire.........

Programming error ......................................

Power outage ..............................................

Power outage ..............................................

Failed oven lamp.........................................

Failed wiring ................................................

Failed light socket ........................................

Failed light plunger......................................

Programming error ......................................

Oven is self-cleaning...................................

Oven is still hot............................................

Normal.........................................................

Electronically Controlled..............................

WARNING

• Check element for continuity,

replace if failed.

• Verify all connections are clean

and tight, replace broken wire.

• Check element for continuity,

replace if failed.

• Verify all connections are clean

and tight, replace broken wire.

• Shut off power to oven for five

minutes by switching off ciruit

breaker. Reset circuit breaker

and try oven again.

• Verify power is presen t at unit.

Verify that the circuit breaker is

not tripped.

• Replace household fuse, but do

not fuse capacity.

• Verify power is presen t at unit.

Verify that the circuit breaker is

not tripped.

• Replace household fuse, but do

not fuse capacity.

• Refer to Use and Care Manual

“Operating Instructions”, if

continues contact service.

• Check lamp and replace is

necessary.

• Check for broken, loose or dirty

connections.

• Check light socket for continuity.

• Check plunger for continuity.

• Shut off power to oven for five

minutes by switching off ciruit

breaker. Reset circuit breaker

and try oven again.

• Allow cycle to complete.

• Will not unlock until unit has

cooled to safe temperature. Do

not force door open, this will void

warranty. Blow cool air on door

latch area to quicken process.

• Minor smoking or order is normal

the first few times of oven usage.

• Ventilate area wel l and perform

self-clean cycle.

• Refer to specific Technical Sheet

for diagnostic checks.

10

16022821 Rev. 0 ©2004 Maytag Appli ances Company

Microwave Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

CAUTIONS

1. Check grounding before checking for trouble.

2. Be careful of the high voltage cir cuit.

3. Discharge the high voltage capacitor.

4. When checking the continuity of the switches or of the high voltage transformer, disconnect one lead wire

from these parts and the n check continuity with the AC plug removed. To do otherwise may result in a

false reading or damage to your meter.

5. Do not touch any part of the circuit on the P.C.B. since static electric discharge may damage this control

panel.

Always touch yourself to ground while working on this panel to discharge any static charge built up in your

body.

CONDITIO N

Micr owav e oven

does not work.

Inserting many plugs into one

outlet and using them at the

same time.

(blown fuse or breaker)

CAUSE

REMEDY

Avoid using other electrical

appliances when you use the

microwave oven.

Microwave oven plug is not

inserted ti ghtly .

Output power is too low. Low AC input voltage.

Sparks occur.

Unev en cooki ng.

Food t em pe r atur e

Using metallic ware and

allowing it to touch the oven

wall.

Ceramic ware trimmed in

gold or silver powder is used.

Inconsistent inte nsity of

microwave by their

charact eristics.

is t oo low.

Insert microwave oven plug

secu rely.

Use the microwave oven at

ade quate li ne voltag e.

This may not be a defect.

It is possible that the food

should be cooked for a

longer time period.

Do not use metallic ware for

cooking except that noted in

the coo king guide .

Do not use any type of

cookware with metallic

trimming.

1. Use plastic wrap or lid.

2. Stir once or twice while

cooking soup, cocoa or

milk, etc.

©2004 Maytag Appliances Company 16022821 Rev. 0 11

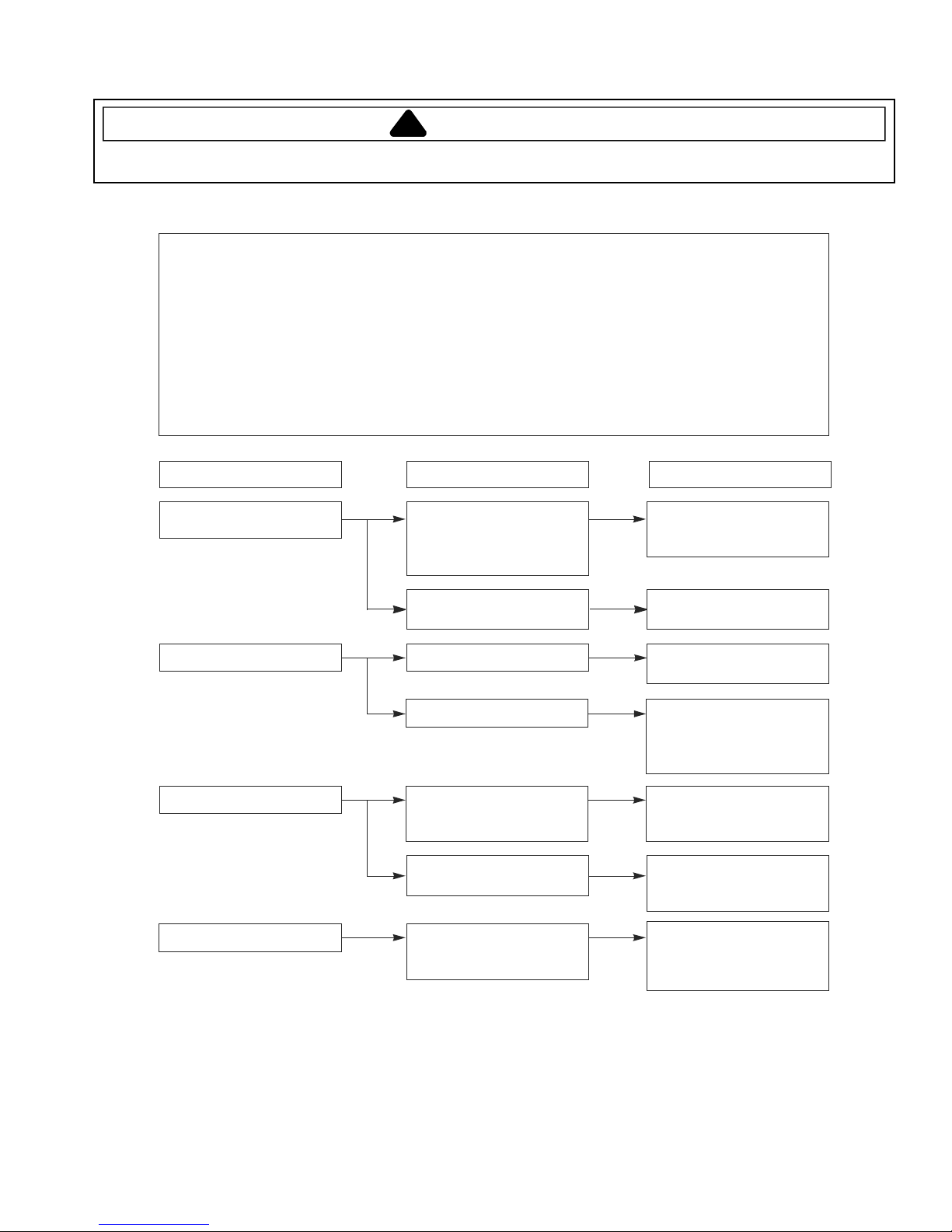

Microwave Troubleshooting Procedures

CAUSE

REMEDY

P.C.B Assembly.

voltage capacitor.

voltage capacitor.

Failed high voltage

P.C.B Assembly.

of primary switch

switch (with door

to the high voltage

No continuity.

No continuity.

Failed

Replace

!

WARNING

To avoid risk of electrical shock, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

CONDITION CHECK RESUL

1. Fuse blows. Continuity.

Check continuity

of monitor

switch (with

door closed).

Replace fuse

Check continuity

and door sensing

opened)

No continuity.

Continuity.

No continuity.

Malfunction of the

monitor switch.

Shorted contact at

the primary switch.

Replace fuse,

primary, monitor,

Replace fuse,

primary, monitor,

2. Fuse

not blow.

does

Disconnect one

side of the wire

lead connected

from transformer

capacitor and

operate the unit.

Check continuity

of thermostat.

Check continuity

of power supply

cord.

Normal.

Fuse blows again

Continuity.

Failed high

transformer.

thermostat.

Failed power

supply cord.

Replace high

Replace high

voltage

transformer.

thermostat.

Replace power

supply cord.

16022821 Rev. 0 ©2004 Maytag Appli ances Company

12

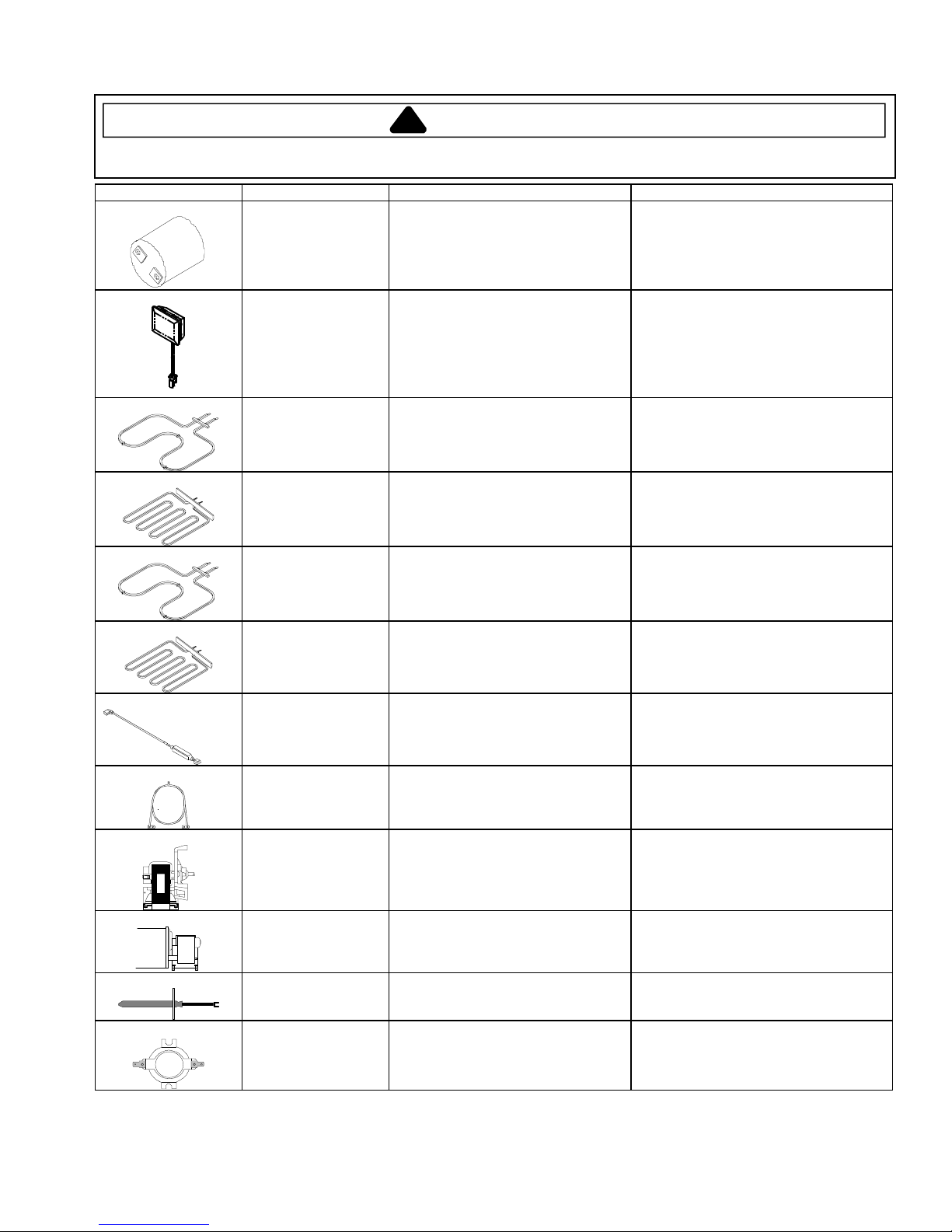

Wall Oven Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

Oven light socket Test continuity of receptacle terminals.

Measure voltage at oven light..............

Oven light housing Disconnect connector and test

resistance of terminals.........................

Measure voltage at oven light..............

Bake element Test continuity of terminals..............

Test voltage to term inals..................

Bake element Test continuity of terminals................

Test voltage to term inals....................

Broil element Test continuity of terminals..............

Test voltage to term inals..................

Indicates cont inuity with bulb screwed in.

120 VAC; see wiring diagram for terminal

identification. If no voltage is present at

oven light check wiring.

Verify bulb is plugged in properly.

Indicates cont inuity with bulb installed.

12 VAC, see wiring diagram for terminal

identification.

If no voltage is present at oven light,

check wiring or light switches.

2600 W - Approximately 21 Ω - cold

2800 W - Approximately 20 Ω - cold

240 / 208 VAC

Approximately 20 Ω - cold

240 / 208 VAC

Approximately 25 Ω - cold

240 / 208 VAC

Broil element Test continuity of terminals................

Resistor assembly Test continuity of resistor...................

Convection element Test continuity of terminals................

Convection motor fan Verify supply voltage..........................

Cooling fan motors Verify supply voltage..........................

Temperature sensor Measure resistance............................

Controls Verify proper operation.

Test voltage to term inals....................

Test voltage to term inals....................

Check continuit y of terminals, and

verify terminal s are not shorted to

chassis...............................................

Check continuit y of terminals, and

verify terminal s not shorted to chassis

Approximately 15 Ω - cold

240 / 208 VAC

Approximately 41 Ω

Approximately 30 Ω - cold

240 / 208 VAC

120 VAC

Approximately 400 Ω

120 VAC

Continuity

Approximately 1080 Ω at room

temperature (70ºF).

Open at 260°F, Closes at 200°F

Open at 225°F, Closes at 165°F

Open at 215°F, Closes at 155°F

©2004 Maytag Appliances Company 16022821 Rev. 0 13

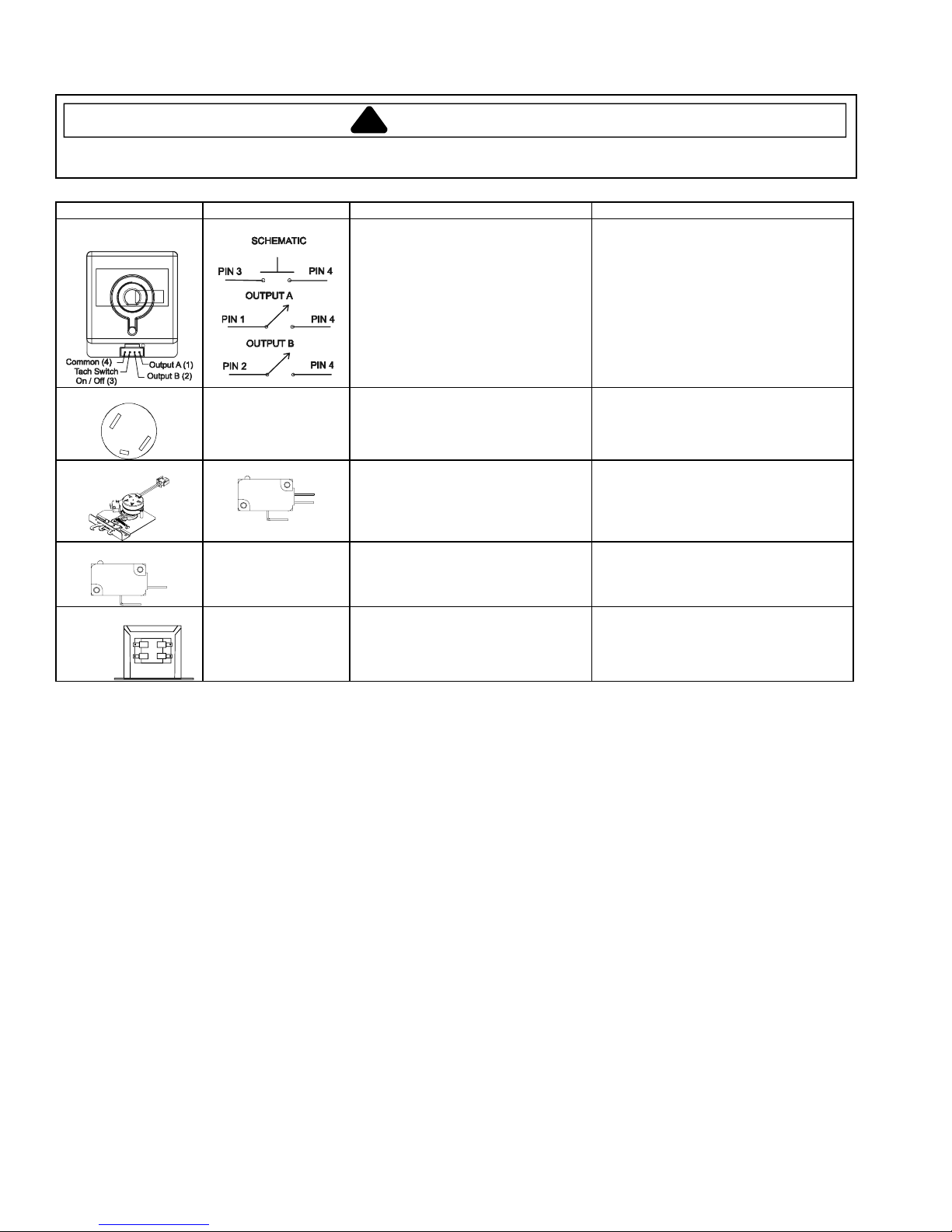

Wall Oven Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

Bottom View

Rotary encoder

Test continuity of terminals

Pin 3 to Pin 4..................................

Pin 1 to Pin 4..................................

Pin 2 to pin 4...................................

Door plunger switch Remove switch from unit and

measure the following points:

NC

C

NO

C-NO..................................................

No continuity with switch at rest position.

Continuity with swi tch depressed.

No continuity with switch at rest position.

Continuity with switch depressed and

changes stat as sw itch is rotated.

No continuity with switch at rest position.

Continuity with switch depressed and

changes stat as sw itch is rotated.

Plunger in continuity, Plunger out infinite.

Motorized door latch

NC

NO

COM

Door switch Remove switch from unit and

Switch connection in following

positions:

Unlocked............................................

Locked................................................

measure the following points:

NO

COM

C-NO..................................................

COM-NO=Open, COM-NC=Closed

COM-NO=Closed, COM-NC=Open

Plunger in continuity, Plunger out infinite.

Primary

Secondary

Stepdown transfor m er Verify input voltage.............................

Verify output voltage...........................

Approximately 120 VAC

Approximately 12 VDC

14 16022821 Rev. 0

©2004 Maytag Appliances Company

Loading...

Loading...