MicrowaveOvenBuilt-InKit

ModelsMK271andMK301

With use on Models M170 & MMC5000Microwave Ovens.

STEP 1: ELECTRICAL REQUIREMENTS

OBSERVEALL GOVERNINGCODESAND ORDINANCES.

A.. A 120-Volt,60 Hz,AC, 15ampere,fusedelectricalsupply

is required (time-delay fuse or circuit breaker is

recommended).However,ifyourhomehasa circuitwired

and fusedfor20 amperes,this is preferred.If youare

installinga new circuit,one wired and fused for 20

amperesisrecommended.Itisalsorecommendedthata

separatecircuitservingonlythisappliancebe provided.

Donotuseanextensioncord.

B, ElectricalConnection

ELECTRICAL GROUND IS REQUIRED ON THIS

APPLIANCE. DO NOT UNDER ANY CIRCUM-

STANCES, REMOVE THE POWER SUPPLY CORD

GROUNDPRONG.

LJ

Foryourpersonalsafety,thisappliancemustbeproperly

groundedand polarized.Thisapplianceisequippedwith

a powersupplycordhavinga 3-pronggroundingplug.To

minimize possible shock hazard, the cord must be

plugged into a mating 3-hole grounding type wall

receptacle, grounded in accordance with the National NOTE: A 27" minimum wide cabinet must be provided to

ElectricalCode,local codesand ordinances.If a mating installTrimKit MK271.

wall receptacle is not available, it is the personal NOTE: A 30" minimum wide cabinet must be provided to

responsibility and obligation of the customer to have a

properly grounded and polarized3-hole wall receptacle installTrimKit MK301.

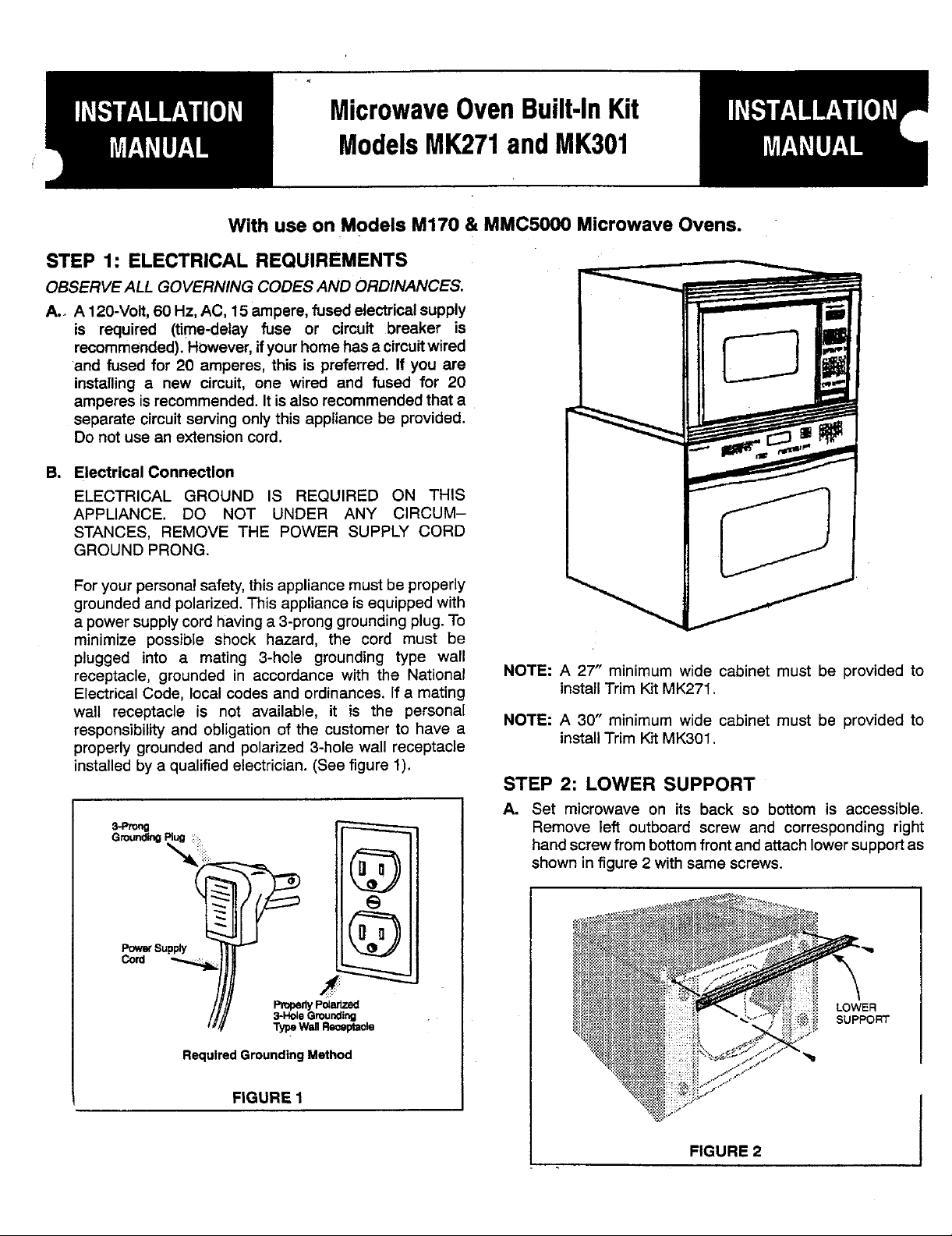

installed bya qualifiedelectrician.(Seefigure 1).

STEP 2: LOWER SUPPORT

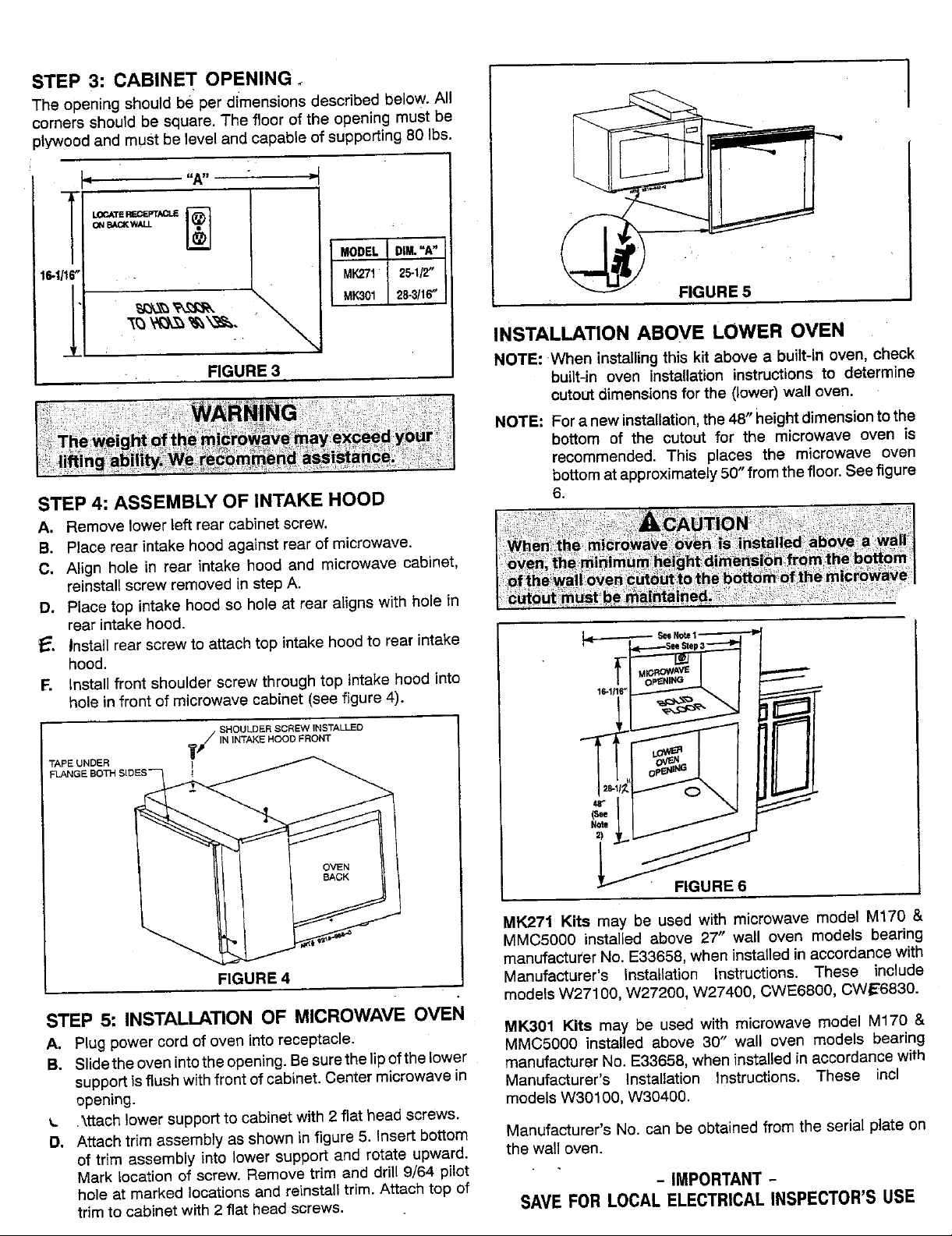

A. Set microwave on its back so bottom is accessible.

s-Prong "_ Remove left outboard screw and corresponding right

eroundh__g :_i_ handscrewfrom bottomfrontandattachlowersupportas

PowerSupply (_

_i _ @e shownin figure2 withsamescrews.

co_ _

Propedypolarized LOWER

3-1,,i_eGrounding SUPPORT

TypeWallRe--de

Required Grounding Method "_

FIGURE1 I

FIGURE2

STEP 3: CABINET OPENING, I

The opening should be per dimensions described below. All

corners should be square. The floor of the opening must be

_tywood and must be level and capable of supporting 80 Ibs.

"A" -jd

MODEL DIM."A"

16-1 MK271 25-1/2"

_ _=L_l_k , _ MK301 28-3/16" FIGURE 5

I

lit LOCAT_ R_,F.PTACLE

_ k_:_k._.. _ INSTALLATION ABOVE LOWER OVEN

FIGURE 3 NOTE: When installing this kit above a built-in oven, check

NOTE: For a new installation,the 48" heightdimension tothe

built-in oven installation instructions to determine

cutoutdimensionsfor the (lower) wall even.

bottom of the cutout for the microwave oven is

recommended. This places the microwave oven

bottom at approximately 50" fromthe floor. See figure

STEP 4: ASSEMBLY OF INTAKE HOOD 6.

A. Remove lower left rear cabinet screw.

B. Place rear intake hood against rear of microwave.

C. Align hole in rear intake hood and microwave cabinet,

reinstall screw removed in step A.

D. Place top intake hood so hole at rear aligns with hole in

rear intake hood.

_. Install rear screw to attach top intake hood to rear intake _ . s,,=,_

F. Install front shoulder screw through top intake hood into

hood

" _TAPEhOleUNDERin front of microwavel--_*/___ SHOULDER_NINTAKEcabinetHOODSCREWFRONT(seeINSTALLEDfigure 4), _=_l_'_ _16"1116"_ I

FIGURE 6

MK271 Kits may be used with microwave model M170 &

MMC5000 installed above 27" wall oven models bearing

manufacturer No. E33658, when installed in accordance with

[ FIGURE4 Manufacturer's Installation Instructions. These include

models W27100, W27200, W27400, CWE6800, CWE6830.

STEP 5" INSTALLATION OF MICROWAVE OVEN

MK301 Kits may be used with microwave model M170 &

A. Plug power cord of oven into receptacle. MMC5000 installed above 30" wall oven models bearing

B. Slide the oven into the opening. Be sure the lip ofthe lower manufacturer No. E33658, when installed in accordance with

support is flush with front ofcabinet. Center microwave in Manufacturer's Installation Instructions. These incl

opening, models W30100, W30400.

L ._,ttachlower support to cabinet with 2 flat head screws.

D. Attach trim assembly as shown in figure 5. Insert bottom Manufacturer's No. can be obtained from the serial plate on

of trim assembly into lower support and rotate upward, the wall oven.

Mark location of screw. Remove trim and drill 9J64 pilot

hole at marked locations and reinstall trim. Attach top of - IMPORTANT-

trim to cabinet with 2 flat head screws. SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE

Loading...

Loading...