www.dexpress.com DIMENSION EXPRESS Fax on Demand (775) 833-3600

This Data Sheet Includes Information On

Jenn-Air

• Product Model Number (s): •

Laundry Centers (Gas Dryer):

• Dimensions (Actual Size) •

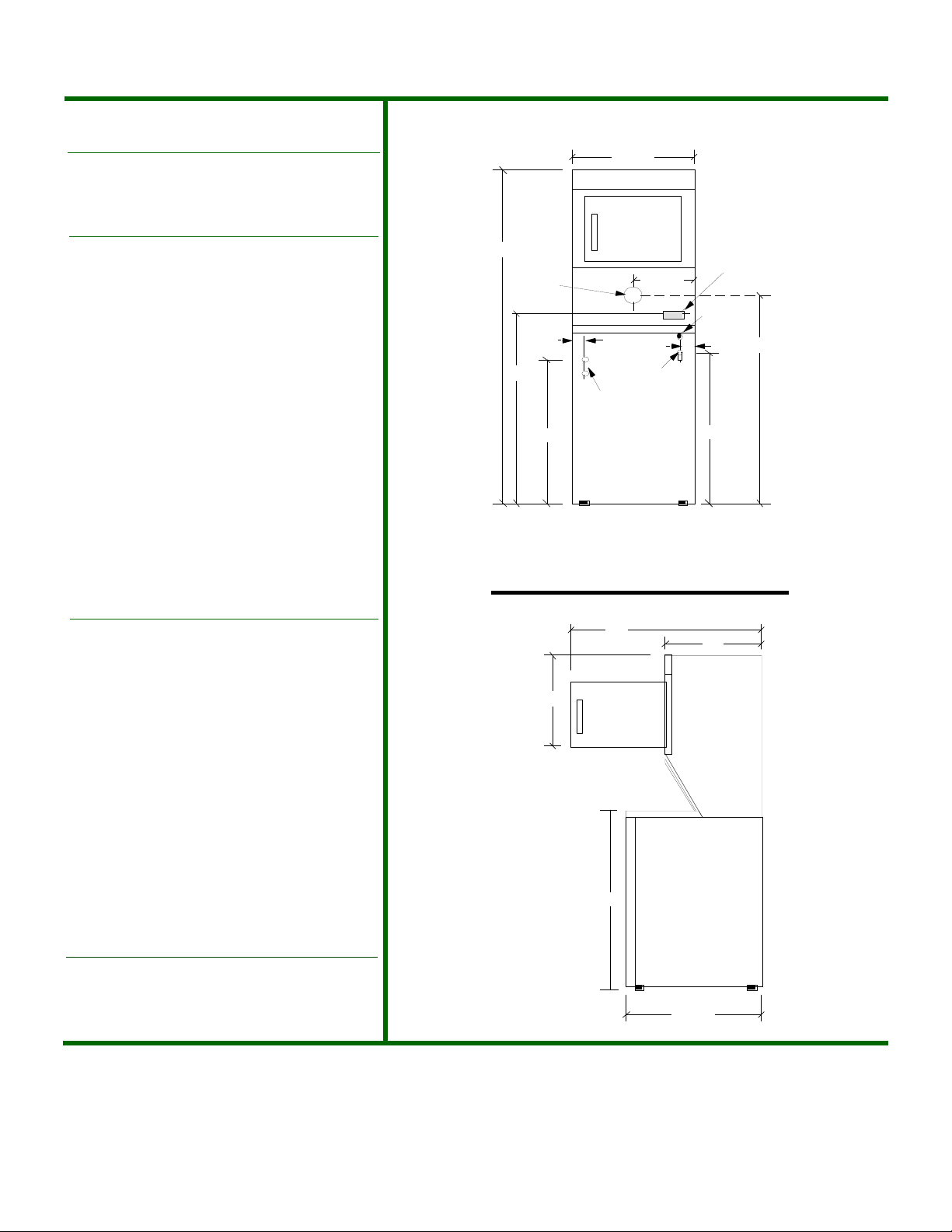

Height of washing machine unit:

Height of dryer (from top of unit):

Floor to centerline of exhaust vent:

Distance from right side of unit to

Floor to centerline of electrical:

Floor to centerline of drain outlet:

Distance from right side of unit to

Floor to centerline of water inlets:

Distance from left side of unit to

LSG2700W

Overall height:

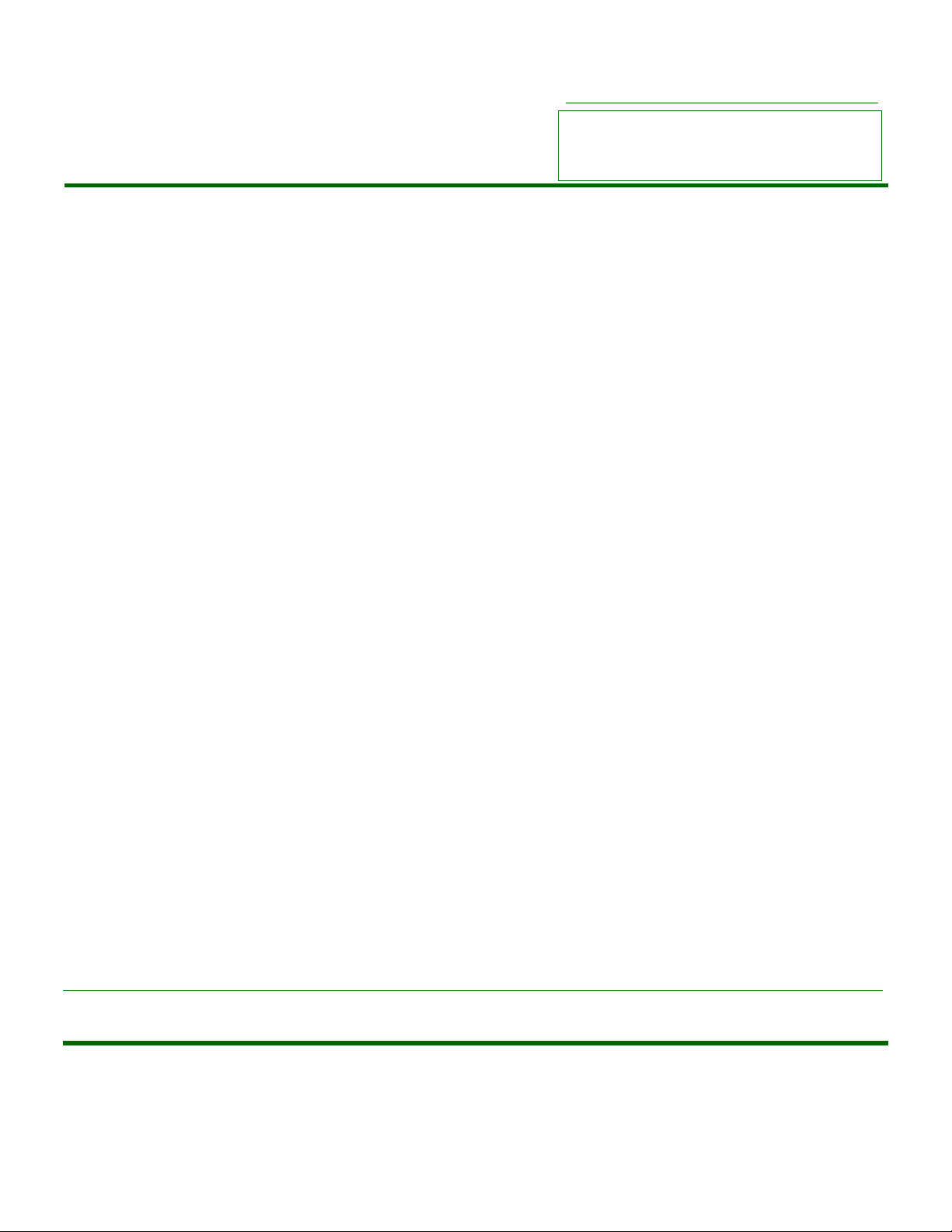

Width:

Lower depth:

Upper depth:

centerline of exhaust vent:

centerline of drain outlet:

centerline of water inlets:

73"

35"

27"

27 1/2"

27 1/2"

21"

43 3/16"

13 3/4"

40"

30 13/16"

3 7/8"

25 7/16"

3 1/2"

Front View

(not to scale)

27 1/2"

Control Panel

73"

Exhaust

13 3/4"

Vent

3 1/2"

40"

3 7/8"

Drain Outlet

Water Inlets

25 7/16"

30 13/16"

NOTE: Exhaust Vent, Electrical location,

Drain Outlet, Gas stub and Water Inlets

are located on the rear of the unit.

Electrical

location

Gas

stub

43 3/16"

• Additional Information •

• Approved for zero clearance installation on the sides

and the back (depending on venting used).

• Floor must be capable of supporting weight of unit

(approx. 340 lbs.) PLUS water (approx. 130 lbs.).

• For proper operation, it is important to make sure the

location has adequate make-up air. This is especially

important in any confined area such as bathroom or

closet. There must be at least two 36 square inch

unobstructed openings for intake air. This can be a

louvered door or other equivalent opening.

• Minimum clearances to combustible surfaces must be

maintained and are as follows: Clearance to side walls

is 0". Clearance to ceiling or cabinet above is 6".

Clearance to rear wall is 0" when exhausting to the

outside or 4" when exhausting inside (not

recommended). Clearance in front of washer is 1/2"

(28" minimum cutout depth when venting outside).

27"

Side View

(not to scale)

41"

21"

35"

See page 2 for additional information.

Subject to change without notice. This system is designed to

be updated daily if necessary. Dimension Express is not

responsible for use of superseded, voided, or outdated data

sheets. Because of the difficulty or impracticability of determining actual damages, liability of Dimension Express shall

not exceed $50.00.

Copyright © Dimension Express, 2000.

• NEVER reuse Data Sheets. Data Sheets are subject to change without • Call Dimension Express if you have any questions at (775) 833-3633 •

notice. Dimension Express is a FREE service bureau and is updated daily, • Always refer to a current Code at a Glance or manufacturer directory •

it makes far more sense to spend the time necessary to request new Data • Data Sheet codes change on the first of odd numbered months at 12:01am •

Sheets for each project, as opposed to the problems, time, costs, and risks

associated with reusing old Data Sheets.

231

BN141 • A231B149 • 30626 • 002906 • 111718 • 12923

27 1/2"

www.dexpress.com

DIMENSION EXPRESS

Fax on Demand (775) 833-3600

Additional Information:

• Certified for installation in mobile homes.

• Electrical requirements: 115 volt 60Hz. protected by a 15 amp fuse.

• Gas requirements: Factory shipped for Natural gas. If dryer is to be

operated on LP gas, it must be converted correctly for safety and

proper performance. Conversion kit from Natural to LP is available

from your Jenn-Air dealer. A 1/2" gas supply line is recommended and

must be reduced to connect to the 3/8" gas line on the dryer.

Additionally, a 1/8" NPT plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of the gas supply

connection to the dryer. The dryer and its individual shut-off valve

must be disconnected from the gas supply piping system during any

pressure testing of the system at test pressures in excess of 1/2

PSIG. The minimum permissible gas (Natural or LP) supply pressure

for purposes of input adjustment is 4.5 inches of water column.

• Supply requirements: Hot and cold connections with water pressure

within 30-120 PSI range. At least 140°F hot water temp.

• Drain requirements: Because of the desirability of flush to the wall

installation of the stacked washer/dryer, a drain directly behind the

unit is preferred to a drain located on either side. The washer unit is

equipped with a built-in siphon break which allows for a variance in

height of the drain facility. The drain must be capable of accepting a

flow rate of approx. 20 gallons per minute. An inside diameter of at

least 1 1/2" is required. The portion of the drain hose from the siphon

break to the drain can be extended to a floor drain. The use of a

laundry built-in wall box can greatly simplify installation of the unit.

• Duct requirements: 4" duct permits up to a maximum of 50 feet rigid

aluminum ductwork (rigid ductwork is recommended). Flexible metal

ductwork should not exceed 34 feet of straight 4" duct. Subtract 8

feet for each 90° elbow and 8 feet for an exhaust hood. No more than

three 90° bends in any duct run. Dryer vents out the back.

• An exhaust hood positioned to line up with the dryer exhaust can be

installed directly through the outside wall. To exhaust up, route

standard 4" diameter ducting up the recess in the units back to get

nearly flush to the wall. To exhaust to the side or down the unit will be

positioned about 4-1/2" away from the wall (flush to wall side

exhausting may be done by going above the dryer before going

sideways).

• There should be no less than a 12" clearance between the bottom of

the exhaust hood and the ground.

• When located in a bedroom, bathroom or closet the dryer MUST be

exhausted to the outside.

• The free flow rate is approx. 180 cubic feet per minute. Do NOT

exhaust dryer into any wall, ceiling, crawl space or a concealed space

of a building, vent connection, gas vent or chimney. NEVER use

plastic or other combustible ductwork.

• LSG2700W : White.

Page 2

This Data Sheet Includes Information On

Jenn-Air

• Product Model Number (s): •

Laundry Centers (Gas Dryer):

LSG2700W

Subject to change without notice. This system is designed to be updated daily if necessary. Dimension Express is not responsible for use of superseded, voided, or

outdated data sheets. Because of the difficulty or impracticability of determining actual damages, liability of Dimension Express shall not exceed $50.00.

Copyright © Dimension Express, 2000.

• NEVER reuse Data Sheets. Data Sheets are subject to change without • Call Dimension Express if you have any questions at (775) 833-3633 •

notice. Dimension Express is a FREE service bureau and is updated daily, • Always refer to a current Code at a Glance or manufacturer directory •

it makes far more sense to spend the time necessary to request new Data • Data Sheet codes change on the first of odd numbered months at 12:01am •

Sheets for each project, as opposed to the problems, time, costs, and risks

associated with reusing old Data Sheets.

BN141 • A231B149 • 30626 • 002906 • 111718 • 12923

149

Loading...

Loading...