Page 1

JXT-B Series

Range Hood

Use & Care / Installation Manual

Models

JXT9030BDP

JXT9036BDP (36” wide - Stainless Steel)

JXT9048BDP (48” wide - Stainless Steel)

(30” wide - Stainless Steel)

HB0026

! !

INTENTED FOR DOMESTIC COOKING ONLY

V05729 rev. A JENN-AIR COMPANY, One Dependabilty SQ., Newton, Iowa 50208-0039 www.jennair.com

Page 2

READ AND SAVE THESE INSTRUCTIONS

TABLE OF CONTENTS

SECTION ..................................................................... PAGE

Warranty .............................................................................. 2

Safety Instructions............................................................... 3

Operation............................................................................. 4

Cleaning.............................................................................. 4

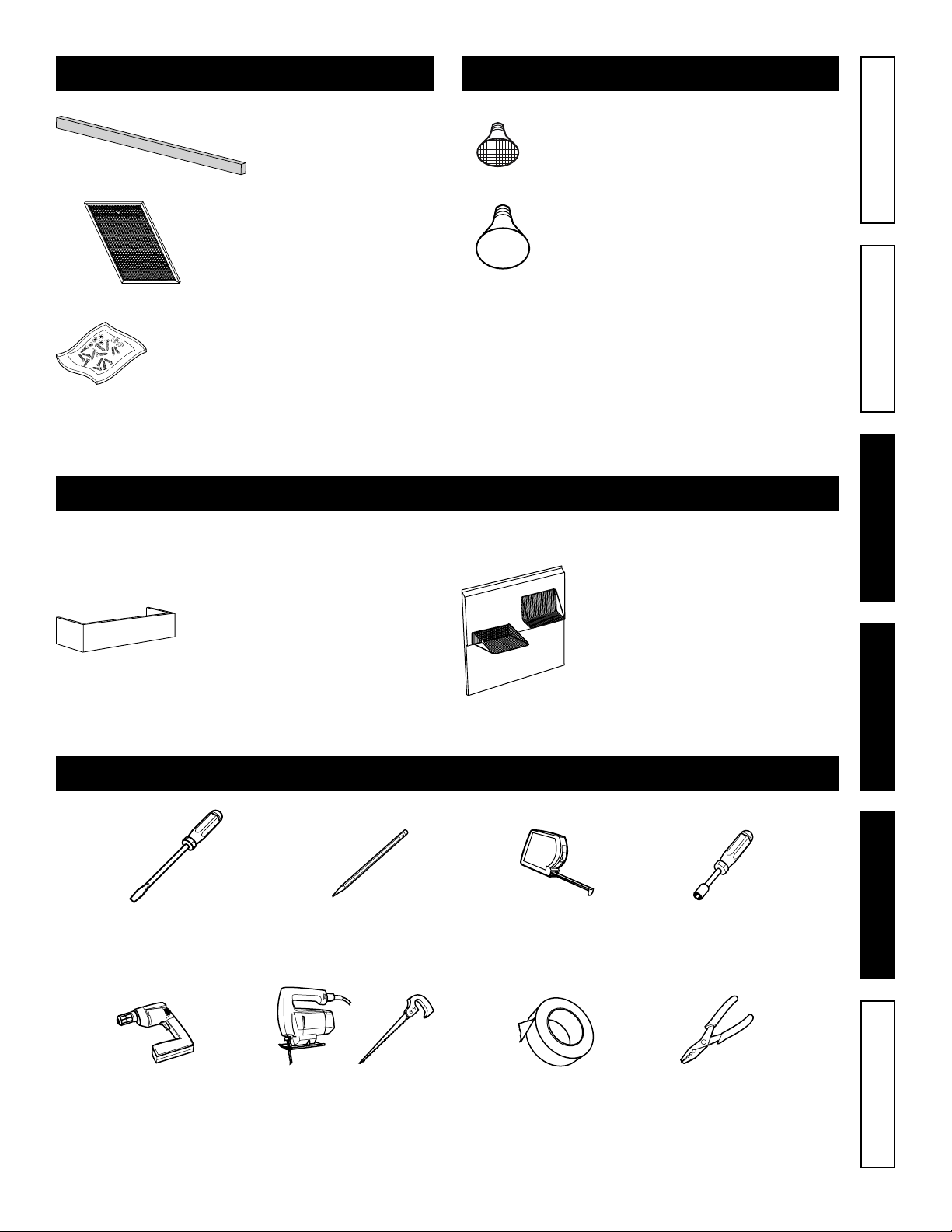

Parts Included With Hood ................................................... 5

Parts Not Included With Hood ............................................ 5

Optional Parts...................................................................... 5

Tools Needed ...................................................................... 5

SECTION ..................................................................... PAGE

Jenn-Air Range Hood System............................................ 6

Prepare The Hood Location ............................................... 7

Prepare The Hood .............................................................. 8

Install The Hood .................................................................. 9

Connect The Wiring .......................................................... 1 0

Wiring Diagram ................................................................. 10

Finalize the Installation ..................................................... 1 0

Install The Filters............................................................... 11

Service Parts ..................................................................... 12

WARRANTY

JENN-AIR WARRANTY

Congratulations on your purchase of a Jenn-Air appliance. We wish to express our confidence in the product by advising you of your warranty.

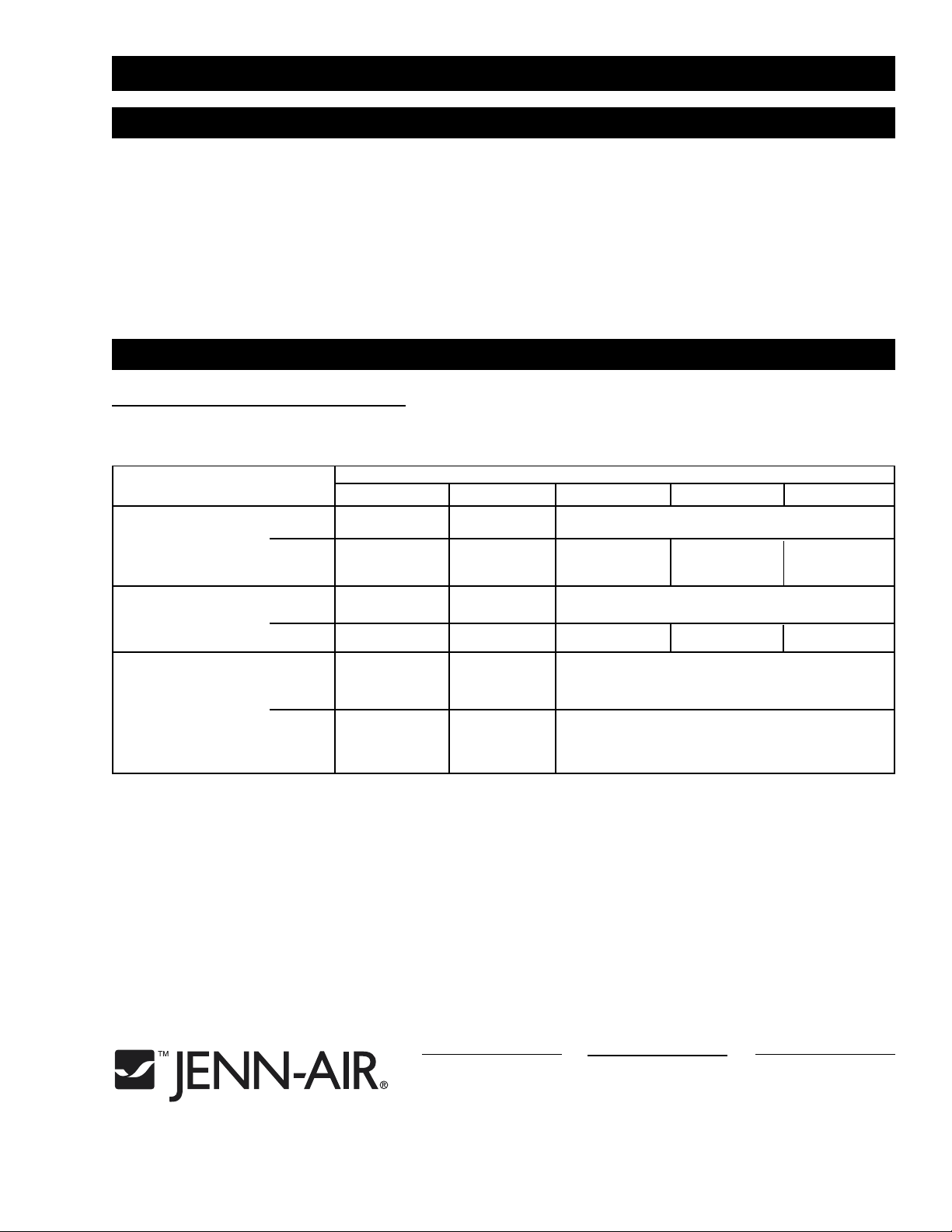

All Jenn-Air appliances carry a minimum warranty of 1st year full warranty parts and labor, plus a 2nd year limited warranty parts only.

Waranties begin on the date of purchase. Tne chart below details specific warranties by product category. The years after date of original

purchase are listed across the top.

YEARS

PRODUCT 1 2 3 4 5

Cooktop, Range, Glass Ceramic Top due to thermal breakage.

Wall Oven Radiant, Halogen and Solid Element Failure.

(Gas or Electric)

Accessories Radiant, Halogen and Solid Element Failure.

Parts All All

Electronic

Labor Yes Control Panel

Components

Parts All All

Glass Ceramic Top due to thermal breakage.

Labor Yes

Limited to Magnetron, Touch Pad Assembly,

Combination Parts All All Microprocessor, Power & Microprocessor Transformer,

Microwave Wall/Oven Capacitor, Rectifier, Triac Assembly

or Microwave Oven Electronic Limited to Magnetron, Touch Pad Assembly,

Labor Yes Control Panel Microprocessor, Power & Microprocessor T ransformer,

Components Capacitor, Rectifier, Triac Assembly

OWNWER’S RESPONSIBILITIES

The customer has certain responsibilities which must be satisfied to qualify for coverage under these warranties.

For all products, the owner is responsible for providing normal care and maintenance in accordance with the Use & care instructions, providing proof of

purchase on request, proper installation and making the appliance reasonably accessible for service. Warranties are for failure in normal use.

WARRANTY SERVICE

Under the full warranty, service must be performed by an Authorized Jenn-Air Service Contractor. To obtain service, contact the dealer from

whom the unit was purchased, an authorized service contractor, or contact Jenn-Air Customer Assistance, c/o Maytag Customer Service,

P.O. Box 2370, Cleveland, TN 37320-2370, 1-800-688-1100. Please include model number, serial number, and date of original retail purchase in

all correspondence. Service will be provided during normal business hours. All replacement parts assume the unused portion of this warranty.

Limited parts warranty covers costs of parts only. Trip charge, transportation and labor costs are the responsibility of the owner.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

CANADIAN RESIDENTS

This warranty covers only those appliances installed in Canada that have been listed with Canadian Standards Association of Canadian Gas

Association unless the appliances are brought into Canada due to transfer of residence from the United states to Canada.

FOR YOUR RECORDS

Record the following information and retain this entire sheet for your future reference

Model Number Serial Number Date Purchased

JENN-AIR COMPANY

ONE DEPENDABILTY SQ.

NEWTON, IOWA 50208-0039

2

Page 3

SAFETY INSTRUCTIONS

Warranty Safety CleaningOperation Installation Service Parts

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the

address listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Do not use this range hood with any additional solid state

speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only steel ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods.

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels

- This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

*Based on “Kitchen Fire safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. Your hood motor has a thermal overload which will

automatically shut off the motor if it becomes overheated.

The motor will restart when it cools down. If the motor

continues to shut off and restart, have the hood serviced.

4. For best capture of cooking impurities, the bottom of the

hood should be a minimum of 24” and a maximum of 30”

above the cooking surface.

5. To reduce the risk of fire and to properly exhaust air on a

ducted installation, be sure to duct air outside - Do not

exhaust air into spaces within walls or ceiling or into attics,

crawl spaces, or garage.

6. This product is equipped with a thermostat which may

start blower automatically. To reduce the risk of injury and

to prevent power from being switch on accidentally, switch

power off at service panel and lock or tag service panel.

7. The Jenn-Air hood must be installed with blower models

H325B or H326B only. Other blowers cannot be

substituted. (Blowers sold separately).

8. Use with approved cord-connection kit only.

9. Please read specification label on product for further

information and requirements.

!

3

Page 4

OPERATION CLEANING

Always turn ON your hood before you begin cooking in order

to establish an air flow in the kitchen. Let the blower run for a

few minutes to clear the air after you turn off the range. This

will help keep the whole kitchen cleaner and brighter.

HC0004K

4

5

3

3

1

2

6

1

3

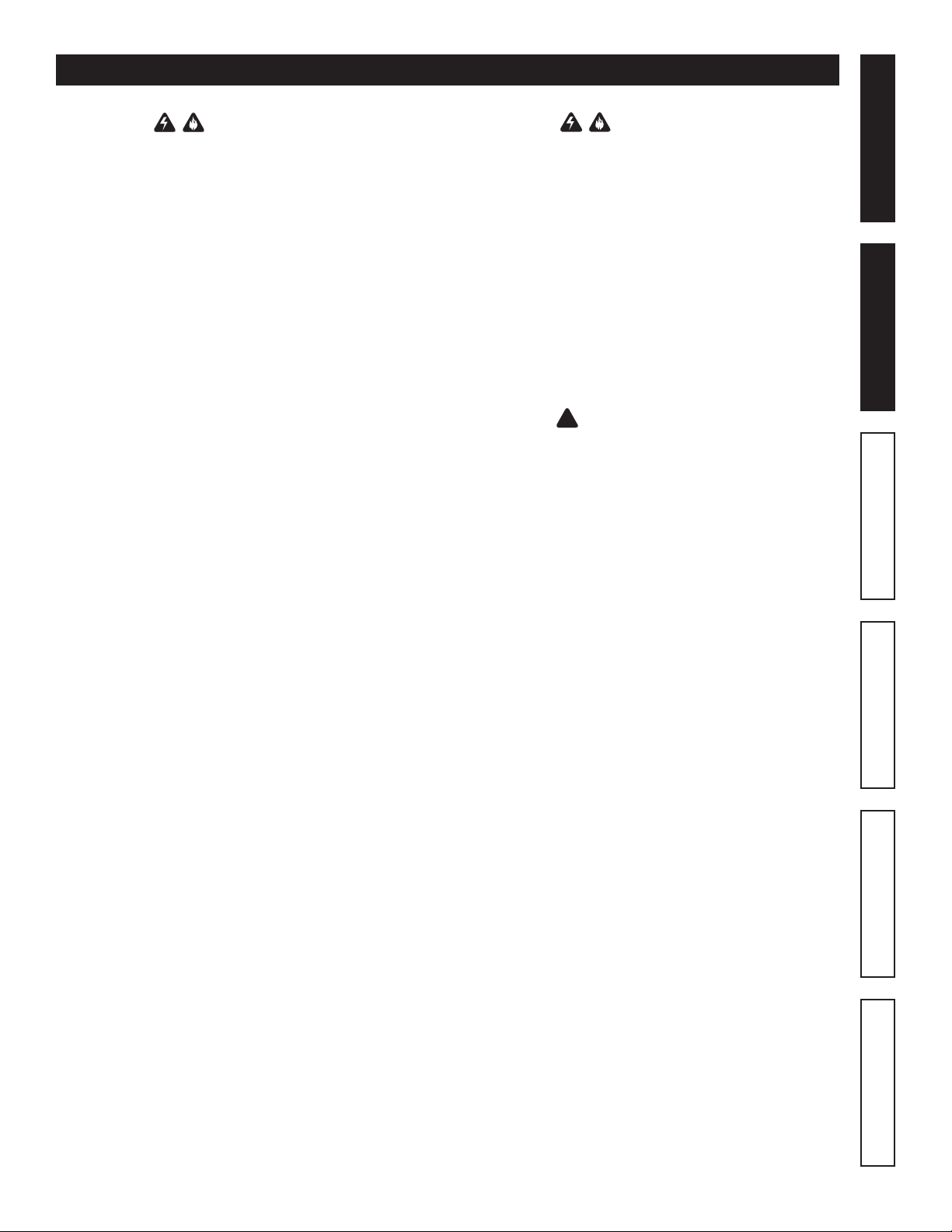

1. Warming lamps 4. Halogen light switches

2. Warming lamp switches 5. ON/OFF Blower switch

3. Halogen lights 6. Blower speed control

Warming Lamps (Infrared)

Each warming lamp (item 1 on picture above) is controlled

with is own ON/OFF switch (item 2 on picture above).

Use only BR40 Size, 250W Max., Infrared bulbs. (Purchase

separately.)

WARNING: Do not place highly flammable

material on warming shelves.

Cooktop Lighting (Halogen)

A double set of ON/OFF switches (item 4 on picture above)

control the halogen lights (item 3 on picture above).

The front rocker controls the center light. The rear rocker

controls both side lights. Select one, two, or three lights for

best cooktop lighting.

Use PAR 20, 50W halogen bulbs. (Purchase separately.)

Blower

The blower is operated using two (2) controls.

Use the ON/OFF blower switch (item 5 on picture above) to

start and stop the blower. When turned on, the blower will

operate at the previous setting of the speed control (item 6 on

the picture above).

Turn the speed control knob clockwise to decrease blower

speed - counterclockwise to increase speed.

HEAT SENTR Y™

Your hood is equipped with a HEAT SENTRY™

This thermostat is a device that will turn on or speed up the

blower if it senses excessive heat above the cooking surface.

1) If blower is OFF - it turns blower ON to high speed.

2) If blower is ON at a lower speed setting - it turns blower up

to HIGH speed.

When the temperature level drops to normal, the blower will

return to its original setting.

thermostat.

WARNING: The HEA T SENTRY™ thermostat can

start the blower even if the hood is turned OFF .

When this occurs, it is impossible to turn the

blower OFF with the switch. If you must stop

the blower, do it from the main electrical panel.

Grease filters

The grease filters should be cleaned frequently. Use a warm

detergent solution. Grease filters are dishwasher safe.

Wash more often if your cooking style generates greater

grease - like frying foods or wok cooking.

Remove filters by pushing filters towards the back of hood

and rotating filters downward.

Blower Cleaning

Remove the grease filters in order to access the blower.

Vacuum blower to clean. Do not immerse in water. Refer to

blower instruction manual for more details.

Grease Rail

The grease rail should be cleaned frequently. Remove filters,

then, disassemble the grease rail from the hood by removing

its 3 retaining screws. See illustration below.

HD0069

Refer to

below. Once the grease rail is clean and dry, reassemble it to

the hood and reinstall filters.

Hood Cleaning

Stainless steel cleaning: How to maintain its ‘’BRIGHT LOOK’’

Do:

- Regularly wash surfaces with clean cloth or rag soaked with

warm water and mild soap or liquid dish detergent.

- Always clean in the direction of original polish lines.

- Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

- You may also use a specialized household stainless steel

cleaner.

Don’t:

- Do not use any steel or stainless steel wool or any other

scrapers to remove stubborn dirt.

- Do not use any harsh or abrasive cleaners.

- Do not allow dirt to accumulate.

- Do not let plaster dust or any other construction residues

reach the hood. During construction/renovation, cover the

hood to make sure no dust sticks to stainless steel surface.

Avoid: when choosing a detergent

- Any cleaners that contains bleach will attack stainless steel.

- Any products containing: chloride, fluoride, iodide, bromide

will deteriorate surfaces rapidly.

- Any combustible products used for cleaning such as

acetone, alcohol, ether, benzol, etc., are highly explosive

and should not be used close to a range.

Stainless steel cleaning

in Hood Cleaning section

4

Page 5

PARTS INCLUDED WITH HOOD

PARTS NOT INCLUDED WITH HOOD

Warranty Safety CleaningOperation Installation Service Parts

Wood mounting strip

Grease Filters

(3 per 30’’ and 36’’ hood)

(4 per 48’’ hood)

Parts Bag

(includes 4 flat head screws #10-2’’,

8 screws #8-3/4’’, 4 Nuts #10-32,

2 Wall anchors and

2 Washers 3/16’’ ID x 3/4’’ OD)

OPTIONAL PARTS

PAR 20 50W

Light Bulb

(3 per hood)

BR40, 250W Max.

Warming Lamp

(2 per hood)

Blowers

(See “Jenn-Air JXT-B Range Hood System” on page 6 for

Blower Model Nos.)

Ducting Accessories

(See “Jenn-Air JXT-B Range Hood System” on page 6 for

Ducting Accessory Model Nos.)

Pro Style Soffit Chimney

Description Model Number

30’’ Stainless JXA9030BDP

36’’ Stainless JXA9036BDP

48’’ Stainless JXA9048BDP

TOOLS NEEDED FOR HOOD INSTALLATION

Screwdriver

(Robertson or Phillips) Pencil

Tape

Measure

Pro Style Backsplash

Description Model Number

30’’ Stainless JXA9003BDP

36’’ Stainless JXA9002BDP

48’’ Stainless JXA9001BDP

3/8”

Nutdriver

Drill

Sabre

Saw

-or-

Keyhole

Saw

Duct Tape

5

Wire

Stripper

Page 6

Wall & Roof Caps

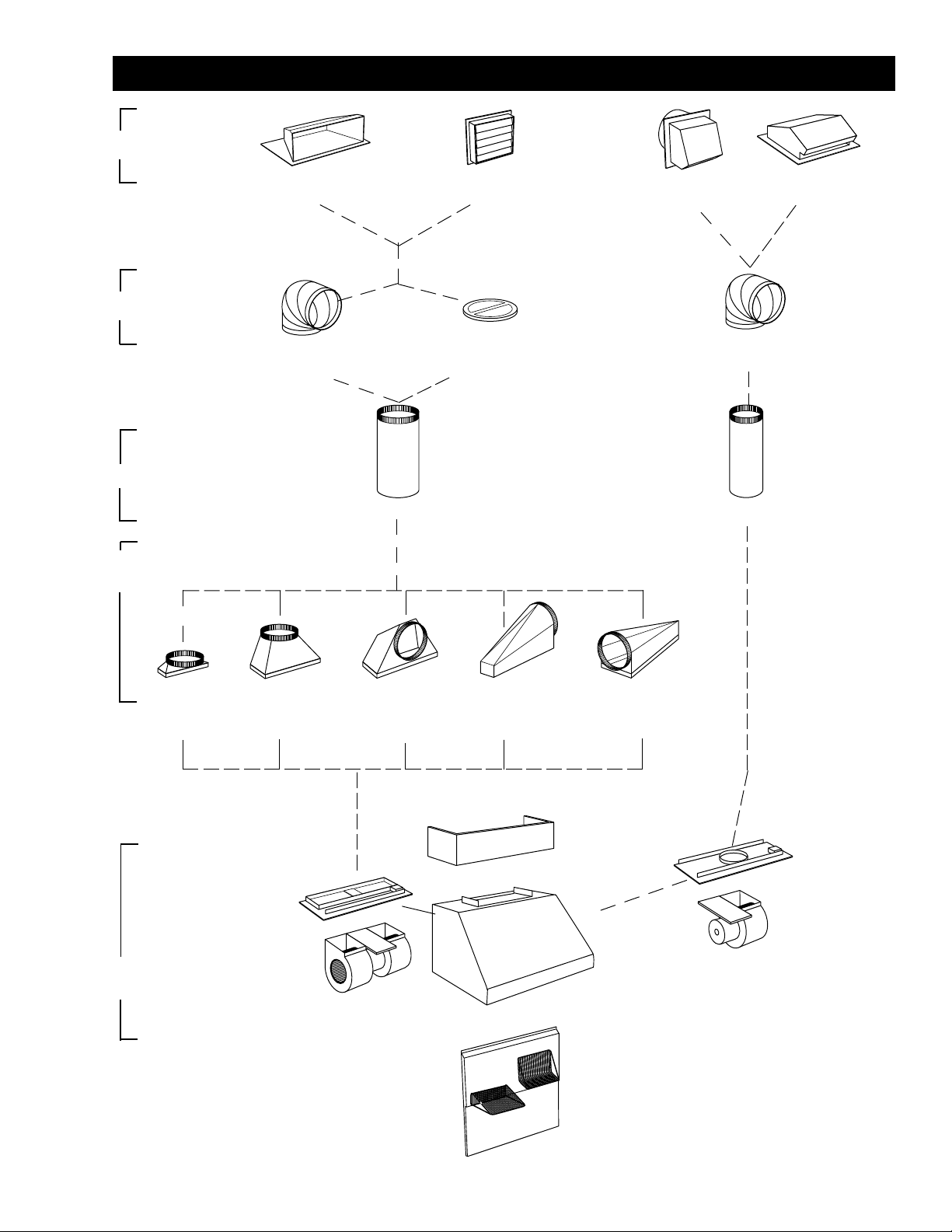

JENN-AIR JXT-B RANGE HOOD SYSTEM

Elbows and

In-Line Damper

Ductwork

Choose 1 of 5

Discharge

Transitions

High Capacity

Roof Cap

10’’ Round

Adjustable Elbow

10’’ Round Duct

10’’ Round

Wall Cap

10’’ Round Vertical

In-Line Damper

7’’ Round

Wall Cap

7’’ Round

Adjustable Elbow

7’’ Round Duct

Roof Cap

4 ½’’ x 18 ½’’

to 10’’ Rd.,

6’’ high - lateral

Choose 1 of 2

Blower Systems

4 ½’’ x 18 ½’’

to 10’’ Rd.,

- vertical

4 ½’’ x 18 ½’’

to 10’’ Rd., Horiz.

front - rear

Model H326B

Blower / Rough-in Kit

(1200 cfm Interior Blower and

Rough-in Plate)

4 ½’’ x 18 ½’’

to 10’’ Rd., Horiz.

Horiz. / right

Optional

Pro Style

Soffit Chimney

(See page 5 for

model numbers)

6

4 ½’’ x 18 ½’’

to 10’’ Rd., Horiz.

Horiz. / left

Model H325B

Hood

(Canopy with blower

controls & lighting.

Required for all

installations.)

Blower /

Rough-in Kit

(600 cfm Interior

Blower and

Rough-in Plate)

Optional Pro Style Backsplash

(Stainless steel wall covering

with warming shelves.)

(See page 5 for model numbers.)

HL0034

Page 7

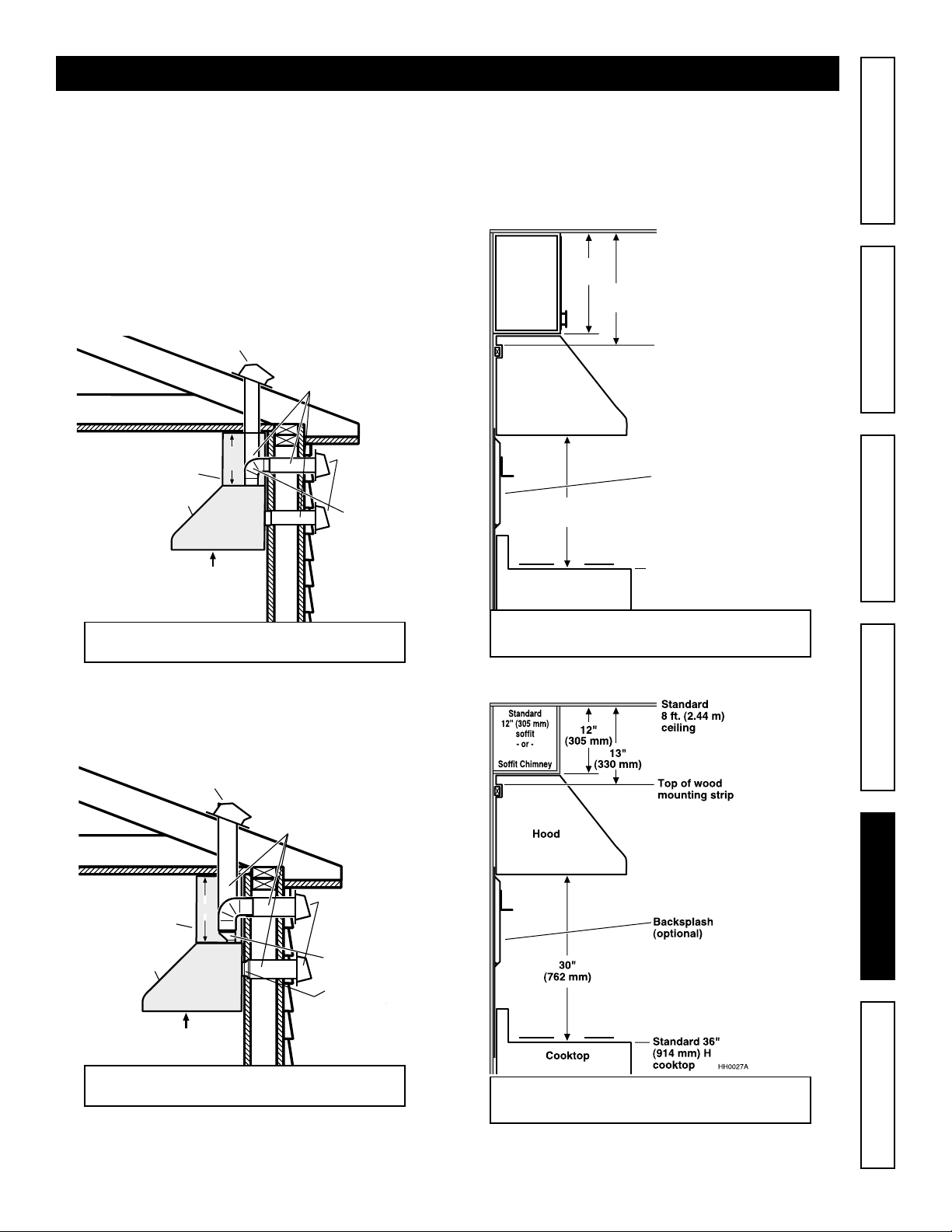

PREPARE THE HOOD LOCATION

1. The Jenn-Air hood must be installed with interior blower

model H325B or H326B only. Other blowers cannot be

substituted. (Blowers sold separately.)

In addition to the blower models listed above, the hood is

also compatible with older internal blower versions H325

and H326. However, discard the installation instructions

included with those blowers and contact Jenn-Air to obtain

replacement instructions.

Plan where and how the ductwork will be located.

Install proper-sized ductwork, transition(s), elbow(s), and

roof or wall cap for the model of blower you are using.

For best results, use a minimum number of transitions and

elbows.

2. Dimensions for the most common installations are shown

below.

Adjust your measurements for various heights of ceilings,

soffits, cabinets or cooktops. For proper operation, the

hood must be a minimum of 24” and a maximum of 30”

above the cooktop.

Standard

8 ft. (2.44 m)

Standard 18"

(457 mm) H

over-cooktop

cabinet

18"

(457 mm)

(483 mm)

19"

ceiling

Warranty Safety CleaningOperation Service PartsInstallation

ROOF CAP

HH0024A

DECORATIVE

FLUE

or SOFFIT

HOOD

24" TO 30" (609 to 762 mm)

ABOVE COOKING SURFACE

12"

(305 mm)

MODEL H325B SINGLE BLOWER

TYPICAL DUCTWORK

ROOF CAP

7" (178 mm)

ROUND DUCT

WALL CAP

7" (178 mm)

ROUND

ELBOW

Top of wood

mounting strip

Hood

Pro Style

RMP Series

Backsplash

(optional)

24"

(610 mm)

Minimum distance

between the hood and

the cooktop

Standard 36"

Cooktop

(914 mm)

H cooktop

HH0028A

INSTALLATION WITH ST ANDARD 18’’ HIGH

OVER-COOKTOP CABINET

Pro Style

DECORATIVE

FLUE

or SOFFIT

24" TO 30" (609 to 762 mm)

ABOVE COOKING SURFACE

HH0025A

(305 mm)

HOOD

MODEL H326B DUAL BLOWER

TYPICAL DUCTWORK

12"

10" (254 mm)

ROUND DUCT

WALL CAP

4-1/2" x 18-1/2"

(114 x 470 to

254 mm) ROUND

TRANSITION

(see page 4)

Pro Style

to 10"

Maximum distance

between the hood and

the cooktop

INST ALLA TION WITH 12’’ SOFFIT OR

OPTIONAL PRO STYLE SOFFIT CHIMNEY

7

Page 8

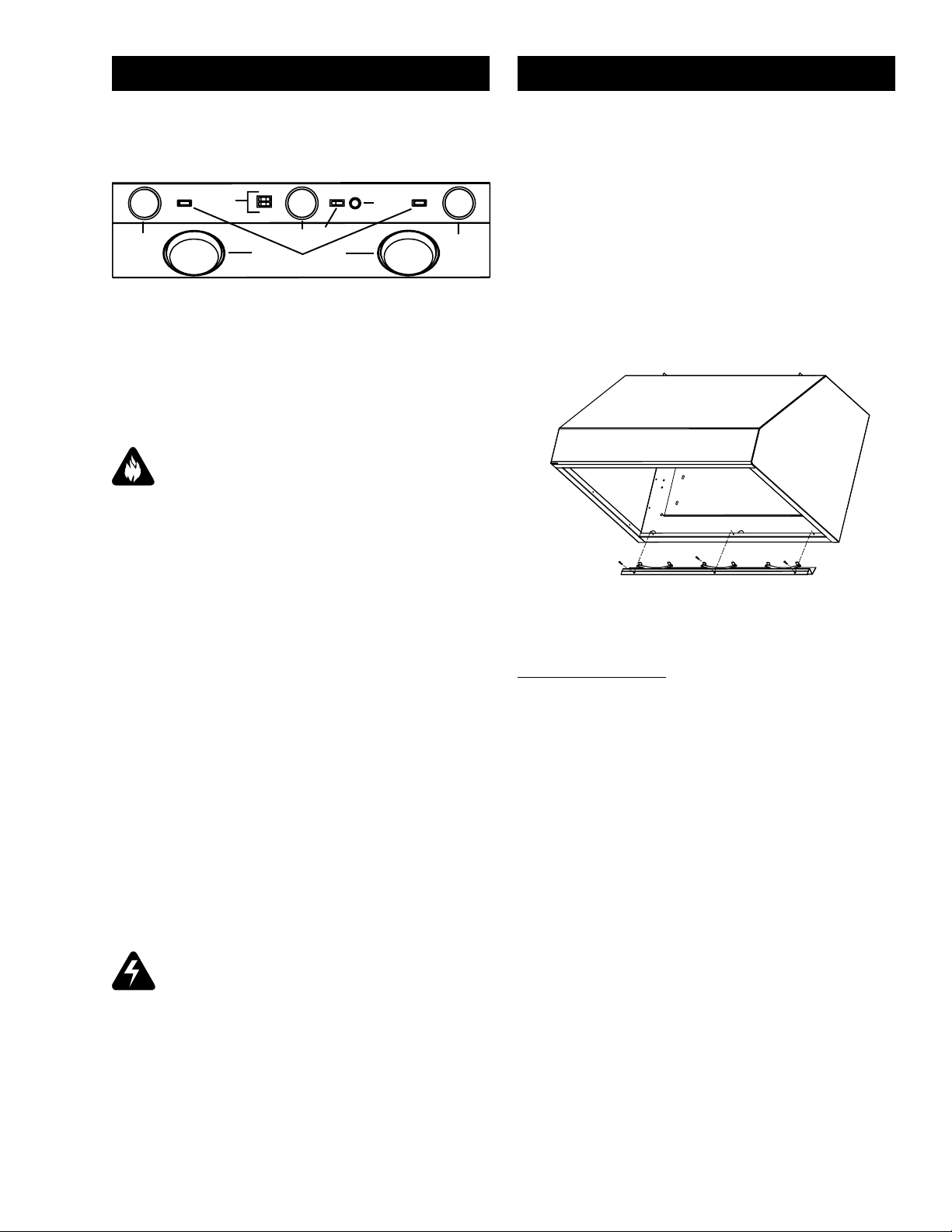

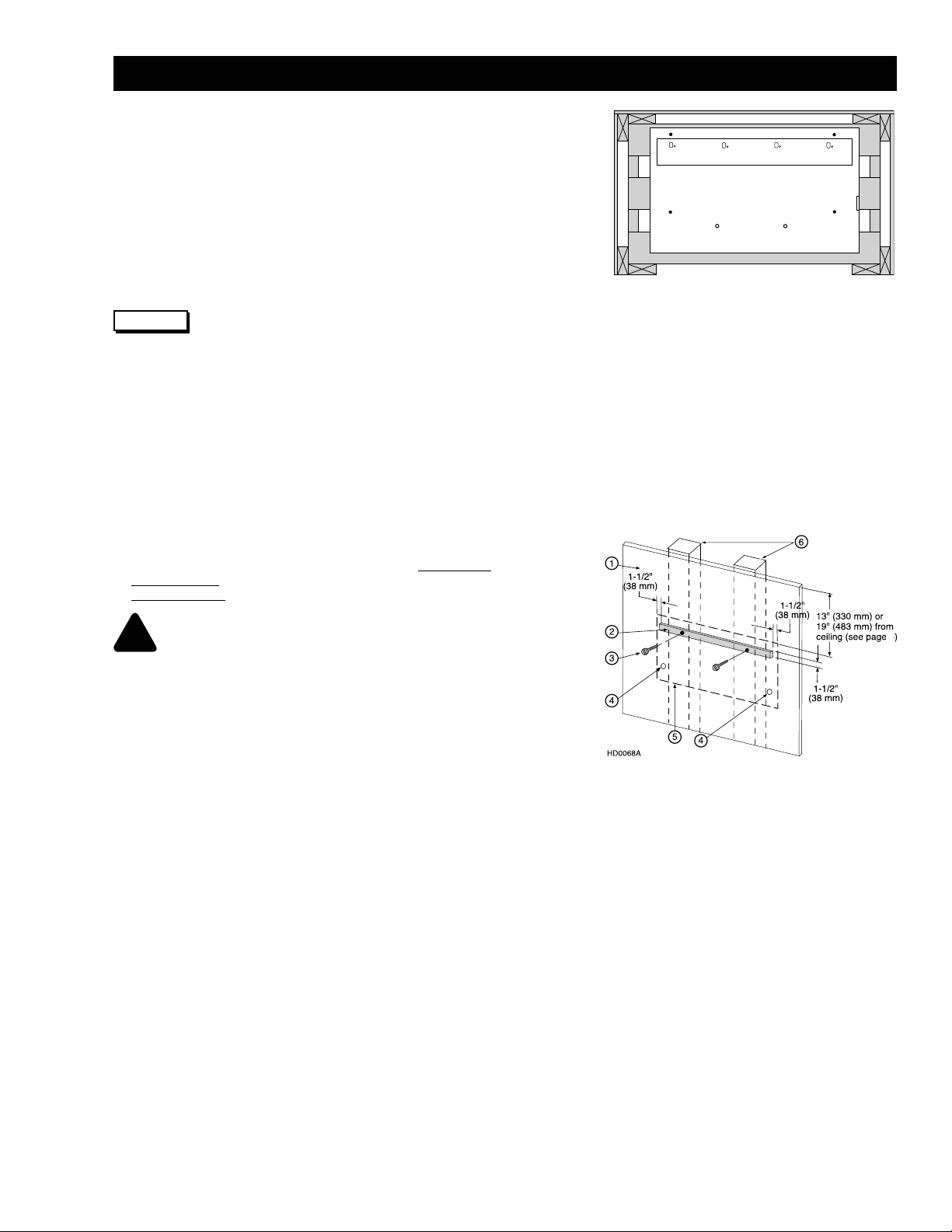

PREPARE THE HOOD

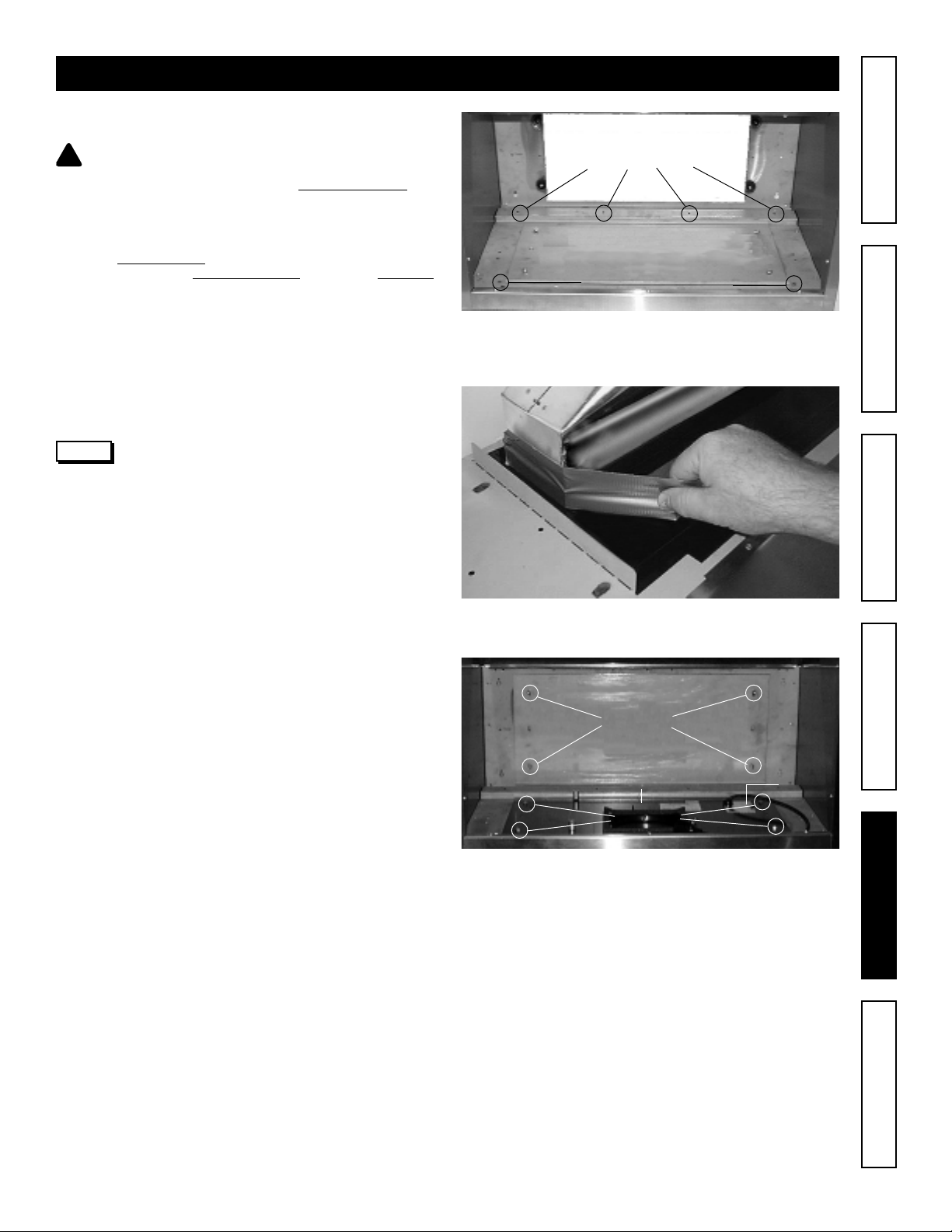

1. Using a Phillips #2 or a Robertson #2 screwdriver,

unscrew the hood from the bottom of crate. Refer to figure

to the right to locate all 4 screws. Discard these screws

and remove hood from wood pallet.

OPTION

A Pro Style backsplash is available (see page 5 for more

details). This backsplash must be installed before the hood

shell because the hood shell covers the backsplash top

mounting screws. In order to be able to install the backsplash,

make sure you have at least 18” (457 mm) clearance between

bottom of hood and range control panel or cooktop. (Refer to

instructions included with backsplash.)

2. Measure and mark a level line on wall above cooktop

location for the wood mounting strip (see illustrations

to the right and under step 2 on page 7). Use

head screws (included in the parts bag) to secure the

mounting strip to the drywall. Make sure to hit the wall studs.

#10-2” flat

CAUTION: Due to the weight of this hood,

ensure that the wood strip is attached to all of

!

the available wall studs (2 studs minimum for

the 30” hood, more as hood width increases);

not into drywall alone.

HR0002

3

1

4

2

7

1. Drywall

2. Wood Mounting Strip

3. Flat Head Screw

4. Wall Anchor Location

5. Outline of the Back of the Hood

6. Wall Studs

8

Page 9

INSTALL THE HOOD

1. Rest the back cavity of the hood on the wood mounting

strip.

CAUTION: Hold the hood until it is completely

!

secured to the wood mounting strip.

Secure hood to wood strip with (4) screws #8 - 3/4” (for

30” and 36” width hoods) or (6) screws (for 48” width hood)

provided at location shown. Drill (2) 3/16” size holes into

the drywall for wall anchors through the existing holes in

the inside hood back in the locations shown. Then install

wall anchors and attach the hood to these anchors

the (2)

with the remaining

provided.

2. Attach transition (if required) to blower rough-in plate.

Refer to page 6 for available models.

Use duct tape to make all joints secure and air-tight.

NOTE

Model H325B blower plate connects directly to 7” round

duct without a transition.

#8 - 3/4” screws and the (2) washers

Warranty Safety CleaningOperation Installation Service Parts

Top of hood (inside view)

Mounting screw locations

Back of hood (inside view)

Wall anchor locations

HD0064

3. Run power cable to installation location. Refer to the

instructions included with the selected blower / rough-in

kit (sold separately) for details on installing the rough-in

plate. Install the rough-in plate so that the wiring box is

located on the right side as you are facing the hood.

For ducting through back of hood, remove existing plate

from inside back of hood and attach to inside top of hood

to cover hole. Secure to threaded studs with same (4)

nuts.

For ducting through top of hood, existing plate remains in

place on inside back of hood.

Connect ducting to transition or rough-in plate as you are

installing the rough-in plate. Use duct tape to make all

joints secure and air-tight.

HD0049

HD0063

Plate on top of hood

Locknuts

Rough-in plate on back of

hood

Locknuts

Wiring

cover

9

Page 10

CONNECT THE WIRING

WARNING: Risk of electrical shock. Electrical

wiring must be done by qualified personnel

in accordance with all applicable codes and

standards. Before connecting wires, switch

power off at service panel and lock service

disconnecting means to prevent power from

being switched on accidentally.

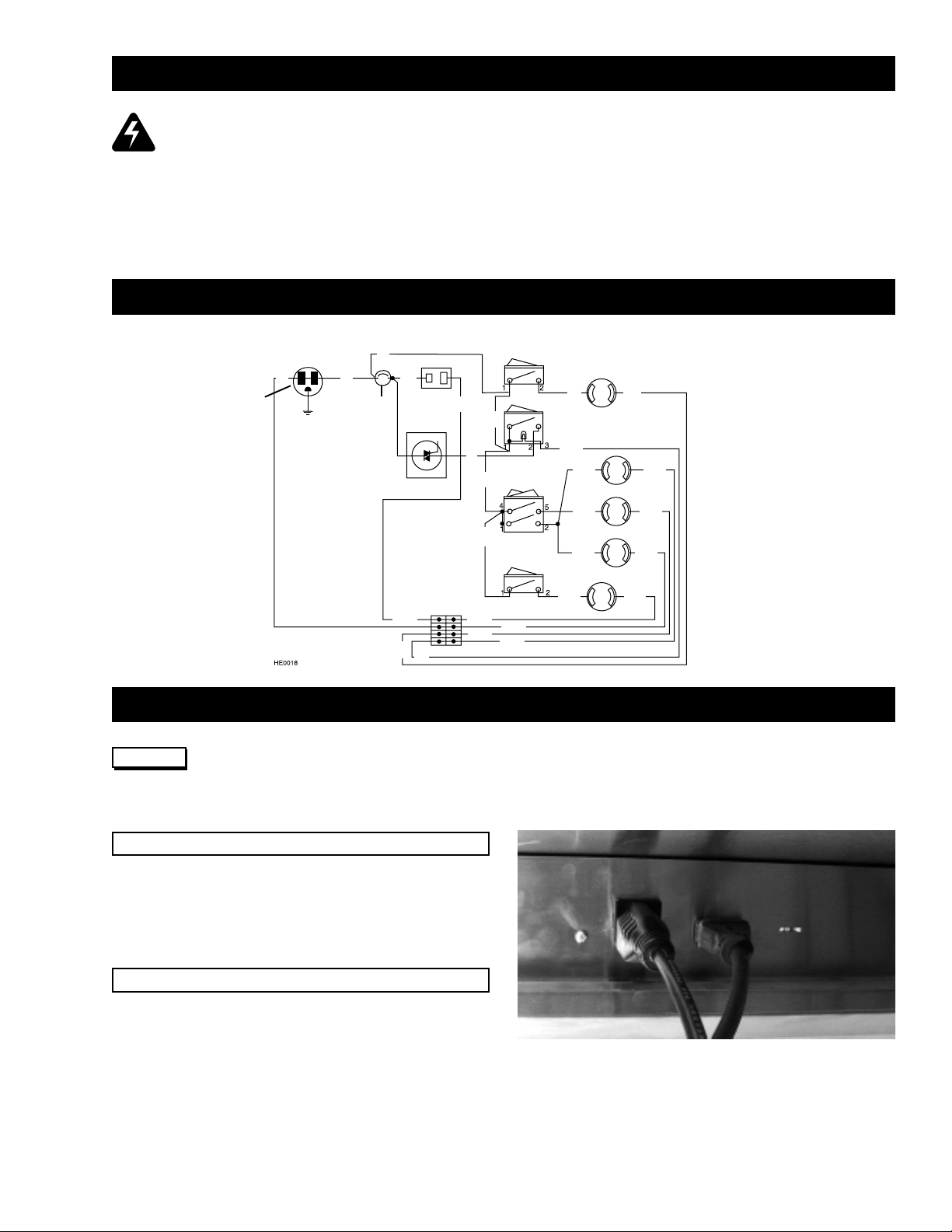

WIRING DIAGRAM

B

TO FAN MOTOR

B

HS

SPEED

CONTROL

TERMINAL BLOCK

W

W

W

W

B

W

W

NEMA

5-15P PLUG

120V 60Hz IN

W B

G

THERMOSTAT

1. Remove wiring cover from rough-in plate and set aside.

2. Remove appropriate knock-out from rough-in plate. As you

are installing the rough-in plate, feed 6” of power cable

through knock-out opening and attach cable to wiring box

with appropriate connector.

3. Connect BLACK to BLACK, WHITE to WHITE and GREEN

or bare wire under GREEN ground screw. Reinstall wiring

cover.

RIGHT HEAT LAMP SWITCH

RIGHT HEAT LAMP SOCKET

FAN SWITCH

B

LIGHT

SWITCH

B

B

LEFT HEAT

LAMP SWITCH

W

W

B

W

B

CENTER LIGHT SOCKET

B

LEFT LIGHT SOCKET

B

LEFT HEAT LAMP SOCKET

B

W

RIGHT LIGHT

SOCKET

W

W

W

W

FINALIZE THE INSTALLATION

OPTION

A Pro Style decorative soffit chimney is available - to hide

ductwork if the hood is not installed under a cabinet. Refer

to the instructions included with the soffit chimney.

Refer to page 5 for ordering information.

1. To install blower, refer to instructions included with blower

/ rough-in kit. Once the blower is installed, plug the blower

unit into the female receptacle and the power supply onto

the male connector inside the hood. DO NOT plug the two

cords into each other.

See page 6 for blower / rough-in kit information.

2. Install (2) heat lamp bulbs. Use BR40 size, 250W Max.,

infrared bulbs only (purchase separately).

Install (3) halogen light bulbs. Use PAR20 50W size

(purchase separately).

HE0003

10

Page 11

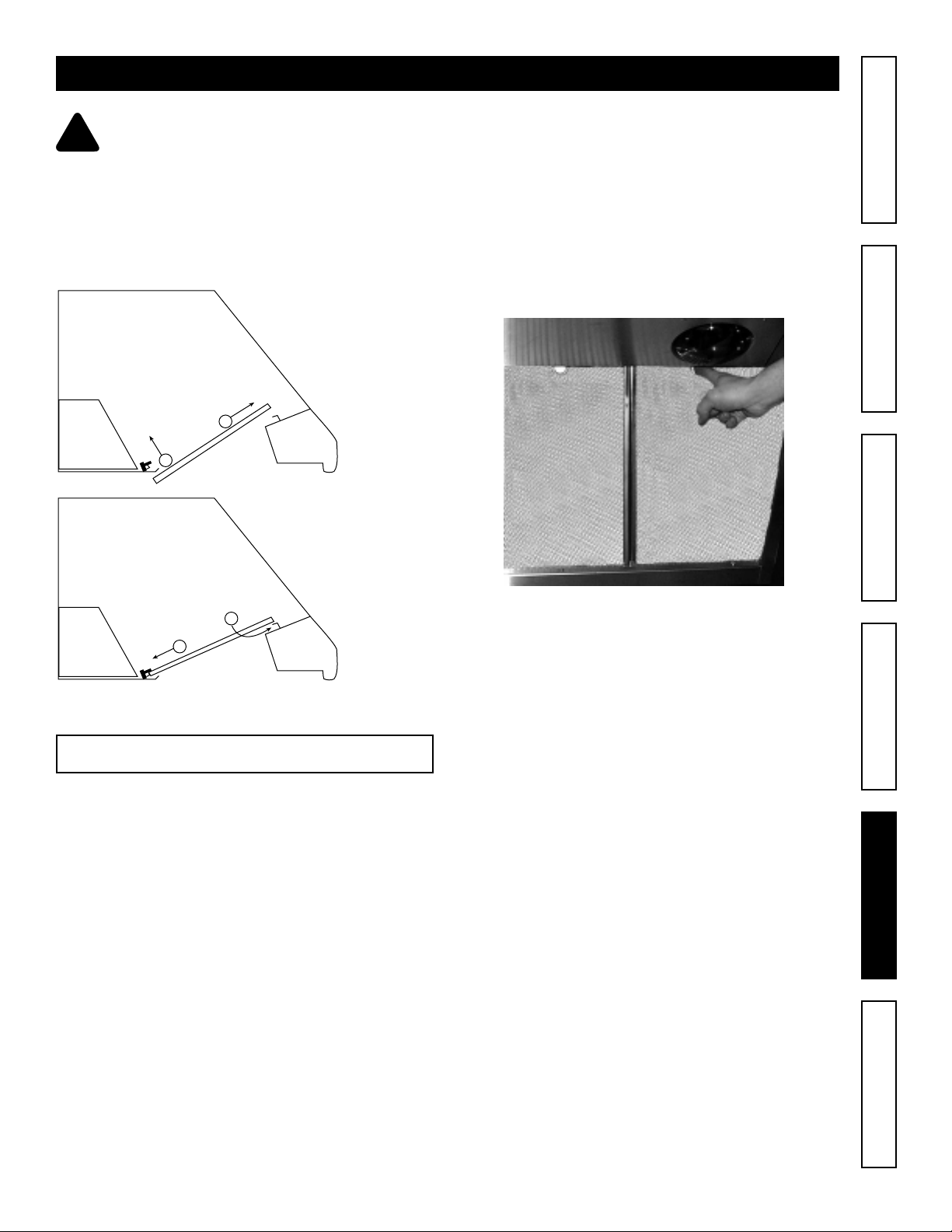

INSTALL FILTERS

CAUTION: Remove protective plastic film covering

!

filters before installing them.

It is recommended to install side filters first and finish with

center one(s).

1) Insert upper end of filter into the hood (pull tab side).

2) Raise lower end toward the inside of hood.

3) Position rear part of filter into channel and pull.

4) Using the pull tab, pull on the upper end of filter and slide it

under the front inner retaining piece.

1

2

Warranty Safety CleaningOperation Installation Service Parts

HD0024

HD0075

4

3

Replacement filters are available.

Refer to page 12 for ordering information.

11

Page 12

SERVICE PARTS

1

20

21

14

4

3

10

9

HL0031

12

13

7

2

8

KEY NO. PART NO. DESCRIPTION

1 V05617 Jenn-Air Logo

2 V02264 Porcelain Lamp Socket

3 V02773 Male Motor Connector

4 V02772 Female Motor Connector

5 V03435 Thermostat

6 V03436 Thermostat Bracket

7 V02563 SPST Single Switch for

Heat Lamps

8 V03502 SPST Double Switch for

Halogen Lights

9 V03503 SPST Lighted Single Switch

for Blower

10 V03504 Speed Control Button

11 V03501 Speed Control

12 V03505 Terminal Block

** V03517 Power Cord

** V03519 Control Wire

** V03520 Lighted Switch Wire

13 V00673 Lock Nut 8-32

14 V02512 Machine Screw 8-32 x ½ Quadrex

15 V01869 Machine Screw 6-32 x ¼ Pan Quadrex

19

17

18

11

16

6

5

15

7

2

22

20

KEY NO. PART NO. DESCRIPTION

16 V01582 Lock Nut 6-32

17 V05730 Micromesh Filter for 30” Hood

9.5 x 15.25 x 0.355 (3 required)

V05731 Micromesh Filter for 36” Hood

11.61 x 15.25 x 0.355 (3 required)

V05731 Micromesh Filter for 48” Hood

11.61 x 15.25 x 0.355 (4 required)

18 V14763 Grease Rail 30”

V14764 Grease Rail 36”

V14766 Grease Rail 48”

19 V05528 Filter Spring 5.265” x 0.350”

20 V05521 Sealing Extrusion 20.625”

21 V14744 Left Side Liner

22 V14745 Right Side Liner

** V05729 Manual for Jenn-Air

** V12971 Installation Bag (Flat head screws

#10 x 2” (4), Screws #8 x 3/4” (8),

Nuts #10-32 (4), Wall anchors (2),

Washers 3/16” ID x 3/4” OD (2))

** V02544 Halogen Lamp P AR20 50W

* Heat Lamp BR40, 250W max.

Order replacement parts by PAR T NO. - not by KEY NO.

* Purchased locally.

** Not illustrated.

12

Page 13

Hotte de cuisinière

Série JXT-B

Guide d’installation, d’utilisation et d’entretien

Modèles JXT9030BDP (Largeur : 30” - Acier inoxydable)

JXT9036BDP (Largeur : 36” - Acier inoxydable)

JXT9048BDP (Largeur : 48” - Acier inoxydable)

HB0026

!

CONÇUE POUR LA CUISSON DOMESTIQUE SEULEMENT

V05729 rev. A JENN-AIR COMPANY, One Dependabilty SQ., Newton, Iowa 50208-0039 www.jennair.com

!

Page 14

LIRE ET CONSERVER CES INSTRUCTIONS

TABLE DES MATIÈRES

SECTION ..................................................................... PAGE

Garantie............................................................................. 14

Instructions de sécurité ..................................................... 1 5

Fonctionnement ................................................................ 16

Nettoyage .......................................................................... 16

Pièces comprises .............................................................. 1 7

Pièces non comprises ...................................................... 17

Pièces optionnelles .......................................................... 17

Outils nécessaires ............................................................ 17

SECTION ..................................................................... PAGE

Système de hotte de cuisinière Jenn-Air ......................... 1 8

Préparation de la localisation de la hotte ........................ 1 9

Préparation de la hotte ..................................................... 2 0

Installation de la hotte....................................................... 2 1

Branchement électrique ................................................... 22

Schéma électrique ............................................................ 22

Finalisation de l’installation .............................................. 22

Installation des filtres ........................................................ 23

Pièces de remplacement .................................................. 2 4

GARANTIE

GARANTIE JENN-AIR

En achetant un appareil Jenn-Air, vous avez fait un choix judicieux. La garantie suivante témoigne de la confiance que nous avons en nos produits.

Tous les appareils Jenn-Air sont couverts au minimumpar une garantie complàte d’un an sur les pièces et la main-d’oeuvre, et d’une garantie

limitée aux pièces pour la deuxième année. Nos garanties débutent à la date d’achat. Le tableau ci-dessous expose les garanties particulières

selon les catégories de produits. Les années écoulées depuis la date d’achat originale figurent en haut du tableau.

ANS

PRODUIT 1 2 3 4 5

Plaques de cuisson, Surface de céramique contre les ruptures thermiques.

cuisinière, fours Défectuosité des éléments radiants, halogènes et en fonte.

encastrés . Composants

(Au gaz ou électrique)

Main-d’oeuvre Oui du panneau

Accessoires Défectuosité des éléments radiants, halogènes et en fonte.

Pièces Toutes T outes

électroniques

de commande

Pièces Toutes T outes

Surface de céramique contre les ruptures thermiques.

Main-d’oeuvre Oui

Limitée au magnétron, panneau de touches,

Fours combinés Pièces T outes Toutes microprocesseur, transformateur d’alimentation et du

micro-ondes/ microprocesseur, condensateur, redresseur et

encastrés ensemble de triac

ou fours Composants Limitée au magnétron, panneau de touches,

micro-ondes Main-d’oeuvre Oui électroniques microprocesseur, transformateur d’alimentation et du

du panneau microprocesseur, condensateur, redresseur et

de commande ensemble de triac

RESPONSABILITÉS DE L’ACHETEUR

L’acheteur doit assumer certaines responsabilités pour avoir droit à la couverture des présentes garanties.

Pour tous les produits, l’ acheteur doit veiller à l’entretien normal de l’appareil conformément aux instructions d’entretien, présenter sur demande une preuve

d’achat, s’assurer que l’appareil est correctement installé et suffisamment accessible pour les réparations. Les présentes garanties s’appliquent aux

défectuosités survenues lors d’une utilisation normale dans une maison.

GARANTIE DE RÉPARATION

Conformément à la garantie complète, les réparations doivent être exécutées par un technicien Jenn-Air agréé. Pour faire réparer votre

appareil, contactez l’établissement où vous avez effectué votre achat, un technicien agréé ou le service à la clientèle Jenn-Air, a/s Service à

la clientèle Maytag, B.P. 2370, Cleveland, TN 37320-2370, 1-800-688-1100. Veuillez indiquer le numéro de modèle, le numéro de série et la date

d’achat originale dans toutes vos correspondances. Les réparations seront exécutées pendant les heures d’affaires normales. Toutes les pièces

de rechange sont couvertes pour la période non utilisée de cette garantie.

La garantie limitée aux pièces ne couvre que les coûts des pièces. L’acheteur assumera les frais de déplacement, de transport et de main-d’oeuvre.

Cette garantie vous accorde des droits légaux particuliers auxquels peuvent s’ajouter d’autres droits pouvant varier d’un état à un autre ou

d’une province à une autre.

RÉSIDENTS CANADIENS

Cette garantie ne couvre que les appareils installés au Canada et homologués par l’Association canadienne de normalisation de l’Association

canadienne du gaz, à moins que les appareils aient été apportés au Canada à la suite d’un déménagement des États-Unis vers le Canada.

POUR VOS DOSSIERS

Veuillez noter les renseignements suivants et conserver cette feuille dans vos dossiers.

Numéro de modèle Numéro de série Date d’achat

JENN-AIR COMPANY

ONE DEPENDABILTY SQ.

NEWTON, IOWA 50208-0039

14

Page 15

INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE BLESSURES CORPORELLES,

SUIVEZ LES INSTRUCTIONS SUIVANTES :

1. N’utiliser cet appareil que de la façon prévue par le

manufacturier. Si vous avez des questions, contactez le

manufacturier à l’adresse et au numéro de téléphone

indiqués sur la garantie.

2. Avant de réparer ou de nettoyer l’appareil, couper

l’alimentation électrique en verrouillant le panneau de

service afin d’éviter sa remise en marche accidentelle. Si

le panneau de service ne peut être verrouillé, y fixer un

avertissement en évidence.

3. Les travaux d’installation et de raccordement électrique

doivent être effectués par un personnel qualifié,

conformément aux codes et standards de construction,

incluant ceux concernant le feu.

4. Une quantité d’air adéquate est requise afin d’assurer une

bonne combustion et l’évacuation des gaz par la cheminée

dans le cas des équipements alimentés au gaz, afin de

prévenir les retours de cheminée. Conformez-vous aux

instructions et aux standards de sécurité des

manufacturiers d’équipement de chauffage, tels que publiés

par le National Fire Protection Association (NFPA) et

l’American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), ainsi que les

responsables des codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un plafond,

prenez garde de ne pas endommager les fils électriques

ou tout appareil cachés.

6. Ne pas utiliser cet appareil avec une commande de vitesse

à semi-conducteur additionnelle.

7. Les ventilateurs avec conduits doivent toujours être ventilés

à l’extérieur.

8. Afin de réduire les risques d’incendie, n’utilisez que des

conduits de métal.

9. Cet appareil doit être mis à la terre.

AFIN DE RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

1. Ne jamais laisser les appareils de cuisson sans

surveillance lorsqu’ils sont réglés à feu vif. Les

débordements engendrent de la fumée et des

déversements graisseux pouvant s’enflammer. Chauffez

l’huile lentement, à feu doux ou moyen.

2. Toujours mettre la hotte en marche lorsque vous cuisinez

à feu vif ou que vous cuisinez des mets flambés.

3. Nettoyez régulilèrement la roue du ventilateur. Ne laissez

pas la graisse s’accumuler sur le ventilateur ou les filtres.

4. Utilisez le bon format de casserole. Servez-vous toujours

de casseroles et d’ustensiles appropriés à la dimension

de la surface chauffante.

AVERTISSEMENT

AFIN D’ÉVITER TOUS RISQUES DE BLESSURES DANS LE

CAS D’UN FEU DE CUISINIÈRE, SUIVEZ CES INSTRUCTIONS :*

1. Étouffez les flammes avec un couvercle hermétique, une

tôle à biscuits ou un plateau métallique et ensuite, éteindre

le brûleur. PRENEZ SOIN D’ÉVITER LES BRÛLURES. SI

LES FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT,

ÉVACUEZ LES LIEUX ET APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES

DANS VOS MAINS - Vous pourriez subir des brûlures.

3. N’UTILISEZ PAS D’EAU, incluant linge à vaisselle

ou serviette mouillés - ceci pourrait occasionner une

violente explosion.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et

que vous en connaissez le fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une

sortie de secours.

* Tirées du “Kitchen Fire Safety Tips” publié par la NFPA.

ATTENTION

1. Pour usage domestique seulement. Ne pas utiliser pour

évacuer des vapeurs ou des produits dangeureux

ou explosifs.

2. Afin d’éviter tout dommage au moteur et de débalancer ou

de rendre bruyante la roue du moteur, garder votre appareil

à l’abri des poussières de placoplâtre et de construction/

rénovation, etc.

3. Le moteur de votre hotte possède une protection thermique

qui éteindra automatiquement le moteur s’il devient

surchauffé. Le moteur repartira automatiquement une fois

refroidi. Si le moteur continue à arrêter et à repartir, faitesle vérifier.

4. Pour une meilleure évacuation des odeurs de cuisine, le

bas de votre hotte devrait être à un minimum de 24’’ et à un

maximum de 30’’ au dessus de la surface de cuisson.

5. Afin de réduire les risques d’incendie, assurez-vous

d’évacuer l’air à l’extérieur - Ne pas évacuer l’air dans des

espaces restreints comme l’intérieur des murs ou plafond

ou dans le grenier, faux plafond ou garage.

6. Ce produit est équipé d’un thermostat pouvant faire

démarrer le ventilateur automatiquement. Afin de réduire

le risque de blessure, couper le courant à partir du panneau

électrique et verrouillez ou apposez un avertisement sur le

panneau afin de prévenir que la hotte soit mise en marche

automatiquement.

7. La hotte Jenn-Air doit être installée uniquement avec un

des ventilateurs suivants : H325B ou H326B (vendus

séparement). Aucun autre ventilateur ne doit être utilisé.

8. Cette hotte ne doit être utilisée seulement qu’avec un

ensemble de cordon d’alimentation approuvé.

9. Veuillez consulter l’autocollant apposé à l’intérieur de la

hotte pour plus d’information ou autres exigences.

!

Garantìe Sécurité EntretienFonctionnement Installation Pièces

15

Page 16

FONCTIONNEMENT

ENTRETIEN

Toujours mettre en marche la hotte avant de commencer la

cuison afin d’établir une circulation d’air dans la cuisine. Aussi,

laisser la hotte fonctionner quelques minutes après l’arrêt de

la cuisinière afin de nettoyer l’air. Ceci aidera à garder la

cuisine plus propre et plus claire.

HC0004K

4

5

3

3

1

2

6

1

3

1. Lampes chauffantes

2. Interrupteurs de lampe chauffante

3. Lampes halogènes

4. Interrupteurs de lampes halogènes

5. Interrupteur Marche/Arrêt du ventilateur

6. Contrôle de la vitesse du ventilateur

Lampes chauffantes (infrarouges) : Chaque lampe

chauffante (item 1 sur l’illustration ci-dessus) possède son

propre interrupteur Marche/Arrêt. N’utiliser que des ampoules

infrarouges (BR40, 250W max.)

A VERTISSEMENT : Ne jamais placer de matières

inflammables sous les lampes chauffantes.

Lampes halogènes : Les interrupteurs doubles Marche/Arrêt

(item 4 sur l’illustration ci-dessus) contrôlent les lampes

halogènes (item 3 sur l’illusration ci-dessus).

L’interrupteur avant contrôle la lampe centrale. L’interrupteur

arrière contrôle les deux lampes de côté. Choisir une, deux

ou trois lampes selon vos préférences d’éclairage.

Utiliser des ampoules halogènes P AR 20, 50W (non comprises).

Ventilateur : Le ventilateur est contrôlé par deux commandes.

Utiliser l’interrupteur Marche/Arrêt (item 5 sur l’illustration ci-

dessus) pour actionner ou arrêter le moteur. Une fois mis en

marche, le moteur fonctionnera à la vitesse pré-sélectionnée

par la commande de vitesse (item 6 sur l’illustration ci-dessus).

Pour augmenter la vitesse du ventilateur, tourner le bouton

de contrôle de vitesse dans le sens horaire - dans le sens

anti-horaire pour diminuer la vitesse.

HEAT SENTRY

Votre hotte est munie d’un thermostat HEAT SENTRY

thermostat est un dispositif qui actionnera ou augmentera la

vitesse du ventilateur s’il détecte une chaleur excessive audessus de la surface de cuisson.

1) Si le ventilateur n’est pas en marche - il actionnera le

ventilateur en haute vitesse.

2) Si le ventilateur fonctionne en basse vitesse - le ventilateur

tournera en haute vitese.

Lorsque la température revient à un niveau normal, le

ventilateur retourne à sa vitesse d’origine.

MC

MC

. Ce

AVERTISSEMENT : Le thermostat HEAT

SENTRY

MC

peu actionner la hotte même si la

hotte est arrêtée. Si tel est le cas, il est impossible

de l’arrêter avec l’interrupteur, le faire à partir

du panneau électrique principal.

16

Filtres

Les filtres doivent être nettoyés fréquemment. Utiliser une solution

d’eau chaude et de détergent. Les filtres sont lavables au lave-vaisselle.

Les filtres doivent être lavés plus souvent si vos habitudes de cuisson génèrent

plus de graisse - comme par exemple de la friture ou des aliments sautés au wok.

Pour retirer les filtres, pousser chaque filtre vers le bas en

utilisant la languette afin de les dégager de la pièce de retenue.

Puis, pousser vers l’intérieur de la hotte et les retirer.

Nettoyage du ventilateur

Retirer les filtres pour accéder au ventilateur. Passer

l’aspirateur pour le nettoyer ; ne pas l’immerger dans l’eau.

Pour plus de détails, consulter le guide d’instruction du ventilateur.

Gouttière

La gouttière doit être nettoyée fréquemment. Retirer les filtres,

puis désassembler la gouttière de la hotte en dévissant ses 3

vis de retenue. Voir l’illustration ci-dessous.

HD0069

Consulter la section nettoyage de l’

section nettoyage de la hotte ci-dessous. Une fois la gouttière

propre et sèche, la réassembler à la hotte et réinstaller les filtres.

Nettoyage de la hotte

Acier inoxydable : Comment préserver son

‘’apparence étincelante’’

À faire :

- Laver régulièrement les surfaces à l’aide d’un chiffon ou

linge propre imbibé d’eau tiède et de savon doux ou de

détergent à vaisselle.

- Toujours nettoyer dans la direction des lignes de grains

(direction du polissage).

- Toujours bien rincer avec de l’eau propre (2 à 3 fois) et

essuyer complètement.

- Un nettoyant domestique conçu spécialement pour l’acier

inoxydable peut aussi être utilisé.

À ne pas faire :

- N’utiliser aucune laine d’acier ou d’acier inoxydable ou tout

autre grattoir pour enlever la saleté tenace.

- N’utiliser aucune poudre nettoyante abrasive ou rugueuse.

- Ne pas laisser la saleté s’accumuler.

- Ne pas laisser la poussière de plâtre ou tout autre résidu de

construction / rénovation atteindre la hotte. Couvrir la hotte pour

la durée des travaux pour s’assurer qu’aucune poussière ne

colle à la surface de l’acier .

À éviter lors du choix d’un détergent :

- Tous produits nettoyant qui comntiennent des agents de

blanchiment ; ils attaqueront l’acier inoxydable.

- Tous produits contenant du chlorure, fluorure, iode ou

bromure ; ils détérioreront rapidement les surfaces.

- Tous produits combustibles utilisés pour le nettoyage :

acétone, alcool, éther, benzol, etc. : ils sont hautement

explosifs et ne devraient jamais être utilisés près d’une cuisinière.

acier inoxydable

dans la

Page 17

PIÈCES COMPRISES

PIÈCES NON COMPRISES

Garantìe Sécurité EntretienFonctionnement Installation Pièces

Lisière de bois

Filtres

(3 par hotte de 30’’ et 36’’)

(4 par hotte de 48’’)

Sac de pièces

(Comprend 4 vis à tête plate #10-2’’,

8 vis #8-3/4’’, 4 écrous #10-32,

2 ancrages de gypse et

2 rondelles 3/16’’ DI x 3/4’’ DE)

PIÈCES OPTIONNELLES

Ampoules halogènes

PAR 20 50W

(3 par hotte)

Lampes chauffantes

BR40, 250W Max.

(2 par hotte)

Ventilateur

(Voir “Système de hotte de cuisinière Jenn-Air JXT-B”

en page 18 pour les numéros de modèle.)

Accessoires pour conduits

(Voir “Système de hotte de cuisinière Jenn-AirJXT-B”

en page 18 pour les modèles.)

Couvre-conduits Pro Style

Description No. de modèle

30’’ Acier inox. JXA9030BDP

36’’ Acier inox. JXA9036BDP

48’’ Acier inox. JXA9048BDP

OUTILS NÉCESSAIRES

Tournevis

(Robertson ou Phillips) Crayon

Ruban à

mesurer

Description No. de modèle

Dosseret Pro Style

30’’ Acier inox. JXA9003BDP

36’’ Acier inox. JXA9002BDP

48’’ Acier inox. JXA9001BDP

Tournevis à

douille 3/8”

Perceuse

Scie

sauteuse

-ou-

passe-partout

Scie

17

Ruban

pour

conduits

Pince à

dénuder

Page 18

Capuchons de

mur ou de toit

SYSTÈME DE HOTTE DE CUISINIÈRE JENN-AIR JXT-B

Coudes et

Volet intérieur

Conduits

Choisir

1 des 5

transitions

Capuchon de toit à

grand rendement

Coude ajustable

10’’ Rond

Conduit rond de 10’’

Capuchon de

mur 10’’ Rond

Volet intérieur vertical

10’’

Capuchon de mur

7’’ Rond

Coude ajustable

7’’ Rond

Conduit rond de 7’’

Capuchon de toit

4 ½’’ x 18 ½’’

à 10’’ Rond,

6’’ haut - latérale

Choisir 1 des 2

systèmes de ventilateur

4 ½’’ x 18 ½’’

à 10’’ Rond

- verticale

4 ½’’ x 18 ½’’

à 10’’ Rd, Horiz.

avant - arrière

Ventilateur/Plaque ventilateur

modèle H326B

(Ventilateur intérieur 1200 pcm

et plaque ventilateur)

4 ½’’ x 18 ½’’

à 10’’ Rd.,

Horiz. / droite

18

4 ½’’ x 18 ½’’

à 10’’ Rd.,

Horiz. / gauche

Couvre-conduits

Pro Style optionnel

(Voir page 17 pour

les nos. de pièce.)

Ventilateur/Plaque

Hotte

(Avec contrôle ventilateur

et éclairage.

Requise pour

toutes les installations)

ventilateur

Modèle H325B

(Ventilateur intérieur

600 pcm et plaque

ventilateur)

Dosseret optionnel Pro Style

(Recouvrement de mur en acier inoxydable

avec tablettes réchaud)

(Voir les nos. de pièces en page 17.)

HL0034

Page 19

PRÉPARATION DE LA LOCALISATION DE LA HOTTE

1. La hotte Jenn-Air utilise uniquement les ventilateurs

intérieurs de modèle H325B ou H326B. Aucun autre

ventilateur ne doit être utilisé.

(Ventilateurs vendus séparément.)

En plus des modèles de ventilateur listés plus haut, la

hotte est aussi compatible avec les versions antérieures

des ventilateurs intérieurs; soit les H325 et H326. Si ces

ventilateurs sont utilisés, jeter les instructions d’installation

incluses avec ces ventilateurs et contacter Jenn-Air pour

recevoir les instructions de remplacement.

Déterminer à quel endroit et de quelle façon les conduits

seront localisés.

Installer les conduits de dimension appropriée,

transition(s), coude(s) et capuchon de toit ou de mur selon

le modèle de ventilateur utilisé.

Pour des résultats optimum, n’utiliser qu’un minimum de

transitions et de coudes.

CAPUCHON DE TOIT

CONDUIT ROND

7" (178 mm)

CHEMINÉE

DÉCORATIVE

ou SOFFITE

HOTTE

12"

(305 mm)

CAPUCHON

DE MUR

COUDE ROND

7" (178 mm)

Garantie Sécurité EntretienFonctionnement PiècesInstallation

2. Les dimensions pour les installations les plus courantes

sont indiquées plus bas.

Ajuster vos mesures selon les différentes hauteurs de

plafond, soffite, armoires ou surfaces de cuisson. Afin

d’assurer un meilleur fonctionnement, la hotte doit être

à un minimum de 24”(610 mm) et à un maximum de 30”

(762 mm) au-dessus de la surface de cuisson.

Pro Style

Distance minimale entre la

hotte et la surface de cuisson

24" À 30" (609 à 762 mm)

AU-DESSUS DE LA

HH0024F

SURFACE DE CUISSON

CONDUITS ST ANDARDS

VENTILA TEUR SIMPLE MODÈLE H325B

CAPUCHON DE TOIT

CONDUIT ROND

10" (254 mm)

CAPUCHON

DE MUR

TRANSITION

4-1/2" x 18-1/2" à

10" (114 x 470 à

(voir page 20)

HH0025F

CHEMINÉE

DÉCORATIVE

ou SOFFITE

24" À 30" (609 à 762 mm)

SURFACE DE CUISSON

(305 mm)

HOTTE

AU-DESSUS DE LA

12"

CONDUITS ST ANDARDS

VENTILATEUR DOUBLE MODÈLE H326B

INSTALLA TION SOUS DES ARMOIRES

ST ANDARDS DE 18’’ HAUT

Pro Style

Pro Style

Distance maximale entre la

hotte et la surface de cuisson

RONDE

254 mm)

INST ALLATION A VEC UN SOFFITE DE 12’’ OU

LE COUVRE-CONDUITS OPT . PRO STYLE

19

Page 20

PRÉPARATION DE LA HOTTE

1. À l’aide d’un tournevis Phillips #2 ou d’un Robertson #2,

retirer les vis retenant la hotte au fond de la caisse. Voir la

figure ci-contre pour localiser les 4 vis. Jeter ces vis et

retirer la hotte de la caisse.

3

4

OPTION

Un dosseret Pro Style est disponible (voir en page 17 pour

plus de détails). Ce dosseret doit être installé avant la hotte

puisque celle-ci couvre les vis d’installation du dosseret. Pour

l’installation du dosseret, s’assurer d’avoir au moins 18” (457 mm)

entre le dessous de la hotte et le panneau de contrôle de la

cuisinière ou de la surface de cuisson. (Voir les instructions

fournies avec le dosseret.)

2. Mesurer puis tracer une ligne droite, au-dessus de la surface

de cuisson, pour la localisation de la lisière de bois. (Voir

l’illustration à droite et ainsi celles de l’étape 2 en page

19). À l’aide de

sac de pièces), fixer la lisière de bois au mur en vous

assurant d’atteindre les montants.

vis à tête plate #10-2” (incluses dans le

A TTENTION : À cause du poids élevé de cette

hotte, s’assurer que la lisière de bois est bien

!

rattachée à tous les montants disponibles (un

minimum de 2 montants doivent être en contact

avec la lisière de bois pour une hotte de 30”,

plus pour une plus large). Ne pas visser la lisière

de bois seulement au mur.

HR0002

1

2

19

20

1. Mur

2. Lisière de bois

3. Vis à tête plate

4. Localisation des ancrages de gypse

5. Arrière de la hotte

6. Montants

Page 21

INSTALLATION DE LA HOTTE

1. En appuyant la hotte au mur, insérer la lisière de bois dans

la cavité arrière de la hotte.

ATTENTION : Retenir la hotte jusqu’à ce qu’elle

!

soit complètement vissée à la lisière de bois.

Fixer la hotte à la lisière de bois à l’aide des (4) vis #8 - 3/4”

incluses (pour une hotte de 30” ou 36” de largeur) ou (6)

vis (pour une hotte de 48” de largeur), aux endroits

indiqués. En se servant des trous existants dans la paroi

arrière de la hotte, percer (2) trous de 3/16” pour les

ancrages de gypse, aux endroits indiqués. Puis, insérer

ancrages de gypse et fixer la hotte à ces ancrages

les (2)

avec les

2. Fixer la transition (si requise) à la plaque ventilateur. Voir

en page 18 pour les modèles disponibles.

Sceller tous les joints avec du ruban à conduit.

NOTE

La plaque ventilateur du modèle H325B à un ventilateur se

branche directement à un conduit rond de 7”, sans transition.

vis #8 - 3/4” restantes et les (2) rondelles fournies.

Garantie Sécurité Fonctionnement PiècesInstallation

Dessus de la hotte

(Vue de l’intérieur)

Localisation des vis

Paroi arrière de la hotte

(Vue de l’intérieur)

Localisation des ancrages de gypse

HD0064

3. Amener le câble d’alimentation à la localisation de la hotte.

Voir les instructions incluses avec le ventilateur et sa plaque

ventilateur, pour les détails concernant l’installation de la

plaque ventilateur (vendue séparément). Installer la plaque

de façon à ce que son boîtier électrique soit à droite lorsque

vous faites face à la hotte.

Si l’évacuation par l’arrière est choisie, retirer la plaque de

la hotte et l’installer sur le dessus pour couvrir l’ouverture.

Fixer à la hotte avec les mêmes (4) écrous dentelés.

Pour une évacuation par le dessus, la plaque de la hotte

demeure en place sur la paroi arrière de la hotte.

Relier le conduit rond à la transition ou à la plaque

ventilateur. Sceller tous les joints avec du ruban à conduit.

HD0049

HD0063

Plaque sur le dessus de

la hotte

Écrous

Plaque ventilateur sur la

paroi arrière de la hotte

Écrous

Entretien

Couvercle

du boîtier

électrique

21

Page 22

BRANCHEMENT ÉLECTRIQUE

AVERTISSEMENT : Risque de choc électrique.

Le raccordement électrique doit être effectué

par du personnel qualifié conformément aux

codes et standards. Avant d’effectuer le

branchement, couper l’alimentation électrique

au panneau de service et le verrouiller pour

éviter une mise en marche accidentelle.

SCHÉMA ÉLECTRIQUE

N

VERS MOTEUR

N

B

HS

N

BORNIER

B

B

B

B

B

PRISE

NEMA

5-15P

120V 60Hz

B N

V

THERMOSTAT

CONTRÔLE DE

VITESSE

1. Retirer le couvercle du boîtier électrique de la plaque

ventilateur et mettre de côté.

2. Retirer l’ouverture pré-amorcée du boîtier électrique. En

installant la plaque ventilateur, insérer une longueur de 6’’ de

câble d’alimentation dans le boîtier électrique par son ouverture

et brancher le câble en utilisant le connecteur approprié.

3. Effectuer le branchement électrique en reliant le fil NOIR

au NOIR, le BLANC au BLANC et le fil VERT ou dénudé à

la vis VERTE de mise à la terre. Réinstaller le couvercle du

boîtier électrique.

INTER. LAMPE

CHAUFFANTE

DROITE

INTER. VENTILATEUR

N

INTERRUPTEUR

N

D’ÉCLAIRAGE

N

INTER. LAMPE

CHAUF. GAU.

B

B

DOUILLE LAMPE

CHAUFFANTE DROITE

N

DOUILLE D’AMPOULE

B

N

DOUILLE AMPOULE CENT.

N

DOUILLE AMPOULE GAU.

N

DOUILLE LAMPE CH. GAU.

N

B

DROITE

B

B

B

B

FINALISATION DE L’INSTALLATION

OPTION

Un couvre-conduits Pro Style est disponible - afin de cacher

les conduits si la hotte n’est pas installée sous des armoires.

Vo ir les instructions fournies avec le couvre-conduits optionnel.

V oir en page 17 pour les détails de commande.

1. Pour installer le ventilateur, voir les instructions fournies

avec celui-ci. Une fois installé, brancher le ventilateur et le

cordon de la boîte électrique aux prises, à l’intérieur de la

hotte. NE PAS brancher ensemble les 2 cordons.

V oir en page 18 pour les détails concernant le ventilateur

et la plaque ventilateur.

2. Installer (2) lampes chauffantes. Utiliser des ampoules

infrarouges de format BR40, 250W Max. (non incluses).

Installer (3) ampoules halogènes. Utiliser des ampoules

de format PAR20 50W (non incluses).

22

HE0003

Page 23

INSTALLATION DES FILTRES

ATTENTION : Retirer le film de plastique

!

protecteur des filtres avant de les installer.

Il est recommandé d’installer d’abord les filtres situés aux

extrémités et de terminer par celui (ou ceux) du centre.

1) Insérer la partie supérieure du filtre dans la hotte (côté de

la languette).

2) Faire pivoter la partie inférieure vers l’intérieur de la hotte.

3) Placer le filtre sous l’attache située au fond de la hotte.

4) En utilisant la languette, glisser le filtre sous la pièce de

retenue intérieure.

1

2

Garantie Sécurité Fonctionnement PiècesInstallation

4

3

HD0024

Des filtres de remplacement sont disponibles.

V oir en dernière page pour les détails de commande.

HD0075

Entretien

23

Page 24

PIÈCES DE REMPLACEMENT

20

1

21

14

12

13

7

2

HL0031

4

8

9

NO. RÉF. PIÈCE NO. DESCRIPTION

1 V05617 Logo

Jenn-Air

2 V02264 Douille de porcelaine

3 V02773 Connecteur mâle pour moteur

4 V02772 Connecteur femelle pour moteur

5 V03435 Thermostat

6 V03436 Support pour thermostat

7 V02563 Interrupteur simple UPST pour

lampe chauffante

8 V03502 Interrupteur double UPST pour

lampe halogène

9 V03503 Interrupteur simple illuminé UPST

pour ventilateur

10 V03504 Bouton contrôle de vitesse

1 1 V03501 Contrôle de vitesse

12 V03505 Plaque à bornes

** V03517 Cordon d’alimentation

** V03519 Fil de contrôle

** V03520 Fil de l’interrupteur illuminé

13 V00673 Écrou dentelé 8-32

14 V02512 Vis mécanique 8-32 x ½

15 V01869 Vis mécanique 6-32 x ¼

19

17

18

11

3

10

16

6

5

15

7

2

22

20

NO. RÉF . PIÈCE NO. DESCRIPTION

16 V01582 Écrou 6-32

17 V05730 Filtre pour hotte de 30”

9.5 x 15.25 x 0.355 (3 requis)

V05731 Filtre pour hotte 36”

1 1.61 x 15.25 x 0.355 (3 requis)

V05731 Filtre pour hotte 48”

1 1.61 x 15.25 x 0.355 (4 requis)

18 V14763 Gouttière 30”

V14764 Gouttière 36”

V14766 Gouttière 48”

19 V05528 Ressort de filtre 5.265” x 0.350”

20 V05521 Extrusion d’étanchéité 20.625”

21 V14744 Paroi intérieure gauche

22 V14745 Paroi intérieure droite

** V05729 Guide d’installation Jenn-Air

** V12971 Sac d’installation (vis à tête plate

#10 x 2” (4), vis #8 x 3/4” (8), écrous

#10-32 (4), Ancrages de gypse (2),

rondelles 3/16” DI x 3/4” DE (2))

** V02544 Ampoule halogène P AR20 50W

* Ampoule chauffante BR40, 250W max.

Commander les pièces par le No. DE PIÈCE - pas le No. RÉF .

* Pièce standard - s’approvisionner localement.

** Non illustré.

Page 25

Campana de cocina

Serie JXT-B

Manual de uso y cuidado / instalación

Modelos JXT9030BDP (Largo : 30” - Acero inoxidable)

JXT9036BDP (Largo : 36” - Acero inoxidable)

JXT9048BDP (Largo : 48” - Acero inoxidable)

HB0026

! !

CONCEBIDO SÓLO PARA USO DOMÉSTICO

V05729 rev. A JENN-AIR COMPANY, One Dependabilty SQ., Newton, Iowa 50208-0039 www.jennair.com

Page 26

LEA Y CONSERVE ESTAS INSTRUCCCIONES

TABLA DE CONTENIDO

SECCIÓN ................................................................ PÁGINA

Garantia............................................................................. 26

Instrucciones de seguridad .............................................. 2 7

Operación.......................................................................... 28

Limpieza ............................................................................ 28

Piezas incluidas ................................................................ 29

Piezas non incluidas ......................................................... 2 9

Piezas opcionales ............................................................ 29

Herramientas necesarias ................................................. 29

SECCIÓN ................................................................ PÁGINA

Sistema de la campana Jenn-Air ..................................... 30

Prepare la localización para la campana........................ 3 1

Prepare la campana ......................................................... 32

Instale la campana ............................................................ 3 3

Conecte el cableado ......................................................... 34

Esquema eléctrico ............................................................ 34

Terminar la instalación ...................................................... 34

Instale los filtros ................................................................ 35

Piezas de servicio ............................................................. 36

GARANTIA

GARANTÍA DE JENN-AIR

Felicitaciones por la compra de un electrodoméstico Jenn-Air. Deseamos expresarle nuestra confianza en el producto notificándole nuestra

garantía. Todos los electrodoméstico Jenn-Air tienen como mínimo una garantía completa durante el primer año en el caso de las piezas y la

mano de obra, más una garantía limitada durante el segundo año sólo en el caso de las piezas. Las garantías comienzan en la fecha de la

compra. La siguiente tabla contiene detalles específicos por categoría de productos. A lo largo de la parte superior se listan los años

posteriores a la fecha de la compra original.

AÑOS

PRODUCTO 1 2 3 4 5

Superficie para Superficie de cerámica y vidrio, debido a rompiento térmico.

cocinar, estufa, Radiante de halógeno y sólido falla del elemento.

horno de pared . Componentes

(gas o eléctrico)

Mano de obra Sí de control

Accesorios Falla del elemento radiante, de halógeno y sólido.

Piezas Todas Todas

del panel

electrónico

Piezas Todas Todas

Superficie de cerámica y vidrio, debido a rompiento térmico.

Mano de obra Sí

Limitada al magnetrón, conjunto de la almohadilla

Combinatción Piezas Todas Todas sensible al tacto,microprocesador, transformador

microondas de potencia y del microprocesador,

de pared condensador, rectificador, conjunto de triac

o horno Componentes Limitada al magnetrón, conjunto de la almohadilla

microondas Mano de obra Sí del panel sensible al tacto,microprocesador, transformador

de control de potencia y del microprocesador,

electrónico condensador, rectificador, conjunto de triac

RESPONSABILIDADES DEL PROPIET ARIO

El cliente tiene ciertas responsabilidades que debe cumplir para tener derecho a la cobertura de estas garantía. Respecto a todos los

productos, el dueño es responsable de proporcionar cuidado y mantenimiento normales de acuerdo con las instricciones de uso uy cuidado,

proporcionar el comprobante de la compra cuando se le solicite, instalar el electrodoméstico adecuadamente y de manera que quede

accesible para darle servicio. Las garantías cubren fallos durante el uso doméstico normal.

SERVICIO BAJO LA GARANTÍA

Bajo la garantía completa, el servicio debe realizarlo un contradista de servicio autorizado por Jenn-Air. Para obtener servicio, comuníquese

con la concesionaria donde compró la unidad, con un contratista de servicio autorizado, o comuníquese con Jenn-Air Customer Assistance,

c/o Maytag Customer Service, P.O. Box 2370, Cleveland, TN 37320-2370, 1-800-688-1100. Por favor incluya en toda la correspondencia el

número de modelo, el número de serie y la fecha de la compra minorista original. El servicio se proporcionará durante las horas hábiles normales.

Todas las piezas de repuesto asumen la porción no usada de esta garantía.

La garantía limitada de las piezas sólo cubre el costo de las piezas. Los cargos de viaje, transportación y mano de obra son responsabilidad del propietario.

Esta garantía le da derechos legales específicos, y usted puede tener otros derechos que varían entre estados.

RESIDENTES DE CANADÁ

Esta garantía cubre sólo aquellos electrodomésticos instalados en Canadá que se han listado en la Asociación de Normas Canadienses de

la Asociación Canadiense de Gas (Canadian Standards Association of Canadian Gas Association) a menos que los electrodomésticos se

hayan llevado a Canadá debido a una transferencia de residencia, de Estados Unidos a Canadá.

PARA GARDAR EN SUS ARCHIVOS

Anote la siguiente información y conserve esta hoja completa para consultarla en el futoro.

Número de modelo Número de serie Fecha de la compra

JENN-AIR COMPANY

ONE DEPENDABILTY SQ.

NEWTON, IOWA 50208-0039

26

Page 27

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE

ELECTRICO, O LESION A PERSONAS, PROCURE LO

SIGUIENTE:

Garantìa Seguridad LimpiezaOperación Instalación Piezas de servicio

ADVERTENCIA

PARA EVITAR RIESGO DE LESIONES PERSONALES EN

CASO DE INCENDIO DE GRASA EN LA SUPERFICIE DE

LA ESTUFA, OBSERVE LO SIGUIENTE:*

1. Utilice esta unidad sólo en la manera prescrita por el

fabricante. Si tiene usted alguna pregunta, comuníquese

con el fabricante a la dirección indicados en la garantía.

2. Antes de efectuar algún servicio o limpieza, se debe

desconectar la corriente eléctrica en el armario de circuitos

y asegurarlo con llave para evitar que la corriente sea

conectada accidentalmente. Cuando el dispositivo para

desconectar el servicio eléctrico no puede ser cerrado

con algùn tipo de traba, sujete fuertemente al panel de

servicio, una etiqueta de advertencia prominente.

3. Todo trabajo de instalación y cableado eléctrico debe ser

realizado por personal calificado y de acuerdo con todos

los códigos y normas pertinentes, incluyendo los códigos

y normas relacionados con construcción clasificada para

incendio.

4. Aire suficiente es necesario para facilitar la combustión

adecuada y la salida apropiada de gases por la chimenea

de la unidad y para evitar corrientes de aire invertidas.

Siga las instrucciones y medidas de seguridad del

fabricante del equipo y los publicados por la Asociaciòn

nacional de protecciòn contra incendidos (NFPA por sus

siglas in Inglés), y la Sociedad americana de ingenieros

de calefacciòn, refrigeraciòn y aire acondicionado

(ASHRAE por sus siglas in Inglés), y los reglamentos de

seguridad locales.

5. A cortar o perforar la pared o el techo, no dañe el cableado

eléctrico ni otros servicios públicos ocultos a la vista.

6. No utilice este ventilador con ningún dispositivo de una

control de velocidad de estado sólido adicional.

7. Los abanicos con ducto deberán siempre tener una salida

hacia el exterior.

8. Para reducir el riesgo de incendio, use sólo ductos de

metal.

9. Esta unidad se debe instalar con tierra efectiva.

PARA REDUCIR EL RIESGO DE INCENDIO DE GRASA

EN LA SUPERFICIE DE LA ESTUFA:

1. No deje nunca los aparatos de cocer sin vigilencia a fuego

vivo. Los desbordamientos producen humo y derrames

grasiendos que pueden inflamarse. Caliente el aceite

despacio, a fuego lento o mediano.

2. Ponga en marcha siempre la campana al cocinar a

temperaturas elevadas o al cocinar alimentos flameados.

3. Limpie con frecuencia los ventiladores. No debe permitir

que la grasa se acumule en el ventilador ni en el filtro.

4. Utilice un sartén de tamaño adecuado. Siempre utilice el

utensilio adecuado al tamaño del elemento de superficie.

1. Cubra y sofoque las llamas con una tapa ajustada, azafate

de hornear galletas, o azafate de metal, y luego apague el

calentador. TENGA CUIDADO PARA EVITAR QUEMADURAS.

Si las llamas no se apagan inmediatamente, HAY QUE

EVACUAR Y LLAMAR LOS BOMBEROS.

2. NUNCA ALCE UNA SARTÉN QUE TENGA LLAMAS - Usted se

puede quemarse.

3. NO UTILICE AGUA, incluyendo trapos, lavaplatos mojados

o toallas - puede que occuran explosiones de vapor

violentas.

4. Utilice un extinguidor SOLAMENTE si:

A. Usted sabe que tiene un extinguidor de clas ABC y lo sabe

utilizar.

B. El incendio es pequeño y contenido dentro del área donde

se inició.

C. Los bomberos han sido avisados.

D. Usted puede combatir el incendio con una salida a su

espalda.

* Basado en las recomendaciones para “Seguridad en la

Cocina” publicadas por la NFPA de los EEUU.

PRECAUCIÕN

1. Sólo para uso de ventilación general. No se use para extra

materiales o vapores peligrosos o explosivos.

2. Para evitar daños al cojinente del motor y/o impulsores

ruidosos o desequilibrados, mantenga la fuente de

potencia lejos de rocíos de pared seca, de polvo de

construcciòn, etc.

3. El motor dela campana tiene un dispositivo contra

sobrecargas térmicas que apaga el motor en forma

automática si éste se sobrecalienta. El motor volverá

arrancar cuando se enfríe. Si el motor sigue apagándose,

haga verificar la campana.

4. Para lograr una mejor captura de las impurezas producidas

al cocinar, la parte inferior de la campana deberá estar a

un mínimo de 24’’ y un máximo de 30’’ sobre el nivel la

superficie para cocinar.

5. A fin de reducir los riesgos de incendio y para bien evacuar

el aire de salida, asegúrese de evacuar el aire al exterior No evacue el aire en espacios limitados como el interior de

la paredes o deltecho e en el desván, falso techo o garaje.

6. Este producto está equipado de un termostato que puede

hacer partir el ventilador automáticamente. Para evitar los

riesgo de daño, apague la corriente de panel eléctrico y

cierre con candado o afiche una advertancia en el panel

para prevenir que la campana funcione automáticamente.

7. La campana Jenn-Air debe ser instalada con ventiladores

modelos H325B o H326B solamente. Otros ventiladores no

debe ser utilisado. (Ventiladores vendidos separadamente.)

8. Utilíce sólo con un conjunto autorizado de conexión con

cordón.

9. Por favor, lea la etiqueta de especificaciones en el producto

para mayor información y requisito.

!

27

Page 28

OPERACIÓN

LIMPIEZA

Siempre hacer funcionar la campana antes de comenzar a

cocinar a fin de establacer una circulación de aire en la cocina.

Deje igualmente funcionar la campana algunos minutos después

de que pare de cocinar a fin de limpiar el aire. Esto ayuda a

concervar la cocina mas limpia y un aire puro.

HC0004K

4

5

3

3

1

2

6

1

3

1. Lámparas termogénas

2. Interruptores de lámparas termogénas

3. Luces halógenas

4. Interruptor de luces halógenas

5. Interruptor de encender/apagar del ventilador

6. Control de velocidad del ventilador

Lámparas termogénas: Cada lámpara es controlada

independientemente con su propio interruptor. Utilice las

bombillas infrarrojas (BR40, 250W max.)

ADVERTENCIA: No dejar materias inflamables

en los estantes que calientan.

Luces halógenas: Los dos interruptores de encender/apagar

controlan las luces halógenas.

El interruptore a báscula antes, controla la luz del centro. El

interruptor detrás controla las luces de cada lado. Encenda

una, dos o tres luces según su necesidad.

Utilice las bombillas de halógenas PAR 20, 50W (comprar

separadamente; refierse a la página 29 para información

sobre pedido).

Ventilador: El ventilador funciona con la ayuda de dos controles.

Utilice el interruptor endender/apagar tiene una luz roja para

encender y apagar el ventilador. Cuando está en tensión, el

ventilador funciona a la velocidad utilizada la última vez.

Utilice el control de velocidad del ventilador girando en el

sentido de las agujas del reloj para disminuir la velocidad y

en el sentido contrario de las agujas del reloj para augmentar

la velocidad.

HEAT SENTRY

Su campana esta equipida con HEAT SENTRY

termostato tiene un mecanismo que se encenderá o acelerará

el ventilador si se detecta un calor excesivo encima de la

cocina.

1) Si el ventilador esta apagado - el se penderá a una velocidad

máxima.

2) Si el ventilador esta encendiro a una velocidad mínima - el

se penderá a una velocidad máxima.

Cuando la temperatura disminuye a un nivel normal, el

ventilador vuelve a la función de origen.

TM

ADVERTENCIA: El HEA T SENTRY

TM

TM

termostato

. Este

puede comenzar a funcionar al igual si la

campana esta parada. Cuando este situación

ocurre, es imposible parar el ventilador con los

interruptores. Si usted para la campana, halago

a partir del pânel eléctrico principal.

28

Filtros para grasa

Limpie frecuentemente los filtros con agua caliente y un

detergente suave. Los filtros se pueden lavar en lavaplatos.

Limpie más seguido si su comida crea mucho grasa - como

fritura o preparar la comida con wok.

Empuje los filtros hacia el interior de la campana y leberelos

del canal para que en seguida los retire de la campana.

Limpieza del ventilador

Quitar los filtros para grasa a fin de que tener acceso al

ventilador. Pasar la aspiradora en el ventilador por limpiar.

No permita la entrada de agua en el ventilador. Para más

información, refierse a el manual del ventilador.

Canal

Limpie frecuentemente el canal. Quite los filtros, después

dejunta el canal de la campana en quita los 3 tornillos. Ver

dibujo de abajo.

HD0069

Vea

Acero inoxidable

abajo. Una vez que el canal este limpio y seco, instale en la

campana y instale los filtros.

Limpieza de la campana

Acero inoxidable: Como mantener una ‘’aparencia brillante’’

Lo que debe hacer:

- Lavar regulamente la superficie con un trapo o un paño

empapado de agua tibia y de jabón suave o detergente a vajilla.

- Siempre limpie en el sentido de las líneas originales de pulimento.

- Siempre enjuague bien con agua limpia (2 a 3 veces) después

de haber limpiado seque completamente la superficie.

- Usted puede utilizar un limpiador doméstico hecho

especialmente para el acero inoxidable.

Lo que no debe hacer:

- No utilice ninguna lana de acero o de acero inoxidable o

todo otro raspador para quitar la suciedad tenaz.

- No utilice ningún limpiador en polvo abrasivo o riguroso.

- No deje la suciedad acumularse.

- No deje el polvo de yeso o todo otro residuo de construcción

que caiga en la campana, cúbrala durante el trabajo para

asegurarse que en ningún caso el polvo se pegue a la

superficie del acero.

A evitar cuando elige un detergente:

- Todos los productos de limpieza que contienen agentes de

blanqueo; van a deteriorar el acero inoxidable.

- T odos los productos que contienen cloruro, fluoruro, yoduro

o bromuro; estos deteriorans rápidamente las superficies.

- Todos los productos combustible utilizados para la limpieza:

acetona, alcohol, éter, benzol, etc...; son extremamente

explosivos y no deben ser utilizados cerca de una cocina.

en la parte Limpieza de la campana

Page 29

PIEZAS INCLUIDAS PIEZAS NO INCLUIDAS

Garantìa Seguridad LimpiezaOperación Instalación Piezas de servicio

Tira de madera

Filtros para grasa

(3 para campana de 30’’ y 36’’)

(4 para campana de 48’’)

Bolsa de piezas

(incluye 4 tornillos #10-2’’,

8 tornillos #8-3/4’’, 4 tuercas #10-32,

2 anclas de la pared y

2 arandelas 3/16’’ ID x 3/4’’ OD)

PIEZAS OPCIÓNAL

Bombillas

PAR 20 50W

(3 para campana)

Lámpara termogéna

BR40, 250W Max.

(2 para campana)

Ventilador