Page 1

RANGE HOOD

Model Number: JXT8836AD$

Manufacturer Number: S88M90$

Size: 36"

INSTALLATION

GUIDE

TABLE OF CONTENTS

Safety nstructions .................................................... 1

Mounting Heights ........................ 3

Ducting .................................................................... 4

Specifications ........................................................... 5

Insta Ilation ............................................................ 6-7

Form No. A/04/03 Part No. US8800-0303A _2003 Maytag Appliances Sales Co. Litho U.S.A.

Page 2

MODEL: JXT8836ADS

Installation

Theinstallationinthis manualisintendedforqualifiedinstallers,servicetechniciansorpersons

withsimilarqualifiedbackground.DONOTattemptto installthisapplianceyourself.Injurycould

resultfrominstallingtheunit dueto lackof appropriateelectricalandtechnicalbackground.

All electricalwiringmust beproperlyinstalled,insulatedandgrounded.Overlyaccumulated

greaseinoldductworkshouldbecleanedout orductworkshouldbereplacedif necessaryto

avoidthepossibilityofa greasefire.Checkalljoints onductworkto insureproperconnection

andalljointsshouldbeproperlytaped.

* Please check for latest specification revisions before any custom work or cutouts.

Page 3

INSTALLATION

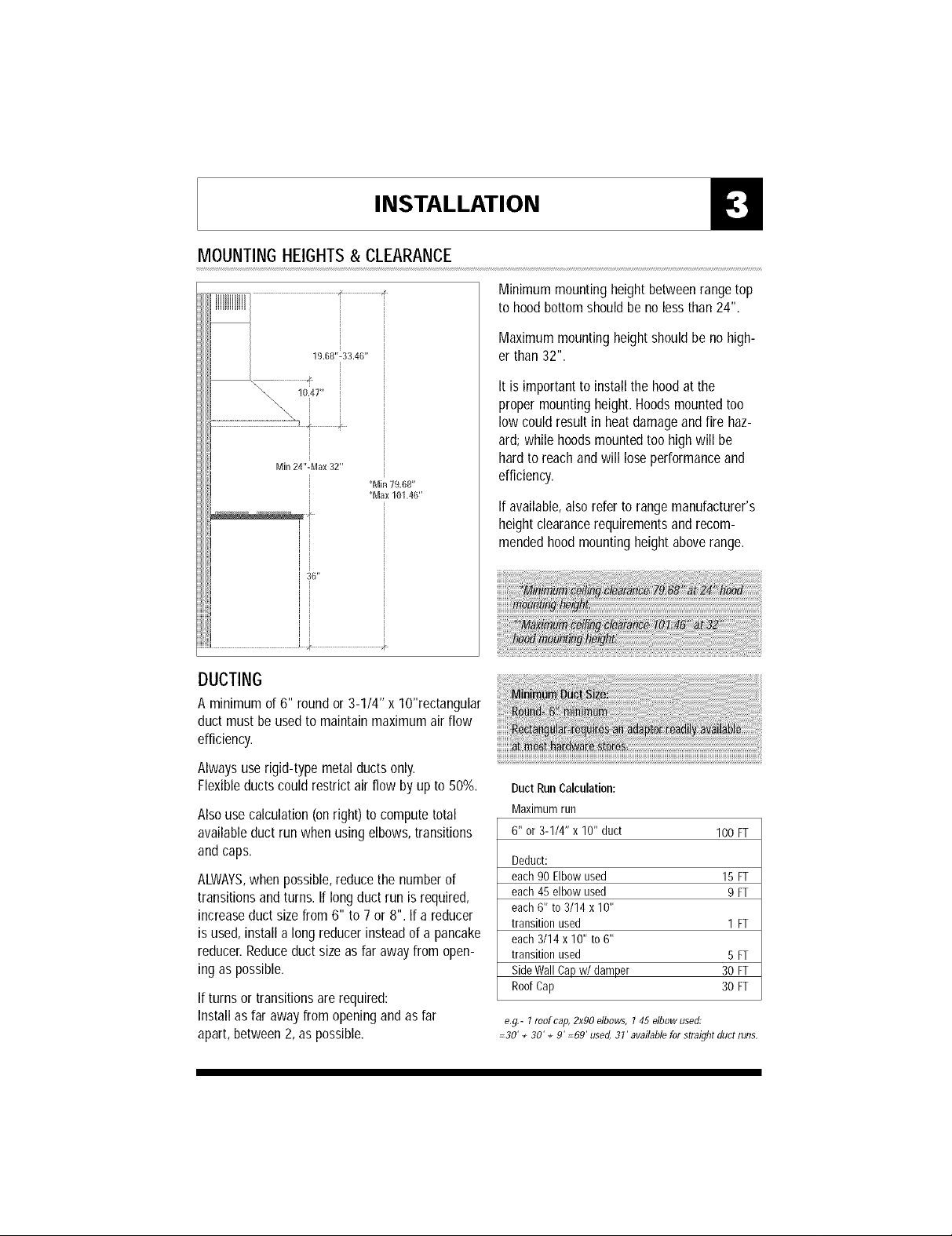

MOUNTINGHEIGHTS& CLEARANCE

Minimummountingheightbetweenrangetop

to hoodbottomshouldbeno lessthan24".

Maximummountingheightshouldbe nohigh-

er than32".

It is importanttoinstallthe hoodatthe

propermountingheight.Hoodsmountedtoo

lowcouldresultin heatdamageandfire haz-

ard;whilehoodsmountedtoohighwillbe

hardtoreachandwillloseperformanceand

efficiency.

If available, alsorefer to rangemanufacturer's

height clearancerequirements and recom-

mended hood mounting height aboverange.

DUCTING

Aminimum of 6" round or 3-1/4" x lO"rectangular

duct must be used to maintain maximum air flow

efficiency.

Alwaysuserigid-typemetalductsonly.

Flexibleductscouldrestrictair flowbyupto 50%.

Alsouse calculation (onright) to compute total

availableduct run when using elbows, transitions

andcaps.

ALWAYS,when possible, reduce the number of

transitions and turns. If long duct run is required,

increase duct size from 6" to 7 or 8". If a reducer

is used, install a long reducer instead of a pancake

reducer.Reduceduct size as far away from open-

ing as possible.

If turns or transitions are required:

Install as far away from opening and asfar

apart, between 2, as possible.

Duct Run Calculation:

Maximumrun

6" or 3-1/4" x 10" duct

Deduct:

each90 Elbowused 15 FT

each45 elbow used 9 FT

each6" to 3/14 x 10"

transitionused 1 FT

each3/14 x 10" to 6"

transitionused 5 FT

SideWallCapw/damper 30 FT

RoofCap 30 FT

e.g.- 1roof cap, 2x90 elbows, 1 45 elbow used:

=30' + 30' + 9' =69' used, 31' available for straight duet runs.

1O0 FT

Page 4

INSTALLATION

DUCTING

NEVERexhaust air or terminate duct work into spaces between walls, crawl spaces,ceiling, attics or

garages. All exhaust must beducted to theoutside.

UseMetal ductwork only.

Fastenall connectionswith sheet metal screws and tape alljoints w/certified Silver Tapeor DuctTape.

SomeDucting Options:

sidewall cap

®/gravity damper

i 1

-\

Soffitor crawtspace

Page 5

SPECIFICATIONS

ELECTRICAL

INSTALLATION

/

All Electricalworkmustbyperformedbyqualifiedelectricianor personwithsimilar technical

knowhowandbackground.

Forpersonalsafety,removehousefuseoropencircuitbreakerbeforebeginninginstallation.

Donotuseextensioncordoradapterplugwith thisappliance.

FollowNationalelectricalcodesor prevailinglocalcodesandordinances.

ElectricalSupply:

Thisappliancerequiresa 120V60Hzelectricalsupply.,andconnectedtoan individual,properly

groundedbranchcircuit,protectedbya 15or 20 amperecircuitbreakerortimedelayruse.Wiring

mustbe2 wirew/ground. PleasealsoreferElectricalDiagramlabeledon product.

CableLock:

Acablelockingconnector(not

supplied)mightalsorequiredby

localcodes.Checkwith local

requirementsandcodes,purchase

andinstallappropriateconnectorif

necessary.

CaNe Lock

<...

Page 6

INSTALLATION

MOUNTINGTHERANGEHOOD

I

I

I

1.Determinehood height, center, mark, level and hang hoodto wall through mounting keyholes on back.

2. Installduct work and electrical.

3. Centerand fasten bracket for upper telescopic duct cover onto the wall.

4. Slip upper and lower telescopic duct covers onto top of blower and screw in place.

5. Secure hood towall studs whenever possible; use appropriate wall fasteners & hardware

(notsupplied) for hollow drywall, tiled, concrete, brick wall applications for mounting hood..

Page 7

INSTALLATION

DUCTLESS CONVERSION

Ductlessconversion is intendedfor applications where an exhaust duct work is not possible to be

installed.When converted, the hoodfunctions as a "purifying" hood rather than an exhaust hood.

Fumesand exhaustfrom cooking is drawn and filtered bya set of optionalCarbonFilters.The air

is then purified and re-circulated back within the home.

Werecommend to ALWAYSexhaust air outside of the home by employing existingor installing

new duct work, if possible. The hood is mosteffective andefficient as an Exhaustunit. Onlywhen

the exhaust option is not possible should you recourse to converting the hood into a "purifying"unit.

Whenconverted to be a "purifying" unit, a set of Carbon Filtersare required ontop of itsstandard

Metal Filter set. Order according to its Part number below. The standard Metal Filtersare intended

to capture residue from cooking and the optional Carbon Filters help to purify fumes exhausted

from cooking for re-circulation.

CarbonFilters (Required)

1.PurchaseductlessCarbonFiltersas follows:

Hood Model: Part No. Filters in pkg.

JTX8836ADS JFLTRC8836 3

2. Remove metal filters on hood.Clip

carbonfilters onto each filter.

3. Re-install metal filters.

4. Turnon filter change indicator on

control panel.

5. Carbon Filters must be replaced after

every 120 hoursof use (or approximately

every 2 to 3 months basedon the average

of 1-2 hrs. of dailycooking time). The

microprocessor in the controlswhen set,

will count usage time and indicate when

carbonfilter replacement is required.

6" strah

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii J

Ducting

1. Install a 6" straight pipe and a "T" connector/

or a 90 elbowto divert air through louvers on

duct cover.

Loading...

Loading...