Page 1

RANGE HOOD

Model Number: JXT8136ADS JXT8142ADS

Manufacturer Number: S98M90S S98E42S

Size: 35-3/8” (90 cm) 42”

INSTALLATION

GUIDE

TABLE OF CONTENTS

Safety Instructions.................................................... 1

List of Materials....................................................... 2

Mounting Heights.................................................... 3

Ducting....................................................................4

Specifications...........................................................5

Installation............................................................6-8

Form No. A/04/03 Part No. IS9800-0303A ©2004 Maytag Appliances Sales Co. Litho U.S.A.

Page 2

INSTALLATION GUIDE

Read all Instructions before Installing and operating this appliance

MODEL: JXT8136ADS JXT8142ADS

IMPORTANT SAFETY NOTICE

WARNING

Installation

The installation in this manual is intended for qualified installers, service technicians or persons

with similar qualified background. DO NOT attempt to install this appliance yourself. Injury could

result from installing the unit due to lack of appropriate electrical and technical background.

All electrical wiring must be properly installed, insulated and grounded. Overly accumulated

grease in old duct work should be cleaned out or duct work should be replaced if necessary to

avoid the possibility of a grease fire. Check all joints on duct work to insure proper connection

and all joints should be properly taped.

This appliance weighs 75 lbs. Two persons are required to lift this appliance during installation.

* Please check for latest specification revisions before any custom work or cutouts.

Page 3

LIST OF MATERIALS

1 - Hood Body

1 - Duct Cover Assembly (2 pieces)

1 - Parts Bag:

1 - Duct Cover Mounting Bracket

2 - Mounting Brackets

Packet of Mounting Screws

2 - Metallic Filters

1 - Metallic Bitterfly Damper

NO DUCTING IS INCLUDED

2

Page 4

INSTALLATION

29"-46.65"

5.31"

36"

Min 24"-Max 32"

*Min 89.94"

*Max 113.71"

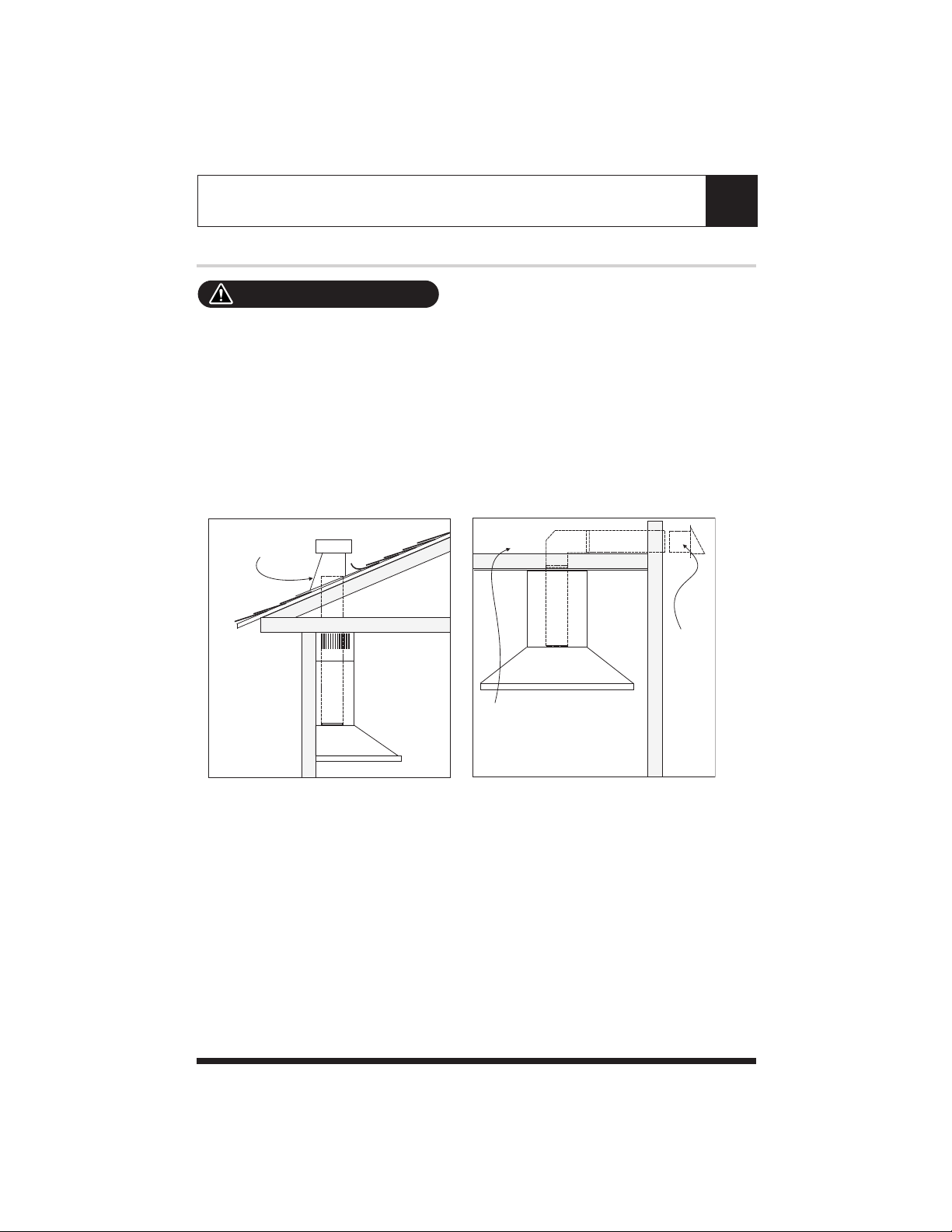

MOUNTING HEIGHTS & CLEARANCE

3

Minimum mounting height between range top to

hood bottom should be no less than 24".

Maximum mounting height should be no higher

than 32".

It is important to install the hood at the

proper mounting height. Hoods mounted too low

could result in heat damage and fire hazard;

while hoods mounted too high will be hard to

reach and will lose performance and efficiency.

If available, also refer to range manufacturer's

height clearance requirements and recommended hood mounting height above range.

Extension kits available to accommodate

10’-12’ ceilings.

*Minimum ceiling clearance 89.94” at 24” hood

mounting height.

**Maximum ceiling clearance 113.71" at 32"

hood mounting height.

DUCTING

A minimum of 6" round or 3-1/4” x 10"rectangular

duct must be used to maintain maximum air flow

efficiency.

Always use rigid-type metal ducts only.

Flexible ducts could restrict air flow by up to 50%.

Also use calculation (on right) to compute total

available duct run when using elbows, transitions

and caps.

ALWAYS, when possible, reduce the number of

transitions and turns. If long duct run is required,

increase duct size from 6" to 7 or 8". If a reducer

is used, install a long reducer instead of a pancake

reducer. Reduce duct size as far away from opening as possible.

If turns or transitions are required:

Install as far away from opening and as far

apart, between 2, as possible.

Minimum Duct Size:

Round- 6" minimum

Rectangular-requires an adaptor readily available

at most hardware stores.

Duct Run Calculation:

Maximum run

6" or 3-1/4” x 10" duct

Calculated Length:

each 90 Elbow used

each 45 elbow used

each 6" to 3/14 x 10"

transition used

each 3/14 x 10" to 6"

transition used

Side Wall Cap w/ damper

Roof Cap

e.g.- 1 roof cap, 2x90 elbows, 1 45 elbow used:

=30' + 30' + 9' =69' used, 31' available for straight duct runs.

100 FT

15 FT

9 FT

1 FT

5 FT

30 FT

30 FT

Page 5

INSTALLATION

side wall cap

w/ gravity damper

Soffit or crawl space

side wall cap

w/ gravity damper

side wall cap

w/ gravity damper

Soffit or crawl space

Roof Pitch w/

Flashing & Cap

4

DUCTING

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces, ceiling,attics or

garages. All exhaust must be ducted to the outside.

Use Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints w/ certified Silver Tape or DuctTape.

Some Ducting Options:

Page 6

SPECIFICATIONS

Cable Lock

ELECTRICAL

INSTALLATION

5

WARNING

All Electrical work must by performed by qualified electrician or person with similar technical

know how and background.

For personal safety, remove house fuse or open circuit breaker before beginning installation.

Do not use extension cord or adapter plug with this appliance.

Follow National electrical codes or prevailing local codes and ordinances.

Electrical Supply:

This appliance requires a 120V 60Hz electrical supply., and connected to an individual, properly

grounded branch circuit, protected by a 15 or 20 ampere circuit breaker or time delay fuse. Wiring

must be 2 wire w/ ground. Please also refer Electrical Diagram labeled on product.

Cable Lock:

A cable locking connector (not

supplied) might also required by

local codes. Check with local

requirements and codes, purchase

and install appropriate connector if

necessary.

Page 7

INSTALLATION

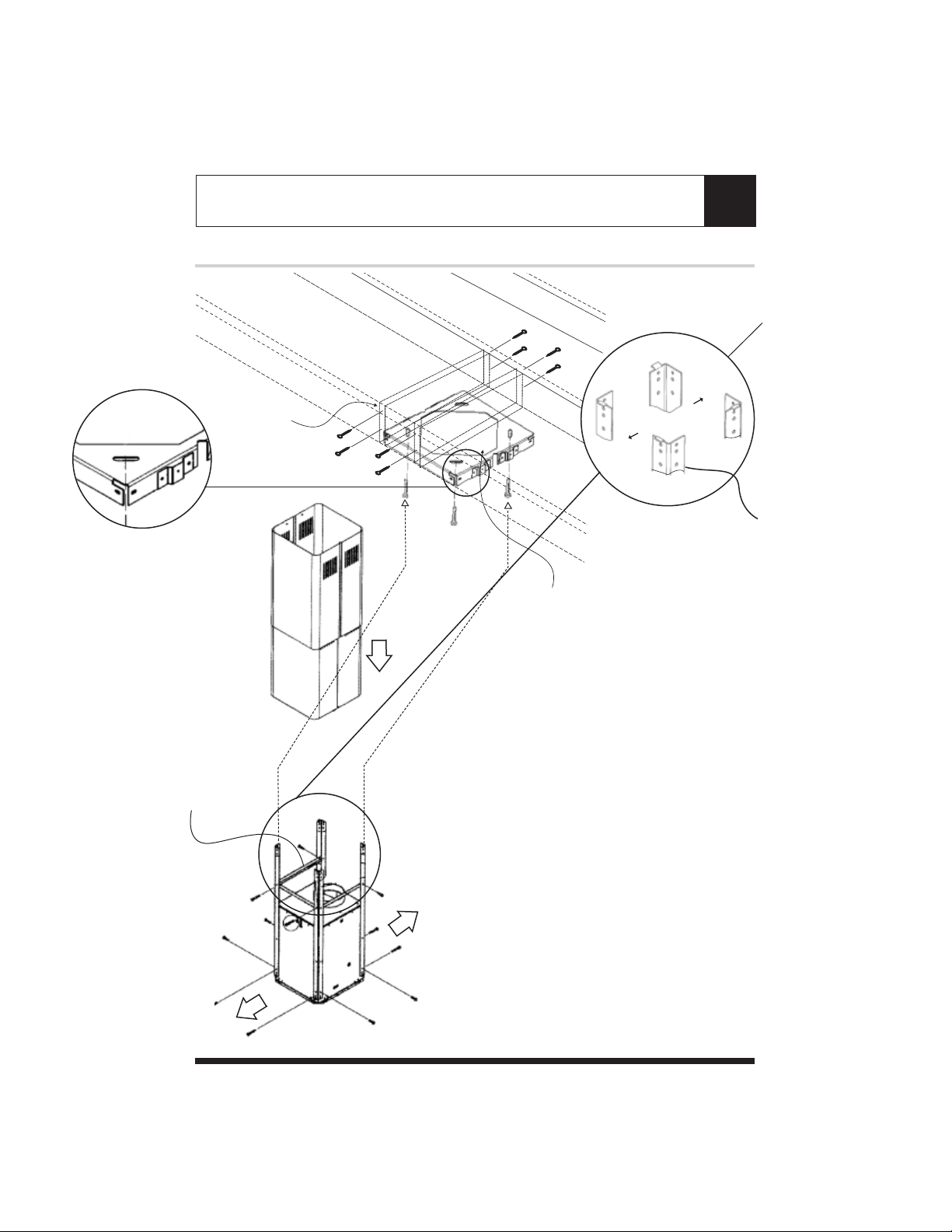

Add Blockings

Fasten Support Frame

front

rear

INSTALLATION

6

Dimensions of

Support Arms

23.25”

Front

Support Bracket

Front

Rear

Support Arms with

Tabs position

Fasten Ceiling Plate

Mounting the Range Hood

1. Add and secure blockings (minimum 2x4 studs)

onto ceiling joist.

2. Center, mark and fasten Ceiling Plate onto ceiling

where hood is to be hung. Make sure front of

bracket is facing as shown on diagram.

3. Determine height of hood, measure and attach four

support arms onto blower unit with screws provided;

use predrilled holes on blower unit and support arms.

Make sure tabs on top of the arms are facing out for the

front, and sideways for the rear, as shown on diagram.

Attach support “U” bracket.

4. Slide telescopic duct covers onto the top of the

blower unit.

5. Attach duct work to the ceiling and position the electrical.

6. Lift blower unit and fasten to Ceiling Plate (lock tabs on

support frame into slots on CeilingPlate); secure support

frame to Ceiling Plate with screws provided.

7. Connect duct work and electrical to the blower unit.

(slide duct covers up to gain access to the top of the

blower unit).

Page 8

INSTALLATION

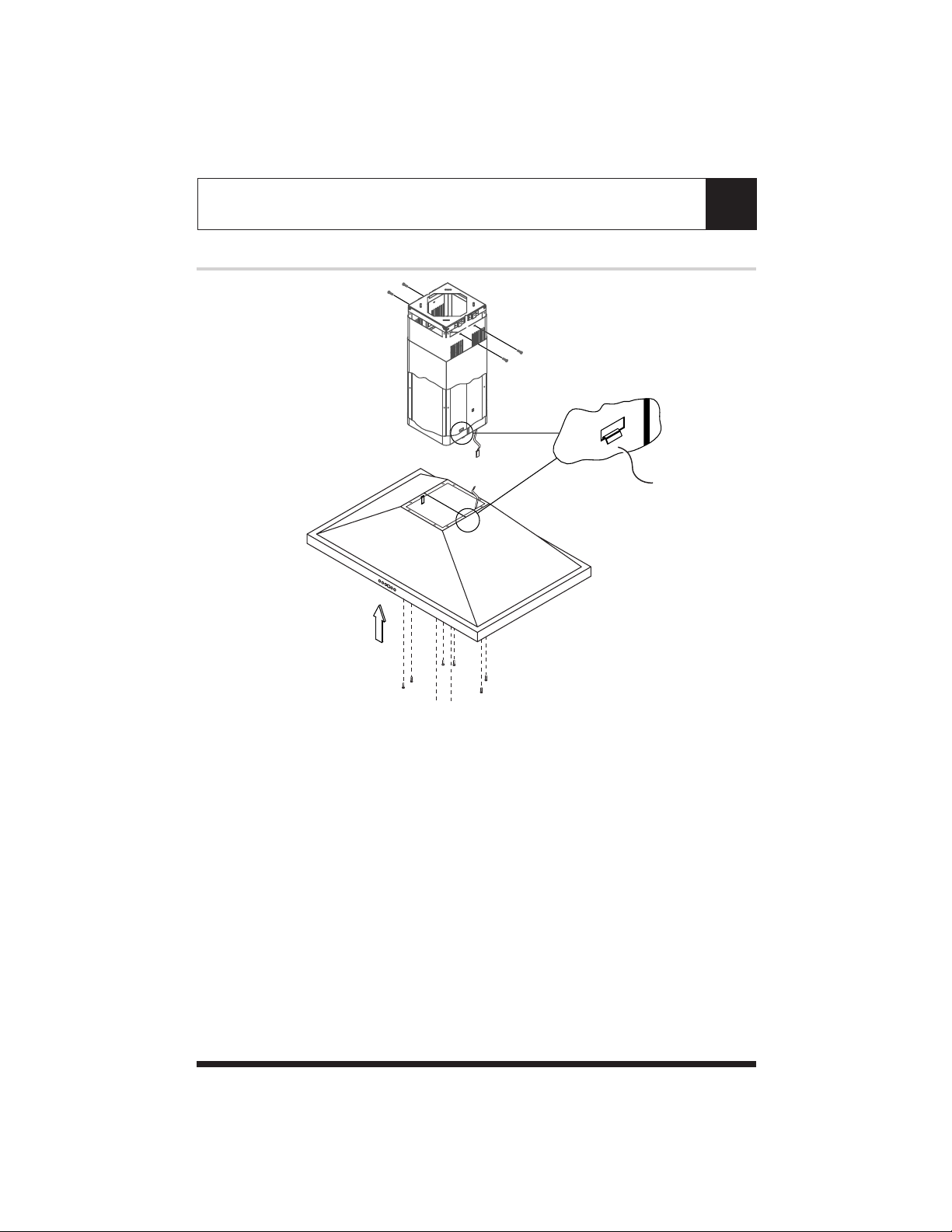

locking tabs

INSTALLATION

7

Mounting the Range Hood

8. Lift canopy and snap locking tabs into

blower unit.

9. Fasten canopy to blower with screw pro

vided from inside of canopy.

10. Push telescopic duct section up in place

and fasten.

Note: Butterfly damper may be installed by

placing it ontop of the motor housing.

Page 9

INSTALLATION

6" straight pipe

wall pipe strap

6" T connector

or 90 elbow

8

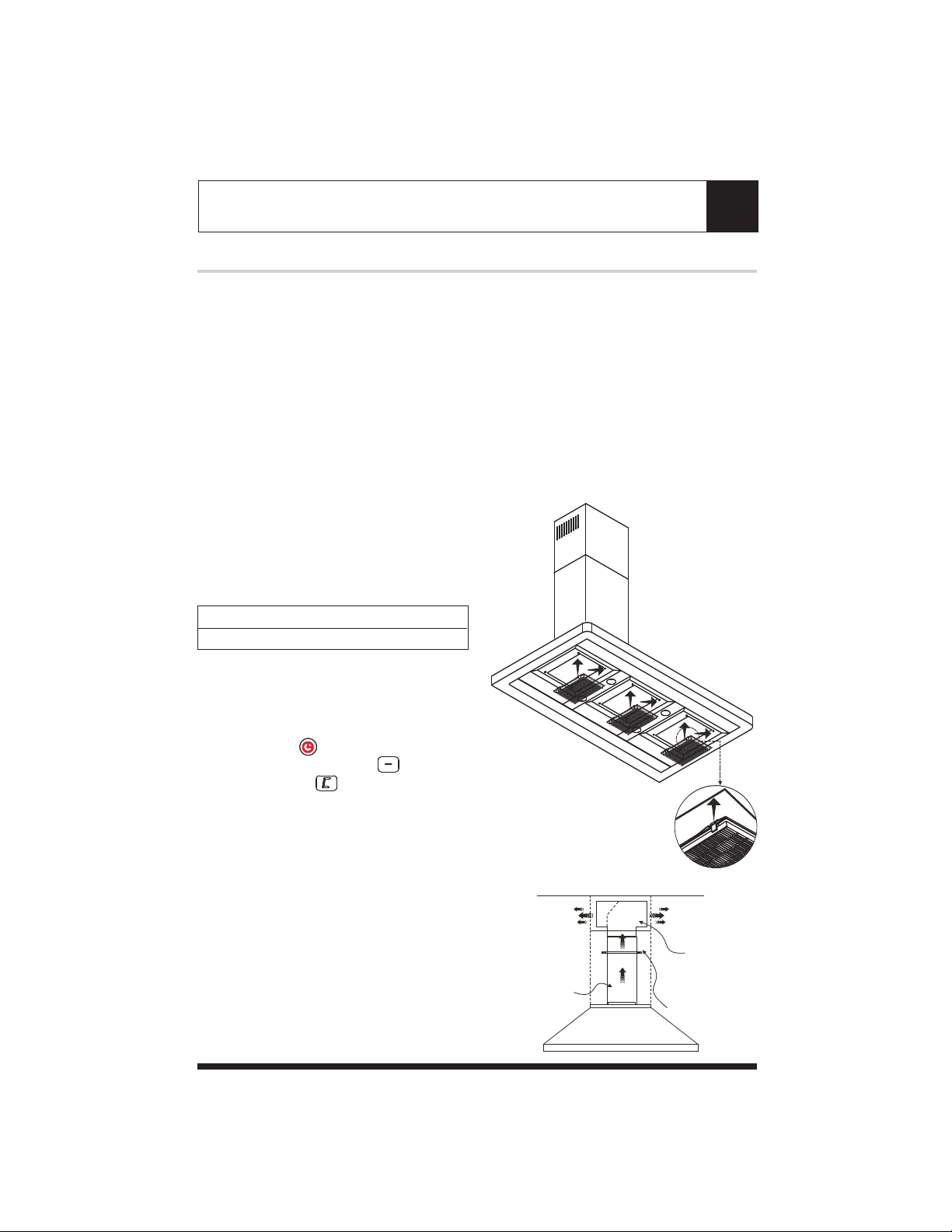

DUCTLESS CONVERSION

Ductless conversion is intended for applications where an exhaust duct work is not possible to be

installed. When converted, the hood functions as a "purifying" hood rather than an exhaust hood.

Fumes and exhaust from cooking is drawn and filtered by a set of optional Carbon Filters. The air

is then purified and re-circulated back within the home.

We recommend to ALWAYS exhaust air outside of the home by employing existing or installing

new duct work, if possible. The hood is most effective and efficient as an Exhaust unit. Only when

the exhaust option is not possible should you recourse to converting the hood into a "purifying"unit.

When converted to be a "purifying" unit, a set of Carbon Filters are required on top of its standard

Metal Filter set. Order according to its Part number below. The standard Metal Filters are intended

to capture residue from cooking and the optional Carbon Filters help to purify fumes exhausted

from cooking for re-circulation.

Carbon Filters (Required)

1. Purchase ductless Carbon Filters as follows:

Hood Model: Part No. Filters in pkg.

JXT8136ADS JFLTRC8036 3

JXT8142ADS JFLTRC8036 3

2. Remove metal filters on hood. Clip

carbon filters onto each slot opening.

3. Re-install metal filters.

4. Set filter change reminder for carbon filters.

When Off, hold for approx. 5 seconds.

The display will change from

(exhaust mode) to , (purifying mode/

carbon filters used) this indicates that the

elapse timer function is switched on and

Carbon Filters are used.

5. Carbon Filters must be replaced after

every 120 hours of use (or approximately

every 2 to 3 months based on the average

of 1-2 hrs. of daily cooking time). The

microprocessor in the controls when set,

will count usage time and indicate when

carbon filter replacement is required.

Ducting

1. Install a 6" straight pipe and a "T" connector/

or a 90 elbow to divert air through louvers on

duct cover.

Carbon Filter Dimensions:

8.98 in x 6.38 in

228 mm x 162 mm

Page 10

HOTTE DE CUISINIÈRE

Numéro de modèle: JXT8136ADS JXT8142ADS

Numéro du fabricant: S98M90S S98E42S

Dimensions: 35-3/8” (90 cm) 42” (106.68 cm)

INSTALLATION

GUIDE

TABLE DES MATIÈRES

Consignes de sécurité...............................................1

Liste des matériaux...................................................2

Hauteurs de montage...............................................3

Canalisation.............................................................4

Caractéristiques techniques......................................5

Installation............................................................6-8

Form No. A/04/03 Pièce No. IS9800-0303A ©2004 Maytag Appliances Sales Co. Litho États-Unis

Page 11

GUIDE D’INSTALLATION

Veuillez lire toutes les directives avant d’installer et de faire fonctionner cet appareil

MODELE: JXT8136ADS JXT8142ADS

AVIS DE SÉCURITÉ IMPORTANT

AVERTISSEMENT

Installation

Les procédures d’installation décrites dans ce guide s’adressent à des installateurs qualifiés, à

des techniciens de service ou à des personnes possédant des compétences similaires. NE tentez PAS d’installer cet appareil vous-même. L’installation de l’unité peut causer des blessures

en raison d’un manque de connaissances techniques et électriques.

Tout le câblage électrique doit être correctement installé, isolé et mis à la masse. Les vieux systèmes de conduits doivent être débarrassés de toute accumulation excessive de graisse. Si cela

est impossible, les conduits doivent être remplacés afin d’éviter les incendies de graisse.

Assurez-vous que les raccords des systèmes de conduits sont solidaires et adéquatement

rubanés.

Cet appareil pèse 75 Livres (34 Kg). Deux personnes sont nécéssaires pour soulever l’appareil

lors de son installation.

* Veuillez vous procurer les révisions les plus récentes des caractéristiques techniques

avant de procéder à des travaux sur mesure ou de découpe.

Page 12

LISTE DES MATÉRIAUX

1 - Hotte

1 - Caches de conduits (2)

1 - Sachet de pièces:

1 - Languettes de montages des caches de conduits

2 - Languettes de montages

Paquet de vis de montage

2 - Filtres Métaliques

1 - Filtre Papillon à registre

AUCUNE CANALISATION N’EST INCLUSE

2

Page 13

29"-46.65"

5.31"

36"

Min 24"-Max 32"

*Min 89.94"

*Max 113.71"

INSTALLATION

HAUTEURS DE MONTAGE ET DÉGAGEMENT

CANALISATION

Un conduit rond d’un diamètre minimum de 15,2 cm

(6 po) ou un conduit rectangulaire de 8,3 cm x 25,4 cm

(3 1/4 po x 10 po) doit être utilisé pour assurer une circulation d’air optimale.

Utilisez toujours des conduits métalliques rigides.

Les conduits flexibles réduisent la circulation d’air

dans une proportion qui peut atteindre 50 %.

Utilisez toujours les valeurs de droite pour calculer le

tracé de conduits possibles lors de l’utilisation de

coudes, de transitions et de capuchons.

Utilisez TOUJOURS un nombre minimal de transitions

et de courbes. Pour un long tracé de conduits, augmentez les dimensions des conduits de 15,2 cm (6 po)

à 17,8 cm à 20,3 cm (7 ou 8 po). Le cas échéant,

privilégiez les longs réducteurs aux réducteurs de type

plat. Réduisez les dimensions du conduit aussi loin de

l’ouverture que possible.

Si des courbes ou des transitions sont utilisées :

Éloignez-les autant que possible de l’ouverture et

des autres courbes ou transitions au moment de

l’installation.

3

La hauteur de montage minimale entre le dessus

de la cuisinière et le dessous de hotte doit être

d’au moins 61 cm (24 po).

La hauteur de montage maximale ne doit pas

excéder 81,3 cm (32 po).

Il est important d’installer la hotte à la hauteur

appropriée. Une hotte trop basse peut causer des

dommages par la chaleur ou des risques d’incendie tandis qu’une hotte trop haute sera difficile à atteindre et perdra de son efficacité.

Reportez-vous aux exigences relatives à la hauteur de dégagement du fabricant de la cuisinière

et à la hauteur de montage au-dessus de la

cuisinière recommandée pour la hotte.

Kits de rallonge disponibles pour plafonds de

3m–3.65m (10’–12’).

*Dégagement minimal au plafond de 228.45 cm

(89.94 po) à une hauteur de montage de la hotte de

61 cm (24 po).

**Dégagement maximal au plafond de 288.82 cm

(113.71 po) à une hauteur de montage de la hotte

de 81.3 cm(32 po).

Dimension minimale du conduit :

Rond - d’un diamètre minimum de 15,2 cm (6 po)

Des conduits rectangulaires nécessitent

l’utilisation d’un adaptateur en vente dans la

plupart des quincailleries.

Calcul du tracé de conduits:

Tracé maximum

conduit 15,2 cm ou 8,3 cm x 25,4 cm (6 po ou 3

1/4 po x 10 po)

Déduisez:

chaque coude de 90 o utilisé

chaque coude de 45 o utilisé

chaque transition de 15,2 cm à 8,3 cm x 25,4 cm

(6 po à 3 1/4 x 10 po) utilisée

chaque transition de 8,3 cm x 25,4 cm à 15,2 cm

( 3 1/4 po x 10 po à 6 po)

Capuchon mural latéral avec registre

Capuchon de toit

p. ex. - 1 capuchon de toit, 2 coudes de 90o, 1 coude de

45o utilisé :

= 9,1 m + 9,1 m + 2,7 m = 20,9 m (30 pi + 30 pi + 9 pi =69 pi)

utilisés, 9,4 m (31 pi) disponible pour les tracés en ligne droite.

30,5 M ( 100 PI)

4,6 M (15 PI)

2,7 M (9 PI)

0,3 M (1 PI)

1,5 M (5 PI)

9,1 M (30 PI)

9,1 M (30 PI)

Page 14

capuchon mural

latéral avec registre

anti-refoulement

Soffite ou vide sanitaire

capuchon mural

latéral avec registre

anti-refoulement

Soffite ou vide sanitaire

capuchon mural

latéral avec registre

anti-refoulement

Pente de toit avec

solin et capuchon

INSTALLATION

4

CANALISATION

AVERTISSEMENT DE RISQUE D’INCENDIE

L’air ne doit JAMAIS être évacué et le système de conduits ne doit JAMAIS se terminer dans des espaces

entre les murs, des vides sanitaires,des plafonds, des greniers ou des garages. Toutes les sorties de ventilation doivent être canalisées vers l’extérieur.

Utilisez seulement des systèmes de conduits métalliques.

Fixez tous les assemblages à l’aide de vis à tôlerie et rubaner tous les raccords à l’aide de ruban argenté approuvé ou de ruban pour canalisations.

Quelques Options de Canalisation:

Page 15

Câble de

verrouillage

INSTALLATION

CARACTÉRISTIQUES TECHNIQUES

ÉLECTRICITÉ

AVERTISSEMENT

5

AVERTISSEMENT

Tous les travaux électriques doivent être effectués par un électricien qualifié ou une personne possédant des connaissances techniques et de l’expérience similaires.

Pour votre sécurité personnelle, retirez le fusible ou coupez le disjoncteur de l’alimentation électrique

domestique avant de débuter l’installation.

N’utilisez pas de rallonge électrique ou de fiches d’adaptateur avec cet appareil.

Suivre les codes d’électricité nationaux ou les codes locaux de même que les ordonnances

en vigueur.

Alimentation électrique:

Cet appareil nécessite une alimentation électrique de 120 V et de 60 Hz branchée à un circuit de dérivation, correctement mis à la terre et protégé par un disjoncteur de 15 à 20 ampères ou un fusible à

action différée. Le câblage doit se composer de deux fils mis à la masse. Veuillez également vous

reporter au diagramme électrique

apposé sur le produit.

Verrou de câble:

Certains codes locaux peuvent également

exiger l’utilisation d’un connecteur de verrouillage de câble (non fourni). Procédez aux

vérifications nécessaires, et le cas échéant,

procurez-vous les connecteurs appropriés

puis installez-les.

Page 16

Ajoutez les

matériaux

d'assujettissement

Fixez les supports de cadre

Avant

INSTALLATION

INSTALLATION

Plaque d’assujettissement au plafond

6

arriere

avant

Bras de support avec

position des languettes

Support

Avant

Arrière

Montage de la hotte de cuisinière

1. Placez les matériaux d’assujettissement (minimum 2 morceaux

de 2 x4 ).

2. Centrez la plaque d’assujettissement sur le plafond, tracez un point

de repère puis fixez-la à l’emplacement de pose de la hotte. Assurezvous que l’avant du support pointe du côté indiqué dans le schema.

3. Determinez la hauteur de la hotte, effectuez les mesures necessaires

puis fixez les quatres bras de support sur la soufflante à l’aide des vis

fournies; utilisez les avant-trous de la hotte et des bras de support.

Asssurez-vous que les languettes situées sur les bras de support

pointent vers l’extérieur pour l’avant, et sur les côtés pour l’arrière, tel

qu’indiqué sur le schéma. Fixez le bras de soutient en U.

4. Faite glisser les caches de conduits télescopiques sur la partie

supérieure de la soufflante.

5. Attachez le conduit au plafond et les composants élétriques.

6. Soulevez la soufflante. Verrouillez ensuite les languettes du cadre de

support dans les fentes de la plaque d’assujettisment pour la fixer au

plafond. Attachez le cadre de support à la plaque d’assujettissement

l’aide des vis fournies. Attachez le cadre de support.

7. Branchez la canalisation et les composants éléctriques à la soufflante.

(Remontez les caches de conduits en les faisant glisser pour accéder

à la partie supérieure de la soufflante.)

Page 17

INSTALLATION

locking tabs

INSTALLATION

7

crochets de montage

Montage de la Hotte de Cuisinière

8. Soulevez le déflecteur et enclenchez les languettes de verrouillage dans

la soufflante.

9. Fixez le déflecteur à la soufflante à l’aide des vis fournies, en vissant depuis

l’intérieur du déflecteur.

10. Poussez la section du conduit télescopique vers le haut pour qu’elle repose en

place et puis fixez.

Note: Le filtre Papillon à registre pillon peut s’installer au dessus de l’habitâcle

du moteur.

Page 18

INSTALLATION

Tuyau droit de

15,2 cm (6 po)

Étrier plat à pattes pour les murs

Raccord en «T» de 15,2 cm (6 po)

ou un coude de 90o

8

TRANSFORMATION EN SYSTÈME DE RECYCLAGE

La transformation de cette unité en système de recyclage est recommandée pour des applications où

il est impossible d’installer un système de conduits d’évacuation. Lors de la conversion, la hotte fonctionne en tant qu’élément « d’épuration » plutôt qu’élément d’évacuation.

L’air vicié ou les émanations de cuisson sont aspirés et filtrés par un ensemble de filtres au charbon.

L’air est ensuite purifié et recirculé à l’intérieur de la maison.

Il est recommandé de TOUJOURS évacuer l’air à l’extérieur de la maison en employant les systèmes

de conduits existants ou en installant un nouveau système de conduits. La hotte est plus efficace en

tant qu’appareil d’évacuation. Cet appareil ne doit être utilisé comme une unité « d’épuration » que s’il

est impossible d’en faire une unité d’évacuation.

Lorsque vous convertissez cet appareil en unité « d’épuration », il est nécessaire de placer un ensemble de filtres au charbon au-dessus de l’ensemble de filtres métalliques conventionnels. Pour passer

des commandes, utilisez le numéro de pièce ci-dessous. Les filtres métalliques sont conçus pour

capter les résidus de cuisson. Pour ce qui est des filtres au charbon optionnels, ils aident à purifier les

émanations crées par la cuisson pour une recirculation de l’air dans la maison.

Filtres au charbon (requis)

1.Procédez comme suit pour acheter des filtres au

charbon pour les systèmes à recyclage :

Modèle de Numéro de Filtres en

hotte pièce paquet

JXT8136ADS JFLTRC8036 3

JXT8142ADS JFLTRC8036 3

2. Retirez les filtres métalliques de la hotte.

Agrafez les filtres au charbon dans chaque rainure.

3. Réinstallez les filtres métalliques.

4. Mettez l’indicateur de remplacement des filtres du

panneau en fonction. A l’arrêt, appuyez sur

pendant environ 5 secondes. L’indicateur passe de

(mode hotte traditionelle) à (mode

recyclage/filtres au charbon) indiquant que la fonc

tion de minuterie de temps écoulé est activée et

que les filtres au charbon sont utilisés.

5. Les filtres au charbon doivent être remplacés à

toutes les 120 heures d’utilisation (ou approxima

tivement à tous les 2 à 3 mois en fonction d’une

moyenne de temps de cuisson de 1 à 2 heures).

Une fois en fonction, le microprocesseur des com

mandes fait le compte du temps d’utilisation et

indique qu’il est nécessaire de remplacer les filtres

au charbon.

Systèmes de conduits

1. Installez un tuyau droit de 15,2 cm (6 po) et

un raccord en « T » ou un coude de 90o pour

diriger l’air dans les louvres du couvercle

de conduit.

Dimension des filtres au charbon:

22.80cm (8.98po) x 16.20cm (6.38po)

228mmx 162mm

Page 19

CAMPANA DE COCINA

Número de Modelo: JXT8136ADS JXT8142ADS

Número del Fabricante: S98M90S S98E42S

Tamaño: 35-3/8” (90 cm) 42” (106.68 cm)

INSTALACION

GUIA

CONTENIDOS

Instrucciones de Seguridad.......................................1

Lista de Materiales................................................... 2

Altura de Montado...................................................3

Tubería de Extracción...............................................4

Especificaciones.......................................................5

Instalación............................................................ 6-8

Form No. A/04/03 Part No. IS9800-0303A ©2004 Maytag Appliances Sales Co. Litho U.S.A.

Page 20

GUIA DE INSTALACION

Lea todas las instrucciones antes de instalar y usar este electrodoméstico

MODELO: JXT8136ADS JXT8142ADS

IIMPORTANTE AVISO DE SEGURIDAD

ADVERTENCIA

Instalación

La instalación descrita en este manual ha sido preparada para instaladores calificados, técnicos

de servicio o personas con un entrenamiento similar y calificado. NO intente instalar este electrodoméstico ud. mismo. La instalación de esta unidad sin el apropiado conocimiento técnico y

eléctrico puede resultar en serios daños personales.

Todo el cableado eléctrico debe ser instalado, aislado, y conectado a tierra de manera apropiada. Se debe limpiar el acumulamiento de grasa en los conductos antiguos o se deben reemplazar por conductos nuevos para evitar la posibilidad del incendio de la grasa. Revise todas las

junturas en los conductos para asegurar que las conexiones estén bien hechas y que todas las

junturas estén selladas con cinta.

Este electrodoméstico pesa 75 lbs. Se requiere de dos personas para levantar este electrodoméstico durante su instalación.

* Por favor esté atento a las últimas revisiones de las especificaciones técnicas antes de

desconectar o realizar cualquier trabajo en la unidad.

Page 21

LISTA DE MATERIALES

1 - Cuerpo de la campana

1 - Ensamblado de la cubierta del conducto (2 partes)

1 - Bolsa de partes:

1 - Sujetador de montaje para la cubierta del conducto

2 - Sujetadores de montaje

Paquete de tornillos de montaje

2 - Filtros metálicos

1 - Regulador de tiro de chimenea metálico tipo mariposa

NO SE INCLUYE LA TUBERIA DE EXTRACCION

2

Page 22

29"-46.65"

5.31"

36"

Min 24"-Max 32"

*Min 89.94"

*Max 113.71"

INSTALACION

ALTURA DE MONTADO Y ESPACIO LIBRE

TUBERIA DE EXTRACCION

Para mantener una máxima eficiencia en el flujo de

aire se debe usar una tubería redonda de un mínimo

de 6” de diámetro o una tubería rectangular de 3-1/4”

por 10”.

Use tuberías metálicas rígidas solamente.

Las tuberías flexibles pueden restringir el flujo de aire

hasta en un 50%.

Use la tabla de cálculos que se encuentra a la derecha

para calcular el total de tubería cuando se usan codos,

transiciones y casquetes.

SIEMPRE que sea posible reduzca el número de transiciones y vueltas. Si se necesita una tubería de

extracción muy larga, aumente el tamaño de la tubería

de 6” a 7” u 8”.Si se usa un reductor,instale un reductor largo en vez de un reductor plano. Reduzca el

tamaño de la tubería lo más lejos de la apertura de la

campana como le sea posible.

Si se requieren vueltas y transiciones: Instálelas lo

más lejos posible de la apertura y distanciadas unas

de otras, entre 2, si le es posible.

3

La altura mínima de montado entre la parte inferior de la campana y la parte superior de la cocina

no debe ser inferior a 24”.

La altura de montado máxima no debe ser superior a 32”.

Es importante instalar la campana a la altura de

montado apropiada. Una campana instalada a

muy baja altura puede sufrir daños debido al calor

y correr peligro de incendio. Una campana montada a mucha altura será difícil de alcanzar y

perderá eficacia.

Si están disponibles, véanse también los requisitos de espacio libre correspondientes al fabricante

de la cocina y la altura de montado de campana

recomendada para su cocina.

Hay equipos de extensión disponibles para

acomodar techos de 2.7m–3.65m (10’–12’).

*Espacio libre mínimo entre el techo y la campana

debe ser de 228.45cm (88.94”) cuando la altura de

montado de la campana es de 61cm (24”).

** Espacio libre mínimo entre el techo y la campana

debe ser de 288.82cm (113.71”) cuando la altura

de montado de la campana es de 81.3cm (32”).

Tamaño Mínimo de la Tubería:

Redonda - 6” mínimo

Rectangular - requiere un adaptador fácil de

conseguir en cualquier ferretería o quincallería.

Tabla de Cálculos para la Tubería:

Largo máximo

Tubería de 6” ó 3-1/4” x 10”

Deduzca:

Por cada codo de 90

Por cada codo de 45

Por cada transición de

6” a 3/14 x 10”

Por cada transición de

3/14 x 10” a 6”

Casquete Lateral de Pared c/ regulador

de tiro

Casquete de Techo

ej- 1 casquete de techo, 2 codos de 90, 1 codo de 45:

= 30’ + 30’ + 9” = 69’ usados, 31’ disponibles para que corra

recto el tubo de extracción.

100 FT

15 FT

9 FT

1 FT

5 FT

30 FT

30 FT

Page 23

INSTALACION

casquete lateral de pared

c/ regulador de tiro

por gravedad

Sofito o intradós

casquete lateral de pared

c/ regulador de tiro

por gravedad

Sofito o intradós

casquete lateral

de pared c/ regulador

de tiro por gravedad

Inclinación de Tejado

c/ Vierteaguas

y Casquete

4

TUBERIA DE EXTRACCION

ADVERTENCIA PELIGRO DE INCENDIO

NUNCA haga escapar el aire o termine las tuberías entre espacios de la pared, sofitos, techos, áticos o

garajes. Todos los escapes de aire deben ser dirigidos hacia el exterior.

Use tuberías metálicas solamente.

Asegure todas las conexiones con tornillos para metal laminado y selle todas las junturas con cinta adhesiva certificada Silver Tape o DuctTape.

Algunas Opciones para la Tubería de Extracción:

Page 24

ESPECIFICACIONES

Seguro de Cable

INSTALACION

ELECTRICA

INSTALACION

5

ADVERTENCIA

Toda instalación eléctrica debe ser realizada por un electricista calificado o por una persona con

conocimientos técnicos similares y con experiencia equivalentes.

Para su seguridad personal, retire los fusibles del hogar o el interruptor abierto antes de comenzar la

instalación.

No utilice alargadores ni adaptadores de tomacorriente con este electrodoméstico.

Siga los códigos del National Electric Code (NEC) o las leyes y códigos locales reinantes.

Suministro Eléctrico:

Esta unidad requiere un suministro eléctrico de 120V 60Hz y que esté conectada a un circuito individual de derivación que esté debidamente conectado a tierra. Debe estar protegido por un interruptor de

15 ó 20 amperios o por un fusible de tiempo retrasado. El cableado debe ser de 2 cables con conexión a tierra. Véase también el Diagrama

Eléctrico en la etiqueta del producto.

Seguro de Cable:

Un conector para asegurar el cable (no se

incluye) puede ser requerido por los códigos locales. Verifique los códigos y

requerimientos locales, compre e instale

el conector apropiado si fuera necesario.

Page 25

Add Blockings

Fasten Support Frame

front

rear

Agregue los

bloqueadores

INSTALACION

6

Dimensiones de los

brazos de soporte

23.25”

Posterior

Frontal

Frontal

Sujetador de soporte

tipo “U”

Nota: se deberán

cortar los brazos de

extensión al ser

instalados bajo un

techo inferior a

3.65m (10’)

Frontal

Posterior

Brazos de soporte con

posición de proyecciones

Asegure la placa para el techo

Montando la Campana de Cocina

1. Agregue y afirme los bloqueadores al techo (mínimo postes de 2x4).

2. Centre, marque y asegure la Placa para el Techo en el lugar donde

se colgará la campana. Asegúrese de que la parte frontal del sujetador

de pared esté en la dirección indicada en el diagrama.

3. Determine la altura de la campana, mida y fije cuatro brazos de

extensión a la unidad de extracción con los tornillos que se proporcio

nan; utilice los orificios pre-hechos en la unidad de extracción y en los

brazos de soporte. Asegúrese de que las proyecciones de la parte

superior de los brazos de soporte estén dirigidas hacia afuera para el

frente, y hacia los lados para la parte posterior, como se muestra en

el diagrama. Fije los sujetadores de soporte tipo “U”.

4. Deslice los cobertores de la tubería telescópica sobre la unidad de

extración.

5. Fije la tubería de extracción al techo y posicione el sistema eléctrico.

6. Levante la unidad de extracción y fíjela a la Placa para el Techo

(enganche las proyecciones del marco de soporte en las ranuras de

la Placa para el Techo); asegure el marco de soporte a la Placa para el

Techo usando los tornillos que se proporcionan.

7. Conecte la tubería y el cableado eléctrico a la unidad de extracción.

(deslice los cobertores de la tubería hacia arriba para ganar acceso a

la parte superior de la unidad de extracción).

Page 26

INSTALACION

locking tabs

INSTALACION

7

lengüetas de cierre

Montando la Campana de Cocina

8. Levante la campana y enganche las proyecciones de cierre

en la unidad de extracción.

9. Fije la campana al extractor con el tornillo que se propor

ciona desde el interior de la campana.

10. Empuje la sección de la tubería telescópica hacia arriba

hasta que quede en el lugar apropiado y luego fíjela.

Nota: El regulador de tiro tipo mariposa de la chimenea se

puede instalar poniéndolo sobre el alojamiento del motor.

Page 27

INSTALACION

conducto recto de 6"

amarra de pared para el conducto

conector en "T" de 6"

o codo de 90

8

CONVERSION SIN TUBERIA DE EXTRACCION

La conversión sin tubería de extracción está hecha para situaciones en las cuales no es posible instalar una

tubería de extracción de aire. Al ser convertida, la campana funciona como una campana de “purificación”

en vez de una campana de extracción. Los humos y vapores producidos al cocinar son aspirados por la campana y filtrados por un conjunto de Filtros de Carbón opcionales. El aire es entonces purificado y reciclado

en el hogar.

Recomendamos SIEMPRE extraer el aire fuera de la casa utilizando tuberías de escape existentes o instalando nuevas, siempre que sea posible. La campana es más eficiente como una unidad de extracción. Sólo

cuando no es posible instalarla como un sistema de extracción se debe usar la opción de conversión transformando la campana en una unidad de “purificación”.

Cuando se convierte en una unidad de “purificación”, se necesitan un conjunto de Filtros de Carbón además

del conjunto de Filtros Metálicos estándar. Para hacer su pedido refiérase al número de repuesto detallado

más adelante. Los Filtros Metálicos estándar están diseñados para capturar los residuos generados al cocinar y los Filtros de Carbón opcionales ayudan a purificar los humos que se generan al cocinar para poder

así reciclar el aire dentro del hogar.

Filtros de Carbón (Requeridos)

1. Compre los Filtros de Carbón para instalación sin tubería de extracción como se detalla a continuación:

Modelo de Número de Filtros por

Campana Repuesto Paquete

JXT8136ADS JFLTRC8036 3

JXT8142ADS JFLTRC8036 3

2. Retire los filtros metálicos de la campana.

Enganche los filtros de carbón a cada apertura.

3. Vuelva a instalar los filtros de metal.

4. Ponga en funcion la advertencia de cambio de

filtro de carbón. Estando en la posición Off

(desconectado), presione durante aproxi

madamente 5 segundos. La visualización

cambiará de ,Exhaust Mode (modo de

extracción) a Purifying Mode/Carbon Filters

Used (modo de purificación/filtros de carbón en

uso). Esto indica que se ha activado la función

del cronómetro y que se están usando los

Filtros de Carbón.

5. Los Filtros de Carbón deben ser reemplazados

después de cada 120 horas de uso

(o aproximadamente cada 2 ó 3 meses,

basándose en un uso promedio de 1 a 2

horas por día). Cuando se activa el microprocesador en los controles, este contará el

tiempo de uso y le indicará cuándo es nece

sario cambiar los filtros de carbón.

Dimensiones de los filtros metálicos:

22.80cm (8.98”) x 16.20cm (6.38”), 228mm x 162mm

Tubería de Extracción

1. Instale un conducto recto de 6” y un conector

en “T” o un codo de 90 para desviar el aire a

través de los respiraderos en la cubierta de la

tubería.

Loading...

Loading...