Jenn-Air JXT5836ADS, JXT5830ADW, JXT5830ADS, JXT5836ADB, JXT6030ADS Service

...

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Vent Hoods

JXT5830ADB/W/S

JXT5836ADB/W/S

JXT6030ADS

JXT6036ADS

JXT8030ADS

JXT8036ADS

JXT8042ADS

JXT8136ADS

JXT8142ADS

JXT9030CDP

JXT9036CDP

JXT9048CDP

JXT9130CDP

JXT9136CDP

16023510

November 2004

©2004 Maytag Services

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

Important Notices for Servicers and Consumers

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.JENNAIR.COM ............................................. 1-800-688-1100

CAIR Center in Canada ........................................... 1-800-688-2002

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023510 ©2004 Maytag Services

Table of Contents

Important Information .................................................... 2

Important Safety Information

In Case of Fire.......................................................... 4

Safety Practices for Servicer .................................... 4

Servicing .................................................................. 4

Electrical Requirements ........................................... 5

Extension Cord ........................................................ 5

Receiving Vent Hood ................................................ 5

Precautions .............................................................. 5

Using the Vent Hood ................................................ 5

General Information

Cooking Nomenclature ............................................. 6

Specifications .......................................................... 7

Placement of the Vent Hood .................................... 7

Do Not Block Air Vents ............................................ 7

Location of Model Number ........................................ 7

Grounding Instructions ............................................. 7

Model Identification .................................................. 7

Service ..................................................................... 7

Parts and Accessories ............................................. 7

Extended Service Plan ............................................. 7

Vent Hood Description ............................................. 8

Troubleshooting Procedures ......................................... 9

Testing Procedures ......................................................11

Disassembly Procedures for Models JXT9030CDP,

JXT9036CDP, JXT9048CDP, JXT9130CDP, JXT9136CDP

Halogen Light Removal ............................................ 13

Heat Lamp Removal ................................................ 13

Grease Filter/Grease Filtger Cover Removal............ 13

Halogen Light Socket .............................................. 13

Heat Lamp Socket Removal .................................... 13

Light Panel Removal ...............................................14

Control Board Removal ............................................ 14

Touch Pad Removal ................................................ 14

Capacitor Removal .................................................. 14

Transformer Removal ............................................... 15

Blower Motor Removal ............................................ 15

Filter Spring Clip Removal ....................................... 15

Disassembly Procedures for Models JXT8042ADS,

JXT8142ADS, JXT58309AD*, JXT5836AD*

Halogen Light Removal ............................................ 16

Grease Filter/Grease Filtger Cover Removal............ 16

Halogen Light Socket .............................................. 16

Control Board Removal ............................................ 16

Control Panel Removal ............................................17

Blower Motor Removal ............................................ 17

Capacitor Removal .................................................. 17

Filter Spring Clip Removal ....................................... 17

Appendix A: Installation Instructions

JXT5830AD*, JXT5836AD* ..................................... A-2

JXT8030ADS, JXT8036ADS, JXT8048ADS ............ A-4

JXT8136ADS, JXT8142ADS ................................... A-6

JXT9030CDP, JXT9036CDP, JXT9048CDP ............ A-8

JXT9130CDP, JXT9136CDP ................................. A-10

Appendix B: Controls and Features

JXT5830AD*, JXT5836AD*, JXT8030ADS,

JXT8036ADS, JXT8048ADS, JXT8136ADS,

JXT8142ADS ......................................................... B-2

JXT9030CDP, JXT9036CDP, JXT9048CDP,

JXT9130CDP, JXT9136CDP ................................... B-5

Care and Cleaning ................................................. B-6

©2004 Maytag Services 16023510 3

Important Safety Information

Recognize this symbol as a safety precaution.

!

WARNING

!

If the information in this manual is not followed exactly,

a fire or explosion may result causing property

damage, personal injury or death.

There can be a risk of injury or electrical shock while

performing services or repairs. Injury or electrical

shock can be serious or even fatal. Consequently,

extreme caution should be taken when performing

voltage checks on individual components of a product.

The electrical power supply should ALWAYS be

disconnected when servicing a product.

This appliance must be properly grounded. Never plug

in or direct-wire an appliance unless it is properly

grounded and in accordance with all local and national

codes. See "Installation Instructions" that accompany

the product for the appropriate grounding procedures.

WARNING!

In Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely, proceed as follows:

Surface Element Fires

1. Smother fire with a nonflammable lid/baking soda,

or use a Class ABC or BC extinguisher. Not

water, salt or flour.

2. As soon as it is safe to do so, turn the surface

controls to “OFF."

Oven Fires

1. Do not open the oven door.

2. Turn all range/oven controls to the OFF position.

3. As an added precaution turn off oven/range

electricity at the main circuit breaker or fuse box.

4. Turn on vent hood to remove smoke.

5. Allow the food or grease to burn itself out in the

oven.

6. If smoke and fire persist, call the local fire

department.

7. If there is any damage to components, call an

authorized servicer before using the vent hood.

WARNING!

To avoid risk of electrical shock, property damage,

personal injury or death; verify wiring is correct, if

components were replaced. Verify proper and complete

operation of unit after servicing.

This appliance contains or produces a chemical or

chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

To reduce the risk from substances in the fuel or from

fuel combustion, make sure this appliance is installed,

operated, and maintained according to the instructions

in this manual.

To avoid risk of property damage or personal injury, do

not obstruct the flow of ventilation air to the vent hood.

To avoid risk of electrical shock, serious personal injury

or death: Verify the vent hood has been properly

grounded and always disconnect the electrical supply

before servicing this unit.

Safety Practices for Servicer

Safe and satisfactory operation of vent hoods depends

upon its design and proper installation.

Servicing

Listed below are some general precautions and safety

practices which should be followed in order to protect

the service technician and consumer during service and

after service has been completed.

1. Check vent hood when service is complete—After

servicing, make visual checks on electrical

connection. Inform consumer of the condition of vent

hood before leaving.

2. Adhere to all local regulations and codes when

performing service.

4 16023510 ©2004 Maytag Services

Important Safety Information

Electrical Requirements

120-volt, 60 Hertz, 40 amp, individual circuit which is

properly grounded, polarized and protected by a circuit

breaker or fuse.

Extension Cord

Due to possible pinching during installation, extension

cords should not be used on products.

Receiving the Vent Hood

• Authorized servicer must install the vent hood, in

accordance with the Installation Instructions.

• Adjustments and service should be performed only by

authorized servicer.

• Plug vent hood into a 120–volt grounded outlet only.

• Do not remove round grounding prong from the plug. If

in doubt about grounding of the home electrical

system, it is consumers responsibility and obligation to

have an ungrounded outlet replaced with a properly

grounded three-prong outlet in accordance with the

National Electrical Code.

• Do not use an extension cord with this vent hood.

• Insure all packing materials are removed from the vent

hood before operating.

• Clean grease and dirt from exisiting duct work to

prevent future fires.

• Check all joints on duct work to ensure proper

connection; all joints should be taped properly.

Precautions

• When cutting or drilling into walls or ceilings, do not

damage electrical wiring and other hidden utilitites.

• Ducted fans must always be vented to the outdoors.

• Clean vent hood frequently. Grease should not be

allowed to accumulate on hood or filter.

• When flaming foods under the hood, turn the fan off.

The fan, if operating, may spread the flame.

• Do not mix household cleaning products. Chemical

mixtures may interact with hazardous results.

Using the Vent Hood

• Do not allow anyone to climb, stand or hang on the

vent hood. They could damage the vent hood and

cause severe personal injury.

• Saturation of greasy residue in the blower and filters

may cause increased flammability. Keep vent hood

claen and free of grease and residue build-up at all

times to prevent possible fires.

• Filters must be cleaned periodically and kept free from

accumulation of cooking residue.

• Old and worn filters must be replaced immediately.

• Do not operate blowers when filters are removed.

• Do not disassemble parts (for cleaning) without proper

instructions. Contact the Service Center for removal

instructions at (800) 536-6247.

• Do not use water on grease fires.

• Do not let grease or other flammable materials collect

in or around the vent hood.

• Do not repair or replace any part of the vent hood

unless it is recommended in this manual.

• Keep vent hood ducts unobstructed.

!

CAUTI ON

Do not store items of interest to children in cabinets

above the vent hood. Children may climb on the vent

hood to reach these items and may become seriously

injured.

©2004 Maytag Services 16023510 5

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing electric vent hoods.

The directions, information, and warnings in this manual

are developed from experience and careful testing of the

product. If the unit is installed according to this manual, it

will operate properly and will require minimal servicing. A

This manual contains information needed by authorized

service technicians to install and service electric vent

hoods. There may be, however, some parts which need

further explanation. Refer to the Installation Instructions,

Use and Care, Technical Sheets or the toll-free technical

support line.

unit in proper operating order ensures the consumer all

the benefits provided by the electric vent hood.

Cooking Nomenclature

J X T 9 1 3 6 C D P

Color

A Almond on Almond

Brand

A Amana

C Magic Chef

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Crosley

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27 ")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

Z RV Top

6 16023510 ©2004 Maytag Services

B Black

C Brushed Chrome

H Traditional White

L Traditional Almond

P Prostyle

Q Monochromatic Bisque

S Stainless

T Traditional Bisque

W White on White

F Frost White (True Color White)

N Natural Bisque (True Color Bisque)

Listing

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

(Singapore)

X Export 120 V / 60 Hz

Production Code

This identifies the

production version.

Feature Content

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn Air

General Information

Specifications

Refer to individual Technical Sheet for specification

information.

Placement of the Vent Hood

This electric vent hood must be placed in the kitchen or

comparable room. All safety guidelines must be followed

(see Chapter 2) and free air flow around the vent hood is

essential.

Do Not Block Air Vents

All air vents must be kept clear during cooking. If air

vents are covered during operation, the vent hood may

overheat.

Location of Model Number

To request service information or replacement parts, the

service center will require the model number of your vent

hood. This number can be found inside or under the vent

hood shroud.

For a permanently connected vent hood: This vent hood

must be connected to a grounded, metallic, permanent

wiring system, or an equipment grounding conductor

should be run with the circuit conductors and connected

to the equipment grounding terminal or lead on the

appliance.

WAR NI NG

!

Attaching adapter ground terminal to wall receptacle

cover screw does not ground the vent hood unless the

cover screw is metal and not insulated, and wall

receptacle is grounded through the house wiring.

Consumer should have circuit checked by a qualified

electrician to verify receptacle is properly grounded.

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing:

• For Jenn-Air product call 1-800-688-1100 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.jennair.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Grounding Instructions

This vent hood must be grounded. If an electrical short

circuit occurs, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

The cord for this vent hood has a grounding wire with a

grounding plug. Put the plug into an outlet that is properly

installed and grounded.

WARNING

!

To avoid risk of electric shock, personal injury or death,

use grounding plug properly.

Ask a qualified electrician if you do not understand the

grounding instructions or if you wonder whether the vent

hood is properly grounded.

Keep the electrical power cord dry and do not pinch or

crush it in any way.

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

servicer:

• For Jenn-Air product call 1-800-688-1100 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.jennair.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Jenn-Air product call 1-800-688-1100 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Sites at www.amana.com or www.maytag.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Jenn-Air’s strong

warranty. This plan covers parts, labor, and travel

charges.

Call 1-800-925-2020 for information.

©2004 Maytag Services 16023510 7

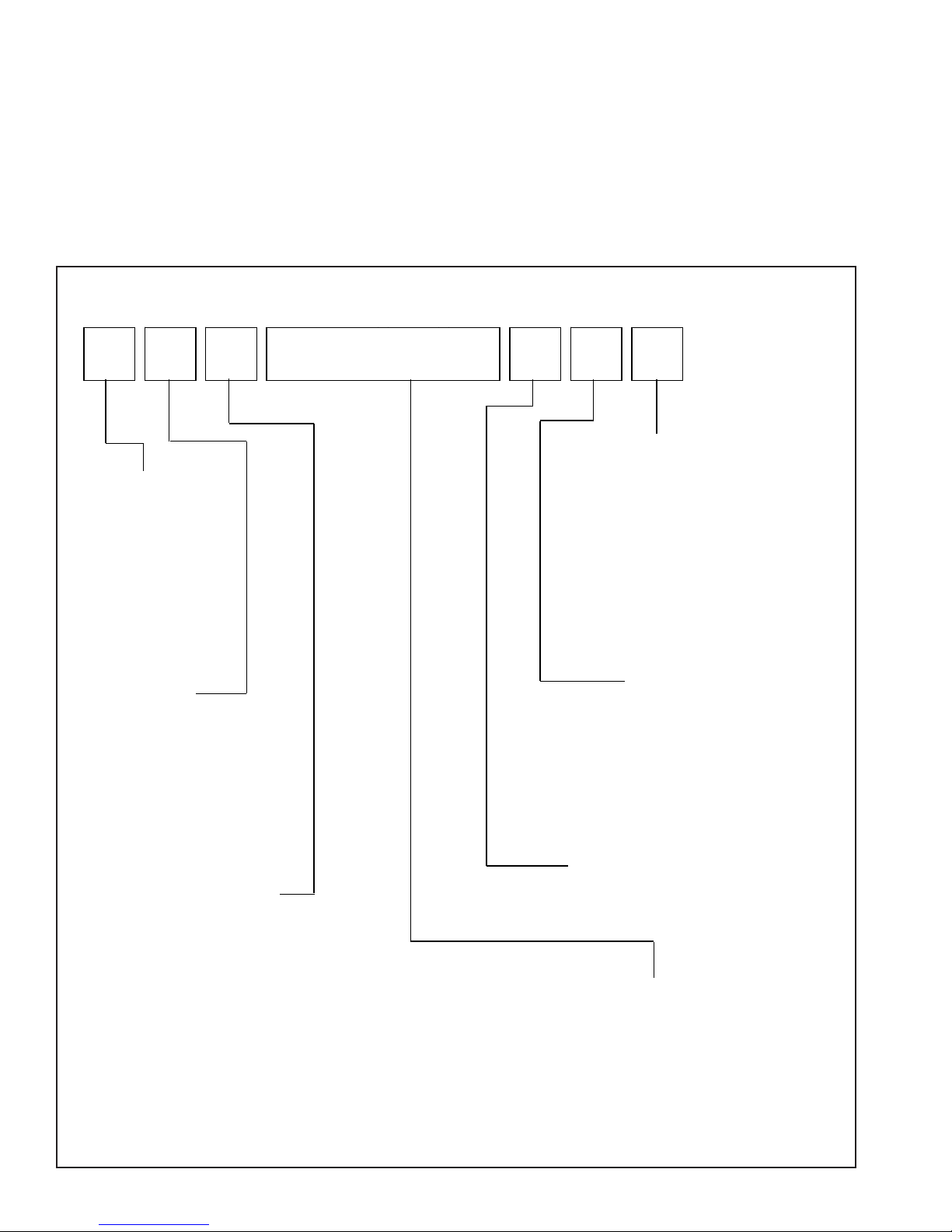

Range Description

Vent Hood Description

Filters/Filter Covers

Touch Pad/Control Pad

Halogen Lights

Blower Motor

Heat Lamps

Filters/Filter Covers

(in vent hood)

Touch Pad/Control Pad

Halogen Lights

Blower Motor

(in vent hood)

8 16023510 ©2004 Maytag Services

Troubleshooting Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to vent hood before servicing, unless

testing requires power.

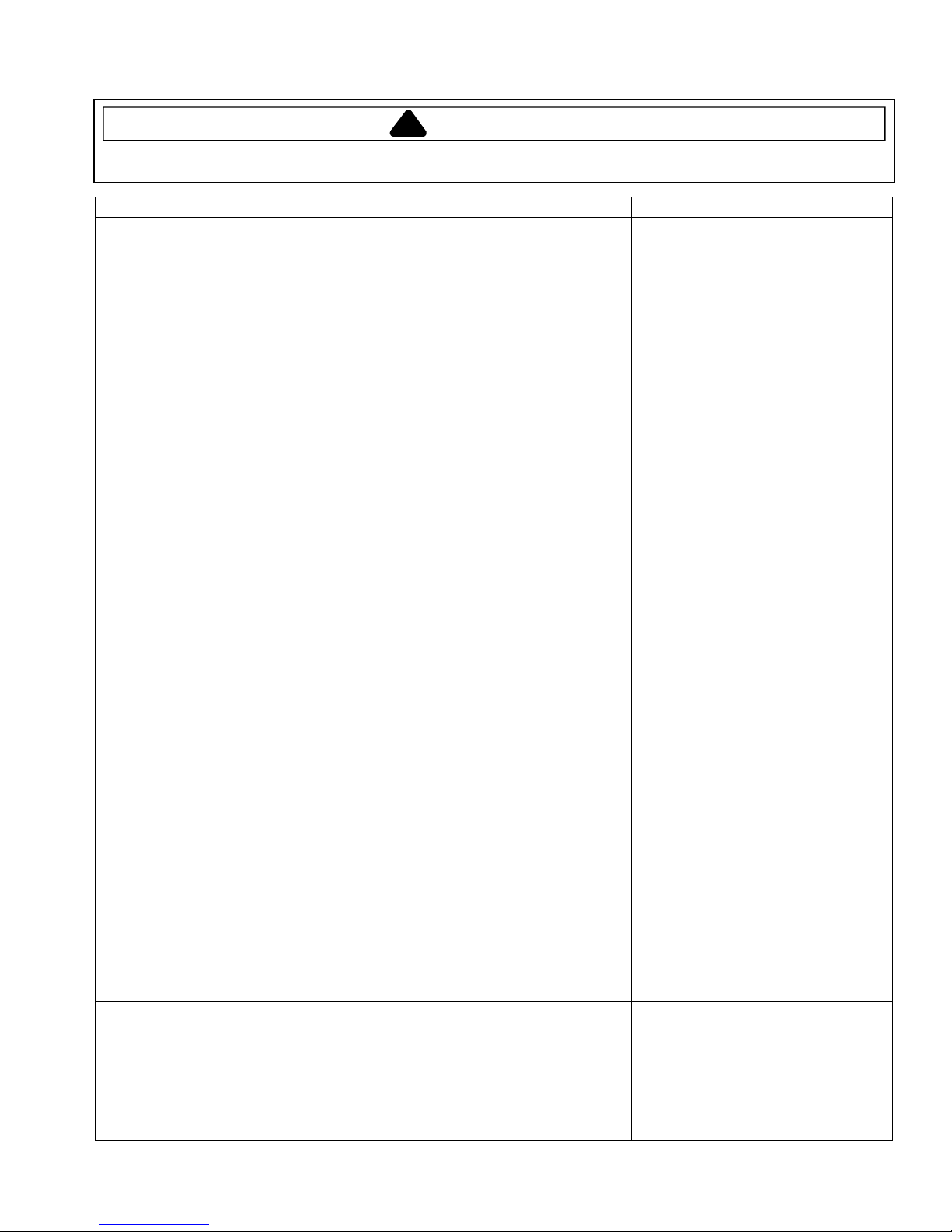

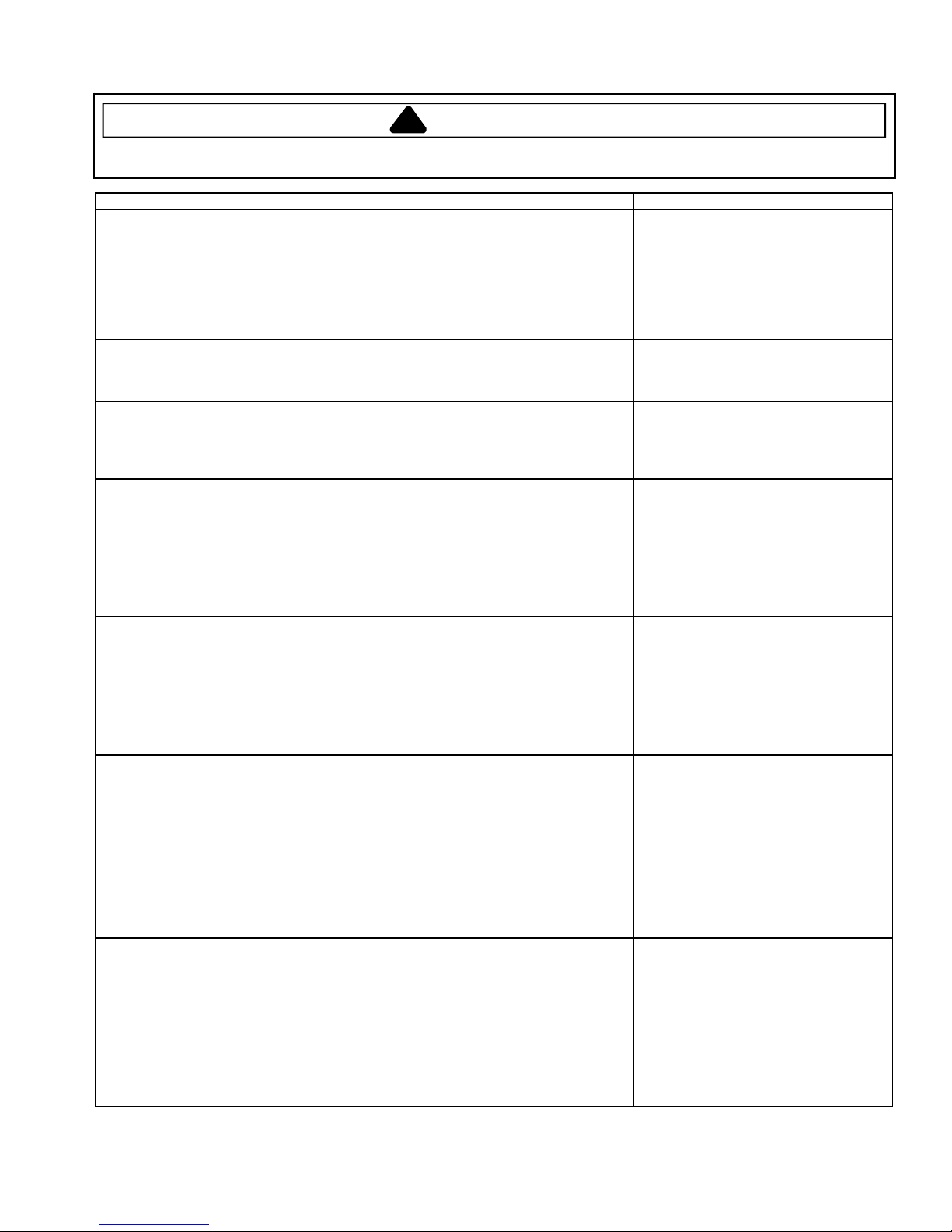

Problem Possible Cause Correction

Blower motor will not

operate, lights will not

illuminate

Blower motor will not operate

(Lights illuminate)

Blower motor starts slow and

will not operate at full speed

(Lights illuminate)

Blower motor operates, but

cannot change fan speed

(Lights illuminate)

Lights will not illuminate

(Blower motor operates)

Lights illuminate at full

brightness only

(Blower motor operates)

No input power ...............................................

Circuit breaker tripped ....................................

Black/white or white wires loose at control

board, no wires connected to control board...

Control board defective..................................

Touch pad/control panel defective .................

Blue wire loose on control board ....................

Blower motor seized.......................................

Blower motor defective...................................

Capacitor damaged or defective ....................

Touch pad or control panel defective.............

Blower motor too hot and has been shut

down by the thermal protection system..........

Capacitor shorted or defective .......................

Blower motor defective...................................

Control board defective..................................

Touch pad or control panel defective.............

Obstructions in blower motor .........................

Capacitor shorted or defective .......................

Blower motor defective...................................

Touch pad or control panel defective.............

Obstructions in blower motor .........................

Light bulb(s) burnt out ....................................

Light bulb not making contact with socket .....

Red wire loose on control board ....................

Touch pad or control panel defective.............

Light socket defective.....................................

Loose wires to lights/control board.................

Light socket defective.....................................

Control board defective..................................

Control panel defective ..................................

Touch pad or control panel defective.............

WARNING

• Verify 120 VAC is present at unit.

• Verify circuit breaker isn’t tripped.

• Verify all connections are tight.

• Perform control board test.

• Perform touch pad or control

panel test.

• Verify blue wire is connected and

tight on control board.

• Verify blower is free from

obstructions and rotates freely.

• Perform blower motor test.

• Perform capacitor test.

• Perform touch pad or control

panel test.

• Allow blower motor to cool.

• Perform capacitor test.

• Perform blower motor test.

• Perform control board test.

• Perform touch pad or control

panel test.

• Verify blower motor is free from

obstructions and rotates freely.

• Perform capacitor test.

• Perform blower motor test.

• Perform touch pad or control

panel test.

• Verify blower motor is free from

obstructions and rotates freely.

• Replace bulb(s).

• Remove power to unit, remove

light bulb and bend the two metal

brackets inside the bulb opening

(bend outwards). This lowers

the light socket.

• Verify red wire is connected and

tight on control board.

• Perform touch pad or control

panel test.

• Perform halogen light test.

• Verify wires are connected and

tight at light socket/control board.

• Perform halogen light test.

• Perform control board test.

• Replace control panel.

• Perform touch pad or control

panel test.

©2004 Maytag Services 16023510 9

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to vent hood before servicing, unless

testing requires power.

WARNING

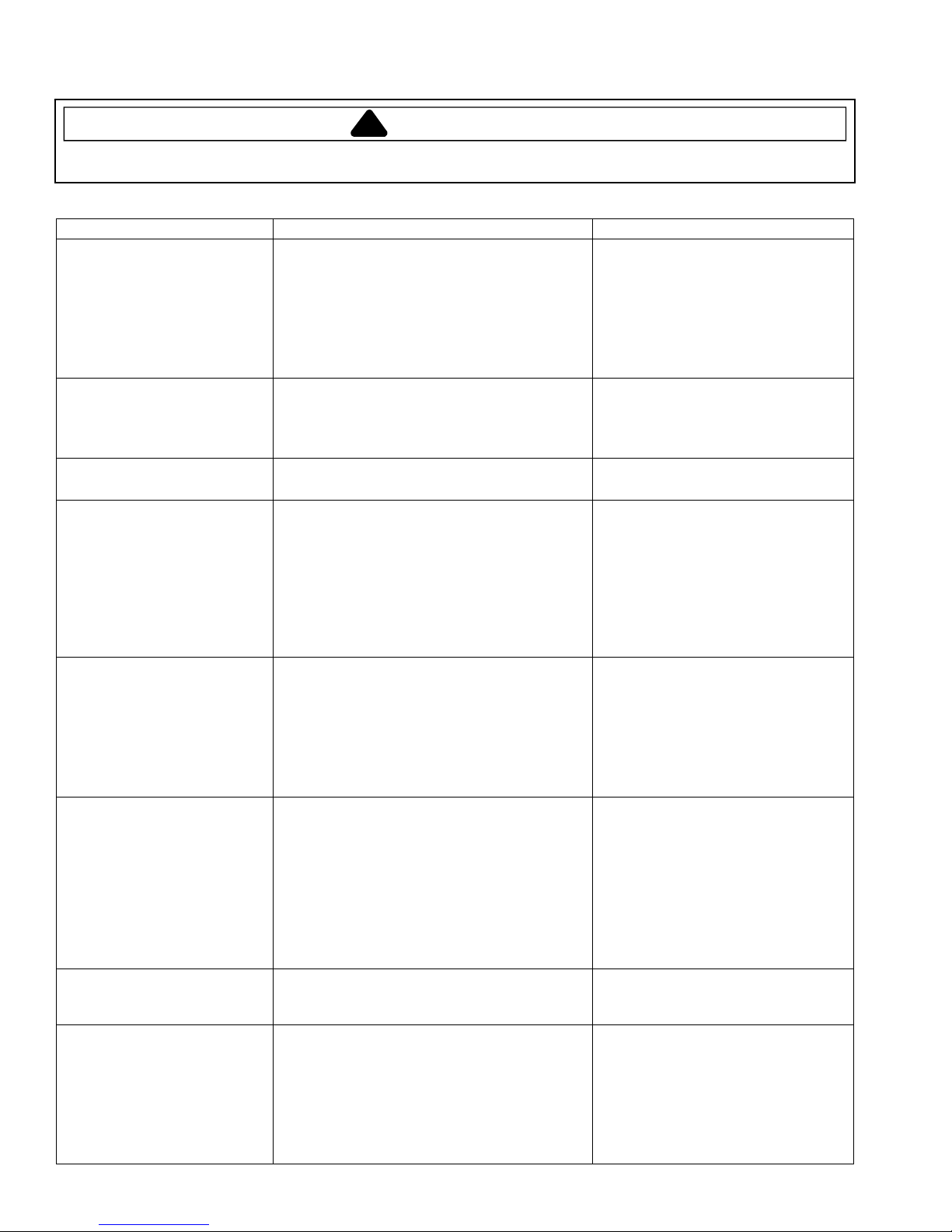

Problem Possible Cause Correction

Lights illuminate at half

brightness only

(Blower motor operates)

Vent hood vibrates when

operating blower motor

Metal filter vibrates when

operating blower motor

Display will not illuminate No input power ...............................................

Heat lamp will not illuminate Heat lamp bulb defective................................

Dim display Loose wire connection or broken wire............

Any one single function on

control panel does not

operate

Vent hood not venting

properly

10 16023510

Loose wires to lights/control board.................

Light socket defective .....................................

Control board defective ..................................

Control panel defective...................................

Touch pad or control panel defective .............

Blower motor loose.........................................

Blower motor wheel damaged........................

Vent hood not securely fastened....................

Metal filter loose .............................................

Broken clip......................................................

Circuit breaker tripped ....................................

Loose wire connection or broken wire............

Control board defective ..................................

Touch pad or control panel defective .............

No input power ...............................................

Circuit breaker tripped ....................................

Loose wire connection or broken wire............

Touch pad or control panel defective .............

Control board requires a reset........................

Control board defective ..................................

Touch pad or control panel defective .............

Touch pad or control panel defective .............

Vent hood not close enough to cooktop.........

Open doors/windows affecting air flow...........

Ductwork clogged or blocked .........................

Duct opening restricted ..................................

Ductwork too small .........................................

• Verify wires are connected and

tight at light socket/control board.

• Perform halogen light test.

• Perform control board test.

• Perform control panel test.

• Perform touch pad or control

panel test.

• Tighten blower motor.

• Replace blower motor wheel.

• Verify vent hood installation;

tighten as necessary.

• Tighten or change metal filter.

• Replace the clip.

• Verify 120 VAC is present at unit.

• Verify circuit breaker isn’t tripped.

• Verify all connections are clean

and tight, wires are not broken.

• Verify voltage is present. If so,

perform control board test.

• Perform touch pad or control

panel test.

• Replace heat lamp bulb.

• Verify 120 VAC is present at unit.

• Verify circuit breaker isn’t tripped.

• Verify all connections are clean

and tight, wires are not broken.

• Perform touch pad or control

panel test.

• Verify all connections are clean

and tight, wires are not broken.

• Disconnect power to unit for 15

minutes. If still dim, replace the

control board.

• Verify voltage is present. If so,

test control board.

• Perform touch pad or control

panel test.

• Perform touch pad or control

panel test.

• Verify distance between hood

and cooktop (24-32 inches).

• Close all nearby doors and

windows.

• Clean the ductwork.

• Adjust the duct opening direction.

• Increase size of ductwork.

©2004 Maytag Services

Testing Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to vent hood before servicing, unless

testing requires power.

Model Numbers Component Test Procedure Results

All Halogen lights

All Halogen light socket Remove one wire from receptacle and test

JXT9030CDP,

JXT9036CDP,

JXT9048CDP,

JXT9130CDP,

JXT9136CDP

JXT8030ADS,

JXT8036ADS,

JXT8042ADS,

JXT8136ADS,

JXT8142ADS,

JXT5830AD*,

JXT5836AD*

JXT9030CDP,

JXT9036CDP,

JXT9048CDP,

JXT9130CDP,

JXT9136CDP

JXT8030ADS,

JXT8036ADS,

JXT8042ADS,

JXT8136ADS,

JXT8142ADS,

JXT5830AD*,

JXT5836AD*

JXT9030CDP,

JXT9036CDP,

JXT9048CDP,

JXT9130CDP,

JXT9136CDP

Heat lamp socket Remove one wire from receptacle and test

Capacitor Disconnect wires. Measure resistance by

Capacitors

(2 ea, red wires input,

yellow wires output)

Transformer Check for input voltage by placing red

Transformer Check for input voltage by placing red

Press light switch once ................................

(measure voltage at light socket).................

Press light switch again...............................

(measure voltage at light socket).................

Press light switch once ................................

(measure voltage at light socket).................

Press and hold light switch for 3 seconds....

(measure voltage at light socket).................

resistance of terminals.................................

Measure voltage at light ..............................

resistance of terminals.................................

Measure voltage at light ..............................

placing red meter lead on positive

terminal, black meter lead on negative

terminal .......................................................

Reverse meter leads on capacitor

terminals......................................................

Check for a short by placing one lead on a

terminal and the other to ground..................

Obtain analog multi-meter. Disconnect

wires. Measure resistance by placing red

meter lead on positive terminal, black

meter lead on negative terminal ..................

Reverse meter leads on capacitor

terminals......................................................

Check for a short by placing one lead on a

terminal and the other to ground..................

lead on black wire (input voltage), black

lead on white wire (neutral)..........................

Check transformer outputs by placing leads

on black (input voltage) and white (neutral),

then set fan speed as follows:

6 ..................................................................

5 ..................................................................

4 ..................................................................

3 ..................................................................

2 ..................................................................

1 ..................................................................

lead on brown wire (input), black lead on

light blue wire (neutral) ................................

Check transformer outputs by placing

meter leads on:

Brown (Input voltage) ..................................

Black ...........................................................

Red..............................................................

Orange ........................................................

Yellow..........................................................

Green (Lowest setting) ................................

Lights illuminate to full brightness

(120 VAC).

Lights extinguish (turn off)

(0 VAC).

Lights illuminate to full brightness

(120 VAC).

Lights illuminate to half brightness

(63 VAC)

Indicates continuity with bulb screwed in.

120 VAC. If no voltage is present at

light, check wiring or light switches.

Indicates continuity with bulb screwed in.

120 VAC. If no voltage is present at

light, check wiring or light switches.

Meter reading should gradually increase

(capacitor charging).

Meter reading should gradually decrease

(capacitor discharging).

Infinity (if shorted, replace capacitor).

Rating: 4 microfarad

Meter reading should gradually increase

(capacitor charging).

Meter reading should gradually decrease

(capacitor discharging).

Infinity (if shorted, replace capacitor).

120 VAC

113 VAC

88 VAC

80 VAC

66 VAC

50 VAC

33 VAC

120 VAC

120 VAC

106 VAC

97 VAC

90 VAC

81 VAC

74 VAC

©2004 Maytag Services 16023510 11

Loading...

Loading...