Jenn-Air JXT19130CDP, JXT19136CDP Installation Manual

RANGE HOOD

ModeJ Number:

Manufacturer Number:

Size:

.[×19130CDP

MK753_}

30"

[×19136CDP

MK7536

36"

GUIDE

TABLE OF CONTENTS

Satet, Instructions .................................................... 1

MountinR Heights ................................................... 2

[)uctin¢ .............................................................. 3-7-8

Specifications ........................................................... 4

Installation ............................................................ 5-6

F:orm No. A/06/04 Part No. 8110P262-60 ,¢2004 Maytag Appliances Sales (o. litho U.S.A.

MODELS: JXT9130 J×T9136

Installation

Theinstallationin thismanuarisintendedforquarifiedinstallers,servicetechniciansor persons

withsimilarqualifiedbackground.DONOTattempttoinstarlthisapplianceyourserf,rniurycourd

resurtfrominstallingtheunitdueto rackofappropriateerectricalandtechnicalbackground.

Air erectricar wiring must be properly installed, insulated and grounded. Overly accumulated

greasein old duct work should becleaned out orduct work should be replaced if necessaryto

avoid the possibility of agrease fire. Checkall ioints on duct work to insure proper connection

andallioints should be properly taped.

* Please check for latest specification revisions before any custom work or cutouts.

LiST OF MATERIALS

=

2=

2=

1=

Hood

Bafflefilters (2°30", 3°36")

Halogenlight bulbs (2°30", 3-36")

Hardwarepacketcontaining:

4 ° 2" drywall screws

4 ° 1 1/2" drywall screws

4 ° 1" drywall screws

4 ° 1/2" washers

3 °wire connectors

1° 6 to 3 1/4" x 10" rectanguhr adapter

NODUOTINGISINCLUDED

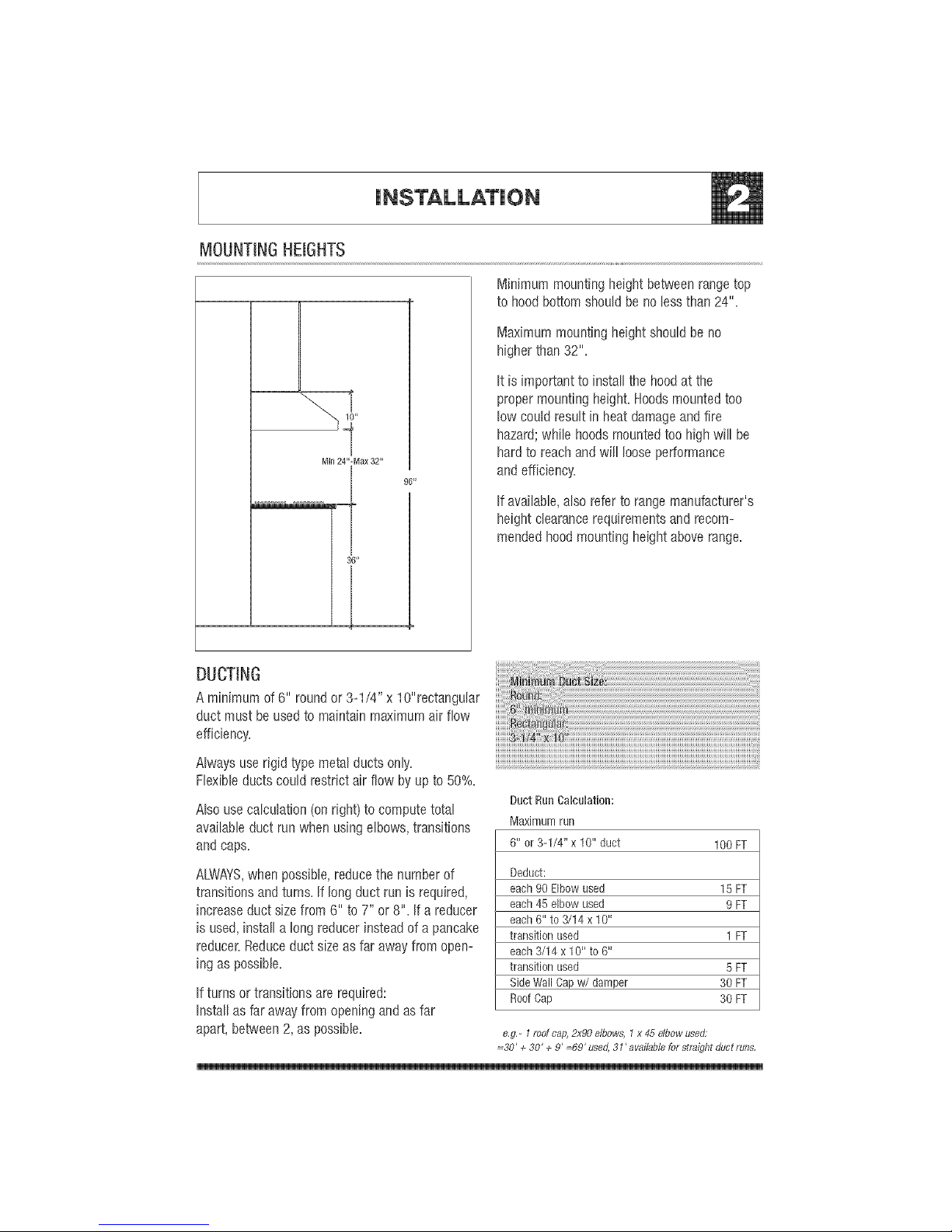

MOUNTINGHEIGHTS

96"

Minimum mounting height between rangetop

to hood bottomshouMbenotess than 24".

Maximum mounting height shourdbe no

higher than 32".

rt is important to instarlthe hoodat the

proper mounting height. Hoodsmounted too

row couM result in heat damageand fire

hazard; while hoods mounted too high will be

hard to reach and will rooseperformance

and efficiency.

ff available, arso refer to range manufacturer's

height clearance requirements and recom-

mended hoodmounting height above range.

DUCTING

A minimum of 6" roundor 3-1/4" x lO"rectangurar

duct must be usedto maintain maximum air flow

efficiency.

Alwaysuserigidtypemetalductsonly,

Flexibleductscouldrestrictair flowbyupto 50%.

Also use calculation (on right) to compute total

availableduct run when using elbows, transitions

andcaps.

ALWAYS,when possible, reducethe number of

transitions and turns. If long duct run is required,

increase duct size from 6" to 7" or 8". If a reducer

is used, install a long reducer instead of a pancake

reducer.Reduceduct size as far away from open°

ing as possible.

If turns or transitions are required:

Install as far away from opening and asfar

apart, between 2, as possible.

Duct RunCalculation:

Maxirnulnrun

6" or 3-1/4' x 10" duct

100FT

Deduct:

each90 Elbowused 15 FT

each45 elbow used 9 FT

each6" to "Y14x 10"

transition used 1 FT

each3/14 x 10" to 6"

transition used 5 FT

SideWallCapw/damper 30 FT

RoofCap 30 FT

e,g,- 1 roof cap, 2x90 elbows, t x 45 elbow used;

=30' + 30' + 9' =69' used, 31' available for stroiqht duct runs,

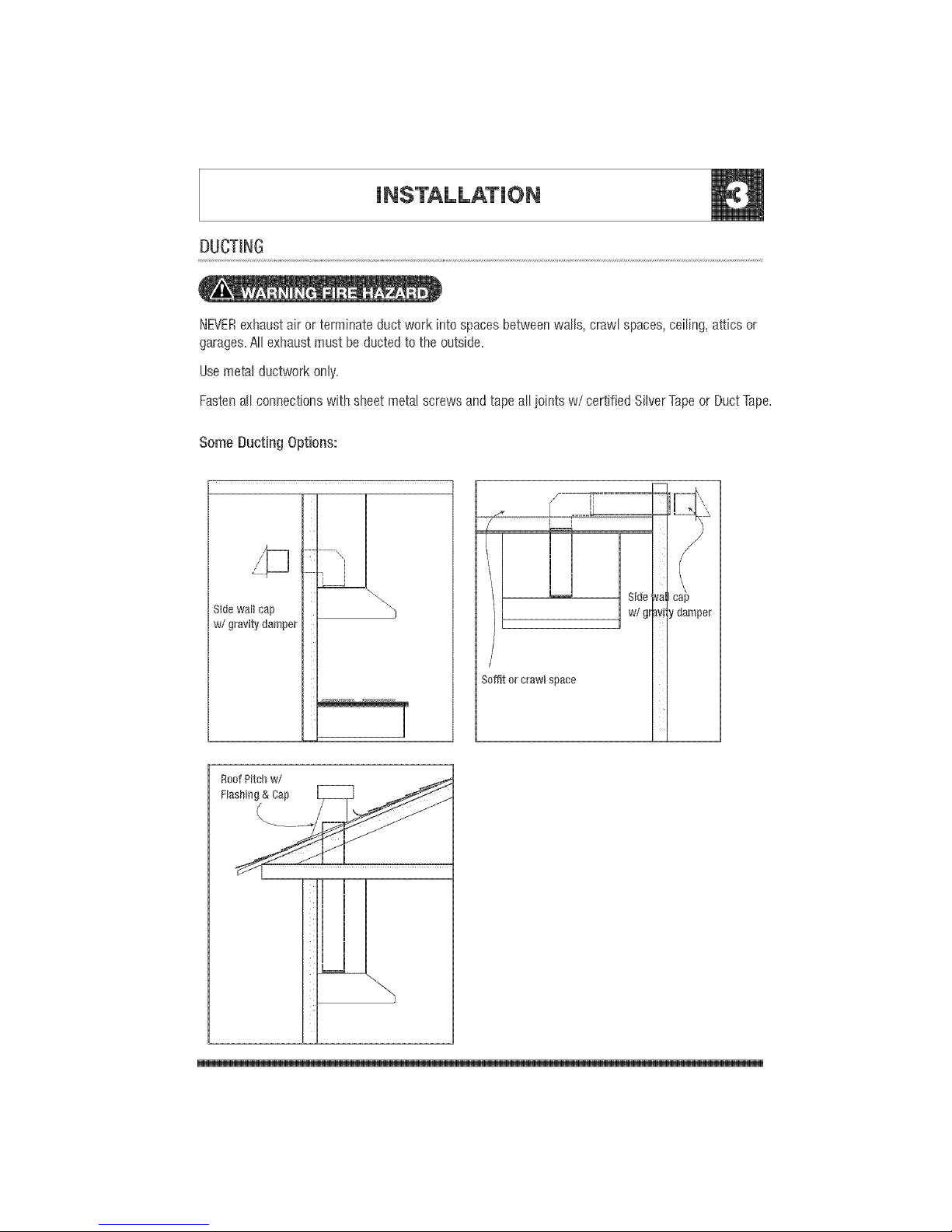

DUCTING

NEVERexhaustair or terminate duct work into spaces betweenwalls, crawl spaces,ceiling, attics or

garages.Airexhaust must be ducted to theoutside.

Usemetal ductwork onry.

FastenaHconnections with sheet metal screws and tape aHjoints w/certified SHyerTapeor Duct Tape.

SomeDucting Options:

Sidewallcap

w/gravitydamper

i

/- T"

[ I

I r .---L.

n H

! !

SideNa

w/gtavi:ydamper

Soffitor crawl space

RoofPitch w/

Flashing& Cap

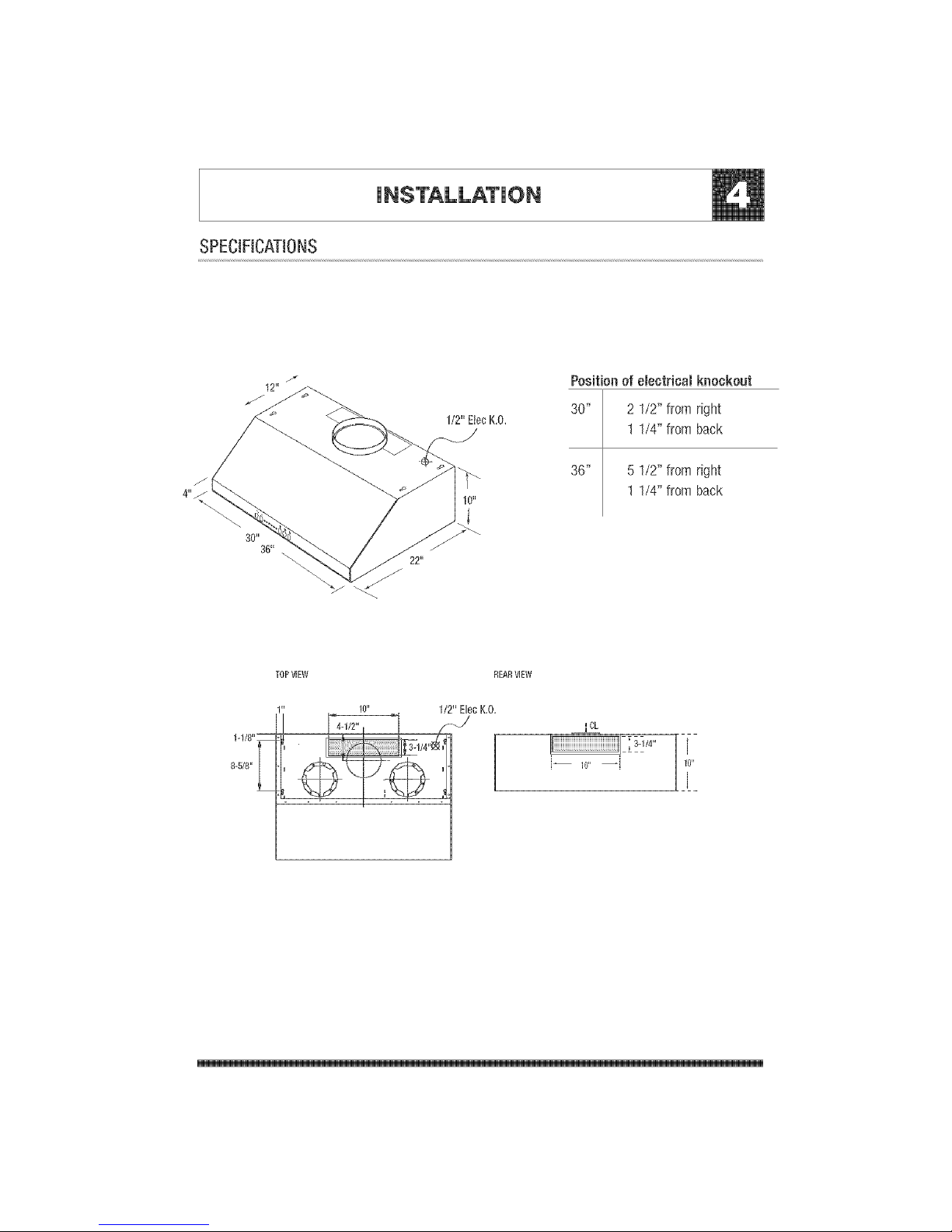

SPECIFICATIONS

4"J

Positionof electricalknockout

30" 2 1/2"fromright

1 1/4"fromback

36" 5 1/2"fromright

1 1/4"fromback

TORVIEW REARVIEW

1-1/R"_

8o5/8"

MOUNTINGTHE IANGEHOOD

ELECTRICAL

All Electricalworkmustbyperformedbyqualifiedelectricianor personwith similartechnical

knowhowandbackground.

Forpersonalsafety,removehousefuseoropencircuitbreakerbeforebeginninginstallation+

Donot useextensioncordoradapterplugwiththis appliance+

FollowNationalelectricalcodesor prevailng localcodesandordinances.

ElectricalSupply:

Thisappliancerequiresa 120V60Hzelectricalsupply,connectedtoanindividual,properlygrounded

branchcircuit,protectedbya 15or20amperecircuitbreakeror timedelayfuse:Wiringmustbe2

wirew/ground:PleasealsoreferElectricalDiagramlabeledonproduct:

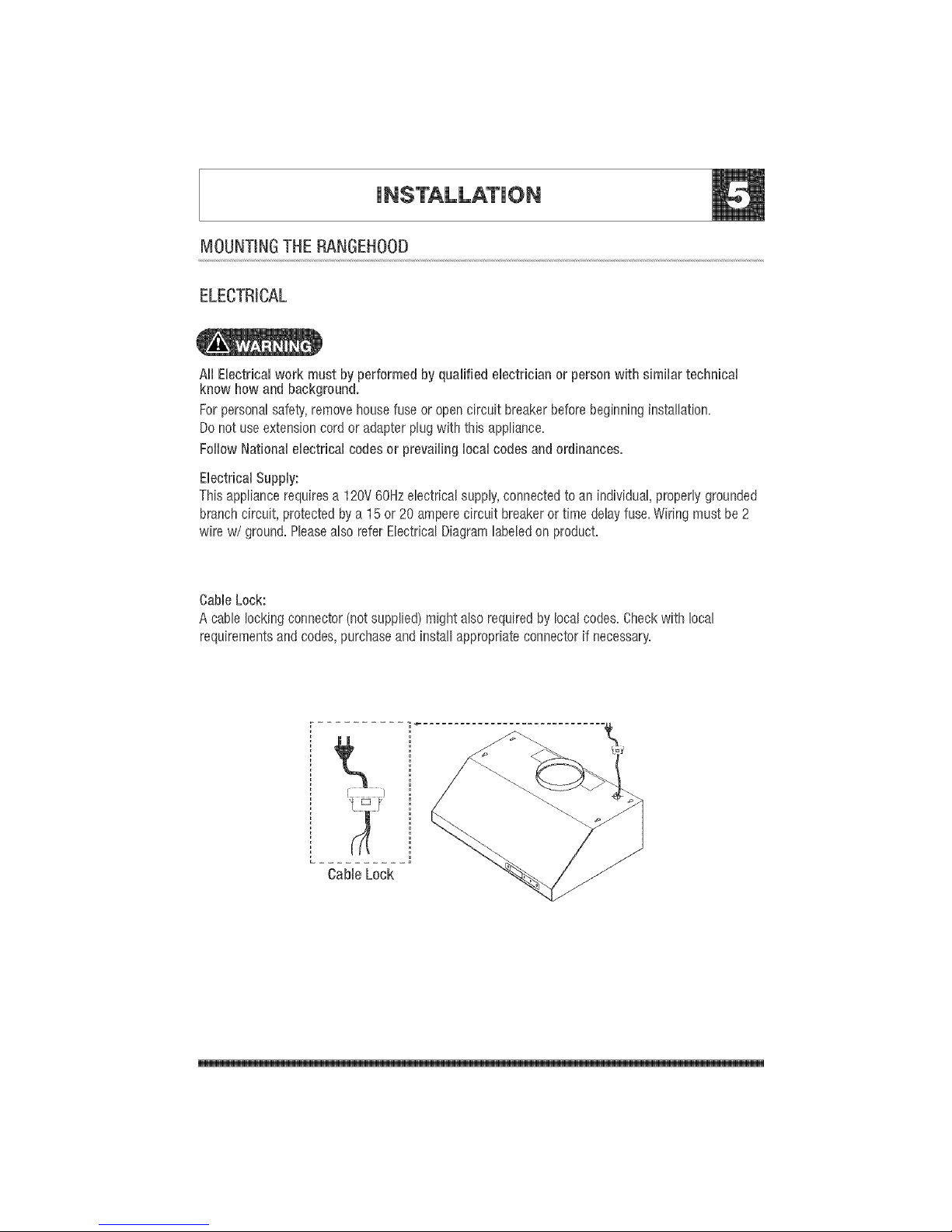

Cable Lock:

A cable locking connector (not supplied) might also required by local codes. Checkwith local

requirements and codes, purchaseand install appropriate connector if necessary.

J

L ..........

CableLock

MOUNTINGTHE RANGEHOOD

1. This range hood is mounted undera

kitchen cabinet unit.

2. Selectpreferred duct location on rear or

top of unit. (Seepage6 & 7 for ducting

conversion options)

3. Begin installation by temporarily removing

the baffle filters.

4. Reinforcecabinet basewith lx2 wood

strips if additional strengthening is

required.

5. Temporarilyposition the range hood in

the desired mounting location.

Measure and mark the mounting holes,

duct and electrical access locations with

a pencil.

6. Drill/cut out the required openings for

duct and electrical access; make sure the

duct opening is large enoughto apply

duct tape.

7. Fastenhood onto cabinet with screws

and washers provided.

8. Install electrical.

9. Install duct work and duct-tape.

10. Reinstall the baffle filters.

11. Power up hood andcheck for leaks

around duct-tape.

6, Duct

opening

cutout

/

4. Add lx2

woodstrips

CONVERTIBLEOPTIONS

This rangehood is equipped with the option of a 6" verticar discharge,3 1/4"x10" vertical discharge,

or 3 1/4"x10" rear discharge.Additionar accessories are provided to convert to either of the above

discharge methods.

Convertible Options

Verticardischarge 6" round

Verticardischarge 3 1/4"xl 0"

Horizontalrear discharge 3 1/4"xl 0"

Convertible Accesories

Roundto rectangurartransition adaptor

Rectangurarto round transition adaptor (pre-mounted)

Gasket(pre°mounted)

Rectangurarrear cap (pro-mounted)

3 1/4"x10" starting corrar

3 1/4"x10" Vertical Discharge

1.Removepro-mounted 6"transition adaptoror duct

opening,Leaveattachedgasketin its originalplace.

3. Mount the3-1/4"x10" starting collaron top of

transition piecewith remainingscrews.

2, Placerectangular transitionadaptor asshown over

gasketand by first installing 4screws on Ilalf round

section,

Loading...

Loading...