Jenn-Air JUW248RWRS, JUW248RWRB, JUW248RBRS, JUW248RBRB, JUW248RBCX Owner's Manual

...

JENN-AIR® WINE CELLAR/BODEGA/CAVE À VIN

Overlay Model/Modelo recubierto/Modèle à panneau décoratif

USE & CARE GUIDE

For questions about features, operation/performance, parts, accessories, or service, call:

1-800-JENNAIR (1-800-536-6247) or visit our website at www.jennair.com.

In Canada, call: 1-800-807-6777, or visit our website at www.jennair.ca.

MANUAL DE USO Y CUIDADO

Si tiene preguntas respecto a las características, funcionamiento, rendimiento, partes, accesorios o servicio técnico, llame al:

1-800-JENNAIR (1-800-536-6247) o visite nuestro sitio de internet www.jennair.com.

En Canadá, llame al: 1-800-807-6777, o visite nuestro sitio de internet www.jennair.ca.

GUIDE D’UTILISATION ET D’ENTRETIEN

Au Canada, pour assistance, installation ou service, composez le 1-800-807-6777 ou visitez notre site web à www.jennair.ca.

Table of Contents/Índice/Table des matières ......................................................................................2

2300283C

TABLE OF CONTENTS

WINE CELLAR SAFETY ..............................................................................3

Proper Disposal of Your Old Wine Cellar .................................................3

INSTALLATION INSTRUCTIONS ...............................................................4

Tools and Parts.........................................................................................4

Custom Overlay Frame............................................................................. 4

Location Requirements............................................................................. 5

Electrical Requirements............................................................................ 5

Unpack the Wine Cellar ............................................................................5

Install Custom Overlay Frame ..................................................................6

Door Closing ............................................................................................. 7

Base Grille.................................................................................................8

WINE CELLAR USE..................................................................................... 8

Normal Sounds ......................................................................................... 8

ÍNDICE

SEGURIDAD DE LA BODEGA ..................................................................14

Cómo deshacerse adecuadamente de su bodega vieja ....................... 14

INSTRUCCIONES DE INSTALACIÓN ...................................................... 15

Piezas y herramientas.............................................................................15

Marco recubierto a la medida................................................................. 15

Requisitos de ubicación ......................................................................... 16

Requisitos eléctricos............................................................................... 16

Desempaque de la bodega ....................................................................17

Cómo instalar el marco recubierto a la medida .....................................17

Cierre de la puerta ..................................................................................19

Rejilla de la base ..................................................................................... 19

USO DE LA BODEGA ................................................................................ 19

Sonidos normales ................................................................................... 19

Using the Control...................................................................................... 8

Wine Racks............................................................................................... 9

Stocking the Wine Cellar ..........................................................................9

Lighting the Wine Cellar............................................................................ 9

WINE CELLAR CARE................................................................................ 10

Cleaning.................................................................................................. 10

Changing the Light Bulb.........................................................................10

Vacation and Moving Care .....................................................................10

TROUBLESHOOTING ...............................................................................11

ASSISTANCE OR SERVICE...................................................................... 12

In the U.S.A............................................................................................. 12

In Canada................................................................................................ 12

WARRANTY ............................................................................................... 13

Uso del control ....................................................................................... 20

Portabotellas........................................................................................... 20

Cómo almacenar en la bodega .............................................................. 21

Cómo iluminar la bodega ....................................................................... 21

CUIDADO DE LA BODEGA ...................................................................... 21

Limpieza.................................................................................................. 21

Cómo cambiar el foco ............................................................................22

Cuidado durante las vacaciones y mudanzas ....................................... 22

SOLUCIÓN DE PROBLEMAS................................................................... 23

AYUDA O SERVICIO TÉCNICO................................................................ 24

En los EE.UU........................................................................................... 24

En Canadá .............................................................................................. 24

GARANTÍA .................................................................................................25

TABLE DES MATIÈRES

SÉCURITÉ DE LA CAVE À VIN................................................................. 27

Mise au rebut de votre vieille cave à vin.................................................27

INSTRUCTIONS D’INSTALLATION ......................................................... 28

Outillage et pièces ..................................................................................28

Cadre décoratif personnalisé .................................................................28

Exigences d’emplacement .....................................................................29

Spécifications électriques....................................................................... 29

Déballage de la cave à vin...................................................................... 30

Installation du cadre décoratif personnalisé .......................................... 30

Fermeture de la porte .............................................................................32

Grille de la base ......................................................................................32

UTILISATION DE LA CAVE À VIN ............................................................32

Sons normaux......................................................................................... 32

Utilisation de la commande....................................................................33

Casiers à vin ...........................................................................................33

Stockage dans la cave à vin................................................................... 34

Éclairage de la cave à vin .......................................................................34

ENTRETIEN DE LA CAVE À VIN .............................................................. 34

Nettoyage ...............................................................................................34

Changement de l'ampoule d'éclairage .................................................. 35

Précautions à prendre pour les vacances

et avant un déménagement.................................................................... 35

DÉPANNAGE ............................................................................................. 36

ASSISTANCE OU SERVICE...................................................................... 37

Aux États-Unis........................................................................................ 37

Au Canada ..............................................................................................37

GARANTIE.................................................................................................. 38

2

WINE CELLAR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

■

Plug into a grounded 3 prong outlet.

■

Do not remove ground prong.

■

Do not use an adapter.

■

Do not use an extension cord.

■

Disconnect power before servicing.

■

Replace all parts and panels before operating.

To reduce the risk of fire, electric shock, or injury when using your wine cellar, follow these basic precautions:

SAVE THESE INSTRUCTIONS

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

■

Remove doors from your old wine cellar.

■

Use nonflammable cleaner.

■

Keep flammable materials and vapors, such as gasoline,

away from wine cellar.

■

Use two or more people to move and install wine cellar.

follow

Proper Disposal of Your Old Wine Cellar

WARNING

Suffocation Hazard

Remove door from your old wine cellar.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned wine cellars are still dangerous

– even if they will sit for “just a few days.” If you are getting rid of

your old wine cellar, please follow these instructions to help

prevent accidents.

Before You Throw Away Your Old Wine Cellar:

■ Take off the door.

■ Leave the racks in place so that children may not easily climb

inside.

3

INSTALLATION INSTRUCTIONS

Tools and Parts

TOOLS NEEDED:

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Hand drill or electric drill

(properly grounded)

■ ¹⁄₂" Brad point doweling

drill bit

■ Phillips screwdriver

■ Scissors

■ Masking tape

■ Tape measure

■ Petroleum jelly

PARTS NEEDED:

Custom Overlay Frame—See “Overlay Frame—Rear View.”

Hardware (Optional)

PARTS SUPPLIED:

■ Flat-head screws (8)

■ Round-head screws (8)

■ Overlay plates (2)

■ Overlay hooks (4)

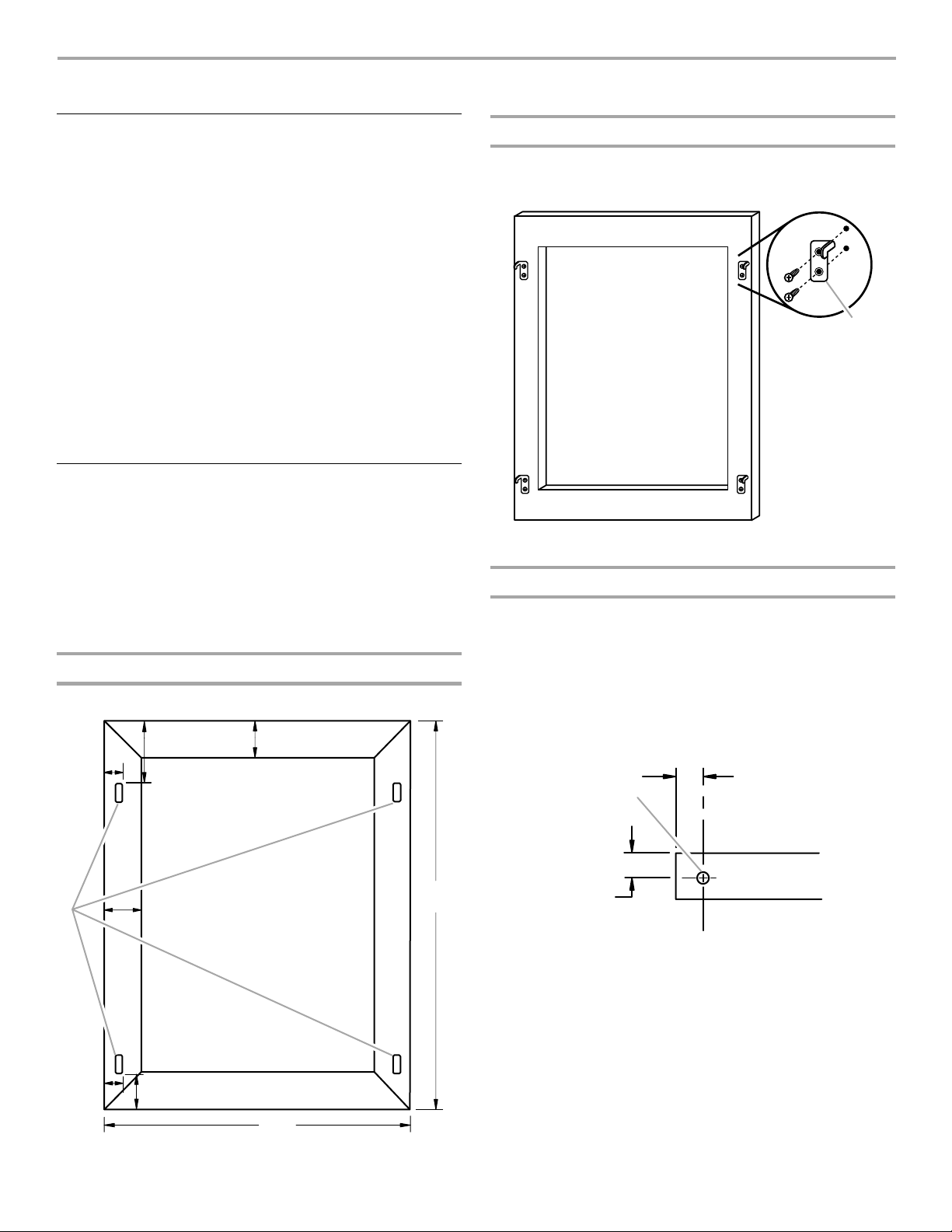

Custom Overlay Frame

If you plan to install a custom overlay frame, you will need to

create the frame yourself or consult a qualified cabinetmaker or

carpenter. See dimension drawings for frame specifications.

IMPORTANT:

■ The thickness of the overlay frame must be ³⁄₄" (1.91 cm).

■ Overlay frame must not weigh more than 10 lbs (4.54 kg).

■ Overlay frames weighing more than recommended may

cause damage to your appliance.

Overlay Frame—Rear View

Create the custom overlay frame using the dimensions shown.

4

¹³⁄₃₂

1

⁵⁄₁₆

(3.33 cm)

"

(11.2 cm)

"

2.95"

(7.5 cm)

Install Overlay Hooks

Using a Phillips screwdriver and eight flat-head screws attach the

overlay hooks to the back of the overlay frame. See “Overlay

Frame–Rear View” for overlay hook locations.

A

A. Overlay hooks (4)

Door Hinge Holes

■ The views of the top and bottom hinge pin hole show a right-

hand hinge. Mirror the image for a left-hand hinge.

■ We recommend using a C-clamp and two pieces of scrap

wood (front and back) to help reinforce the overlay frame

when drilling the hinge pin holes.

1. Using a ¹⁄₂" Brad point doweling drill bit, drill a ¹⁄₂" (1.27 cm)

deep hole into the top of the overlay frame for the top hinge

pin as shown.

Top View

¹⁄₂"

A

(1.2 cm)

A

⁵⁄₁₆

1

(3.33 cm)

4

Front Surface

29

⁷⁄₈

"

2.95"

(7.5 cm)

"

2

¹⁄₂

"

(6.4 cm)

A. Overlay hook locations

23.62"

(60.0 cm)

(75.88 cm)

¹⁷⁄₃₂"

(1.35 mm)

Back Surface

A. Radius 5.0

2. Drill a ¹⁄₂" (1.27 cm) deep hole in the bottom of the overlay

frame for the bottom hinge pin as shown.

Bottom View

Electrical Requirements

¹⁄₂"

(1.2 cm)

Back Surface

Front Surface

¹⁷⁄₃₂"

(1.35 mm)

A

A. Radius 5.0

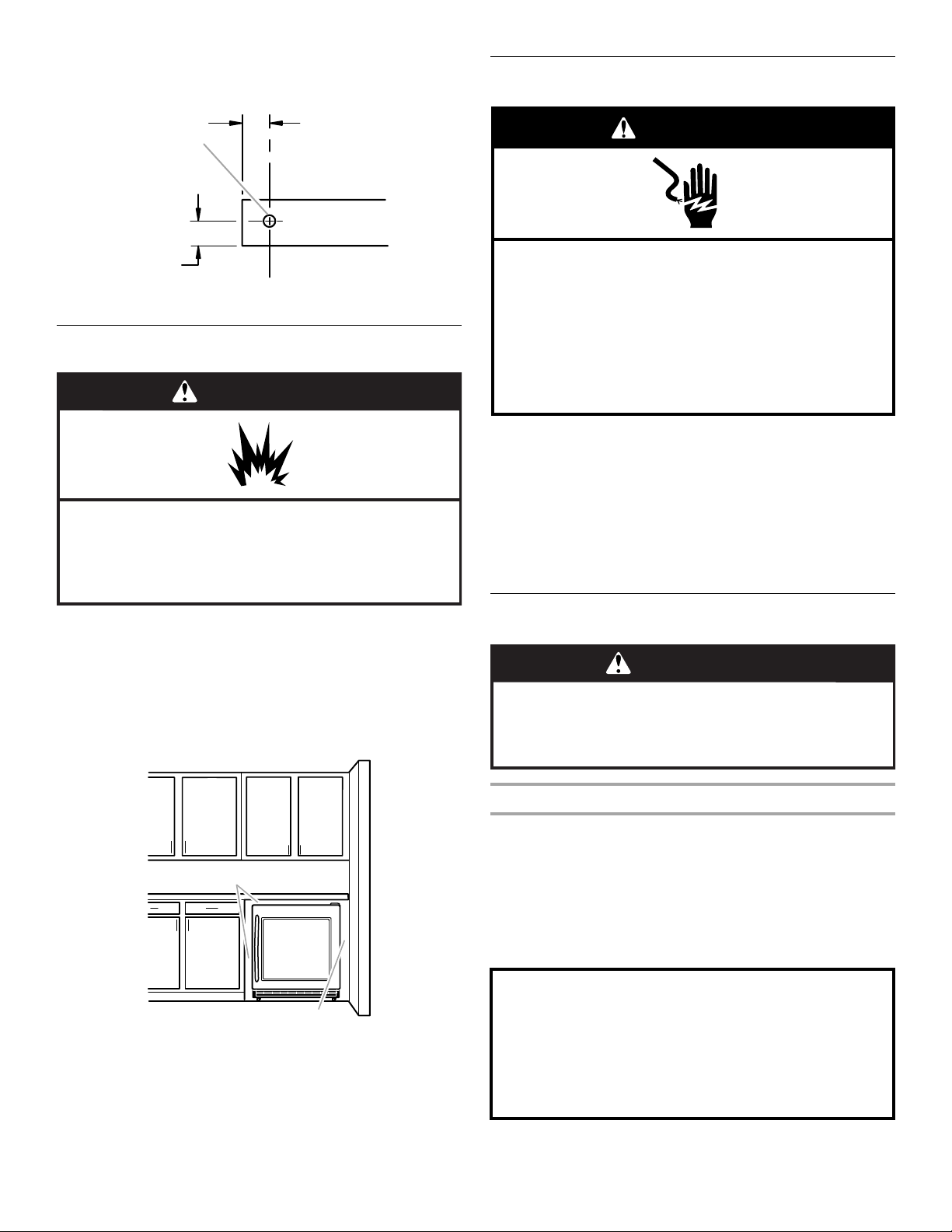

Location Requirements

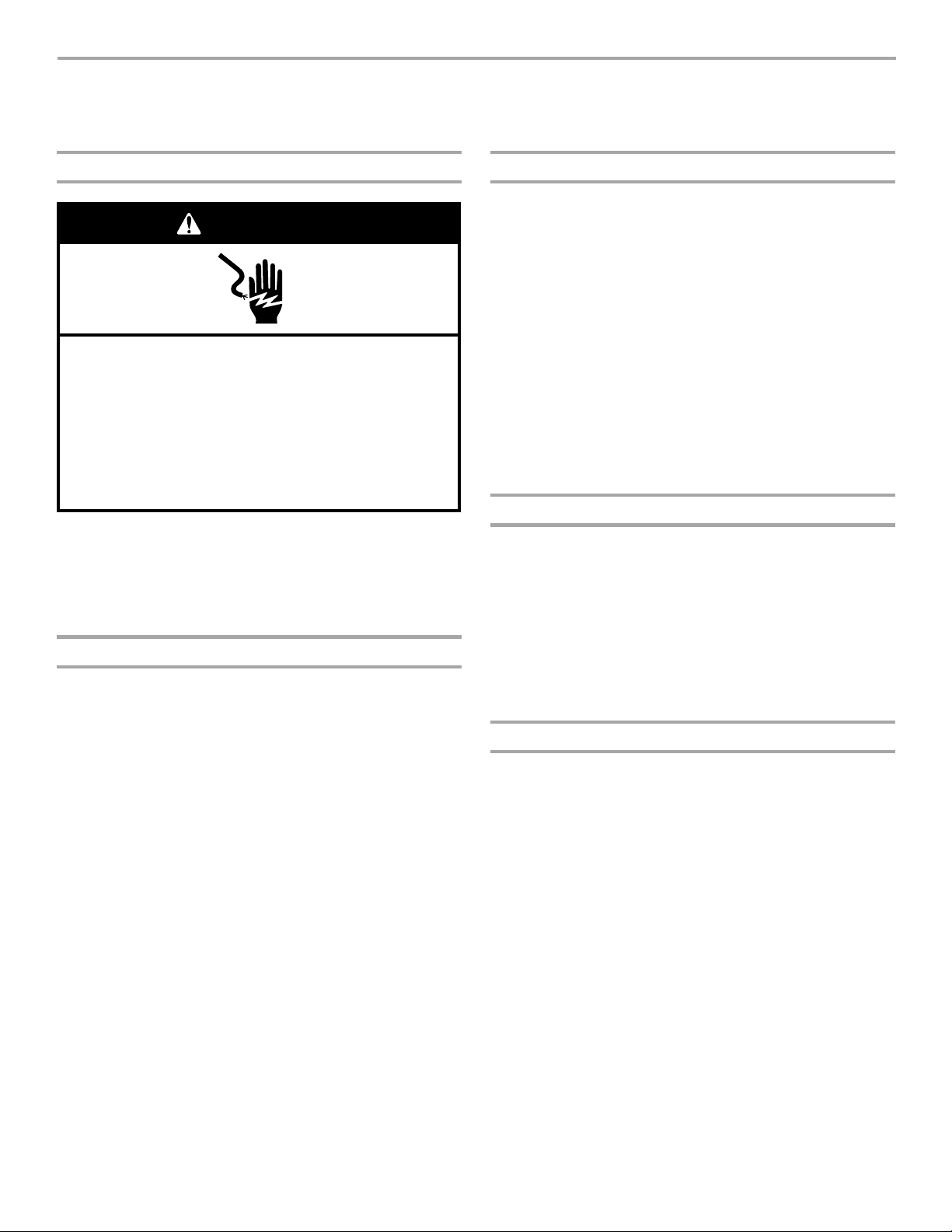

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from wine cellar.

Failure to do so can result in death, explosion, or fire.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Before you move your wine cellar into its final location, it is

important to make sure you have the proper electrical connection.

Recommended grounding method

A 115 Volt, 60 Hz., AC only, 15– or 20–amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your wine cellar be provided. Use an outlet

that cannot be turned off by a switch. Do not use an

extension cord.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, unplug wine cellar or disconnect power.

To ensure proper ventilation for your wine cellar, allow for a ¹/₄"

(6.35 mm) space on each side and at the top. When installing your

wine cellar next to a fixed wall, leave 2¹⁄₂" (6.35 cm) minimum

clearance on the hinge side to allow for the door to swing open.

NOTE: It is recommended that you do not install the wine cellar

near an oven, radiator, or other heat source. Do not install in a

location where the temperature will fall below 55°F (13°C). For

best performance, do not install the wine cellar behind a cabinet

door or block the base grille.

¹⁄₄" (6.35 mm)

2¹⁄₂" (6.35 cm)

Unpack the Wine Cellar

WARNING

Excessive Weight Hazard

Use two or more people to move and install wine cellar.

Failure to do so can result in back or other injury.

Remove the Packaging

■ Remove tape and glue residue from surfaces before turning

on the wine cellar. Rub a small amount of liquid dish soap over

the adhesive with your fingers. Wipe with warm water and dry.

■ Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your wine cellar. For

more information, see “Wine Cellar Safety.”

■ Dispose of/recycle all packaging materials.

When Moving Your Wine Cellar:

Your wine cellar is heavy. When moving the wine cellar for

cleaning or service, be sure to cover the floor with

cardboard or hardboard to avoid floor damage. Always pull

the wine cellar straight out when moving it. Do not wiggle

or “walk” the wine cellar when trying to move it, as floor

damage could occur.

5

Clean Before Using

C

D

E

A

B

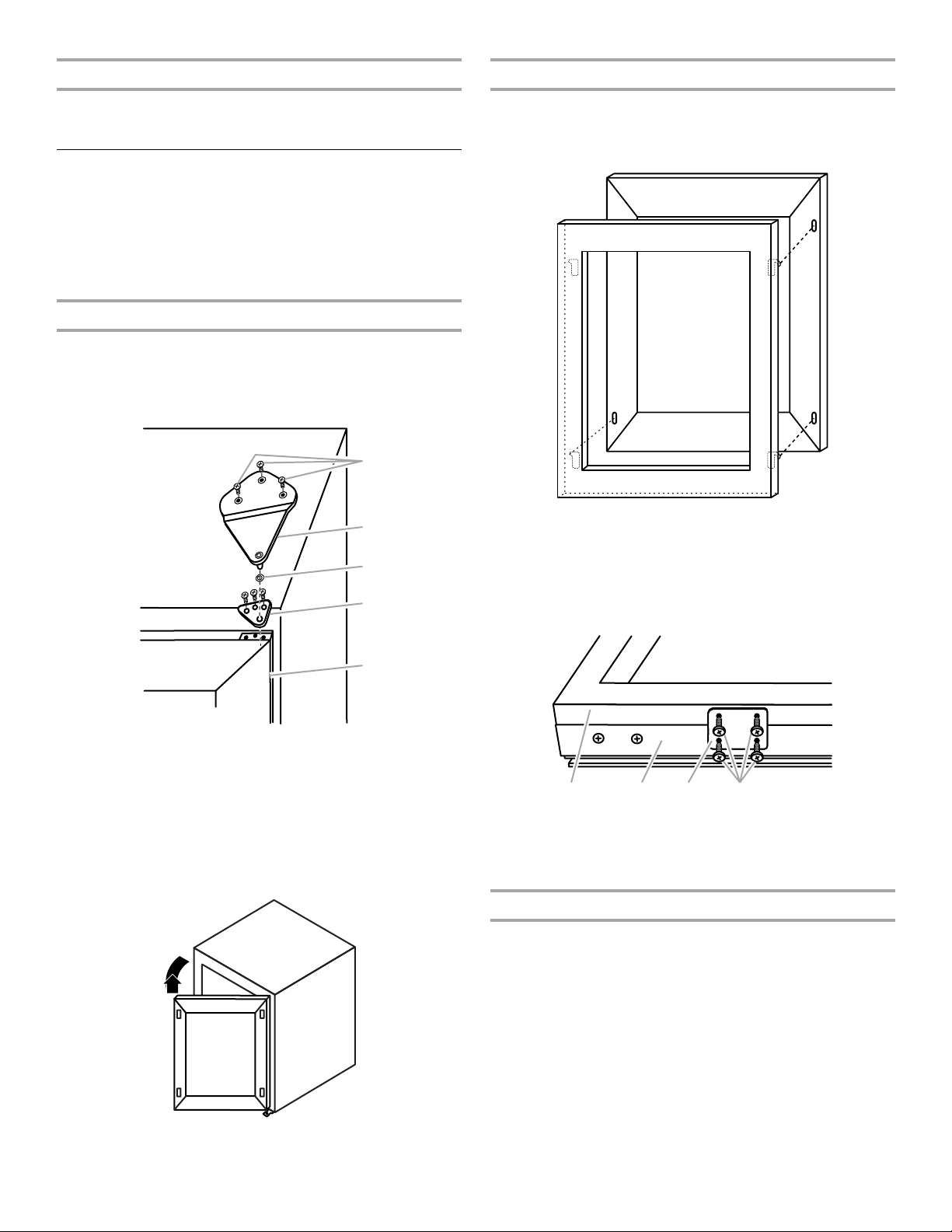

Attach the Overlay Frame

After you remove all of the packaging materials, clean the inside of

your wine cellar before using it. See the cleaning instructions in

“Wine Cellar Care.”

Install Custom Overlay Frame

IMPORTANT:

■ Create custom overlay frame according to the specifications

in the “Custom Overlay Frame” section.

■ Jenn-Air is not responsible for the removal or addition of

molding or decorative panels that would not allow access to

the appliance for service.

Remove the Door

IMPORTANT: Do not remove the grease from the washer, top

spacer or top hinge pin. Be sure to set aside the top hinge, top

spacer and washer for later use.

1. Using a Phillips screwdriver, remove the three screws from the

top hinge. Remove the top hinge.

NOTE: If the overlay hooks are not installed, see “Custom Overlay

Frame” for overlay hook locations.

1. Position the overlay frame ¹⁄₂" (1.27 cm) higher than the door.

Be sure to position the overlay hooks to the pilot holes.

2. Insert the overlay hooks into the top of the holes in the door.

Push against the overlay frame to force the overlay hooks

deeper into the door. Pull the overlay frame straight down to

secure the overlay hooks to the door.

3. Using a Phillips screwdriver, attach the overlay plates to the

bottom of the overlay frame and door as shown.

A. Screws (3)

B. Top hinge

C. Washer

D. Top spacer

E. Door

2. Remove the three screws from the top spacer. Remove the

top spacer and washer.

3. Open the door. Lift the front of the door up, pulling straight out

to remove as shown.

6

ACDB

A. Overlay frame

B. Door

C. Overlay plates (2)

D. Round-head screws (8)

Install the Door

IMPORTANT: To ensure proper operation, be sure to grease the

top hinge, top spacer and washer with petroleum jelly.

1. Using a Phillips screwdriver and three screws, attach the top

spacer to the door.

2. Using petroleum jelly, grease the bottom spacer hole and the

bottom hinge pin. Align the washer with the bottom spacer

hole.

3. Slowly lower the door straight and evenly onto the bottom

A

B

C

D

E

A

B

hinge pin. Be sure the washer stays in place. Close the door.

Be sure the door properly aligns to the cabinet.

NOTE: Provide additional support for the door when moving

the hinges. Do not depend on the door magnets to hold the

door in place while you are working.

4. Using masking tape, secure the door to the cabinet before

installing the top spacer as shown.

A. Top spacer

B. Masking tape

5. Place the washer on the top spacer and align the holes.

Grease the top hinge pin, top spacer and washer with

petroleum jelly. Insert the top hinge pin into the washer and

top spacer.

6. Using a Phillips screwdriver and three screws, attach the top

hinge to the cabinet as shown.

Door Closing

Door Closing

Your wine cellar has four leveling legs. If your wine cellar seems

unsteady or you want the door to close more easily, adjust the

wine cellar’s tilt using the instructions below.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

WARNING

Excessive Weight Hazard

Use two or more people to move and install wine cellar.

Failure to do so can result in back or other injury.

A. Screws (3)

B. Top hinge

C. Washer

7. Remove the masking tape from the door.

D. Top spacer

E. Door

F. Ov e rl ay f ra me

2. Move the wine cellar into its final location.

3. Turn the leveling legs to the right to lower the wine cellar or

turn the leveling legs to the left to raise it. It may take several

turns of the leveling legs to adjust the tilt of the wine cellar.

NOTE: Having someone push against the top of the wine

cellar takes some weight off the leveling legs. This makes it

easier to adjust the leveling legs.

F

4. Open the door and check to make sure that it closes as easily

as you like. If not, tilt the wine cellar slightly more to the rear by

turning both front leveling screws to the right. It may take

several more turns, and you should turn both leveling legs the

same amount.

7

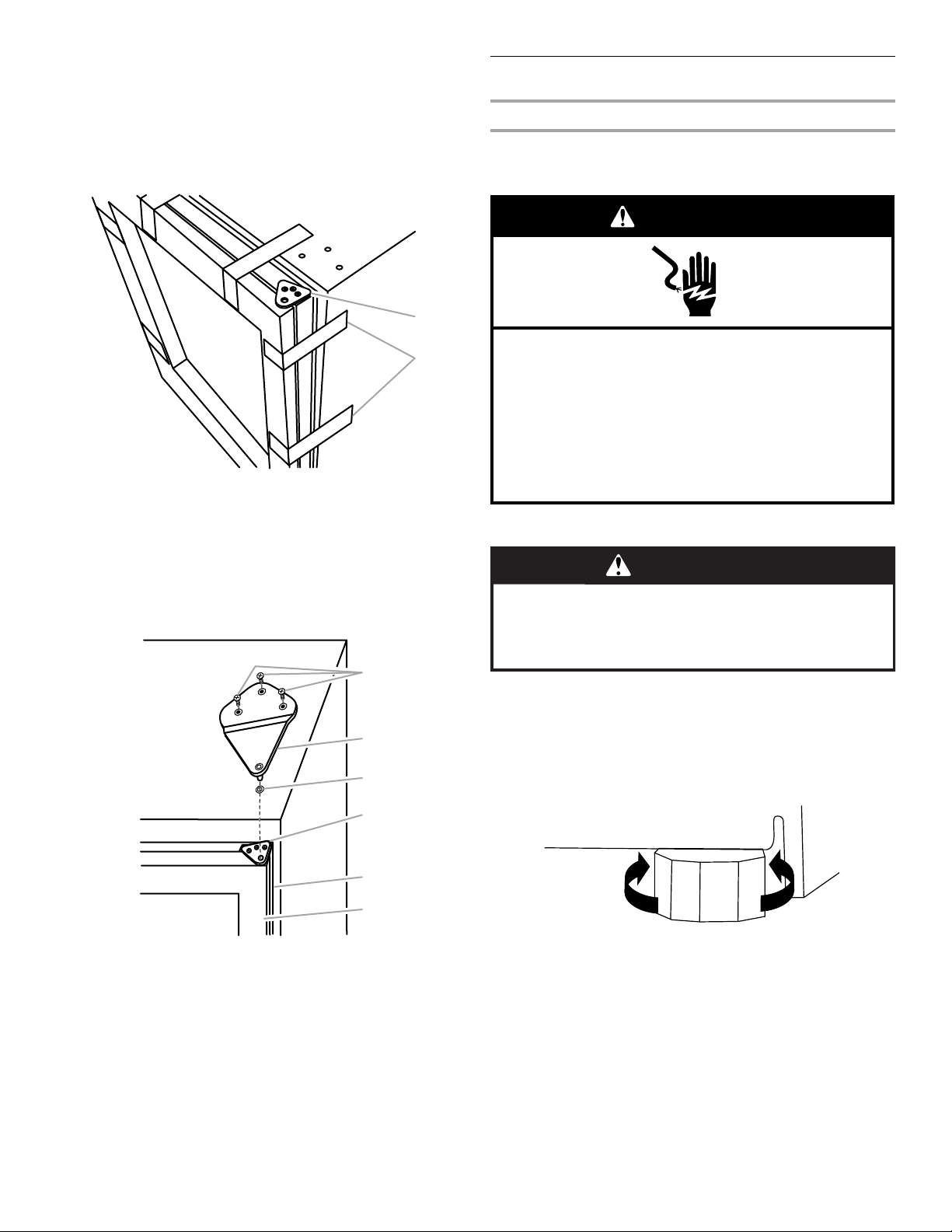

Base Grille

Remove the Base Grille

1. Open the wine cellar door.

2. Using a Phillips screwdriver, remove the two screws. Push

both tabs in toward the center to release the base grille from

the wine cellar.

BAA

A. Tabs

B. Screws

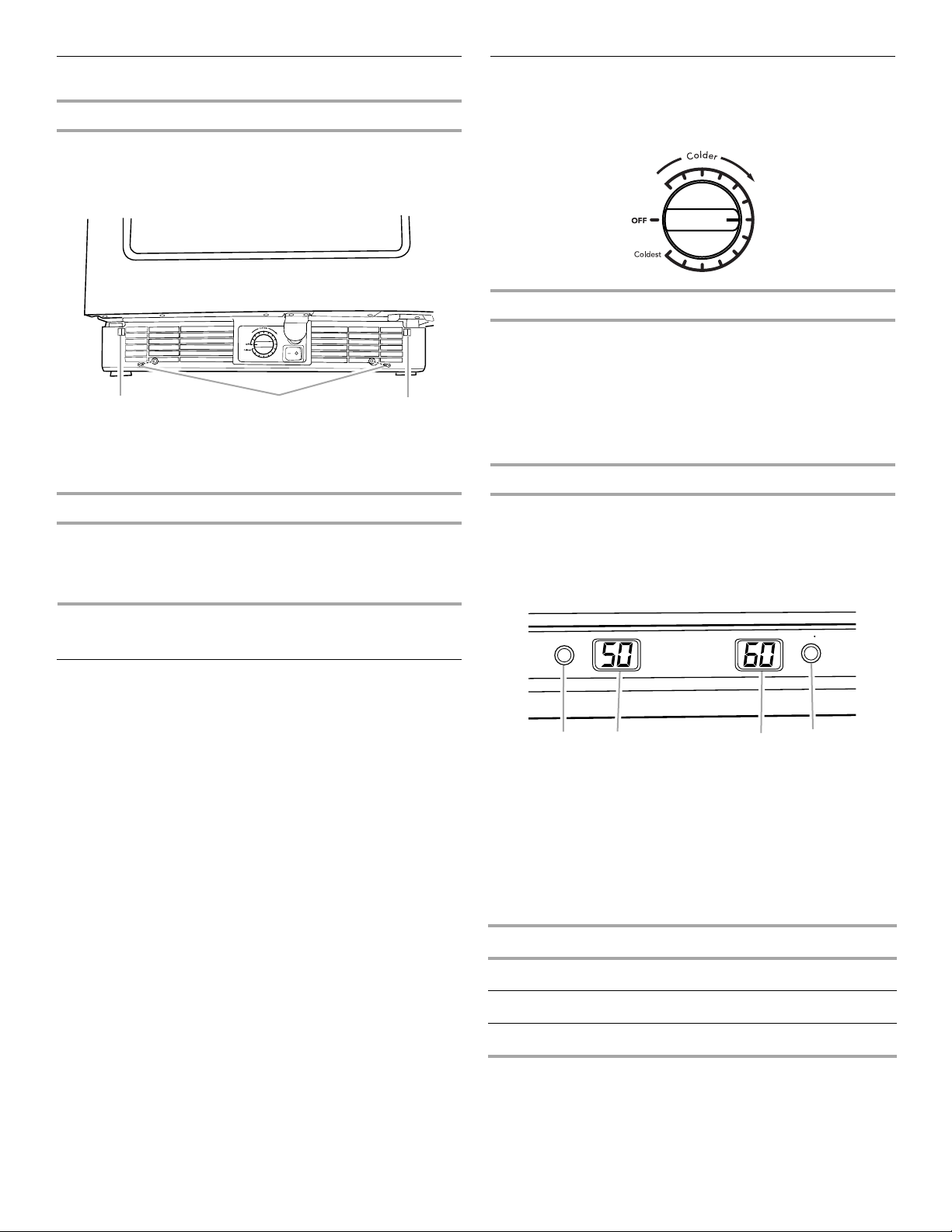

Using the Control

For your convenience, your wine cellar control is preset at the

factory. When you first install your wine cellar, make sure that the

control is still preset to the mid-setting as shown.

Adjusting Controls

The mid-setting indicated in the previous section should be

correct for normal usage. The control is set correctly when

beverages are as cold as you like.

If you need to adjust the temperature, wait at least 24 hours

between adjustments and then recheck the temperature.

To make the wine cellar colder, adjust the control to the next

higher setting. To make the wine cellar less cold, adjust the control

to the next lower setting.

3. Remove the base grille.

Replace the Base Grille

1. Open the wine cellar door.

2. Position the base grille so that both tabs align and the base

grille snaps into place. Replace the two screws. Tighten the

screws.

WINE CELLAR USE

Normal Sounds

Your new wine cellar may make sounds that your old one didn’t

make. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are normal. Hard

surfaces, such as the flooring and surrounding structures, can

make the sounds seem louder. The following describes the kinds

of sounds and what may be making them.

■ Your wine cellar is designed to run more efficiently to keep

your wine at the desired temperatures and to minimize energy

usage. The high efficiency compressor and fans may cause

your wine cellar to run longer than your old one. You may also

hear a pulsating or high-pitched sound from the compressor

or fans adjusting to optimize performance.

■ Rattling noises may come from the flow of refrigerant or items

stored inside the wine cellar.

■ As each cycle ends, you may hear a gurgling sound due to the

refrigerant flowing in your wine cellar.

■ You may hear water running into the drain pan when the wine

cellar is defrosting.

■ You may hear clicking sounds when the wine cellar starts or

stops running.

Temperature Separator (Temperature Display)

The temperature separator displays the current temperatures

(Fahrenheit or Celsius) for the upper and lower zones

(compartments) of the wine cellar. To adjust the temperature

settings, see “Adjusting Controls” earlier in this section.

Dimmer

A

Upper

B

A. Dimmer

B. Upper zone display

C. Lower zone display

D. Fahrenheit/Celsius

Lower

F

C

D

Recommended Zone Storing Locations

For best storing and serving temperatures for your bottle of wine,

use the wine producer's recommended temperature setting. See

the wine’s label for details. It is recommended to store wine for

short-term (few months) at 55°F (13°C).

WINES ZONES

White Wine Upper zone

Lighter Red Wine Lower zone

Red Wine Lower zone

8

Wine Racks

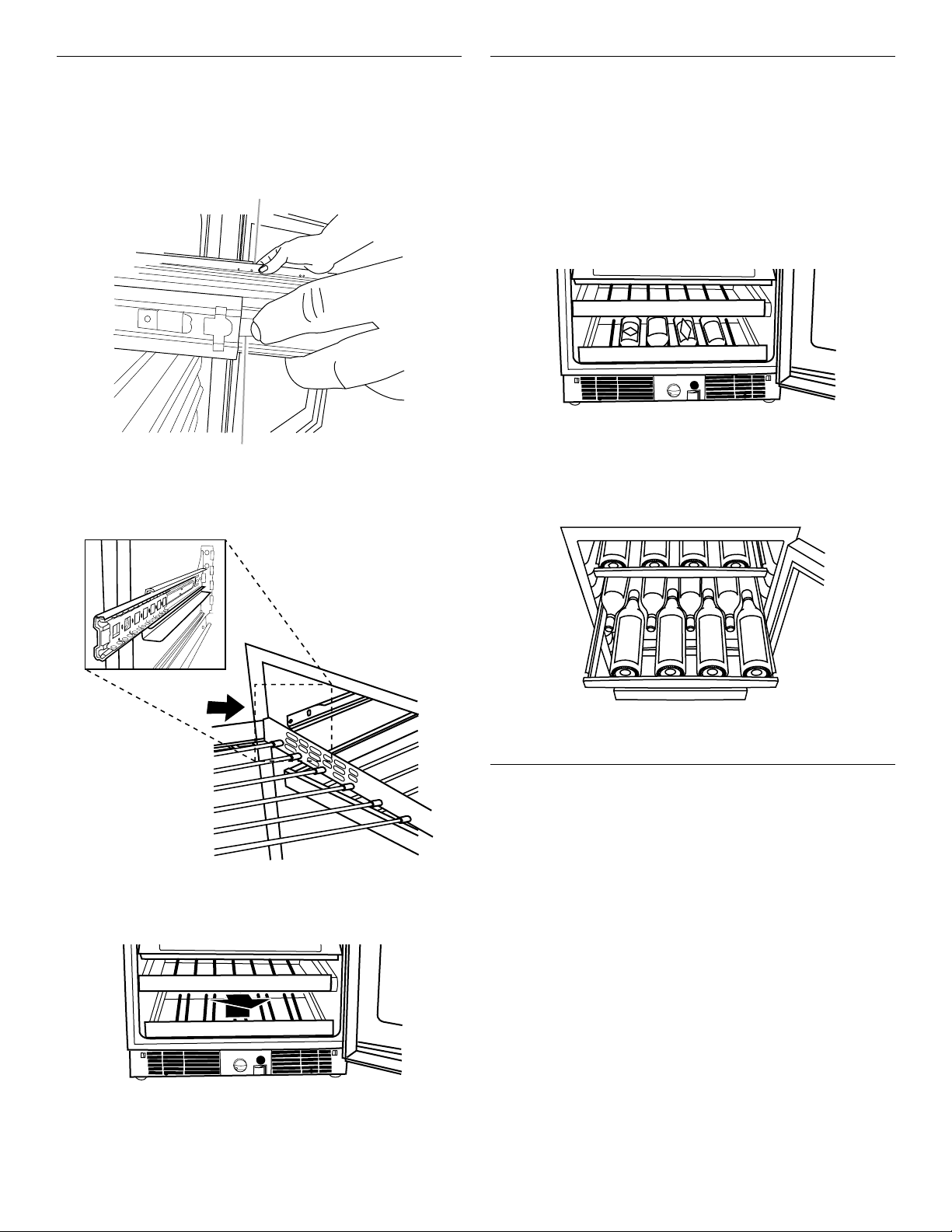

To Remove and Replace the Wine Racks

1. Pull the rack forward until it stops. Push in on the tabs to

release the rack. Continue pulling the rack forward and lift it

up and out of the rack supports.

A

A

A. Tabs

2. Replace the rack by inserting the rack into the supports and

sliding it toward the rear of the wine cellar.

Stocking the Wine Cellar

NOTE: For optimum wine storage, place white wines at the top of

the wine cellar, light red wines in the center and red wines at the

bottom.

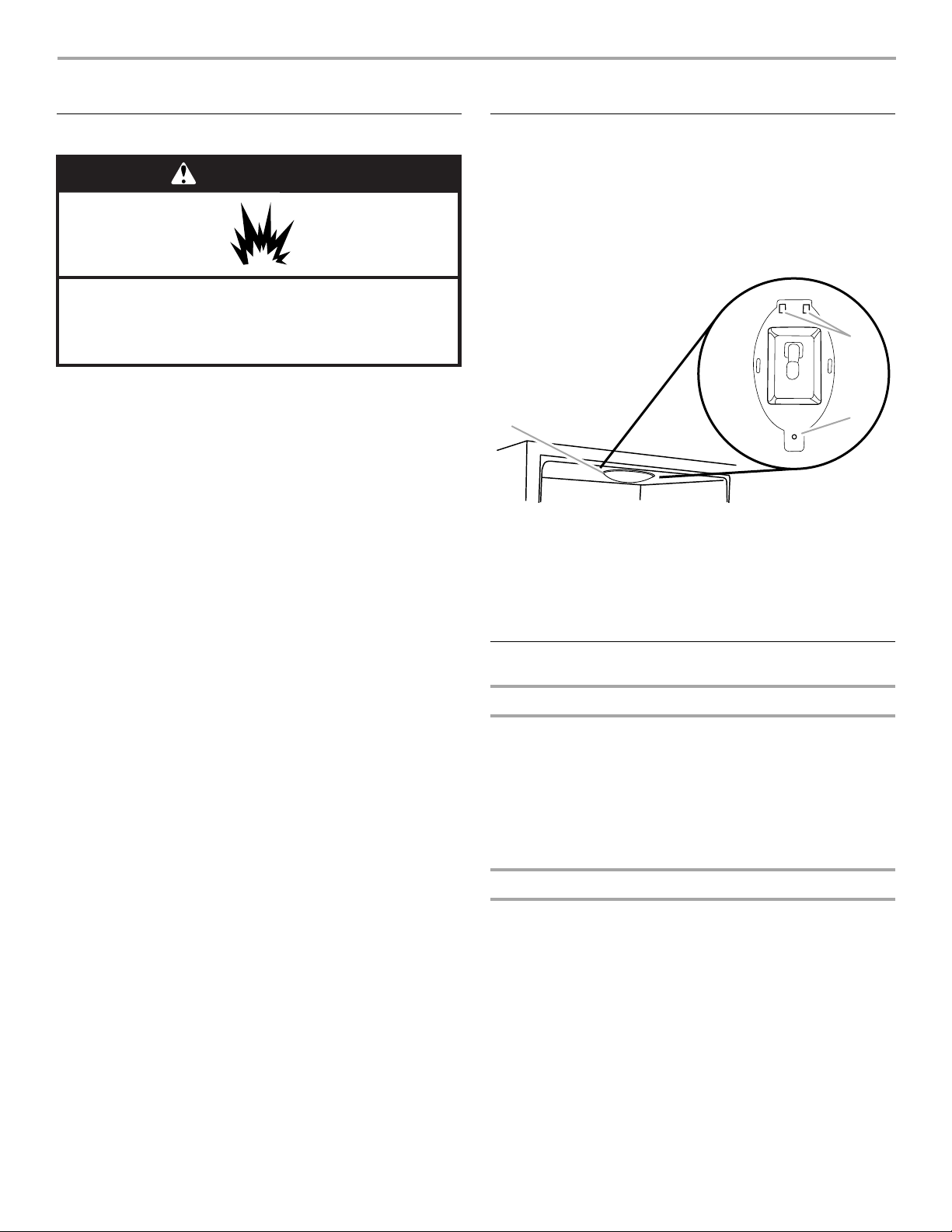

To Stock the Wine Cellar

1. Start stocking the wine cellar with the bottom display rack.

2. Starting on the left-hand side, place the first bottle on the

bottom of the rack with the neck of the bottle facing the back

of the wine cellar.

3. Place the next bottle on its side with the neck of the bottle

facing the front of the wine cellar.

4. Alternate in this manner until the display rack is full.

5. Pull the next rack forward.

6. Starting on the left-hand side, place the first bottle on the rack

with the neck of the bottle facing forward.

7. Place the next bottle on the shelf with the neck of the bottle

facing the rear of the wine cellar.

To Remove and Replace the Bottom Rack

1. Lift the rack (front and back) up and pull straight out to

remove.

2. Replace the rack by pushing it straight back and over the

stop. Continue pushing the rack straight back and evenly until

it is in place.

8. Continue alternating in this manner until the rack is full.

9. Slide the rack into place and continue stocking each

remaining rack as described above.

Lighting the Wine Cellar

The wine cellar has an interior light that comes on any time the

door is opened. You may also turn the light on at any time by

opening the door and pressing the exterior switch located beside

the temperature control knob on the base grille.

NOTE: Leaving the light on for an extended period of time will

slightly increase the temperature of the wine cellar.

9

WINE CELLAR CARE

Cleaning

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Clean the wine cellar about once a month to avoid buildup of

odors. Wipe up spills immediately.

To clean your wine cellar:

1. Unplug wine cellar or disconnect power.

2. Remove all racks from inside the wine cellar.

3. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

■ To avoid damaging wood trim pieces, do not immerse the

entire rack into water when cleaning.

■ Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning

waxes, concentrated detergents, bleaches or cleansers

containing petroleum products on plastic parts, interior

and door liners or gaskets. Do not use paper towels,

scouring pads, or other harsh cleaning tools. These can

scratch or damage materials.

■ To help remove odors, you can wash interior walls with a

mixture of warm water and baking soda (2 tbs to 1 qt

[26 g to 0.95 L] of water).

4. Wash stainless steel and painted metal exteriors with a clean

sponge or soft cloth and a mild detergent in warm water. Do

not use abrasive or harsh cleaners, or cleaners containing

chlorine. These can scratch or damage materials. Dry

thoroughly with a soft cloth.

NOTE: To keep your stainless steel wine cellar looking like

new and to remove minor scuffs or marks, it is suggested that

you use the manufacturer’s approved Stainless Steel Cleaner

and Polish. To order the cleaner, see “Accessories.”

IMPORTANT: This cleaner is for stainless steel parts only!

Do not allow the Stainless Steel Cleaner and Polish to come

into contact with any plastic parts such as the trim pieces,

dispenser covers or door gaskets. If unintentional contact

does occur, clean plastic part with a sponge and mild

detergent in warm water. Dry thoroughly with a soft cloth.

5. Replace the racks.

6. Clean the condenser coils regularly. They are located behind

the base grille. Coils may need to be cleaned as often as every

other month. This may help save energy.

■ Remove the base grille. See “Base Grille.”

■ Use a vacuum cleaner with an extended attachment to

clean the condenser coils when they are dusty or dirty.

■ Replace the base grille.

7. Plug in wine cellar or reconnect power.

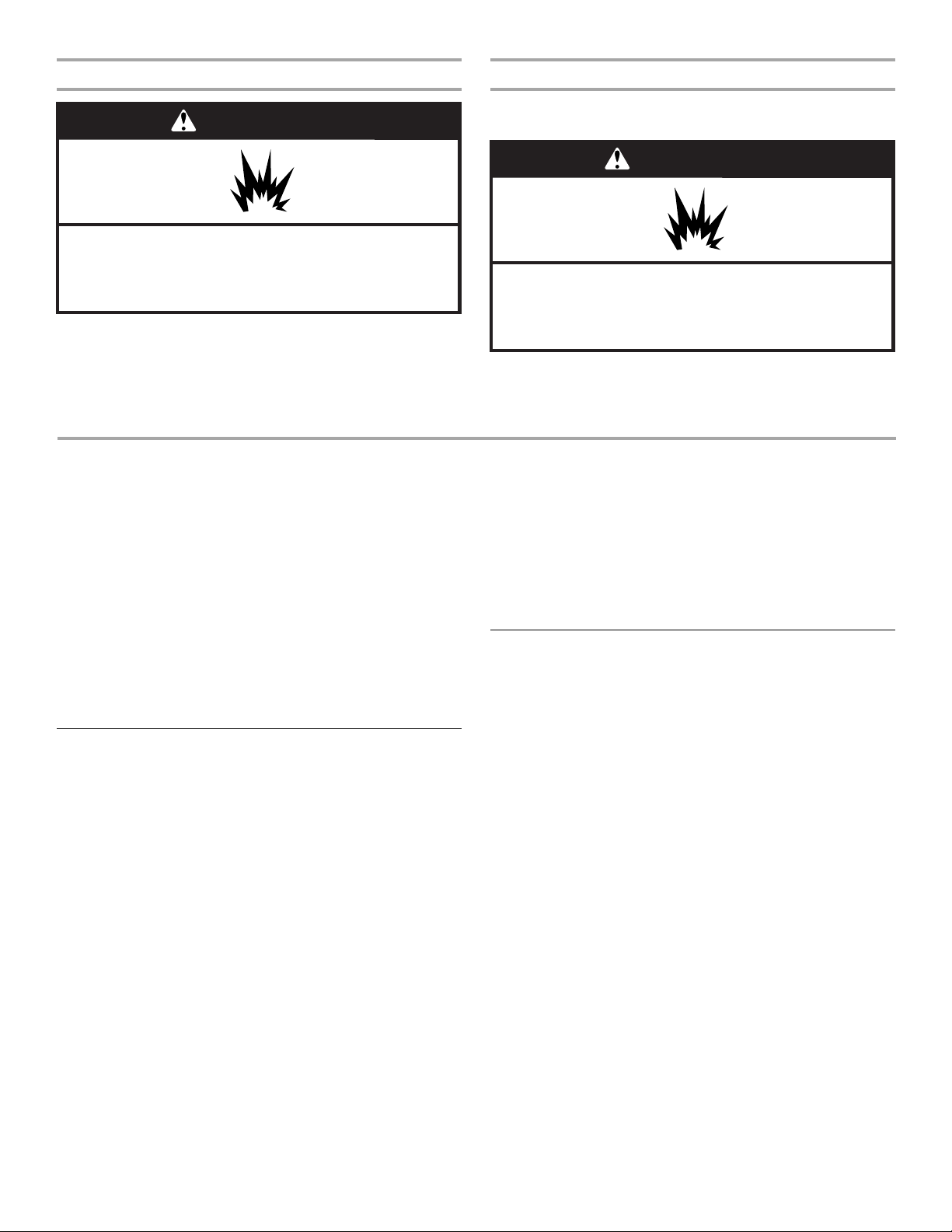

Changing the Light Bulb

NOTE: Not all appliance bulbs will fit your wine cellar. Be sure to

replace the bulb with one of the same size, shape, and wattage.

To change the light bulb:

1. Unplug wine cellar or disconnect power.

2. Using a Phillips screwdriver, remove the screw located at the

back of the light shield. Pull the light shield back to remove the

tabs from the appliance. Remove the light shield.

B

A

A. Light shield

B. Tabs

C. Screw

3. Replace the bulb.

4. Reinstall the light shield by inserting the tabs. Align the holes

and insert the screw. Tighten the screw.

5. Plug in wine cellar or reconnect power.

C

Vacation and Moving Care

Vacations

If you choose to turn the wine cellar off before you leave, follow

these steps.

1. Remove all wine bottles from the wine cellar.

2. Unplug the wine cellar.

3. Clean the wine cellar. See “Cleaning.”

4. Tape a rubber or wood block to the top of the door to prop it

open far enough for air to get in. This stops odor and mold

from building up.

Moving

When you are moving your wine cellar to a new home, follow

these steps to prepare it for the move.

1. Remove all wine bottles from the wine cellar.

2. Unplug the wine cellar.

3. Clean, wipe, and dry it thoroughly.

4. Take out all removable parts, wrap them well, and tape them

together so they don’t shift and rattle during the move.

5. Tape the doors shut and tape the power cord to the wine

cellar.

When you get to your new home, put everything back and refer to

the “Installation Instructions” section for preparation instructions.

10

TROUBLESHOOTING

Try the solutions suggested here first in order to avoid the cost of an unnecessary service call.

Your wine cellar will not operate

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

■ Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

■ Has a household fuse blown, or has a circuit breaker

tripped? Replace the fuse or reset the circuit.

■ Is the Wine Cellar Control turned to the OFF position? See

“Using the Control.”

The lights do not work

■ Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

■ Is a light bulb loose in the socket or burned out? See

“Changing the Light Bulb.”

The motor seems to run too much

■ Is the temperature outside hotter than normal? Expect the

motor to run longer under warm conditions. At normal

temperatures, expect your motor to run about 40% to 80% of

the time. Under warmer conditions, expect it to run even more

of the time.

■ Is the door opened often? Expect the motor to run longer

when this occurs. In order to conserve energy, try to get

everything you need out of the wine cellar at once, keep wine

bottles positioned label side up so that they are easy to find,

and close the door as soon as the wine is removed.

■ Is the control set correctly for the surrounding conditions?

See “Using the Control.”

■ Is the door closed completely? Push the door firmly shut. If

it will not shut all the way, see “The door will not close

completely” later in this section.

■ Are the condenser coils dirty? This obstructs air transfer and

makes the motor work harder. Clean the condenser coils. See

“Cleaning.”

Temperature is too warm

■ Is the door opened often? Be aware that the wine cellar will

warm when this occurs. In order to keep the wine cellar cool,

try to get everything you need out of the wine cellar at once,

keep wine bottles positioned label side up so that they are

easy to find, and close the door as soon as the wine is

removed.

■ Is the control set correctly for the surrounding conditions?

See “Using the Control.”

■ Is the base grille blocked? For best performance, do not

install the wine cellar behind a cabinet door or block the base

grille.

There is interior moisture buildup

■ Is the door opened often? To avoid humidity buildup, try to

get everything you need out of the wine cellar at once, keep

wine bottles positioned label side up so that they are easy to

find, and close the door as soon as the wine is removed.

When the door is opened, humidity from the room air enters

the wine cellar. The more often the door is opened, the faster

humidity builds up, especially when the room itself is very

humid.

■ Is it humid? It is normal for moisture to build up inside the

wine cellar when the air is humid.

■ Is the control set correctly for the surrounding conditions?

See “Using the Control.”

11

The door is difficult to open

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

■ Is the gasket dirty or sticky? Clean the gasket and the

surface that it touches. Rub a thin coat of paraffin wax on the

gasket following cleaning.

ASSISTANCE OR SERVICE

Before calling for assistance or service, please check

“Troubleshooting.” It may save you the cost of a service call. If you

still need help, follow the instructions below.

When calling, please know the purchase date and the complete

model and serial number of your appliance. This information will

help us to better respond to your request.

If you need replacement parts

If you need to order replacement parts, we recommend that you

only use factory specified replacement parts. Factory specified

replacement parts will fit right and work right because they are

made with the same precision used to build every new Jenn-Air

appliance.

To locate factory specified replacement parts in your area, call us

or your nearest designated service center.

In the U.S.A.

Call the Jenn-Air Customer eXperience Center

toll free: 1-800-JENNAIR (1-800-536-6247).

Our consultants provide assistance with:

■ Features and specifications on our full line of appliances.

■ Installation information.

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Specialized customer assistance (Spanish speaking, hearing

impaired, limited vision, etc.).

■ Referrals to local dealers, repair parts distributors, and service

companies. Jenn-Air designated service technicians are

trained to fulfill the product warranty and provide afterwarranty service, anywhere in the United States.

To locate the Jenn-Air designated service company in your area,

you can also look in your telephone directory Yellow Pages.

®

The door will not close completely

■ Are the racks out of position? Put the racks back into their

correct positions. See “Wine Cellar Use” for more information.

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

■ Is the gasket sticking? Clean the gasket and the surface that

it touches. Rub a thin coat of paraffin wax on the gasket

following cleaning.

For further assistance

If you need further assistance, you can write to Jenn-Air with any

questions or concerns at:

Jenn-Air Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence.

Call the Jenn-Air Canada Customer eXperience Centre toll free:

1-800-807-6777.

Our consultants provide assistance with:

■ Features and specifications on our full line of appliances.

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Referrals to local dealers, repair parts distributors, and

services companies. Jenn-Air Canada designated service

technicians are trained to fulfill the product warranty and

provide after-warranty service, anywhere in Canada.

For further assistance

If you need further assistance, you can write to Jenn-Air Canada

with any questions or concerns at:

Jenn-Air Canada

Customer eXperience Centre

200 – 6750 Century Ave.

Mississauga, Ontario L5N 0B7

Please include a daytime phone number in your correspondence.

In Canada

12

Loading...

Loading...