Page 1

Installation Instructions

Tool Requirements:

Tape measure

Level

Stud finder

Drill with various bits

Socket set

Utility knife

Magnetic extended screwdriver

Phillips screwdriver

Torx Bit

Cardboard, carpet remnant or other

protective material for flooring

Steel Hanger Strap

Installation Checklist:

INSTALLER

Doors

[] Handles are solidly attached to doors.

[] Doors seal completely to refrigerator cabinet.

[] Assure correct door handle alignment. Frame models.

[] Assure door seals are not pinched.

[] Do not drive screws / sharp objects into the doors.

Leveling

[] L Brackets are secure to 2x4 wood block.

[] Stabilizing legs are against floor. Cabinet is secure.

[] Toe kickplate is properly attached to refrigerator

and aligned with floor.

Icemaker

[] Water supply to refrigerator is turned on and lines flushed.

[] Water leaks are not present at connection between household

water supply and refrigerator.

[] lcemaker arm is down for ice production.

[] PuriClean ® Ice and Water Filtration System is installed correctly,

if applicable.

[] Purge water from the fountain on dispenser models.

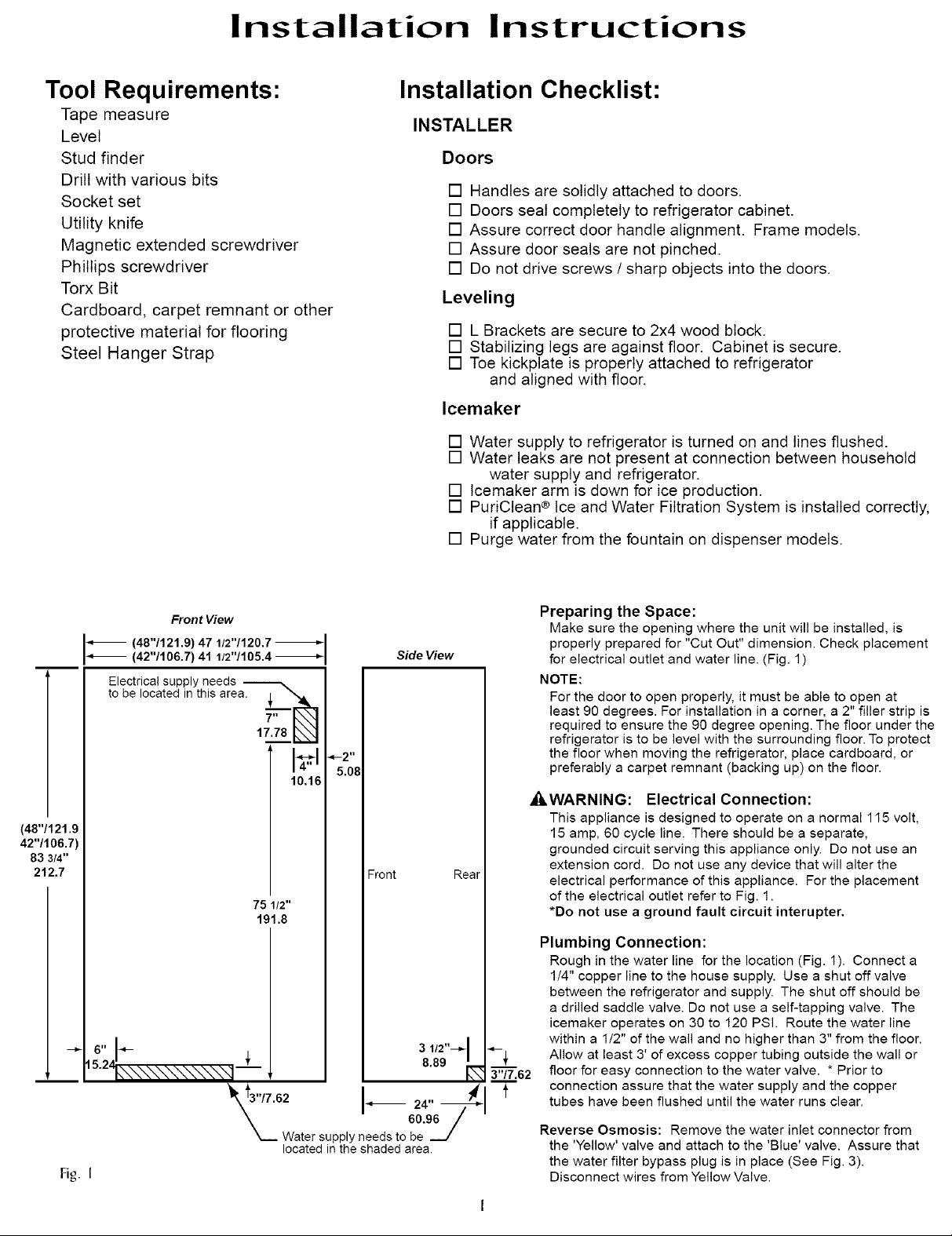

(48"/121.9

42"/106.7'

83 3/4"

212.7

Front View

IX (48"/121.9) 47 1/2"/120.7

(42"/106.7) 41 112"1105.4

Electrical supply needs _.

to be located in this area. ,L ""_

Fig. I

17.78 _

9_--2 '1

5.08

10,1_

75 1/2"

191.8

Water supply )eels to _'49_

located in the shaded area.

Side View

Front Rear

3 1/2"--_ I

Preparing the Space:

Make sure the opening where the unit will be installed, is

properly prepared for "Cut Out" dimension. Check placement

for electrical outlet and water line. (Fig. 1)

NOTE:

For the door to open properly, it must be able to open at

least 90 degrees. For installation in a corner, a 2" filler strip is

required to ensure the 90 degree opening. The floor under the

refrigerator is to be level with the surrounding floor. To protect

the floor when moving the refrigerator, place cardboard, or

preferably a carpet remnant (backing up) on the floor.

_WARNING: Electrical Connection:

This appliance is designed to operate on a normal 115 volt,

15 amp, 60 cycle line. There should be a separate,

grounded circuit serving this appliance only. Do not use an

extension cord. Do not use any device that will alter the

electrical performance of this appliance. For the placement

of the electrical outlet refer to Fig. 1.

*Do not use a ground fault circuit interupter.

Plumbing Connection:

Rough in the water line for the location (Fig. 1). Connect a

1/4" copper line to the house supply. Use a shut off valve

between the refrigerator and supply. The shut off should be

a drilled saddle valve. Do not use a self-tapping valve. The

icemaker operates on 30 to 120 PSI. Route the water line

within a 1/2" of the wall and no higher than 3" from the floor.

Allow at least 3' of excess copper tubing outside the wall or

3'-'_'_.62

floor for easy connection to the water valve. * Prior to

connection assure that the water supply and the copper

t

tubes have been flushed until the water runs clear.

Reverse Osmosis: Remove the water inlet connector from

the 'Yellow' valve and attach to the 'Blue' valve. Assure that

the water filter bypass plug is in place (See Fig. 3).

Disconnect wires from Yellow Valve.

Page 2

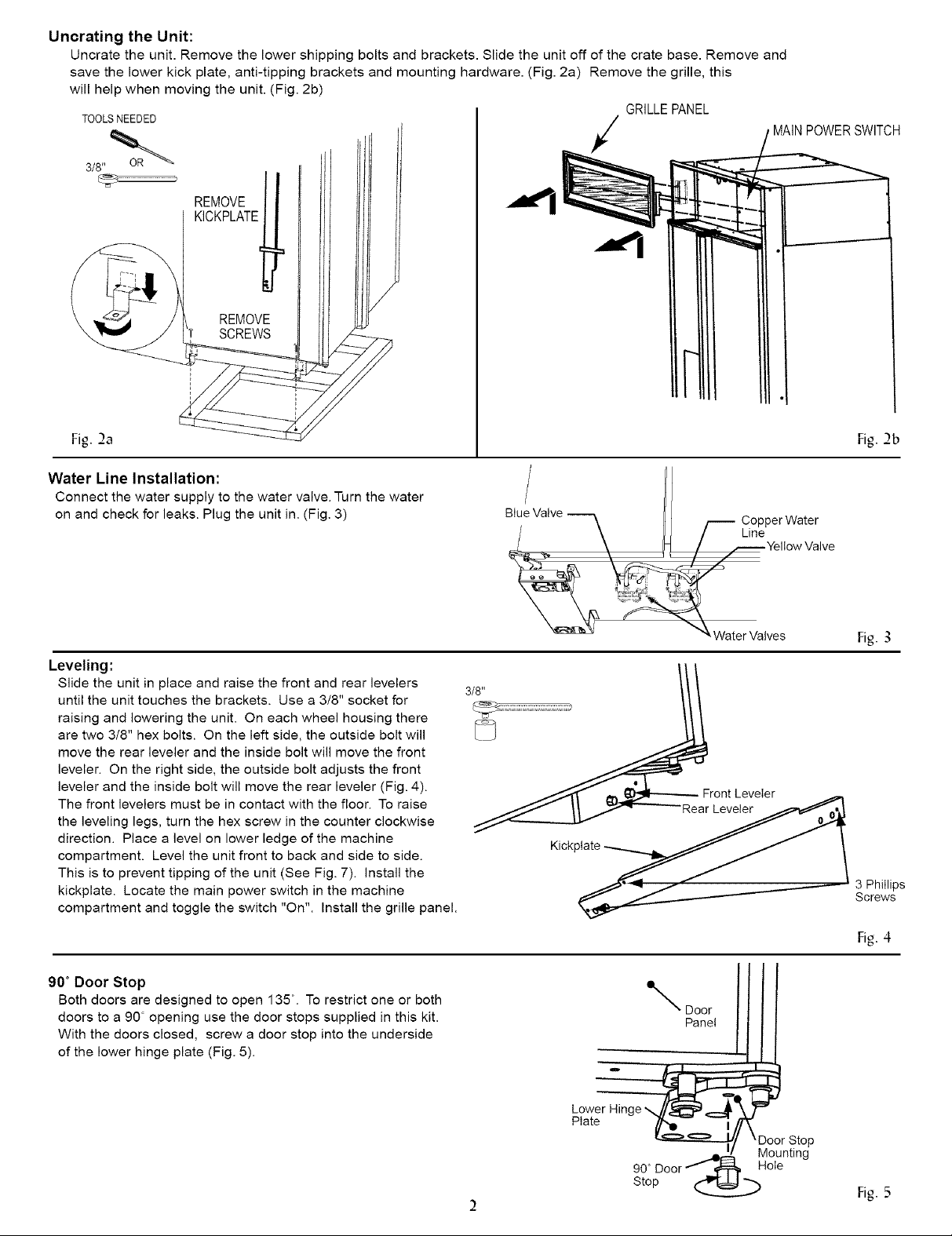

Uncrating the Unit:

Uncrate the unit. Remove the lower shipping bolts and brackets. Slide the unit off of the crate base. Remove and

save the lower kick plate, anti-tipping brackets and mounting hardware. (Fig. 2a) Remove the grille, this

will help when moving the unit. (Fig. 2b)

TOOLS NEEDED

3/8" _

REMOVE

KICKPLATE_

REMOVE

lr SCREWS

GRILLEPANEL

SWITCH

Fig. 2a

Water Line Installation:

Connect the water supply to the water valve. Turn the water

on and check for leaks. Plug the unit in. (Fig. 3)

Leveling:

Slide the unit in place and raise the front and rear levelers

until the unit touches the brackets. Use a 3/8" socket for

raising and lowering the unit. On each wheel housing there

are two 3/8" hex bolts. On the left side, the outside bolt will

move the rear leveler and the inside bolt will move the front

leveler. On the right side, the outside bolt adjusts the front

leveler and the inside bolt will move the rear leveler (Fig. 4).

The front levelers must be in contact with the floor. To raise

the leveling legs, turn the hex screw in the counter clockwise

direction. Place a level on lower ledge of the machine

compartment. Level the unit front to back and side to side.

This is to prevent tipping of the unit (See Fig. 7). Install the

kickplate. Locate the main power switch in the machine

compartment and toggle the switch "On". Install the grille panel.

Fig.2b

Biu!Valve _ 1 C°P_I:wa:lve

:ves

Fig. 3

Front Leveler

90 ° Door Stop

Both doors are designed to open 135 °. To restrict one or both

doors to a 90 opening use the door stops supplied in this kit.

With the doors closed, screw a door stop into the underside

of the lower hinge plate (Fig. 5).

%,,pOOe ' ])

Lower Hinge

Plate _...._/f_

____/ _Door Stop

9toDO°r ____H°Ie

Fig.4

.!/ _4ounting

Fig. 5

Page 3

Blocking the Unit:

If there is a solid soffit above the unit and the clearance is 1"

or less you will not need to block the unit. For installations with

clearances of more than 1", you must use the anti-tipping 2x4

and brackets provided (Fig. 6).

More than

aR 1"

More than 1" clearance:

Use the anti-tipping kit provided with the shipping crate. Locate and

mark the 2 wall studs behind the unit. Mark where the "L" brackets

and 2x4 will be located and drill 2 pilot holes 1/8". Locate the proper

height to clear the unit. The space between the top of the unit and

bottom of the wood block must not exceed 1/4". Secure the "L"

brackets, using the provided screws, into the wall studs (,_1)). Make

sure the screws will extend 7/8" into the wall studs. Align the pilot

holes with the "L" brackets and secure the 2x4 with the screws

provided(,_,5_).

-Wall Studs._ I I

i I/ I

I

I

Fig. 6 /

Installing Backer Panels:

Remove the door handle or trim piece on overlay models. A magnetic backed molding hides the handle or overlay trim screws. Use the

adhesive side of the packaging tape on the magnetic backed molding to pull it away from door (Fig. 8a). Remove the screws with a

phillips screwdriver (Fig. 8b). Slide the backer panel into position. The backer panel needs to be under the trim. Install the handle.

Replace the molding in the channel, and reset the magnetic backed molding. To install the backer panel on the grille remove the screws

on the top and bottom of the upper cover (Fig 8c). DO NOT REMOVE the foam. Slide the backer panel into place and replace screws

(Fig 8d). If the thickness of the backer panel is less than a 1/4", back it up with a sheet of shim material to obtain a 1t4" thickness.

Cardboard is recommended for Stainless Steel application. For panel size refer to Fig. 10.

_&,CAUTION: Do not drive screws or sharp objects into the doors.

Do not pinch door seal when reinstalling handle.

Grille Panel

PhillipsScrewdriver /

r

Use Tape

to Pul! Magnetic

Molding Away

from Door

:!

Fig. 8c

Fi8. 7

Fig. 8a

For Screws

_, CAUTION:

When attaching a raised wood

J

Fig. 8b

panel of 1/2" or thicker secure the

raised panel to the back of the grille

cover frame. Use 4 #8 or similar screws.

See illustration for approximate locations.

Page 4

Panel Installation for Dispenser Models:

See section "installing Backer Panels" for handle / trim piece

removal. With handle / trim piece removed slide upper and lower

panels in post!on. To replace dispenser panels, slide out Spill Tray

grille and remove 2 Torx screws (see inset). Insert replacement

panel. Reinsert Torx screw and reinstall handle / trim piece.

To replace second dispenser panel, open freezer door until 4

phillips screws that hold the door trim in place are accessible.

Remove screws and slide out door trim. Close door and insert

replacement panel. Reinsert Torx screw and reinstall door trim.

iiil

I Grille Pane! I 8T43/4 ''

I [ 461/4" I I

T I Upper Freezer

40 1/4"

20T" I Door Panel

(48)2 9/16" (48)3 7/16"

(42)2 7/16" (42)1 5/16"

b-..t -I F.-

Refrigerator

Door Panel

34" Lower Freezer

Door Panel

Side Pane!

(Dimensions Typ.)

I_' 3/8"

/

26 1/16"

22 5116"

/

'-H t.-21t2,,

27/16" I'1_ 24"u

Spill Tray

Grille

_-(48)f7 5/16"-_ I

(42)15 1/16"--

/

J

Fig.

One-piece Overlay/Frame Panel Installation:

See Owner Manual for switching "OFF O" the unit. Reference Fig. 9 for door panel removal and installation. With panels removed

reattach hinge trim. Lift slide out Spill Tray grille and remove 2 Torx screws (]), (_). Remove stainless steel liner I_). Remove 2 Torx

screws from the control panel (_). Slide control panel down to remove. Disconnect terminals on back of control panel 1_). Tuck

dispenser terminal inside to avoid interfering with one-piece panel I_). Open door and slide one-piece panel into position. Reconnect

control panel to dispenser terminal. Reattach control panel with 2 Torx screws. Reposition stainless steel liner into track and secure

with 2 Torx screws. Reinstall the Spill Tray grille and door trim. Turn unit on.

1_) Terminals

Control Panel

I

I

Fi_. I0

O

I

I

Stainless Steel Liner

I

I

SpillTrayGrille 4

Page 5

Dispenser One-Piece Freezer Framed Panel

,!,1

I (D)

(A)

(A) Panel Height

(B) Panel Width

(C) Top of dispenser cutout to top of panel

(D) Bottom of dispenser cutout to top of panel

(E) Left of dispenser cutout width

(F) Right of dispenser cutout width

,,.-(F)

(B)

Dispenser One-Piece Freezer Overlay Panel

(D)

42"Wide Cabinet

Inches

69 1/8

15 1/16

20 5/8

35 7/16

2 7/16

1 5/16

Cm

175.6

38.26

52.39

90.01

6.19

3.33

48" Wide Cabinet

Inches Cm

69 1/8 175.6

17 5/16 43.97

20 5/8 52.39

35 7/16 90.01

2 9/16 6.51

3 3/8 8.57

(A)

(A) Panel Height

(B) Panel Width

(C) Top of dispenser cutout to top of panel

(D) Bottom of dispenser cutout to top of panel

(E) Left of dispenser cutout width

(F) Right of dispenser cutout width

42" Wide Cabinet

inches Cm

69 1/8 175.6

16 7/16 41.75

21 3/16 53.82

34 13/16 88.42

2 1/16 5.24

2 1/4 5.72

48" Wide Cabinet

Inches

69 1/8

18 11/16

21 3/16

34 13/16

2 3/16

4 3/8

Cm

175.6

47.47

53.82

88.42

5.56

11.11

Page 6

Installing Side Panels:

Optional side panels need to be 1/4-inch thick.

Slide panel into position and secure with screws

indicated by the shaded area (Fig. 1la). A 3/16-inch

batten is required between the cabinet and side

panel (Fig. 11b). A 1/2-inch thick by 10 1/4-inch

tall batten is required if the side panel extends up

into the machine compartment area on the

refrigerator side (Fig. 1 lc).

1/4" side panel fitted up to

the cabinet trim (top view)

on Freezer side,

Backside of Unit

1/2"

Screw

1/4" side panel fitted up to

the cabinet trim (top view)

on Refrigerator side.

Backside of Unit

#8-32

Screw

b----...

J

> 3/16"/.48

Battens

1/4"/.64 Side Panel 1/4"/.64

of Unit

Door Door

112"11.27 Battens

on side of

compartment

(3/16"/,48 below the

machine compartment)

Refrigerator Side of Unit

Fig. lib Fig. I Ic

Fig. I la

Anchor the Unit (Optional):

If you are attaching the unit to cabinetry, drill three 3/16" holes

through both outer trims. Drill 1/8" pilot holes into the cabinetry.

Install screws.

Additionally: If the depth/height of opening is excessive use

steel hanger strap. Double over strap at the achor points to

secure cabinet.

Adjust door hinges:

Check to make sure the doors are properly adjusted. If not,

adjust the top hinges. The hinges are slotted for side to side

movement. Remove and discard the small phillips screw on

the door hinge, which is located on the hinge. Adjust the top

hinges by loosing the 3 large Torx screws. Tighten the screws

after the doors are adjusted. Extruded door handles can be

adjusted for alignment by loosening the screws under the

magnetic backed molding (See fig. 8a).

, Drill 3 holes through

vertical frame into

cabinetry. Where

applicable.

(approx.location)

111406-1

6 (060402)

Loading...

Loading...