Page 1

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions with the homeowner.

Homeowner: Keep Installation Instructions for future

reference.

Save Installation Instructions for local electrical inspector's use. Compactor

Before ¥o= start...

Proper installation is your

responsibility. Make sure you have

everything necessary for correct

installation. It isthe personal

responsibility and obligation of the

customer to contact a qualified

installer to assure that electrical

installation meets national and all

local codes and ordinances.

Grounded electrical outlet is

required. (See "Electrical

requirements," Page 2.)

Check the location where your

compactor will be installed. The

cabinet opening should be square.

You should be able to fully open the

compactor drawer. Six inches

(15.2 cm) of clearance is needed

on the right side of compactor

drawer to be able to remove

compactor bag. Allow 23 inches

(58.4 cm) in front of the compactor

to remove drawer.

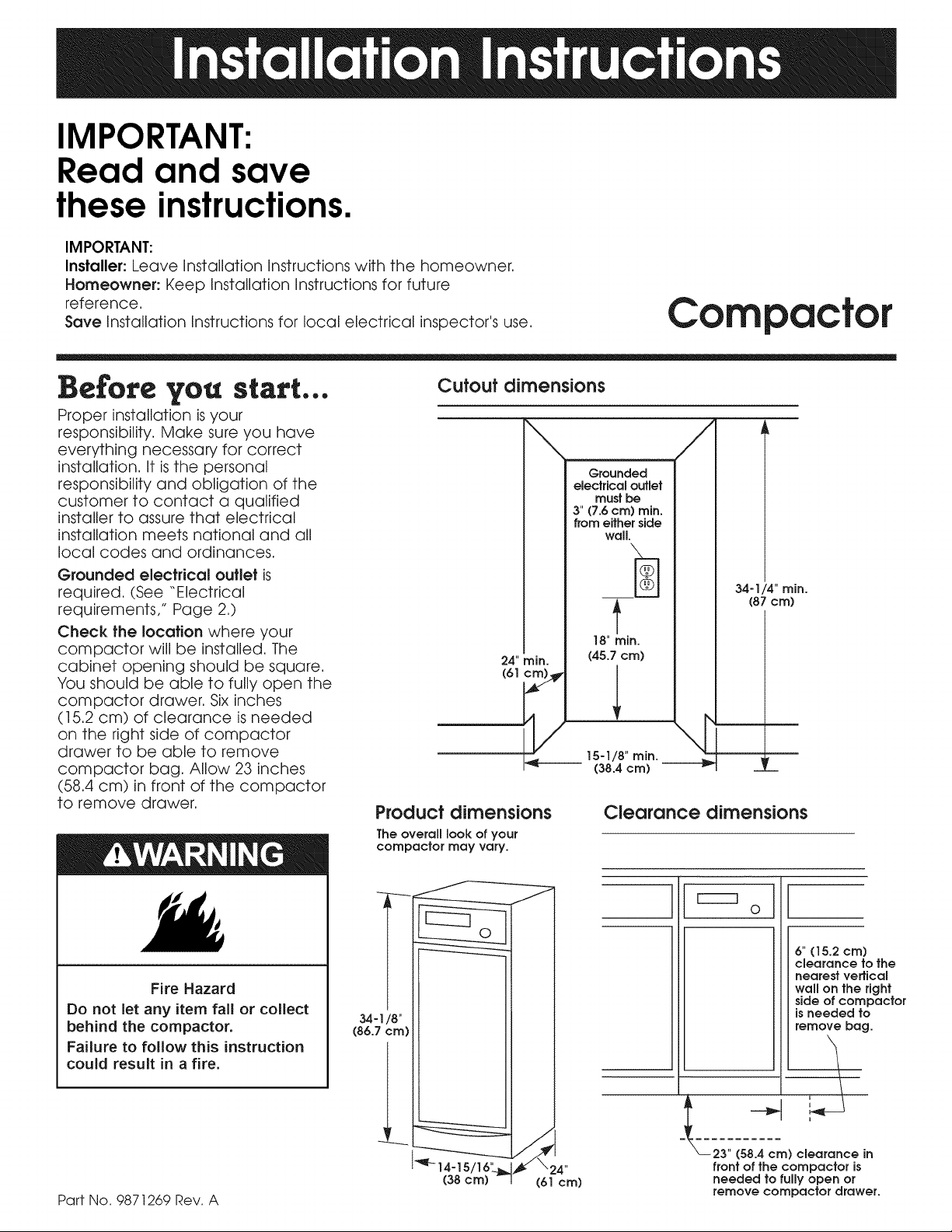

Cutout dimensions

24" rain. (45.7 era)

Product dimensions

The overall look of your

compactor may vary.

\ /

Grounded

electricaloutlet

must be

3" (7.6cm) rain.

from either side

wall.

t

18"rain.

i._b______15-1/8" rain.

(38.4 era) --

Clearance dimensions

34-1/4" min.

(87 cm)

m

Fire Hazard

Do not let any item fall or collect

behind the compactor.

Failure to follow this instruction

could result in a fire.

Part No. 9871269 Rev. A

34-I/8"

(86.7 cm)

1_q-14-15

(38cm)

(61 cm)

1I ol

23" (58.4 cm) clearance in

front of the compactor is

needed to fully open or

remove compactor drawer.

6" (15.2 cm)

clearance to the

nearest vertical

wall on the right

side of compactor

is needed to

remove bag.

Page 2

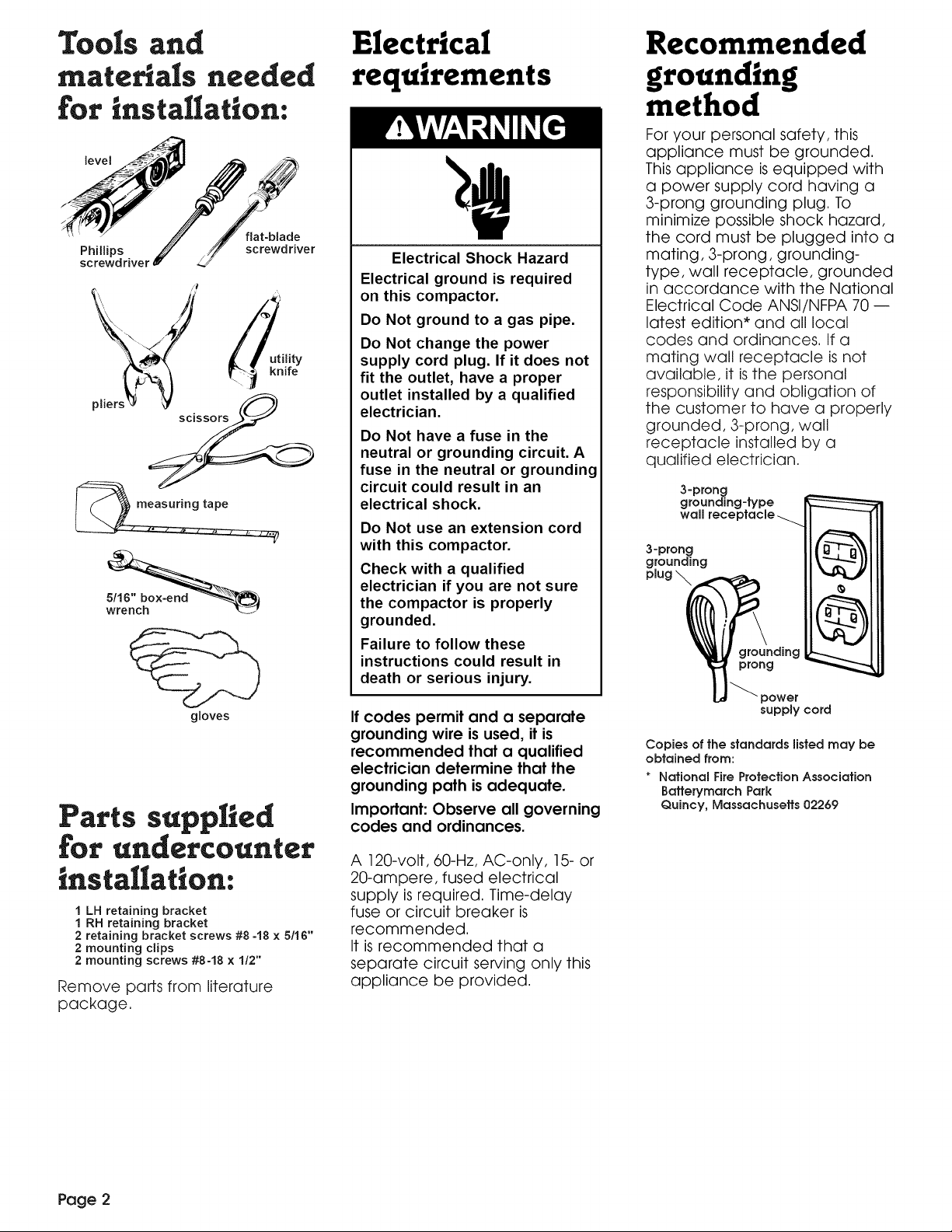

Tools and

Electrical

Recommended

mate als needed

for installation:

flat-blade

Phillips

screwdriver

gloves

screwdriver

Parts supplied

for undet¢ountet

{nstalla{iom

1 LH retaining bracket

1 RH retaining bracket

2 retaining bracket screws #8-18 x 5/16"

2 mounting clips

2 mounting screws #8-18 x 1/2"

Remove parts from literature

package.

requirements

Electrical Shock Hazard

Electrical ground is required

on this compactor.

Do Not ground to a gas pipe.

Do Not change the power

supply cord plug. If it does not

fit the outlet, have a proper

outlet installed by a qualified

electrician.

Do Not have a fuse in the

neutral or grounding circuit. A

fuse in the neutral or grounding

circuit could result in an

electrical shock.

Do Not use an extension cord

with this compactor.

Check with a qualified

electrician if you are not sure

the compactor is properly

grounded.

Failure to follow these

instructions could result in

death or serious injury.

If codes permit and a separate

grounding wire is used, it is

recommended that a qualified

electrician determine that the

grounding path is adequate.

Important: Observe all governing

codes and ordinances.

A 120-volt, 60-Hz, AC-only, 15- or

20-ampere, fused electrical

supply is required. Time-delay

fuse or circuit breaker is

recommended.

It is recommended that a

separate circuit serving only this

appliance be provided.

grounding

method

For your personal safety, this

appliance must be grounded.

This appliance is equipped with

a power supply cord having a

3-prong grounding plug. To

minimize possible shock hazard,

the cord must be plugged into a

mating, 3-prong, grounding-

type, wall receptacle, grounded

in accordance with the National

Electrical Code ANSI/NFPA 70 --

latest edition* and all local

codes and ordinances. If a

mating wall receptacle isnot

available, it is the personal

responsibility and obligation of

the customer to have a properly

grounded, 3-prong, wall

receptacle installed by a

qualified electrician.

3-prong

grounding-type

wall receptacle _

3-prong

grounding

plug \

groundinc

prong

power

supply cord

Copies of the standards listed may be

obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Page 2

Page 3

Now start...

With compactor in room where it

will be installed.

Do Not grasp console to move

compactor.

Slide compactor onto

cardboard or hardboard before

moving compactor across floor

to prevent damaging floor

covering.

Do not allow the rear frame of

the compactor to touch the

floor covering when lifting or

moving compactor.

I • Remove compactor from

shipping carton. Remove all

protective packaging materials

such as tape and shipping pads.

Remove waxy residue caused

by protective shipping material

with a mild solution of liquid

household cleaner and water.

clip

cord _

• Check that power supply

cord is attached to the cord clip

on the rear of the compactor.

• Place two corner posts

from carton on floor near

compactor. Open compactor

drawer and remove any

shipping materials or other items

shipped in the drawer. Do Not

remove the compactor bag (if

installed). Grasp the handle and

raise the front of drawer until it

clears stops. Grasp sides of

drawer and lift drawer out of

compactor. Place the drawer

on the two corner posts.

leveling legs

• Place the other two corner

posts on the floor to the side of

the compactor. Grasp the sides

of the compactor cabinet and

put compactor on its side on

top of the corner posts. Remove

the shipping base from the

bottom of compactor.

cabinet

wheel _ loca.,ting stud

bracket lJ/{' _ ""

assembly_

fJ "self-tapping

screw (pivot) _i

• Freestanding installation:

Go to Step 7.

Undercounter installation:

Measure the height of your

cabinet opening. The top of the

compactor should be at least

1/8" (3 mm) from the top of the

cabinet opening.

The rear wheels are preset for a

cabinet opening height of

34-1/4" (87 cm) (Position "A').

To adjust for other cabinet

opening heights, loosen screw

just enough to clear stud from

hole in position "A'. Move the

rear wheel and stud to position

"B" or "C" as needed for your

cabinet opening measurement:

Position B: 34-1/4" to 34-7/16"'

(87 to 87.5 cm)

Position C: 34-7/16" to 34-5/8"

(87.5 to 88 cm)

Tighten screw. Repeat for other

rear wheel.

• Use pliers to lower leveling

legs away from cabinet. Adjust

legs so there will be a 1/8"

(3 mm) to 1/4" (6.4 mm) space

between the top of the

compactor and the top of the

cabinet opening. Stand the

compactor upright.

7 -

• Use pliers to lower leveling

legs away from cabinet. Place

level inside on the floor of the

cabinet. Check that the

compactor is level from front to

back and side to side. Adjust the

leveling legs until the compactor

is level.

countertop

....... " retaining

• Freestandinginstallation:

Go to Step 9.

Undercounter installation:

For model with cabinet, remove the

plastic plugs from the compactor

cabinet top. Determine if you want

the compactor frame or drawer

front flush with the cabinet front.

Using the two #8 -18 x 5/16" screws,

install the retaining brackets to

cabinet top as needed:

If the compactor frame is to be flush

with the cabinet front, place

retaining bracket screws through

\\A/' ,

If the compactor drawer front isto

be flush with the cabinet front,

place retaining bracket screws

through "C'.

If the compactor is to be midway

between "A" and "C', place

retaining bracket screws

through "B'. Page 3

bracket

Page 4

retaining

Adjusting the

Injury Hazard

When moving or lifting the

compactor, use a glove to

protect and cushion your hand.

More than one person is

recommended to lift or move

compactor because of its size

and weight. Use proper lifting

methods.

Failure to follow these

instructions could result in

injury.

lift here

.. Move the compactor

close to its final position. Plug

the power supply cord into a

properly grounded receptacle.

Freestanding installation:

Carefully move compactor into

its final position. Check that

compactor isstill level. (See Step

7, Page 3.) Go to Step 10.

mountin(

screw

Countertop mounting

retaining

bracket

mounting

clip

screw

Cabinet-front mounting

Undercounter installation:

Carefully lift the front slightly and

roll compactor into the cabinet

opening until the retaining

brackets stop the unit.

Using the two #8 -18 x 1/2" screws,

fasten the retaining brackets to

the underside of the countertop

with the mounting screws.

If brackets cannot be attached

to the underside of countertop,

attach mounting clips to

brackets. Fasten compactor to

cabinet front with mounting

screws through mounting clips.

toe plate

If the toe plate rubs the floor

covering, the toe plate

clearance may be changed as

follows:

a, Mark on each side of the toe

plate the amount of toe plate

that rubs the floor covering.

b, Remove the drawer from the

unit. (See Step 3, Page 3.)

c, Use a ruler and a pencil or

chalk to draw a line between

the marks on each side of

toe plate.

e, Use scissors or utility knife to

cut toe plate along line.

,g

f, Replace drawer. (See Step

10.) If toe plate still rubs floor

covering, repeat Steps a-f.

Page 4

0• Grasp sides of

compactor drawer and place

bottom of drawer into tracks. Lift

at the handle so the front of

drawer will go over drawer stops.

Close drawer. Check if drawer

opens freely. If the toe plate rubs

against floor, see "Adjusting the

toe plate" for further instructions.

To get the most efficient use

from your new compactor,

read your Use and Care

Guide/Operation Instructions.

Keep literature close to

compactor for easy

reference.

Page 5

Models KCCC151,

KUCC151 and

YKCCC151

A custom-made flat or raised

panel can be installed in place of

the color panel. A new Trim Kit,

(Part No. 9871381 brushed stainless

steel, 9871382 white, 9871383

black or 9871384 almond) must be

ordered. The front panel must be

removed. Follow trim kit instructions

to install your customized panel.

Paint, wallpaper or other material

can be applied to a flat panel

and installed with the new trim kit

listed above. The existing

compactor color panel and trim

cannot be customized.

Custom-made panel

dimensions

23-13/16"

(60.5cm)

_( 14-518"-_

37.2cm) I

Flat panel: A 7/32" (5.6 mm) thick

panel is required. This isthe same

thickness as a standard 1/4"

plywood or paneling.

7132"

(5.6

ram)

raised --

panel or

decorative

trim

outer--

section of

panel

5116"

(8 ram) -],

both sides

Raisedpanel:The outer section of

panel must be 7/32" (5.6 mm) thick

to fit into trim. Raised decorative

trim or raised panel sections must

be 5/16" (8 mm) from the side and

bottom edges and 25/32" (20 mm)

from the top edge of the outer

section.

14-5/8" --I_

(37.2cm)

_(8 ram)

321-1/4"

23-13/16"

(60.5cm)

5/16"

All other models

Changing color panel:

Injury Hazard

Wear gloves and handle

panel(s) carefully.

Replace handle before

operating compactor.

Failure to follow these

instructions could result in

injury.

outside front

panel

•drawer

trim

1. Remove the drawer from the

unit. (See Step 3, Page 3.)

2. Remove the screws that

attach the handle to the

drawer.

3. Remove one spacer panel.

4. Remove color panel(s) by

carefully pulling up.

5. Select the color you wish to

show and carefully push that

panel into the drawer trim.

6. Replace the spacer panels

and other color panel.

7. Attach the handle.

8. Replace the drawer. (See

Step10, Page 4.)

Installing a custom-made

panel:

Paint, wallpaper or other material

can be applied to the color

panel.

A custom-made flat or raised

panel can be installed in place

of the color panel(s) and

spacers.

Custom-made panel

dimensions

_ 14-5/8" --_

(37.2cm) /

Flat panel: A 7/32" (5.6 mm)

thick panel isrequired. This is the

same thickness as a standard

1/4" plywood or paneling.

(5!/32" ----.4_

ram)

raised--

panel or

decorative

trim

outer--

section of

panel

Raised panel: The outer section

of panel must be 7/32" (5.6 mm)

thick to fit into trim. Decorative

trim or raised panel sections

must be 5/16" (8 mm) from all

edges of outer section.

I.Follow Steps 1through 4

"Changing color panel," but

remove all the cardboard

spacers.

2. Slide customized panel into trim.

3. Reattach handle.

4. Replace the drawer. (See Step

10, Page 4.)

14-5/8"--_

_-. (37.2 cm) I

"N

"N

T

22-15/16"

(58.3cm)

-5/16" (8 ram)

all around

22-15/16"

(58.3cm)

Page 5

Page 6

Before you call

for service...

If you need

asszstance...

If your compactor does not

operate properly, check the

following before calling for

service.

If the compactor won't operate:

• Is the power supply cord

securely plugged into an

electrical outlet?

• Has the house fuse blown or

circuit breaker tripped?

• Is the drawer completely

closed?

• Is the key-knob turned all the

way to STARTposition before it

isreleased?

If compactor stops during

operation:

• Push drawer in firmly while

turning key-knob to START.

Repeat if necessary.

• Rearrange trash load -- Do

Not load rigid items at front of

drawer.

Trashnotcompacted:

• Drawer must be at least 1/3 full

to see compaction.

Not enough compaction or

force:

• Compacting works best when

only a few items are loaded.

Use the compacting cycle

frequently.

Drawer won't open:

• Drawer will open only when

ram is all the way up. To raise

the ram, push drawer in firmly

and turn key-knob to START.

Release key-knob. Open

drawer and lay items flat in

center of drawer. Start

compactor again.

• If you are using EXTRA PACK,

DENSE PACK, SOLID PACK or

COMPACT/HOLD, make sure

the rocker switch is in the

NORMAL position and the

indicator light is OFF.

Check your Use and Care Guide

for a toll-free number to call, or

call the dealer from whom you

purchased this appliance. The

dealer is listed in the Yellow

Pages of your phone directory

under "Appliances -- Household

-- Major -- Service and Repair."

When you call, you will need the

compactor model number and

serial number. Both numbers are

on the model/serial rating plate,

which can be found by pulling

out the drawer and looking on

the left-hand side of the cabinet

opening.

Part No. 9871269 Rev. A

© 1996 Printed in U.S.A.

Loading...

Loading...