Page 1

FOR SERVICE TECHNICIAN’S USE ONLY

WARNING

DANGER

Tech Sheet Do not remove or destroy

W11284425B

Electrical Shock Hazard

Only authorized technicians should

perform diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can

result in death or electrical shock.

When performing live voltage measurements, you must do the following:

■ Verify the controls are in the off position so that the appliance does not start when energized.

■ Allow enough space to perform the voltage measurements without obstructions.

■ Keep other people a safe distance away from the appliance to prevent potential injury.

■ Always use the proper testing equipment.

■ After voltage measurements, always disconnect power before servicing.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Voltage Measurement Safety Information

10/18

Page 2

FOR SERVICE TECHNICIAN’S USE ONLY

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished, but failure may occur at a later date due to ESD stress.

■ Use an antistatic wrist strap. Connect wrist strap to green ground connection point or unpainted metal in the

appliance

-OR-

Touch your finger repeatedly to a green ground connection point or unpainted metal in the appliance.

■ Before removing the part from its package, touch the antistatic bag to a green ground connection point or

unpainted metal in the appliance.

■ Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

■

When repackaging failed electronic control assembly in antistatic bag, observe above instructions.

2

Page 3

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID

POSSIBLE EXPOSURE TO EXCESSIVE

MICROWAVE ENERGY

a. Do not operate or allow the oven to be operated with the door open.

b. Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

1. Interlock Operation

2. Proper Door Closing

3. Seal and Sealing Surfaces (Arcing, Wear and Other Damage)

4. Damage to or Loosening of Hinges and Latches

5. Evidence of Dropping or Abuse

c. Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, waveguide or transmission line, and cavity for proper alignment,

integrity and connections.

d. Any defective or misadjusted components in the interlock, monitor, door seal, and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures described

in service manual before the oven is released to the owner.

e. A microwave leakage check to verify compliance with the CSA should be performed on each oven prior

to release to the owner.

f. Do not attempt to operate the oven if the door glass is broken.

3

Page 4

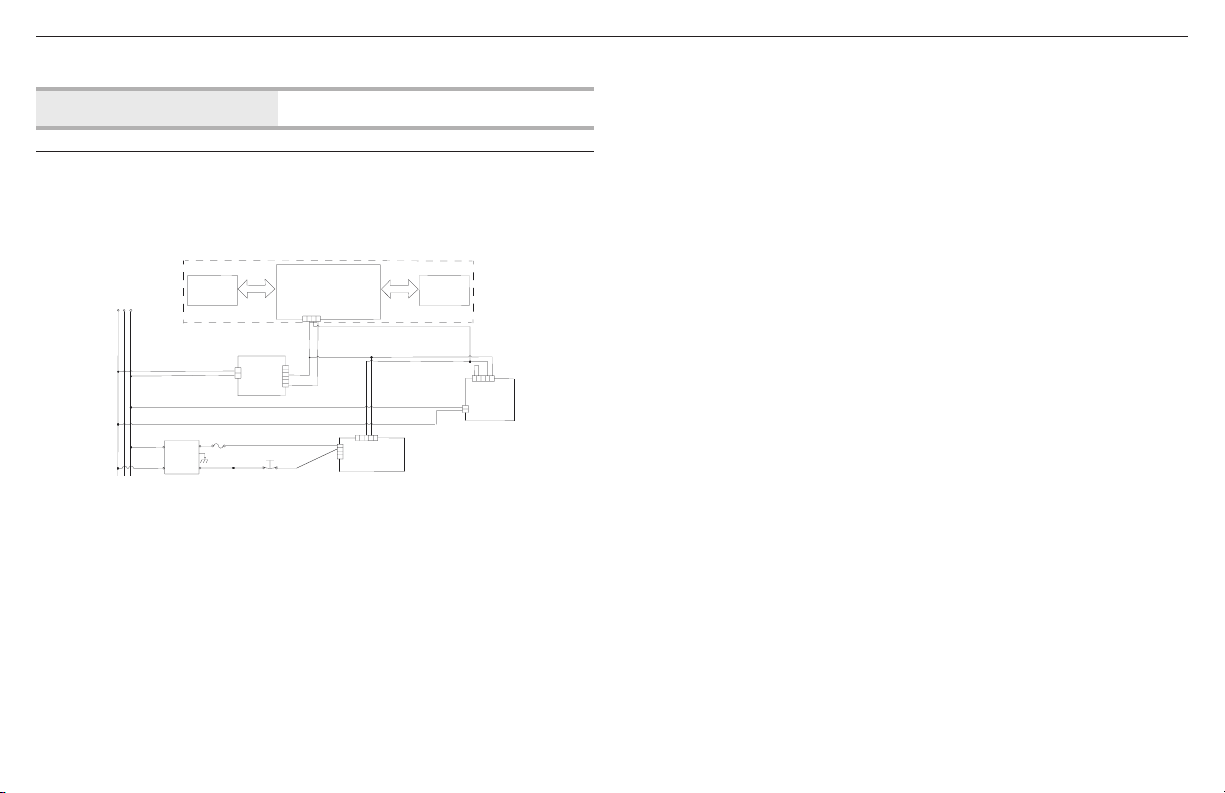

FOR SERVICE TECHNICIAN’S USE ONLY

35

0

Diagnostics

IMPORTANT: Before powering microwave (MW) magnetron, be surethat a

load, such as a microwave-safe cup of water, is present in the microwave

oven cavity.

Unplug oven or disconnect power before performing thefollowing checks:

■ A potential cause of a control not functioning is corrosion on connections.

Observe connections andcheck for continuity with an ohmmeter.

■ All tests/checks should be made with a VOM or DVM having a sensitivity

of 20,000 Ω per volt DC or greater.

■ Check all connections before replacing components, looking for broken

or loose wires, failed terminals, or wires not pressed into connectors far

enough. Damaged harness must be entirely replaced. Do not rework a

harness.

■ Resistance checks must be made with power cord unplugged from outlet

and with wiring harness or connectors disconnected.

IMPORTANT: Do not replace the control if there is no evidence of any failure.

To Enter Diagnostics Mode:

Before proceeding with any corrective action, perform the following steps to

enter the Diagnostics mode:

1. Enter Diagnostics mode by pressing LOWER OVEN>LOWER

LIGHT>OVEN CANCEL (repeat 2more times).

TIP: You can also swipe your nger from left to right overthe keypads 3

times.

NOTE: You do not need to wait for any audible or visual feedback from

the control between keypad presses.

2. If control does not enter Diagnostics mode, continue repeating the

keypad sequence from Step 1. All the keypads will light up when the

control enters Diagnostics mode.

3. From the Diagnostics menu, scroll to the desired selection using the

touch screen.

Error Diagnostics: View and clear the failure history.

Component Activation: Manually activate each relay.

Sensors & Switches: View the traditional oven cavity temperatures and

door/latch switch status.

System Information: View the model number, serial number, and

software versions.

Exit Diagnostics

General Procedure: Error Codes

NOTE: All failures are stored in the failure history. To check if the error code

is still present, start a cooking function and wait 1 minute to check if the error

appears.

1. Plug in oven or connect power.

2. Enter Diagnostics mode.

3. Touch or scroll to “Error Diagnostics” in the Diagnostics menu, and then

touch “OK.”

4. To clear error codes, touch “Clear History.”

5. If no failures are listed, the message “No Error” will appear on the screen.

4

Page 5

General Procedure: Component Activation

1. Plug in oven or connect power.

2. Enter Diagnostics mode.

3. Touch or scroll to “Component Activation” in the Diagnostics menu, and

then touch “OK.”

4. Touching the following selections will activate/ deactivate corresponding

relay.

Selection Relay

MW Light MW Light Relay

MW Turntable MW Turntable Relay

MW Cooling Fan MW Cooling Fan Relay

MW Grill MW Broil Element Relay

MW Convection Element MW Convection ElementRelay

MW Convection Fan MW Convection fan Relay

MW Magnetron/Cooling Fan

Oven Bake Element Oven Bake Element Relay

Oven Broil Element Oven Broil Element Relay

Oven Convection Element Oven Convection ElementRelay

Oven Convection Fan Oven Convection Fan Relay

Oven Cooling FanHigh Speed Oven Cooling Fan High-SpeedRelay

Oven Cooling FanLowSpeed Oven Cooling Fan Low-SpeedRelay

Oven Light Oven Light Relay

Oven Door LatchMotor Oven Door Latch Motor Relay

MW Magnetron and MWCooling Fan

Relay

General Procedure: Sensors & Switches

NOTE: This procedure is to view the current status of oven switches and

sensor readings.

Display Status

MW Door Switch Open or Closed

MW Cavity Temp Degrees in Celsius

Oven Door Switch Open or Closed

Oven Latch Switch Open or Closed

Oven Cavity Temp Degrees in Celsius

Oven Meat Probe Temp Degrees in Celsius

1. Plug in oven or connect power.

2. Enter Diagnostics mode.

3. Touch or scroll to “Sensors & Switches” in the Diagnostics menu, and

then touch “OK.”

4. Touch or scroll through the Sensors & Switches menu to view the desired

status.

NOTE: Touching “Back” will return the display to the main Diagnostics

menu.

5

Page 6

FOR SERVICE TECHNICIAN’S USE ONLY

General Procedure: System Information

NOTE: This procedure is to view the following system information:

System Information Display

Model # Model Information

Serial # Product Serial Number

UI Serial # User Interface Serial Number

Oven ACU Serial # Appliance Control UnitSerialNumber

UI Version User Interface Software Version

HMI Central SW HMI Central Board SoftwareVersion

HMI Left SW HMI Left Keyboard SoftwareVersion

HMI Left EE HMI Left Keyboard EEPROMVersion

HMI Right SW HMI Right Keyboard SoftwareVersion

HMI Right EE HMI Right Keyboard EEPROMVersion

Kernel Version HMI Central Board SoftwareVersion

Touch Calibration Version LCD/TP FPC Tail SoftwareVersion

Database Version HMI Central Board DatabaseStructure

Audio Version HMI Central Board SoftwareVersion

Oven ACU SW

MWO ACU SW

Diagnostics Entries

Oven Appliance Control UnitSoftware

Version

Microwave Oven Appliance Control

Unit Software Version

Number of times Diagnostics menu has

been entered.

1. Plug in oven or connect power.

2. Enter Diagnostics mode.

3. Touch or scroll to “System Information” in the Diagnostics menu, and

then touch “OK.”

4. Touch or scroll through the System Information menu to view the desired

status.

NOTE: Touching “Back” will return the display to the main Diagnostics

menu.

General Procedure: Model Selection

NOTE: When a new User Interface (UI) is installed, you will beprompted to

select a new model number upon power-up. To change the model number on

an existing UI,follow the steps below.

1. Plug in oven or connect power.

2. Enter Diagnostics mode.

3. Touch or scroll to “System Information” in theDiagnostics menu, and

then touch “OK.”

4. Touch or scroll to “Model Number,” and then touch“OK.”

5. Touch or scroll to the correct model number inthelist, and then touch

“Select.”

6

Page 7

Failure/Error Display Codes

NL

Thermostat

No Display - control is blank

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

1. Unplug oven or disconnect power.

2. Remove plastic cover from UI. Check connection from display to UI.

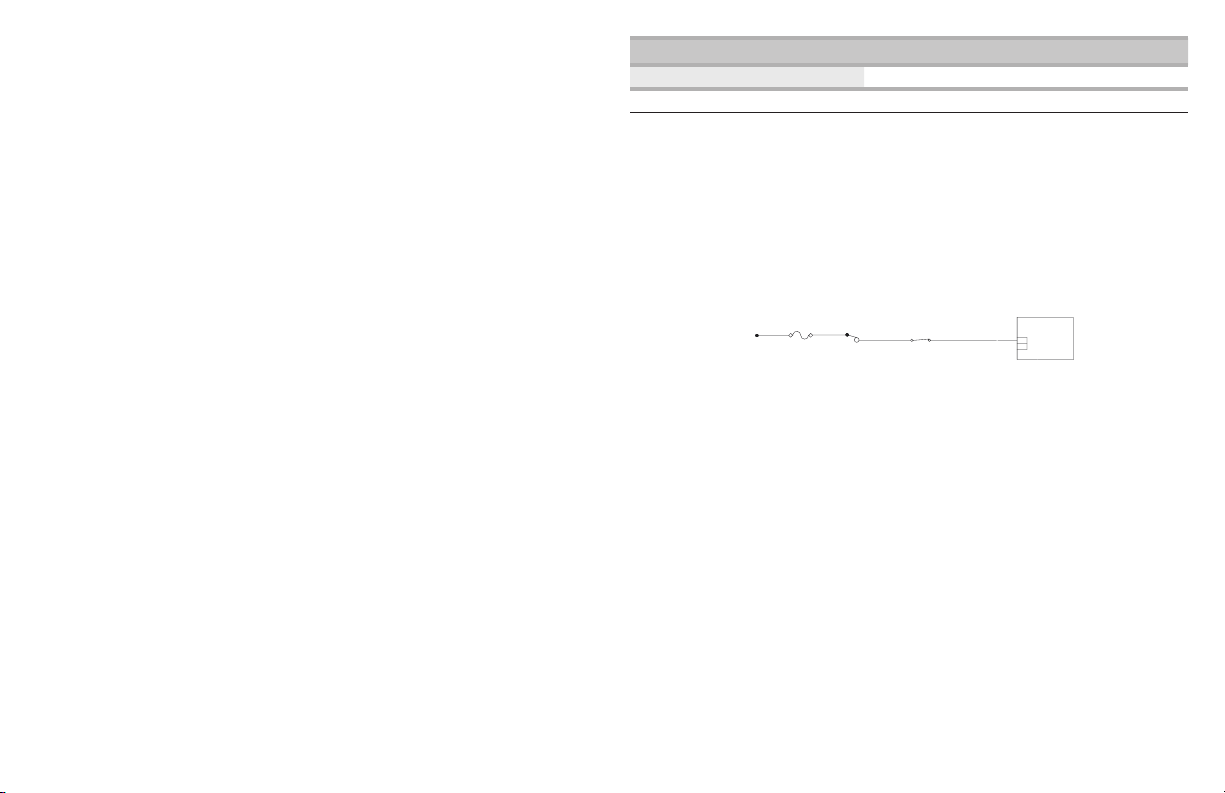

3. Check wiring from main line to SMPS (CONN 7).

Switch Mode Power Supply (SMPS), User

Interface (UI)

12. Check for control board display. If still no display, unplug oven or

disconnect power.

13. Replace HMI-Central/UI board.

14. Reassemble all parts and panels before operating.

15. Plug in oven or reconnect power. If the UI was replaced, follow the on-

screen prompts to select themodel number.

16. Verify operation is normal. If problem persists, replacethe Control Panel

Assembly and repeat steps14 through 16.

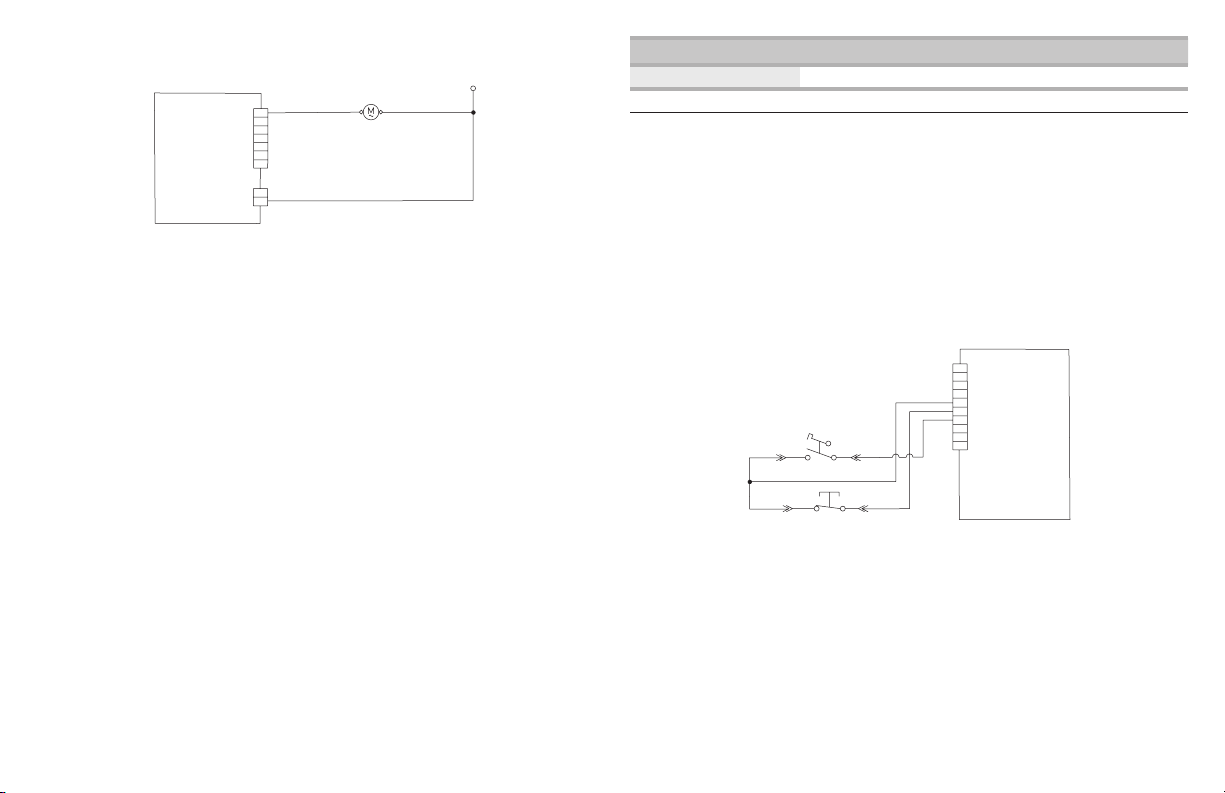

SMPS

14 V DC

15W

CONN2

Cavity

User Interface

1234

6

5

YL

4

3

2

BU

1

52 BU

J15

2L1

BK

P32

WH

P31

J6

CONN7

WH

2

1

BK

Line

20A Fuse

P33

BR

Line

L1

Filter

42 WH

41 WH

P34

OR

12345

P1

4

3

Microwave

2

1

Appliance

Manager

J5

J7 HMI RightHMI Left J4

Control Panel Assembly

OR

YL

OR

YL

BK

WH

P26

OR

BR

12345

Oven

Appliance

1

2

Manager

J8

4. Check connection from wiring harness to UI (J15).

5. Check proper voltage input at J15-2 (GND) to J15-4 (14 VDC) on the UI

by completing the following steps.

6. Connect voltage measurement equipment to J15-2 and J15-4 on UI.

7. Plug in oven or reconnect power.

8. Measure voltage and conrm voltage reading is 14VDC. If voltage is

correct, unplug oven or disconnect power and go to Step 13. If voltage

isnotcorrect, go to Step 9.

9. Unplug oven or disconnect power. Replace theSMPS.

10. Reassemble all parts and panels before operating.

11. Plug in oven or reconnect power.

P1

7

Page 8

FOR SERVICE TECHNICIAN’S USE ONLY

Speaker

User Interface not reacting

to touch

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

1. Enter the Diagnostics menu, and then touch POWER.

2. To reset Touch Calibration: unplug oven or disconnect power, wait 10

seconds, and then pluginoven or reconnect power. If still no response,

go to Step 3.

3. Unplug oven or disconnect power.

4. Replace Control Panel Assembly.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. Verify operation is normal.

Control Panel Assembly

No Sound Speaker, Control Panel Assembly

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

1. Verify sound is enabled. Touch the Tools menu, and then scroll to the

Sound menu. Conrm Key Press, Timer & Alert, and Power On & Off

actions are all turned on and set to the desired volume.

2. Unplug oven or disconnect power.

3. Conrm the speaker is rmly connected to the HMI-Central/UI board at

J8. If speaker is rmly connected, go to Step 4. If speaker connection

isloose, reconnect and proceed to Step 5.

BK

2

J8

1

RD

4. Replace speaker.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. Conrm operation of the speaker. If problem persists, unplug oven or

disconnect power, replace Control Panel Assembly, and repeat steps 5

through 7.

HMI-C

User Interface

8

Page 9

FAILURE ERROR LIKELY FAILURE CONDITION

F1

Internal

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

NOTE: If other error codes are stored, troubleshoot those other error codes

rst.

1. Unplug oven or disconnect power.

2. Conrm the control panel assembly is grounded to the oven chassis. If it

is, go to Step 6. If it is not, x the connection.

3. Reassemble all parts and panels before operating.

4. Plug in oven or reconnect power and cycle power.

5. If error persists unplug oven or disconnect power.

6. Replace HMI-Central/UI board.

7. Reassemble all parts and panels before operating.

8. Plug in oven or reconnect power and cycle power.

9. If error persists after HMI-Central/UI board is replaced, unplug oven or

disconnect power and replace Control Panel Assembly.

10. Reassemble all parts and panels before operating.

11. Plug in oven or reconnect power. Follow the on-screen prompts for model

selection.

12. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history. If the Control Panel Assembly was

replaced, there is noneed to clear the error history.

E0 Oven user interface failure

FAILURE ERROR LIKELY FAILURE CONDITION

F1 E1 Internal oven ACU error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

NOTE: If other error codes are stored, troubleshoot those other error codes

rst.

1. Unplug oven or disconnect power.

2. Replace the Copernicus Appliance Manager.

3. Reassemble all parts and panels before operating.

4. Plug in oven or reconnect power.

5. If error persists after Copernicus Appliance Manager is replaced, unplug

oven or disconnect power, and then go to Step 6. If not, go to Step 9.

6. Replace Control Panel Assembly.

7. Reassemble parts and panels before operating.

8. Plug in oven or reconnect power.

9. Follow the on-screen prompts to select the modelnumber

10. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history. If the Control Panel Assembly was

replaced, there is noneed to clear the error history.

9

Page 10

FOR SERVICE TECHNICIAN’S USE ONLY

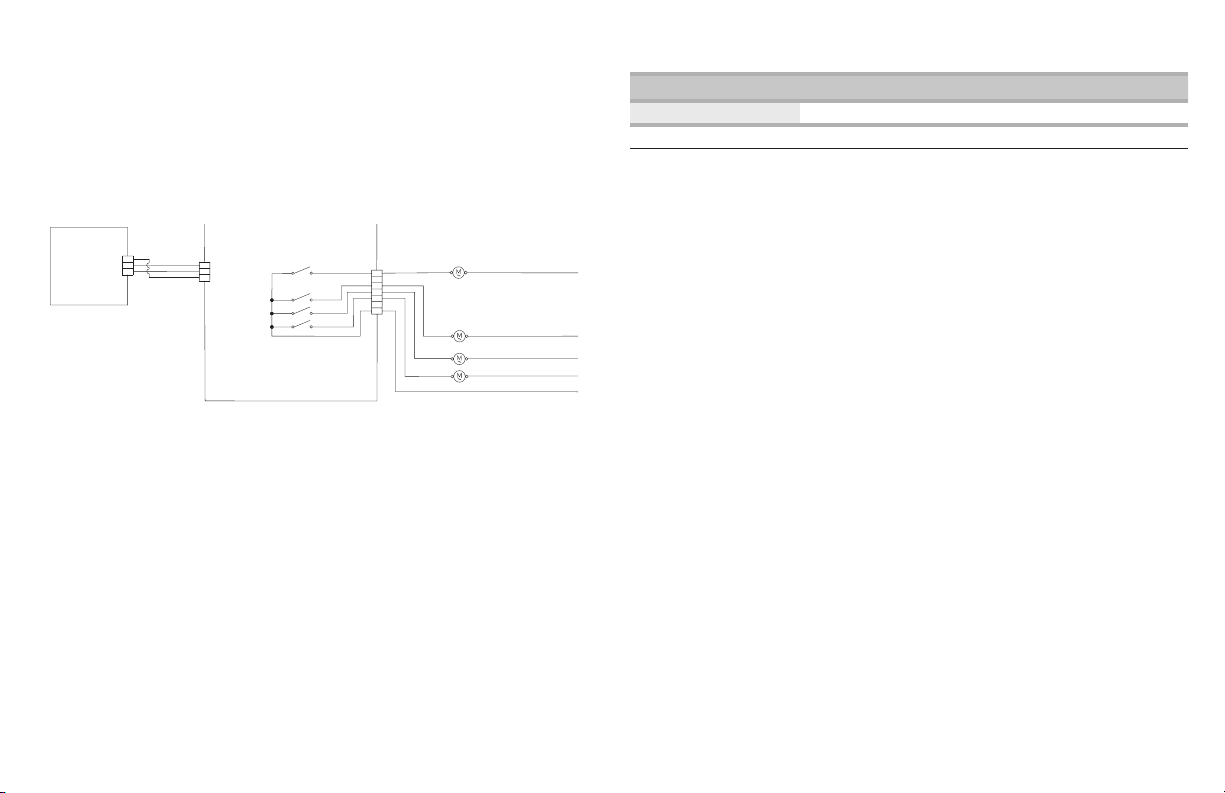

Line Fuse

Switch

L1

To

FAILURE ERROR LIKELY FAILURE CONDITION

F1 E4 Microwave oven relay4903error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Make sure that all interlock switches work properly: when door is open,

microwave light is on; when dooris closed, microwave light is off.

2. Unplug oven or disconnect power.

3. Check the following on the Microwave ApplianceManager:

a. Wire connections to Relay 4903

20A

BR

Primary

Interlock

b. Check if Relay 4903 is shorted. If so then gotoStep 7.

4. Reassemble all parts and panels before operating.

5. Plug in oven or reconnect power.

6. To check if the error code is still present, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Wait 1minute to

check if the error appears. If error remains, go to Step 7. If not, go to Step

10.

7. Unplug oven or disconnect power and replace the Microwave Appliance

Manager.

8. Reassemble all parts and panels before operating.

9. Plug in oven or reconnect power.

10. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear thehistory.

1

4

Microwave Relay

4903

BU

Inverter

CN702

FAILURE ERROR LIKELY FAILURE CONDITION

F1 E5 Microwave oven inverter error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Make sure that all interlock switches work properly: when door is open,

microwave light is on; when dooris closed, microwave light is off.

2. Unplug oven or disconnect power.

3. Check the following on the Microwave ApplianceManager:

a. Relay 4903

b. Connector P8

P8

MW

Relay

4903

P355

P354

1

2

3

BU

WH

CN702

Magnetron

3

2

CN701

1

MW Inverter

RD RD

PWM

CN703

E701

YL/

GN

4. Check the following connections on the Inverterboard:

a. CN701

b. CN702

c. CN703

5. If the door works properly and all connections areokay, replace the

Microwave Inverter Board.

6. Reassemble all parts and panels before operating.

7. Plug in oven or reconnect power.

10

Page 11

8. To check if the error code is still present, be sure that a load, such as a

Line Fuse

Switch

L1

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Wait 1minute to

check if the error appears. If error remains, then go to Step 9. If not, go to

Step 17.

9. Unplug oven or disconnect power.

10. Replace the Magnetron.

11. Reassemble all parts and panels before operating.

12. Plug in oven or reconnect power.

13. To check if the error code is still present, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Wait 1minute to

check if the error appears. If error remains, then go to Step 14. If not, go

to Step 17.

14. Unplug oven or disconnect power and replace theMicrowave ACU.

15. Reassemble all parts and panels before operating.

16. Plug in oven or reconnect power.

17. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear thehistory.

FAILURE ERROR LIKELY FAILURE CONDITION

F1 E6 Microwave generation error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Make sure that all interlock switches work properly: when door is open,

microwave light is on; when dooris closed, microwave light is off.

2. Unplug oven or disconnect power.

3. Check the following on the Microwave ApplianceManager:

a. Relay 4903

20A

BR

Primary

Interlock

1

4

Microwave Relay

4903

BU

Inverter

CN702

4. If the door works properly and all connections areokay, replace the

Magnetron.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. To check if the error code is still present, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Wait 1minute to

check if the error appears. If error remains, then go to Step 8. If not, go to

Step 16.

8. Unplug oven or disconnect power and replace theInverter Board.

9. Reassemble all parts and panels before operating.

10. Plug in oven or reconnect power.

11. To check if the error code is still present, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Wait 1minute to

check if the error appears. If error remains, then go to Step 12. If not, go

to Step 16.

12. Unplug oven or disconnect power.

13. Replace the Microwave ACU.

14. Reassemble all parts and panels before operating.

11

Page 12

15. Plug in oven or reconnect power.

FOR SERVICE TECHNICIAN’S USE ONLY

16. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear thehistory.

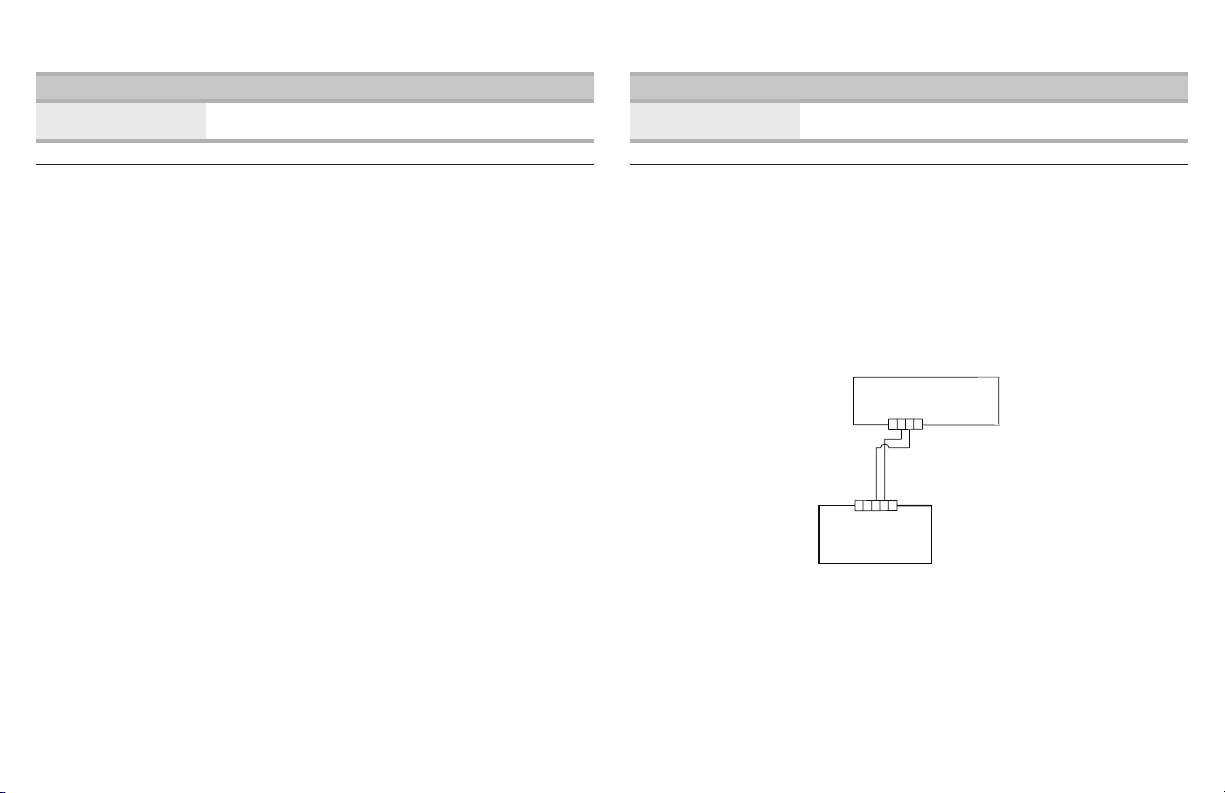

FAILURE ERROR LIKELY FAILURE CONDITION

F2

Keypad

E0 Keypad disconnected

E1 Stuck/Shorted keypad

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Check that connectors J4, J5, J6, and J7 are rmly connected. If they are

not, go to Step 3. If they are, go to Step 6.

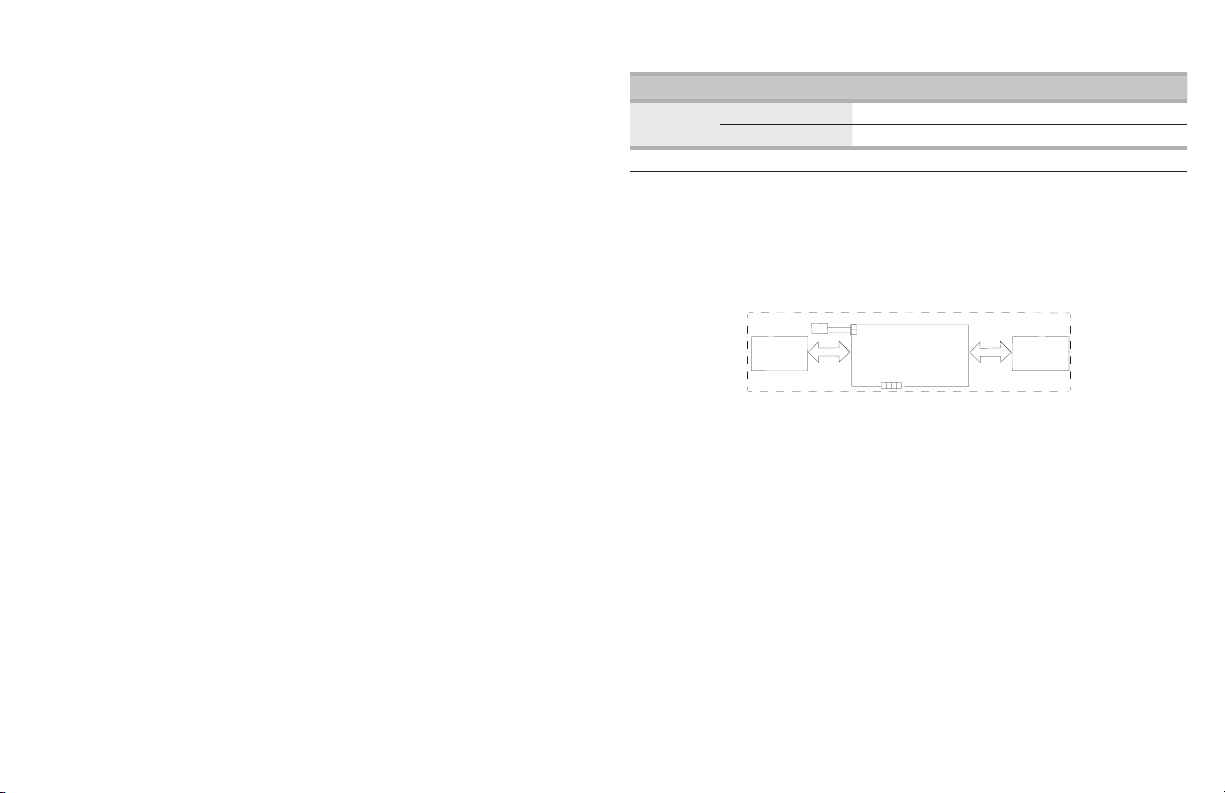

Speaker

21

BK

J8

RD

User Interface

HMI Left

J4J6

J15

1 2 3 4

J7J5

HMI Right

Control Panel Assembly

3. Reconnect any loose connectors.

4. Reassemble all parts and panels before operating.

5. Plug in oven or reconnect power. If the failure is gone, go to Step 9. If the

failure is still present, unplug oven or disconnect power.

6. Replace the Control Panel Assembly.

7. Reassemble all parts and panels before operating.

8. Follow the on-screen prompts to select the model number.

9. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history. If the Control Panel Assembly was

replaced, there is no need to clear the error history.

12

Page 13

FAILURE ERROR LIKELY FAILURE CONDITION

T

V

Meat Probe

F3

Sensors

E0 Main oven sensor openorshorted

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Disconnect connector P3 from Oven Appliance Manager, and measure

the resistance of the sensor between P3-1 and P3-2. Test for 1000 Ω to

1200 Ω at77°F (25°C). Check sensor for short to ground. If checks on

sensor are not correct, replace sensor andrepeat the checks.

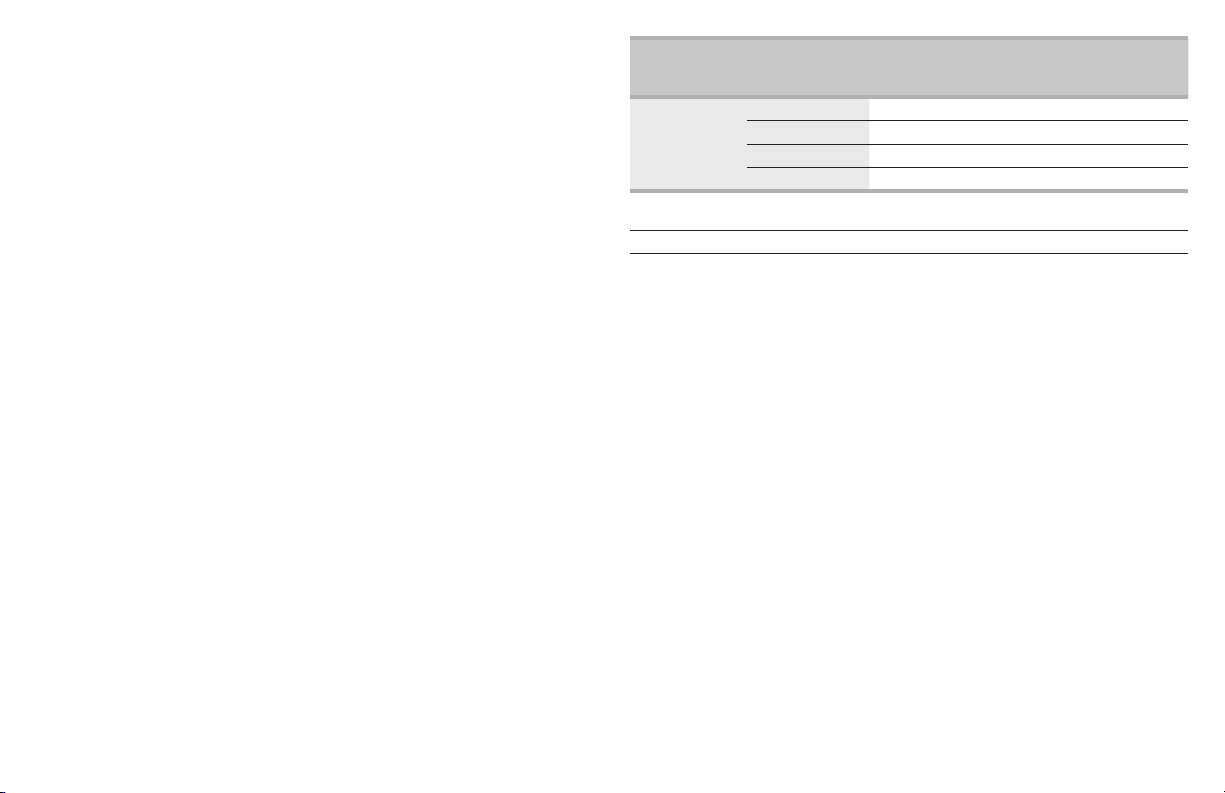

Oven

emperature

Sensor

1

V

2

3

4

Copernicus

5

6

Appliance Manager

7

8

9

10

P3

3. Reassemble all parts and panels and plug in oven orreconnect power.

4. Enter Diagnostics mode and select “Sensors & Switches” to verify if

the temperature shown in the Cavity Temp display is correct (ambient

temperature). If it is, go to Step 8. If not, unplug oven or disconnect

power.

NOTE: On the status screen, the unit of measurement is Celsius.

5. Replace the Copernicus Appliance Manager board.

6. Reassemble all parts and panels before operating.

7. Plug in oven or reconnect power.

8. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history.

FAILURE ERROR LIKELY FAILURE CONDITION

F3

Sensors

E3

Meat probe connector jack ormeat probe

shorted

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Remove meat probe if connected.

3. Disconnect connector P3 from Copernicus ApplianceManager.

1

2

3

4

5

6

7

8

9

10

P3

Copernicus

Appliance Manager

Sensor

OR

GN

4. Check connector jack resistance between P3-3 and P3-4. If it is 0 Ω,

change the jack assembly, and then go to Step 5.

If it is not 0 Ω, the jack assembly is working properly. Go to Step 5.

5. Plug in the meat probe and check for short to ground or open. If checks

on meat probe are not correct, replace the meat probe. At 77°F (25°C) the

expected value is approximately 50 KΩ. If they are correct, replace the

Copernicus Appliance Manager.

6. Reassemble all parts and panels before operating.

7. Plug in oven or reconnect power.

8. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history. Check the meat probe reading by

entering Diagnostics mode and selecting “Sensors & Switches.” The meat

probe should detect the ambient temperature.

13

Page 14

FOR SERVICE TECHNICIAN’S USE ONLY

Ca

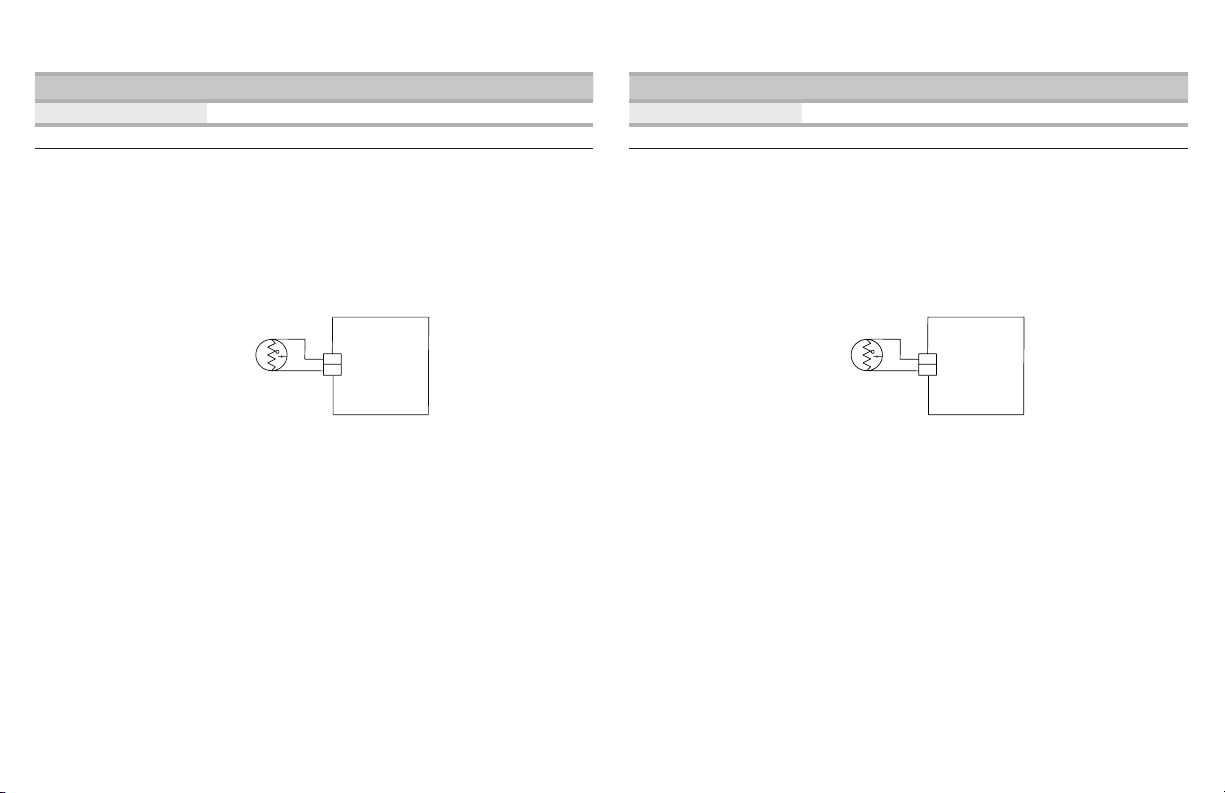

Ther

Microwave

Magnetron

Ther

FAILURE ERROR LIKELY FAILURE CONDITION

F4 E1 Microwave cavity temperaturesensor error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function that uses the temperature sensor, such as

a Convect cycle. Wait 1minute, and then verify that the failure happens again.

1. Unplug oven or disconnect power.

2. Check that the P22 connection of the Microwave Appliance Manager is

rmly connected. If it is, go to Step 3. If it is not, reconnect and go to

Step 5.

P22

Appliance

Manager

vity

mistor

FAILURE ERROR LIKELY FAILURE CONDITION

F4 E2 Magnetron temperature sensorerror

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Unplug oven or disconnect power.

2. Check that the P21 connection of the Microwave Appliance Manager is

rmly connected. If it is, go to Step 3. If it is not, reconnect and go to

Step 5.

Microwave

Appliance

mistor

Manager

P21

3. Disconnect connector P22 from the Microwave Appliance Manager, and

measure the resistance of the thermistor. It should be (approximately)

230kΩ at77°F ± 10°F (25°C ± 10°C).

4. Check thermistor for short to ground. If check on thermistor is not

correct, replace the thermistor. If thermistor check is correct, replace the

Microwave Appliance Manager.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

3. Disconnect connector P21 from the Microwave Appliance Manager, and

measure the resistance of the thermistor. It should be (approximately)

10kΩ at77°F ± 10°F (25°C ± 10°C).

4. Check thermistor for short to ground. If check on thermistor is not

correct, replace the thermistor. If thermistor check is correct, replace the

Microwave Appliance Manager.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

14

Page 15

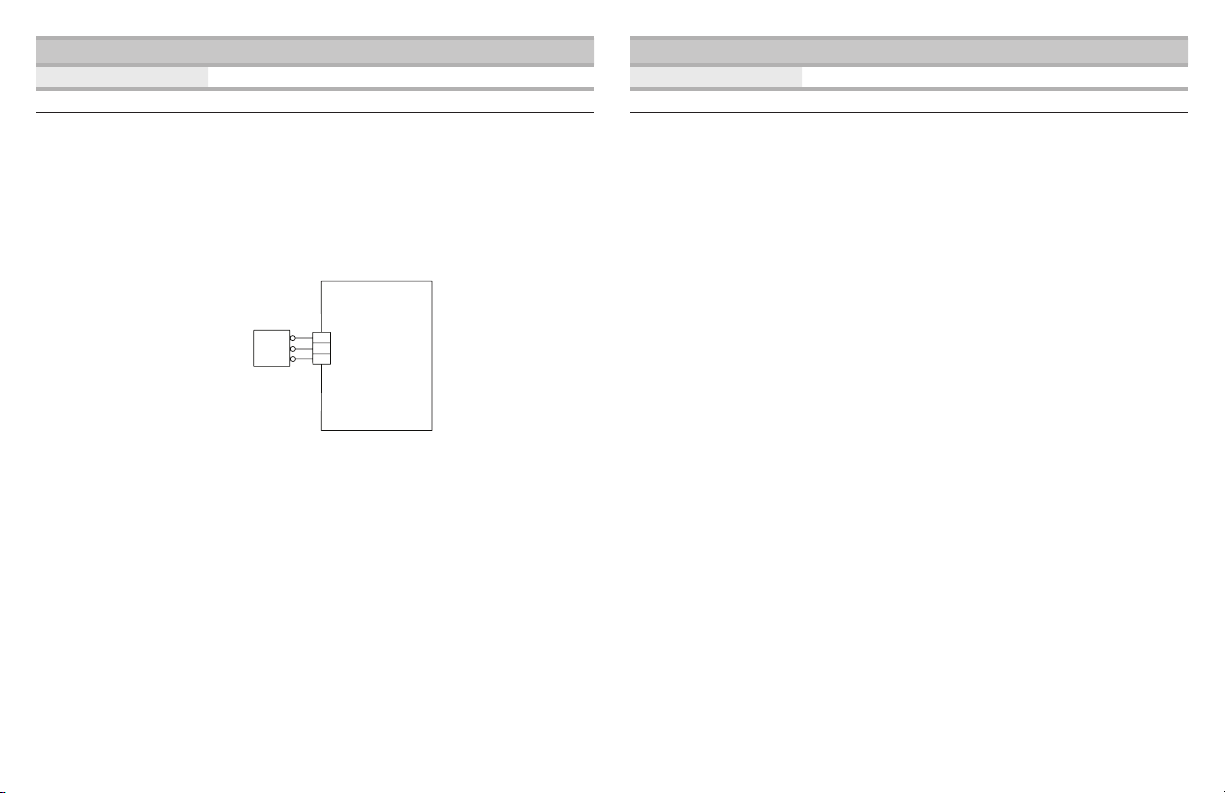

FAILURE ERROR LIKELY FAILURE CONDITION

Humidity

Sensor

1600

F4 Inputs E4 Microwave oven humiditysensor error

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function that uses the humidity sensor, such as a

Steam cycle. Wait 1minute, and then verify that the failure happens again.

1. Unplug oven or disconnect power.

2. Check that the P23 connection of the Microwave Appliance Manager is

rmly connected. If it is, go toStep 3. If it is not, reconnect and go to

Step 5.

Microwave

Appliance

Manager

P23

3. Disconnect connector P23 from Microwave Appliance Manager and

measure the resistance ofthe sensor:

Between pins 3 and 1. It should be approximately 2800 Ω at 77°F ± 10°F

(25°C ± 10°C).

Between pins 3 and 2. It should be approximately 2800 Ω at 77°F ± 10°F

(25°C ± 10°C).

4. Check sensor for short to ground. If checks on sensor are not correct,

replace the sensor. If sensor checks are correct, replace the Microwave

Appliance Manager.

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

FAILURE ERROR LIKELY FAILURE CONDITION

F4 E8 Inverter over temperature

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Unplug oven or disconnect power.

2. Check the following:

a. Cooling fan connection for any loose connectors

b. Oven installation and make sure there is no air blockage

3. Reassemble all parts and panels before operating.

4. Plug in oven or reconnect power.

5. To check if the cooling fan is stalled, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Make sure the fan is

running. If it is not, unplug oven or disconnect power, replace the fan, and

go to Step 8. Otherwise, go to Step 6.

6. Unplug oven or disconnect power.

7. Replace the inverter board.

8. Reassemble all parts and panels before operating.

9. Plug in oven or reconnect power.

10. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

15

Page 16

FOR SERVICE TECHNICIAN’S USE ONLY

Door Switch

FAILURE ERROR LIKELY FAILURE CONDITION

F4 E9 Inverter and magnetron overtemperature

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven (power off, wait 10

seconds, and power on). After powering on, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity, and

start a microwave cooking function. Wait 1minute, and then verify that the

failure happens again.

1. Unplug oven or disconnect power.

2. Check the following:

a. Cooling fan connection for any loose connectors

b. Oven installation and make sure there is no air blockage

3. Reassemble all parts and panels before operating.

4. Plug in oven or reconnect power.

5. To check if the cooling fan is stalled, be sure that a load, such as a

microwave-safe cup of water, is present in the microwave oven cavity,

and start a cooking function in the microwave oven. Make sure the fan is

running. If it is not, unplug oven or disconnect power, replace the fan, and

go to Step 8. Otherwise, go to Step 6.

6. Unplug oven or disconnect power.

7. Replace the Magnetron and the inverter board.

8. Reassemble all parts and panels before operating.

9. Plug in oven or reconnect power.

10. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

FAILURE ERROR LIKELY FAILURE CONDITION

F5 Inputs E0 Door and latch switch donotagree

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Enter the Diagnostics menu and select “Component Activation.” Touch or

scroll to “Door Latch Motor,” and then touch “OK.” Touch “Latch Door.”

Wait at least 15 seconds, and then check if latch status changes on

screen. If status does not change, unplug oven or disconnect power and

go to Step 2. If status changes, unplug oven or disconnect power and go

to Step 5.

2. If the oven door did not unlatch, unplug connector P3 and check for

continuity (on the latch wire) between P3-5 and P3-7.

1

2

3

4

5

6

7

Copernicus

8

9

Appliance Manager

BU

Motor Latch Switch

TN

BR

OR/BK

10

P3

3. Disconnect J8 connector from Copernicus Appliance Manager.

16

Page 17

4. Measure the resistance between connectors J8-2 and P5-1. It should be

Appliance Manager

N

Door Switch

500 Ω to 3000 Ω at 77°F (25°C).

WH

Copernicus

YL

1

2

3

4

5

6

7

P5

1

WH

2

J8

Motor Door Latch

5. If the resistance check is outside the range, replace the affected door

latch assembly. Verify that the error is gone.

6. Reassemble all parts and panels.

7. Plug in oven or reconnect power.

8. Enter the Diagnostics menu and select “Component Activation.” Check

the door status on the screen by opening and closing the oven door.

9. If status does not change, unplug the oven or disconnect power.

10. Check for continuity with door open and closed at P3-5 to P3-6. Door

open = innite resistance. Door closed = zero resistance.

11. If continuity check is not correct, replace the door latch assembly. If all

checks were correct, replace Copernicus Appliance Manager.

12. Reassemble all parts and panels before operating.

13. Plug in oven or reconnect power.

14. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

FAILURE ERROR LIKELY FAILURE CONDITION

F5 Inputs E1 Latch not operating

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Enter the Diagnostics menu and select “Component Activation.” Touch or

scroll to “Door Latch Motor,” and then touch “OK.” Touch “Latch Door.”

Wait at least 15 seconds, and then check if latch status changes on

screen. If status does not change, go to Step 2. If status changes, unplug

oven or disconnect power, replace Copernicus Appliance Manager and

go to Step 6.

2. If latch status on screen is “open,” unplug oven ordisconnect power and

check for loose harness connection between motor latch switch and P3-5

andP3-7.

1

2

3

4

5

6

7

Copernicus

8

9

Appliance Manager

BU

Motor Latch Switch

TN

BR

OR/BK

10

P3

3. Disconnect connector J8 from Copernicus ApplianceManager.

17

Page 18

4. Measure the resistance between connectors J8-2 and P5-1. It should be

Appliance Manager

N

NL

FOR SERVICE TECHNICIAN’S USE ONLY

500 Ω to 3000 Ω at 77°F (25°C).

YL

1

Copernicus

2

3

4

5

6

7

P5

1

WH

2

J8

Motor Door Latch

5. If the resistance check is outside the range, replace the door latch

assembly. Verify that the error is gone. If all checks were correct, replace

Copernicus Appliance Manager.

6. Reassemble all parts and panels before operating.

7. Plug in oven or reconnect power.

8. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

WH

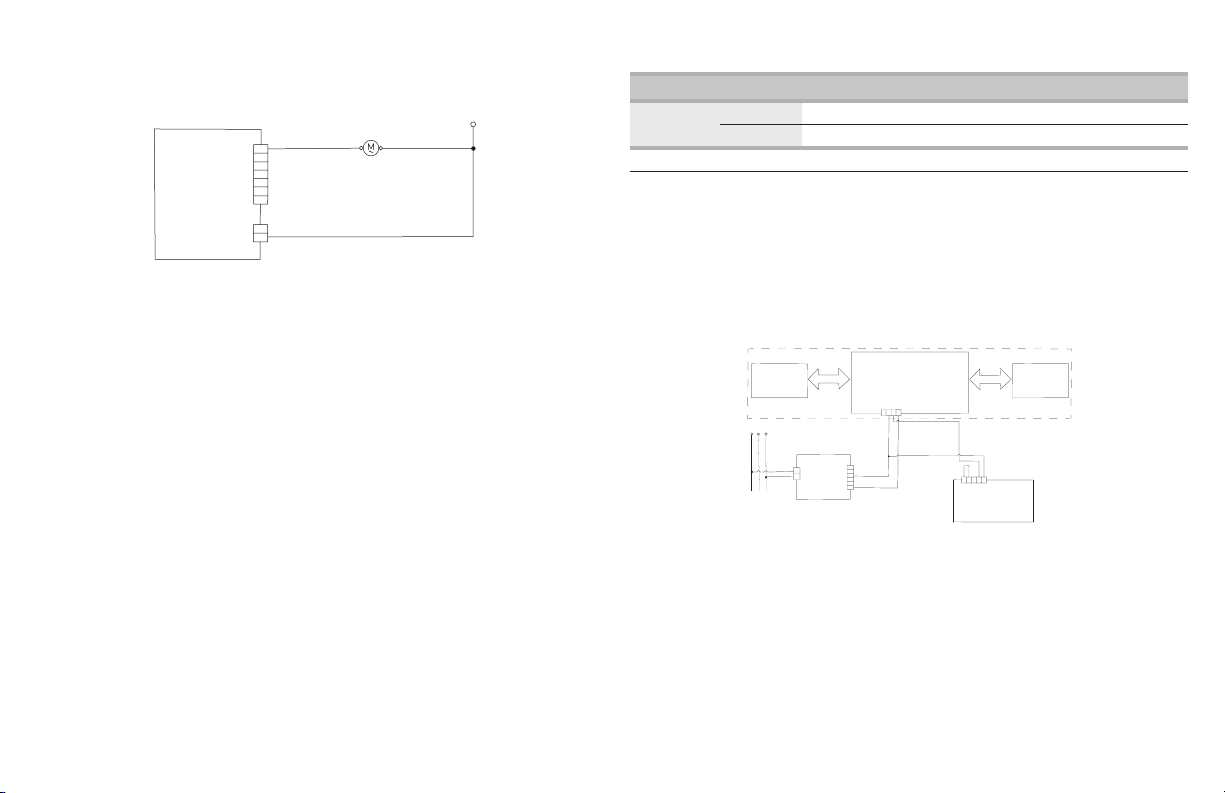

FAILURE ERROR LIKELY FAILURE CONDITION

F6

E0 Oven user interface - lostcommunication

E6 Oven appliance manager - lostcommunication

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Check continuity of wirings between P1-4 and J15-3, then P1-5 and

J15-2.

3. Check for continuity between P1-1 and P1-2.

4. If all checks are correct, replace Copernicus Appliance Manager.

HMI Left

2L1

J4J6

J15

1 2 3 4

OR

CONN2

CONN7

WH

BK

6

2

5

4

SMPS

1

3

2

14V DC

1

15 W

YL

YL

BU

BR

J7J5

Control Panel Assembly

OR

P1

123 4 5

Oven Appliance

Manager

HMI Right

User Interface

5. Reassemble all parts and panels before operating.

6. Plug in oven or reconnect power.

7. If the error appears again, unplug oven or disconnectpower.

8. Replace the HMI-Central/UI board.

9. Reassemble all parts and panels before operating.

10. Plug in oven or reconnect power.

11. Follow the on-screen prompts to select the model number if the UI was

replaced.

12. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history.

18

Page 19

FAILURE ERROR LIKELY FAILURE CONDITION

RD/WH

NL2L1

T

V

F6 E1 Over temperature

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Check for elements shorted to ground. Checkresistance of elements:

a. PX4-2 and PX3-2 to check Broil element (13.2 Ωto 14.6 Ω)

b. PX1-1 and PX3-2 to check Bake element (19 Ωto21 Ω)

c. PX1-3 and PX3-2 to check Upper Convect element (15.2 Ω to 17.3 Ω)

3. If any element is shorted to ground, replace theelement.

4. Check for shorted relays.

For Core Models: Disconnect PX1 and PX4 connectors

andcheckforshorts between:

a. PX1-1 and PX1-2 (Bake relay)

b. PX1-3 and PX1-4 (Up Convect relay)

c. PX4-1 and PX4-2 (Broil relay)

8. Check sensor for short to ground. If checks on sensor are not correct,

replace the sensor and repeat the checks.

Oven

emperature

Sensor

1

V

2

3

4

Copernicus

5

6

Appliance Manager

7

8

9

10

P3

9. Reassemble all parts and panels before operating.

10. Plug in oven or reconnect power.

11. Enter the Diagnostics menu and select “Sensors & Switches” to verify

that the corresponding oven temperature displayed is correct (ambient

temperature). If not, unplug oven or disconnect power, and replace the

Copernicus Appliance Manager board.

NOTE: On the status screen, the unit of measurementis Celsius.

12. Reassemble all parts and panels before operating.

13. Plug in oven or reconnect power.

14. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history.

Copernicus Appliance Manager

K11

K10

K2

K3

BU

Broil - 4000W

1

BU

2

PX4

PX1

PX3

Bake - 2800W

RD

1

2

3

YL

4

Convect - 3200W

RD RD

1

2

Temperature Limiter

Oven Temp 338°F (170°C)

BU

RD

BK

YL

BK

5. If there is a shorted relay, replace the Copernicus Appliance Manager

control. Go to Step 9.

6. If everything is correct, disconnect connector P3 from the Copernicus

Appliance Manager.

7. Measure the resistance of the oven sensor. It should be 1000 Ω to1200 Ω

at 77°F (25°C).

19

Page 20

FOR SERVICE TECHNICIAN’S USE ONLY

FAILURE ERROR LIKELY FAILURE CONDITION

F6 E4

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

NOTE: If other error codes are stored, troubleshoot those other error codes

rst.

1. Unplug oven or disconnect power.

2. Replace Copernicus Appliance Manager.

3. Reassemble all parts and panels before operating.

4. Plug in oven or reconnect power.

5. Cycle power. If error persists after the Copernicus Appliance Manager is

replaced, unplug oven or disconnect power. Go to Step 7.

6. If the error is gone, go to Step 10.

7. Replace the HMI-Central/UI board.

8. Reassemble parts and panels before operating.

9. Plug in oven or reconnect power, and follow the

on-screen prompts for model selection.

10. Verify operation is normal. If operation is normal, goto Step 14. If error

still exists, go to Step 11.

11. Unplug oven or disconnect power.

12. Replace the control panel assembly.

13. Plug in oven or reconnect power.

14. Follow the on-screen prompts for model selection.

15. Verify operation is normal. Enter Diagnostics mode, select “Error

Diagnostics,” and clear the history.

User interface/Appliance manager state status

mismatch

FAILURE ERROR LIKELY FAILURE CONDITION

F6 E8

Lost communications with microwave oven

appliance manager

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Make sure the oven is plugged in. Open microwave door to check if light

comes on.

2. Ensure the Sabbath mode is disabled.

3. Unplug oven or disconnect power.

4. Check the connection between Oven User Interface Board J15-2 (yellow)

and J15-3 (orange) and Microwave Appliance Manager P26-3 (orange)

andP26-4 (yellow).

User Interface

Wide/Power Nav

1

432

J15

YL

OR

YL

OR

21

543

P26

Microwave

Appliance Manager

5. If harness is correct, replace the Microwave Appliance Manager.

6. Reassemble all parts and panels before operating.

7. Plug in oven or reconnect power.

8. If the error appears again, unplug or disconnect power and replace HMI-

Central/UI board.

9. Reassemble all parts and panels before operating.

10. Plug in oven or reconnect power.

20

Page 21

11. Follow the on-screen prompts to select the modelnumber if the UI was

replaced.

12. Verify operation is normal. Enter the Diagnostics menu, select “Error

Diagnostics,” and clear the history.

FAILURE

(Left-most 2

Clock digits)

F8

LOW FAN SPEED MESSAGE ON SINGLE/DOUBLE: The product

isexperiencing a problem and can no longer be used.

SUGGESTED CORRECTIVE ACTION PROCEDURE

1. Unplug oven or disconnect power.

2. Wait for at least 30 seconds.

3. Plug in oven or reconnect power.

4. Enter Diagnostics mode and navigate to the Component Activation list.

5. Turn on the Cooling Fan Low Speed.

6. Check for proper voltage input at P5-5 and neutral for high speed fan,

P5-4 and neutral for low speed fan when cooling fan should be running

by completing following steps.

7. Unplug oven or disconnect power.

8. Connect voltage measurement equipment.

9. Plug in oven or reconnect power. Measure voltage and conrm voltage

reading is 120 V. If it is not, unplug oven or disconnect power and go to

Step 13. If it is, go to Step 10.

10. Check for proper voltage input at P4-1 and P4-2 and conrm voltage

reading is 5 VDC. If it is not, unplug oven or disconnect power and go to

Step 13. If it is, go to Step 11.

11. Unplug oven or disconnect power.

12. Replace cooling fan. Go to Step 15.

13. Check integrity of all harness wires and connections between the oven

appliance manager and the cooling fan.

Ensure no shorted wires to chassis.

If the wiring is pinched or damaged, replace the cooling fan harness. Go

to Step 15.

If the wiring is good, go to Step 14.

14. Replace oven appliance manager. Go to Step 15

ERROR

(Right-most 2

Clock digits)

E0 Product not wired correctly

E1 Low fan speed overspeed

E2 High fan speed underspeed

E3 High fan speed overspeed

LIKELY FAILURE CONDITION

21

Page 22

15. Replace all parts and panels before operating.

FOR SERVICE TECHNICIAN’S USE ONLY

16. Plug in oven or reconnect power.

17. Enter into Diagnostics mode and verify that fan speed is running within

oven. (High speed: 1000-3300, Low speed: 400-3000)

Once Fan Speed is completed, navigate back to the activation list and

activate the Cooling Fan High Speed and return to “More Information” screen

for fan speed.

Hall Effect

Sensor

(Cooling Fan)

YL

P1

GN GN

P2

GY GY

P3

3

2

YL

1

P4

Copernicus

Appliance

Manager

K4

K6

K7

K8

YL

1

2

3

4

5

6

7

P5

GY/BK

OR

GY

Motor Door Latch

Convect Fan

LS Cooling Fan

HS Cooling Fan

FAILURE ERROR LIKELY FAILURE CONDITION

F9 E0 Product not wired correctly

SUGGESTED CORRECTIVE ACTION PROCEDURE

NOTE: Before starting any test, cycle power to the oven(power off, wait 10

seconds, and power on).

PROCEDURE: Before proceeding, verify the error codeby entering the

Diagnostics mode and selecting “Error Diagnostics.”

1. Unplug oven or disconnect power.

2. Access the electrical wiring from the house power supply to the oven.

3. Check house wiring to the product. Check to see ifthe neutral connection

is switched with L1 or L2(refer to the installation instructions for

productwiring).

4. Reassemble all parts and panels before operating.

5. Plug in oven or reconnect power.

6. Verify operation is normal by running a cooking function. Enter

Diagnostics mode, select “Error Diagnostics,” and clear the history.

22

Page 23

Component Locations

K

Upper Microwave Oven

A

B

C

Microwave Oven Components

A. Convect motor

T

S

R

Q

P

U

V

O

N

D

E

F

G

H

I

J

B. Convect thermostat (behind cover)

C. Convect element

D. Line filter

E. Humidity sensor

F. Magnetron fan motor

G. Copernicus appliance manager (lower oven)

H. Switch mode power supply (SMPS)

I. Secondary interlock switch

J. Turntable motor

M

K. Broil element

L

L. Microwave appliance manager

M. Cavity halogen lamp

N. Primary interlock switch

O. Monitor interlock switch

P. Magnetron thermistor

Q. Magnetron

R. Microwave light transformer

S. Microwave inverter

T. Cavity temperature sensor

U. Grill thermostat

V. Cavity thermostat

Not shown: Monitor fuse, 20 A line fuse

23

Page 24

Lower Oven

A

D

FOR SERVICE TECHNICIAN’S USE ONLY

B

C

J

I

E

F

F

H

G

A. HMI-Central/UI board

B. Cooling fan

C. Oven temperature sensor

D. Convection assembly

E. Temperature limiter

F. Light assembly

G. Bake element (hidden)

H. Broil element

I. Door lock assembly

J. Control panel assembly

24

Page 25

Cooling Fan Relay Logic

Oven High-Speed

Blower (Main/Upper or

Lower)

Oven Cooking - Cold - O

Oven Cooking - Warm - O

Oven Cooking - Hot O Oven Self-Clean O -

Oven Low-Speed

Blower (Main/

Upper or Lower)

LEGEND

Cold Cavity Temperature is less than 212°F (100°C).

Warm

Hot Cavity Temperature is greater than 599°F (315°C).

Cavity Temperature is between 212°F and 599°F (100°C and

315°C).

Mode Bake Broil

Convect Frozen Pizza C C C O

Convect Pastry C C C C

Convect Slow Roast 12 hrs C C C O

Convect Slow Roast 8 hrs C C C O

Convect Slow Roast 4 hrs C C C O

Convect Roast C C C O

Convect Broil - C - C

Convect Bake C C C C

Convect Bake- Rapid Preheat C C C C

Bake C C C C

Broil - C - Keep Warm C C - C

Rapid Proof C C - Proof C C - Self Clean C C - -

Convect

Ring

LEGEND

Relay Off Relay Cycles Relay On Not Available

- C O NA

Convect

Fan

25

Page 26

FOR SERVICE TECHNICIAN’S USE ONLY

Component Testing Chart - Oven

To properly check for voltage, complete the following steps:

1. Unplug oven or disconnect power.

2. Connect voltage measurement equipment tocheckpoints.

Component Serviceable Side Check Points Copernicus Results-Resistance Results-Voltage

Lights Front P7-1 to L1 (J8-1) 0-40 Ω 120 V

Latch Switch Front P3-7 to P3-5 Open circuit

Door Switch Front P3-6 to P3-5 Closed circuit with oven door closed

Latch Motor Front P5-1 to N (J8-2) 500-3000 Ω 120 V motor running

Oven Temperature Sensor Front P3-1 to P3-2 1075 Ω at 68°F (20°C) DLB

Meat Probe Side P3-3 to P3-4 9876-10075 Ω

Blower Motor - HighSpeed Rear P5-5 to N (P7-1) 15-23 Ω 120 V motor running

Blower Motor - LowSpeed Rear P5-4 to N (J8-2) 15-23 Ω 120 V motor running

Thermal Limiter Rear PX3-1 to L2 (Main line) Closed circuit 0 V closed, N/A open

Convection Fan* Rear P5-3 to N (J8-2) 16-20 Ω 120 V motor running

Convection Element* Front PX1-3 to PX3-2 16.63-18.38 Ω

Bake Element Rear PX1-1 to PX3-2 19.0-21.6 Ω

Broil Element Front PX4-2 to PX3-2 13.5-14.92 Ω 240 V Broil cycle operating

3. Plug in oven or reconnect power and conrmvoltagereading.

4. Unplug oven or disconnect power.

240 V Convection cycle

operating

240 V Bake cycle

operating

26

Page 27

Component Serviceable Side Check Points Copernicus Results-Resistance Results-Voltage

PX3

2

1

Pin

Pin 1

User Interface Board Front J15-2 to J15-4 N/A 14 VDC

Copernicus Appliance Manager Side (Combo) P1-2 to P1-5 N/A 14 VDC

* NOTES:

■ Disconnect the harness from the board before performing measurements.

■ See the following table for connector pin identication.

Copernicus Appliance Manager Harness Connector Pin Copernicus Appliance Manager Pin

PX1-1 J12

PX1-2 J16

PX1-3 J13

PX1-4 J17

Pin 1

Pin 1

K9

K1

K2

K10

Pin 1

K11

PX1-4

K9A

K1A

K2A

K10A

PX4

PX1-4

PX1-3

PX1-

PX1-

Pin 1

Pin 1

K3

P4

P3

1

P1

P6

Pin 1

Pin 1

P7

K4

K5

P5

K6

K7

J8

K8

27

Page 28

FOR SERVICE TECHNICIAN’S USE ONLY

Component Testing Chart - Microwave

Component

Appliance Manager Top Check wiring to MW appliance manager:

Cavity Thermostat Top 1. Unplug microwave oven or disconnect power.

Magnetron Fan

Motor

Turntable Motor Bottom 1. Unplug microwave oven or disconnect power.

Serviceable

Side

Top 1. Unplug microwave oven or disconnect power.

Procedure Results - Resistance

1. Unplug microwave oven or disconnect power.

2. Visually inspect connectors on the microwave appliance

manager, P1, P2, P8, P21, P22, P23, P26, P354, P355,

and the top connectors (relays 4903, 4904, and 4905) to

see whether there are signs of overheating or any signs

of failure due to loose wires, bad crimping, etc.

3. Reassemble all parts and panels before operating.

4. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance (ohmmeter scale: Rx1).

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance (ohmmeter scale: Rx1).

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Normal = Continuity

Abnormal = Innite

Normal = 15 Ω

Abnormal = Innite

Normal =2500 Ω (approximately)

Abnormal = Innite

Component

Location

G

V

F

J

28

Page 29

Component

Monitor Fuse To p 1. Unplug microwave oven or disconnect power.

MW Light

Transformer

Line Fuse Top 1. Unplug microwave oven or disconnect power.

Serviceable

Side

Top 1. Unplug microwave oven or disconnect power.

Procedure Results - Resistance

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance (ohmmeter scale: Rx1).

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Normal = Continuity

Abnormal = Innite

Primary Winding = 40 Ω

(approximately)

Secondary Winding = 0.4 Ω

(approximately)

Normal = Continuity

Abnormal = Innite

Component

Location

Not shown

R

Not shown

29

Page 30

Component

Primary Interlock

Switch

Secondary Interlock

Switch

Monitor Interlock

Switch

FOR SERVICE TECHNICIAN’S USE ONLY

Serviceable

Side

Top Test 1:

Top 1. Unplug microwave oven or disconnect power.

Top 1. Unplug microwave oven or disconnect power.

Procedure Results - Resistance

Test 1:

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Primary Interlock Switch.

3. Check from the common terminal (brown wire) to the

normally open terminal (yellow wire).

4. Reconnect the wires at the Primary Interlock Switch.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Test 2:

1. Unplug microwave oven or disconnect power.

2. Disconnect the wires at the Primary Interlock Switch.

3. Check from the common terminal (brown wire) to the

normally closed terminal (blue wire).

4. Reconnect the wires at the Primary Interlock Switch.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Disconnect the wires at the Secondary Interlock Switch.

3. Check from the common terminal (blue wire) to the

normally open terminal (white wire).

4. Reconnect the wires at the Secondary Interlock Switch.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Disconnect the wires at the Monitor Interlock Switch.

3. Check from the common terminal (yellow wire) to the

normally closed terminal (blue wire).

4. Reconnect the wires at the Monitor Interlock Switch.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Door Open = Innite

Door Closed = Continuity

Test 2:

Door Open = Continuity

Door Closed = Innite

Door Open = Continuity

Door Closed = Innite

Door Open = Continuity

Door Closed = Innite

30

Component

Location

N

I

O

Page 31

Component

Halogen Light Top 1. Unplug microwave oven or disconnect power.

Inverter Top Check wiring to MW inverter:

Magnetron Top 1. Unplug microwave oven or disconnect power.

Line Filter Top 1. Unplug microwave oven or disconnect power.

Serviceable

Side

Procedure Results - Resistance

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

1. Unplug microwave oven or disconnect power.

2. Visually inspect 4 connectors on the MW inverter

boards, CN701, CN702, CN703, and E701 to see

whether there are signs of overheating or any signs of

failure due to loose wires, bad crimping, etc.

3. Reassemble all parts and panels before operating.

4. Plug in microwave oven or reconnect power.

2. Remove wire leads. Check that the seal is in good

condition.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Normal = approximately 3 Ω

Abnormal = Innite

Filament Terminals Normal =

<1W

Filament to Chassis Normal =

Innite

P31 to P32, P33toP34 Normal

>/= 300 kΩ

Abnormal

</= 100 kΩ

P31 to P34, P32 to P33 Normal

= 0 Ω

Abnormal

>/= 100 kΩ

Component

Location

M

S

Q

D

31

Page 32

FOR SERVICE TECHNICIAN’S USE ONLY

Component

Humidity Sensor To p 1. Unplug microwave oven or disconnect power.

Magnetron

Thermistor

Grill Thermostat Top 1. Unplug microwave oven or disconnect power.

Convect Thermostat Rear 1. Unplug microwave oven or disconnect power.

Serviceable

Side

Procedure Results - Resistance

2. Remove the 3-pin connector from MW Appliance

Manager.

3. Measure resistance across pins 1 and 3 andacross pins

2 and 3.

4. Replace the 3-pin connector from MWAppliance

Manager.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

1. Unplug microwave oven or disconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Normal = 2.8 kΩ (approximately)

at 77°F ± 10°F (25°C± 10°C)

Abnormal = Innite

Normal = 10 kΩ (approximately)

at 77°F ± 10°F (25°C± 10°C)

Abnormal = Innite

Normal = Continuity

Abnormal = Innite

Normal = Continuity

Abnormal = Innite

Component

Location

E

P

U

B

32

Page 33

Component

Broil Element Rear 1. Unplug microwave oven or disconnect power.

Convect Element Rear 1. Unplug microwave oven or disconnect power.

Cavity Temp Sensor Rear 1. Unplug microwave oven or disconnect power.

Convect Fan Motor Rear 1. Unplug microwave oven or disconnect power.

Serviceable

Side

Procedure Results - Resistance

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

2. Remove wire leads.

3. Measure resistance.

4. Replace wire leads.

5. Reassemble all parts and panels before operating.

6. Plug in microwave oven or reconnect power.

Normal = 9 Ω

Abnormal = Innite

Normal = 12 Ω

Abnormal = Innite

Normal = 230 KΩ

(approximately) at77°F ± 10°F

(25°C ± 10°C)

Abnormal = Innite

Normal = 48 Ω

Abnormal = Innite

Component

Location

K

C

T

A

33

Page 34

FOR SERVICE TECHNICIAN’S USE ONLY

34

Page 35

35

Page 36

FOR SERVICE TECHNICIAN’S USE ONLY

For patent information, please see Pat. www.patent-listing.com W11284425B

NOTE: This sheet contains important Technical Service Data.

FOR SERVICE TECHNICIAN ONLY

DO NOT REMOVE OR DESTROY

W11284425B

©2018 All rights reserved.

10/18

FOR SERVICE TECHNICIAN’S USE ONLY

Page 37

À L’USAGE DU TECHNICIEN DE MAINTENANCE SEULEMENT

Mesures de tension — Information de sécurité

Fiche technique Ne pas enlever ou détruire

W11284425B

DANGER

Risque de choc électrique

Seul un technicien autorisé est habilité à

effectuer des mesures de tension aux fins

de diagnostic.

Après avoir effectué des mesures de

tension, déconnecter la source de courant

électrique avant toute intervention.

Le non-respect de ces instructions peut

causer un décès ou un choc électrique.

Lors des mesures de tension, observer les précautions suivantes :

■ Vérifier que les commandes sont à la position d’interruption de l’alimentation, pour que l’appareil

ne puisse se mettre en marche dès le raccordement à une source d’énergie.

■ Ménager un espace adéquat pour l’exécution des mesures de tension.

■ Maintenir toute personne présente à distance de l’appareil, pour éviter tout risque de blessure.

■ Toujours utiliser les instruments et outils de test appropriés.

■ Après les mesures de tension, veiller toujours à interrompre l’alimentation électrique de l’appareil

avant toute intervention sur l’appareil.

AVERTISSEMENT

Risque de choc électrique

Déconnecter la source de courant

électrique avant l'entretien.

Replacer pièces et panneaux avant de faire

la remise en marche.

Le non-respect de ces instructions peut

causer un décès ou un choc électrique.

10/18

Page 38

À L’USAGE DU TECHNICIEN DE MAINTENANCE SEULEMENT

IMPORTANT:

Le risque de décharge électrostatique est permanent. Une décharge électrostatique peut détruire ou détériorer les

circuits électroniques de la machine. La nouvelle carte peut sembler fonctionner correctement après la réparation,

mais une décharge électrostatique peut lui avoir fait subir des contraintes qui provoqueront une défaillance plus tard.

■

Utiliser un bracelet de décharge électrostatique. Connecter le bracelet de décharge électrostatique au point vert

de raccordement à la terre ou à une surface métallique non peinte à l'intérieur de l'appareil.

Toucher plusieurs fois de suite avec le doigt un point vert de raccordement à la terre ou une surface métallique

non peinte à l'intérieur de l'appareil.

■

Avant de retirer la pièce de son emballage, placer le sachet antistatique en contact avec un point vert de

raccordement à la terre ou une surface métallique non peinte à l'intérieur de l'appareil.

■

Éviter de toucher les composants électroniques ou les broches de contact; manipuler les circuits électroniques de

la machine uniquement par les bords

■

Lors du remballage de circuits électroniques défectueux dans le sachet antistatique, observer les instructions cidessus

Circuits électroniques sensibles aux décharges électrostatiques

-OU-

.

.

38

Page 39

PRÉCAUTIONS À OBSERVER AVANT ET

DURANT LES RÉPARATIONS POUR ÉVITER

UNE EXPOSITION EXCESSIVE À L’ÉNERGIE

DES MICRO-ONDES

a. Ne pas laisser fonctionner le four lorsque la porte est ouverte.

b. Sur chaque four, avant d’alimenter le magnétron ou une autre source de micro-ondes, exécuter les

contrôles de sécurité suivants et effectuer les réparations nécessaires:

1. Système d’interverrouillage – fonctionnement correct

2. Porte – fermeture correcte

3. Joint et surfaces de scellement (formation d’arcs, usure et autres détériorations)

4. Charnières et loquets – détérioration ou ajustement déficient (desserrage)

5. Indices de détérioration par chute ou emploi abusif

c. Avant de déclencher la production de micro-ondes pour des opérations de test ou inspection dans les

compartiments de génération de micro-ondes, contrôler magnétron, guide d’ondes/canal de

transmission et cavité–contrôler/vérifier alignement correct, intégrité, connexions.

d. Avant de remettre le four à son propriétaire, toute défectuosité ou déficience d'ajustement de

composant affectant interverrouillage, moniteur, joint de porte et génération/transmission des microondes devra être éliminée par réparation/remplacement/réglage conformément aux procédures

décrites dans ce manuel.

e. Avant de remettre le four à son propriétaire, effectuer un contrôle des fuites du four à micro-ondes pour

vérifier la conformité aux prescriptions de la norme fédérale de performance.

f. Ne pas tenter de faire fonctionner le four si le hublot de la porte est brisé.

39

Page 40

À L’USAGE DU TECHNICIEN DE MAINTENANCE SEULEMENT

35

0

Diagnostic

IMPORTANT: Avant de mettre sous tension le magnétron du four à microondes (MO), s’assurer qu’une charge, par exemple une tasse d’eau allant

auxmicro-ondes, est présente dans la cavité du four à micro-ondes.

Débrancher le four ou déconnecter la source de courant électrique avant

d’exécuter les contrôles suivants:

■ La corrosion des pièces de connexion est une cause potentielle

de défaillance du fonctionnement des commandes. Inspecter les

connexionset contrôler la continuité des circuits à l’aide d’un ohmmètre.

■ Exécuter tous les tests ou contrôles à l’aide d’un voltmètre ou multimètre

à résistance interne de 20000Ω par VCC ou plus.

■ Contrôler toutes les connexions avant de remplacer des composants;

rechercher les conducteurs brisés ou mal branchés, les connexions

mal réalisées ou les ls insufsamment engagés dans les connecteurs.

Unfaisceau de câblage endommagé doit être remplacé dans son

intégralité. Ne pas réparer un faisceau de câblage.

■ Exécuter les mesures de résistance après avoir débranché le cordon

d’alimentation de la prise de courant et déconnecté les connecteurs

oulefaisceau de câblage.

IMPORTANT: Ne pas remplacer le module de commande en l’absence de

preuve d’une défaillance.

Pour accéder au mode de diagnostic :

Avant d’entreprendre toute action corrective, exécuter le processus décrit

ci-dessous pour accéder au mode de diagnostic:

1. Accéder au mode de diagnostic en appuyant sur LOWER OVEN>LOWER

LIGHT>OVEN CANCEL (four inférieur>lampe inférieure>annulation du

four) – répéter 2 autres fois.

CONSEIL: Il est aussi possible de glisser le doigt 3 fois de la gauche

vers la droite sur les touches.

REMARQUE: Il n’est pas nécessaire d’attendre pour une rétroaction

audible ou visuelle de la commande après chaque appui sur les touches.

2. Si la commande ne passe pas en mode de diagnostic, continuer

à répéter la séquence des touches à partir de l’étape1. Toutes les

touchess’allumeront lorsque la commande passe en mode de diagnostic.

3. À partir du menu de diagnostic, faire déler la liste jusqu’à la sélection

souhaitée en utilisant l’écran tactile.

Error Diagnostics (diagnostic d’erreur): Afcher et effacer l’historique

des défaillances.

Component Activation (activation composant) : Activer manuellement

chaque relais.

Sensors & Switches (capteurs et contacteurs) : Afcher les températures

de la cavité du four traditionnel et le statut du contacteur de porte/loquet.

System Information (informations système): Afcher le numéro de

modèle, le numéro de série et les versions de logiciel.

Sortir Diagnostics

Procédure générale : Codes d’erreur

REMARQUE: Toutes les défaillances sont mémorisées dans l’historique des

défaillances. Pour vérier si le code d’erreur est toujours présent, lancer une

fonction de cuisson et patienter 1 minute.

1. Brancher le four ou reconnecter la source de courant électrique.

2. Accéder au mode de diagnostic.

3. Appuyer sur ou faire déler la liste jusqu’à l’élément “Error Diagnostics”

dans le menu de diagnostic, puis appuyer sur “OK”.

4. Pour effacer les codes d’erreur, appuyer sur “Clear History” (effacer

l’historique).

5. Si aucune défaillance n’est répertoriée, le message “No Error” (aucune

erreur) s’afche à l’écran.

40

Page 41

Procédure générale : Activation composant

1. Brancher le four ou reconnecter la source de courant électrique.

2. Accéder au mode de diagnostic.

3. Appuyer sur ou faire déler la liste jusqu’à l’élément “Component

Activation” (activation composant) dans le menu de diagnostic, puis

appuyer sur “OK”.

4. Appuyer sur les sélections suivantes activer/désactiver les relais

correspondants.

Sélection Relais

MW Light (lampe du MO) Relais de la lampe MO

MW Turntable (plateau rotatif du MO) Relais du plateau rotatif MO

MW Cooling Fan (ventilateur de

refroidissement du MO)

MW Grill (gril du MO) Relais de l’élément du gril MO

MW Convection Element (élément de

convection du four à micro-ondes)

MW Convection Fan (ventilateur de

convection du MO)

MW Magnetron/Cooling Fan (ma-

gnétron/ventilateur de refroidissement du four à micro-ondes)

Oven Bake Element (élément de

cuisson du four)

Oven Broil Element (élément de

grillage du four)

Oven Convection Element (élément

de convection du four)

Oven Convection Fan (ventilateur de

convection du four)

Oven Cooling Fan High Speed

(ventilateur de refroidissement du

four – vitesse élevée)

Relais du ventilateur de

refroidissement MO

Relais de l’élément de convection

MO

Relais du ventilateur de convection

MO

Relais du magnétron et du

ventilateur de refroidissement MO

Relais de l’élément de cuisson du

four

Relais de l’élément de grillage du

four

Relais de l’élément de convection

du four

Relais du ventilateur de convection

du four

Relais de vitesse élevée du

ventilateur de refroidissement du four

Sélection Relais

Oven Cooling Fan Low Speed

(ventilateur de refroidissement

dufour – vitesse basse)

Lampe du four Relais de la lampe du four

Oven Door Latch Motor (moteur du

loquet de porte du four)

Relais de vitesse basse du

ventilateur de refroidissement

dufour

Relais du moteur du loquet de porte

du four

Procédure générale : Capteurs et contacteurs

REMARQUE: Cette procédure est utile pour afcher le statut actuel des

contacteurs du four et des lectures du capteur.

Afchage État

MW Door Switch (contacteur porte

MO)

MW Cavity Temp (temp. cavité MO) Degrés en Celsius

Oven Door Switch (contacteur porte

four)

Oven Latch Switch (contacteur

loquet four)

Oven Cavity Temp (temp. cavité four) Degrés en Celsius

Oven Meat Probe Temp (temp. de la

sonde de cuisson du four)

1. Brancher le four ou reconnecter la source de courant électrique.

2. Accéder au mode de diagnostic.

3. Appuyer sur ou faire déler la liste jusqu’à l’élément “Sensors &

Switches” (capteurs et contacteurs) dans le menu de diagnostic, puis

appuyer sur “OK”.

4. Appuyer sur ou faire déler le menu Sensors & Switches (capteurs et

contacteurs) pour afcher l’état désiré.

REMARQUE: Appuyer sur “Back” pour revenir au menu de diagnostic

principal.

Ouvert ou Fermé

Ouvert ou Fermé

Ouvert ou Fermé

Degrés en Celsius

41

Page 42

À L’USAGE DU TECHNICIEN DE MAINTENANCE SEULEMENT

Procédure générale : Informations système