JennAir JIC4536XS, JIC4430XB, JIC4536XB, JIC4430XS User Manual [EN]

FOR SERVICE TECHNICIAN’S USE ONLY

Y

Tec h S he et Do not discard

DANGER

Electrical Shock Hazard

Only authorized technicians should perform diagnostic

voltage measurements.

After performing voltage measurements, disconnect

power before servicing.

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Electrical Shock Hazard

Failure to follow these instructions can result in death

or electrical shock.

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

■ Verify the controls are in the off position so that the appliance does not start when energized.

■ Allow enough space to perform the voltage measurements without obstructions.

■ Keep other people a safe distance away from the appliance to prevent potential injury.

■ Always use the proper testing equipment.

■ After voltage measurements, always disconnect power before servicing.

Acronyms and Abbreviations

■ PC: Power Control Board

■ NTC: Negative Temperature Coefficient

Manual Configuration Mode

To Enter Manual Configuration Mode:

NOTE: This menu is accessible only during the first minutes after the

cooktop is plugged in.

1. Remove the key-lock functionality by pressing the Control Lock

button.

2. Press the following keys sequentially (a beep will sound after each key

press): Timer “-”, Timer “+”, Timer “-”, Timer “+”, Control Lock.

After the keystroke combination is pressed, a “CO” will appear on the

display.

3. Press the Control Lock button.

An “00” will appear on the display.

■ UI: User Interface board

4. Configure the correct cooktop model number by choosing one of the

following numbers.

Configuration Number Cooktop

23 KICU509X

24 JIC4430X

25 JIC4536X

26 KICU569X

Use the Timer buttons to see different numbers on the display, moving

sequentially and beginning at “00.” The Timer “+” button will increase

the number by 1, and the Timer “-” button will decrease the number

by 1.

5. Press the Control Lock button to confirm the configuration. The

configuration will then be downloaded into the cooktop.

This process will last a few seconds. The number of the cooktop

chosen will blink on the display. The cooktop will restart with the new

configuration written.

6. The cooktop is ready to use.

501961902035 FOR SERVICE TECHNICIAN’S USE ONL

FOR SERVICE TECHNICIAN’S USE ONLY

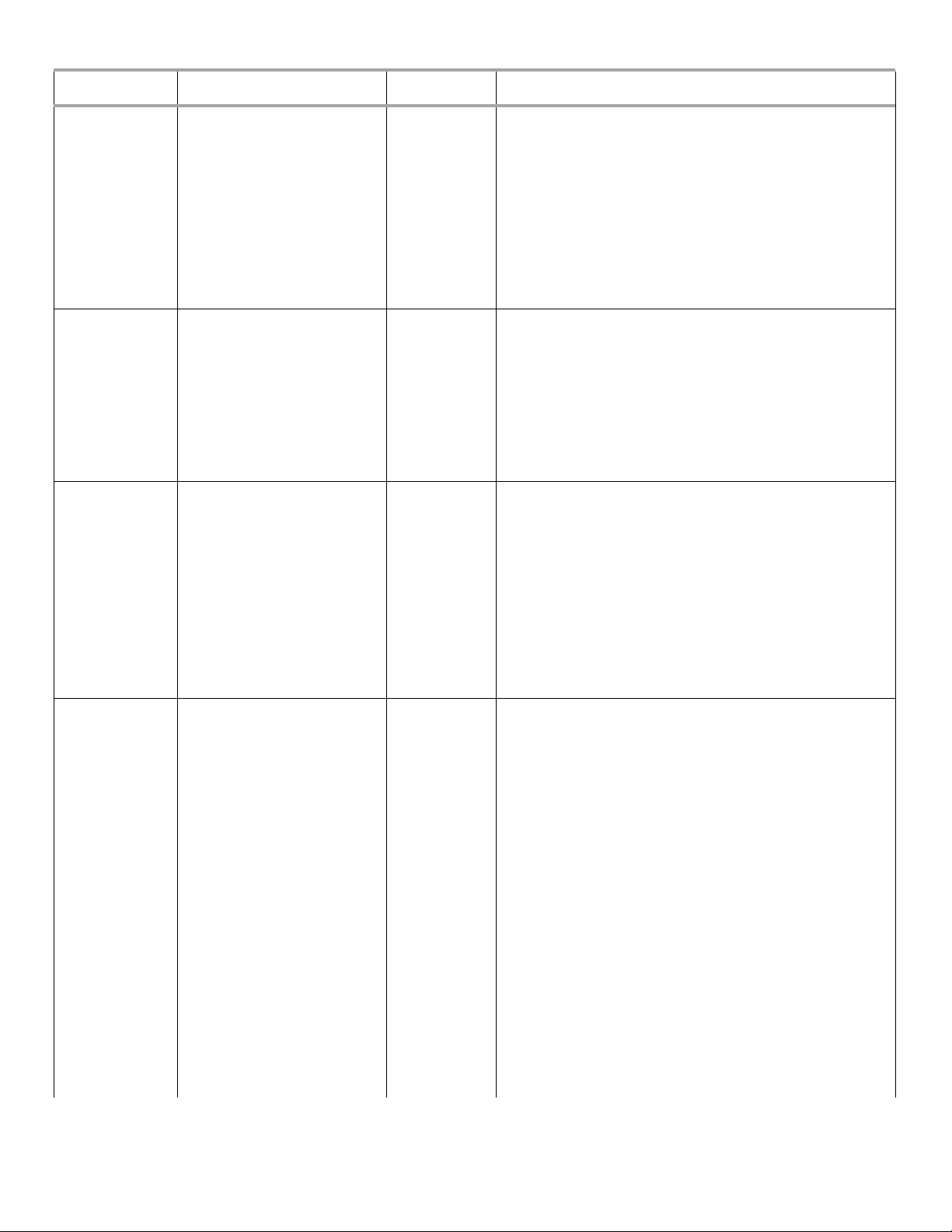

Failure/Error Codes

If all the lights on the User Interface are Off and there is no response from the cooktop, complete the following steps:

1. Disconnect power.

2. Check the continuity between the black lug on the terminal block and

both L1 and L2 terminals on the EMI filter board.

3. Replace all parts and panels before operating.

4. Reconnect power.

5. Check that it is working. If it is not, go to Step 6.

6. Disconnect power.

7. Check the continuity of the fuses on the EMI board. If one or more of

the fuses is blown, replace with a new fuse.

8. Replace all parts and panels before operating.

9. Reconnect power.

10. Check that it is working. If it is not, go to Step 11.

11. Disconnect power.

There are 3 types of failures associated with the cooktop. The description of these failures and the impact they will have on the rest of the cooktop are

listed in the following.

Failure – Type 1

Failure type 1 comes from the power control board. This failure will affect only one burner. The user may continue to use the other burners.

Failure – Type 2

Failure type 2 usually comes from the power control board (there could be some exceptions). These failures affect all burners associated with that power

control board; the user may continue to use the burners that belong to the other power control board.

Failure – Type 3

Failure type 3 comes from the User Interface. This failure disables the entire cooktop. When this type of failure occurs, all the burners are switched Off by

the User Interface.

Service Code

Shown on Display

F-12 Coil under current Type 1 1. Disconnect power.

F-21 Supply power frequency Type 2 1. Disconnect power.

F-25 Stuck fan on power control board

Failure Description Type of Failure Repair Suggestions

(right or left side fan, depending on

which side of the display the

failure is on)

Typ e 2 1. Disconnect power.

12. Change both power control boards.

13. Replace all parts and panels before operating.

14. Reconnect power.

15. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

16. Check that it is working. If it is not, go to Step 17.

17. Disconnect power.

18. Change the User Interface and cable.

19. Replace all parts and panels before operating.

20. Reconnect power.

21. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

2. Check for the correct connections at T2A - T2B or T3A - T3B on

the power control board (whichever connection the burner is

plugged into). If connections are correct, go to Step 3.

3. Replace the burner coil.

4. Replace all parts and panels before operating.

5. Reconnect power.

6. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

7. Check for proper operation.

8. If everything operates, end service. If error code still appears,

disconnect power and go to Step 9.

9. Replace the power control board.

10. Replace all parts and panels before operating.

11. Reconnect power.

12. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

2. Replace the power control board.

3. Replace all parts and panels before operating.

4. Reconnect power.

5. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

6. If the issue is not fixed, contact a qualified electrician to verify the

frequency of the home power supply is 60 Hz.

2. Check that the cooling fan connector is firmly plugged in.

3. Replace all parts and panels before operating.

4. Reconnect power.

5. If the issue is not fixed, disconnect power.

6. Replace the cooling fan.

7. Replace all parts and panels before operating.

8. Reconnect the power.

9. If the issue is not fixed, disconnect power.

10. Replace the power control board.

11. Replace all parts and panels before operating.

12. Reconnect power.

13. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

2

FOR SERVICE TECHNICIAN’S USE ONLY

Service Code

Shown on Display

F-36, F37 Temperature sensor is not working Type 1 1. Disconnect power.

F-40 Power control board failure Type 1 or Type 2 1. Disconnect power.

F-42 Power supply Type 2 1. Check for 240 volts AC at the main incoming power supply

F-47 Power supply from power control

Failure Description Type of Failure Repair Suggestions

2. Check that the temperature sensor is between 184,000 Ω -

292,000 Ω at room temperature and is firmly plugged in. If the

sensor is not between 184,000 Ω - 292,000 Ω, replace the coil

and go to Step 5. If the sensor is between 184,000 Ω - 292,000 Ω

and the electrical connection is good, go to Step 3.

3. Replace all parts and panels before operating.

4. Reconnect power and check that the coil is working. If it is not

working, disconnect power and replace the nonworking coil and

the power control board.

5. Replace all parts and panels before operating.

6. Reconnect power.

7. If the control was replaced in Step 4, reconfigure the cooktop

following the directions in “Manual Configuration Mode.”

2. Check that the cable between the User Interface and the power

control board is not damaged and is firmly plugged in.

3. Replace all parts and panels before operating.

4. Reconnect power.

5. Verify if error is still present. If yes, disconnect power.

6. Replace the power control board.

7. Replace all parts and panels before operating.

8. Reconnect power.

9. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

connection by completing the following steps.

2. Disconnect power.

3. Connect voltage measurement equipment.

4. Reconnect power and check for 240 volts at J1 L to N, and then

J2 L to N at the EMI filter board, and then J1 L to N at both power

control boards. If voltage is correct, disconnect power, replace

the power control board and go to Step 5. If voltage is not

correct, disconnect power and check for an open fuse on the EMI

filter board. If there is not an open fuse, have a qualified

electrician check the home power supply.

5. Replace all parts and panels before operating.

6. Reconnect power.

7. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

board to User Interface is missing

or WIDE communication error

between UI and power control

board or an open fuse on the filter

board

Typ e 2 1. Disconnect power.

2. Check that the cables between the User Interface and the power

control board are not damaged and are firmly plugged in.

3. Replace all parts and panels before operating.

4. Reconnect power and check that it is working. If it is not working,

disconnect power and replace the cables between the User

Interface and the power control board.

5. Replace all parts and panels before operating.

6. Reconnect power and check that it is working. If it is not working,

go to Step 7.

Disconnect power.

7.

8. Check the continuity of the fuses on the EMI board. If either of the

fuses is blown, replace with a new one.

9. Replace all parts and panels before operating.

10. Reconnect power and check that it is working. If it is not working,

go to Step 11.

11. Disconnect power.

12. Change both power control boards.

13. Replace all parts and panels before operating.

14. Reconnect power and reconfigure the cooktop following the

directions in “Manual Configuration Mode.” Check that it is

working. If it is not working, go to Step 15.

15. Disconnect power.

16. Change the User Interface.

17. Replace all parts and panels before operating.

18. Reconnect power and reconfigure the cooktop following the

directions in “Manual Configuration Mode.”

3

FOR SERVICE TECHNICIAN’S USE ONLY

Service Code

Shown on Display

F-56 Wrong or invalid configuration Type 3 1. Disconnect power.

F-58 Wrong or invalid configuration Type 2 1. Disconnect power.

F-60 UI does not work Type 3 1. Disconnect power.

F-61 Power control board does not

C-81, C-82 Over temperature Type 2 Not enough ventilation: Check the cooktop installation according to

Failure Description Type of Failure Repair Suggestions

2. Reconnect power.

3. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

4. If the issue is not fixed, disconnect power.

5. Replace the User Interface.

6. Replace all parts and panels before operating.

7. Reconnect power.

8. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

2. Reconnect power.

3. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

4. If the issue is not fixed, disconnect power.

5. Replace the power control board.

6. Replace all parts and panels before operating.

7. Reconnect power.

8. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

2. Replace the User Interface.

3. Replace all parts and panels before operating.

4. Reconnect the power.

5. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

work

Typ e 2 1. Disconnect power.

2. Check that the cables between the User Interface and the power

control board are not damaged and are firmly plugged in.

3. Check for 240 volts AC at the J1 connector on the power control

board by completing the following steps.

4. Connect voltage measurement equipment.

5. Reconnect power and confirm voltage reading. If voltage is not

correct, disconnect power and have a qualified electrician check

the home power supply.

6. If voltage is correct, disconnect power and replace the cable

between the User Interface and the power control board.

7. Replace all parts and panels before operating.

8. Reconnect power.

9. Reconfigure the cooktop following the directions in “Manual

Configuration Mode.”

the Installation Instructions. In particular, check the blower intakes.

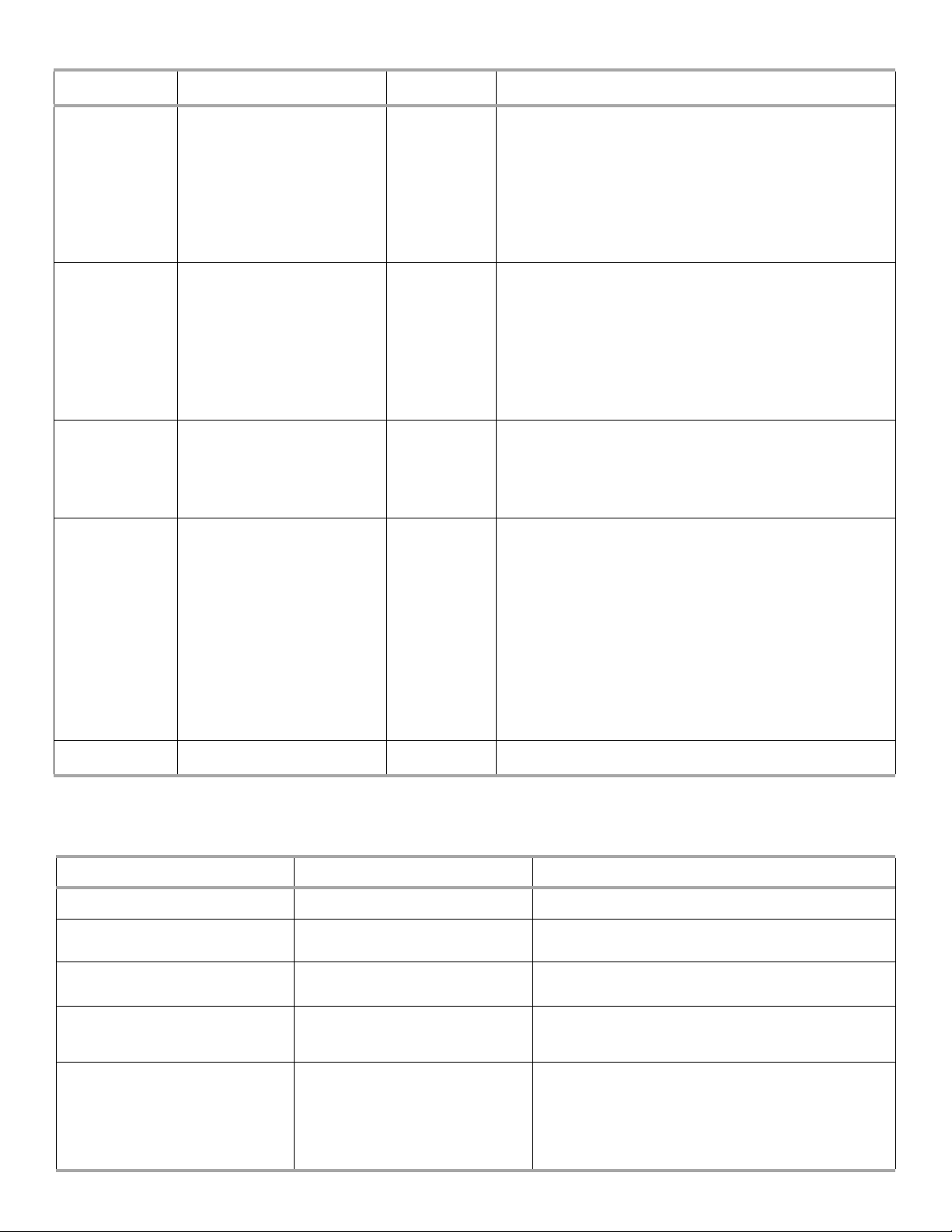

Component Testing Chart

To check for proper voltage, complete the following steps:

1. Disconnect power.

2. Connect voltage measurement equipment.

Location on the cooktop Checkpoints Results Voltage

EMI filter board J1 - (L) (N) From 208VAC to 240 VAC -60Hz

Power control board (PC)

Left and right

Power control board (PC) to blower fan

Left and right

Power control board (PC) to the element

sensor

Left and right

Power control board (PC) to the User

Interface

J1 - (L) (N) From 208VAC to 240 VAC -60Hz

J205 - (00) - (22)

J205 - (00) - (60)

J604 - (1) - (2)

J605 - (1) - (2)

J806 - 00

J806 - 88

J806 - 99

J806 - 22

J806 - 44

(Each of these pins refers to J806 - 99

[0VDC, Neutral pin])

3. Reconnect power and confirm voltage reading.

4. Disconnect power after performing voltage measurements.

From 0VDC to 12VDC

+5VDC

0V

+10.5V

0VDC

From 0VDC to 12VDC

4

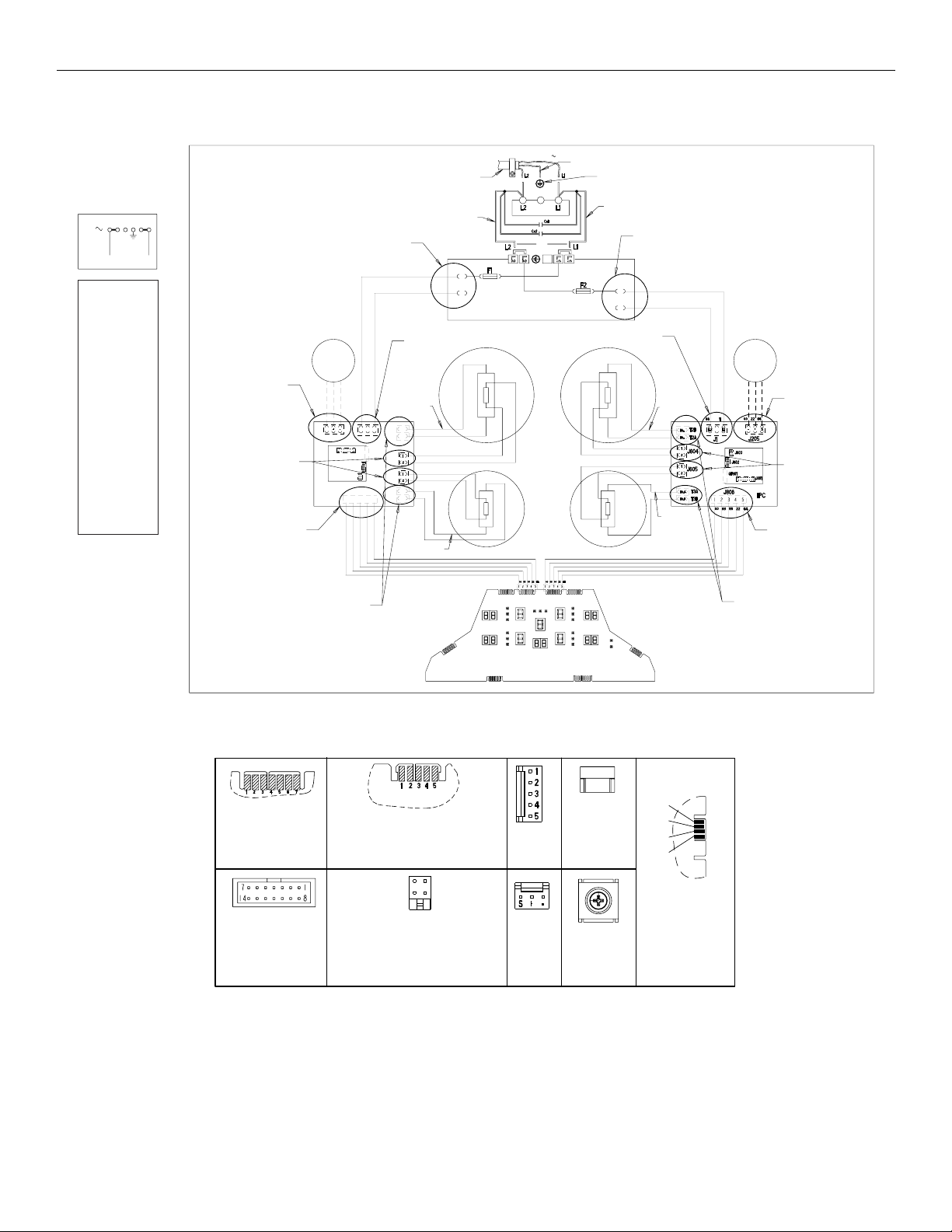

30" (76.2 cm) models

Main Connection

L2

L1 L1L1L2

E

2

J1 - Filter Main Power Connector 1

J2 - Filter Main Power Connector 2

IPC - Induction Power Control Board

EMI - Filter Board

BL - Blower (Left)

BR - Blower (Right)

I1 - Inductor (Single Zone)

SI - Sensor

UI - User Interface (Touch Control)

W1 - Main Ter minal Block

W - Power Housing Terminal Block

CX1/CX2 - Filter Capacitor

F1-F2 - Fuse (25A)

Wire Color:

00 - Black

11 - Brown

22 - Red

44 - Yellow

45 - Yellow/Green

66 - Blue

88 - Blue/Sky

99 - White

Shrinking Sleeve Lead Color:

BK - Black

R - Red

Y - Yellow

G - Green

BU - Blue

W - White

208 - 240V

60Hz

Legend

L2

FOR SERVICE TECHNICIAN’S USE ONLY

Wiring Diagrams

208 -240V

Yellow/Green cable

From 0VDC

to 12VDC

Variable from

0VDC to 5VDC

10.5VDC to 5VDC

Power cord

Black cable

From 208VAC

to 240 VAC 60 Hz

11

L1

J1

66

L2

From 208VAC

66

L1

L2

J1

44

22

to 240 VAC 60 Hz

Inductor Dia. 240 : Y

Inductor Dia. 180: G

T3B

Mo.

BK

Mo.

T3A

J605

J604

Mo.

T2A

BK

Mo.

T2B

Inductor Dia. 145 : W

Inductor Dia. 180: G

S1

S1

BL

66

22

00

11

S

J205

J801

GF801

J802

J803

J806

1

2345

IPC

00

88 99

G

W1

240V

W

EMI

I1

I1

Ground to

burner box

Red cable

From 208VAC

to 240 VAC 60 Hz

11

L1

J2

66

L2

From 208VAC

to 240 VAC 60 Hz

I1

S1

S1

I1

Inductor Dia.

280 : BU

Inductor Dia.

210 : Y

BK

BK

Inductor Dia.

145 : W

BL

From 0VDC to 12VDC

Variable from 0VDC to 5VDC

10.5VDC to 5VDC

From 0VAC to 500VAC

J007 - Service

connector (SAM)

(manufacturing only)

J801 - MCU connector

J803 - Jumper connector with jumper

(for factory

programming only)

J006

UI

J005

CONNECTOR NOTE:

J003 - WIDE 2 connector

from IPC2

J004 - WIDE 1 connector

from IPC1

for IPC board in right position

(ref. pos. “B” in assembly module.)

No jumper for IPC board

in left position

(ref. pos. “A” in assembly module)

J008

J004

J806 - UI

connector

J205 Blower

connector

J004

J002

J007

J604/J605 -

Coil thermistor

connector

T3A/T3B/T2A/

T2B - Induction

coil connector

From 0VAC to 500VAC

J001

7

6

5

4

GF801 - “SAM”

Service connector

zone

(manufacturing

only)

5

Loading...

Loading...