INSTALLATION

INSTRUCTIONS

NOTICE TO INSTALLER: Leave these instructions with the appliance.

NOTICE TO CONSUMER: Retain these instructions for future reference.

Triple Bay Conventional Gas

J

Prostyle

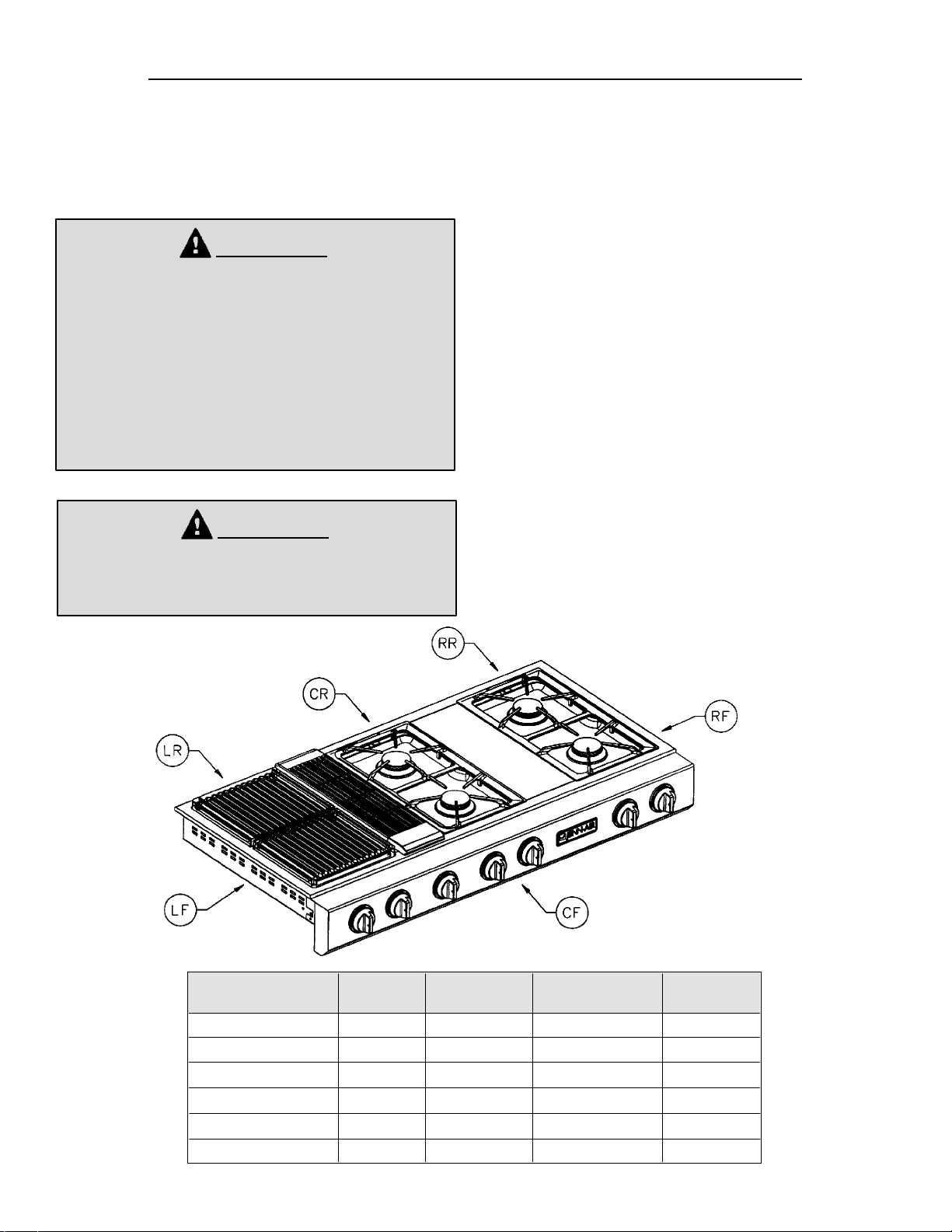

Model JGD8348BDP

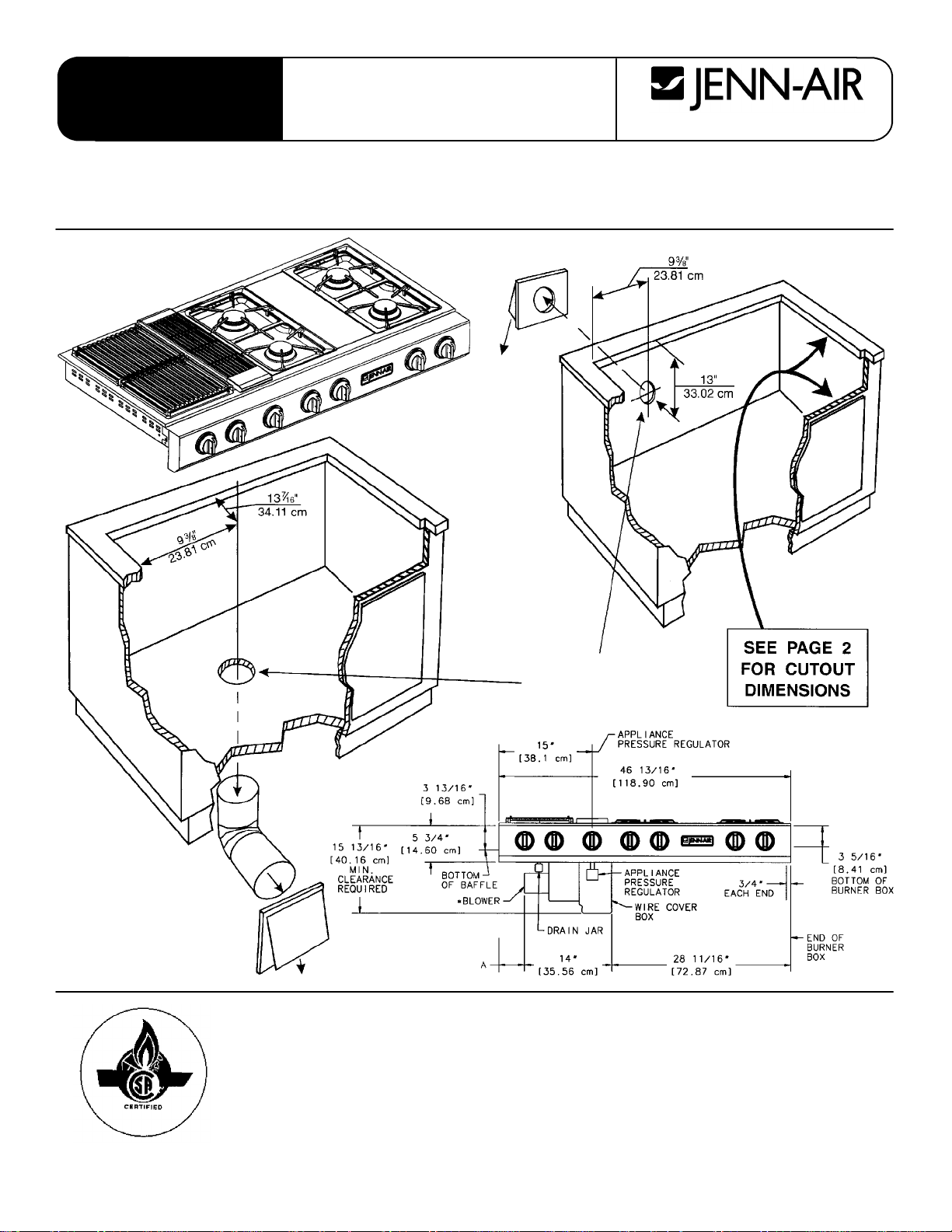

Dimensions shown in both inches and centimenters

J Grill Cooktop

JJ

403 WEST FOURTH STREET, NORTH D NEWTON, IA 50208

* Blower may be

rotated for horizontal

or vertical direction by

loosening nuts

around blower inlet.

Accessible inside

ventilation chamber.

SELECT APPROPRIATE

DUCT CUTOUT

(SEE DUCTING

INSTALLATION INSTRUCTIONS.)

INSTRUCTIONS TO INSTALLER:

S Dimension “A” - provide 2² min. (5.08 cm) cabinet clearance to motor for cooling purpose.

S NOTE: Where possible, 6² (15.54 cm) is recommended for motor/blower service.

S Side Clearance: Grills installed near a side wall must allow a minimum clearance of

8² (20.32 cm).

S Access must be provided to remove and empty grease container.

8101P399-60

(09-01-00)

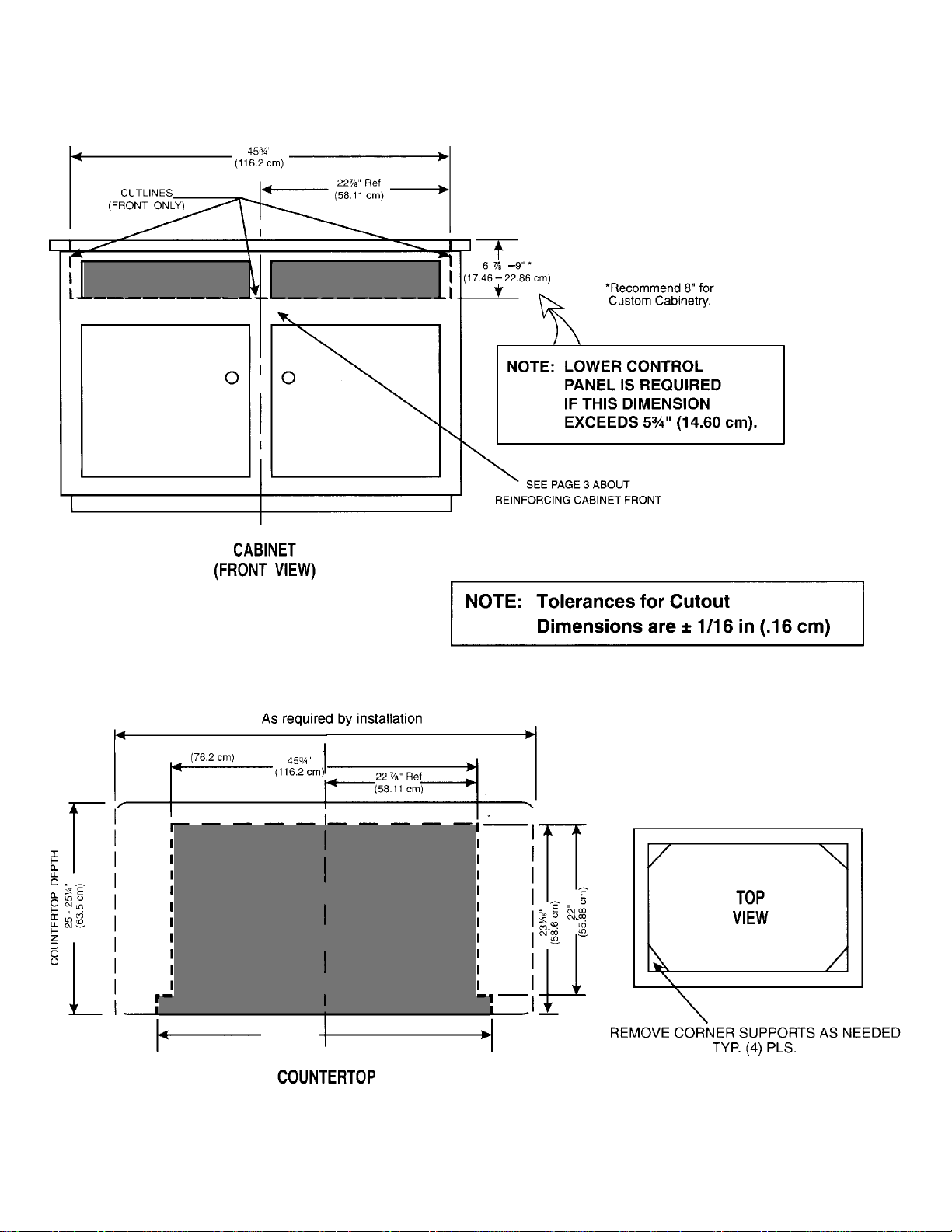

CABINET and COUNTERTOP CUTOUTS

EXISTING

OPENING

EXISTING

OPENING

See cutout suggestions 1-4 on page 6.

COUNTERTOP

CUTOUT

AREA

46 13/16²

(118.90 cm)

2

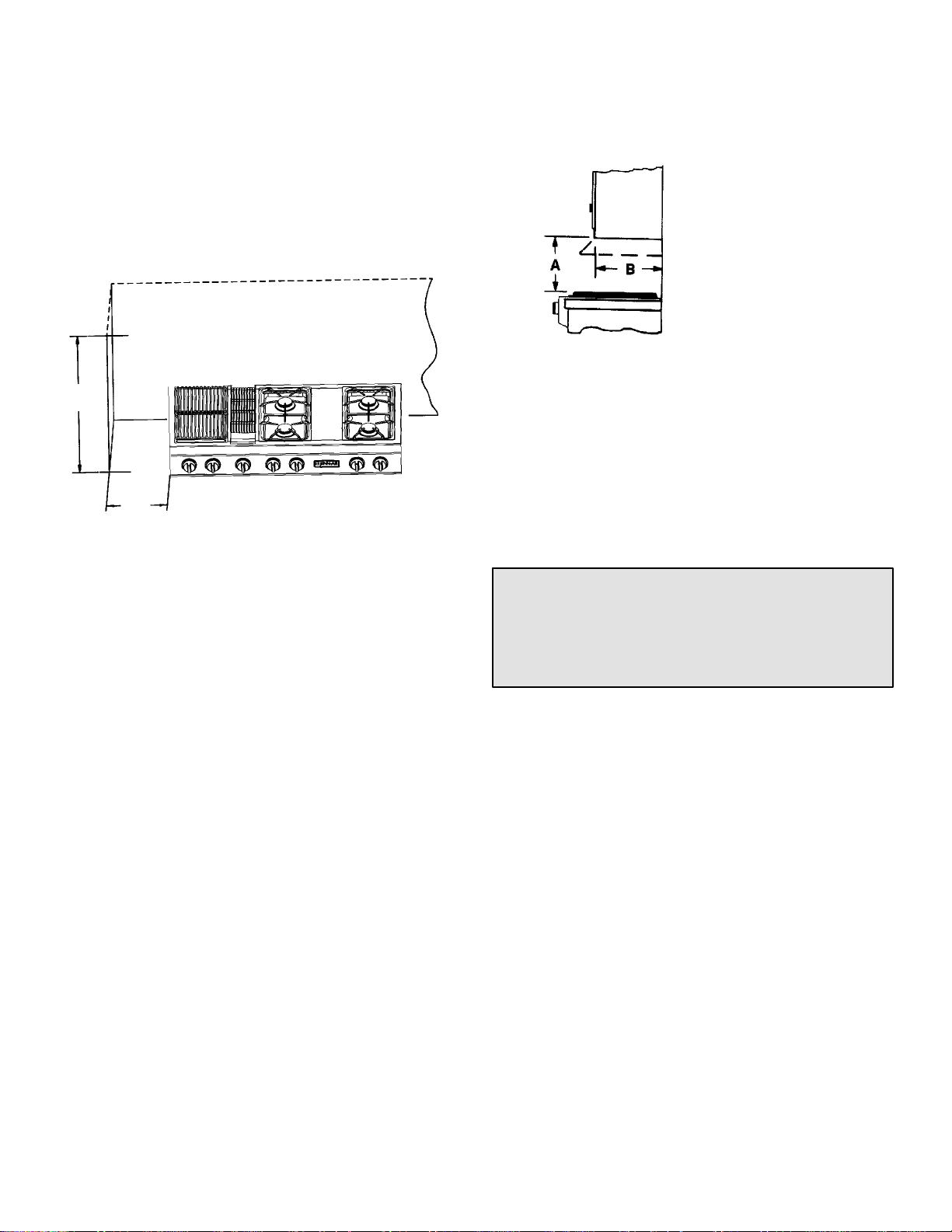

Installing Cabinetry Over Your

Jenn-Air Grill

Minimum horizontal clearance between the edge of the

appliance and combustible construction extending from

the cooking surface to 18² (45.7 cm) above the cooking

surface is:

:² (4.45 cm) at rear

1

8² (20.32 cm) at sides

NOTE: This is not the recommended clearance, but

minimum allowable clearance.

18²

(45.7 cm)

Avoid use of cabinets above cooktop for storage space to

eliminate associated potential hazards such as reaching

over open flames.

Dotted lines indicate range

hood construction.

* To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the

cabinets.

8²

(20.3 cm)

MIN. CLEARANCE

*A = 30² (76.2 cm) minimum vertical clearance

between cooking surface and construction above

the appliance.

B=13² (33.02 cm) maximum depth of cabinets

installed above cooking top.

Cabinets Above Cooking Top

Maximum depth of cabinets installed above cooking top is

13 inches.

CAUTION: SOME CABINETS AND BUILDING

MATERIALS ARE NOT DESIGNED TO WITHSTAND

THE HEAT PRODUCED BY THE NORMAL SAFE

OPERATION OF A LISTED APPLIANCE. DISCOLORATION OR DAMAGE, SUCH AS DELAMINATION, MAY OCCUR.

3

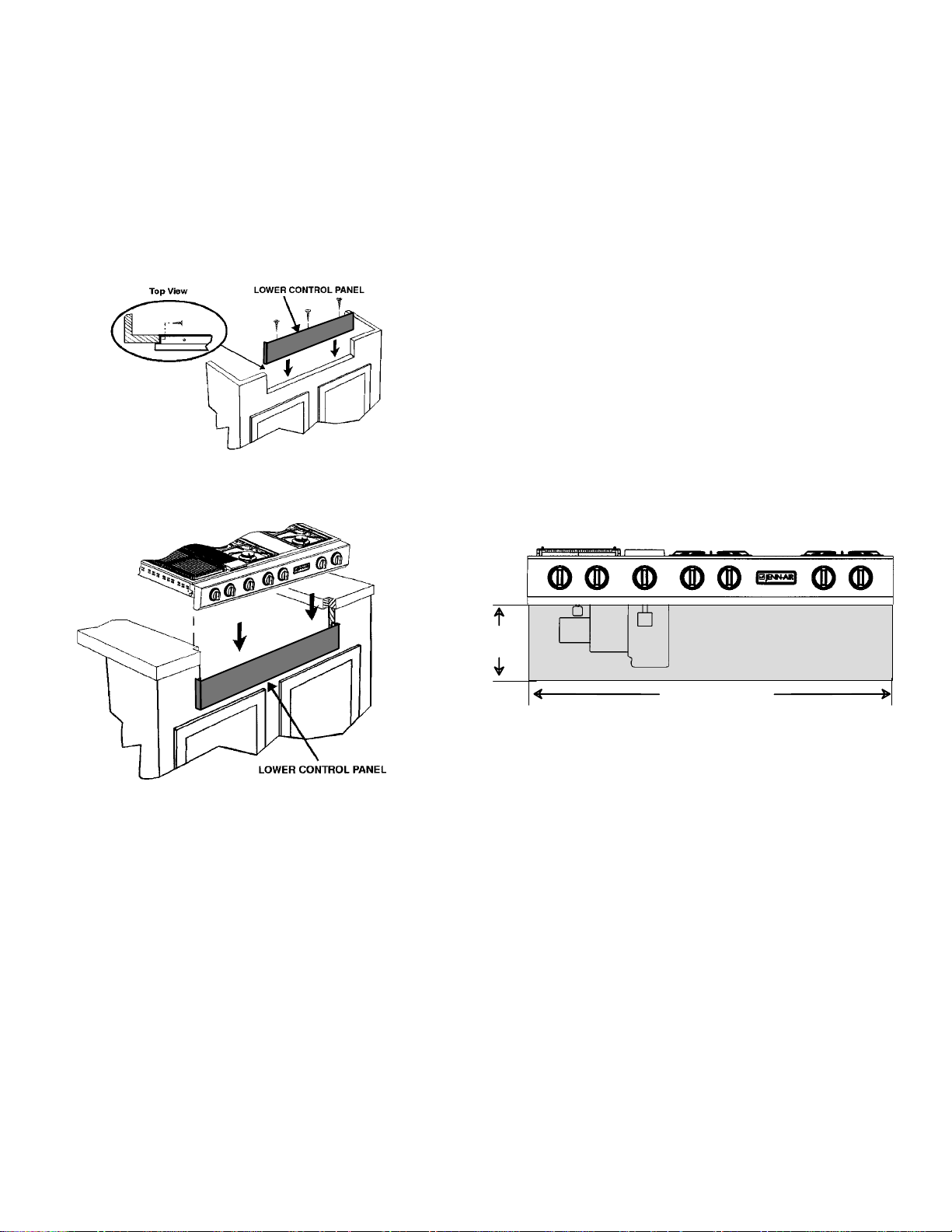

Installation Of Appliance

Follow accompanying ducting instructions carefully.

This appliance is designed to always be vented outdoors.

NOTE: For some cabinet styles, it may be necessary to

reinforce the front of the cabinet by attaching a brace

from front to rear inside the cabinet under the Burner Box.

The Countertop Cutout, Cabinet Front Cutout and Duct

Opening should be prepared according to the illustration

on pages 1 and 2.

Install the Lower Control Panel in the bottom of the

Cabinet Cutout as shown using screws from Hardware

pack. (Figure 1).

Figure 1

Position unit in the Countertop Cutout. Main Control Panel

should overlap top of Lower Control Panel as shown.

(Figure 2).

Install ductwork per ducting instructions provided. Duct

openings in cabinet are shown in the drawing on page 1.

Make electrical and gas connections as described below

in this section of the instructions.

The installation of this appliance must conform with local

codes or, in the absence of local codes, with the latest

edition of the National Fuel Gas Code, ANSI Z.223.1 USA

or current CAN/CGA-B149 INSTALLATION CODE.

The electrical supply required is 110/120-volt, A.C., 15

amp, 60 Hz. This appliance is equipped with a grounded

type power cord. A grounded outlet must be provided. It is

recommended, for convenience, this outlet be located in

the area shown in the shaded illustration. This appliance,

when installed, must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the latest edition of the National Electrical

Code ANSI/NFPA No. 70 USA or current CSA

STANDARD C22.1 Canadian Electrical Code part 1.

Figure 2

10 1/16²

(25.56 cm)

46 13/16² (118.90 cm)

Servicing Cooktop

When servicing cooktop it is necessary to remove the

main top, prior to removing the control panel.

4

Connecting Appliance To Gas Supply

A TRAINED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the instructions

given.

Air Shutter Adjustment

This appliance is shipped from the factory with air shutters

adjusted for use with Natural Gas. If further adjustment is

necessary, or to reset for use with LP, adjust air shutters as

follows:

Install a manual shutoff valve in an accessible location in

the gas line external to this appliance for the purpose of

turning on or shutting off gas to the appliance.

Make the gas connection to the inlet of the appliance

pressure regulator on this appliance with a 1/2² male pipe

thread. Use an approved pipe joint compound resistant to

the action of LP gas at pipe connections. Test all joints for

gas leaks with a soap and water solution or other

accepted leak detection means. Never test for gas leaks

with an open flame.

CAUTION: WARRANTY IS VOID ON JENN-AIR

EQUIPMENT INSTALLED OTHER THAN AS

RECOMMENDED BY MANUFACTURER. RECOMMENDED WALLCAPS ANDTRANSITIONS MUSTBE

UTILIZED FOR PROPER OPERATION AND INSTALLATION.

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A THREEPRONG GROUNDING PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND

SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED RECEPTACLE. DO NOT

CUT OR REMOVE THE GROUNDING PRONG FROM

THIS PLUG.

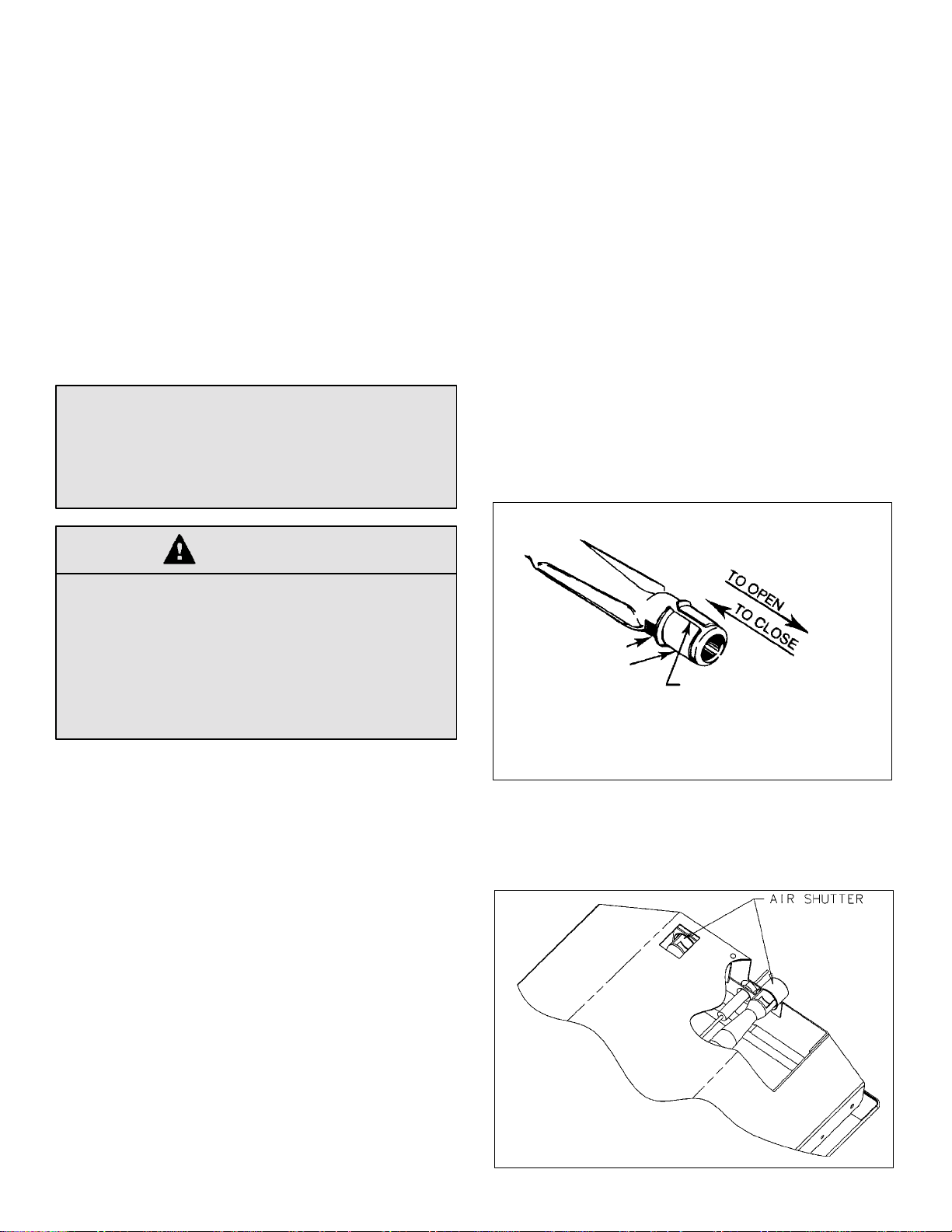

Grill Burner and Surface Burner

Cartridge Air Shutters

(See Illustrations “A” & “B”)

The left hand air shutter controls the rear half of the burner.

The right hand shutter controls the front half. Access to air

shutters on the surface burner cartridge may be found

through openings on the bottom of the cartridge housing.

Slide air shutters backward or forward to increase or

decrease the size of the air opening. Air shutters fit snugly,

soascrewdriver bladeor needle nose pliersmay berequired

to make this adjustment (see illustration).

Observe change in flame appearance as the air shutter is

moved. Adjustment is satisfactory when a clearly defined,

even blue flame results at the high flame setting. The snug

fitof theairshutter assuresit will remainpositionedcorrectly.

Grill Burner Air Shutter and Surface Burner

(if so equipped)

AIR OPENING

AIR SHUTTER

INSERT SCREWDRIVER

BLADE IN SLOT AND TWIST

WITH SLIGHT PRESSURE TO

ALLOW AIR SHUTTER TO

SLIDE EASILY

Illustration “A”

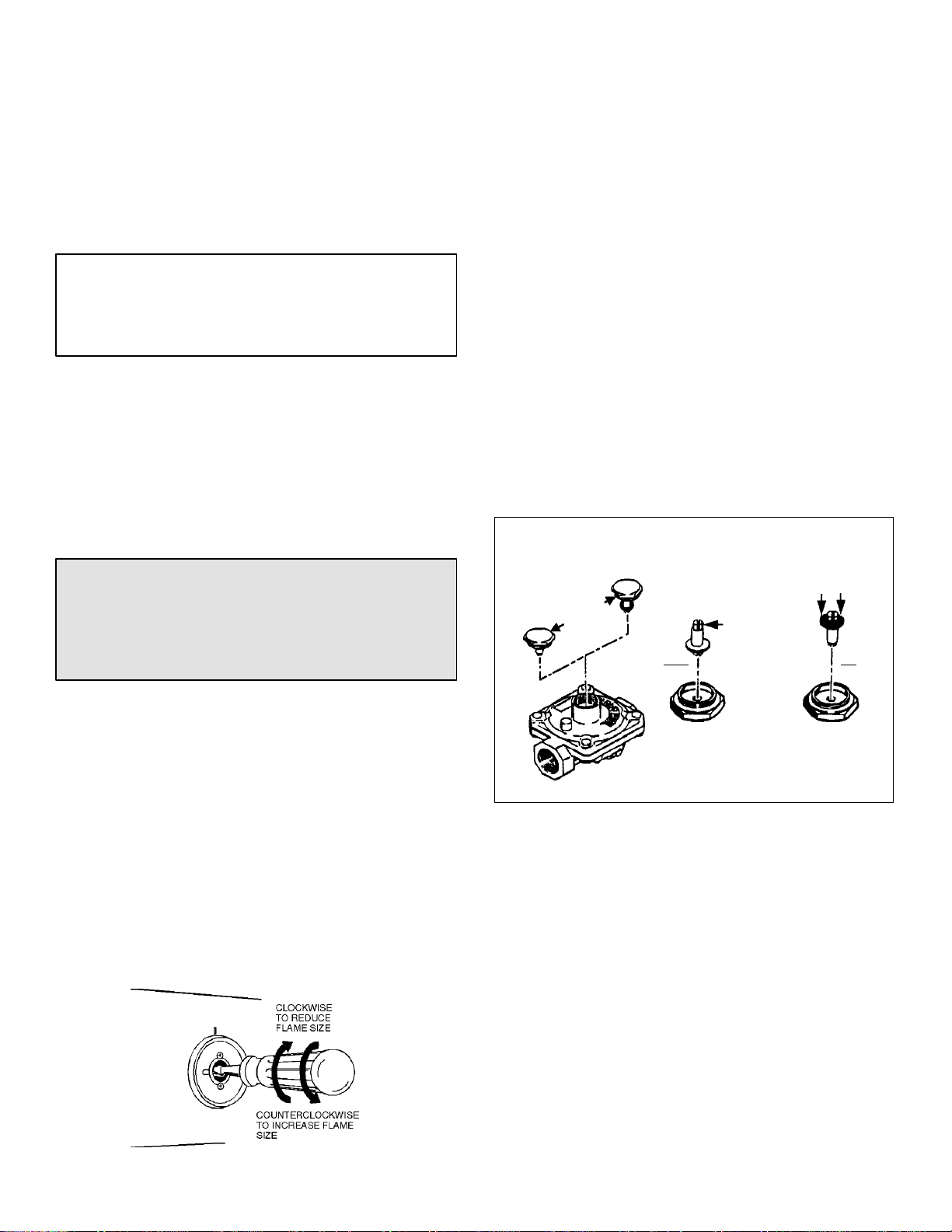

On any burner, closing the air shutter too far will cause the

flame to become soft and yellow tipped. Opening the air

shutter too wide will cause the flame to blow away from the

burnerports. Properadjustment willproduceasharp,clearly

defined, even blue flame.

Illustration “B”

5

Important Installation Suggestions

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of the

countertop laminate.

4. Countertop must be supported within 3² of cutout.

On any burner, closing the air shutter too far will

cause the flame to become soft and yellow tipped.

Opening the air shutter too wide will cause the flame

to blow away from the burner ports. Proper adjustment

will produce a sharp, clearly defined, even blue flame.

Pressure Testing

The maximum gas supply pressure for the appliance

pressure regulator supplied on this appliance is 14² W.C.

The test pressure for checking this appliance pressure

regulator must be at least 6² W.C. for Natural Gas, and at

least 11² W.C. for LP. It is shipped from the factory set for

Natural Gas at 5² W.C.

This appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2² PSIG (3.5 k Pa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2² PSIG

(3.5 k Pa).

Low Flame Adjustment

(See Illustration “C”)

This appliance is shipped from the factory with low and

medium flame settings adjusted for use with Natural Gas.

If further adjustment is necessary, or to re-adjust for use

with LP, proceed as follows:

1. Light burner and set control knob for low flame.

2. Remove control knob from valve stem.

CAUTION: NEVER USE A METAL BLADE TO PRY

KNOB OFF. IF KNOB CANNOT BE EASILY

REMOVED, TUCK THE FOLDS OF A CLOTH

DISHTOWEL UNDER THE KNOB AND PULL THE

TOWEL UPWARD WITH STEADY, EVEN PRESSURE.

3. Insert a slender, thin-blade screwdriver into the recess

at center of valve stem and engage blade with slot in

adjusting screw.

4. Turn center stem adjusting screw to set flame size.

...clockwisetoreduce.

...counterclockwise to increase.

5. Replace control knob when adjustment is completed.

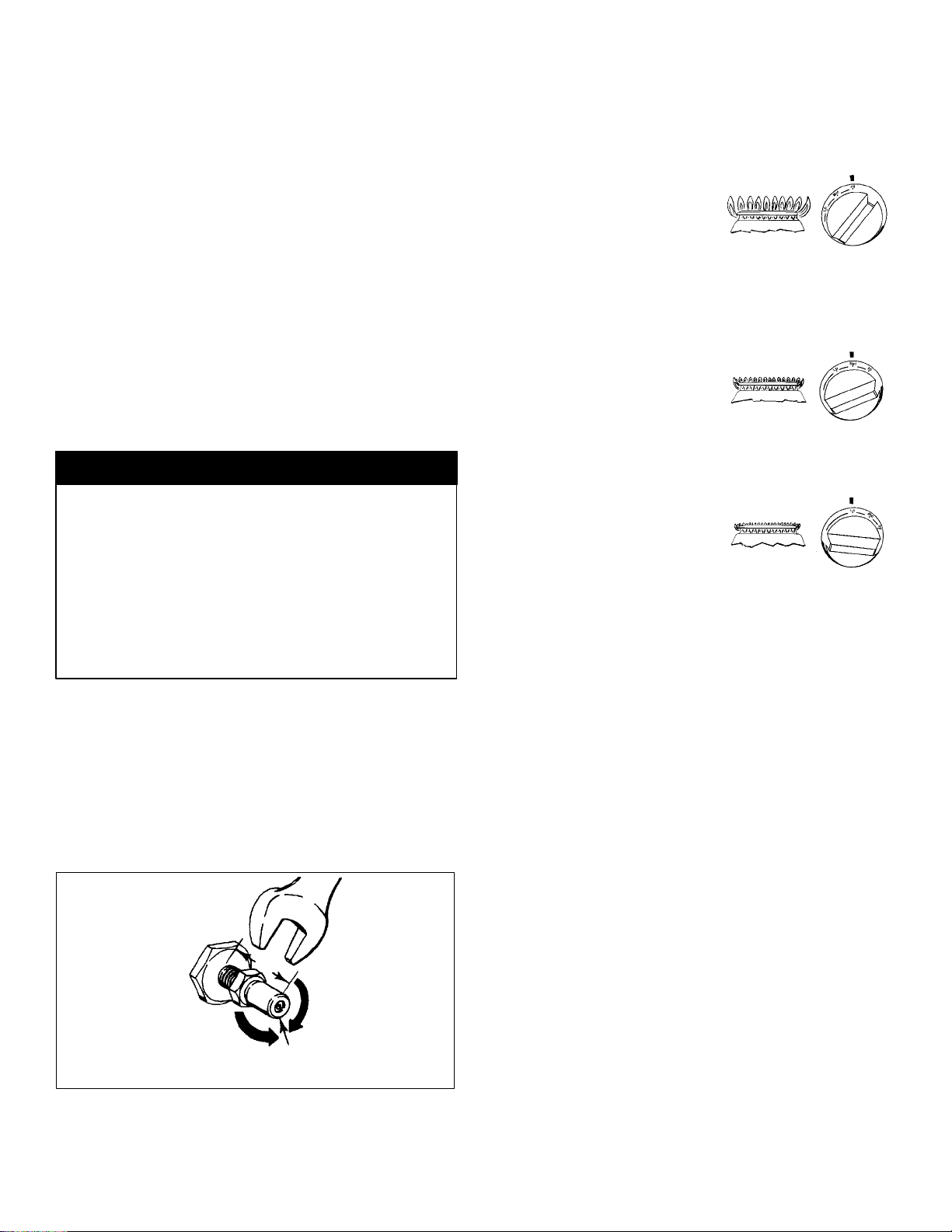

Appliance Pressure Regulator

Conversion

(See Illustration “D”)

This unit is supplied with a Maxitrol Appliance Pressure

Regulator. Follow the instructions in illustration “D”.

MAXITROL APPLIANCE PRESSURE REGULATOR

APPLY DOWNWARD

FINGER PRESSURE

AT DISC EDGES TO

REPLACE PIN IN CAP

APPLY

SIDEWARD

FINGER

PRESSURE TO

REMOVE PIN

FROM CAP

NAT

CONVERTER

CAP

AND PIN

LP

NAT LP

Illustration “D”

Proper adjustment will produce a stable, steady blue flame

of minimum size. The final adjustment should be checked

by turning knob from high to low several times without

extinguishing the flame.

This adjustment, at low setting, will automatically provide

the proper flame size at medium setting.

Illustration “C”

6

Conversion To LP Gas

This appliance is shipped from the factory equipped for

use with Natural Gas. To convert it from Natural Gas for

use with LP Gas, perform steps 1 through 4.

1. Remove Natural Gas orifice hoods. Install color coded

orifice hoods supplied. Located in a pack attached to

the outer plenum area of this appliance.

(See Illustration “E”, below, and LP Gas Conversion

instructions page 8).

2. Invert cap in convertible pressure regulator (if so

equipped) located at entrance to gas manifold.

3. Adjust air shutters on individual burners for proper

flame appearance.

4. Adjust low flame setting at each burner by turning

adjustment screw in center of valve stem.

To make these conversions adjustments follow the

instructions and illustrations (“A” through “E”, pages

5-7).

IMPORTANT

Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fitting

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing

around fittings and connections will indicate a leak. If a

leak appears, turn off supply line gas shut-off valve,

tighten connections, turn on the supply line gas shut

off valve, and retest for leaks. Never test for gas leaks

with an open flame.

Control Settings

The size and type of cookware and the amount and type

of food being cooked will influence the setting needed for

best cooking results. The setting indicated should serve as

a guide while you become familiar with your cooktop.

Use the HI flame setting to

quickly bring foods to a boil or to

begin a cooking operation. Then

reduce to a lower setting to

continue cooking. Never lease

food unattended over a HI flame

setting.

Med setting is used to continue a

cooking operation. Food will not

cook any faster when a HI flame

setting is used than that needed

to maintain a gentle boil.

Remember, water boils at the

same temperature whether boiling

gently or vigorously.

Use LO setting to keep food at

serving temperatures without

further cooking You may find that

some cooking may take place if

the cookware is covered.

This appliance is shipped from the factory with orifice

hoods drilled for use with Natural Gas. To convert from

Natural Gas to LP, apply a 1/2² open-end wrench to hex

section of orifice hood. Turn counterclockwise to remove.

Save the Natural Gas orifice hoods just removed from this

appliance for future use. Install color coded orifice hoods

supplied. (See LP Gas Conversion instructions above and

page 8). Turn clockwise to install. Hold dimension

specified in illustration “E”.

1/2² OPEN END

WRENCH

11/16²²²²

TURN

CLOCKWISE

COUNTERCLOCKWISE

TURN

TO REMOVE

ORIFICE HOOD

TO TIGHTEN

Illustration “E”

7

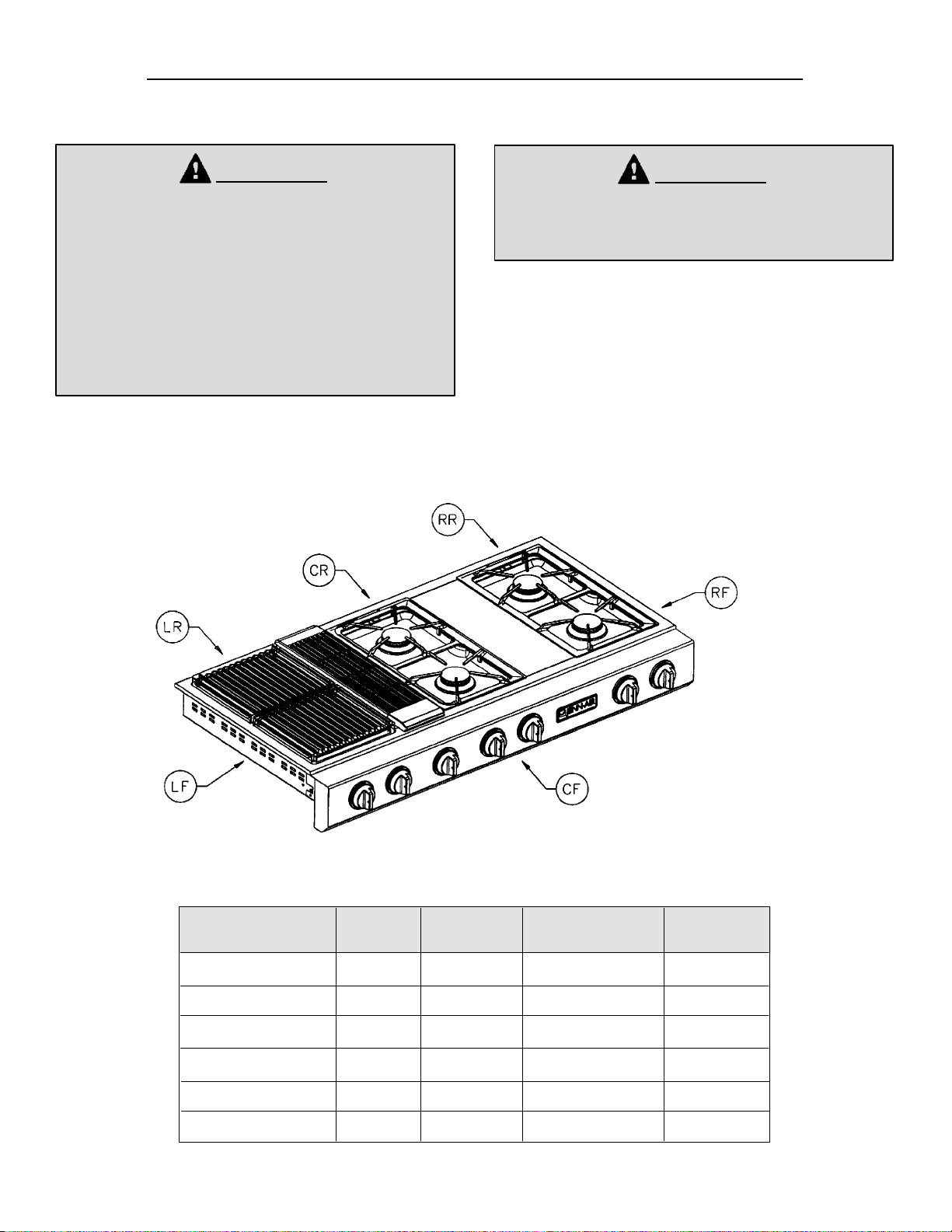

TO CONVERT APPLIANCE FOR USE WITH PROPANE GAS

Natural Gas To Propane Gas (LP) Conversion Instructions

WARNING

Propane Gas conversion is to be performed by

a Jenn-Air Authorized Service Contractor (or

other qualified agency) in accordance with the

manufacturer’s instructions and all codes and

requirements of the authority having

jurisdiction. Failure to follow instructions could

resultin serious injury or property damage.The

qualifiedagency performing this work assumes

responsibility for this conver sion.

WARNING

ELECTRICAL POWER AND GAS MUST BE

TURNED OFF PRIOR TO CONVERSION

Models - JGD8348BDP

Manifold - Propane Gas pressure required - 10² W.C.

Incoming Propane Gas pressure required to appliance

pressure regulator - 11² -12² W.C.

Propane Conversion Orifice Hoods are supplied with this

model.

Propane Gas input specified - 46,000 BTU/hr.

JGD8348BDP

INCHES

BURNER BTU/hr ORIFICE DIAMETER COLOR

Left Rear (LR) 7500 #66 .033 Zinc

Left Front (LF) 7500 #66 .033 Zinc

Center Rear (CR) 6500 #68 .031 Red

Center Front (CF) 9000 #63 .037 Blue

Right Rear (RR) 6500 #68 .031 Red

Right Front (RF) 9000 #63 .037 Blue

8

TO CONVERT APPLIANCE FOR USE WITH NATURAL GAS

Propane Gas (LP) To Natural Gas

Conversion Instructions

If this appliance has been converted for use with LP Gas,

each of the following modifications must be performed to

convert the unit back to Natural Gas.

WARNING

NaturalGasconversion isto be performed by a

Jenn-Air Authorized Service Contractor (or

other qualified agency) in accordance with the

manufacturer’s instructions and all codes and

requirements of the authority having

jurisdiction. Failure to follow instructions could

resultin serious injury or property damage.The

qualifiedagency performing this work assumes

responsibility for this conver sion.

WARNING

ELECTRICAL POWER AND GAS MUST BE

TURNED OFF PRIOR TO CONVERSION

Model - JGD8348BDP

Manifold - Natural Gas pressure required - 5² W.C.

Incoming Natural Gas pressure required to appliance

pressure regulator - 6² -7² W.C.

Natural Gas input specified - 56,000 BTU/hr.

A. Replaceall orifice hoods - Performsteps 1through 4 on

page7.Locatethe (6)sixNaturalGas hoods(withsmall

numbersstamped on theirsides savedfrom theoriginal

Natural Gas unit). Page 5 Illustration “E”. The two

hoods with .0520 (#55 orifice) stamped on them are for

the left front and left rear burners. The four hoods with

the .0595 (#53 orifice) stamped on them are for the two

right burners.

To make these conversion adjustments follow the

instructionsand illustrations (“A”through “E”) pages

5-7.

B. Invert cap in appliance pressure regulator (see

Illustration “D”, page 6). With the appliance installed,

the appliance pressure regulator is located on the right

underside of the appliance at the inlet to the gas

manifold. Identify the type of appliance pressure

regulator on the unit and follow the instructions in the

appropriate illustration.

C. Adjust low flame setting for each burner. Follow the

instructions for burner low flame adjustment on page 7

to increase the simmer flame size.

JGD8348BDP

INCHES

BURNER BTU/hr ORIFICE DIAMETER COLOR

Left Rear (LR) 8,000 #55 .0520 Green

Left Front (LF) 8,000 #55 .0520 Green

Center Rear (CR) 10,000 #53 .0595 Brass

Center Front (CF) 10,000 #53 .0595 Brass

Right Rear (RR) 10,000 #53 .0595 Brass

Right Front (RF) 10,000 #53 .0595 Brass

9

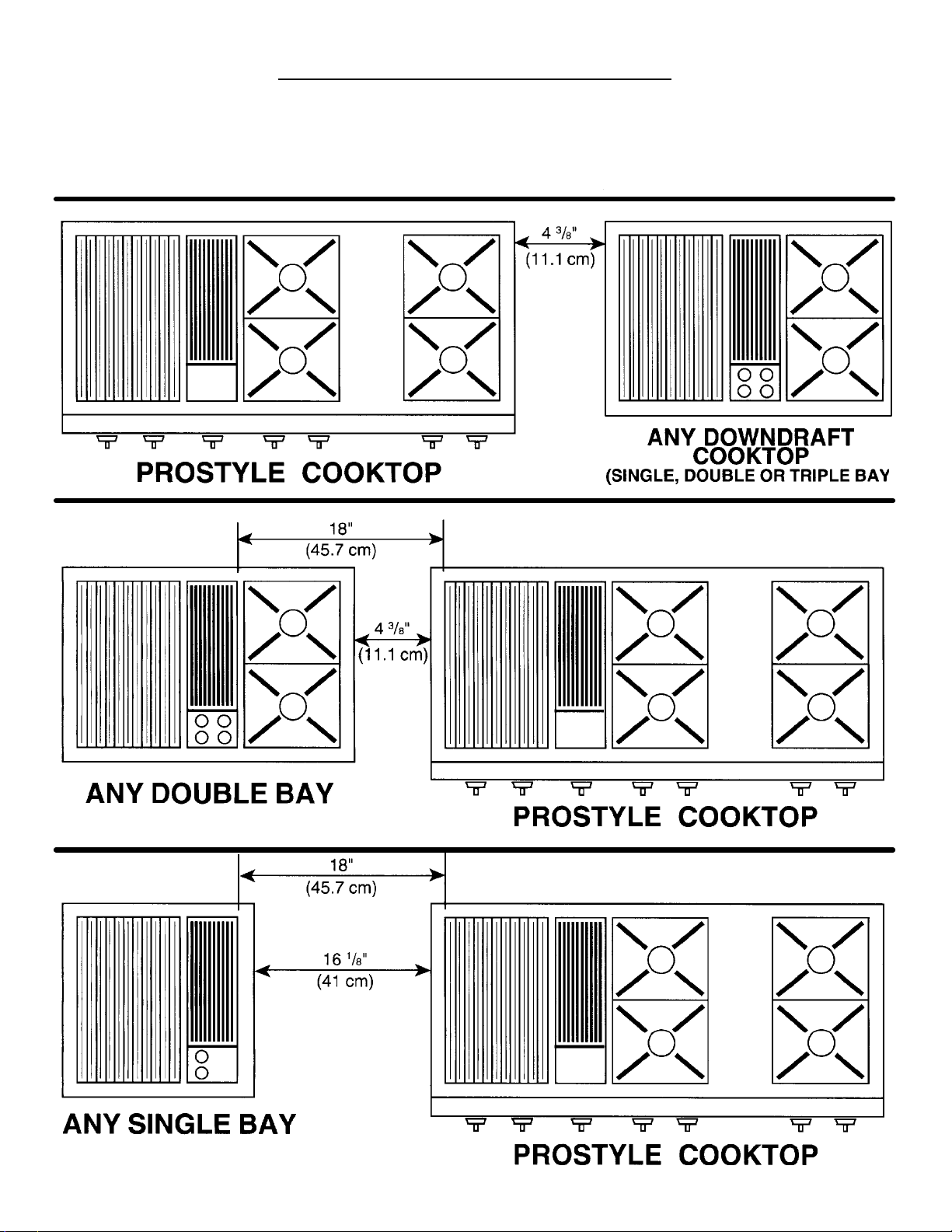

MINIMUM SPACING REQUIREMENT

GAS GRILL COOKTOPS

Forinstallinga TripleBayDowndraftCooktopincombinationwithanother DowndraftCooktop,theminimum spacing between adjacent units must be provided, as shown, for satisfactory performance.

10

REQUIRED ADJUSTMENTS AT TIME OF INSTALLATION

The installation of this appliance must conform with local codes, or in the absence of local codes, with

thelatesteditionoftheNationalFuelGasCodeANSIZ223.1USAorcurrentCAN/CGA-B149Installation

Code.

ThisrangewasmanufacturedforusewithNaturalGas. IfLPgasisthe fuelofchoice,followtheconversion

to LP procedure found in the installation instructions.

Test all external connections for gas leaks. Never test for gas leaks with an open flame.

Test all electrical connections.

Adjust all air shutters for proper flame.

Adjust all valves for low flame settings.

Test the ventilation system for proper installation.

If a problem exists with the downdraft system, check the ducting installation to make sure it conforms to

the Jenn-Air specifications. Most downdraft system problems are attributed to poor ducting practices.

Contact your installer if the ventilation system will not remove smoke or cooking fumes from well trimmed

cuts of meat.

If ventilation problems persist contact your authorized Jenn-Air Service Contractor.

11

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

INSTRUCCIONES

DE

INSTALACIÓN

Las dimensiones se muestran en pulgadas y centímetros

AVISO AL INSTALADOR: Deje estas instrucciones con el electrodoméstico.

AVISO AL CONSUMIDOR: Conserve estas instrucciones como referencia futura.

Superficie convencional para

cocinar de gas con parrilla

Prostyletttt de módulo triple

Modelo JGD8348BDP

403 WEST FOURTH STREET, NORTH D NEWTON, IA 50208

* El ventilador puede

girarse para orientarlo

horizontalo verticalmente aflojando las

tuercas de la entrada del

ventilador.

Asequible desde adentro

de la cámara de

ventilación.

VEALAPÁGINA2

PARA

ESPACIO LIBRE

MÍNIMO

REQUERIDO

PARTE INFERIOR

DE LA TABLA

VENTILADOR

SELECCIONE EL CORTE

APROPIADO PARA EL DUCTO

(VEA LAS INSTRUCCIONES DE

INSTALACIÓN DEL DUCTO).

REGULADOR DE

PRESIÓNDEL

ELECTRODOMÉSTICO

REGULADOR

DE PRESIÓN

DEL ELECTRODOMÉSTICO

CAJA DE

CUBIERTA DE

RECIPIENTE

DE DRENAJE

CABLES

ENCONTRAR LAS

DIMENSIONES

DEL HUECO

CADA

EXTREMO

EXTREMO

DE LA CAJA

DEL

QUEMADOR

PARTE

INFERIOR

DE LA CAJA

DEL

QUEMADOR

INSTRUCCIONES PARA EL INSTALADOR:

S La dimensión “A” - proporciona 2² mínimas (5.08 cm) de espacio libre del gabinete al

motor para fines de enfriamiento.

S NOTA: En donde sea posible, se recomiendan 6² (15.54 cm) para darle servicio al motor

y al ventilador.

S Espacio libre lateral: Las parrillas instaladas muy cerca de una pared deben tener un

espacio libre de 8² (20.32 cm) como mínimo.

S Debe proporcionarse acceso para quitar y vaciar el recipiente de grasa.

LÍNEAS DE CORTE

(SOLAMENTEDEL

FRENTE)

RECORTES DEL GABINETE y DEL MOSTRADOR

HUECO

EXISTENTE

(VISTA DE FRENTE)

HUECO

EXISTENTE

GABINETE

Según se requiera para la instalación

*Se recomiendan 8² (20.32 cm)

para los gabinetes a la medida.

NOTA: SE REQUIERE UN

PANEL INFERIOR DE CONTROL

SI ESTA DIMENSIÓN EXCEDE

53/4²²²² (14.60 cm).

VEA LA PÁGINA 3 EN RELACIÓN

AL REFUERZO DE LA PARTE

DELANTERA DEL GABINETE

Vea las sugerencias de recorte 1-4 en la página 6.

NOTA: Las tolerancias de las dimensiones del

hueco son de 1/16 pulg (0.16 cm)

ÁREA

VISTA DESDE

ARRIBA

DE RECORTE

PROFUNDIDAD DEL MOSTRADOR

DEL MOSTRADOR

46 13/16²

(118.90 cm)

QUITE LOS APOYOS DE L AS ESQUINAS

SEGÚN SEA NECESARIO

TÍP. (4) HOJAS

MOSTRADOR

2

Instalación de gabinetes encima de la

parrilla Jenn-Air

El espacio libre horizontal mínimo entre el borde del

electrodoméstico y la construcción combustible que se

extienda de la superficie para cocinar a 18² (45.7 cm) por

encima de la superficie para cocinar es:

1:² (4.45 cm) en la parte posterior

8² (20.32 cm) a los lados

NOTA: Éste no es el espacio libre que se recomienda

sino el espacio libre mínimo permitido.

18²

(45.7 cm)

Las líneas punteadas

indican la construcción de

la campana de la estufa.

* Para eliminar el riesgo de quemaduras o incendios al

atravesarse por encima de las unidades calientes de la

superficie, debe evitarse el uso del espacio de

almacenamiento de los gabinetes localizados encima

de las unidades de la superficie. Si los gabinetes se

van a usar para almacenamiento, el riesgo puede

reducirse usando una campana de estufa que

sobresalga horizontalmente cuando menos 5 pulgadas

(12.7 cm) de la parte inferior de los gabinetes.

8²

(20.3 cm)

ESPACIO LIBRE MÍNIMO

*A = 30² (76.2 cm) espacio libre mínimo vertical entre

la superficie para cocinar y la construcción

encima del electrodoméstico.

B= 13² (33.02 cm) profundidad máxima de los

gabinetes instalados por encima de la superficie

para cocinar.

Trate de no usar los gabinetes que están encima de la

superficie para cocinar como espacios para almacenar ya

que así eliminará los riesgos potenciales de tener que

atravesarse cuando haya llamas encendidas.

Gabinetes encima de la superficie para

cocinar

La profundidad máxima de los gabinetes instalados por

encima de la superficie para cocinar es de 13 pulgadas

(33 cm).

PRECAUCIÓN: ALGUNOS GABINETES Y

MATERIALES DE CONSTRUCCIÓN NO ESTÁN

DISEÑADOS PARA RESISTIR EL CALOR

PRODUCIDO DURANTE LA OPERACIÓN NORMAL

DEL ELECTRODOMÉSTICO INDICADO, POR LO

TANTO PODRÍA OCURRIR DECOLORACIÓN O

DAÑOS, TALES COMO DESLAMINACIÓN.

3

Instalación del electrodoméstico

Siga cuidadosamente las instrucciones adjuntas acerca

de los ductos.

Este electrodoméstico está diseñado para ventilarse

siempre hacia el exterior.

NOTA: En algunos estilos de gabinetes, podría ser

necesario tener que reforzar la parte delantera del

gabinete sujetando una abrazadera del frente a la parte

posterior del gabinete por dentro desde debajo de la caja

del quemador.

El recorte del mostrador, el recorte del frente del gabinete

y los huecos de los ductos deberán prepararse de

acuerdo con las ilustraciones de las páginas 1 y 2.

Instale el panel de control inferior en el fondo del recorte

del gabinete según se muestra, usando los tornillos del

paquete de herrajes. (Figura 1).

Vista desde arriba

PANEL INFERIOR DE CONTROL

Figura 1

Coloque la unidad en el recorte del mostrador. El panel

principal de control debe sobreponerse a la parte superior

del panel inferior de control según se muestra. (Figura 2).

Instale los ductos de acuerdo con las instrucciones

provistas. Los huecos de los ductos en el gabinete se

muestran en el dibujo de la página 1. Haga las

conexiones eléctricas y de gas según se describe más

adelante en esta sección de instrucciones.

La instalación de este electrodoméstico debe estar en

conformidad con los códigos locales, o si éstos no

existieran, con la última edición del Código Nacional de

Gas Combustible, ANSI Z.223.1 EE.UU. o el CÓDIGO

DE INSTALACIÓN actual CAN/CGA-B149.

El suministro eléctrico requerido es de 110/120-voltios,

C.A., 15 amp, 60 Hz. Este electrodoméstico está

equipado con un tipo de cordón eléctrico conectado a

tierra. Debe proveerse un tomacorriente conectado a

tierra. Se recomienda, por comodidad, que este

tomacorriente se ubique en el área que se muestra en la

ilustración sombreada. Cuando se instale este

electrodoméstico, debe conectarse a tierra de acuerdo

con los códigos locales, o si éstos no existieran, con la

última edición del Código Nacional Eléctrico ANSI/NFPA

No. 70 EE.UU. o al Código Canadiense Eléctrico CSA

STANDARD C22.1 parte 1.

PANEL INFERIOR DE

CONTROL

Figura 2

10 1/16²

(25.56 cm)

46 13/16² (118.90 cm)

Para darle servicio a la superficie para

cocinar

Cuando se le de servicio a la superficie para cocinar es

necesario quitar la parte superior principal, antes de

quitar el panel de control.

4

Conexión del electrodoméstico al

suministro de gas

LA CONEXIÓN AL SUMINISTRO DE GAS DEBE

REALIZARLA UN TÉCNICO CAPACITADO DE

SERVICIO O UN INSTALADOR DE ELECTRODOMÉSTICOS DE GAS. Las pruebas de fugas de gas

del electrodoméstico las debe realizar el instalador de

acuerdo con las instrucciones proporcionadas.

Instale una válvula de cierre manual en un lugar accesible

en la tubería de gas de la parte exterior de este

electrodoméstico para fines de abrir y cerrar el gas que

va al electrodoméstico.

Haga la conexión de gas a la entrada del regulador de

presión del electrodoméstico con una rosca de tubería

machode1/2². Use en las conexiones de la tubería un

compuesto para uniones de tubería aprobado que sea

resistente a la acción del gas butano. Pruebe todas las

uniones para asegurarse de que no haya fugas con una

solución de agua y jabón u otro medio aprobado de

detección de fugas. Nunca pruebe las fugas con las

llamas encendidas.

PRECAUCIÓN: LA GARANTÍAQUEDA ANULADAEN

EL EQUIPO JENN-AIR CUANDO SE INSTALE PARA

OTRO FIN QUE NO SEA EL RECOMENDADO POR

EL FABRICANTE. DEBEN UTILIZARSE LAS TAPAS

DE PARED Y LAS TRANSICIONES RECOMENDADAS PARA OBTENER UNA OPERACIÓN E

INSTALACIÓN CORRECTAS.

Obturadores de aire de cartucho del

quemador de la parrilla y del quemador

de la superficie para cocinar

(Vea las ilustraciones “A” y “B”)

El obturador de aire del lado izquierdo controla la mitad

posterior de los quemadores. El obturador de aire del lado

derechocontrolala mitaddelantera. Los obturadores deaire

del cartucho del quemador de la superficie se acceden a

través de las aberturas en la parte inferior de la caja del

cartucho.

Deslice los obturadores deaire hacia atrás o hacia adelante

para aumentar o reducir el tamaño de la abertura del aire.

Losobturadoresquedan muy bienajustados,así que podría

ser necesario tener que usar la hoja de un destornillador o

unas pinzas con punta de aguja para hacer este ajuste (vea

la ilustración).

Observe los cambios en la apariencia de la llama conforme

mueve el obturador de aire. El ajuste es aceptable cuando

aparece una llama claramente definida, azul y uniforme en

el ajuste más alto de la llama. El buen ajuste del obturador

de aire garantizaque permanezca correctamente colocado.

Obturador de aire del quemador de la parrilla y

quemador de la superficie para cocinar

(si así está equipado)

(PARA

ABRIR)

ADVERTENCIA

INSTRUCCIONES ELÉCTRICAS DE

CONEXIÓN A TIERRA

ESTE ELECTRODOMÉSTICO ESTÁ EQUIPADO

CON UNA CLAVIJA DE TRES PUNTAS DE

CONEXIÓN A TIERRA PARA PROTEGERLO

CONTRA RIESGOS DE DESCARGAS Y DEBE

CONECTARSE DIRECTAMENTE EN UN

RECEPTÁCULO CORRECTAMENTE CONECTADO

A TIERRA. NO CORTE NI QUITE LA PUNTA DE

TIERRA DE ESTA CLAVIJA.

Ajuste del obturador de aire

Este electrodoméstico se embarca de fábrica con los

obturadores de aire ajustados para usarse con gas

natural. Si es necesario ajustarlos más o reajustarlos para

usarse con gas butano, ajuste los obturadores de aire del

modo siguiente:

ABERTURA

DEL AIRE

OBTURADOR

DE AIRE

INSERTE LA HOJA DE UN DESTORNILLADOR EN LA RANURA Y

GIRE EJERCIENDO UNA PRESIÓN

LEVE PARA PERMITIR QUE EL

OBTURADOR DE AIRE SE

DESLICE CON FACILIDAD

(PARA

CERRAR)

Ilustración “A”

Encualquierquemador, el cerrardemasiadoelobturadorde

aire haráque la llama se vuelva suave y con puntaamarilla.

Abrir demasiado el obturador de aire hará que la llama se

separe de los puertos del quemador. El ajuste correcto

producirá una llama claramente definida, azul y uniforme.

OBTURADOR

DE AIRE

Ilustración “B”

5

Sugerencias importantes de

instalación

1. Achaflane todos los bordes expuestos del laminado

decorativo para evitar daños por desportilladuras.

2. Haga radiales en las esquinas de los recortes y líjelas

para asegurarse que los bordes queden lisos y evitar

que se quiebren las esquinas.

3. Los bordes disparejos, las esquinas interiores que no

se han redondeado y los ajustes forzados pueden

contribuir a que se quiebre el laminado del mostrador.

4. El mostrador debe estar apoyado a 3² (7.6 cm) del

recorte.

En cualquier quemador, cerrar demasiado el

obturador de aire hará que la llama se vuelva suave y

de punta amarilla. Abrir demasiado el obturador de

aire hará que la llama se separe de los puertos del

quemador. El ajuste correcto producirá una llama

claramente definida, azul y uniforme.

Ajuste de llama baja

(Vea la ilustración “C”)

Este electrodoméstico se embarca de fábrica con ajustes

de llama bajo y medio para usarse con gas natural. Si son

necesarios ajustes adicionales, o para reajustarlo para

usarse con gas butano, continúe del modo siguiente:

1. Encienda el quemador y coloque la perilla de control en

la llama baja.

2. Quite la perilla de control del vástago de la válvula.

EN EL SENTIDO DE LAS

MANECILLASDEL RELOJ

PARA REDUCIR EL

TAMAÑO DE LA LLAMA

Ilustración “C”

EN SENTIDO CONTRARIO AL

DE LAS MANECILLAS DEL

RELOJ PARA AUMENTAR EL

TAMAÑO DE LA LLAMA

Prueba de presión

La presión máxima de suministro de gas para el regulador

de presión del electrodoméstico proporcionado con este

electrodoméstico es de 14² W.C. La presión de prueba

para revisar el regulador de presión del electrodoméstico

debe ser cuando menos de 6² W.C. para gas natural, y

cuando menos de 11² W.C. para gas butano. Se embarca

de fábrica ajustado para usarse con gas natural a 5² W.C.

Este electrodoméstico y su válvula de cierre individual

deben estar desconectados del sistema de tubería de

suministro de gas durante las pruebas de presión a

presiones de prueba por encima de 1/2² PSIG (3.5 k Pa).

Este electrodoméstico debe estar aislado del sistema de

tubería del suministro de gas cerrando la válvula de cierre

individual durante las pruebas de presión del sistema de

tubería de suministro de gas a presiones de prueba

iguales o menores de 1/2² PSIG (3.5 k Pa).

PRECAUCIÓN: NUNCA USE UNA HOJA METÁLICA

PARA SACAR LA PERILLA. SI ÉSTA NO PUEDE

SACARSE CON FACILIDAD, INTRODUZCA UN

SECADOR DOBLADO DE TELA POR DEBAJO DELA

PERILLA Y TIRE DEL SECADOR HACIA ARRIBA

EJERCIENDO UNA PRESIÓN UNIFORME.

3. Inserte un destornillador de hoja delgada y plana dentro

del receso al centro del vástago de la válvula y

enganche la hoja en la ranura en el tornillo de ajuste.

4. Gire el tornillo de ajuste del centro del vástago para

ajustar el tamaño de la llama.

...enelsentidodelasmanecillas del reloj para

reducirla.

...ensentidocontrarioaldelasmanecillas del reloj

para aumentarla.

5. Coloque de nuevo la perilla de control cuando termine

el ajuste.

Un ajuste apropiado producirá una llama estable, uniforme

en color azul de tamaño mínimo. El ajuste final debe

revisarse girando la perilla de alto a bajo varias veces sin

apagar la llama.

Este ajuste, en el ajuste bajo, proporcionará

automáticamente el tamaño correcto de llama para el

ajuste medio.

Conversión del regulador de presión

del electrodoméstico

(Vea la ilustración “D”)

Esta unidad se suministra con un regulador de presión para

electrodomésticos Maxitrol. Siga las instrucciones de la

ilustración “D”.

REGULADOR DE PRESIÓN PARA

ELECTRODOMÉSTICOS MAXITROL

APLIQUE PRESIÓN HACIA ABAJO CON

EL DEDO EN LOS BORDES DEL DISCO

PARA VOLVER A COLOCAR EL

PASADOR EN LA TAPA

APLIQUE

PRESIÓN

LATERAL CON

EL DEDO PARA

NAT LP

QUITAR EL

PASADOR DE

LA TAPA

NAT

CONVERTIDOR

TAPA Y

PASADOR

LP

Ilustración “D”

6

Conversión a gas butano

Este electrodoméstico se embarca de fábrica equipado

para usarse con gas natural. Para convertirlo de gas

natural a gas butano, realice los pasos 1 al 4.

1. Quite las campanas de orificio de gas natural. Instale

las campanas adjuntas de orificio codificadas por color.

Se encuentran en un paquete que está sujeto en el

área impelente externa de este electrodoméstico.

(Vea la ilustración “E”, más adelante, y las

instrucciones de conversión a gas butano de la

página 8).

2. Invierta la tapa en el regulador de presión convertible

(si está equipado) localizado en la entrada del múltiple

de gas.

3. Ajuste los obturadores de aire en los quemadores

individuales para obtener la apariencia correcta de la

llama.

4. Coloque el ajuste bajo de llama en cada quemador

girando el tornillo de ajuste en el centro del vástago de

la válvula.

Para realizar estos ajustes de conversión siga las

instrucciones y las ilustraciones (“A” a la “E”, en las

páginas 5-7).

IMPORTANTE

Aplique un líquido anticorrosivo detector de fugas en

todas las uniones y accesorios de la conexión de gas

entre la válvula de cierre de la tubería de suministro y

la estufa. Incluya los accesorios de gas y las uniones

de la estufa si las conexiones se alteraron durante la

instalación. Revise si hay fugas. Las burbujas que

aparezcan alrededor de los accesorios y las

conexiones indicarán que hay fugas. Si aparece una

fuga, cierre la válvula de la tubería de suministro de

gas, apriete las conexiones, abra la válvula de cierre

de la tubería de suministro de gas, y vuelva a revisar

si hay fugas. Nunca realice pruebas de fugas con la

llama encendida.

Este electrodoméstico se embarca de fábrica con

campanas de orificio para usarse con gas natural. Para

convertirlo de gas natural a gas butano, coloque una llave

española de 1/2² a la sección hexagonal de la campana

de orificio. Gire en sentido contrario al de las manecillas

del reloj para quitarla. Conserve las campanas de orificio

de gas natural que quitó del electrodoméstico para usarlas

en el futuro. Instale las campanas suministradas de

orificio codificadas por color. (Vea las instrucciones de

conversión a gas butano anteriores y en la página 8). Gire

en el sentido de las manecillas del reloj para instalarla.

Mantenga la dimensión especificada en la ilustración “E”.

LLAVE

ESPAÑOLA DE

1/2²

GIRE EN SENTIDO

CONTRARIO AL DE LAS

MANECILLASDEL RELOJ

PARA QUITARLA

11/16²²²²

CAMPANA DE ORIFICIO

GIRE EN EL

SENTIDO DE LAS

MANECILLASDEL

RELOJ

PARA APRETARLA

Ilustración “E”

Ajustes de control

El tamaño y tipo de recipientes de cocina y la cantidad y

tipo de alimentos que se cocinen influirán en el ajuste que

se necesita para obtener los mejores resultados de

cocción. El ajuste indicado deberá servir como una guía

mientras se familiariza con la superficie para cocinar.

Use el ajuste de llama HI (alto)

para hacer que los alimentos

hiervan rápidamente o para

comenzar una operación de

cocción. Luego reduzca el ajuste

para continuar el cocimiento.

Nunca desatienda los alimentos

cuando estén en el ajuste de

llama HI (alto).

El ajuste Med (medio) se usa

para continuar una operación de

cocción. Los alimentos no se

cocinarán más rápido cuando se

usaelajustedellamaHI (alto)

que con el que se necesita para

mantener un hervor suave.

Recuerde, el agua hierve a la

misma temperatura aunque

hierva suave o vigorosamente.

Use el ajuste LO (bajo) para

mantener los alimentos a

temperatura de servir sin que se

sigan cocinando. Se dará cuenta

que podría haber un poco de

cocción adicional si el recipiente

se encuentra tapado.

7

PARA CONVERTIR EL ELECTRODOMÉSTICO PARA USARSE CON GAS BUTANO

Instrucciones de conversión de gas natural a gas butano (LP)

ADVERTENCIA

La conversión a gas butano debe realizarla un

contratista autorizado de servicio de Jenn-Air

(u otra agencia calificada) de acuerdo con las

instruccionesdel fabricante y todos los códigos

y requisitos de la autoridad que tenga

jurisdicción. El no seguir las instrucciones

podría causar lesiones graves o daños

materiales.La agencia calificadaque realice el

trabajo asume la responsabilidad de esta

conversión.

CP

ADVERTENCIA

LA ENERGÍA ELÉCTRICA DEBE ESTAR

APAGADA Y EL GAS CERRADO ANTES DE

REALIZAR LA CONVERSIÓN

Modelos - JGD8348BDP

Múltiple — presión necesaria del gas butano - 10² W.C.

Presión necesaria de entrada del gas butano al regulador

de presión del electrodoméstico - 11² -12² W.C.

Las campanas de orificio de conversión se adjuntan con

este modelo.

Entrada de gas butano especificada - 46,000 BTU/hora.

DP

DD

IP

JGD8348BDP

ID

QUEMADOR BTU/hora ORIFICIO PULGADAS COLOR

Izquiero posterior (IP) 7500 #66 .033 Zinc

Izquierdo delantero (ID) 7500 #66 .033 Zinc

Centro posterior (CP) 6500 #68 .031 Rojo

Centro delantero (CD) 9000 #63 .037 Azul

CD

DIÁMETRO

Derecho posterior (DP) 6500 #68 .031 Rojo

Derecho delantero (DD) 9000 #63 .037 Azul

8

PARA CONVERTIR EL ELECTRODOMÉSTICO P ARA USARSE CON GAS NATURAL

Instrucciones de conversión de gas butano

(LP) a gas natural

Si este electrodoméstico se ha convertido para uso con

gas LP, deben realizarse cada una de las siguientes

modificaciones paraconvertirla unidad nuevamente a gas

natural.

ADVERTENCIA

La conversión a gas natural debe realizarla un

contratista autorizado de servicio de Jenn-Air

(u otra agencia calificada) de acuerdo con las

instruccionesdel fabricante y todos los códigos

y requisitos de la autoridad que tenga

jurisdicción. El no seguir las instrucciones

podría causar lesiones graves o daños

materiales. La agencia calificada que realice

este trabajo asume toda la r e sponsabilidad de

dicha conversión.

ADVERTENCIA

LA ENERGÍA ELÉCTRICA DEBE ESTAR

APAGADA Y EL GAS CERRADO ANTES DE

REALIZAR LA CONVERSIÓN

DP

Modelo - JGD8348BDP

Múltiple — presión de gas natural necesaria - 5² W.C.

Presión necesaria de entrada de gas natural al regulador

de presión del electrodoméstico - 6² -7² W.C.

Gas natural especificado de entrada - 56,000 BTU/hora.

A. Coloquede nuevolas campanasde orificio. Realice los

pasos 1 al 4 dela página7. Localice seis (6) campanas

de orificio para gas natural (con los números pequeños

estampados por un lado que conservó de la unidad

original de gas natural). Página 5, ilustración “E”. Las

dos campanas marcadas con el número .0520 (orificio

#55) son para los quemadores izquierdo delantero e

izquierdo posterior. Las cuatro campanas marcadas

con el número .0595 (orificio #53) son para los dos

quemadores derechos.

Para realizar estos ajustes de conversión siga las

instrucciones e ilustraciones (“A” a la “E”) páginas

5-7.

B. Invierta la tapa del regulador de presión del

electrodoméstico(vealailustración “D”,página6). Con

el electrodoméstico instalado, el regulador de presión

está ubicado en el lado inferior derecho del

electrodoméstico en la entrada del múltiple de gas.

Identifique el tipo del regulador de presión de la unidad

y siga las instrucciones en la ilustración apropiada.

C. Ajuste la llama en bajo en cada quemador. Siga las

instrucciones para el ajuste de llama bajo de

quemadores en la página 7 para aumentar el tamaño

de la llama para hervir a fuego lento.

CP

IP

JGD8348BDP

ID

QUEMADOR BTU/hora ORIFICIO PULGADAS COLOR

Izquierdo posterior (IP) 8,000 #55 .0520 Verde

Izquierdo delantero (ID) 8,000 #55 .0520 Verde

Centro posterior (CP) 10,000 #53 .0595 Cobre

Centro delantero (CD) 10,000 #53 .0595 Cobre

Derecho posterior (DP) 10,000 #53 .0595 Cobre

Derecho delantero (DD) 10,000 #53 .0595 Cobre

CD

DIÁMETRO

DD

9

REQUISITOS MÍNIMOS DE ESPACIAMIENTO

SUPERFICIES PARA COCINAR CON PARRILLA DE GAS

Para instalar la Superficie para cocinar de módulo triple con tiro invertido en combinación con otra

superficie para cocinar con tiro invertido, debe mantenerse el espaciamiento mínimo entre las

unidades adyacentes, según se muestra, para obtener un desempeño satisfactorio.

CUALQUIER SUPERFICIE PARA

COCINAR DE TIRO INVERTIDO

SUPERFICIE PARA COCINAR PROSTYLE

(MÓDULO SENCILLO, DOBLE O TRIPLE)

CUALQUIERA DE

MÓDULO DOBLE

CUALQUIERA DE

MÓDULO SENCILLO

SUPERFICIE PARA COCINAR PROSTYLE

SUPERFICIE PARA COCINAR PROSTYLE

10

AJUSTES QUE SE REQUIEREN A LA HORA DE LA INSTALACIÓN

La instalación de este electrodoméstico debe estar en conformidad con los códigos locales, o si éstos

no existieran, con la última edición del Código Nacional de Gas Combustible ANSI Z223.1 EE.UU. o el

Código de Instalación CAN/CGA-B149 actual.

Esta estufa fue fabricada para usarse con gas natural. Si se elige usar gas LP, siga el procedimiento de

conversión a LP en las instrucciones de instalación.

Pruebe todas las conexiones externas para verificar que no haya fugas de gas. Nunca realice pruebas

de fugas de gas con una llama encendida.

Pruebe todas las conexiones eléctricas.

Ajuste los obturadores de aire para obtener una llama adecuada.

Ajuste todas las válvulas en los ajustes de llama baja.

Pruebe el sistema de ventilación para verificar la instalación correcta.

Siexiste un problemacon el sistemade tiro invertido,revisela instalaciónde losductos para asegurarse

que esté en conformidad con las especificaciones de Jenn-Air. La mayoría de los problemas con el

sistema de tiro invertido son debido a los procedimientos incorrectos de la instalación de los ductos.

Comuníquese con el instalador si el sistema de ventilación no absorbe el humo o los gases de cocción

de los cortes de carne magra.

Si persisten los problemas de ventilación, comuníquese con el contratista autorizado de servicio de

Jenn-Air.

11

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

MISE EN

SERVICE

Dimensions montrées en pouce et en centimètres

À L’INTENTION DE L’INSTALLATEUR : Veuillez laisser ces instructions avec l’appareil.

À L’INTENTION DU CONSOMMATEUR : Veuillez conserver ces instructions pour référence ultérieure.

Prostyletttt àtriplebaie

Modèle JGD8348BDP

403 WEST FOURTH STREET, NORTH D NEWTON, IA 50208,

ÉTA TS--UNIS

Plaque de cuisson à grilloir

*Le ventilateur peut être

orienté à l’horizontale ou

àlaverticaleen

desserrant les écrous qui

se trouvent autour de

l’admission du ventilateur.

Accessible à l’intérieur de

la chambre de ventilation.

VOIR PAGE 2

POUR LES

DIMENSIONS DE

LA DÉCOUPE

À CHAQUE

EXTRÉMITÉ

DU FOND

DE LA

BOÎTE DES

BRÛLEURS

EXTRÉMITÉ

DE LA

BOÎTE DES

BRÛLEURS

DÉGAGE-

MENT

MIN. DE

15 13/15²

(40.2 CM)

REQUIS

FOND DE L’ARRÊT

DE GRAISSE

VENTILATEUR

SÉLECTIONNEZ LA DÉCOUPE

POUR CONDUIT QUI CONVIENT

(VOIR LES INSTRUCTIONS DE

POSE DE CONDUITS.)

DÉTENDEUR DE

L’APPAREIL

DÉTENDEUR

DE

L’APPAREIL

BOÎTIER

GODET

D’ÉCOULE-MENT

COUVRE-FILS

INSTRUCTIONS À L’INTENTION DE L’INSTALLATEUR :

S La dimension A prévoit un dégagement minimum de 2 po (5,08 cm) par rapport au moteur à

des fins de refroidissement.

S REMARQUE : Si les conditions le permettent, un dégagement de 6 po (15,54 cm) est

recommandé afin de permettre l’accès au moteur/ventilateur à des fins de service après-vente.

S Dégagement latéral : Les grilloirs qui se trouvent à côté d’une paroi latérale doivent avoir un

dégagement minimum de 8 po (20,32 cm).

S Il doit pouvoir y avoir accès au récipient à graisse pour le vider.

LIGNES DE

DÉCOUPE(DEVANT

SEULEMENT)

DÉCOUPES DANS L’ARMOIRE ET LE COMPTOIR

OUVERTURE

EXISTANTE

(VUE DE L’AVANT)

Tel que requis pour la mise en service

ARMOIRE

OUVERTURE

EXISTANTE

*8 po (20,32 cm)

recommandés pour les

armoirespersonnalisées.

REMARQUE : UN PANNEAU DE

COMMANDE PLUS BAS EST

EXIGÉ SI CETTE DIMENSION

EST SUPÉRIEURE À 5 3/4 PO

(14,60 CM).

VOIR LA PAGE 3 POUR LE

RENFORCEMENT DE L’AVANT

DE L’ARMOIRE

Voirlessuggestions1à4concernantladécoupe page 6.

REMARQUE : Tolérance prévue de + 1/16 po

(0,16 mm) dans les dimensions de la découpe

SURFACE DE LA

VUE

DU DESSUS

DÉCOUPE DU

PROFONDEUR DU COMPTOIR

COMPTOIR

46 13/16²

(118,90 cm)

ENLEVER LES CORNIÈRES DE

SUPPORT S’IL Y A LIEU NORMALEMENT

4 ÉPAISSEURS

COMPTOIR

2

Pose d’armoires au-dessus de votre

grilloir Jenn-Air

Le dégagement horizontal minimum entre le bord de

l’appareil et des structures combustibles dépassant de la

surface de cuisson jusqu’à une hauteur de 18 po

(45,7 cm) au-dessus de la surface de cuisson est le

suivant :

1 3/4 po (4,45 cm) à l’arrière

8 po (20,32 cm) sur les côtés

REMARQUE : Ceci n’est pas le dégagement

recommandé mais le dégagement minimum possible.

Éviter l’utilisation d’armoires de rangement au-dessus dela

surface de cuisson pour éliminer les risques potentiels qui

y sont liés, tels que se pencher au-dessus de flammes pour

prendre un article dans l’armoire.

Les pointillés indiquent

l’emplacement de la hotte.

18 po

(45,7

cm).

8po

(20,3 cm).

DÉGAGEMENT

MIN.

*A = 30 po (76,2 cm) de dégagement vertical minimum

entre la surface de cuisson et les structures qui

se trouvent au-dessus de l’appareil.

B = 13 po (33,0 cm) de profondeur maximum pour les

armoires qui se trouvent au-dessus de la surface

de cuisson.

*Pour éliminer les risques de brûlure ou d’incendie en se

penchant au-dessus de surfaces brûlantes, il est

fortement conseillé d’éviter de placer des espaces de

rangement au-dessus de brûleurs ou d’éléments

chauffants de la surface de cuisson. S’il doit y avoir des

armoires au-dessus de la surface de cuisson, les

risques peuvent être réduits en posant une hotte qui

dépasse d’un minimum de 5 po (12,7 cm) du bas

des armoires.

Armoires au-dessus de la surface de

cuisson

La profondeur maximum des armoires posées au-dessus

de la surface de cuisson est de 13 po (33 cm).

PRUDENCE : CERTAINES ARMOIRES ET

CERTAINS MATÉRIAUX DE CONSTRUCTION NE

SONT PAS CONÇUS POUR SUPPORTER LA

CHALEUR PRODUITE LORS DU

FONCTIONNEMENT NORMAL D’UN APPAREIL.

UNE DÉCOLORATION OU DES DÉGÂTS TELS QUE

LA DÉLAMINATION PEUVENT SE PRODUIRE.

3

Mise en service de l’appareil

Suivre les instructions concernant les conduits fournies

avec ceux-ci avec soin.

Cet appareil est conçu pour que l’air aspiré soit toujours

rejeté à l’extérieur.

La découpe dans le comptoir, la découpe dans le devant

de l’armoire et la découpe pour le conduit doivent être

préparées conformément à l’illustration des pages 1 et 2.

Poser le panneau de commande inférieur dans la

découpe inférieure de l’armoire tel qu’indiqué, en utilisant

les vis fournies dans le paquet de visserie. (Voir la figure

1).

Vue du dessus

Figure 1

Placer l’appareil dans la découpe dans le comptoir. Le

panneau de commande principal doit chevaucher le

dessus du panneau de commande inférieur tel qu’indiqué.

(Voir la figure 2).

PANNEAU DE COMMANDE INFÉRIEURTROL

REMARQUE : Certains styles d’armoires pourront exiger

le renforcement de l’avant de l’armoire en fixant un renfort

de l’avant vers l’arrière à l’intérieur de l’armoire, sous la

boîte des brûleurs.

Poser le conduit conformément aux instructions fournies.

Les ouvertures prévues pour le conduit dans l’armoire

sont montrées sur l’illustration de la page 1. Effectuer les

raccordements à l’électricité et au gaz tel qu’indiqué

ci-dessous.

La mise en service de cet appareil doit être conforme aux

codes locaux ou, en l’absence de tels codes, avec la

norme ANSI Z.223.1, dernière édition, du National Fuel

Gas Code ou du CODE DES INSTALLATIONS B149

CAN/ACG en vigueur.

L’alimentation électrique fournie doit être de 110/220 V

alternatifs, 15 A et 60 Hz. Cet appareil est équipé d’un

cordon d’alimentation avec raccordement à la terre. Il doit

être branché dans une prise de courant reliée à la terre. Il

est recommandé que, pour plus de facilité, la prise soit

dans la zone indiquée par une région grisée sur

l’illustration. Une fois en place, l’appareil doit être relié à la

terre conformément aux codes locaux ou, en l’absence de

codes locaux, aux normes ANSI/NFPA n 70 de l’édition la

plus récente du National Electrical Code ou aux normes

CSA C22.1 du Code canadien de l’électricité, partie 1,

en vigueur.

PANNEAU DE COMMANDE

INFÉRIEURTROL

Figure 2

10 1/16 po

(25,6 cm)

46 13/16 po (118.9 cm)

Dépannage de la plaque de cuisson

Si la plaque de cuisson exige des réparations, il faudra

enlever le dessus principal avant d’enlever le panneau de

commande.

4

Raccordement de l’appareil au gaz

LE RACCORDEMENT AU GAZ DOIT ÊTRE EFFECTUÉ

PAR UN TECHNICIEN AYANT REÇU LA FORMATION

APPROPRIÉE OU PAR UN INSTALLATEUR

D’APPAREILS À GAZ. La vérification de l’absence de

fuites sera effectuée par l’installateur conformément aux

directives fournies.

Poser un robinet de gaz dans un endroit accessible de la

conduite de gaz extérieure à l’appareil afin de pouvoir

couper ou ouvrir l’alimentation en gaz de l’appareil.

Effectuer le raccordement à l’arrivée de gaz du détendeur

de cet appareil avec une conduite mâle filetée de 1/2 po

(13 mm). Utiliser une pâte à filetage résistant à l’action du

gaz GPL sur les raccords. Vérifier la présence éventuelle

de fuites au niveau de tous les joints à l’aide d’eau

savonneuse ou de tout autre moyen reconnu de détection

de fuites. Ne jamais vérifier la possibilité de fuites à l’aide

d’une flamme.

PRUDENCE : LA GARANTIE EST ANNULÉE POUR

TOUT MATÉRIEL JENN-AIR INSTALLÉ

AUTREMENT QUE TEL QUE RECOMMANDÉ PAR

LE FABRICANT. LES CAPUCHONS DE MUR ET LES

TRANSITIONS RECOMMANDÉS DOIVENT ÊTRE

UTILISÉS POUR ASSURER UNE POSE ET UN

FONCTIONNEMENT CORRECTS.

Obturateurs des cartouches du

brûleur du gril et des brûleurs de la

plaque de cuisson

(Voir les illustrations A et B)

L’obturateur d’air gauche contrôle la moitié arrière du

brûleur. L’obturateur d’air droit contrôle la moitié avant.

L’accès aux obturateurs d’air de la cartouche des brûleurs

de la plaque de cuisson se fait par les ouvertures au fond du

logement de la cartouche.

Faire coulisser les obturateurs d’air vers l’arrière ou vers

l’avant pour augmenter ou diminuer la grandeur du trou de

prise d’air. Les obturateurs d’air sont ajustés serrés et une

lame de tournevis ou des pinces à bec pourront être

nécessaires pour faire ce réglage (voir l’illustration).

Observer le changement dans l’apparence de la flamme en

fonction du mouvement de l’obturateur d’air. Le réglage est

terminé lorsque la flamme produite à plein feu est uniforme,

bleue et clairement définie. Le fait que l’obturateur soit

ajusté serré garantit qu’ilrestera correctement en placeune

fois réglé.

Obturateur du brûleur du gril et brûleur de la plaque

de cuisson

(si équipée)

ATTENTION :

INSTRUCTIONS DE MISE À LA TERRE

CET APPAREIL EST MUNI D’UNE FICHE À TROIS

BROCHES AVEC MISE À LA TERRE POUR

ASSURER LA PROTECTION CONTRE LES

RISQUES D’ÉLECTROCUTION ET DOIT ÊTRE

BRANCHÉ DIRECTEMENT DANS UNE PRISE DE

COURANT CORRECTEMENT RELIÉE À LA TERRE.

NE PAS ENLEVER NI COUPER LA BROCHE DE

TERRE DE CETTE FICHE ÉLECTRIQUE.

Réglage de l’obturateur d’air

Les obturateurs d’air de cet appareil sont réglés en usine

pour un usage avec du gaz naturel. S’ils ont besoin d’être

réglés, ou s’ils doivent être utilisés avec du GPL, les régler

comme suit :

(POUR

OUVRIR)

OUVERTURE DE

LA PRISE D’AIR

OBTURATEUR

D’AIR

INSÉRER LA LAME D’UN

TOURNEVIS DANS LA FENTE ET

LE FAIRE TOURNER EN FAISANT

LÉGÈREMENTPRESSIONPOUR

PERMETTRE À L’OBTURATEUR DE

GLISSER AVEC FACILITÉ.

(POUR

FERMER)

Illustration A

Quelquesoitlebrûleur, unobturateur d’air tropfermédonne

une flamme molle, à pointe jaune. Un obturateur d’air trop

ouvert donne une flamme qui se soulève des brûleurs. Un

obturateur d’air bien réglé donne une flamme bien définie,

nette, uniforme et bleue.

OBTURATEUR

D’AIR

Illustration B

5

Suggestions de mise en service

importantes

1. Arrondir les angles de tous les rebords des laminés

décoratifs pour éviter qu’ils ne s’écaillent.

2. Arrondir les coins de la découpe et les limer pour

assurer des rebords lisses et éviter que les coins ne se

fendillent.

3. Les rebords mal finis, les coins intérieurs non arrondis

et les endroits où il faut forcer pour permettre la mise

en place de la plaque de cuisson peuvent favoriser le

fendillement du laminé du dessus du comptoir.

4. Le dessus du comptoir doit avoir un support à une

distance maximum de 3 po (7,6 cm) de la découpe.

Quel que soit le brûleur, un obturateur d’air trop fermé

donne une flamme molle, à pointe jaune. Un

obturateur d’air trop ouvert donne une flamme qui se

soulève des brûleurs. Un obturateur d’air bien réglé

donne une flamme bien définie, nette, uniforme et

bleue.

Réglage de la flamme à feu doux

(Voir l’illustration C)

La flamme à feu doux et feu moyen des brûleurs de cet

appareil est réglée en usine pour un usage avec du gaz

naturel. Si elle a besoin d’être réglée davantage ou si

l’appareil doit utiliser du GPL, procéder comme suit :

1. Allumer le brûleur et régler le bouton de commande sur

un feu doux.

2. Retirer le bouton de commande de la tige.

PRUDENCE : NE JAMAIS UTILISER DE LAME

MÉTALLIQUE POUR FAIRE LEVIER SUR LE

BOUTON POUR L’ENLEVER. SI LE BOUTON NE

S’ENLÈVEPASFACILEMENT, GLISSERUN LINGEÀ

VAISSELLE PLIÉ SOUS LE BOUTON ET TIRER LE

LINGE À VAISSELLE VERS LE HAUT EN EXERÇANT

UNE PRESSION RÉGULIÈRE ET UNIFORME.

DANS LE SENS

HORAIRE POUR

RÉDUIRE LA

FLAMME

Illustration C

DANS LE SENS

ANTIHORAIRE POUR

AUGMENTER LA

FLAMME

Vérification de la pression

La pression maximum de l’alimentation en gaz pour le

détendeur fourni sur cet appareil est de 14 po de colonne

d’eau. La pression nécessaire pour vérifier ce détendeur

doit être d’un minimum de 6 po de colonne d’eau dans le

cas de gaz naturel et d’un minimum de 11 po de colonne

d’eau dans le cas de GPL. La plaque de cuisson est

réglée pour une pression de gaz naturel de 5 po de

colonne d’eau en usine.

L’appareil à gaz et son robinet d’alimentation doivent être

désolidarisés des conduites de gaz pendant toute

vérification de la pression à des pressions supérieures à

2

0,5 lb/po

(3,5 kPa).

L’appareil à gaz doit être coupé des conduites de gaz en

fermant son robinet de gaz individuel pendant toute

vérification de la pression dans les conduites de gaz à des

2

pressions égales ou inférieures à 0,5 lb/po

(3,5 kPa).

Conversion du détendeur de l’appareil

(Voir l’illustration D )

Cet appareil est fourni équipé d’un détendeur Maxitrol pour

appareil électroménager. Suivre les indications de

l’illustration D.

3. Insérer un tournevis à lame fine dans le creux au centre

de la tige et insérer la lame dans la fente de la vis de

réglage.

4. Tourner la vis du centre de la tige pour régler la

flamme.

. . . dans le sens horaire pour réduire la flamme.

. . . dans le sens antihoraire pour l’augmenter.

5. Remettre le bouton de réglage en place une fois le

réglage terminé.

Une flamme bien réglée sera stable, bleue et d’une

longueur minimum. Le réglage final doit être vérifié en

faisant tourner le bouton de feu doux à plein feu et vice

versa à plusieurs reprises sans que la flamme s’éteigne.

Le réglage à feu doux assure automatiquement une

flamme correcte au réglage à feu moyen.

NAT

6

DÉTENDEUR MAXITROL POUR APPAREIL

CAPUCHON ET TIGE

DE CONVERSION

MÉNAGER

GPL

NAT GPL

APPUYER VERS LE BAS SUR

LES BORDS DU DISQUE

AVEC LES DOIGTS POUR

REMETTRELATIGEEN

PLACE DANS LE CAPUCHON

FAIRE

PRESSIONSUR

LE CÔTÉ DE LA

TIGE POUR LA

RETIRER DU

CAPUCHON

Illustration D

Conversion au GPL

Cet appareil est équipé pour le gaz naturel en usine. Pour

le convertir du gaz naturel au GPL, effectuer les étapes 1

à4.

1. Enlever les capuchons d’orifice pour gaz naturel. Poser

les capuchons d’orifice à code-couleur fournis. Ils se

trouvent dans un paquet attaché à la partie extérieure

du plénum de l’appareil.

(Voir l’illustration E ci-dessous et les instructions

concernant la conversion au gaz GPL, page 8.)

2. Inverser le capuchon dans le détendeur convertible (si

l’appareil en est équipé) se trouvant à l’entrée de la

rampe à gaz.

3. Régler les obturateurs d’air de chaque brûleur de façon

à ce que la flamme ait l’apparence qui convient.

4. Régler la flamme à feu doux pour chaque brûleur en

tournant la vis de réglage au centre de chaque tige de

bouton de commande.

Pour faire ces réglages suite à la conversion, suivre les

indications et les illustrations A à E des pages 5 à 7.

IMPORTANT

Appliquer du liquide de détection de fuites non corrosif

sur tous les joints et raccords entre le robinet de la

conduite de gaz et l’appareil. Inclure les joints et

raccords de l’appareil si ceux-ci ont pu se trouver

desserrés pendant la mise en service. Vérifier les

fuites ! Si des bulles apparaissent autour des joints et

des raccords, il y a une fuite. En cas de fuite, fermer

le robinet d’alimentation de gaz, serrer les raccords,

ouvrir le robinet de gaz et revérifier s’il y a des fuites.

Ne jamais vérifier la possibilité de fuites à l’aide

d’une flamme.

Cet appareil est équipé de capuchons d’orifice percés

pour être utilisés avec du gaz naturel. Pour le convertir du

gaz naturel au GPL, insérer une clé à fourche de 1/2 po

sur la partie hexagonale du capuchon d’orifice. Tourner

dans le sens horaire pour l’enlever. Mettre les capuchons

d’orifice pour gaz naturel qui viennent d’être enlevés de

côté pour un usage ultérieur. Poser les capuchons

d’orifice à code-couleur fournis. (Voir les instructions pour

la conversion au GPL ci-dessus et page 8.) Tourner dans

le sens horaire pour mettre en place. Utiliser une clé de la

dimension indiquée sur l’illustration E.

CLÉ À FOURCHE

DE 1/2 PO

11/16²²²²

TOURNER

DANS LE SENS

HORAIRE POUR

TOURNER DANS LE

SENS ANTIHORAIRE

POUR ENLEVER

CAPUCHON D’ORIFICE

SERRER

Illustration E

Réglages de cuisson

La grandeur et le type des récipients ainsi que la quantité

et le type de nourriture dictent le réglage nécessaire pour

assurer des résultats optimums à la cuisson. Le réglage

indiqué servira de guide uniquement pendant la phase de

familiarisation avec l’appareil.

Utiliser le réglage Hi (plein feu)

pour amener rapidement les

liquides à ébullition ou pour

commencer une cuisson.

Baisser ensuite le feu et

continuer la cuisson. Ne jamais

laisserdelanourritureàcuiresur

le réglage HI (plein feu) sans

surveillance.

Le réglage Med (feu moyen)

s’utilise pour continuer la cuisson.

La nourriture ne cuit pas plus

rapidement à HI (plein feu) que

sur un réglage suffisant pour

qu’elle mijote simplement. Ne pas

oublier que l’eau bout à la même

température, que ce soit à gros

bouillons ou lorsqu’on maintient

un simple frémissement.

Utiliser le réglage LO (feu doux)

pour garder la nourriture à la

température de service, sans

qu’elle continue à cuire. La

nourriture pourra toutefois

continuer à cuire si elle est

couverte.

7

POUR CONVERTIR L’APPAREIL AU PROPANE

Conversion du gaz naturel au propane (GPL)

ATTENTION

La conversion au propane doit être effectuée

par un prestataire de service agréé Jenn-Air

(ou tout autre service qualifié) conformément

aux consignes du fabricant et à tous les codes

et exigences de toutes autorités compétentes.

La non-observation des consignes pourrait

entraîner des blessures graves ou des dégâts.

Leservicequalifiéqui effectue la conversionen

assume l’entière responsabilité.

ArC

ATTENTION

FERMER LE GAZ ET L’ÉLECTRICITÉ AVANT

DE PROCÉDER À LA CONVERSION

Modèles JGD8348BDP

Rampe - pression requise pour le gaz propane - 10 po de

colonne d’eau.

Pression requise pour l’alimentation enpropane auniveau

du détendeur -11 à 12 po de colonne d’eau.

Les capuchons d’orifice pour la conversion au propane

sont fournis avec ce modèle.

Arrivée de gaz propane nécessaire - 46 000 BTU/h.

ArD

AvD

ArG

JGD8348BDP

AvG

BRÛLEUR BTU/h ORIFICE DIAMÈTRE COULEUR

Arrière gauche (ArG) 7500 n 66 0,033 Zinc

Avant gauche (AvG) 7500 n 66 0,033 Zinc

Arrière centre (ArC) 6500 n 68 0,031 Rouge

Avant centre (AvC) 9000 n 63 0,037 Bleu

AvC

POUCES

Arrière droit (ArD) 6500 n 68 0,031 Rouge

Avant droit (AvD) 9000 n 63 0,037 Bleu

8

POUR CONVERTIR L’APPAREIL AU GAZ NATUREL

Conversion du propane (GPL) au gaz naturel

Si cet appareil a été converti au GPL, chacune des

modifications suivantes doit être effectuée pour le

reconvertir au gaz naturel.

ATTENTION

Laconversion augaznatureldoit êtreeffectuée

par un prestataire de service agréé Jenn- Air

(ou tout autre service qualifié) conformément

aux consignes du fabricant et à tous les codes

et exigences de toutes autorités compétentes.

La non-observation des consignes pourrait

entraîner des blessures graves ou des dégâts.

Leservicequalifiéqui effectue la conversionen

assume l’entière responsabilité.

ATTENTION

FERMER LE GAZ ET L’ÉLECTRICITÉ AVANT

DE PROCÉDER À LA CONVERSION

ArD

Modèle JGD8348BDP

Rampe - pression requise pour le gaz naturel - 5 po de

colonne d’eau.

Pression requise pour l’alimentation en gaz naturel au

niveau du détendeur - 6à7podecolonne d’eau.

Arrivée de gaz naturel nécessaire - 56 000 BTU/h.

A. Remplacer tous les capuchons d’orifice - Effectuer les

étapes 1 à 4 de la page 7. Localiser les six (6) orifices

(avec des chiffres en petits caractères estampés sur le

côté) provenant du modèle d’origine et mis de côté lors

de sa conversion au propane (page 5, illustration E).

Les deux capuchons portant le chiffre .0520 (orifice n

55) estampé sur le côté correspondent aux brûleurs

avant gauche et arrière gauche. Les quatrecapuchons

portantlechiffre.0595(orificen53) estampésur le côté

correspondent aux deux brûleurs de droite.

Pour faire ces réglages suite à la conversion, suivre

les indications et les illustrations A à E des pages 5 à

7.

B. Inverser le capuchon du détendeur (voir l’illustration D,

page 6). Lorsque l’appareil est en place, le détendeur

doit se trouver sur la droite du dessous de l’appareil, à

l’arrivée de la rampe à gaz. Identifier le type de

détendeur de l’appareil et suivre les instructions de

l’illustration qui convient.

C. Régler la flamme à feu doux de chaque brûleur. Suivre

les consignes de réglage de la flamme à feu doux de la

page7 pouraugmenter la flamme quisera utilisée pour

faire mijoter les aliments.

ArC

ArG

JGD8348BDP

AvG

BRÛLEUR BTU/h ORIFICE DIAMÈTRE COULEUR

Arrière gauche (ArG) 8 000 n 55 0,0520 Vert

Avant gauche (AvG) 8 000 n 55 0,0520 Vert

Arrière centre (ArC) 10 000 n 53 0,0595 Cuivre

Avant centre (AvC) 10 000 n 53 0,0595 Cuivre

Arrière droit (ArD) 10 000 n 53 0,0595 Cuivre

Avant droit (AvD) 10 000 n 53 0,0595 Cuivre

AvC

POUCES

AvD

9

ESPACEMENT MINIMUM REQUIS

PLAQUES DE CUISSON AVEC GRILLOIR

Pour poser une plaque de cuisson triple à aspiration descendante combinée à une autre plaque de

cuisson à aspiration descendante, l’espace minimum entre les appareils adjacents doit être tel

qu’indiqué pour un fonctionnement optimum.

TOUTEPLAQUEDECUISSON

À ASPIRATION DESCENDANTE

PLAQUE DE CUISSON PROSTYLE

(BAIE SIMPLE, DOUBLE OU TRIPLE)

TOUTE DOUBLE BAIE

TOUTE BAIE SIMPLE

PLAQUE DE CUISSON PROSTYLE

PLAQUE DE CUISSON PROSTYLE

10

RÉGLAGES REQUIS LORS DE LA MISE EN SERVICE

La mise en service de cet appareil doitêtre conforme aux codes locaux ou, en l’absence de telscodes,

avec la norme ANSI Z223.1, dernière édition, du National Fuel Gas Code ou avec le code de mise en

service CAN/CGA-B149 en vigueur.

Cetappareilestconçupourfonctionneraugaznaturel.S’ildoitêtreutilisé avecdu GPL,suivre la méthode

de conversion au GPL qui se trouve dans les instructions de mise en service.

Vérifier qu’il n’y a pas de fuite au niveau des raccords externes. Ne jamais vérifier la possibilité de fuites

à l’aide d’une flamme.

Vérifier toutes les connexions électriques.

Régler tous les obturateurs pour obtenir une flamme appropriée.

Régler tous les robinets de réglage à feu doux.

Vérifier le système d’aspiration pour s’assurer de sa bonne mise en service.

S’ilse présente un problèmeau niveau de l’aspiration descendante,vérifierque la posedes conduitsest

bien conforme aux caractéristiques techniques de Jenn-Air. La plupart des problèmes rencontrés au

niveau de l’aspiration descendante sont dus à de mauvaises méthodes de pose des conduits.

Contacter l’installateur si le système d’aspiration descendante n’évacue pas la fumée ou les odeurs de

cuisson de pièces de viande dont l’excès de gras a été enlevé.

Si le problème d’évacuation persiste, contacter votre prestataire de service après-vente agréé Jenn-Air.

11

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208, ÉTATS- UNIS

Loading...

Loading...