Page 1

CONVERTIBLEGAS GRILL

COOKTOPSERIES

JGD8130 & JGD8345

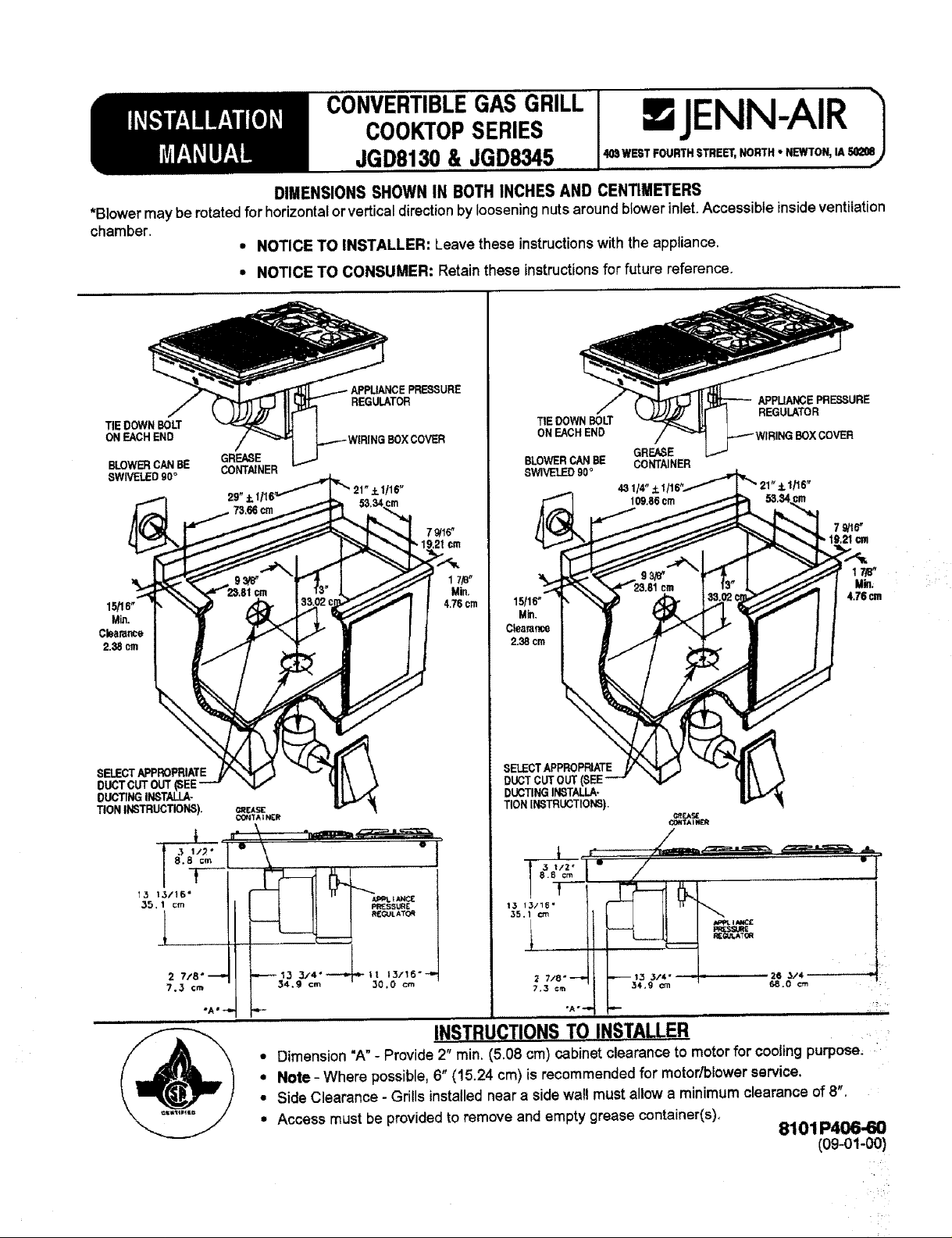

DIMENSIONS SHOWN IN BOTH INCHES AND CENTIMETERS

*Blowermaybe rotated for horizontal or verticaldirection by looseningnuts aroundblowerinlet. Accessible insideventilation

chamber.

• NOTICE TO INSTALLER: Leave these instructions with the appliance.

• NOTICE TO CONSUMER: Retain these instructions for future reference.

JENN-AIR

REGULATOR

TIEDOWNBOLT

ON EACHEND BOXCOVER

BLOWERCANBE CONTAINER

SWIVELED90°

Min.

Cbarar_e

2.38cm

SELECTAPPROPRIATE

DUCTCUTOUT(SEE

DUCTINGINSTALLA-

TIONINSTRUCTIONS). _EAS[

GREASE

29"_1/

CONTA tNER

21"+1116"

7Q/16"

TtEDOWNBOLT

ONEACHEND

BLOWERCANBE CONTAINER

SWIVELED90'=

SELECTAPPROPRIATE

DUCTCUTOUT

DUCTINGINSTALLA-

TIONINSTRUCTIONS).

GREASE

43 114" +lt 21" _- 1/16"

COH_AI_

APPUANCEPRF.SSURE

REGULATOR

79/16"

19.21cm

17_"

Min.

4.76cm

2 7/8 °_ _13 3/4"--,.*_.|t 13/115-_..

7.3 Cm 34.9 cm 30.0 cm

• Dimension"A"- Provide 2" rain. (5.08 cm)cabinetclearance to motorfor coolingpurpose,

• Note - Where possible,6" (15.24 cm) isrecommendedfor motor/blowerservice.

• Side Clearance - Grills installednear a side wall must allow a minimum clearance of8".

• Access must be providedto remove and empty grease container(s),

INSTRUCTIONSTO INSTALLER

8101P406-60

(o9-ol-oO)

/

Page 2

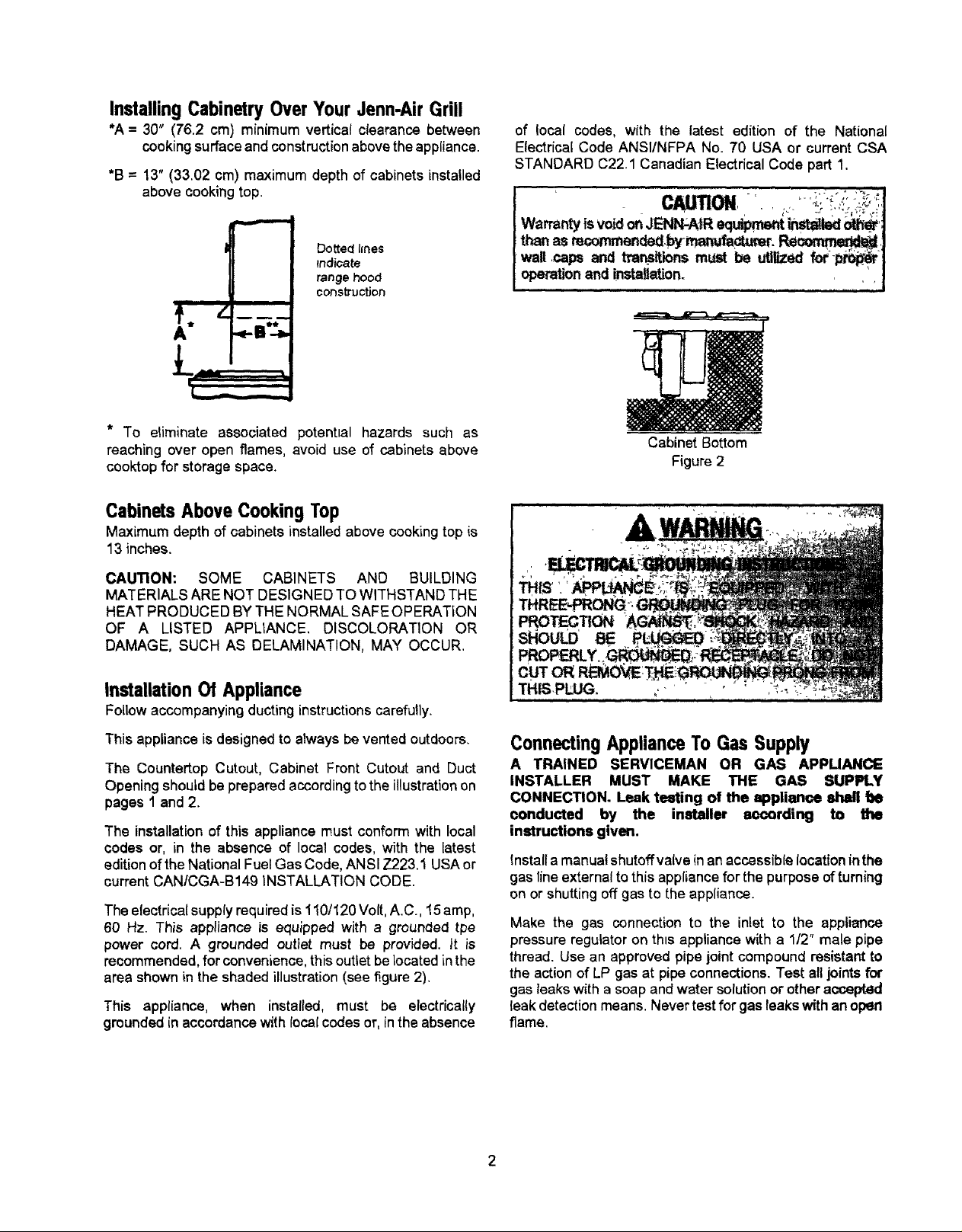

Installing Cabinetry Over Your Jenn-Air Grill

*A = 30" (76.2 cm) minimum verticat clearance between

cooking surface and construction above the appliance.

*B = 13" (33.02 cm) maximum depth of cabinets installed

above cooking top.

Do_edl_nes

tnd_a_

_nge hood

i

construction

* ÷B*_.

(,....-.,_.-_

of local codes, with the latest edition of the National

Electrical Code ANSI/NFPA No. 70 USA or current CSA

STANDARD C22.1 Canadian Electrical Code part 1.

Warranty Isvoid onJEN_AIR equ_rne_ _ _'_l

tt-_ asr_x_nmen_.bymar_fa_. _,]

walt,capsand tr__ _,ns must be _Uzed fot--_ J

operationand installation. ,

f ............ ,:1

* To eliminate associated potential hazards such as

reaching over open flames, avoid use of cabinets above

cooktop for storage space.

Cabinets Above Cooking Top

Maximum depth of cabinets installed above cooking top is

13 inches.

CAUTION: SOME CABINETS AND BUILDING

MATERIALS ARE NOT DESIGNED TO WITHSTAND THE

HEAT PRODUCED BYTHE NORMAL SAFE OPERATION

OF A LISTED APPLIANCE. DISCOLORATION OR

DAMAGE, SUCH AS DELAMINATION, MAY OCCUR.

Installation Of Appliance

Follow accompanying ducting instructions carefully.

This appliance is designed to alwaysbe vented outdoors,

The Countertop Cutout, Cabinet Front Cutout and Duct

Opening should be prepared according to the illustration on

pages 1 and 2.

The installation of this appliance must conform with local

codes or, in the absence of local codes, with the latest

edition of the National Fuel Gas Code, ANSI Z223.1 USA or

current CAN/CGA-B149 INSTALLATION CODE.

The electricalsupplyrequired is 110/120 Volt, A.C., 15 amp,

60 Hz. This appliance is equipped with a grounded tpe

power cord. A grounded outlet must be provided, it is

recommended, for convenience, this outlet be located inthe

area shown in the shaded illustration (see figure 2).

This appliance, when installed, must be electrically

grounded in accordance with local codes or, in the absence

Cabinet Bottom

Figure 2

ConnectingApplianceTo Gas Supply

A TRAINED SERVICEMAN OR GAS APPUANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak teating of the appliance shall f_e

oonducted by the installer aoeording to rite

instructions given.

install a manual shutoffvalve in an accessiblelocation inthe

gas line external to this appliance for the purpose of turning

on or shutting off gas to the appliance.

Make the gas connection to the inlet to the appliance

pressure regulator on this appliancewith a 112" male pipe

thread. Use an approved pipe joint compound resistant to

the action of LP gas at pipe connections. Test alljoints for

gas leaks with a soap and water solution or other accepted

leak detection means. Never test for gas leaks with an open

flame.

Page 3

InstructionsTo Installer

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2, Radius corners of cutout and file to insure smooth

edges and prevent corner cracking. Recommend

1/4" or 3/8" diameter drill in each corner,

3. Rough edges, inside comers which have not been

rounded and forced fit can contribute to cracking of the

counter top laminate.

4. Countertop must be supported within 3" of cutout.

Minimum horizontal clearance between the edge of the

appliance and combustible construction extending from the

cookingsurface to 18" (45,7 cm) above the cooking surface

is:

15116"(2.38 cm) at rear

8" at sides

This is not the recommended clearance, but minimum

allowable clearance.

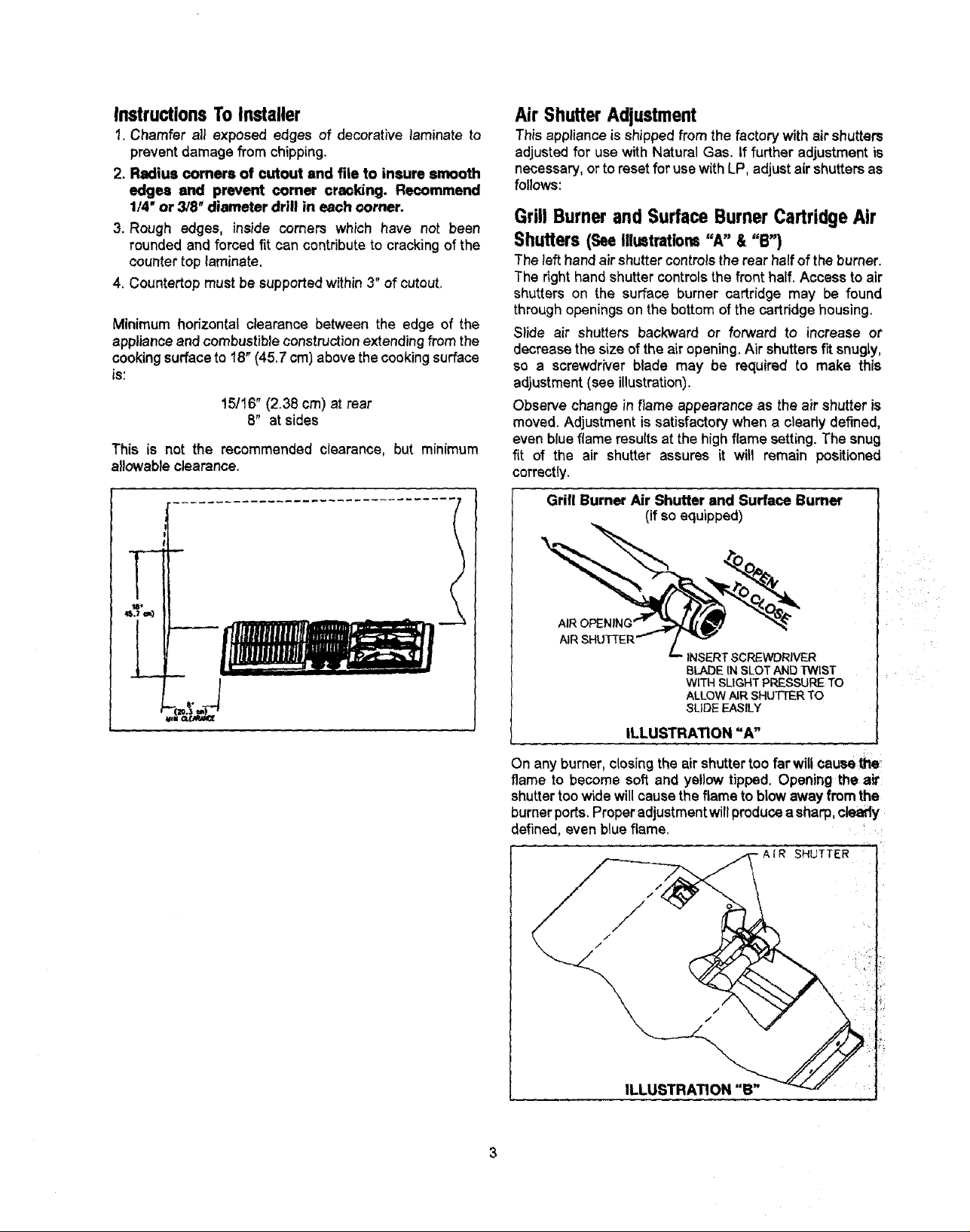

Nr Shutter Adjustment

This appliance is shipped from the factory with air shutters

adjusted for use with N=ural Gas. If further adjustment is

necessary, or to reset for use with LP, adjust air shutters as

follows:

Grill Burner and Surface Burner Cartridge Air

Shutters (SeeIllustrations"A" &"B")

The lefthand air shuttercontrols the rear half of the burner.

The right hand shutter controlsthe front half. Access to air

shutters on the surface burner cartridge may be found

through openings on the bottom of the cartridge housing.

Slide air shutters backward or forward to increase or

decrease the size of the air opening. Air shutters fit snugly,

so a screwdriver blade may be required to make this

adjustment (see illustration).

Observe change in flame appearance as the air shutter is

moved. Adjustment is satisfactory when a cleady defined,

even blue flame results at the high flame setting. The snug

fit of the air shutter assures it will remain positioned

correctly.

Grill Burner Air Shutter end Surface Bumer

(if so equipped)

AIR

INSERT SCREWDRIVER

BLADE IN SLOT AND TWIST

WITH SLIGHT PRESSURE TO

ALLOW AIR SHUTTER TO

SLIDE EASILY

ILLUSTRATION "A"

On any burner, closingthe air shuttertoo far wiltcausethe

flame to become soft and yellow tipped. Opening the air

shutter too wide will causethe flame to blow away from the

burner ports. Proper adjustmentwill produce a sharp,clearly

defined, even blue flame.

-A{R SHUTTER

ILLUSTRATION "B"

Page 4

Low Flame Adjustment (SeeIllustration"C")

This appliance is shipped from the factory with low and

mediumflame settingsadjustedforusewithNaturalGas. If

furtheradjustment is necessary, orto readjustforusewith

LP, proceed as follows:

1. Light burner and set control knob for low flame.

2. Remove control knob from valve stem.

, CAUTION

_EVER_USE A METAL BLADE TO PRY KNOB OFF.

LE_"CAN_DT BE EASILY REMOVED, TUCK THE

_FA_ -C-LOTHDISHTOWEL UNDER THE,KNOB

_D._LoTHE TOWEL UPWARD WITH STEADY,

i i i i i '11 i i i ii ,,, " i ' if

3. Inserta slender, thin-bladescrewdriver into the recess at

center of valve stem and engage blade w_th slot in

adjusting screw.

4. Turn center stem adjusting screw to set flame size.

• clockwise to reduce.

• counterclockwise to increase.

5, Replace control knob when adjustment is completed.

Proper adjustmentwillproducea stable, steady blue flame

of minimum size. The final adjustmentshould be checked by

turning knob from high to low several times without

extinguishing the flame

PressureTesting

The maximum gas supply pressure for the appliance

pressure regulator suppliedonthis appliance is 14" W.C.

The test pressure for checking this appliance pressure

regulator must be at least 6" W.C. for Natural Gas, and at

least 11" W.C for LP. It is shipped from the factory set for

Natural Gas at 5" W.C. output pressure

This appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 112"PSIG (3.5 k Pa)

This appliance must be isolated from the gas supply piping

system by closingits individual manual shutoffvalve during

any pressuretesting of the gas supply piping system at test

pressures equal to or less than 112"PSIG (3.5 k Pa).

Appliance Pressure Regulator Conversion

(See Illustration"D")

This unit is supplied with a Maxitrol Appliance Pressure

Regulator Follow the instructions in illustration=D".

MAXITROL APPLIANCE PRESSURE REGULATOR

APPLY DOWhhNARD

FINGER PRESSURE

This adjustment, at low setting, willautomatically provide the

proper flame size at medium setting.

COUNTERCLOCKWISE TO

INCREASE FLAME SIZE

CLOCKWISE

TO REDUCE

FLAME SIZE

VALVE

ILLUSTRATION "C"

N.A,_"AN D PJN._'" NAT_I'- !ilEG_EWR_RETO

ILLUSTRATION "D"

Page 5

ConversionToLP Gas

This applianceis shippedfrom the factory equipped for use

with Natural Gas. To convert it from Natural Gasfor usewith

LP Gas, perform steps 1 through 4.

1. Remove natural gas orifice hoods. Install color coded

orifice hoods supplied, located in a pack attached to the

outer plenum area of this appliance. (See illustration "E"

below, and LP Gas Conversion Instructions on page 6).

2. Invert cap in convertible appliance pressure regulator (if

so equipped) located at entrance to gas manifold.

3. Adjust air shutterson individual burners for proper flame

appearance.

4. Adjust low flame setting at each burner by turning

adjustment screw in center of valve stem.

To make these conversion adjustments follow the

instructions and illustrations ("A" through "E" on

pages 3 - 4).

iApply a non-corrosive leak detection fluid to alljoints and

fittings in the gas connection between the supply fine

shut-off valve and the range. Include gas fittings and

joints in the range if connections were disturbed during

installation. Check for leaks! Bubbles appearing around

fittings and connections will indicate a leak. If a leak

appears, turn off supply hnegas shut-off valve and retest

for leaks. Never test for gas leaks with an open flame.

This applianceis shippedfrom the factorywith orifice hoods

ddlledfor usewithNatural Gas. Toconvertfrom Natural Gas

toLP,applya 1/2"open-endwrenchto hexsectionoforifice

hood.TURN COUNTERCLOCKWISE TO REMOVE. Save

the Natural Gas orifice hoods just removed from this

appliance for future use. Instatl color coded odfice hoods

supplied. (See LP Gas Conversion Instructions above and

page 6). TURN CLOCKWISE TO INSTALL. Hold dimension

specifiedin Illustration"E".

I_OPEN END

WRENCH

TURN

CLOCKWISE

TURN

COUNTERCLOCKWISE

TO REMOVE ORIFICE HOOD

iLLUSTRATION "E"

TO TIGHTEN

ControlSettings

The size and type ofcookwara and the amount and type of

food beingcookedwi(Iinfluence the settingneeded forbest

cookingresults. The setting indicated should serve as a

guide whileyou become familiar with your cooktop.

Use the HI flame setting to

quickly bringfoods toa boilor

to begin a cooking operation.

Then reduce to a lower

setting to continue cooking.

Never leave food unattended

over a HI flame setting.

Mad setting is used to

continue a cooking opera-

tion. Food will not cook any

faster when a HI flame

setting is used than that is

needed to maintain a gentle

boil. Remember, water boils

at the same temperature

whether boiling gently or

vigorous},/.

Use Lo setting to keep food

at serving temperatures

withoutfurther cooking. You

may find that some cooking

may take place if the

cookware is covered.

|

I

Minimum Spacing Requirement

Convertible Gas Cooktops

For installing a Double Bay Downdraft

Cooktop in combination with another

Downdraft Cooktop, the minimum spacing

between adjacent units must be provided, as

shown, for satisfactoryperformance.

DOUBLE BAY

DOUBLE BAY

Page 6

TO CONVERTAPPLIANCEFORUSE WITH PROPANEGAS

Natural Gas To Propane Gas (LP) ConversionInstructions

...,, .

F.LECTmCAL e, S.UST

__ Authorized Service Contractor (or

otherqualifiedagency) in accordancewith the

_man_s:!nstructlons anda, codesand

='_uL_'n_, ,of _the , authority having

u_o_ Failure to follow instructions could

.,_ult_ serious "injury or property damage. The

_ualif!_ agency performing this work assumes

responsibility for this conversion.

r

Models - JGD8130 & JGD8345 Series

Manifold - Propane Gas pressure required - 10" W.C.

Incoming Propane Gas pressure required to appliance

pressureregulator- 11" - 12" W,C.

Propane Gas conversionorifice hoods are suppliedwith

these models•

Propane Gas input specified - JGD8130/JGD8345 -

33,000 BTUthr / 51,000 BTU/hr.

TURNEDOFFPRIOR.TOC0¢__:' r_,

TIE DOWN

BOLT ON

EACH END

GREASE

CONTAINER

®

REGULATOR

BLOWERCANBE

SWIVELED90°

JGD8345(Shown)

INCHES

BURNER BTU/hr ORIFICE DIAMETER COLOR

Left Rear(LR) 7,500 #66 .0330 Zinc

Left Front (LF) 7,500 #66 .0330 Zinc

Right Rear (RR) 9,000 #63 .0310 Blue

Right Front (RF) 9,000 #63 .0370 Blue

Center Rear (CR) 9,000 #63 .0370 Blue

Center Front (CF) 9,000 #63 .0370 Blue

Page 7

TO CONVERTAPPLIANCEFOR USEWITH NATURALGAS

Propane Gas (LP) To Natural Gas

Conversion Instructions

If this appliance has been convertedfor usewith LP Gas,

each of the following modifications must be performed to

convert the unit back to Natural Gas

'_Natur_GascOnverslonistobeperformed,bya

3e_.ir /Authorized Service Contractor (or

_,er:qua!ifiedagency) in accordancewiththe

__._s instructionsandallcodesand

_Ve_l=_metlts_ :-of ,the authority , having

_dsdtcti0p,' F_Um to follow instructions could

__i_ury rOrproperty damage. The

___o_ng t_ work_ornes

o , -

'__"RAJmv'GASrareSTeE

Models - JGD8130 & JGD8345 Series

Manifold - Natural Gas pressure required - 5" W.C.

Incoming Natural Gas pressure required to appliance

pressure regulator - 6" - 7" W.C.

Natural Gas input specified, Model JGD8130/JGD8345 -

36,000 BTU/hr / 56,000 BTU/hr.

A. Replace al!orificehoods- Perform steps 1through 4 on

page4 Locatethe (4)four or (2)two Natural Gas hoods

(with small numbers stamped on their sides) saved

from the original Natural Gas unit. Page 4 Illustration

"E". The two hoods with .0520 (#55 orifice) stamped on

them are for the left front and left rear burners. The two

hoods with the .0550 (#54 odfice) stamped on them are

for the two right burners.

To make these conversion adjustments follow the

instructions and illustrations ("A" through "E") pages

3 and 4.

B. invert cap in appliance pressure regulator (see

Illustration "D"). With the appliance installed, the

appliance pressure regulator is located on the center

underside of the appliance at the inlet to the gas

manifold. Identify the type of appliance pressure

regulator on the unit and follow the instructionsin the

appropriate Illustration.

C. Adjust low flame setbng for each bumer. Follow the

instructions for burner low flame adjustment on page 4

to increasethe simmerflame size.

JGD8345 (Shown)

BURNER BTU/hr ORIFICE DIAMETER COLOR

Left Rear (LR) 8,000 #55 .0520 Brass

Left Front(LF) 8,000 #55 0520 Brass

Right Rear (RR) 10,000 #54 .0550 Brass

RightFront (RF) 10,000 #54 .0550 Brass

Center Rear (CR) 10,000 #54 .0550 Brass

Center Front (CF) 10,000 #54 .0550 Brass

TIEDOWN

BOLTON

EACHEND

GREA3E

CONTAINER

®

REGULATOR

INCHES

PRESSURE

BLOWERCANBE

SWIVELED90o

Page 8

REQUIREDADJUSTMENTSAT TIME OF INSTALLATION

The installation of this appliance must conform with local codes, or in the absence of local codes, with

the latest edition of the National Fuel Gas CodeANSI Z223.1 USA or current CAN/CGA-B149 Installation

Code.

-'-']This range was manufactured for use with Natural Gas. If LP gas is the fuel of choice, follow the conversion

to LP procedure found in the installation instructions.

----] Test all external connections gas leaks. Never test for gas leaks with an open flame.

----] Test all electrical connections.

Adjust all air shutters for proper flame.

Adjust all valves for low flame settings.

Test the ventilation system for proper inst_llation.

lf a problem exists with the downdraft system, check the ducting installation to make sure it conforms tc

the Jenn-Air specifications. Most downdraft system problems are attributed to poor ducting practices.

for

Contact your installer if the ventilation system will not remove smoke or cooking fumes from well trimmed

cuts of meat.

If ventilation problems persist contact your authorized Jenn-Air Service Contractor.

ZJENN-AIR

4_ WEST FOURTH STREET, NORTH • NEWTON, IA 50208

Loading...

Loading...