Jenn-Air JGD8130, JGD8345 User Manual 2

INSTALLATION

CO.VERT,BLEGASGRILL JENN-AIR

MANUAL

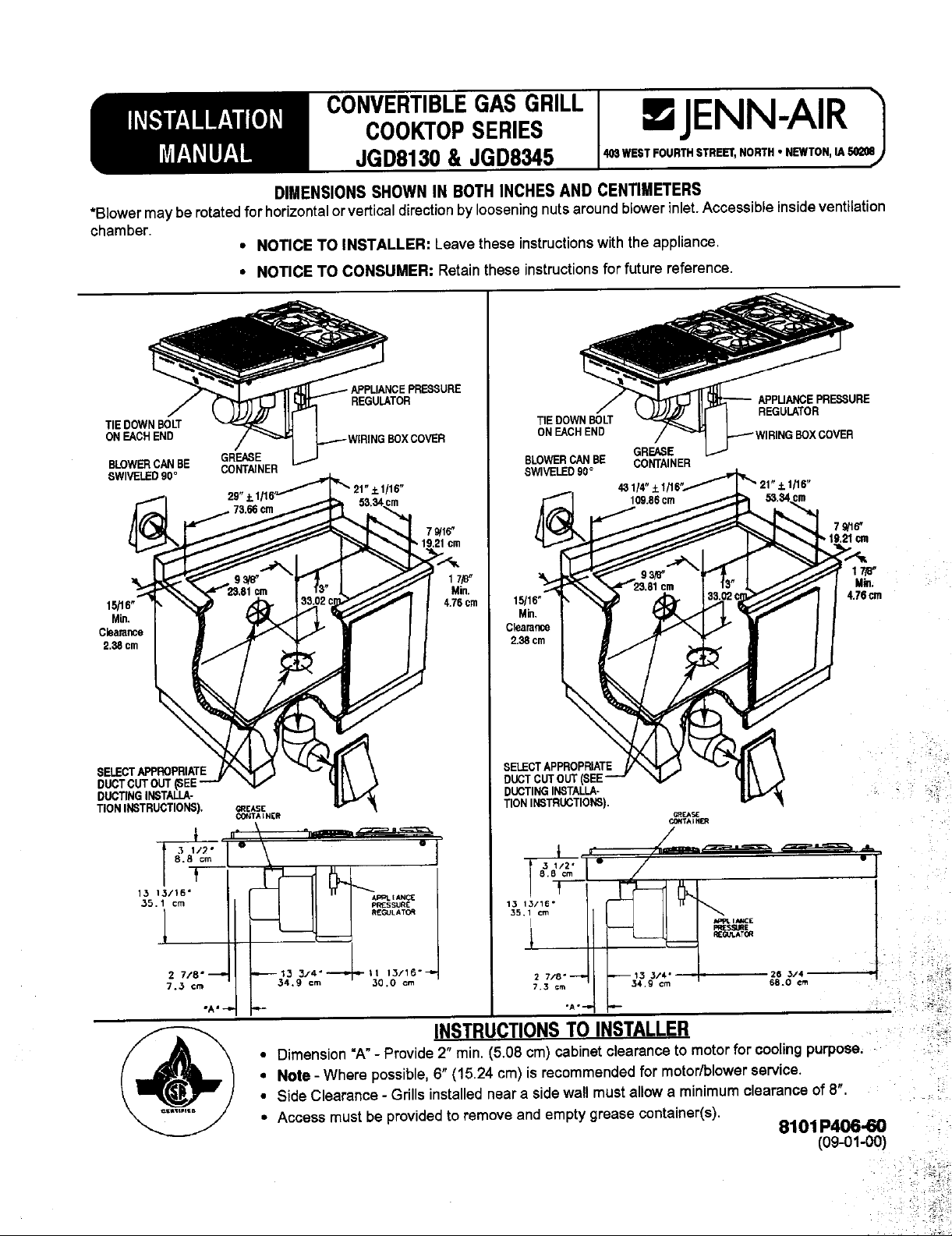

DIMENSIONSSHOWNIN BOTHINCHESANDCENTIMETERS

*Blowermayberotatedforhorizontalorverticaldirectionbylooseningnutsaroundblowerinlet.Accessibleinsideventilation

chamber.

• NOTICETO INSTALLER:Leavetheseinstructionswiththeappliance.

• NOTICETO CONSUMER:Retaintheseinstructionsforfuturereference.

JGD8130&JGD8345

COOKTOPSERIES

REGULATOR -- APPUANCEPRESSURE

TIEDOWNBOLT TIEDOWNBOLT

ONEACHEND ONEACHEND ,OVER

BLOWERCANBE GREASE BLOWERCANBE CONTAINER

SWIVELED90° CONTAINER _WIVELED90°

29".t.1/ 431/4":i 1/16"

79/16" 7_6"

• 19.21cm =.19.21om

Min. Min.

Clearance Clearance

2.38cm 2.38cm

SELECTAPPROPRIATE SELECTAPPROPRIATE

DUCTCUTOUT DUCTCUTOUT4

DUCTINGINSTALl.A- DUCTINGINSTALLA-

TIONINSTRUCTIONS). TIONINSTRUCTIONS).

.3 1/_ ° 0 0 _ , It....... =_--'="r "_--=--_"

15/16" 4.76cm

GREASE

_EA_,E

REGULATOR

Min.

_5.11_ ,_g_ ,3 ,_,,_-

27/8" =" "- 133/4" L J tl 13/16 °--m

7.3 ¢m ._4.9 cm ]O,O cm 7.327/8"_¢m _1334.93/4"cm I 68.0263/4¢m " _ _-_!

35,1 cm

• Dimension"A"- Provide2" rain.(5.08cm)cabinetclearancetomotorforcoolingpurpose.

• Note-Wherepossible,6" (15.24cm)isrecommendedformotor/blowerservice.

• SideClearance-Grillsinstalledneara sidewallmustallowaminimumclearanceof 8".

• Accessmustbeprovidedtoremoveandemptygreasecontainer(s).

INSTRUCTIONSTOINSTALLER

8101 P406..60

(09-01-00)

L

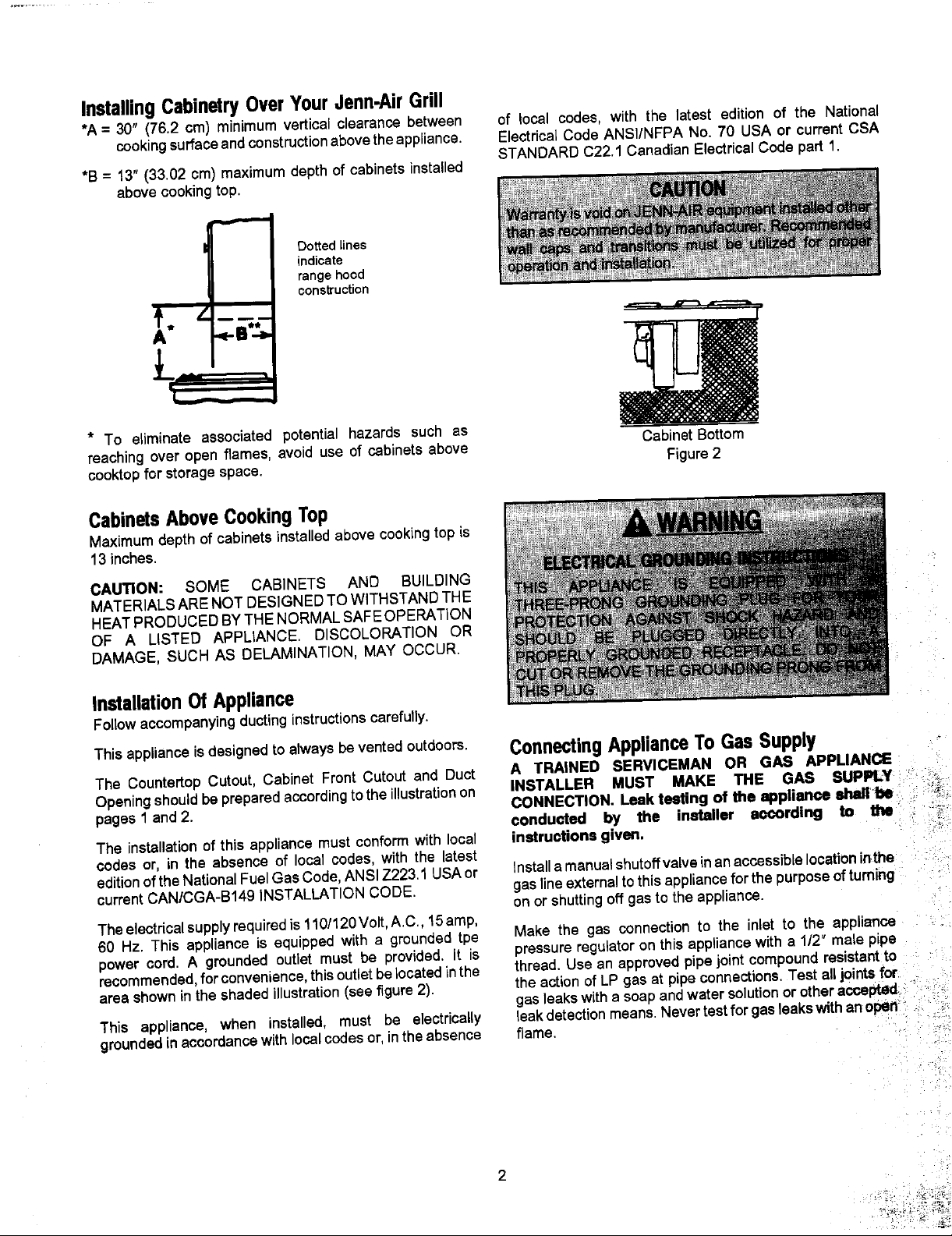

InstallingCabinetryOverYourJenn.AirGrill

*A = 30" (76.2 ¢m) minimum vertical clearance between of local codes, with the latest edition of the National

cookingsurfaceandconstruction above theappliance. Electrical Code ANSI/NFPA No. 70 USA or currant CSA

*B = 13" (33.02 cm) maximum depth of cabinets installed

above cooking top.

STANDARD C22.1 Canadian ElectricalCode part 1.

I Dottedlines

' rangehood

i construction

* To eliminate associated potential hazards such as

reaching over open flames, avoid use of cabinets above Cabinet Bottom

cooktop for storage space. Figure 2

indicate

CabinetsAboveCookingTop

Maximum depth of cabinets installed above cooking top is

13 inches.

CAUTION: SOME CABINETS AND BUILDING

MATERIALS ARE NOT DESIGNED TOWITHSTAND THE

HEAT PRODUCED BY THE NORMAL SAFE OPERATION

OF A LISTED APPLIANCE. DISCOLORATION OR

DAMAGE, SUCH AS DELAMINATION, MAY OCCUR.

InstallationOfAppliance

Followaccompanyingducting instructionscarefully.

This appliance isdesigned to always be vented outdoors. ConnectingApplianceToGasSupply

The Countertop Cutout, Cabinet Front Cutout and Duct A TRAINED SERVICEMAN OR GAS APPLIANCE

Openingshouldbepreparedaccordingtotheillustrationon INSTALLER MUST MAKE THE GAS SUPPLY _ - ._

pages 1 and 2. CONNECTION. Leak testing of the appliance _1"_ . ''_

The installationof this appliancemust conform with local instructions given.

codes or, in the absence of local codes, with the latest

editionoftheNationalFuelGas Code,ANSI Z223.1 USA or Installa manualshutoffvalve inanaccessiblelocationinthe

currentCAN/CGA-B149 )NSTALLATION CODE. gas lineexternaltothisapplianceforthe purposeofturning

Theelectricalsupplyrequiredis 110/120 Volt,A.C., 15amp,

60 Hz. This appliance is equipped with a grounded tpe Make the gas connection to the inlet to the appliance

power cord. A grounded outlet must be provided. It is pressure regulator on thisappliancewith a 1/2" male p_pe

recommended, for convenience, this outlet be located inthe thread. Use an approved pipe joint compound resistant to

area shown in the shaded illustration (see figure 2). the action of LP gas at pipe connections.Test all joints for

This appliance, when installed, must be electrically leak detection means. Never test for gas leakswith an opeIT" .. ::

groundedin accordance with localcodes or, in the absence flame....

conducted by the installer according to the _ -7

on orshuttingoffgas to theappliance.

gas leaks with a soap and water solution or other accepted

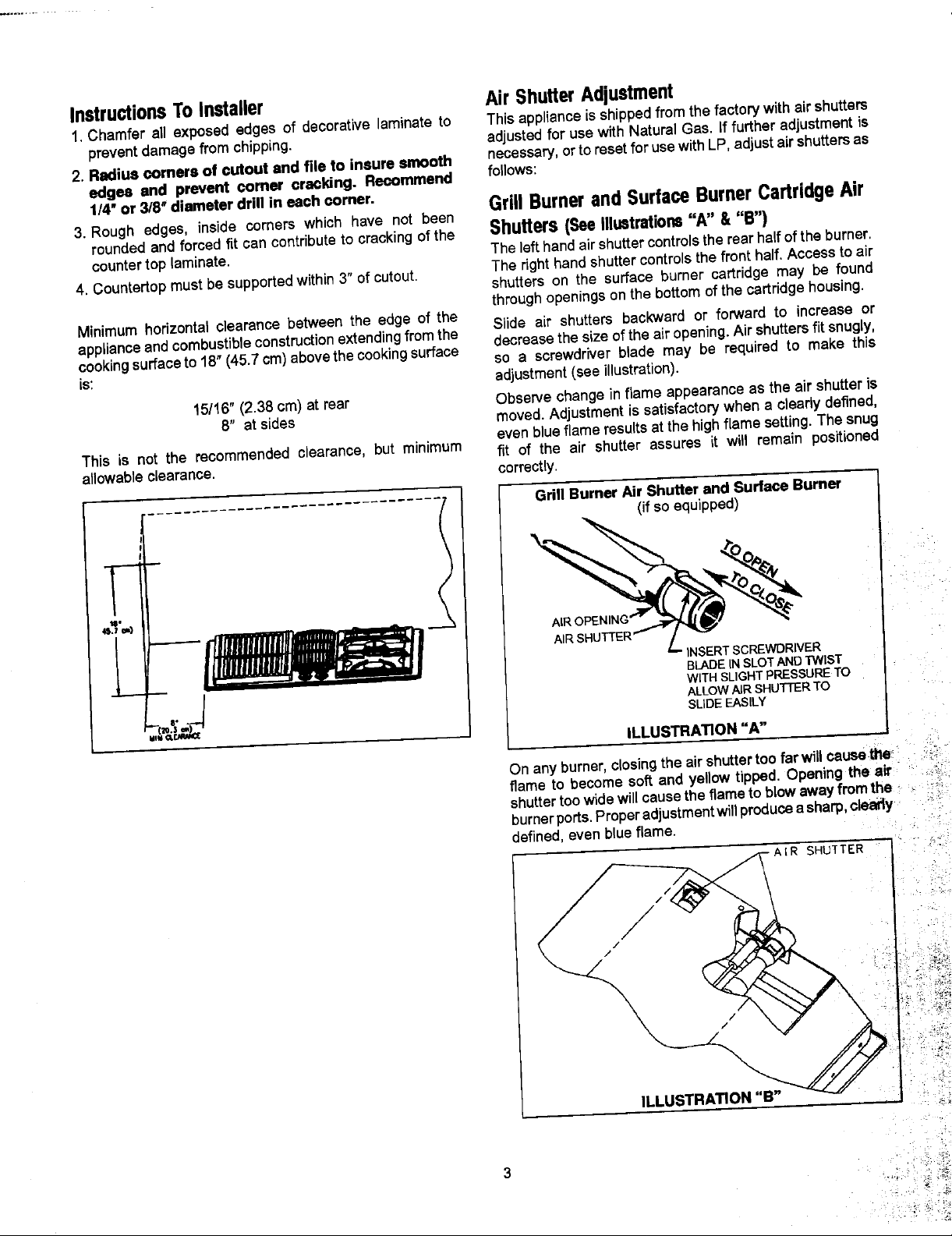

InstructionsToInstaller AirShutterAdjustment

1.Chamfer all exposed edges of decorative laminate to This appliance isshippedfrom the factory with air shutters

prevent damage from chipping, adjusted for use with Natural Gas. If further adjustment is

2. Radius corners of outout and file to insure smooth necessary,or to resetfor usewith LP, adjustair shuttersas

edges and prevent corner cracking. Recommend follows:

1/4" or 3/8" diameter drill in each corner, GrillBurnerandSurfaceBurnerCartridgeAir

3. Rough edges, inside comers which have not been

rounded and forced fit can contribute to crackingof the Shutters(SeeIllustrations"A" &"B')

counter top laminate. The left handair shuttercontrolstherear halfof the burner,

4, Countertopmustbe supportedw(thin3" of cutout. The right handshuttercontrolsthe fronthalf. Accesstoair

Minimum horizontal clearance between the edge of the

appliance and combustible construction extending from the decreasethe size of the air opening. Air shutters fit snugly,

cookingsurface to 18" (45.7 cm)above the cookingsurface so a screwdriver blade may be required to make this

is: adjustment (see illustration).

15/16" (2.38 cm) at rear Observe change in flame appearance as the air shutter is

8" at sides moved. Adjustment is satisfactory when a cleady defined,

This is not the recommended clearance, but minimum fit of the air shutter assures it will remain positioned

allowable clearance, correctly.

j'"- (if SOequipped)

shutters on the surface burner cartridge may be found

throughopeningson the bottomof the certridgehousing.

Slide air shutters backward or forward to increase or

even blue flame resultsat the high flame setting. The snug

,.o

............................. t Grill Burner Air Shutter and Surface Burner

BLADE IN SLOT AND TWIST

So

J WITH SLIGHT PRESSURE TO

ILLUSTRATION "A"

On any burner, closing the air shuttertoo farwildcause tile- _:i'

flame to become soft and yellow tipped. Opening the air _

shuttertoowidewillcausethe flameto blowaway fromthe - .:

burner ports.Properadjustmentwillproduceasharp,clearly "

defined, even blue flame.

ALLOW AIR SHUTTER TO

ILLUSTRATION _ _'_-"//

Loading...

Loading...