Jenn-Air JES9750CAB00, JES9750CAB01, JES9750CAS00, JES9750CAS01, JES9750CAS02 Installation Guide

...

_IENN-AIRo

INSTALLATIONINSTRUCTIONS

ELECTRICDOWNDRAFTSLIDE-INRANGES

INSTRUCTI(_NSD'INSTA.LI_TION

DESCUISINIERESELECTRIQUEA EVACUATION

DESCENDANTEENCASTRABLE

Table of Contents/Table des mati_res

RANGE SAFETY ............................................................................. 2

INSTALLATION REQUIREMENTS ................................................ 3

Tools and Parts ............................................................................ 3

Location Requirements ................................................................ 3

Venting Requirements .................................................................. 5

Venting Methods .......................................................................... 5

Calculating Vent System Length .................................................. 6

Electrical Requirements - U.S.A. Only ......................................... 7

Electrical Requirements - Canada Only ....................................... 8

Countertop Preparation ............................................................... 8

INSTALLATION INSTRUCTIONS .................................................. 9

Unpack Range .............................................................................. 9

Adjust Leveling Legs .................................................................... 9

Install Anti-Tip Bracket ................................................................. 9

Install Downdraft System ........................................................... 10

Electrical Connection - U.S.A. Only ........................................... 14

Connect Range to Downdraft System ....................................... 19

Complete Installation ................................................................. 21

Moving the Range ...................................................................... 21

SI_CURITI_ DE LA CUISINII=RE ................................................... 23

EXIGENCES D'INSTALLATION ................................................... 24

Outils et pieces ........................................................................... 24

Exigences d'emplacement ......................................................... 24

Exigences concernant I'evacuation ........................................... 26

Methodes d'evacuation .............................................................. 27

Calcul de la Iongueur effective du circuit d'evacuation ............. 28

Specifications electriques .......................................................... 29

Preparation du plan de travail .................................................... 29

INSTRUCTIONS D'INSTALLATION ............................................. 30

Deballage de la cuisiniere .......................................................... 30

Reglage des pieds de nivellement ............................................. 30

Installation de la bride antibasculement .................................... 31

Installation du circuit d'evacuation par le bas ........................... 31

Raccordement de la cuisiniere au circuit d'evacuation

par le bas .................................................................................... 35

Achever I'installation .................................................................. 37

Deplacement de la cuisiniere ..................................................... 38

iMPORTANT:

Save for local electrical inspector's use.

iMPORTANT:

,&,conserver pour consultation par I'inspecteur local des installations 61ectriques.

W10253462A

RANGESAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

2

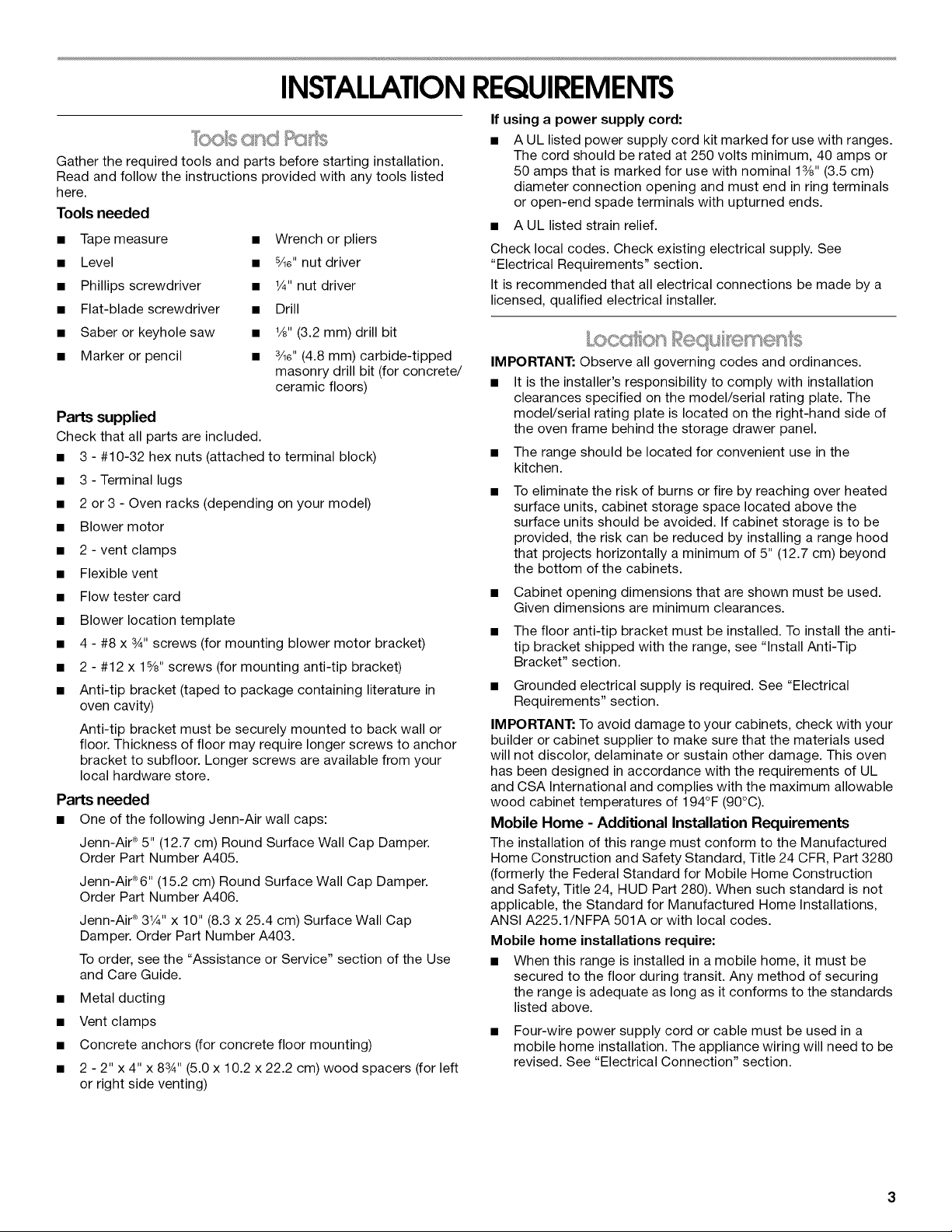

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure

• Level

• Phillips screwdriver

• Flat-blade screwdriver

• Saber or keyhole saw

• Marker or pencil

Parts supplied

Check that all parts are included.

3 - #10-32 hex nuts (attached to terminal block)

3 - Terminal lugs

2 or 3 - Oven racks (depending on your model)

Blower motor

2 - vent clamps

Flexible vent

Flow tester card

Blower location template

4 - #8 x 34" screws (for mounting blower motor bracket

2 - #12 x 13/8"screws (for mounting anti-tip bracket)

Anti-tip bracket (taped to package containing literature in

oven cavity)

Anti-tip bracket must be securely mounted to back wall or

floor. Thickness of floor may require longer screws to anchor

bracket to subfloor. Longer screws are available from your

local hardware store.

Parts needed

• One of the following Jenn-Air wall caps:

Jenn-Air ®5" (12.7 cm) Round Surface Wall Cap Damper.

Order Part Number A405.

Jenn-Air®6 '' (15.2 cm) Round Surface Wall Cap Damper.

Order Part Number A406.

Jenn-Air ®3W' x 10" (8.3 x 25.4 cm) Surface Wall Cap

Damper. Order Part Number A403.

To order, see the "Assistance or Service" section of the Use

and Care Guide.

• Metal ducting

• Vent clamps

• Concrete anchors (for concrete floor mounting)

• 2 - 2" x 4" x 83A'' (5.0 x 10.2 x 22.2 cm) wood spacers (for left

or right side venting)

• Wrench or pliers

• 3/ld' nut driver

• 1¼,nut driver

• Drill

• 1/8"(3.2 mm) drill bit

• 3/le"(4.8 mm) carbide-tipped

masonry drill bit (for concrete/

ceramic floors)

If using a power supply cord:

• A UL listed power supply cord kit marked for use with ranges.

The cord should be rated at 250 volts minimum, 40 amps or

50 amps that is marked for use with nominal 13/8"(3.5 cm)

diameter connection opening and must end in ring terminals

or open-end spade terminals with upturned ends.

• A UL listed strain relief.

Check local codes. Check existing electrical supply. See

"Electrical Requirements" section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

IMPORTANT: Observe all governing codes and ordinances.

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the right-hand side of

the oven frame behind the storage drawer panel.

• The range should be located for convenient use in the

kitchen.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

• Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

• The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, the Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as itconforms to the standards

listed above.

• Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need to be

revised. See "Electrical Connection" section.

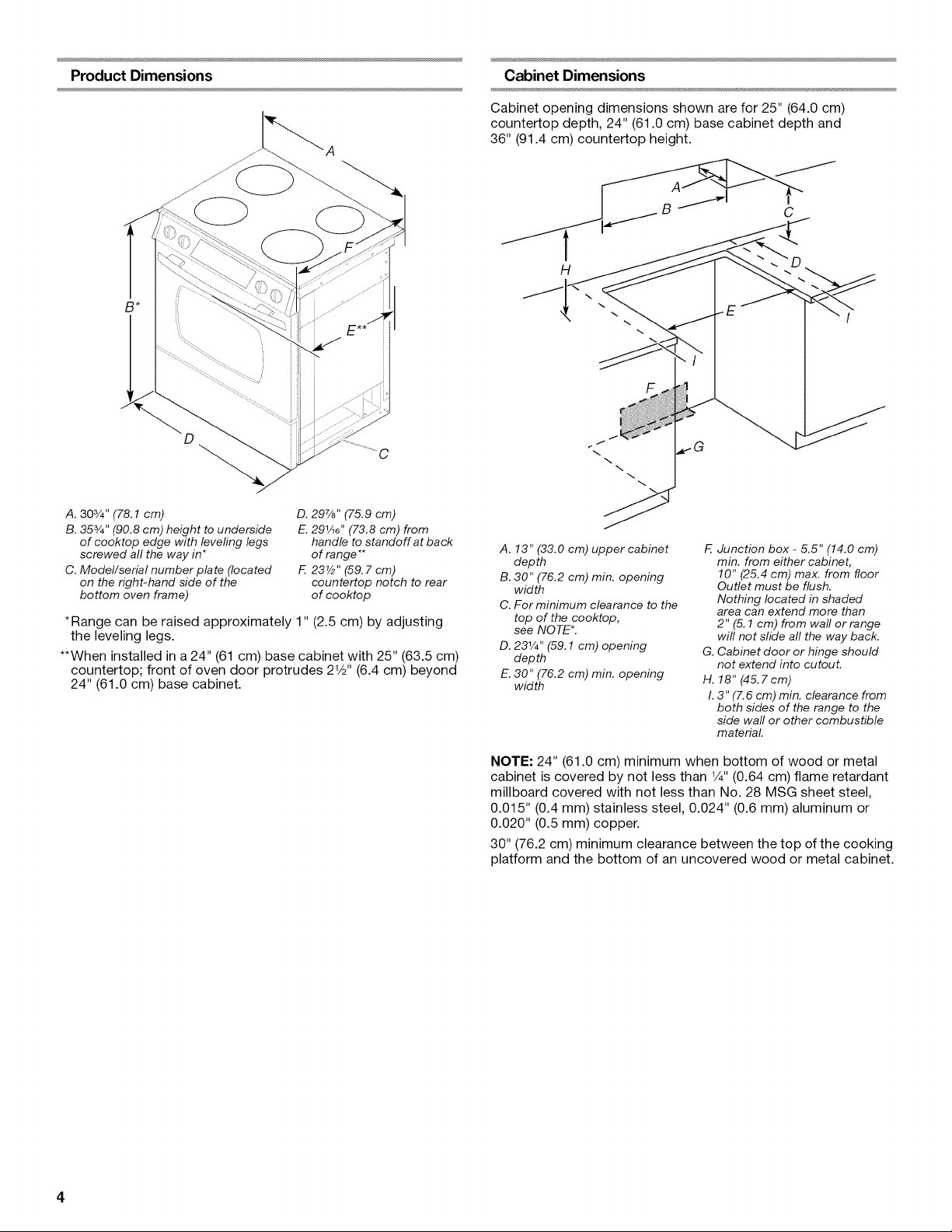

Product Dimensions Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

H

\

C

F

A. 303/4" (78.1 cm)

B. 353/4" (90.8 cm) height to underside

of cooktop edge with levering legs

screwed all the way in*

C. Model/serial number plate (located

on the right-hand side of the

bottom oven frame)

D. 297/8'' (75.9 cm)

E. 291/18'' (73.8 cm) from

handle to standoff at back

of range**

F. 23V2" (59. 7 cm)

countertop notch to rear

of cooktop

*Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

**When installed ina 24" (61 cm) base cabinet with 25" (63.5 cm)

countertop; front of oven door protrudes 21/2'' (6.4 cm) beyond

24" (61.0 cm) base cabinet.

A. 13" (33.0 cm) upper cabinet

depth

B. 30" (76.2 cm) min. opening

width

C. For minimum clearance to the

top of the cooktop,

see NOTE*.

D. 231/4"(59.1 cm) opening

depth

E. 30" (76.2 cm) min. opening

width

E Junction box - 5.5" (14.0 cm)

min. from either cabinet,

10" (25.4 cm) max. from floor

Outlet must be flush.

Nothing located in shaded

area can extend more than

2" (5.1 cm) from wall or range

will not slide all the way back.

G. Cabinet door or hinge should

not extend into cutout.

H. 18" (45.7cm)

I. 3" (7.6 cm) min. clearance from

both sides of the range to the

side wall or other combustible

material.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

%%_'_ ' _ _" _ _ _ _ _ s_ _ ._ .I_

IMPORTANT: This range must be exhausted outdoors. See

"Venting Methods" section.

• Do not terminate the vent system in an attic or other enclosed

area.

• Use a Jenn-Air wall cap.

• Vent system must terminate to the outside.

• Use only a 6" (15.2 cm) round metal vent or a 3_¼x 10 ''

(8.3 cm x 25.4 cm) rectangular vent, except as follows:

5" (12.7 cm) round metal vent may be used for venting

straight out the back of the range and directly through the

wall for vent lengths of 10 ft (3.0 m) or less.

• Rigid metal vent is recommended. For best performance, do

not use plastic or metal foil vent.

• Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

• Do not cut a joist or stud unless absolutely necessary. If a

joist or stud must be cut, then a supporting frame must be

constructed.

• The size of the vent should be uniform.

• The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

• Use vent clamps to seal all joints in the vent system.

• Use caulking to seal exterior wall or roof opening around the

cap.

• Determine which venting method is best for your application.

For Best Performance:

• Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

• Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

• Do not install 2 elbows together.

• Use no more than three 90 ° elbows.

• If an elbow is used, install it as far away as possible from the

hood's vent motor exhaust opening.

• Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

• Elbows too close together can cause excess turbulence that

reduces airflow.

• Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or 3V4"x 10"

(8.3 x 25.4 cm) system.

• Do not reduce to a 5" (12.7 cm) system after using a

6" (15.2 cm) or 3V4"x 10" (8.3 x 25.4 cm) fittings.

• Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

• Use a Jenn-Air vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is

not reduced and that it has a backdraft damper.

• Use vent clamps to seal all joints in the vent system.

• Use caulking to seal exterior wall or roof opening around the

cap.

The length of vent system and number of elbows should be kept

to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is

60 ft (18.3 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

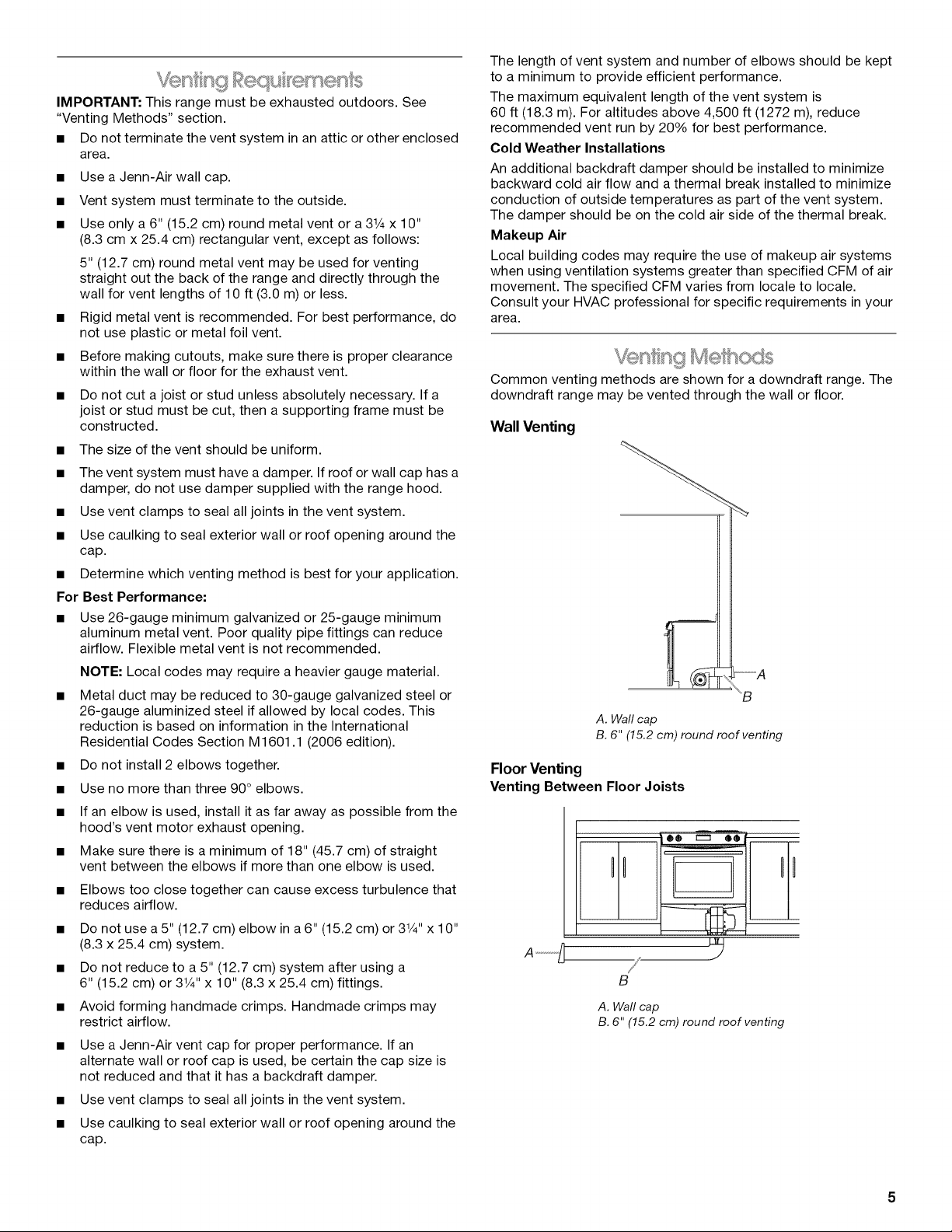

Common venting methods are shown for a downdraft range. The

downdraft range may be vented through the wall or floor.

Wall Venting

%

\B

A. Wall cap

B. 6" (15.2 cm) round roof venting

Floor Venting

Venting Between FloorJoists

O® _ QQ --

O)I

-

B

A. Wallcap

B.6" (15.2 cm)round roof venting

Left or Right Side Venting

Venting BehindCabinet Kickplate

m 00 r'_ Q®

/

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

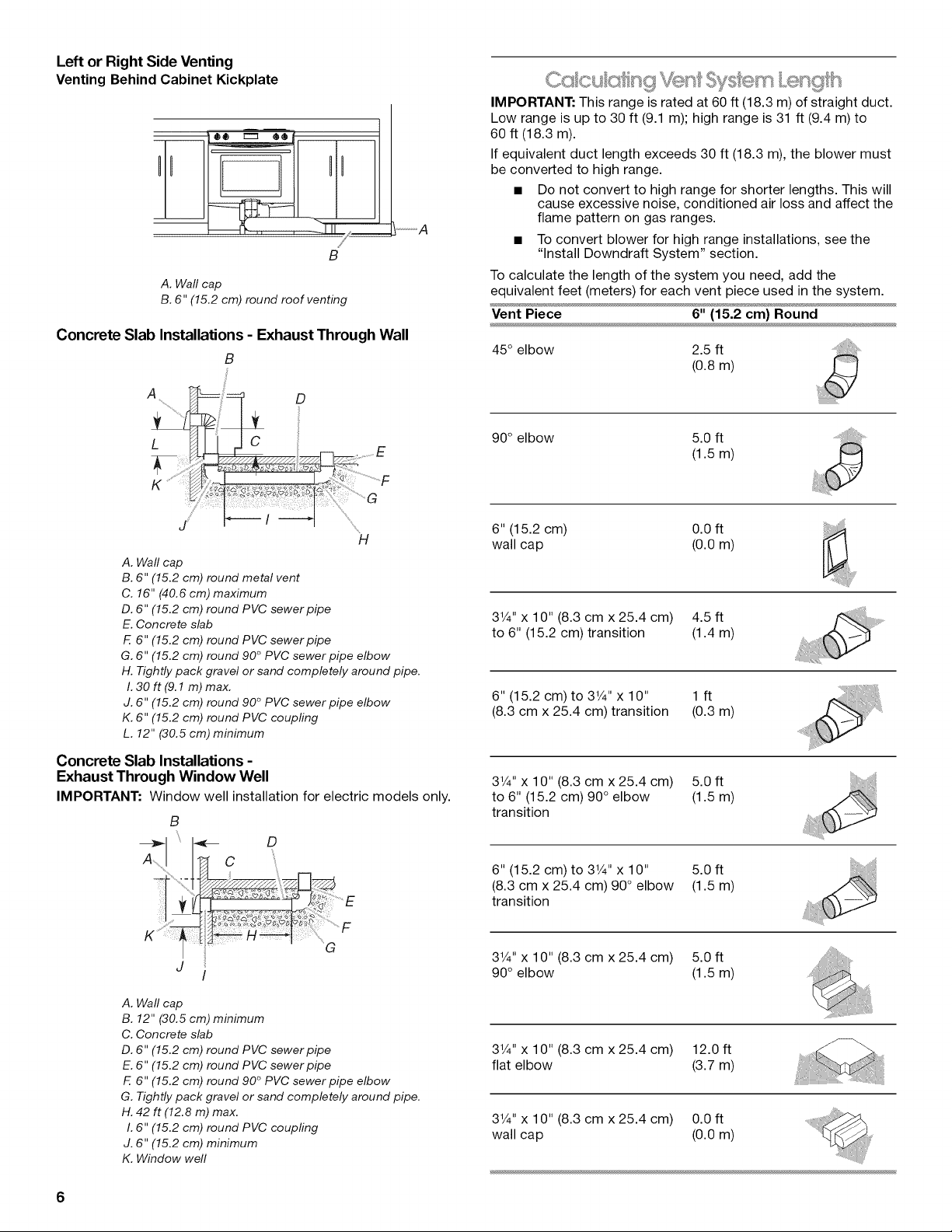

Concrete Slab Installations - Exhaust Through Wall

B

A

D

--A

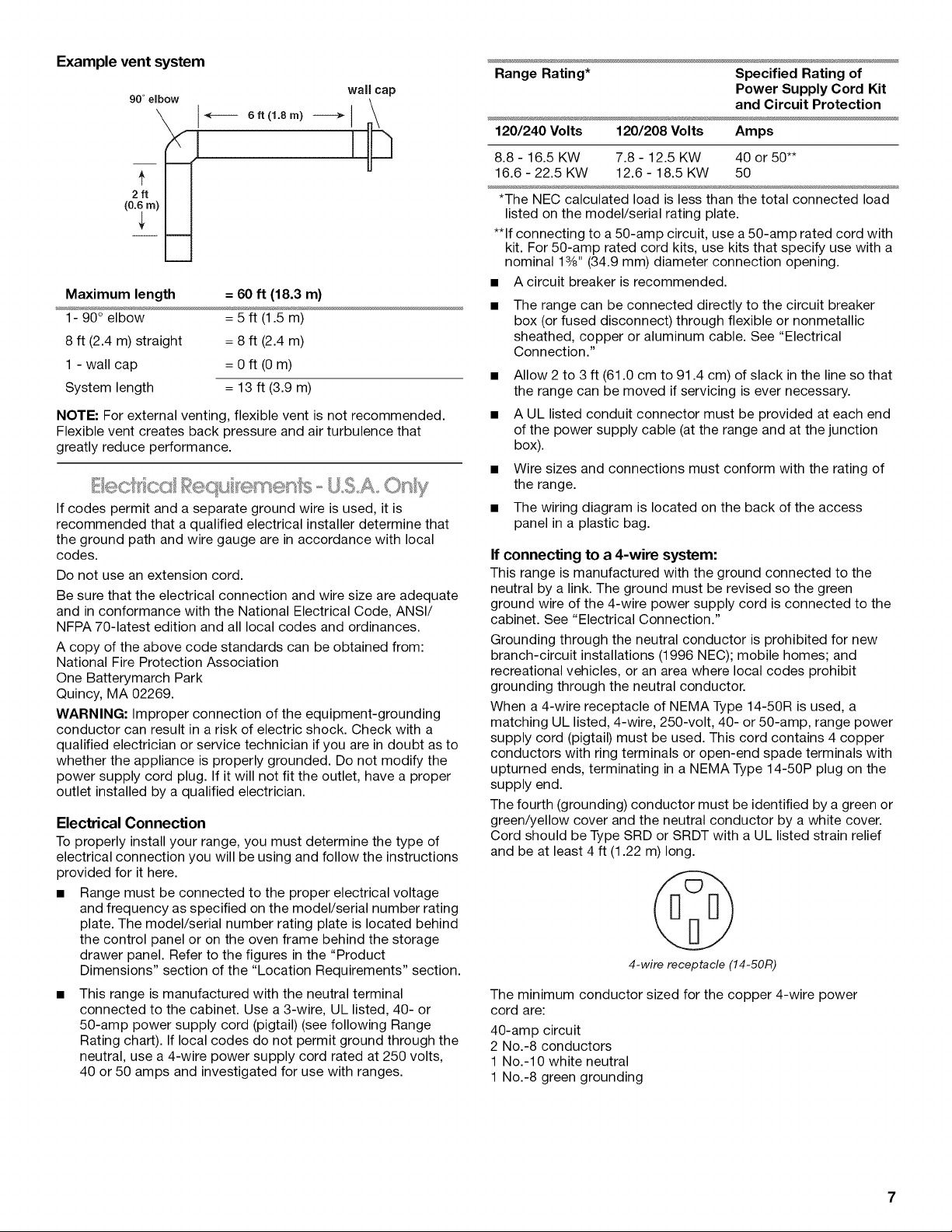

IMPORTANT: This range is rated at 60 ff (18.3 m) of straight duct.

Low range is up to 30 ft (9.1 m); high range is 31 ff (9.4 m) to

60 ft (18.3 m).

If equivalent duct length exceeds 30 ft (18.3 m), the blower must

be converted to high range.

• Do not convert to high range for shorter lengths. This will

cause excessive noise, conditioned air loss and affect the

flame pattern on gas ranges.

• To convert blower for high range installations, see the

"Install Downdraft System" section.

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8m)

L

iiii!iiii!iii!

.......di

/

H

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. Concrete slab

F. 6" (15.2 cm) round PVC sewer pipe

G. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

H. Tightly pack gravel or sand completely around pipe.

1.30ft(9.1 m) max.

J. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

K. 6" (15.2 cm) round PVC coupling

L. 12" (30.5 cm) minimum

Concrete Slab Installations -

Exhaust Through Window Well

IMPORTANT: Window well installation for electric modelsonly.

B

D

A! /n C

90° elbow 5.0 ft

(1.5m)

6" (15.2 cm) 0.0 ft

wall cap (0.0 m)

3V4" x 10" (8.3 cm x 25.4 cm) 4.5 ft

to 6" (15.2 cm) transition (1.4 m)

6" (15.2 cm) to 3V4" x 10" 1 ft

(8.3 cm x 25.4 cm) transition (0.3 m)

3V4" x 10" (8.3 cm x 25.4 cm) 5.0 ft

to 6" (15.2 cm) 90 ° elbow (1.5 m)

transition

6" (15.2 cm) to 3V4" x 10" 5.0ft

(8.3 cm x 25.4 cm) 90° elbow (1.5 m)

transition

..... ........F

n _ I_ _ M----_t .............

J

A. Wall cap

B. 12" (30.5 cm) minimum

C. Concrete slab

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round PVC sewer pipe

F. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

G. Tightly pack gravel or sand completely around pipe.

H. 42 ft (12.8 m) max.

I. 6" (15.2 cm) round PVC coupling

J. 6" (15.2 cm) minimum

K. Window well

G

3V4" x 10" (8.3 cm x 25.4 cm) 5.0 ft

90° elbow (1.5 m)

3V4" x 10" (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

3V4" x 10" (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

6

Example vent system

90 °eibow

Maximum length = 60 ft (18.3 m)

1- 90° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

NOTE: For external venting, flexible vent is not recommended.

Flexible vent creates back pressure and air turbulence that

greatly reduce performance.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial number rating

plate. The model/serial number rating plate is located behind

the control panel or on the oven frame behind the storage

drawer panel. Refer to the figures in the "Product

Dimensions" section of the "Location Requirements" section.

• This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40- or

50-amp power supply cord (pigtail) (see following Range

Rating chart). If local codes do not permit ground through the

neutral, use a 4-wire power supply cord rated at 250 volts,

40 or 50 amps and investigated for use with ranges.

wall cap

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8- 16.5 KW 7.8- 12.5 KW 40 or 50"*

16.6 - 22.5 KW 12.6 - 18.5 KW 50

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 13/8"(34.9 mm) diameter connection opening.

A circuit breaker is recommended.

The range can be connected directly to the circuit breaker

box (or fused disconnect) through flexible or nonmetallic

sheathed, copper or aluminum cable. See "Electrical

Connection."

• Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack in the line so that

the range can be moved if servicing is ever necessary.

• A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

• Wire sizes and connections must conform with the rating of

the range.

• The wiring diagram is located on the back of the access

panel in a plastic bag.

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green

ground wire of the 4-wire power supply cord is connected to the

cabinet. See "Electrical Connection."

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

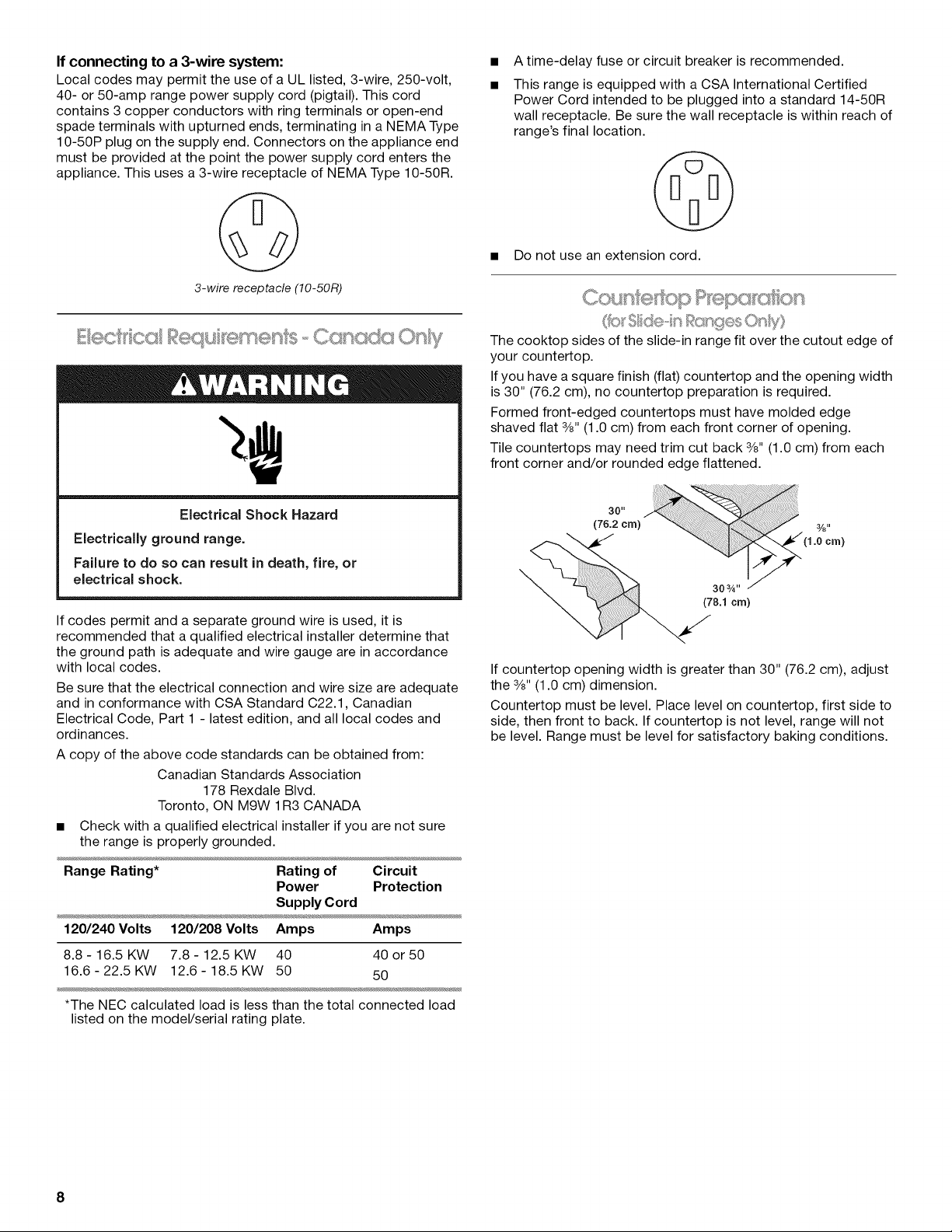

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). This cord

contains 3 copper conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance end

must be provided at the point the power supply cord enters the

appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

A time-delay fuse or circuit breaker is recommended.

This range is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range's final location.

• Do not use an extension cord.

3-wire receptacle (10-50R)

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

• Check with a qualified electrical installer if you are not sure

the range is properly grounded.

Coupset' op P 'epcx r£ion

(fo_"S <s@,_"/%xqges O_y;

The cooktop sides of the slide-in range fit over the cutout edge of

your countertop.

If you have a square finish (flat) countertop and the opening width

is 30" (76.2 cm), no countertop preparation is required.

Formed front-edged countertops must have molded edge

shaved flat 3/8"(1.0 cm) from each front corner of opening.

Tile countertops may need trim cut back 3/8"(1.0 cm) from each

front corner and/or rounded edge flattened.

30"

(76.2 cm)

(1.o_cm)

303A"

(78.1 cm)

If countertop opening width is greater than 30" (76.2 cm), adjust

the 3/8"(1.0 cm) dimension.

Countertop must be level. Place level on countertop, first side to

side, then front to back. If countertop is not level, range will not

be level. Range must be level for satisfactory baking conditions.

Range Rating* Rating of Circuit

Power Protection

Supply Cord

120/240 Volts 120/208 Volts Amps Amps

8.8 - 16.5 KW 7.8 - 12.5 KW 40 40 or 50

16.6-22.5KW 12.6-18.5KW 50 50

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

8

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3.

When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the anti-

tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To remove cardboard bottom, place range on its back, take

4 cardboard corners from the carton. Stack one cardboard

corner on top of another. Repeat with the other 2 corners.

Place them lengthwise on the floor behind the range to

support the range when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

1.

If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

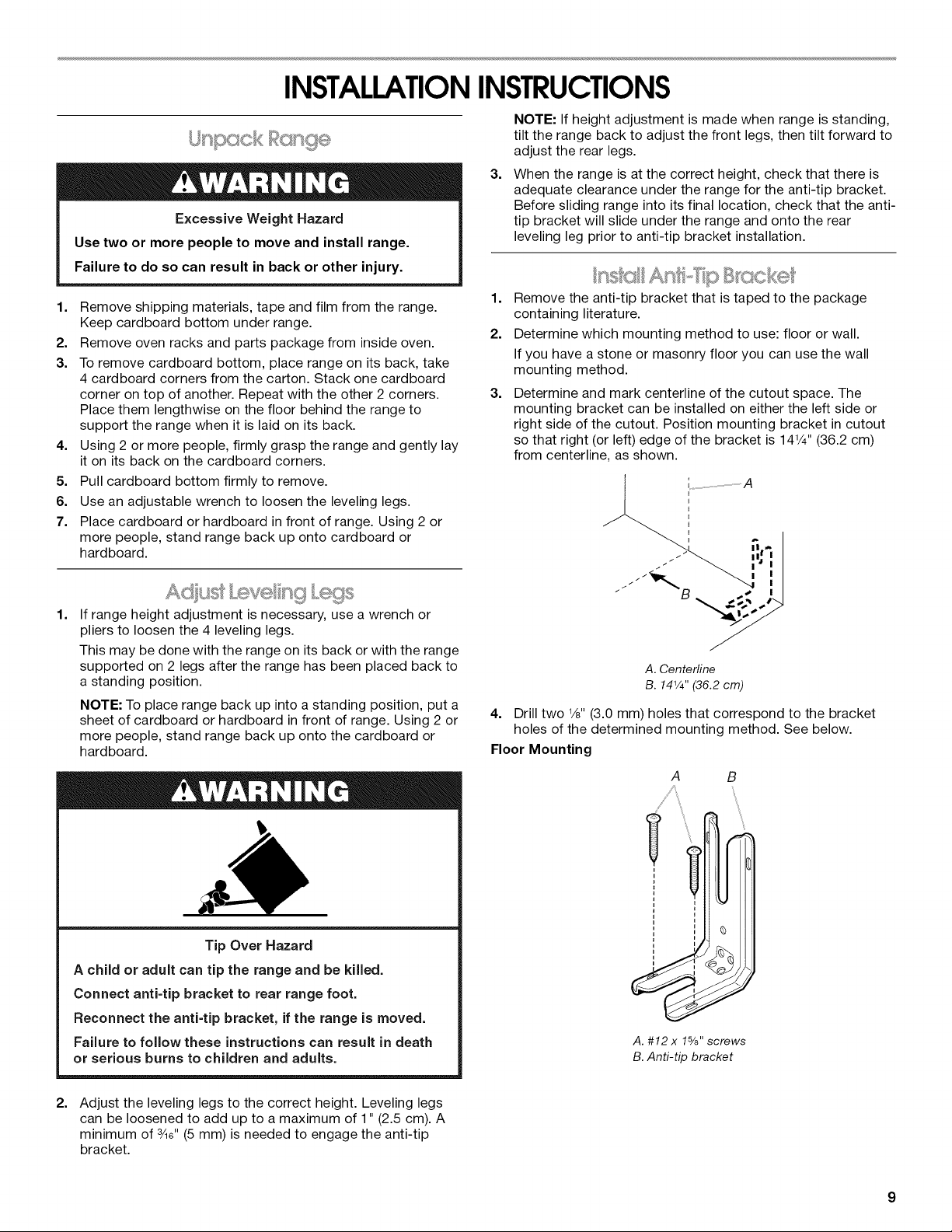

1. Remove the anti-tip bracket that is taped to the package

containing literature.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor you can use the wall

mounting method.

3. Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is 14¼" (36.2 cm)

from centerline, as shown.

J _ i°I i

ii. i' I

I I

_

A. Centerline

B. 141/4'' (36.2 cm)

4. Drill two V8"(3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See below.

Floor Mounting

A B

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

2.

Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3Ad'(5 mm) is needed to engage the anti-tip

bracket.

% %

A. #12 x 1%" screws

B.Anti-tip bracket

Wall Mounting

2.

Check for obstructions before marking the vent hole location.

Mark a horizontal line 83/le'' (20.8 cm) from the floor. Mark a

vertical line up to a maximum of 21¼'' (7.9 cm) from the right-

hand side of the cabinet centerline.

s _

A. #12 x 1%" screws

B. Anti-tip bracket

5. Using the Phillips screwdriver, mount anti-tip bracket to the

wall or floor with the two #12 x 1%" screws provided.

n ©ownd m

Determine Equivalent Length of Vent System

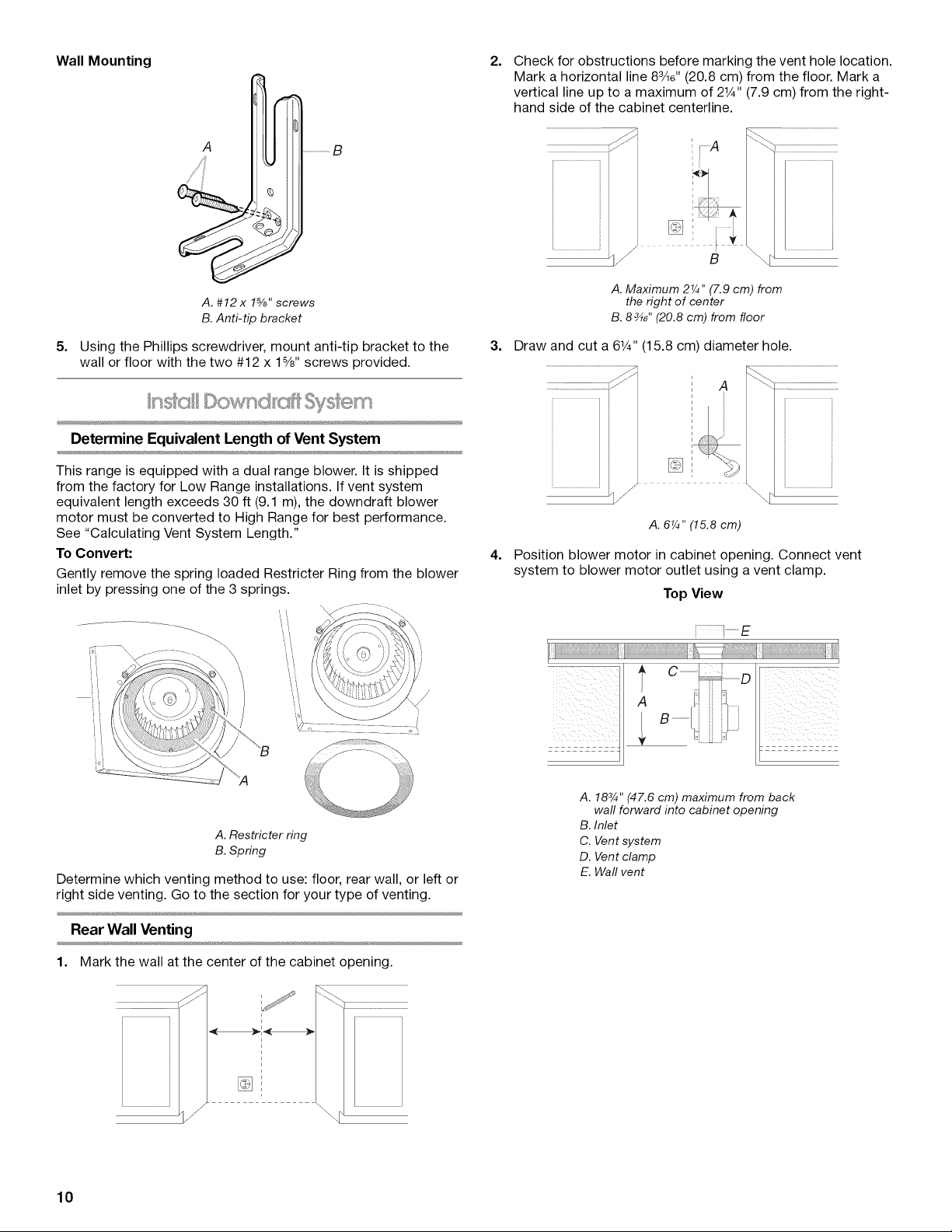

This range is equipped with a dual range blower. It is shipped

from the factory for Low Range installations. If vent system

equivalent length exceeds 30 ft (9.1 m), the downdraft blower

motor must be converted to High Range for best performance.

See "Calculating Vent System Length."

To Convert:

Gently remove the spring loaded Restricter Ring from the blower

inlet by pressing one of the 3 springs.

J

A. Maximum 2¼" (7.9 cm) from

the right of center

B. 8_" (20.8 cm) from floor

B

3. Draw and cut a 61¼"(15.8 cm) diameter hole.

A

i

[]

A. 6¼" (15.8 cm)

4,

Position blower motor in cabinet opening. Connect vent

system to blower motor outlet using a vent clamp.

Top View

A

ii ii

;B

A. Restricter ring

B. Spring

Determine which venting method to use: floor, rear wall, or left or

right side venting. Go to the section for your type of venting.

Rear Wall Venting

1. Mark the wall at the center of the cabinet opening.

/J

i

i

.........................................=

\

10

A. 183/4'' (47.6 cm) maximum from back

wall forward into cabinet opening

B. Inlet

C. Vent system

D. Vent clamp

E. Wall vent

5. Mount blower motor to the floor with 4 - #8 x 3_,,hex head

screws provided.

Top View

JZZ2

6. Go to the "Electrical Connection" section.

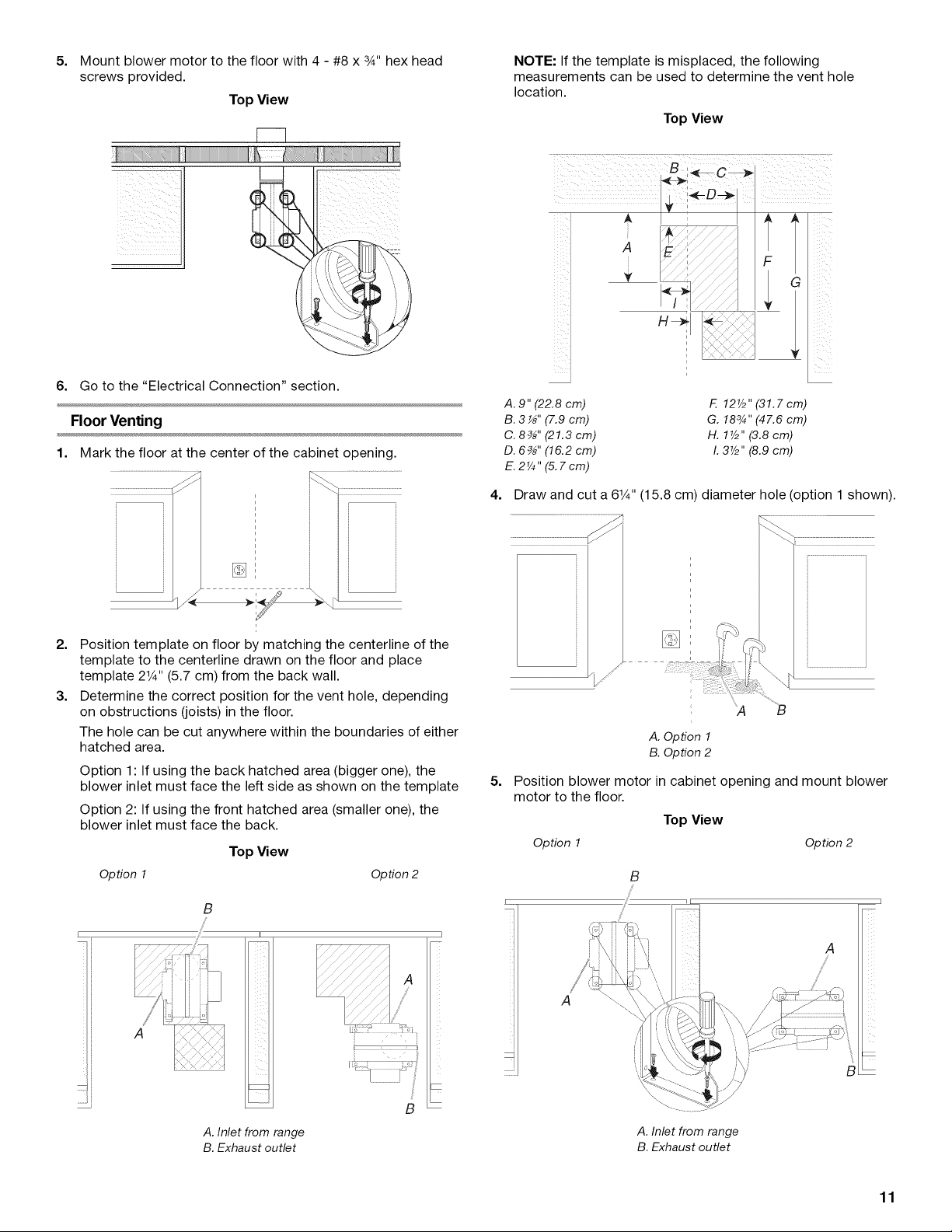

Floor Venting

1. Mark the floor at the center of the cabinet opening.

NOTE: If the template is misplaced, the following

measurements can be used to determine the vent hole

location.

Top View

F I

I G

A. 9" (22.8 cm)

B. 3 _" (7.9 cm)

C. 8_" (21.3 cm)

D. 6_" (16.2 cm)

E. 2¼ " (5.7 cm)

F. 12Y2" (31.7 cm)

G. 183/4" (47.6 cm)

H. lY2" (3.8 cm)

I. 3Y2" (8.9 cm)

4. Draw and cut a 61¼'' (15.8 cm) diameter hole (option 1 shown).

2. Position template on floor by matching the centerline of the

template to the centerline drawn on the floor and place

template 21¼'' (5.7 cm) from the back wall.

3. Determine the correct position for the vent hole, depending

on obstructions (joists) in the floor.

The hole can be cut anywhere within the boundaries of either

hatched area.

Option 1: If using the back hatched area (bigger one), the

blower inlet must face the left side as shown on the template

Option 2: If using the front hatched area (smaller one), the

blower inlet must face the back.

Top View

Option 1 Option 2

B

_r

I

A

A

A. Option 1

B. Option 2

5.

Position blower motor in cabinet opening and mount blower

motor to the floor.

Top View

Option 1 Option 2

i......

A

A. Inlet from range

B. Exhaust outlet

B

A. Inlet from range

B. Exhaust outlet

11

6. Connect vent system to blower motor outlet (option 1 shown)

with 4 - #8 x 3_,,hex head screws provided.

A. Inlet

B. Vent clamp

C. Floor

D. Vent system

7. Go to the "Electrical Connection" section.

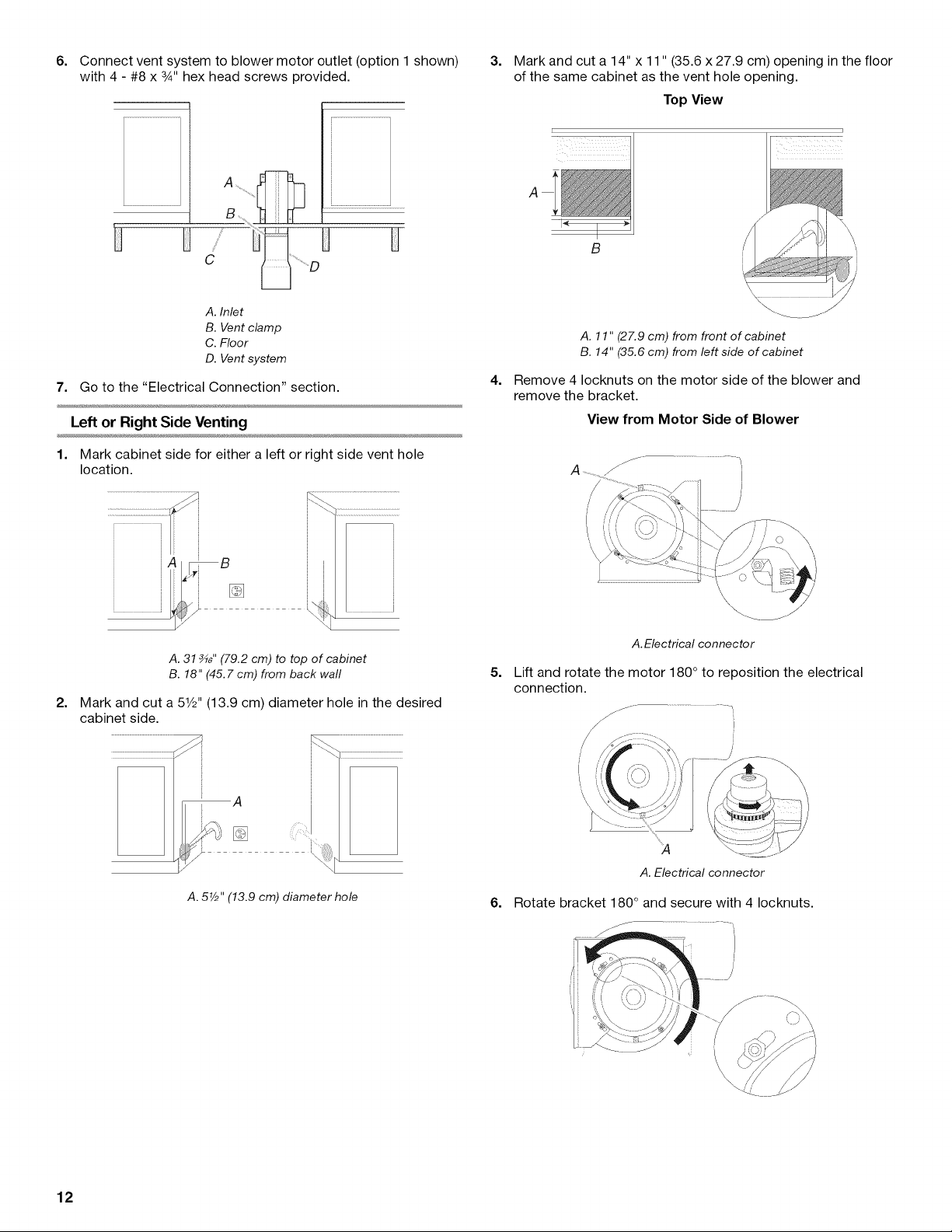

Left or Right Side Venting

1. Mark cabinet side for either a left or right side vent hole

location.

3=

Mark and cut a 14" x 11" (35.6 x 27.9 cm) opening in the floor

of the same cabinet as the vent hole opening.

Top View

A. 11" (27.9 cm) from front of cabinet

B. 14" (35.6 cm) from left side of cabinet

4=

Remove 4 Iocknuts on the motor side of the blower and

remove the bracket.

View from Motor Side of Blower

A. 31 _" (79.2 cm) to top of cabinet

B. 18" (45.7 cm) from back wall

2=

Mark and cut a 51/2"(13.9 cm) diameter hole in the desired

cabinet side.

A. 5V2" (13.9 cm) diameter hole

A.Electrical connector

5=

Lift and rotate the motor 180° to reposition the electrical

connection.

/

A.Electrical connector

6. Rotate bracket 180 ° and secure with 4 Iocknuts.

12

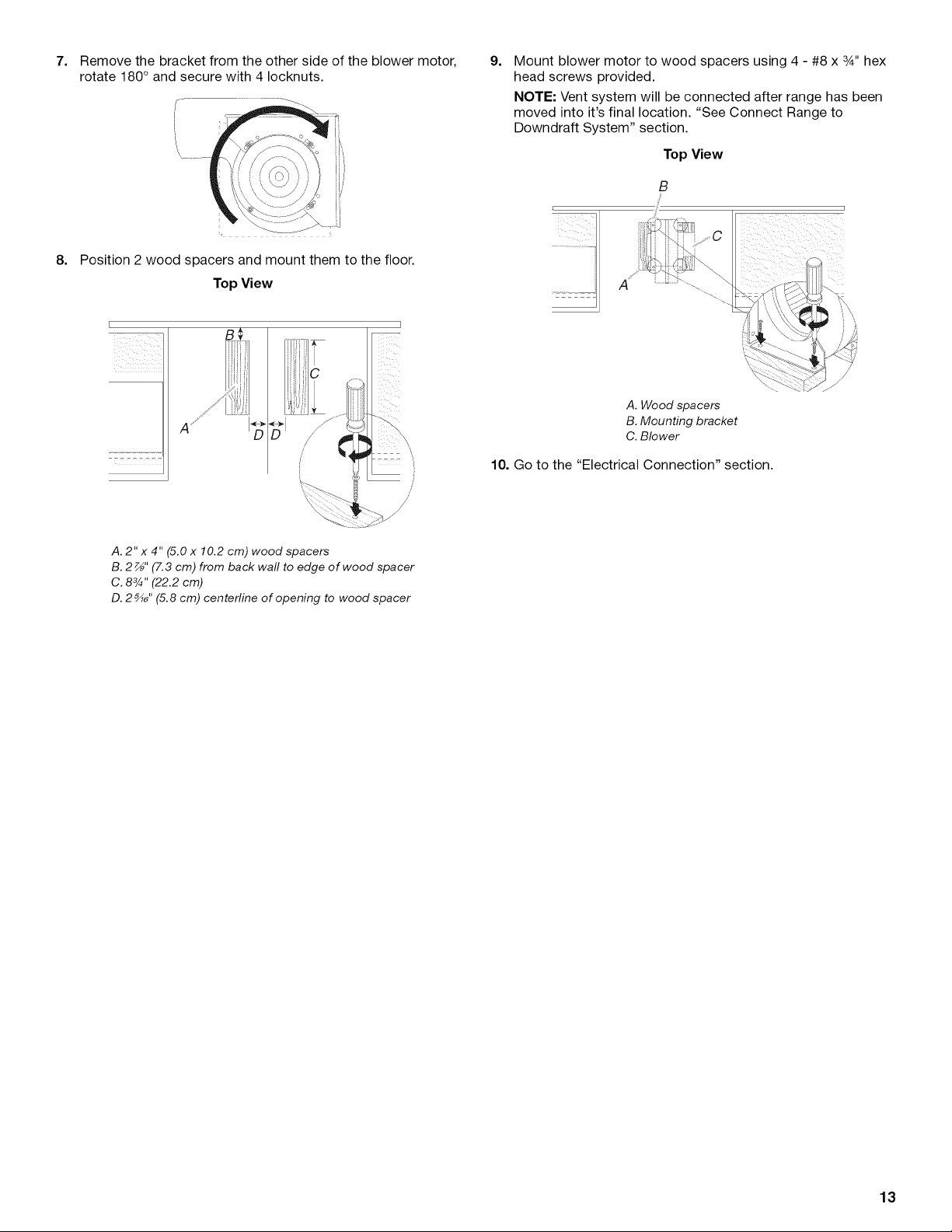

7=

Remove the bracket from the other side of the blower motor,

rotate 180 ° and secure with 4 Iocknuts.

8. Position 2 wood spacers and mount them to the floor.

Top View

9.

Mount blower motor to wood spacers using 4 - #8 x 3A" hex

head screws provided.

NOTE: Vent system will be connected after range has been

moved into it's final location. "See Connect Range to

Downdraft System" section.

Top View

B

j_

F

B_

iii

/

/

A. 2" x 4" (5.0 x 10.2 cm) wood spacers

B. 2 _" (7.3 cm) from back wall to edge of wood spacer

C. 83_" (22.2 cm)

D. 2 _" (5.8 cm) centerline of opening to wood spacer

A. Wood spacers

B. Mounting bracket

C. Blower

10. Go to the "Electrical Connection" section.

J

/

/

/

13

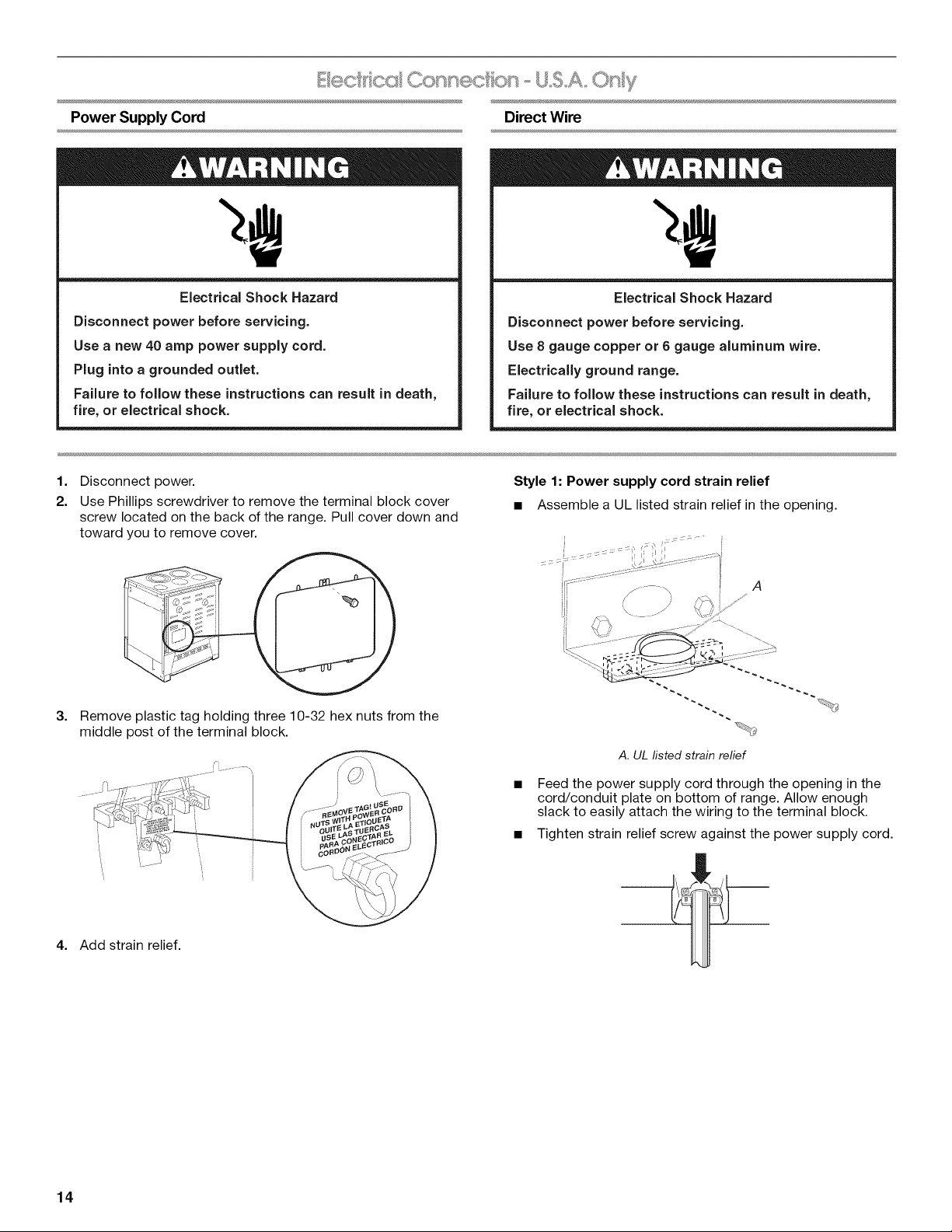

Power Supply Cord Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1=

Disconnect power.

2.

Use Phillips screwdriver to remove the terminal block cover

screw located on the back of the range. Pull cover down and

toward you to remove cover.

3.

Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Style 1: Power supply cord strain relief

• Assemble a UL listed strain relief in the opening.

A

A. UL listed strain relief

4. Add strain relief.

14

Feed the power supply cord through the opening in the

cord/conduit plate on bottom of range. Allow enough

slack to easily attach the wiring to the terminal block.

• Tighten strain relief screw against the power supply cord.

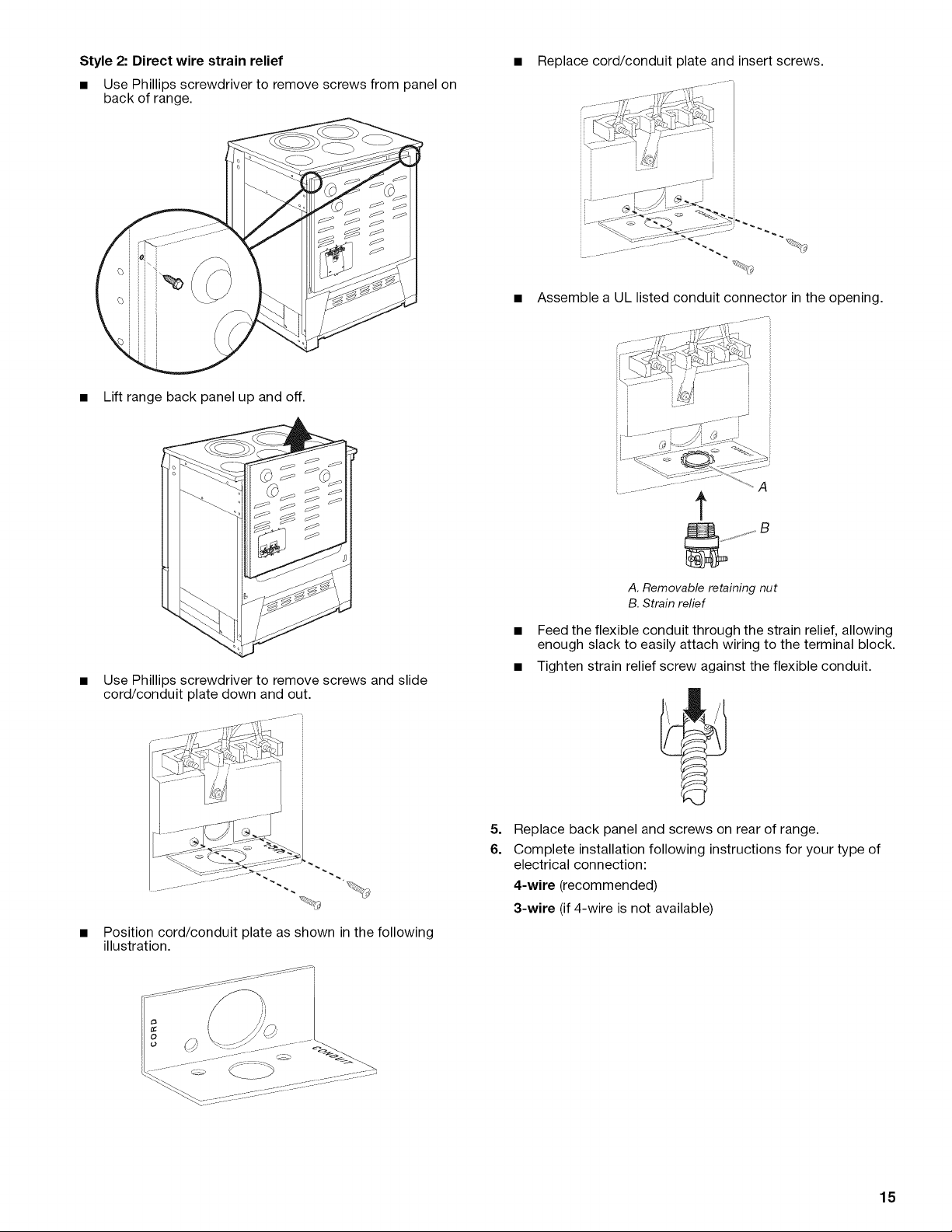

Style 2: Direct wire strain relief

• Use Phillips screwdriver to remove screws from panel on

back of range.

• Lift range back panel up and off.

• Replace cord/conduit plate and insert screws.

Assemble a UL listed conduit connector in the opening.

F..............

!

t

Use Phillips screwdriver to remove screws and slide

cord/conduit plate down and out.

Position cord/conduit plate as shown in the following

illustration.

A. Removableretaining nut

B.Strainrelief

• Feed the flexible conduit through the strain relief, allowing

enough slack to easily attach wiring to the terminal block.

• Tighten strain relief screw against the flexible conduit.

5=

Replace back panel and screws on rear of range.

6.

Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

15

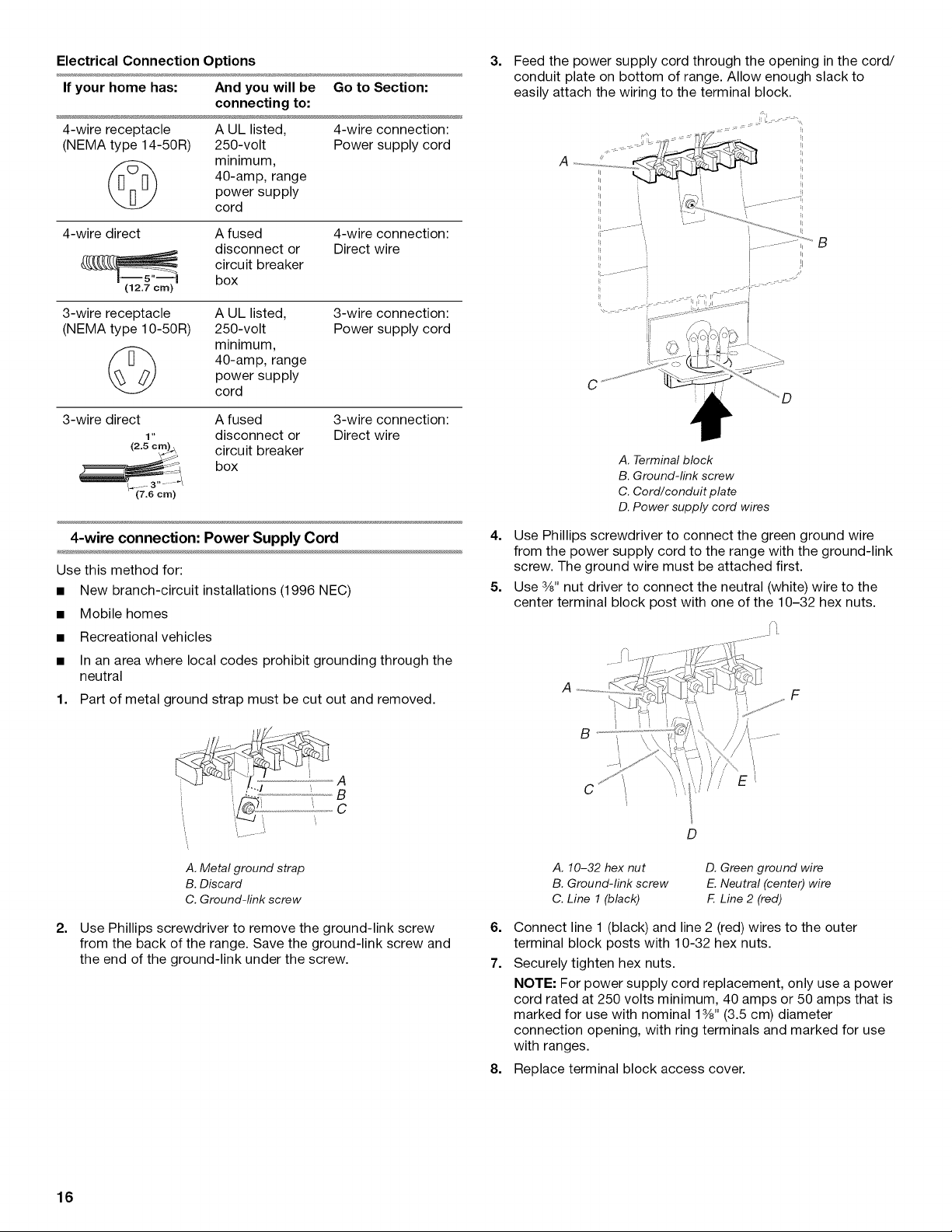

Electrical Connection Options 3.

If your home has: And you will be Go to Section:

connecting to:

4-wire receptacle A UL listed, 4-wire connection:

(NEMA type 14-50R) 250-volt Power supply cord

40-amp, range

minimum,

power supply

cord

4-wire direct A fused 4-wire connection:

disconnect or Direct wire

circuit breaker

(12.7 crn)

3-wire receptacle A UL listed,

(NEMA type 10-50R) 250-volt

box

3-wire connection:

Power supply cord

minimum,

power supply

40-amp, range

cord

3-wire direct A fused

1" disconnect or

3-wire connection:

Direct wire

circuitboxbreaker

Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

//

C

D

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

4-wire connection: Power Supply Cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A

B

C

A. Metal ground strap

B. Discard

C. Ground-link screw

2=

Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground-link under the screw.

4. Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

5. Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

F

D

A. 10-32 hex nut

B. Ground-link screw

C. Line 1 (black)

6=

Connect line 1 (black) and line 2 (red) wires to the outer

D. Green ground wire

E. Neutral (center) wire

F. Line 2 (red)

terminal block posts with 10-32 hex nuts.

7.

Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

8=

Replace terminal block access cover.

16

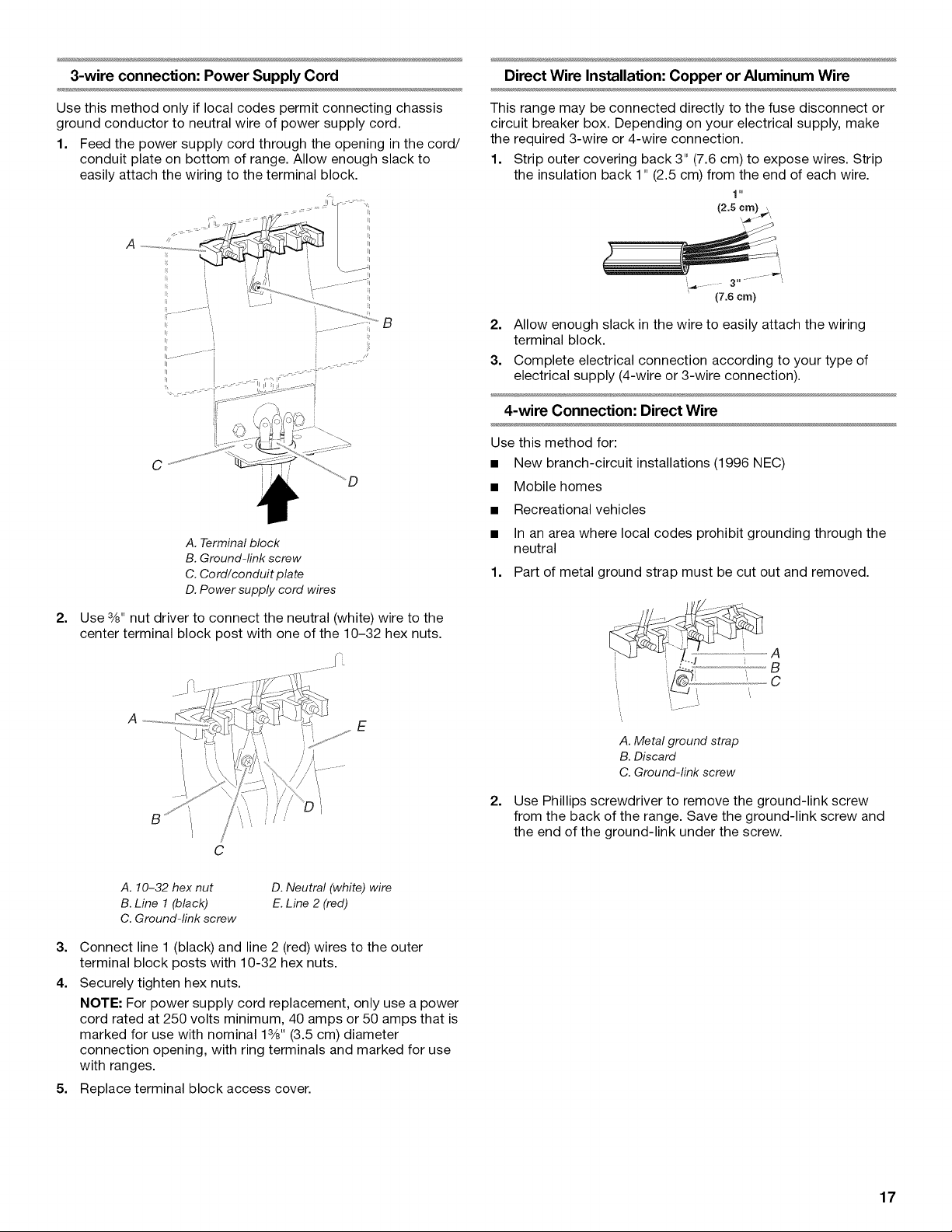

3-wire connection: Power Supply Cord

Direct Wire Installation: Copper or Aluminum Wire

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

. d ........... I

...... /! '-- II

i: ......................I

B

i

C

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

2.

Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

This range may be connected directly to the fuse disconnect or

circuit breaker box. Depending on your electrical supply, make

the required 3-wire or 4-wire connection.

1. Strip outer covering back 3" (7.6 cm) to expose wires. Strip

the insulation back 1" (2.5 cm) from the end of each wire.

1 "

(2.5cm) ..

3" ..... "

(7.6 crn)

2. Allow enough slack in the wire to easily attach the wiring

terminal block.

3. Complete electrical connection according to your type of

electrical supply (4-wire or 3-wire connection).

4-wire Connection: Direct Wire

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A

B

C

A

E

C

A. 10-32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Neutral (white) wire

E.Line 2 (red)

3. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

4. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

5. Replace terminal block access cover.

A.Metal ground strap

B.Discard

C.Ground-link screw

2.

Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground-link under the screw.

17

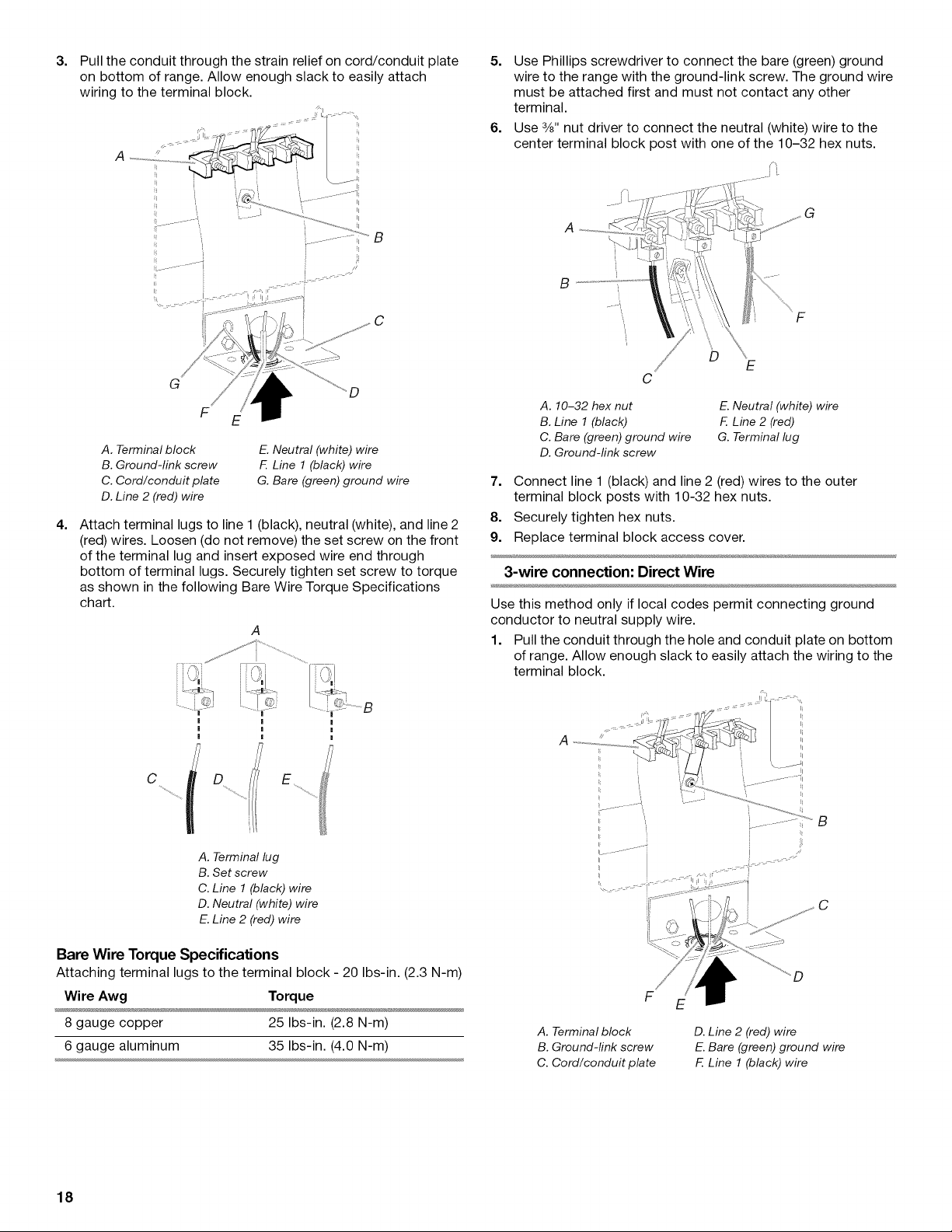

3.

C

G

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Line 2 (red) wire

4=

Attach terminal lugs to line 1 (black), neutral (white), and line 2

E. Neutral (white) wire

F. Line 1 (black) wire

G. Bare (green) ground wire

(red) wires. Loosen (do not remove) the set screw on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to torque

as shown in the following Bare Wire Torque Specifications

chart.

5. Use Phillips screwdriver to connect the bare (green) ground

wire to the range with the ground-link screw. The ground wire

must be attached first and must not contact any other

terminal.

6. Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

i,

F

A. 10-32 hex nut

B. Line 1 (black)

C. Bare (green) ground wire

D. Ground-link screw

E. Neutral (white) wire

F. Line 2 (red)

G. Terminal lug

7. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover.

3-wire connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the conduit through the hole and conduit plate on bottom

of range. Allow enough slack to easily attach the wiring to the

terminal block.

C

A. Terminal lug

B. Set screw

C. Line 1 (black) wire

D. Neutral (white) wire

E.Line 2 (red) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 Ibs-in. (2.8 N-m)

6 gauge aluminum 35 Ibs-in. (4.0 N-m)

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

Ii

Jl

I //

C

F

D. Line 2 fled) wire

E. Bare (green) ground wire

F. Line 1 (black) wire

18

2.

Attach terminal lugs to line 1 (black), bare (green) ground, and

line 2 (red) wires. Loosen (do not remove) the set screw on the

front of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to torque

as shown in the following Bare Wire Torque Specifications

chart.

A. Terminal lug

B. Set screw

C. Line 1 (black) wire

D. Bare (green) ground wire

E.Line 2 (red) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Aw9 Torque

8 gauge copper 25 Ibs-in. (2.8 N-m)

6 gauge aluminum 35 Ibs-in. (4.0 N-m)

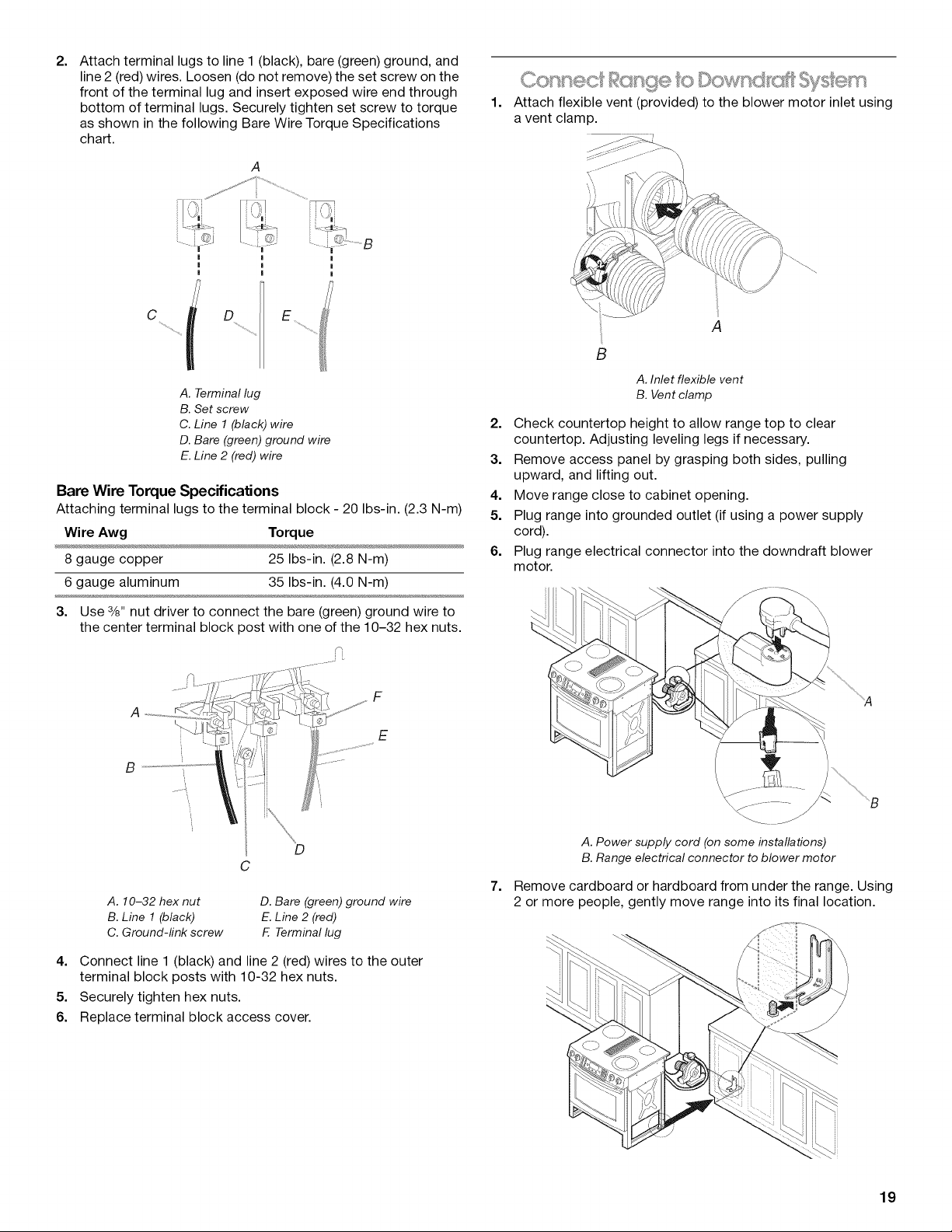

1.

Attach flexible vent (provided) to the blower motor inlet using

a vent clamp.

A

B

A. Inlet flexible vent

B. Vent clamp

2. Check countertop height to allow range top to clear

countertop. Adjusting leveling legs if necessary.

3. Remove access panel by grasping both sides, pulling

upward, and lifting out.

4. Move range close to cabinet opening.

5. Plug range into grounded outlet (if using a power supply

cord).

6. Plug range electrical connector into the downdraft blower

motor.

3. Use 3/8"nut driver to connect the bare (green) ground wire to

the center terminal block post with one of the 10-32 hex nuts.

F

A

E

B

D

C

A. 10-32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Bare (green) ground wire

E.Line 2 (red)

F. Terminal lug

4. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

5. Securely tighten hex nuts.

6. Replace terminal block access cover.

\ J ............ j

A. Power supply cord (on some installations)

B. Range electrical connector to blower motor

7.

Remove cardboard or hardboard from under the range. Using

2 or more people, gently move range into its final location.

....A

.....B

19

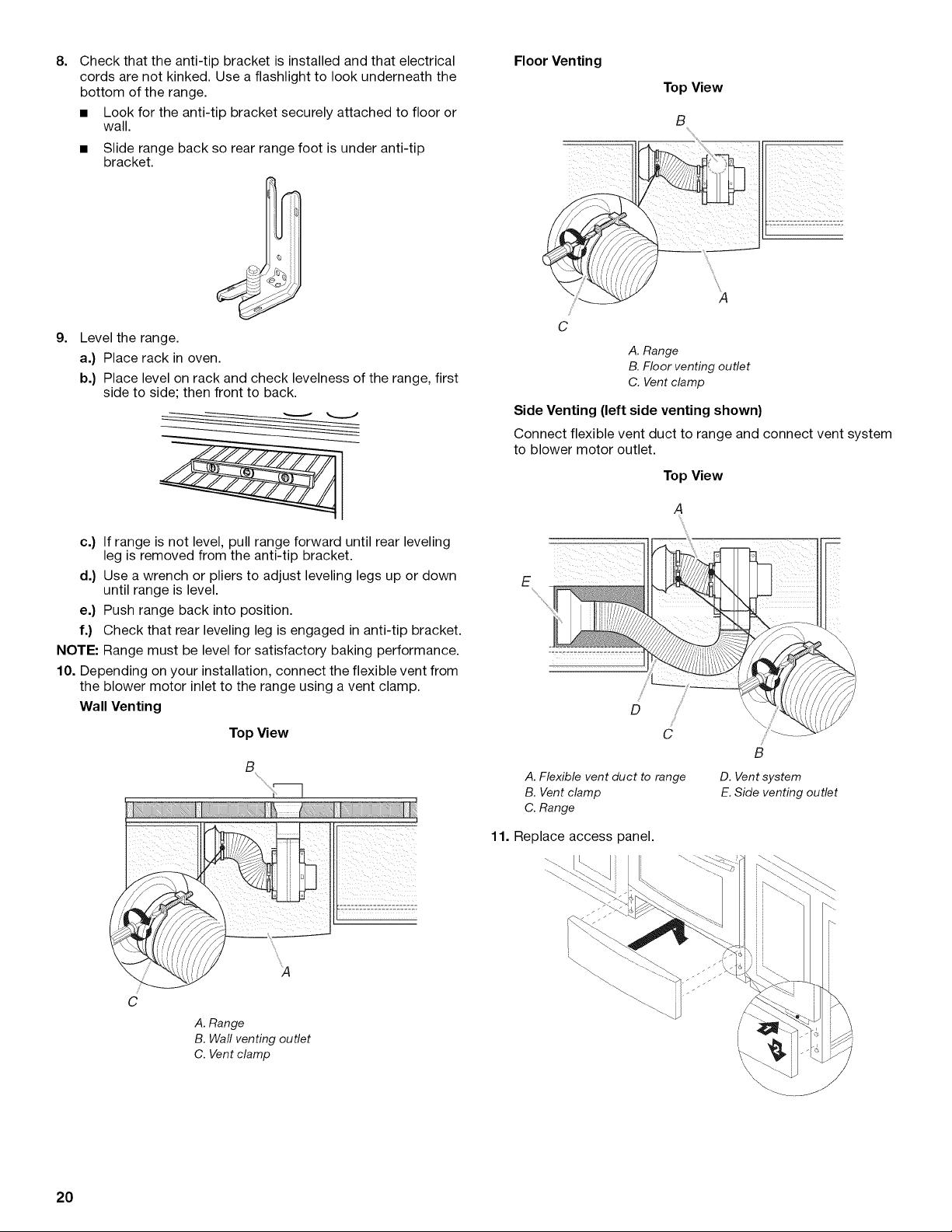

8. Floor Venting

Check that the anti-tip bracket is installed and that electrical

cords are not kinked. Use a flashlight to look underneath the

bottom of the range.

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is under anti-tip

bracket.

g=

Level the range.

a.) Place rack in oven.

b.) Place level on rack and check levelness of the range, first

side to side; then front to back.

Side Venting (left side venting shown)

Connect flexible vent duct to range and connect vent system

to blower motor outlet.

Top View

A

A. Range

B. Floor venting outlet

C. Vent clamp

Top View

A

c.) If range is not level, pull range forward until rear leveling

leg is removed from the anti-tip bracket.

d.) Use a wrench or pliers to adjust leveling legs up or down

until range is level.

e.) Push range back into position.

f.) Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

10. Depending on your installation, connect the flexible vent from

the blower motor inlet to the range using a vent clamp.

Wall Venting

Top View

B

i ¸_ .... !

E

A. Flexible vent duct to range

B. Vent clamp

C. Range

11. Replace access panel.

C

/

B

D. Vent system

E. Side venting outlet

20

C,

A. Range

B. Wall venting outlet

C. Vent clamp

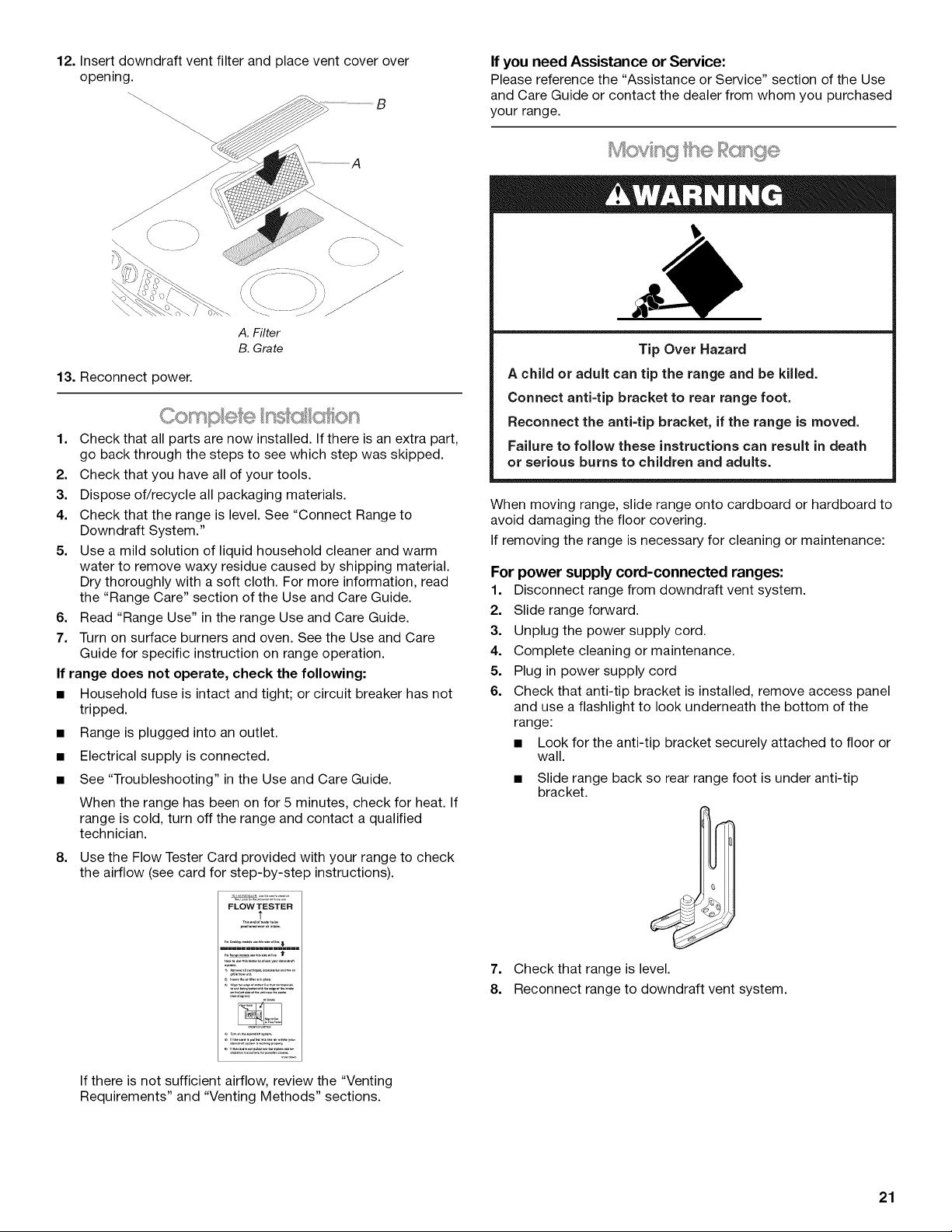

12. Insert downdraft vent filter and place vent cover over

opening.

B

A. Filter

B. Grate

13. Reconnect power.

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See "Connect Range to

Downdraft System."

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, read

the "Range Care" section of the Use and Care Guide.

6. Read "Range Use" in the range Use and Care Guide.

7. Turn on surface burners and oven. See the Use and Care

Guide for specific instruction on range operation.

If range does not operate, check the following:

• Household fuse is intact and tight; or circuit breaker has not

tripped.

• Range is plugged into an outlet.

• Electrical supply is connected.

• See "Troubleshooting" in the Use and Care Guide.

When the range has been on for 5 minutes, check for heat. If

range is cold, turn off the range and contact a qualified

technician.

8. Use the Flow Tester Card provided with your range to check

the airflow (see card for step-by-step instructions).

If you need Assistance or Service:

Please reference the "Assistance or Service" section of the Use

and Care Guide or contact the dealer from whom you purchased

your range.

Tip Over Hazard

A chi(d or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

When moving range, slide range onto cardboard or hardboard to

avoid damaging the floor covering.

If removing the range is necessary for cleaning or maintenance:

For power supply cord-connected ranges:

1. Disconnect range from downdraft vent system.

2. Slide range forward.

3. Unplug the power supply cord.

4. Complete cleaning or maintenance.

5. Plug in power supply cord

6. Check that anti-tip bracket is installed, remove access panel

and use a flashlight to look underneath the bottom of the

range:

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is under anti-tip

bracket.

FLOW TESTER

::;.j2£;?-?/:??72::o::......

,=,,.................. _.......

If there is not sufficient airflow, review the "Venting

Requirements" and "Venting Methods" sections.

7. Check that range is level.

8. Reconnect range to downdraft vent system.

21

For direct-wired ranges:

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Disconnect power.

2. Disconnect range from downdraft vent system.

3. Slide range forward.

4.

Complete cleaning or maintenance.

5.

To check that anti-tip bracket is installed, remove access

panel and use a flashlight and look underneath the bottom of

the range:

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is under anti-tip

bracket.

6. Check that range is level.

7. Reconnect range to the downdraft vent system.

8. Reconnect power.

22

SECURITEDELACUISINIERE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves & vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisiniere ce qui peut causer un d_ces.

Joindre la bride antibasculement au pied arriere de la cuisiniere.

Joindre de nouveau la bride antibasculement si la cuisiniere est d_plac_e.

Le non-respect de ces instructions peut causer un d_ces ou des brl)lures graves aux enfants et

aux adultes.

23

EXIGENCESD'INSTALLATION

Rassembler les outils et composants nicessaires avant

d'entreprendre I'installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils n_cessaires

• Metre-ruban

• Niveau

• Tournevis Phillips

• Tournevis a lame plate

• Scie sauteuse ou scie

guichet

• Marqueur ou crayon

Pi6ces fournies

Verifier que toutes les pieces sont presentes.

3 ecrous hexagonaux de #10-32 (visses au boiler de

connexion)

• 3 attaches de bornes

• 2 ou 3 grilles de four (en fonction du modele)

• Moteur du ventilateur

• 2 brides pour conduit

• Conduit flexible

• Fiche de test du debit

• Gabarit pour I'emplacement du ventilateur

• 4 vis n° 8 x %" (pour le montage de la bride du ventilateur)

• 2 vis n° 12 x 13/8"(pour le montage de la bride

antibasculement)

• Bride antibasculement (fixee par du ruban adhesif & la

pochette contenant la documentation dans la cavite du four)

La bride antibasculement doit _tre bien fixee & la cloison

arriere ou au plancher. La profondeur du plancher peut

necessiter des vis plus Iongues pour I'ancrage de la bride

dans le sous-plancher. Des vis plus Iongues sont disponibles

aupres de votre quincaillerie locale.

Pi_ces n_cessaires

• L'une des bouches de decharge murales Jenn-Air suivantes :

Clapet de decharge mural en surface rond Jenn-Air ®de

5" (12,7 cm). Commander la piece n°A405.

Clapet de decharge mural en surface rond Jenn-Air ®de

6" (15,2 cm). Commander la piece n°A406.

Clapet de decharge mural en surface Jenn-Air ®31¼'' x 10"

(8,3 x 25,4 cm). Commander la piece n° A403.

Pour commander, voir la section "Assistance ou service" du

Guide d'utilisation et d'entretien.

• Conduit metallique

• Brides pour conduit

• Chevilles a beton (pour montage sur sol en beton)

• 2 cales en bois 2" x 4" x 83_'' (5 x 10,2 x 22,2 cm) (pour

evacuation par la gauche ou par la droite)

• Cle ou pince

• Tourne-ecrou de ¾e"

• Tourne-ecrou de 1¼,,

• Perceuse

• Foret de 1/8"(3,2 mm)

• Foret & ma£:onnerie & pointe

carburee de ¾e" (4,8 mm)

(pour planchers en beton/

ceramique)

En cas d'utilisation d'un cordon d'alimentation _lectrique :

• Cordon d'alimentation (homologation UL) con£:u pour

I'utilisation avec une cuisiniere. Pour service 250 volts

minimum, 40 A ou 50 A, compatible avec une ouverture de

diametre nominal 13/8'' (3,5 cm) pour le raccordement, et avec

cosses rondes ou en fourche a pointes relevees a I'extremite

de chaque conducteur.

• Un serre-c&ble (homologation UL).

Consulter les codes Iocaux. Verifier I'alimentation electrique

existante. Voir la section "Specifications electriques".

II est recommande de faire realiser tousles raccordements

electriques par un electricien qualifie agree.

IMPORTANT : Observer les dispositions de tousles codes et

reglements en vigueur.

• C'est a I'installateur qu'incombe la responsabilite de

respecter les distances de separation exigees, specifiees sur

la plaque signaletique de I'appareil. La plaque signaletique

est situee sur le c6te droit du ch&ssis du four, derriere le

panneau du tiroir de remisage.

• La cuisiniere doit _tre installee a un endroit pratique dans la

cuisine.

• Afin de supprimer le risque de brQlures ou d'incendie lie au

fait de se pencher au-dessus des plaques de cuisson

chaudes, les meubles de rangement au-dessus des plaques

doivent _tre evites. Si des placards de rangement sont

envisages, le risque peut _tre reduit par I'installation d'une

hotte de cuisine depassant le bas des placards d'au moins 5"

(12,7 cm) horizontalement.

• Respecter les dimensions indiquees pour les ouvertures

decouper dans les placards. Ces dimensions constituent les

valeurs minimales des degagements.

• La bride antibasculement de plancher doit _tre installee. Pour

I'installation de la bride antibasculement fournie avec la

cuisiniere, voir la section "Installation de la bride

antibasculement".

• Une source d'electricite avec liaison & la terre est necessaire.

Voir la section "Specifications electriques".

IMPORTANT : Afin d'eviter d'endommager les placards,

consulter le constructeur de la maison ou le fabricant des

placards pour determiner si les materiaux utilises peuvent subir

un changement de couleur, une destratification ou d'autres

dommages. Ce four a ete con(;u conformement aux exigences

des normes UL et CSA International et respecte les temperatures

maximales permises de 194°F (90°C) pour les placards en bois.

R_sidence mobile - Specifications additionnelles

respecter Iors de I'installation

L'installation de cette cuisiniere doit _tre conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD Part 280). Lorsque cette norme n'est pas applicable,

I'installation doit satisfaire aux criteres de la norme Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A ou

aux dispositions des codes Iocaux.

24

Loading...

Loading...