JENN-AIR JES9800ACW, JES9800ACS, JES9800ACB, JES9750AAS, JES9750AAB Installation Instructions

...

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Electric 30-inch Wide

Jenn-Air Downdraft Range

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in Use &

Care book before using range.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

· ALL RANGES CAN TIP AND

CAUSE INJURIES TO PERSONS.

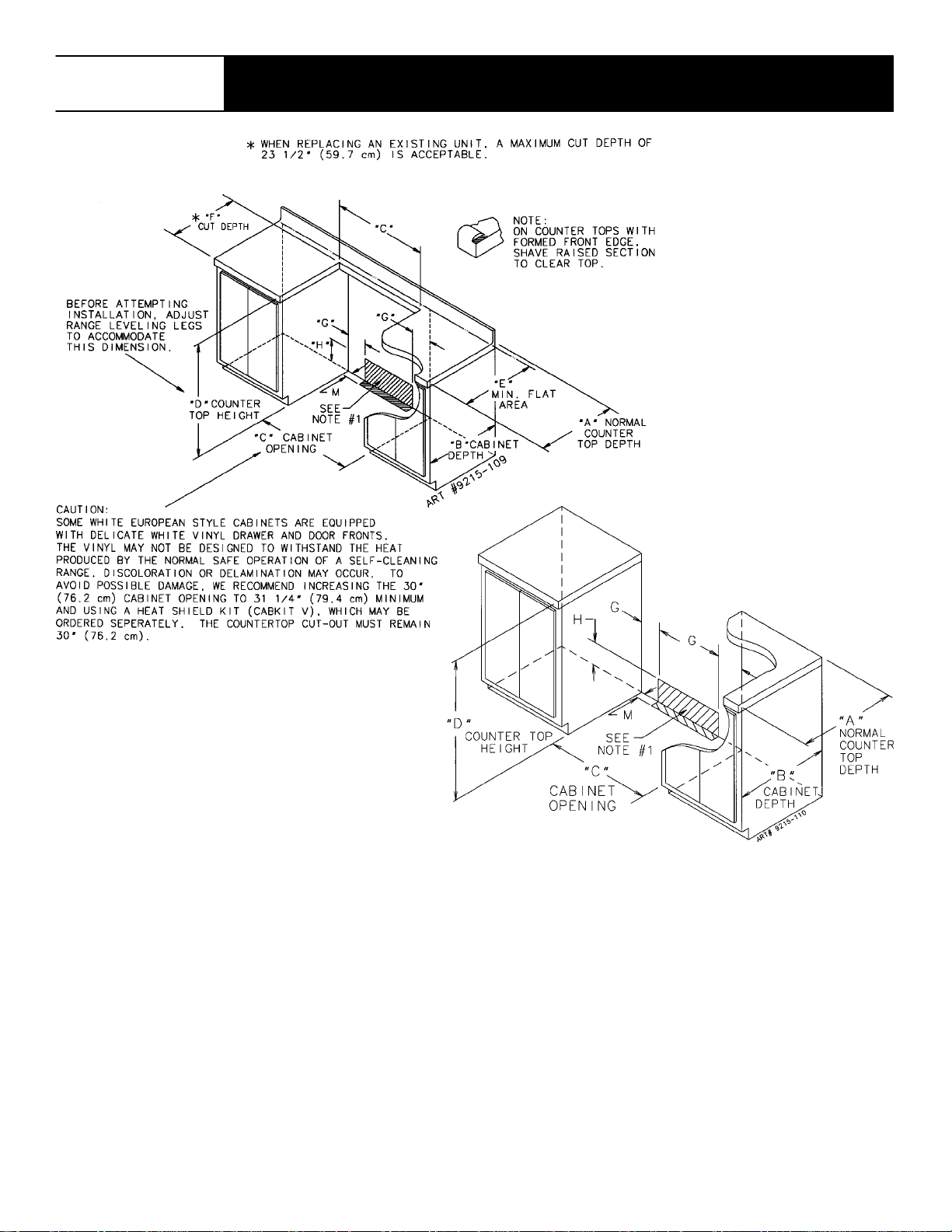

CLEARANCE DIMENSIONS

For complete information in regard to installation of

Jenn-Air range, see figures 1, 2, 3 and 4. For SAFETY

CONSIDERATIONS, do not install a range in any

combustible cabinetry which is not in accord with the

installation clearances shown in figure 1.

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range

is installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur.

Your range may not be equipped

with some of the features referred

to in this manual.

· INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

· FOLLOW ALL INSTALLATION

INSTRUCTIONS.

ENGLISH '''' PP. 1-11

ESPAÑOL '''' pág. 12-22

FRANCAIS '''' p. 23-33

8101P427-60

(03-02-02)

INSTALLATION DRAWINGS (Pages 2, 3 & 4)

IMPORTANT

PLEASE KEEP FOR THE USE OF THE LOCAL ELECTRICAL INSPECTOR.

FIGURE 1

NOTE: Figure may not be representative of actual unit.

The 30 inches (76.2 cm) minimum clearance between the

top of the cooking surface and the bottom of an

unprotected wood or metal cabinet can be reduced to 24

inches (61 cm) minimum when bottom of wood or metal

cabinet is protected by not less than 1/4-inch (6.4 mm)

thick flame-retardant millboard covered with not less than

No. 28 MSG sheet steel, 0.015-inch (0.381 mm) thick

stainless steel, 0.024-inch (0.610 mm) thick aluminum, or

0.020-inch (0.508 mm) thick copper.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches (13 cm) beyond the bottom of the

cabinets.

FIGURE 1

1 COMBUSTIBLE BACK WALL....

2 COMBUSTIBLE SIDE WALL....

3 COMBUSTIBLE WALL CABINET....

DIMENSION “A” IS TO BE A MINIMUM OF3INCHES (7.5

CM).

A SLIDE-IN RANGE, IF EQUIPPED WITH OPTIONAL

BACKGUARD KIT, MAY BE INSTALLED ZERO INCHES

FROM COMBUSTIBLE WALL 1 (SEE FIGURE 1).

-2-

30²

²

²²

JENN-AIR RANGES

FIGURE 2

FIGURE 3

NOTES:

1. Provide for either a 3-wire or 4 -wire 120/208, 120/240 volt outlet per applicable cord in shaded area shown. Refer

to installation instructions for proper positioning of outlet.

2. Dimension K (figure 4, page 4) is from the wall to the side edge of the oven door.Itdoes not include the curvature

of the glass or the depth of the handle.

3. Dimension L (figure 4, page 4) is with the leveler legs adjusted all the wayin. This may vary slightly upon leveling

leg adjustment.

4. Do not use grout, epoxy, etc., to install this unit. Installation must allow for removal of this appliance from t he

installed location for purposes of servicing.

-3-

30²

²

²²

JENN-AIR RANGES

Slide-In Range

Dimensions

FIGURE 4

JJJJ

A

B

C

D

E

F

G

H

J

2*

K

3*

L

M

* SEE NOTES ON PAGE 3

Inches

25

24

30

36

23 5/8

23 1/4

51/2

10

29 7/8

26 3/16

35 3/4

2/1/4

Centimeters

63.5

61.0

76.2

91.4

60.0

59.1

14.0

25.4

75.9

66.5

90.8

5.7

-4-

MOBILE HOMES

LOCATING THE RANGE

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, Part 280) or,

when such standard is not applicable, the Standard for

Manufactured Home Installations 1982 (Manufactured

Home Sites, Communities and Set-Ups), ANSI

A225.1-latest edition, or with local codes.

Place range in a well lit area. Do not set range over holes

in the floor or other locations where it may be subject to

strong drafts. Any opening in the wall behind the range

and in the floor under the range should be sealed. Make

sure the flow of cooling/ventilation air is not obstructed

below the range.

NOTE: A range should NOT be installed over kitchen

carpeting.

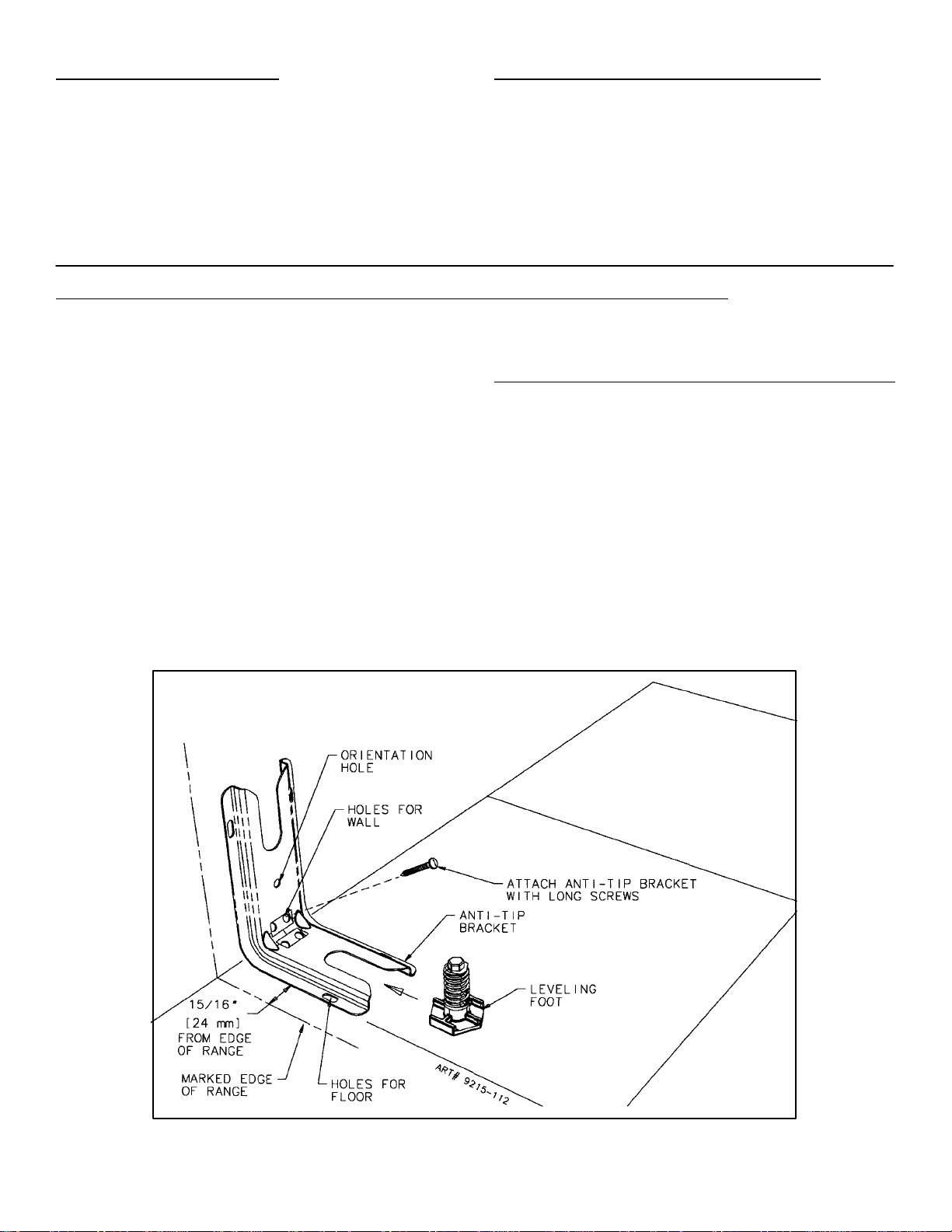

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

WARNING: A risk of range tip-over exists if the

appliance is not installed in accordance with the provided

installation instructions. The proper use of this device

minimizes the risk of TIP-OVER. In using this device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven doors as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall. The bracket may be installed

to engage the LEFT or RIGHT rear leveling foot.

Install the bracket with the orientation hole in the longer

leg against the wall as shown in figure 5.

STEP 1 - Locating The Anti-tip Bracket (See Figure

A. Determine where either the right or left “EDGE” of the

range will be located and mark the floor or wall.

B. Place the BRACKET 15/16² (24mm) from the marked

“EDGE” toward center of opening and against the

back wall as shown in figure 5, with orientation hole

against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 5, for the type of

construction you will be using.

5)

NOTE: The bracket provided is designed for use with

flush mount and non-flush mount outlet receptacles.

D. Anti-tip bracket may be secured to either floor or wall.

See Step 2 on page 6 for bracket installation options.

FIGURE 5

-5-

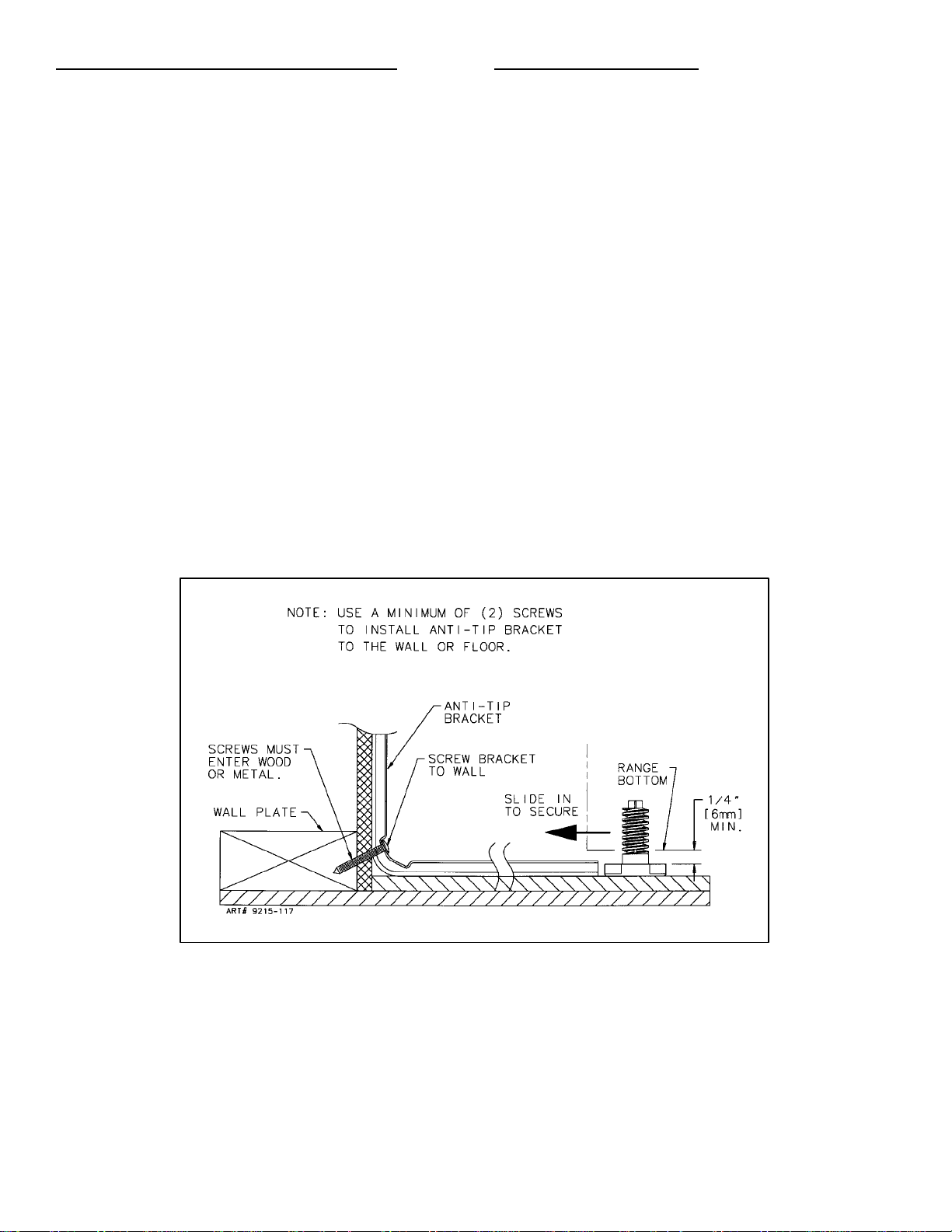

STEP 2 - Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 5 as “HOLES FOR FLOOR.” Drill a 1/8²

(3 mm) pilot hole in the center of each hole (a nail

or awl may be used if a drill is not available).

Secure the ANTI-TIP bracket to the floor with the

two screws provided. Proceed to STEP 3.

2. Wall: Locate the center of the two holes identified

in figure 5 as “HOLES FOR WALL.” Drill an

angled 1/8² (3 mm) pilot hole in the center of each

hole as shown in figure 6. (A nail or awl may be

used if a drill is not available). Secure the

ANTI-TIP bracket to the wall with the two screws

provided as shown in figure 6. Proceed to STEP

3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at the hardware store. Drill the required

size hole for the hardware obtained into the

concrete at the center of the holes identified in

figure5 as “HOLES FOR FLOOR”. Secure the

ANTI-TIP bracket to the floor. Proceed to STEP 3.

Options

STEP 3 - Range

A. A Jenn-Air range may be installed by one person.

B. Align the range to its designated location and slide it

back into position. Note: A minimum clearance of 1/4²

(6 mm) is required between the range and the leveling

foot that will engage the ANTI-TIP bracket, see figure

6.

C. All Jenn-Air ranges have a non lift-up top.

D. For SAFETY CONSIDERATIONS as well as optimum

performance adjust the range so that it is level. This

may be checked by placing a spirit level or a large

pan of water on the cooktop or the oven rack. If an

adjustment is required pull the range forward, tip the

range and rotate the leveling feet as required.

E. To check the range for proper installation of the

anti-tip bracket: Use a flashlight and look underneath

the bottom of the range to see that one of the rear

leveling feet is engaged in the bracket slot.

F. Proceed with the remainder of the installation

instructions provided with the range.

Installation

FIGURE 6

-6-

CONNECTING THE RANGE

ELECTRIC SUPPLY

The range must be installed in accordance with Local and

National Electric Code (NEC) ANSI/NFPA No. 70-latest

edition. See rating plate for total connected KW rating.

ELECTRIC SUPPLY (Canada)

The range must be installed in accordance with Local and

Canadian Electric Code CSA STD.C22.1 latest edition.

See rating plate for total connected KW rating.

OUTSIDE WIRING

Your local utility company will tell you whether the present

electric service to your home is adequate. It may be

necessary to increase the size of the wiring to the house

and service switch to take care of the electrical load

demanded by the range. The kilowatt rating for the range

is specified on the rating plate located on the front of the

range.

HOUSE WIRING

Most local Building Regulations and Codes require that all

electrical wiring be done by licensed electricians. All

wiring should conform to Local and National Electrical

Codes. This range requires a single phase three wire

120/240 or a 120/208 volt, 60 Hz, AC circuit. Wiring codes

require a separate circuit be run from the main entrance

panel to the range and that it be equipped with separate

disconnect switch and fuses, either in the main entrance

panel or in a separate switch and fuse box. In some

communities, a solid or flexible continuous armored

conduit must be used from main entrance panel to the

terminal box on the rear of the range. Others will permit

the termination of the range circuit at a polarized three or

four wire plug-in outlet placed at a convenient point near

the back of the range. The range is then connected to this

outlet through an approved range connector (pigtail)

fastened securely to the terminal block with proper strain

relief at the range and a three or four pronged plug at the

opposite end.

RANGE CONNECTIONS

Some models are shipped direct from the factory with

service cords (pigtails) attached. There are no range

connections necessary on these models. Just plug into

the range outlet. On models not provided with a service

cord, connection to the power supply is necessary.

REMEMBER - only a 4-conductor cord is to be used on

new branch-circuit installations (1996 NEC), mobile

homes, recreational vehicles, or in an area where local

codes prohibit grounding through the neutral conductor.

Hence, 4-wire service MUST be provided for such

installations. 3-wire service may be used when permitted

by local code. USE COPPER OR ALUMINUM

CONDUCTORS. Main terminal block is recognized for

Copper or Aluminum conductors. If a flexible power cord

is required, it is recommended a cord no longer than 4 ft.

be used. Make connections as explained below and with

reference to the appropriate illustration (see figures 8 and

9). After installation, insure tightness of all electrical

connections and replace all covers.

Remove terminal block access cover from range back.

(See figure 7).

RANGE CONNECTIONS (Canada)

This model was shipped direct from the factory with

service cord (pigtail) attached. There are no range

connections necessary. Just plug into the range outlet.

See figure 2 on page 3 for outlet location.

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

13/8² (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

-7-

FIGURE 7

3-WIRE SERVICE CORD OR CONDUIT

INSTALLATION

1. Insure that the copper ground strap IS CONNECTED

between the middle post of the main terminal

connection block and the range chassis.

2. The middle wire of the service cord or ground lead of

3-wire conduit MUST connect to the neutral (middle)

post of the main terminal block. The other two wires of

the service cord or conduit connect to the outside

posts of the main terminal connection block. Polarity is

unimportant.

3. A appropriate strain relief for service cord or conduit

must be attached to the conduit plate.

4-WIRE SERVICE CORD OR CONDUIT

INSTALLATION

(MOBILE HOMES OR AS REQUIRED BY CODES)

1. The copper ground strap connected between the

neutral (middle) post of the main terminal block and the

chassis MUST be cut off as shown in figure 9. Save the

green ground screw to attach the ground from the 4

wire cord. Only a 4 wire cord or conduit should be

used.

2. The ground wire from the service cord or conduit must

connect to the range chassis using the green ground

screw.

3. The white wire of the service cord or conduit must

connect to the neutral (middle) post of the main

terminal block. The other two wires of the service cord

or conduit connect to the red and black posts of the

main terminal block, respectively.

4. An appropriate strain relief for service cord or conduit

must be attached to the conduit plate.

CONVERSION FROM 3-WIRE TO 4-WIRE

SERVICE

(Model With 3-Wire Service Cord Attached)

Disconnect range from power. Remove the access cover

on back of range and remove the 3-wire service cord from

the main terminal block. Follow instructions as outlined in

figure 9 to connect the 4-wire service cord.

FIGURE 8

ACCEPTABLE 3-WIRE PLUG INSTALLATION

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

13/8² (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

FIGURE 9

ACCEPTABLE 4-WIRE PLUG INSTALLATION

-8-

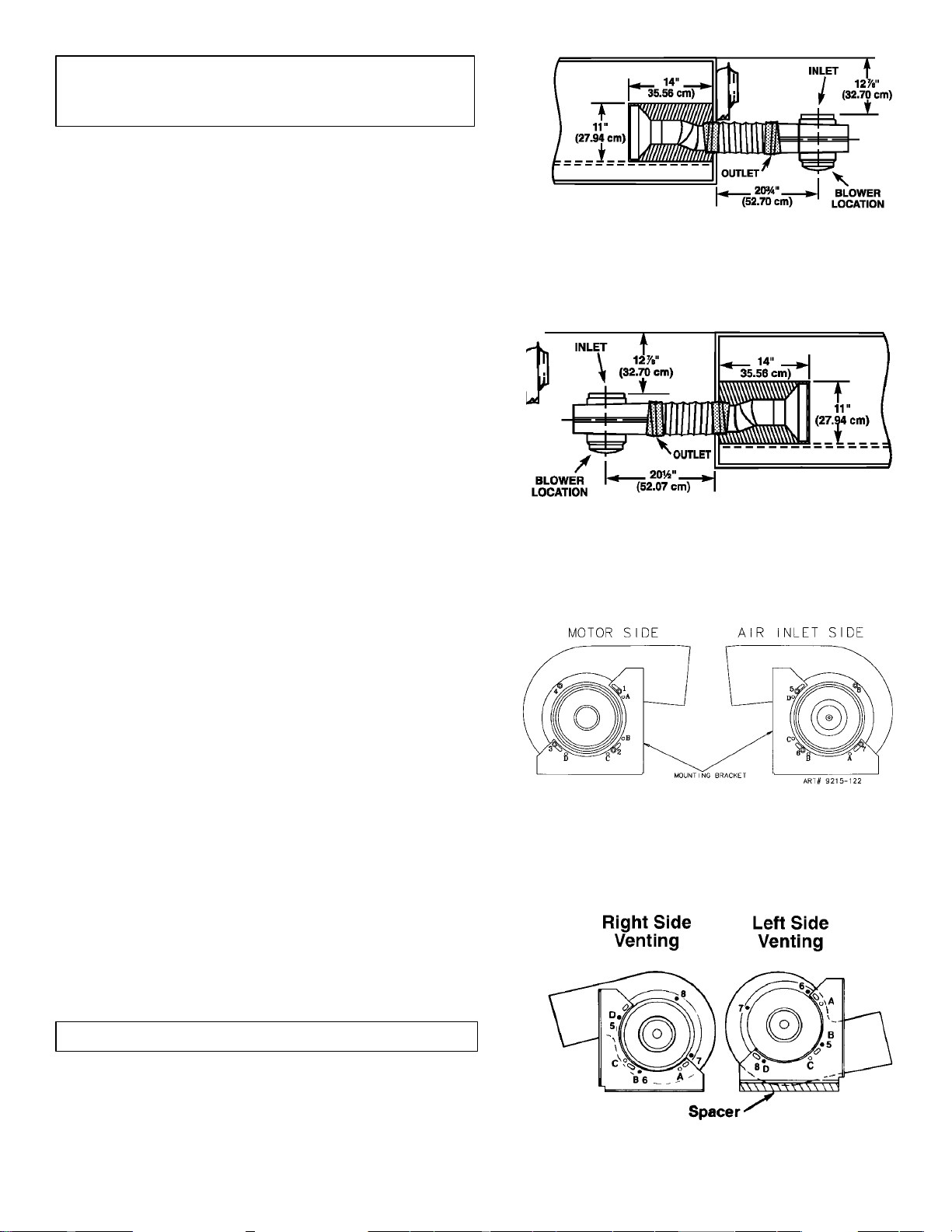

DOWNDRAFT INSTALLATION INSTRUCTIONS

S Determine where you will be locating the electrical

outlet. It must be in the floor or on the wall within the

area shown in figure 2 or 3.

S Determine how you will be venting your downdraft

blower. You may vent through the rear wall, the floor,

or the sides. When locating the downdraft vent

opening make sure it will not interfere with your

electrical outlet.

a. Through the rear wall. (See figure 10) Mark the

centerline of the cabinet opening on the rear wall.

The61/4² vent opening must be located on a

centerline 8 3/8² above the floor and within 3 1/4²

to the right (when facing the cabinet opening) of

the centerline of the cabinet opening as shown in

figure 10.

Cuta61/4² diameter hole on the marked

centerline making sure to miss any wall studs.

Install the blower as shown in figure 12.

Figure 10

b. Through the floor. (See figure 11) Making sure to

miss any floor joists cut a 6 1/4² diameter hole in

the shaded area as shown in figure 11. Install the

blower as shown in figure 12.

NOTE: If the floor is a concrete slab, see

the enclosed ducting instructions.

c. Through the Left or Right side cabinet.

(See figure 13).

1. Additional materials required:

1pc5² diameter x 19² long (12.7 cm x 48.26

cm).

Flex duct (P/N 702935).

1pc6² (15.25 cm) 90_ elbow.

2 Hose Clamps (P/N 702331).

1pc5² to31/4² x10² (12.7cmto8.26cmx

25.4 cm) Transition.

2 pcs Wood spacers (right side vent only)

11/2² thickx9² long (3.81 cm x 22.68 cm).

Figure 11

Figure 12

(See your local dealer for these accessories).

2. Cut hole in either the left or right side of the

cabinet wall as shown in figure 13.

3. Make cutout in the cabinet floor of either the right

or left side cabinet as shown in figures 14 or 15.

4. Relocate the mounting brackets on the blower

housing as shown in figure 17.

Figure 13

-9-

NOTE: The mounting brackets shown in figure 16

are as assembled at the factory for floor or rear wall

venting.

a. Right side venting (figure 17).

1. Remove nuts from studs 1, 2 and 3 on the motor

side.

2. Remove bracket and reattach with studs 1 and 2

inserted in holes A and C and replace 3 nuts.

3. Remove nuts from studs 5, 6 and 7 on air inlet side.

4. Remove bracket and reattach with studs 5 and 6

inserted in holes D and B and replace 3 nuts.

b. Left side venting (figure 17).

1. Remove nuts from studs 1, 2, 3 and 4 on motor

side.

2. Remove bracket.

3. Rotate motor and cover assembly 180 degrees.

4. Reattach bracket with studs 4 and 1 inserted in

holes A and C and replace all 4 nuts.

5. Remove nuts from studs 5, 6, 7 and 8 on inlet side.

6. Remove bracket and reattach with studs 8 and 5

inserted in holes D and B and replace all 4 nuts.

5. Attach the blower housing to the floor with the outlet

towards the direction of the venting and the inlet towards

the front of the cabinets. In addition, for left side venting, a

spacer of approximately 1-1/2² thickx9² long (3.81 cm x

22.86 cm) is required under the mounting bracket flanges

of the blower assembly (see figure 17).

6. Remove the inside wire and outside string from the first

1-1/2² (3.81 cm) of one end of the 5² (12.7 cm) flex duct

(P/N 702935). Stretch this end of the flex duct over the

end of the 5² x3-1/4² x10² (12.7 cm x 25.4 cm) transition

and secure with hose clamp (P/N 702331).

7. When the range is placed in position, feed the open end of

the 5² (12.7 cm) flex duct through the hole in the cabinet

side wall and attach to the outlet of the blower housing

with hose clamp (P/N 702331). The transition should then

be attached to the 3-1/4² x10² (12.7 cm x 25.4 cm)

ducting in the cabinet toe space through the cabinet floor

cutout.

8. Install the 6² (15.24 cm) elbow of the blower housing and

secure with duct tape. The open end of the elbow should

be pointed to the left. Attach the 6² (15.24 cm) flex duct

(provided with the range) to the elbow and to the range.

Note: For right side venting, the 6² (15.24 cm) diameter

flex duct may be cut in half and used in order to make

assembly easier.

Figure 14

Left Cabinet (Top View)

Figure 15

Right Cabinet (Top View)

Figure 16

Blower Assembly

INSTALLING THE BLOWER

NOTE: Install the blower prior to installing the range.

S Refer to your duct plan. It may be easier to attach part of

the ducting to the blower before it is installed.

S Position the blower and attach to the floor with at least 2

screws.

S Apply duct tape to blower exhaust duct joint. (See figure

12).

Figure 17

View from Air Inlet Side of Blower

-10-

Loading...

Loading...