JENN-AIR JES8850ACW, JES8850ACS, JES8850ACB, JES8750AAW, JES8750AAB Installation Instructions

...Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Electric 30-inch Wide

Jenn-Air Radiant Element Range

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in Use &

Care book before using range.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

· ALL RANGES CAN TIP AND

CAUSE INJURIES TO PERSONS.

CLEARANCE DIMENSIONS

For complete information in regard to installation of

Jenn-Air range, see figures 1, 2, 3 and 4. For SAFETY

CONSIDERATIONS, do not install a range in any

combustible cabinetry which is not in accord with the

installation clearances shown in figure 1.

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range

is installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur.

Your range may not be equipped

with some of the features referred

to in this manual.

· INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

· FOLLOW ALL INSTALLATION

INSTRUCTIONS.

ENGLISH '''' PP. 1-8

ESPAÑOL '''' pág. 9-16

FRANCAIS '''' p. 17-24

8101P429-60

(03-02-01)

Page 2

INSTALLATION DRAWINGS (Pages 2, 3 & 4)

IMPORTANT

PLEASE KEEP FOR THE USE OF THE LOCAL ELECTRICAL INSPECTOR.

FIGURE 1

NOTE: Figure may not be representative of actual unit.

The 30 inches (76.2 cm) minimum clearance between the

top of the cooking surface and the bottom of an

unprotected wood or metal cabinet can be reduced to 24

inches (61 cm) minimum when bottom of wood or metal

cabinet is protected by not less than 1/4-inch (6.4 mm)

thick flame-retardant millboard covered with not less than

No. 28 MSG sheet steel, 0.015-inch (0.381 mm) thick

stainless steel, 0.024-inch (0.610 mm) thick aluminum, or

0.020-inch (0.508 mm) thick copper.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches (13 cm) beyond the bottom of the

cabinets.

FIGURE 1

1 COMBUSTIBLE BACK WALL....

2 COMBUSTIBLE SIDE WALL....

3 COMBUSTIBLE WALL CABINET....

DIMENSION “A” ISTOBEA MINIMUM OF 3 INCHES (7.5

CM).

A SLIDE-IN RANGE, IF EQUIPPED WITH OPTIONAL

BACKGUARD KIT, MAY BE INSTALLED ZERO INCHES

FROM COMBUSTIBLE WALL 1 (SEE FIGURE 1).

-2-

Page 3

30²

²

²²

JENN-AIR RANGES

FIGURE 2

FIGURE 3

Notes:

1. Provide for either a 3-wire or 4-wire 120/208, 120/240 volt outlet per applicable cord in shaded area shown. Refer

to installation instructions for proper positioning of outlet.

2. Dimension K (figure 4, page 4) is from the wall to the side edge of the oven door. It does not include the curvature

of the glass or the depth of the handle.

3. Dimension L (figure 4, page 4) is with the leveler legs adjusted all the way in. This may vary slightly upon leveling

leg a djustment.

4. Do not use grout, epoxy, etc., to install this unit. Installation must allow for removal of this appliance from the

installed location for purposes of servicing.

-3-

Page 4

30²

²

²²

JENN-AIR RANGES

Unity II Slide-In Range

Dimensions

FIGURE 4

JJJJ

A

B

C

D

E

F

G

H

J

2*

K

3*

L

M

* SEE NOTES ON PAGE 3

Inches

25

24

30

36

23 5/8

23 1/4

51/2

10

29 7/8

26 3/16

35 3/4

2/1/4

Centimeters

63.5

61.0

76.2

91.4

60.0

59.1

14.0

25.4

75.9

66.5

90.8

5.7

-4-

Page 5

MOBILE HOMES

LOCATING THE RANGE

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, Part 280) or,

when such standard is not applicable, the Standard for

Manufactured Home Installations 1982 (Manufactured

Home Sites, Communities and Set-Ups), ANSI

A225.1-latest edition, or with local codes.

Place range in a well lit area. Do not set range over holes

in the floor or other locations where it may be subject to

strong drafts. Any opening in the wall behind the range

and in the floor under the range should be sealed. Make

sure the flow of cooling/ventilation air is not obstructed

below the range.

NOTE: A range should NOT be installed over kitchen

carpeting.

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

WARNING: A risk of range tip-over exists if the appliance

is not installed in accordance with the provided installation

instructions. The proper use of this device minimizes the

risk of TIP-OVER. In using this device the consumer must

still observe the safety precautions as stated in the USE

and CARE MANUAL and avoid using the oven doors as a

step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall. The bracket may be installed

to engage the LEFT or RIGHT rear leveling foot.

NOTE: The bracket provided is designed for use with

flush mount and non-flush mount outlet receptacles.

Install the bracket with the orientation hole in the longer

leg against the wall as shown in figure 5.

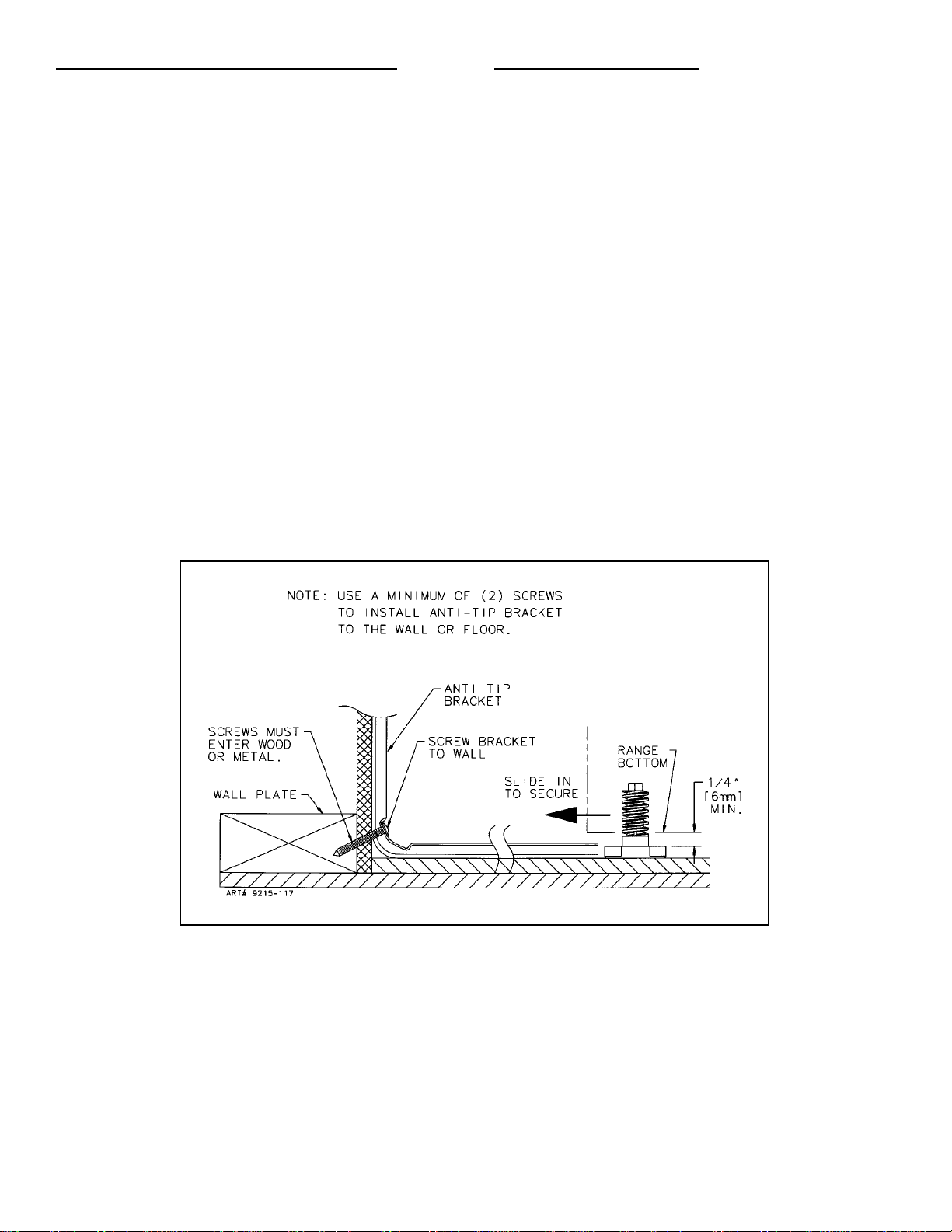

STEP 1 - Locating The Anti-tip Bracket (See Figure

A. Determine where either the right or left “EDGE” of the

range will be located and mark the floor or wall.

B. Place the BRACKET 15/16² (24mm) from the marked

“EDGE” toward center of opening and against the

back wall as shown in figure 5, with orientation hole

against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 5, for the type of

construction you will be using.

D. Anti-tip bracket may be secured to either floor or wall.

See Step 2 on page 6 for bracket installation options.

5)

FIGURE 5

-5-

Page 6

STEP 2 - Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor:Locatethecenterofthetwoholesidentifiedin

figure 5 as “HOLES FOR FLOOR.” Drill a 1/8² (3

mm) pilot hole in the center of each hole (a nail or

awlmaybeusedifa drillisnotavailable).Securethe

ANTI-TIP bracket to the floor with the two screws

provided. Proceed to STEP 3.

Options

STEP 3 - Range

A. A Jenn-Air range may be installed by one person.

B. Align the range to its designated location and slide it

back into position. Note: A minimum clearance of 1/4²

(6 mm) is required between the range and the leveling

foot that will engage the ANTI-TIP bracket, see figure

6.

Installation

2. Wall:Locate the center of the two holes identified in

figure 5 as “HOLES FOR WALL.” Drill an angled

1/8² (3 mm) pilot hole in the center of each hole as

showninfigure 6. (A nailorawlmaybe used if adrill

isnotavailable).SecuretheANTI-TIPbracket tothe

wallwiththetwo screws provided as shown in figure

6. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at the hardware store. Drill the required

size hole for the hardware obtained into the

concreteatthecenteroftheholesidentifiedinfigure

5 as “HOLES FOR FLOOR”. Secure the ANTI-TIP

bracket to the floor. Proceed to STEP 3.

C. All Jenn-Air ranges have a non lift-up top.

D. For SAFETY CONSIDERATIONS as well as optimum

performance adjust the range so that it is level. This

may be checked by placing a spirit level or a large

pan of water on the cooktop or the oven rack. If an

adjustment is required pull the range forward, tip the

range and rotate the leveling feet as required.

E. To check the range for proper installation of the

anti-tip bracket: Use a flashlight and look underneath

the bottom of the range to see that one of the rear

leveling feet is engaged in the bracket slot.

F. Proceed with the remainder of the installation

instructions provided with the range.

FIGURE 6

-6-

Page 7

CONNECTING THE RANGE

ELECTRIC SUPPLY

The range must be installed in accordance with Local and

National Electric Code (NEC) ANSI/NFPA No. 70-latest

edition. See rating plate for total connected KW rating.

ELECTRIC SUPPLY (Canada)

The range must be installed in accordance with Local and

Canadian Electric Code CSA STD.C22.1 latest edition.

See rating plate for total connected KW rating.

OUTSIDE WIRING

Your local utility company will tell you whether the present

electric service to your home is adequate. It may be

necessary to increase the size of the wiring to the house

and service switch to take care of the electrical load

demanded by the range. The kilowatt rating for the range

is specified on the rating plate located on the front of the

range.

HOUSE WIRING

Most local Building Regulations and Codes require that all

electrical wiring be done by licensed electricians. All

wiring should conform to Local and National Electrical

Codes. This range requires a single phase three wire

120/240 or a 120/208 volt, 60 Hz, AC circuit. Wiring codes

require a separate circuit be run from the main entrance

panel to the range and that it be equipped with separate

disconnect switch and fuses, either in the main entrance

panel or in a separate switch and fuse box. In some

communities, a solid or flexible continuous armored

conduit must be used from main entrance panel to the

terminal box on the rear of the range. Others will permit

the termination of the range circuit at a polarized three or

four wire plug-in outlet placed at a convenient point near

the back of the range. The range is then connected to this

outlet through an approved range connector (pigtail)

fastened securely to the terminal block with proper strain

relief at the range and a three or four pronged plug at the

opposite end.

RANGE CONNECTIONS

Some models are shipped direct from the factory with

service cords (pigtails) attached. There are no range

connections necessary on these models. Just plug into

the range outlet. On models not provided with a service

cord, connection to the power supply is necessary.

REMEMBER - only a 4-conductor cord is to be used on

new branch-circuit installations (1996 NEC), mobile

homes, recreational vehicles, or in an area where local

codes prohibit grounding through the neutral conductor.

Hence, 4-wire service MUST be provided for such

installations. 3-wire service may be used when permitted

by local code. USE COPPER OR ALUMINUM

CONDUCTORS. Main terminal block is recognized for

Copper or Aluminum conductors. If a flexible power cord

is required, it is recommended a cord no longer than 4 ft.

be used. Make connections as explained below and with

reference to the appropriate illustration (see figures 8 and

9). After installation, insure tightness of all electrical

connections and replace all covers.

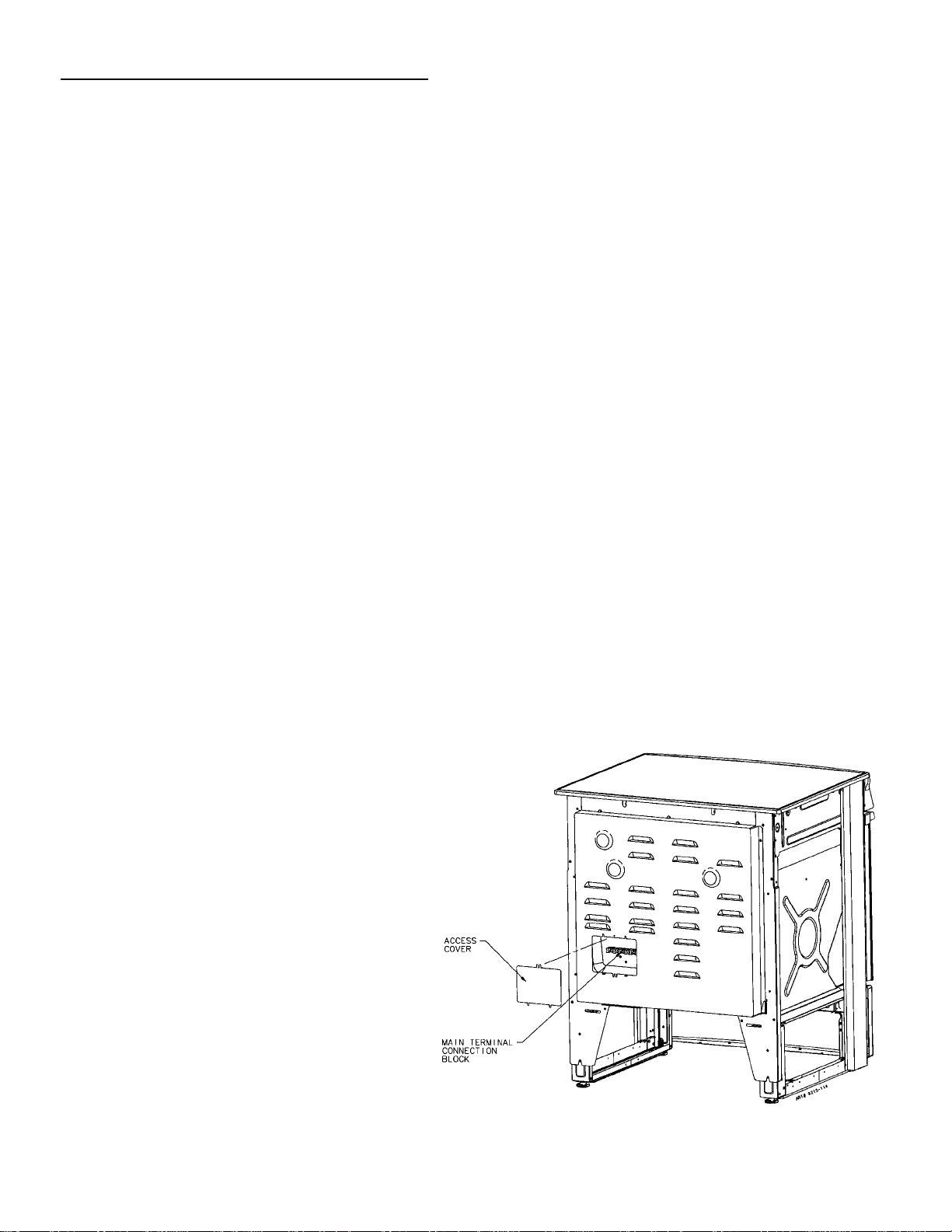

Remove terminal block access cover from range back.

(See figure 7).

RANGE CONNECTIONS (Canada)

This model was shipped direct from the factory with

service cord (pigtail) attached. There are no range

connections necessary. Just plug into the range outlet.

See figure 2 on page 3 for outlet location.

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

13/8² (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

-7-

FIGURE 7

Page 8

3-WIRE SERVICE CORD OR CONDUIT

INSTALLATION

1. Insure that the copper ground strap IS CONNECTED

between the middle post of the main terminal

connection block and the range chassis.

2. The middle wire of the service cord or ground lead of

3-wire conduit MUST connect to the neutral (middle)

post of the main terminal block. The other two wires of

the service cord or conduit connect to the outside

posts of the main terminal connection block. Polarity is

unimportant.

3. A appropriate strain relief for service cord or conduit

must be attached to the conduit plate.

4-WIRE SERVICE CORD OR CONDUIT

INSTALLATION

(MOBILE HOMES OR AS REQUIRED BY CODES)

1. The copper ground strap connected between the

neutral (middle) post of the main terminal block and the

chassis MUST be cut off as shown in figure 9. Save the

green ground screw to attach the ground from the 4

wire cord. Only a 4 wire cord or conduit should be

used.

2. The ground wire from the service cord or conduit must

connect to the range chassis using the green ground

screw.

3. The white wire of the service cord or conduit must

connect to the neutral (middle) post of the main

terminal block. The other two wires of the service cord

or conduit connect to the red and black posts of the

main terminal block, respectively.

4. An appropriate strain relief for service cord or conduit

must be attached to the conduit plate.

CONVERSION FROM 3-WIRE TO 4-WIRE

SERVICE

(Model With 3-Wire Service Cord Attached)

Disconnect range from power. Remove the access cover

on back of range and remove the 3-wire service cord from

the main terminal block. Follow instructions as outlined in

figure 9 to connect the 4-wire service cord.

FIGURE 8

ACCEPTABLE 3-WIRE PLUG INSTALLATION

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

13/8² (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

FIGURE 9

ACCEPTABLE 4-WIRE PLUG INSTALLATION

-8-

Page 9

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL APARATO

MANUAL DE INSTALACIÓN

Estufa eléctrica Jenn-Air de 30 pulgadas

(76,2 cm) de ancho con elemento radiante

CONSERVE ESTE MANUAL PARA REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE AYUDARLE EN LA INSTALACIÓN Y LOS AJUSTES INICIALES DE LA ESTUFA.

ADVERTENCIA ESPECIAL

Solamente personal calificado debe

instalar o darle servicio a esta estufa.

Lea las “Instrucciones de seguridad”

en el manual de Uso y cuidado antes

de utilizar la estufa.

La instalación, el ajuste, las

alteraciones, el servicio, el

mantenimiento o el uso incorrectos

de la estufa pueden causar lesiones

graves o daños materiales.

ADVERTENCIA

· TODAS LAS ESTUFAS PUEDEN

LADEARSE Y CAUSAR

LESIONES A LAS PERSONAS.

DIMENSIONES DEL HUECO

Para obtener la información completa relacionada con la

instalación de la estufa Jenn-Air, vea las figuras 1, 2, 3 y

4. Por RAZONES DE SEGURIDAD no instale la estufa

en ningún gabinete que sea combustible y que no esté de

acuerdo con las dimensiones de los espacios de

instalación que se muestran en la figura 1.

PRECAUCIÓN: Esta estufa se ha diseñado en

conformidad con los requisitos de varias agencias de

seguridad y cumple con las temperaturas máximas

permisibles de 194°F(90°C) para los gabinetes de

madera. Si se instala esta estufa en gabinetes que

tengan temperatura de trabajo menor de 194°F

(90°C), podría ocurrir decoloración, pérdida del

laminado o podría derretirse.

Es posible que su estufa no esté

equipada con algunas de las

características que se mencionan

en este manual.

· INSTALE LOS SOPORTES

ESTABILIZADORES QUE SE

INCLUYEN CON LA ESTUFA.

· SIGA TODAS LAS INSTRUCCIO-NES DE INSTALACIÓN.

ENGLISH '''' PP. 1-8

ESPAÑOL '''' pág. 9-16

FRANÇAIS '''' p. 17-24

Page 10

DIBUJOS DE LA INSTALACIÓN (Páginas 10, 11 y 12)

IMPORTANTE

SÍRVASE CONSERVARLO PARA QUE LO USE EL INSPECTOR ELÉCTRICO LOCAL.

MÁXIMA PROFUNDIDAD DE LOS GABINETES ENCIMA

DE LA SUPERFICIE DE COCINAR DE 13” [33 cm].

0” DE ESPACIO LIBRE ENTRE LA CONSTRUCCIÓN

COMBUSTIBLE ADYACENTE Y LAS PARTES

POSTERIOR Y LATERALES DE LA ESTUFA DEBAJO

DE LA SUPERFICIE DE COCINAR.

NOTA: La figura no es necesariamente representativa de la unidad real.

Las 30 pulgadas (76,2 cm espacio mínimo entre la parte

superior de la superficie de cocinar y la parte interior de

un gabinete sin protección de madera o metal, pueden

reducirse a 24 pulgadas (61 cm) como mínimo cuando la

parte interior de un gabinete de madera o metal este

protegido por cuando menos un cartón de 1/4 pulg. (6,4

mm) de grueso, resistente a las llamas, recubierto con

una hoja de acero que no sea menor del No. 28 MSG,

una hoja de acero inoxidable de 0,015 pulg. (0,381 mm)

de espesor 0,024 pulg. (0,610 mm), o una de cobre de

0,020 pulg. (0,508 mm) de espesor.

Para eliminar el riesgo de quemaduras o incendios al

alcanzar cosas por encima de las unidades calientes de

la superficie, no almacene nada en el espacio de

almacenamiento del gabinete que está ubicado encima

de las unidades de la superficie. Si se va a proporcionar

FIGURA 1

almacenamiento de gabinete, el riesgo puede reducirse

instalando una campana de estufa que sobresalga

horizontalmente cuando menos 5 pulgadas (13 cm) de la

parte inferior de los gabinetes.

FIGURA 1

1 PARED POSTERIOR COMBUSTIBLE....

2 PARED LATERAL COMBUSTIBLE....

3 GABINETE COMBUSTIBLE DE PARED ....

LA DIMENSIÓN “A” TIENE QUE SER CUANDO MENOS

DE 3 PULGADAS (7.5 CM).

LAS ESTUFAS DESLIZABLES, SI ESTÁN EQUIPADAS

CON EL JUEGO DEL PROTECTOR DE SEGURIDAD

OPCIONAL, PUEDEN INSTALARSE A CERO

PULGADAS DE LA PARED COMBUSTIBLE 1 (VEA LA

FIGURA 1).

-10-

Page 11

30²²²² (76,2 cm)

ESTUFAS JENN--AIR

* CUANDO ESTÉ REEMPLAZANDO UNA UNIDAD EXISTENTE, LA MÁXIMA

PROFUNDIDAD DEL CORTE DE 23 1/2² (59,7 CM) SERÁ ACEPTABLE.

*

PROFUNDI

DAD DEL

CORTE

“F”

ANTESDETRATARDE

INSTALARLA, AJUSTE

LAS PATAS

NIVELADORAS PARA

QUESEAJUSTENA

ESTA DIMENSIÓN.

ALTURA A LA PARTE

SUPERIORDEL MOSTRADOR

“D”

ABERTURADEL

GABINETE“C”

VEA LA

NOTA

NO. 1

FIGURA 2

PRECAUCIÓN:

ALGUNOS GABINETES DE ESTILO EUROPEO EN COLOR BLANCO

ESTÁN EQUIPADOS CON FRENTES DEVINILO DELICADO EN

COLOR BLANCO EN EL CAJÓN Y EN LA PUERTA. ESTE VINILO

PODRÍA NO ESTAR DISEÑADO PARA SOPORTAR EL CALOR

PRODUCIDO POR LA OPERACIÓN SEGURA NORMAL DE UNA

ESTUFA CON LIMPIEZA AUTOMÁTICA. PODRÍA OCURRIR

DECOLORACIÓN O DELAMINACIÓN. SE RECOMIENDA AUMENTAR

LA ABERTURA DEL GABINETE DE 30² (76,2CM)A311/4² (79,4 CM)

CUANDO MENOS Y USAR UN JUEGO DE CORAZA PROTECTORA

CONTRA CALOR (CABKIT V). LA CUAL PUEDE PEDIRSE POR

SEPARADO. EL CORTE DEL MOSTRADOR DEBE PERMANECER DE

30² (76,2 CM)

ÁREA

HORIZONTA

L MÍNIMA “E”

PROFUNDIDAD DEL

GABINETE “B”

NOTA:

EN LAS SUPERFICIES DE LOS

MOSTRADORES CON BORDE

DELANTERO FORMADO, REBAJE

LA SECCIÓN REALZADA PARA

LIBRAR LA PARTE SUPERIOR.

PROFUNDIDAD NORMAL DE

LA SUPERFICIE DEL

MOSTRADOR “A”

PROFUN--

DIDAD

ALTURA A LA PARTE

SUPERIOR DEL

MOSTRADOR “D”

ABERTURA

DEL GABINETE

“C”

VEA LA

NOTA

NO. 1

PROFUNDIDAD

DEL GABINETE

“B”

NORMAL DE

LA SUPER --

FICIE DEL

MOSTRADOR

“A”

FIGURA 3

Notas:

1. Provea un tomacorriente de 120/208, 120/240 voltios de 3 ó 4 cables por cordón eléctrico correspondiente en el

área sombreada que se muestra. Consulte las instrucciones de instalación para obtener la colocación correcta

del t omacorriente.

2. La dimensiónK (figura 4, página 12) es de la pared al borde lateral de la puerta del horno. No incluye la curvatura

del vidrio ni la profundidad del asa.

3. La dimensión L (figura 4, página 12) es con las patas niveladoras ajustadas completamente. Esto podría variar

ligeramente dependiendo del ajuste de las patas niveladoras.

4. No use lechada, epoxia, etc., para instalar esta unidad. La instalación debe permitir que se pueda quitar este

aparato de su lugar para fines de servicio.

-11-

Page 12

30²²²² (76,2 cm)

ESTUFAS JENN--AIR

Estufa deslizable Unity II

Dimensiones

FIGURA 4

JJJJ

A

B

C

D

E

F

G

H

J

2*

K

3*

L

M

* VEA LAS NOTAS EN LA PÁGI NA 11

Pulgadas

25

24

30

36

23 5/8

23 1/4

51/2

10

29 7/8

26 3/16

35 3/4

21/4

Centímetros

63,5

61,0

76,2

91,4

60,0

59,1

14,0

25,4

75,9

66,5

90,8

5,7

-12-

Page 13

CASAS MÓVILES

La instalación de una estufa diseñada para casas móviles

debe estar en conformidad con las Normas de Seguridad

y Construcción de Cas as Prefabricadas (Manufactured

Home Cons truction and Safety Standard, Título 24 CFR,

Parte 3280 (anteriormente Federal Standard for Mobile

Home Cons truction and Safety, Título 24 HUD, Parte 280)

o, cuando dichas normas no correspondan, las Normas

UBICACIÓN DE LA ESTUFA

Coloque la estufa en un área bien iluminada. No la

coloque sobre agujeros del piso ni en algún lugar en

donde pueda rec ibir corrientes fuertes de aire. Deben

sellarse los orificios de la pared posterior y del piso debajo

de la estufa. Asegúrese de que el flujo de enfriamiento o

el aire de ventilación no estén obstruidos debajo de la

estufa.

para Instalaciones en Casas Prefabricadas de 1982

(Manufactured Home Sites, Communities and Set-Ups),

ANSI A225.1, última edición o con los códigos locales.

NOTA: No debe instalarse la estufa sobre alfombra

de cocina.

INSTRUCCIONES DE INSTALACIÓN DEL DISPOSITIVO ESTABILIZADOR

ADVERTENCIA: Existe la posibilidad de que la estufa se

ladee si no está instalada de acuerdo c on las

instrucciones de instalación que se proporcionan. El uso

correcto de este dispositivo reduce el riesgo de LADEO.

Al usar este dispositivo el consumidor aún debe acatar las

precauciones de seguridad que se dictan en el MANUAL

DE USO Y CUIDADO y debe evitar utilizar las puertas del

horno como banquillo.

Las instrucciones de instalación se proporcionan para

madera y c emento tanto en piso como en pared.

Cualquier otro tipo de construcción podría necesitar

técnicas especiales de instalación según se determine

necesario para proporcionar la sujeción adecuada del

soporte ESTABILIZADOR al pisooalapared. Elsoporte

puede instalarse para sujetar la pata niveladora posterior

IZQUIERDA o DERECHA.

NOTA: El soporte proporcionado está diseñado para

utilizarse con receptáculos de los tomacorrientes

montados al ras y realzados.

Instale el soporte con el orificio de orientación en la pata

más larga, contra la pared o el piso según se muestra en

la figura 5.

PASO 1 - Ubicación del soporte estabilizador (Vea la

figura 5.)

A. Decida en dónde se ubicará el “BORDE” derecho o

izquierdo de la estufa y marque el piso o la pared.

B. Coloque el SOPORTE a 15/16² (24mm) del “BORDE”

marcado hacia el centro de la abertura y contra la

pared posterior según se muestra en la figura 5, con el

orificio de orientación contra la pared.

C. Us e el soporte como plantilla y marque los orificios

necesarios, según se muestra en la figura 5, para el

tipo de construcción que se utilizará.

D. El soporte estabilizador puede asegurarse al piso o a

la pared. Vea el Paso 2 en la página 14 para

encontrar las opciones de instalación del soporte.

15/16²

(24 MM)

DEL BORDE

DE LA

ESTUFA

BORDE MARCADO

DE LA ESTUFA

ORIFICIO DE

ORIENTACIÓN

ORIFICIOS

PARA LA

PARED

SUJETE EL SOPORTE

ESTABILIZADOR CON

TORNILLOSLARGOS

SOPORTE

ESTABILIZADOR

PATA

NIVELADORA

ORIFICIOS

PARA EL PISO

FIGURA 5

-13-

Page 14

PASO 2 — Opciones para la instalación del

soporte

estabilizador

A. Construcción de madera:

1. Piso: Ubique el centro de los dos orificios que se

identifican en la figura 5 como “ORIFICIOS PARA

EL PISO.” Taladre un agujero piloto de 1/8²

(3 mm) en el centro de cada orificio (puede

utilizarse un clavo o una lezna si no tiene una

broca). Asegure el soporte ESTABILIZADOR al

piso con los dos tornillos que se proporcionan.

Continúe con el PASO 3.

2. Pared: Ubique el centro de los dos orificios que

se identifican en la figura 5 como “ORIFICIOS

PARA LA PARED.” Taladre un agujero piloto en

ángulo de 1/8² (3 mm) en el centro de cada

orificio según se muestra en la figura 6. (Puede

utilizarse un clavo o una lezna si no tiene una

broca.) Asegure el soporte a la pared con los dos

tornillos que se proporcionan según se muestra

en la figura 6. Continúe con el PASO 3.

PASO 3 — Instalación de la

estufa

A. Las estufas Jenn-Air puede instalarlas una sola

persona.

B. Alinee la estufa en la ubicación que se desee y

deslícela hacia atrás en su lugar. Nota: Se necesita

una distancia mínima de 1/4² (6 mm) entre la estufa y

la pata niveladora que se asegurará al soporte

estabilizador, vea la figura 6.

C. Todas las estufas Jenn-Air tienen una tapa que no

puede levantarse.

D. Por RAZONES DE SEGURIDAD así como para

obtener el funcionamiento óptimo, ajuste la estufa

para que quede bien nivelada. Esto puede revisarse

colocando un nivel de burbuja o un recipiente grande

con agua sobre la estufa o en la parrilla del horno. Si

es necesario ajustarla estire la estufa hacia adelante,

ladéela y gire las patas niveladoras según sea

necesario.

B. Construcción de cemento o concreto:

1. En una ferretería pueden obtenerse los tornillos

adecuados para las construcciones de concreto.

Taladre un agujero del tamaño necesario para los

tornillos que se tengan, en el concreto en el

centro de los orificios que se identifican en la

figura 5 como “ORIFICIOS PARA EL PISO”.

Asegure el soporte ESTABILIZADOR al piso.

Continúe con el PASO 3.

NOTA:USE CUANDO MENOS DOS (2)

TORNILLOS PARA INSTALAR EL

SOPORTE ESTABILIZADOR A LA PARED O

AL PISO.

LOS TORNILLOS

DEBEN ENTRAR

EN LA MADERA

O EL METAL.

PLACA DE PARED

E. Para verificar que el soporte estabilizador esté

instalado correctamente en la estufa: Use una linterna

y vea debajo de la parte inferior de la estufa para

comprobar que una de las patas niveladoras

posteriores esté asegurada a la ranura del soporte.

F. Continúe con el resto de las instrucciones de

instalación que se proporcionan con la estufa.

SOPORTE

ESTABILIZADOR

ATORNILLE EL

SOPORTE A LA PARED

DESLÍCELO PARA

ASEGURARLO

PARTE

INFERIOR

DE LA

ESTUFA

1/4²

(6 MM)

MÍN.

FIGURA 6

-14-

Page 15

CONEXIÓN DE LA ESTUFA

SUMINISTRO ELÉCTRICO

La estufa debe instalarse de acuerdo con los Códigos

Eléctricos Nacionales y Locales (NEC) ANSI/NFPA No.

70, última edición. Vea la placa de clasificación para

obtener la clasificación total de kilovatios conectados.

SUMINISTRO ELÉCTRICO (Canadá)

La estufa debe instalarse de acuerdo con los Códigos

Eléctricos Canadienses y Locales CSA STD.C22.1, última

edición. Vea la clasificación para obtener la clasificación

total de kilovatios conectados.

CABLEADO EXTERIOR

La compañía local de servicios públicos le informará si es

adecuado el servicio eléctrico actual de su casa. Podría

ser necesario aumentar el tamaño del cableado a la casa

y el interruptor de servicio para poder con la carga

eléctrica que la estufa demanda. La clasificación de

kilovatios para la estufa está especificada en la placa de

clasificación que está ubicada al frente de la estufa.

CABLEADO DE LA CASA

La mayoría de los códigos y reglamentos locales para

edificios exigen que todo el cableado eléctrico lo instale

un electricista con licencia. Todo el cableado debe estar

en conformidad con los Códigos Eléctricos Nacionales y

Locales. Esta estufa requiere un circuito de CA

monofásico de tres o cuatro cables de 120/240 o de

120/208 voltios, 60 Hz. Los códigos de cableado

requieren que se tenga un circuito separado del tablero

principal de entrada a la estufa y que esté equipado con

fusibles y con un interruptor de desconexión, ya sea en el

tablero principal de entrada o en un interruptor y caja de

fusibles separados. En algunas comunidades, debe

usarse un conductor flexible o sólido acorazado continuo

del tablero principal de entrada a la caja terminal en la

parte posterior de la estufa. Otras comunidades

permitirán que el circuito de la estufa termine en un

tomacorriente de conexión polarizada de tres o cuatro

cables colocado en un lugar conveniente cerca de la

parte posterior de la estufa. Entonces se puede conectar

la estufa a este tomacorriente mediante un conector de la

clasificación aprobada (cable flexible de conexión)

asegurado con firmeza al bloque terminal, con el protector

contra tirones apropiado, a la estufa y a un enchufe de

tres o cuatro puntas en el otro extremo.

CONEXIONES DE LA ESTUFA

Algunos modelos se envían directamente de fábrica con

los cordones de servicio (cables flexibles de conexión)

sujetos. No es necesario hacer ninguna conexión en

estos modelos de estufa. Sencillamente conéctelos en el

tomacorriente de la estufa. En los modelos que no vienen

con el cordón de servicio, es necesario hacer la conexión

al suministro de energía. ¿RECUERDA, debe usarse

solamente un cordón con cuatro conductores en las

instalaciones de circuitos en derivaciones nuevas (1996

NEC), en casas móviles, vehículos recreativos, o en

lugares en donde los códigos locales prohiben la

conexión a tierra mediante el conductor neutro. Por lo

tanto, DEBE proveerse un cordón de servicio de 4

alambres para dichas instalaciones. Puede usarse un

cordón de servicio de 3 cables cuando lo permitan los

códigos locales. USE SOLAMENTE CONDUCTORES DE

COBRE O ALUMINIO. El bloque terminal principal está

indicado para uso con conductores de cobre o aluminio.

Si se requiere un cordón flexible de energía, se

recomienda que no se use un cordón más largo de 4 pies.

Haga las conexiones según se explica más adelante y

consultando la ilustración correspondiente (vea las figuras

8 y 9). Después de la instalación, asegúrese de que estén

bien aseguradas las conexiones eléctricas y coloque las

cubiertas de nuevo.

Quite la cubierta de acceso al bloque terminal de la parte

posterior de la estufea. (Vea la figura 7).

CONEXIONES DE LA ESTUFA (Canadá)

Este modelo se embarcó directamente de fábrica con el

cordón de servicio (cable flexible de conexión). No es

necesario hacer ninguna conexión en la estufa.

Sencillamente conéctela en el tomacorriente de la estufa.

Vea la figura 2 en la página 11 para saber la ubicación del

tomacorriente.

NOTA: Reemplazo del cordón: SOLAMENTE deberá

utilizarse un cordón de suministro eléctrico de

clasificación mínima de 240 voltios, 40 ó 50 amperios que

esté marcado para usarse con una abertura nominal de

conexión de 1 3/8² (34,93 mm) de diámetro, con

terminales de lazo cerrado y que estén marcados para

utilizarse con estufas.

CUBIERTA

DE ACCESO

BLOQUE DE

CONEXIÓN

DEL TERMINAL

PRINCIPAL

-15-

FIGURA 7

Page 16

INSTALACIÓN DEL CORDÓN ELÉCTRICO

DE 3 CABLES O DEL CONDUCTOR

1. Verifique que la tira de conexión a tierra de cobre

ESTÉ CONECTADA entre el poste medio del bloque

de conexión del terminal principal y del bastidor de la

estufa.

2. El cable medio del cordón o del terminal de tierra del

conductor de tres cables DEBE estar conectado al

poste neutro (medio) del bloque del terminal principal.

Los otros dos cables del cordón de servicio o del

conductor deben conectarse a los postes de fuera del

bloque de conexión del terminal principal. La

polarización no es muy importante.

3. Debe instalarse un protector contra tirones para el

cordón de servicio o del conductor a la placa del

conductor.

ROJO

BLANCO

NEGRO

TIRA DE

CONEXIÓN

A TIERRA

(CONECTADA

DE FÁBRICA)

PROTECTOR

CONTRA

TIRONES

CORDÓN

ESTAMPADO

FIGURA 8

INSTALACIÓN ACEPTABLE DEL ENCHUFE DE 3

CABLES

BLOQUE DE CONEXIÓN

DEL TERMINAL PRINCIPAL

CABLE MEDIODEL

CORDÓN DE SERVICIO O

DEL TERMINAL DE TIERRA

DEL CONDUCTOR

PLACA DEL

CONDUCTOR

CONDUCTO

ESTAMPAD

O

PARA UTILIZARLO

CON EL CONDUC-TOR, QUITE EL SO-PORTE, VOLTÉELO Y

VUELVA A SUJETAR-LO CON EL ORIFICIO

MARCADO“CONDUIT”

HACIA ABAJO.

INSTALACIÓN DEL CORDÓN DE SERVICIO

DE 4 CABLES O DEL CONDUCTOR

(COMO LO REQUIEREN LAS CASAS MÓVILES O LOS

CÓDIGOS LOCALES)

1. La tira de conexión a tierra de cobre que está

conectada entre los postes neutro (medio) del bloque

del terminal principal y el bastidor DEBE cortarse

según se muestra en la figura 9. Conserve el tornillo

verde de conexión a tierra para sujetar a la tierra desde

el cordón de 4 cables. Solamente debe utilizarse un

cordón o conductor de 4 cables.

2. El cable de conexión a tierra del cordón de servicio o

del conductor debe conectarse al bastidor de la estufa

usando el tornillo verde de conexión a tierra.

3. El cable blanco del cordón de servicio o del conductor

debe conectarse al poste neutro (medio) del bloque del

terminal principal. Los otros dos cables del cordón de

servicio o del conductor se conectan a los postes rojo y

negro del bloque del terminal principal,

respectivamente.

4. Debe colocarse a la placa del conductor un protector

contra tirones apropiado en el cordón de servicio o el

conductor.

CONVERSIÓN DE SERVICIO DE 3 CABLES

A 4 CABLES

(Modelo con cordón sujeto de servicio de 3 cables)

Desconecte la estufa del suministro eléctrico. Quite la

cubierta de acceso en la parte posterior de la estufa y

quite el cordón de servicio de 3 cables del bloque del

terminal principal. Siga las instrucciones a continuación

según se indica en la figura 9 para conectar el cordón de

servicio de 4 cables.

NOTA: Reemplazo del cordón: deberá utilizarse

SOLAMENTE un cordón de suministro de energía con

clasificación mínima de 240 voltios, 40 ó 50 amperios que

esté marcado para utilizarse con aberturas nominales de

13/8² (34,93 mm) de diámetro, con terminales de lazo

cerrado y marcados para utilizarse con estufas.

BLANCO

NEGRO

CONEXIÓN A

TIERRA DEL

BASTIDOR

PROTECTOR

CONTRA

TIRONES

DEBE QUITARSE ESTA

PORCIÓN DE LA TIRA DE

ROJO

CORDÓN

ESTAMPADO

CONEXIÓN A TIERRA.

BLOQUEDE CONEXIÓN

DEL TERMINAL PRINCIPAL

CABLE BLANCODEL

CORDÓN DE SERVICIO

O DEL CONDUCTOR

PLACA DEL

CONDUCTOR

CONDUCTO

ESTAMPADO

PARA UTILIZARLO CON EL

CONDUCTOR, QUITE EL SOPORTE,

VOLTÉELO Y VUELVA A SUJETARLO

CON EL ORIFICIO MARCADO

“CONDUIT” HACIA ABAJO.

FIGURA 9

INSTALACIÓN ACEPTADA DE UNA CLAVIJA DE 4 CABLES

-16-

CONEXIÓN A TIERRA

DEL BASTIDOR

Page 17

INSTALLER: VEUILLEZ LAISSER CES INSTRUCTIONS AVEC L’APPAREIL

MANUEL DE MISE EN SERVICE

Cuisinière électrique à éléments tubulaires

Jenn-Air de 30 po (76,2 cm)

VEUILLEZ GARDER CE MANUEL POUR RÉFÉRENCE ULTÉRIEURE

CE MANUEL EST DESTINÉ À FACILITER LA MISE EN SERVICE ET LE RÉGLAGE INITIAUX DE LA CUISINIÈRE.

AVERTISSEMENT SPÉCIALE

La mise en service et le dépannage de

cette cu isin ière doivent être réalisés

uniquement par du personnel qualifié.

Lire les « Mesures de sécurité » d an s le

manuel de l’utilisateur avant d’utiliser la

cuisinière.

Une mauvaise réalisation de la mise en

place, du réglage, de modifications, de

réparations ou de l’entretien de la

cuisinière ou son usage incorrect

peuvent entraîner des blessures ou des

dégâts graves.

AVERTISSEMENT

· TOUTES LES CUISINIÈRES

PEUVENT BASCULER ET

PROVOQUER DES BLESSURES.

DÉGAGEMENT NÉCESSAIRE

Pour tous renseignements concernant la mise en service

d’une cuisinière Jenn-Air, voir les figures 1, 2, 3 et 4. Pour

des RAISONS DE SÉCURITÉ, ne pas mettre la cuisinière

en place dans des armoires en matériau combustible qui

ne satisfassent pas aux exigences de dégagement

indiquées à la figure 1.

ATTENTION : Cette cuisinière satisfait aux

exigences de divers organismes de protection et aux

normes relatives à la température maximum permise

de 194° F(90° C) pour les armoires en bois. Si cette

cuisinière est adjacente à des armoires pouvant

supporter une température inférieure à 194° F(90° C)

seulement, celles-ci peuvent se décolorer, se

délaminer ou fondre.

Votre cuisinière peut ne pas être

dotée de toutes les fonctions

mentionnées dans ce manuel.

· POSER LES DISPOSITIFS DE

STABILISATION FOURNIS A VEC

CETTE CUISINIÈRE.

· SUIVRE TOUTES LES

CONSIGNES DE MISE EN

SERVICE.

ENGLISH '''' PP. 1-8

ESPAÑOL '''' pág. 9-16

FRANÇAIS '''' p. 17-24

Page 18

SCHÉMASDEMONTAGE(Pages 18, 19 et 20)

IMPORTANT

CONSERVER À L’USAGE DE L’INSPECTEUR EN ÉLECTRICITÉ LOCAL.

30 PO

(76,2 CM)

30 PO MIN.

(76,2 CM)

36 PO MIN.

(91,4 CM)

18 PO MIN.

(45,7 CM)

FIGURE 1

REMARQUE : L’illustration peut ne pas représenter exactement l’appareil.

Le dégagement minimum de 30 po (76,2 cm) entre la

table de cuisson et le bas d’une armoire non protégée en

bois ou en métal , peut être réduit à 24 po (61 cm)

minimum si le bas de l’armoire en bois ou en métal est

protégée par du carton ignifuge d’un minimum de 1/4 po

(6,4 mm) d’épaisseur couvert, au minimum, de tôle d’acier

n 28 MSG, d’acier inoxydable de 0,015 po (0,381 mm)

d’épaisseur, d’aluminium de 0,024 po (0,610 mm)

d’épaisseur ou de cuivre de 0,020 po (0,508 mm)

d’épaisseur.

Pour éliminer tout risque de brûlure ou d’incendie en

essayant d’atteindre un objet placé au-dessus d’éléments

brûlants, éviter d’avoir un espace de rangement

au-dessus de la table de cuisson. S’il doit y avoir une

armoire au-dessus de la table de cuisson, l’installation

d’une hotte dépassant d’au moins 5 po (13 cm) de sa

ARMOIRE D’UNE PROFONDEUR MAX. DE 13 PO (33 CM)

AU--DESSUS DE LA PLAQUE DE CUISSON

DÉGAGEMENT DE0 PO/CM ENTREUNE PAROI EN

MATÉRIAU COMBUSTIBLE ADJACENTE ET

L’ARRIÈRE ET LES CÔTÉS DE LA CUISINIÈRE

AU--DESSOUS DE LA SURFACE DE CUISSON.

partie inférieure réduira les risques liés à ce type

d’entreposage.

FIGURE 1

1 - CLOISON ARRIÈRE EN MATÉRIAU...

COMBUSTIBLE

2 - CLOISON LATÉRALE EN MATÉRIAU...

COMBUSTIBLE

3 ARMOIRE EN MATÉRIAU COMBUSTIBLE...

LA DIMENSION « A » DOIT ÊTRE D’UN MINIMUM DE 3

POUCES (7,5 CM).

UNE CUISINIÈRE ENCASTRÉE POURRA, SI ELLE A

ÉTÉ ÉQUIPÉE DU NÉCESSAIRE DE POSE DE

DOSSERET OPTIONNEL, POURRA ÊTRE INSÉRÉE

DE FAÇON À ÊTRE À 0 PO (0 CM) D’UNE DES

PAROIS COMBUSTIBLES 1 (VOIR LA FIGURE 1).

-18-

Page 19

30²²²² (76,2 cm)

CUISINIÈRES JENN-AIR

* DANSLE CAS DU REMPLACEMENT D’UN APPAREIL EXISTANT,UNE PROFONDEUR DE

DÉCOUPEMAXIMUM DE 231/2 PO (59,7 CM)EST ACCEPTABLE.

PROFONDEUR

DE DÉCOUPE F

AVANT DE METTRE LA

CUISINIÈRE EN PLACE,

AJUSTER LES PIEDS

RÉGLABLES POUR

L’ADAPTER À CETTE

DIMENSION

HAUTEURDE DESSUS

DE COMPTOIR D

OUVERTURE

D’ARMOIRE C

VOIR LA

REMARQUE

N° 1

FIGURE 2

ATTENTION:

CERTAINES ARMOIRESBLANCHES DE STYLE EUROPÉEN SONT

MUNIES D’UN TIROIR ET DE DEVANTS DE PORTE EN VINYLE BLANC

FRAGILE. LE VINYLE PEUT NE PAS ÊTRE CONÇU POUR SUPPORTER

LA CHALEUR PRODUITE LORS DU FONCTIONNEMENT NORMAL D’UNE

CUISINIÈRE À FOUR AUTO-NETTOYANT. IL PEUT SE PRODUIRE UNE

DÉCOLORATION OU UN DÉLAMINAGE. POUR ÉVITERTOUTE

POSSIBILITÉ DE DOMMAGES, IL EST RECOMMANDÉ DE PRÉVOIR UNE

OUVERTURE DE 31 1/4 PO (92,2 CM) MINIMUMDANS L’ARMOIRE, AU

LIEU DES 30 PO (61,2 CM) NORMALEMENT RECOMMANDÉS, ET

D’UTILISER UN NÉCESSAIRE DE PROTECTION THERMIQUE CABIT V.

LA DÉCOUPE DANS LE COMPTOIR DOIT RESTER DE 30 PO (76,2 CM).

B

PROFONDEUR

DE L’ARMOIRE

REMARQUE :

DANS LE CAS DE DESSUS DE

COMPTOIRS AVEC UN

REBORD AVANT EN RELIEF,

ROGNER LA PARTIE

REHAUSSÉE POUR DÉGAGER

LE HAUT.

SURFACE

PLANE

MINIMUM

E

ILLUSTR.

N° 9215-109

A

PROFONDEUR

DE COMPTOIR

NORMALE

D

HAUTEUR DU

DESSUS DU

COMPTOIR

OUVERTURE

DANS

L’ARMOIRE

VOIR LA

REMARQUE

N° 1

B

PROFONDEUR

DE L’ARMOIRE

ILLUSTR.N° 9215-110

A

PROFONDEUR

DE COMPTOIR

NORMALE

FIGURE 3

Remarques :

1. Prévoiruneprisemuraleà3filsou4filsde120/208, 120/240 V par cordon dans la zone ombrée indiquée.

Se reporter aux consignes de montage pour la position correcte de la prise.

2. La dimensionK(figure4,page 20) est mesurée du muraubordlatéralde la porte du four.Elle n’inclutpaslacourbe

du verre ni la profondeur de la poignée.

3. La dimension L (figure 4, page 20) est mesurée avec les piedsde réglagevissésà fond. Ellepeut varierlégèrement

en fonction du réglage des pieds.

4. Ne pas utiliser de coulis de ciment, d’époxy, etc. pour la pose de cet appareil. Il doit pouvoir être retiré pour en

permettre l’entretien et le dépannage.

-19-

Page 20

30²²²² (76,2 cm)

CUISINIÈRES JENN-AIR

Cuisinière encastrée Unity II

Dimensions

FIGURE 4

JJJJ

A

B

C

D

E

F

G

H

J

2*

K

3*

L

M

* VOIR LES REMARQUES, PAGE 19

Pouces

25

24

30

36

23 5/8

23 1/4

51/2

10

29 7/8

26 3/16

35 3/4

21/4

Centimètres

63,5

61,0

76,2

91,4

60,0

59,1

14,0

25,4

75,9

66,5

90,8

5,7

-20-

Page 21

MAISONS MOBILES

La mise en service d’une cuisinière prévue pour les maisons

mobiles doit être conforme aux normes « Manufactured

Home Construction and Safety Standard », titre 24 CFR,

partie 3280 (précédemment « Federal Standard for Mobile

Home Construction and Safety », titre 24 HUD, partie 280)

ou, lorsque ces normes ne sont pas applicables, les normes

« Standard for Manufactured Home Installations 1982

(Manufactured Home Sites, Communities and Set-Ups) »,

ANSI A225.1-édition la plus récente, ou les codes de la

construction locaux.

EMPLACEMENT DE LA

CUISINIÈRE

Mettre la cuisinière dans un endroit où elle recevra un bon

éclairage. Ne pas placer la cuisinière au-dessus de trous

dans le plancher ou en tout autre endroit où elle sera

exposée à de forts courants d’air. Toute ouverture dans le

mur à l’arrière de la cuisinière et dans le plancher sous la

cuisinière doit être bouchée. S’assurer que le passage de

l’air de refroidissement/ventilation sous la cuisinière n’est pas

entravé.

REMARQUE : Unecuisinière nedoitPAS être placée sur dela

moquette.

MISE EN PLACE DU DISPOSITIF DE STABILISATION

ATTENTION : La cuisinière risque de basculer si elle n’est

pas mise en place conformément aux instructions fournies.

Si le dispositif de stabilisation est utilisé correctement, il

réduit le risque que la cuisinière ne BASCULE. Même si le

dispositif de stabilisation est utilisé correctement, le

consommateur doit observer les précautions indiquées dans

le MANUEL D’UTILISATION ET D’ENTRETIEN et éviter

d’utiliser la porte du four comme un tabouret.

Les instructions sont prévues pour un plancher ou un mur en

bois ou en ciment. Un autre matériau pourra requérir des

techniques spéciales, qu’il conviendra de déterminer, pour

assurer la fixation du SUPPORT DE STABILISATION au

mur ou au plancher. Le support de stabilisation est prévu

pour s’insérer à GAUCHE ou à DROITE du pied de mise à

niveau.

REMARQUE : Le support fourni est conçu pour s’utiliser

avec des prises de courant encastrées ou non.

Placer le support avec le trou d’orientation du pied le plus

long contre le mur ou contre le plancher tel qu’illustré à la

figure 5.

TROU

D’ORIENTATION

ÉTAPE 1 - Emplacement du support de stabilisation

(voir figure 5)

A. Déterminer où le « BORD» gauche ou droit de la

cuisinière se trouvera une fois celle-ci en place et le

marquer d’un repère sur le plancher.

B. Placer le SUPPORT à 15/16 po (24 mm) de la marque «

BORD» en allant vers le centre de l’ouverture et contre

le mur arrière tel qu’indiqué à la figure 5, le trou

d’orientation étant contre le mur.

C. Utiliser le support comme gabarit et marquer

l’emplacement de tous les trous pour le type de matériau

sur lequel le support doit être fixé, tel qu’indiqué à la

figure 5.

D. Le support de stabilisation peut être fixé au mur ou au

plancher. Voir les options de pose à l’étape 2, page 22.

15/16 PO

(24 MM) DU

BORD DE LA

CUISINIÈRE

REPÈRE DU BORD

DE LA CUISINIÈRE

TROUS POUR

LE MUR

TROUS POUR

PLANCHER

FIXER LE SUPPORT DE

STABILISATION EN

PLACE AVEC DE

LONGUES VIS

SUPPORT DE

STABILISATION

PIED DE MISE

À NIVEAU

ILLUSTR. N° 9215-112

FIGURE 5

-21-

Page 22

STEP 2 - Anti-ÉTAPE - Options de pause du

stabilisation

de

A. Bois :

1. Plancher : Déterminer le centre des deux trous

identifiés par « TROUS POUR PLANCHER » à la

figure 5. Percer un trou de positionnement de

1/8 po (3 mm) au centre de chaque trou (un clou

ou un poinçon peut également être utilisé si une

perceuse n’est pas disponible). Fixer le support

de STABILISATION au plancher à l’aide des deux

vis fournies. Passer à l’ÉTAPE 3.

2. Mur : Déterminer le centre des deux trous

identifiés par « TROUS POUR MUR » à la figure

5. Percer un trou de positionnement de 1/8 po

(3 mm) au centre de chaque trou (un clou ou un

poinçon peut également être utilisé si une

perceuse n’est pas disponible) tel qu’indiqué à la

figure 6. Fixer le support de STABILISATION au

mur à l’aide des deux vis fournies tel qu’indiqué à

la figure 6. Passer à l’ÉTAPE 3.

B. Ciment ou béton :

1. On trouve des vis convenant au ciment ou au

béton dans les quincailleries. Percer les trous de

positionnement de la grandeur correspondante à

celle des vis obtenues en quincaillerie au centre

des trous identifiés « TROUS POUR MUR » à la

figure 5. Fixer le support de STABILISATION au

plancher. Passer à l’ÉTAPE 3.

support

ÉTAPE 3 - Mise en place de la

cuisinière

A. Une cuisinière Jenn-Air peut être mise en place par

une seule personne.

B. Placer la cuisinière de façon à ce qu’elle puisse entrer

dans l’ouverture où elle sera placée et la pousser en

place. Remarque : Un dégagement minimum de

1/4 po (6 mm) est exigé entre la cuisinière et le pied

de mise à niveau qui va s’insérer dans le support de

STABILISATION (voir figure 6).

C. Toutes les cuisinières Jenn-Air sont équipées de

dessus qui ne sont pas prévus pour être soulevés.

D. Pour des RAISONS DE SÉCURITÉ et pour obtenir

des résultats optimums à la cuisson, régler la

cuisinière de façon à ce qu’elle soit de niveau. Pour

vérifier le niveau, mettre un niveau à bulle ou une

grande casserole d’eau sur la surface de cuisson ou

sur la grille du four. Si la cuisinière doit être mise de

niveau, la tirer vers soi, la faire basculer légèrement et

faire tourner le pied de mise à niveau autant que

nécessaire.

E. Pour vérifier si le support de stabilisation est bien en

place : Regarder sous la cuisinière à l’aide d’une

lampe électrique et vérifier que l’un des pieds arrière

de mise à niveau est bien inséré dans la fente du

support.

F. Finir la mise en service de la cuisinière tel qu’indiqué

dans les instructions fournies avec la cuisinière.

LES VIS DOIVENT

PÉNÉTRER DANS

LE BOIS OU LE

MÉTAL

PLAQUE MURALE

ILLUSTR. N° 9215-117

REMARQUE : UTILISER AU MOINS 2 VIS POUR

LA FIXATION DU SUPPORT AU

MUR OU AU PLANCHER.

SUPPORT DE

STABILISATION

VISSER LE

SUPPORT AU MUR

GLISSER EN PLACE

POUR STABILISER

FIGURE 6

FOND DE LA

CUISINIÈRE

1/4 PO

(6 MM)

MIN.

-22-

Page 23

RACCORDEMENT DE LA CUISINIÈRE

ALIMENTATION ÉLECTRIQUE

Lors de la mise en service, la cuisinière doit être installée

conformément aux normes ANSI/NFPA n° 70, édition la

plus récente, du code d’électricité local et national (NEC).

Voir la plaque signalétique de la cuisinière pour en

connaître la puissance raccordée totale (en kW).

ALIMENTATION ÉLECTRIQUE (Canada)

Lors de la mise en service, la cuisinière doit être installée

conformément aux normes ACN STD.C22.1, édition la

plus récente, du code d’électricité canadien. Voir la

plaque signalétique de la cuisinière pour en connaître la

puissance raccordée totale (en kW).

RACCORDEMENT AU SECTEUR

La compagnie d’électricité locale vous indiquera si votre

branchement est prévu pour fournir la puissance exigée

par l’appareil. Il pourra être nécessaire d’augmenter la

grosseur des câbles amenant l’électricité à la maison et

au panneau de distribution électrique. La puissance

électrique de la cuisinière (en kW) est spécifiée sur la

plaque signalétique qui se trouve à l’avant de la

cuisinière.

INSTALLATION ÉLECTRIQUE DE LA

MAISON

La plupart des codes et règlements relatifs à la

construction exigent que l’installation électrique d’une

maison soit réalisée par un électricien qualifié. Le câblage

doit être conforme aux codes d’électricité local et national.

Cette cuisinière requiert un circuit alternatif monophasé

trifilaire de 120/240 V ou 120/208 V et 60 Hz. Les codes

exigent que la cuisinière soit dotée d’un circuit distinct

partant du panneau de distribution électrique et que

celui-ci soit protégé par un sectionneur et des fusibles, au

niveau du panneau de distribution électrique ou dans un

coffret électrique séparé. Dans certaines municipalités,

une gaine blindée flexible ou rigide doit être utilisée entre

le panneau de distribution électrique et le boîtier de

raccordement se trouvant à l’arrière de la cuisinière.

D’autres municipalités autorisent le branchement de la

cuisinière sur une prise murale polarisée à trois ou quatre

fils placée dans un endroit pratique près de l’arrière de la

cuisinière. La cuisinière est branchée sur cette prise à

l’aide d’une fiche à trois ou quatre broches avec cordon

d’alimentation (spirale) homologué pour cuisinière

solidement fixé au bornier de la cuisinière par une retenue

mécanique appropriée.

CONNEXIONS DE LA CUISINIÈRE

Certains modèles ont un cordon d’alimentation (spirale)

installé en usine. Dans ce cas, il n’y a aucune connexion

à réaliser au niveau de la cuisinière. Il suffit de brancher la

fiche dans la prise murale. D’autres modèles ne sont pas

munis d’un cordon d’alimentation et dans ce cas, le

raccordement à l’alimentation électrique de la maison est

nécessaire. NE PAS OUBLIER - seul des cordons à

quatre fils peuvent être utilisés avec les circuits de

dérivation nouvellement installés (NEC 1996), les

maisons mobiles, les véhicules de loisir ou dans toute

région où les codes locaux interdisent la mise à la terre

par le neutre. Dans ce cas, une installationà4filsest

OBLIGATOIRE.Uneinstallationà3filspeut être utilisée

si les codes locaux le permettent. UTILISER DES

CONDUCTEURS EN CUIVRE OU EN ALUMINIUM. Le

bornier est prévu pour des conducteurs en cuivre ou en

aluminium. Si un cordon d’alimentation flexible est exigé,

il est recommandé de ne pas utiliser de cordon d’une

longueur supérieureà4pi.Réaliserlesconnexions tel

qu’indiqué ci-dessous en se référant aux illustrations

appropriées (voir les figures 8 et 9). Une fois l’installation

effectuée, vérifier que toutes les connexions n’ont pas de

jeu et remettre tous les couvercles.

Enlever le couvercle d’accès au bornier à l’arrière de la

cuisinière (voir figure 7).

CONNEXIONS DE LA CUISINIÈRE (Canada)

Ce modèle est équipé d’un cordon d’alimentation (spirale)

installé en usine. Aucune connexion n’est nécessaire. Il

suffit de brancher la fiche dans la prise murale. Voir la

figure 2, page 19, pour l’emplacement de la prise.

REMARQUE : Pour remplacer le cordon d’alimentation,

utiliser UNIQUEMENT un cordon d’alimentation pour

cuisinière calibré à 240 V minimum et 40 ou 50 A prévu

pour une utilisation avec une ouverture pour

raccordement nominale de 1 3/8 po (34,93 mm) de

diamètre et muni de serre-fils.

PLAQUE

D’ACCÈS

-23-

BORNIER

FIGURE 7

Page 24

INSTALLATION D’UN CORDON

D’ALIMENTATION OU D’UNE GAINE

À 3 FILS

1. Vérifier que la barrette de mise à la terre en cuivre

EST CONNECTÉE entre la borne du milieu du bornier

et le châssis de la cuisinière.

2. Le fil du milieu du cordon d’alimentation ou le fil de

masse de la gaine à trois fils DOIT être connecté à la

borne neutre (celle du milieu) du bornier. Les deux

autres fils du cordon sont connectés aux bornes des

deux extrémités. La polarité n’a pas à être respectée.

3. Une retenue mécanique appropriée pour cordon

d’alimentation ou gaine doit être fixée sur la plaque

support de gaine.

ROUGE

BLANC

NOIR

BARRETTE DE

MISEÀLATERRE

(INSTALLATION

USINE)

RETENUE

MÉCANIQUE

PASTILLE

PRÉDÉFONCÉE

DU CORDON

FIGURE 8

INSTALLATION ACCEPTABLE - FICHE À TROIS FILS

BORNIER

FIL DU MILIEU DU

CORDON

D’ALIMENTATION OU FIL

DE MASSE DE LA GAINE

PLAQUE

SUPPORT

DE GAINE

PASTILLE

PRÉDÉFONCÉE

DE LAGAINE

ILLUSTR.N° 9215-113

POUR UTILISER

AVEC UNE GAINE,

ENLEVER LE

SUPPORT, LE

RETOURNER E T LE

FIXER EN PLACE

AVEC LE T ROU

MARQUÉ « GAINE »

VERS LE BAS.

INSTALLATION D’UN CORDON

D’ALIMENTATION OU D’UNE GAINE À 4 FILS

(MAISONS MOBILES OU SI LES CODES L’EXIGENT)

1. La barrette de mise à la terre en cuivre reliant la borne

neutre (celle du milieu) du bornier et le châssis DOIT

être enlevée tel qu’indiqué à la figure 9. Garder la vis

de mise à la terre verte pour fixer le fil de terre du

cordonà4fils.Utiliser uniquement un cordon

d’alimentationouunegaineà4fils.

2. Le fil de terre du cordon d’alimentation ou de la gaine

doit être relié au châssis de la cuisinière en utilisant la

visdemiseàlaterreverte.

3. Le fil blanc du cordon d’alimentation ou de la gaine doit

être connecté à la borne neutre (celle du milieu) du

bornier. Les deux autres fils du cordon ou de la gaine

sont connectés aux bornes de même couleur (rouge et

noire) du bornier.

4. Une retenue mécanique appropriée pour cordon

d’alimentation ou gaine doit être fixée sur la plaque

support de gaine.

CONVERSION D’UNE INSTALLATION À

3 FILS À UNE INSTALLATION À 4 FILS

(modèles avec cordon d’alimentation à trois fils en

place)

Débrancher la cuisinière du secteur. Enlever le couvercle

du bornier se trouvant à l’arrière de la cuisinière et

déconnecter le cordon d’alimentationà3filsdubornier.

Suivre les instructions données à la figure 9 pour

connecter le cordonà4fils.

REMARQUE : Pour remplacer le cordon d’alimentation,

utiliser UNIQUEMENT un cordon d’alimentation pour

cuisinière calibré à 240 V minimum et 40 ou 50 A prévu

pour une utilisation avec une ouverture pour

raccordement nominale de 1 3/8 po (34,93 mm) de

diamètre et muni de serre-fils.

NOIR

MISEÀLA

MASSE PAR

LE CHÂSSIS

RETENUE

MÉCANIQUE

BLANC

CETTE PORTION DE LA

BARRETTE DE MISE À LA

TERRE DOIT ÊTRE ENLEVÉE

ROUGE

BORNIER

FIL BLANC DU

CORDON

D’ALIMENTATION

OU DE LA GAINE

PLAQUE

SUPPORTDE

GAINE

PASTILLE PRÉDÉFONCÉE

DU CORDON

PASTILLE

PRÉDÉFONCÉE

DE LA GAINE

ILLUSTR. N° 9215-115

POUR UTILISER AVEC UNE GAINE,

ENLEVER LE SUPPORT, LE

RETOURNER ET LE FIXER EN

PLACE AVECLE TROU MARQUÉ

« GAINE» VERS LE BAS.

FIGURE 9

INSTALLATION ACCEPTABLE - FICHE À QUATRE FILS

MISE À LA MASSE

PAR LE CHÂSSIS

-24-

Loading...

Loading...