Jenn-Air JDB3200AWB5, JDB3200AWS5, JDB3200AWW5, JDB3600AWP5, JDB3600AWS5 Installation Guide

...

JENN-AIR°

LAVE-VAISSELLESOUSPLANDETRAVAIL

INSTALLATIONINSTRUCTIONS

UNDERCOUNTERDISHWASHER

INSTRUCTIONSD'INSTALLATION

Table of Contents .............................................................. 2

Table des matieres .......................................................... 25

W10321619A

TABLEOF CONTENTS

DISHWASHER SAFETY ............................................................................... 2

INSTALLATION REQUIREMENTS ............................................................. 3

Tools and Parts ......................................................................................... 3

Location Requirements ............................................................................. 4

Drain Requirements .................................................................................. 6

Water Supply Requirements ..................................................................... 6

Electrical Requirements ............................................................................ 6

INSTALLATION INSTRUCTIONS ............................................................... 7

Prepare Cabinet Opening--Existing Utilities ............................................ 7

Prepare Cabinet Opening-- New Utilities ................................................. 7

Prepare and Route Water Line ................................................................. 8

Install Drain Hose ...................................................................................... 9

Install Moisture Barrier(under a wood countertop) ................................. 11

Prepare Dishwasher ................................................................................ 11

Make Power Supply Cord Connection ................................................... 12

INSTALLATION REQUIREMENTS (CONT.)

Determine Cabinet Opening ................................................................... 14

Install Door Handle (on some models) ................................................... 14

Install Custom Panel (Model JDB3600AWX) ......................................... 15

Choose Attachment Option .................................................................... 16

Move Dishwasher Close to Cabinet Opening ........................................ 17

Connect to Water Supply ....................................................................... 19

Connect to Drain ..................................................................................... 20

Make Direct Wire Electrical Connection ................................................. 20

Secure Dishwasher in Cabinet Opening ................................................ 22

Bottom Sound Pad Installation (on some models) ................................ 23

Complete Installation .............................................................................. 23

Check Operation ..................................................................................... 24

If Dishwasher Does Not Operate ............................................................ 24

Additional Tips ........................................................................................ 24

DISHWASHERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

You Need to:

• Slowly open dishwasher door while someone grasps the rear

of the dishwasher. Remove shipping materials, drain hose and

lower rack. Close dishwasher door until latched.

• Observe all governing codes and ordinances.

• Install this dishwasher as specified in these instructions.

• Installation should be performed by a qualified service

technician. The dishwasher must be installed to meet all

Tip Over Hazard

Do not use dishwasher until completely installed.

electrical and plumbing national and local codes and

ordinances.

Do not push down on open door.

Doing so can result in serious injury or cuts.

2

Other parts you may also need:

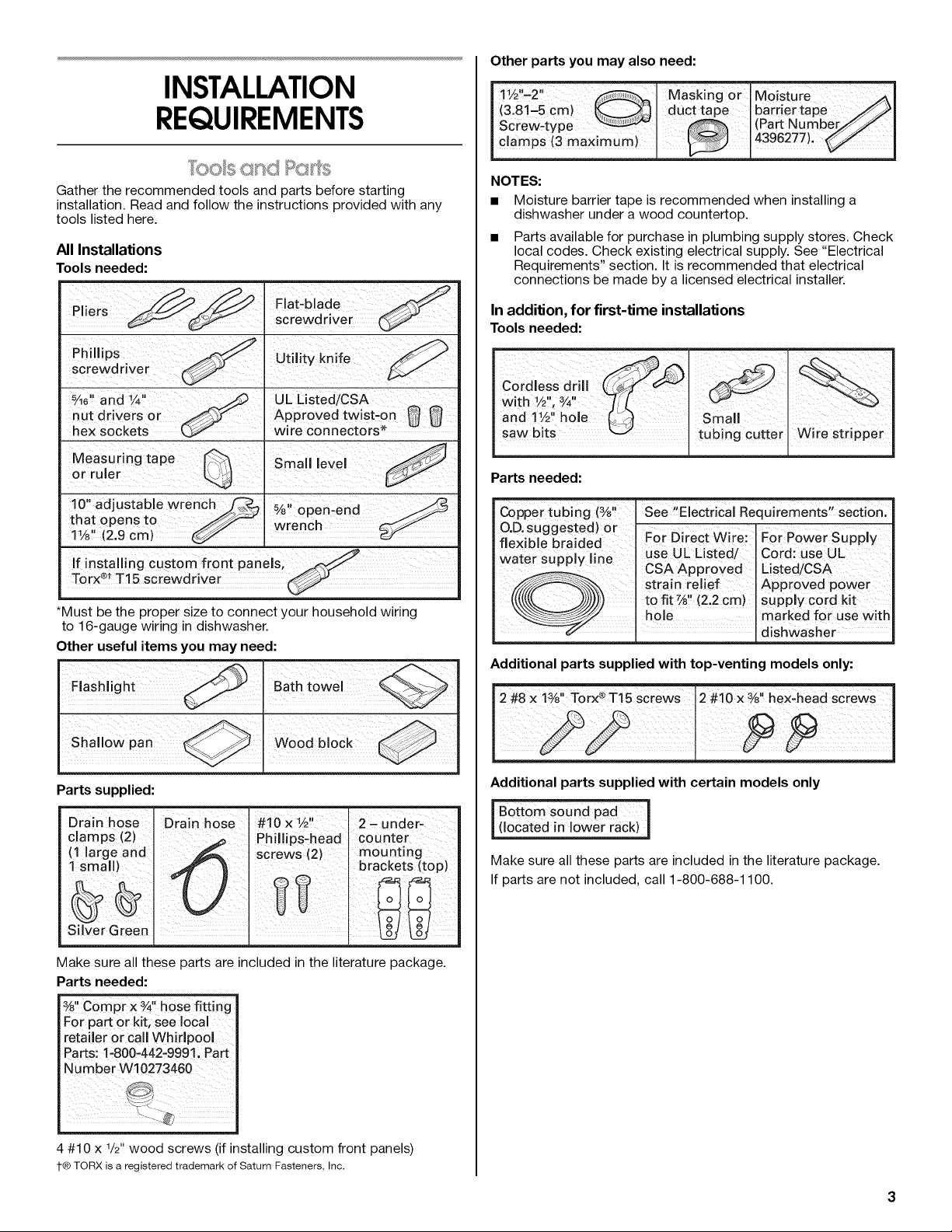

INSTALLATION

REQUIREMENTS

Gather the recommended tools and parts before starting

installation. Read and follow the instructions provided with any

tools listed here.

All Installations

Toolsneeded:

Pliers

Phillips

screwdriver

%d' and V4" _-._

nut drivers or _r"

hex sockets L_].'_/

or ruler

Measuring tape _

10" adjustable wrench

tha! opens to _/_-"

1V8 (2.9 cm)

If installing custom front panels,

Torx ®_T15 screwdriver

*Must be the proper size to connect your household winng

to 16-gauge wiring in dishwasher.

Other useful items you may need:

(

Flat-blade

screwdri,

Utility knife

UL Listed/CSA

Approvedtwist-on g g

wire connectors _

Small level

%" open-end

wrench

! ½.2 I Masking or I Molsture

(3,81-5 Cm)duct tape barrier tape /_.,_

ScreW4ype I (Part Number/_/

clamps (3 maximum)J L4396277)'

NOTES:

• Moisture barrier tape is recommended when installing a

dishwasher under a wood countertop.

Parts available for purchase in plumbing supply stores. Check

local codes. Check existing electrical supply. See "Electrical

Requirements" section. It is recommended that electrical

connections be made by a licensed electrical installer.

In addition, for first-time installations

Toolsneeded:

Parts needed:

Copper tubing (%" See "Electrical Requirements" section.

O.D.suggested) or _ .. : i .. ^ ;

flexible braided _-or uirect wire: I For _'ower bupply

watersuDDv ne use UL Listed/ ICord:useUL

(,(_(.(._L(--_ J)_.)_)I tofit% (2:20m) I su_plycor_J kit

--_" .... dishwasher

Additional parts supplied with top-venting models only:

I

CSA Appr0ved Listed/CSA

Strain !elief I Approved power

h01e I marked f0r use with

!i0,° oai

Parts supplied:

Drain hose

clamps (2)

(1 large and

I small)

Silver Green

Make sure all these parts are included in the literature package.

Parts needed:

3 3

Ys"Compr X N, hose fitting

lFor part 0r kit; See !oCal

Iretailer or call Whirlpool

Parts: 1,800-442,9991. Part

Number w10273460

4 #10 x v2,, wood screws (if installing custom front panels)

1-0 TORX is a registered trademark of Saturn Fasteners, Inc.

Drain h0se #10 x v2 2 _ under-

PhilliPs.head counter

sc[ews (2)mounting

brackets (tOP)

Additional parts supplied with certain models only

IBoSomsoun_ pad j

(located in lower rack).J

Make sure all these parts are included in the literature package.

If parts are not included, call 1-800-688-1100.

@roundedelectricalsupplyrequired.

Donotrundrainlines,waterlinesorelectricalwiringwherethey

caninterferewithorcontactdishwashermotororlegs.

Thelocationwherethedishwasherwillbeinstalledmustprovide

clearancebetweenmotorandflooring.Motorshouldnottouch

thefloor.

Donotinstalldishwasherovercarpetedflooring.

Shelterdishwasherandwaterlinesleadingtodishwasheragainst

freezing.Damagefromfreezingisnotcoveredbythewarranty.

Asidepanelkitisavailablefromyourdealerforinstallingyour

dishwasherattheendofyourcabinetry.

Amoisturebarrieraccessory(PartNumber4396277)isavailable

fromyourdealerforinstallingunderneaththecountertop.

Call1-800-688-1100toorder.

Checklocationwheredishwasherwillbeinstalled.Thelocation

mustprovide:

• easyaccesstowater,electricityanddrain.

convenientaccessforloadingandunloadingdishes.

Cornerlocationsrequirea2"(5.1cm)minimumclearance

betweenthesideofthedishwasherdoorandthewallor

cabinet.

• squareopeningforproperoperationandappearance.

• cabinetfrontperpendiculartofloor.

• levelfloor.(Ifflooratfrontofopeningisnotlevelwithfloor

atrearofopening,shimsmaybeneededtolevel

dishwasher.)

HelpfulTip:Besuretoaccuratelymeasuredimensionsand

ensuredishwasherislevelifthefloorinthedishwasheropeningis

uneven(example:Flooringextendsonlypartwayintoopening).

NOTE:Toavoidshiftingduringdishwasheroperation,shimsmust

besecurelyattachedtothefloor.

Ifdishwasherwillbeleftunusedforaperiodoftimeorina

locationwhereitmaybesubjecttofreezing,haveitwinterizedby

authorizedservicepersonnel.

Makesurepipes,wiresanddrainhosearewithintheshadedarea

showninthe"ProductandCabinetOpeningDimensions"section.

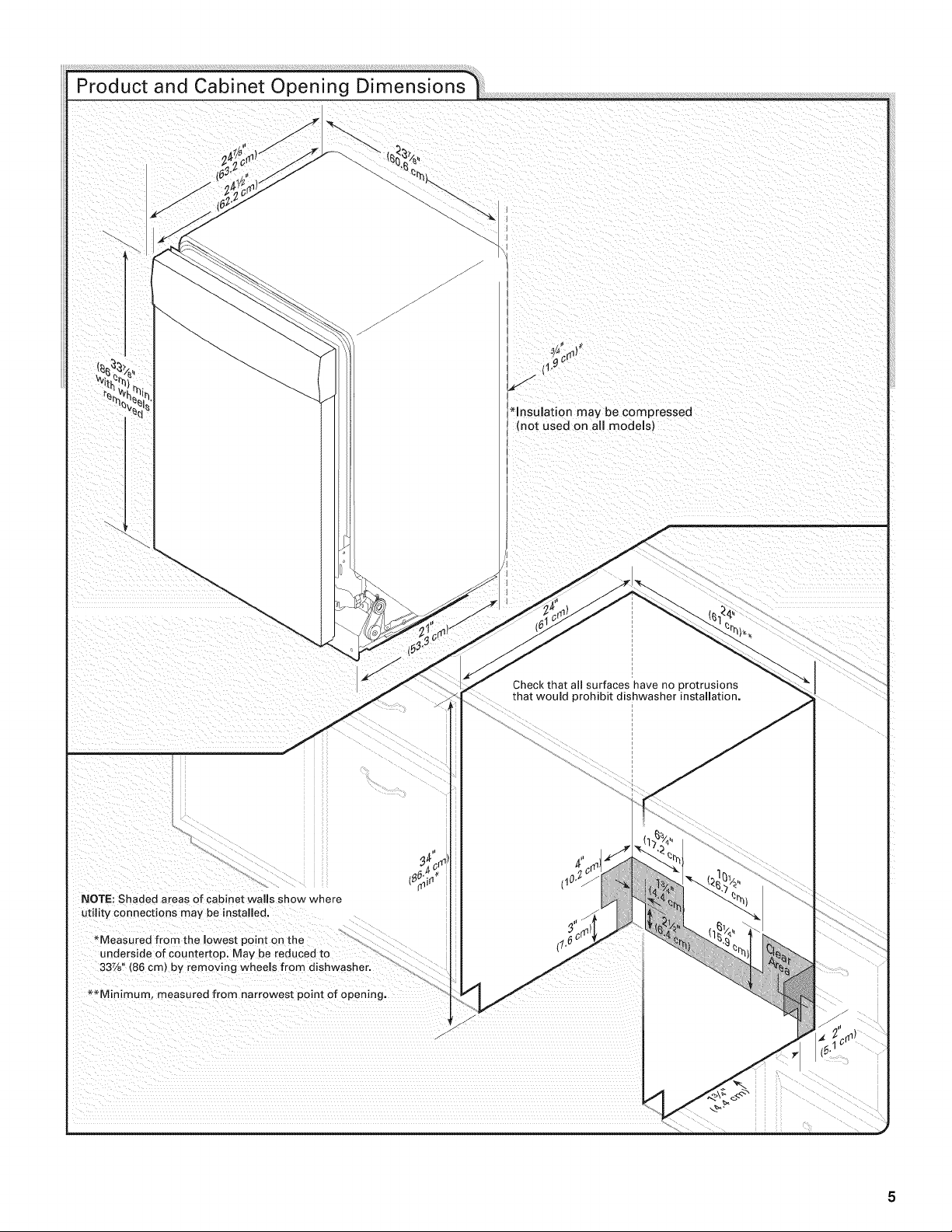

Product and Cabinet Opening Dimensions

5/_j_ ,(1) _

_lnsulatJon may be compressed

(not used on all models)

NOTE: Shaded areas of cabinet walls show where

utility connections may be installed,

*Measured from the lowest point on the

underside of countertop. May be reduced to

7

33%" (86 cm) by removing wheels from dishwasher.

**Minimum, measured from narrowest point of opening,

Check that all surfaces have no protrusions

that would prohibit dishwasher installation.

A new drain hose is supplied with your dishwasher. If drain

hose is not long enough, use a new drain hose with a

maximum length of 12' (3.7 m) (Part Number 3385556) that

meets all current AHAM/IAPMO test standards, is resistant to

heat and detergent, and fits the 1" (2.5 cm) drain connector of

the dishwasher.

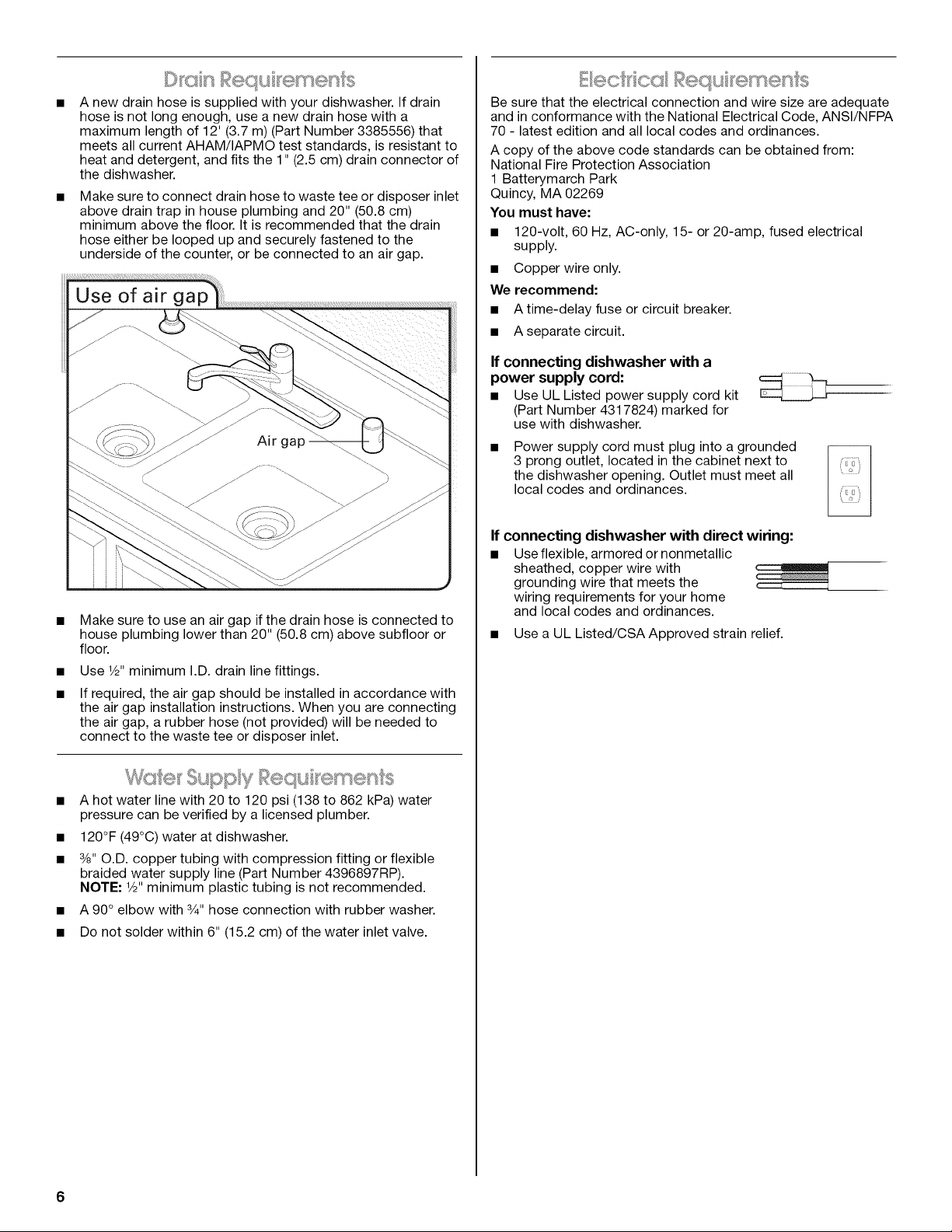

Make sure to connect drain hose to waste tee or disposer inlet

above drain trap in house plumbing and 20" (50.8 cm)

minimum above the floor. It is recommended that the drain

hose either be looped up and securely fastened to the

underside of the counter, or be connected to an air gap.

Make sure to use an air gap if the drain hose is connected to

house plumbing lower than 20" (50.8 cm) above subfloor or

floor.

Use 1/2"minimum I.D. drain line fittings.

If required, the air gap should be installed in accordance with

the air gap installation instructions. When you are connecting

the air gap, a rubber hose (not provided) will be needed to

connect to the waste tee or disposer inlet.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/NFPA

70 - latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

You must have:

• 120-volt, 60 Hz, AC-only, 15- or 20-amp, fused electrical

supply.

• Copper wire only.

We recommend:

• A time-delay fuse or circuit breaker.

• Aseparate circuit.

If connecting dishwasher with a

power supply cord:

Use UL Listed power supply cord kit

(Part Number 4317824) marked for

use with dishwasher.

Power supply cord must plug into a grounded

3 prong outlet, located in the cabinet next to

the dishwasher opening. Outlet must meet all

local codes and ordinances.

If connecting dishwasher with direct wiring:

• Use flexible, armored or nonmetallic

sheathed, copper wire with

grounding wire that meets the

wiring requirements for your home

and local codes and ordinances.

• Use a UL Listed/CSA Approved strain relief.

pp)y 58eq(s emen s

A hot water line with 20 to 120 psi (188 to 862 kPa) water

pressure can be verified by a licensed plumber.

120°F (49°C) water at dishwasher.

3/8"O.D. copper tubing with compression fitting or flexible

braided water supply line (Part Number 4396897RP).

NOTE: 1/2"minimum plastic tubing is not recommended.

A 90° elbow with 3/4"hose connection with rubber washer.

Do not solder within 6" (15.2 cm) of the water inlet valve.

6

INSTALLATIONINSTRUCTIONS

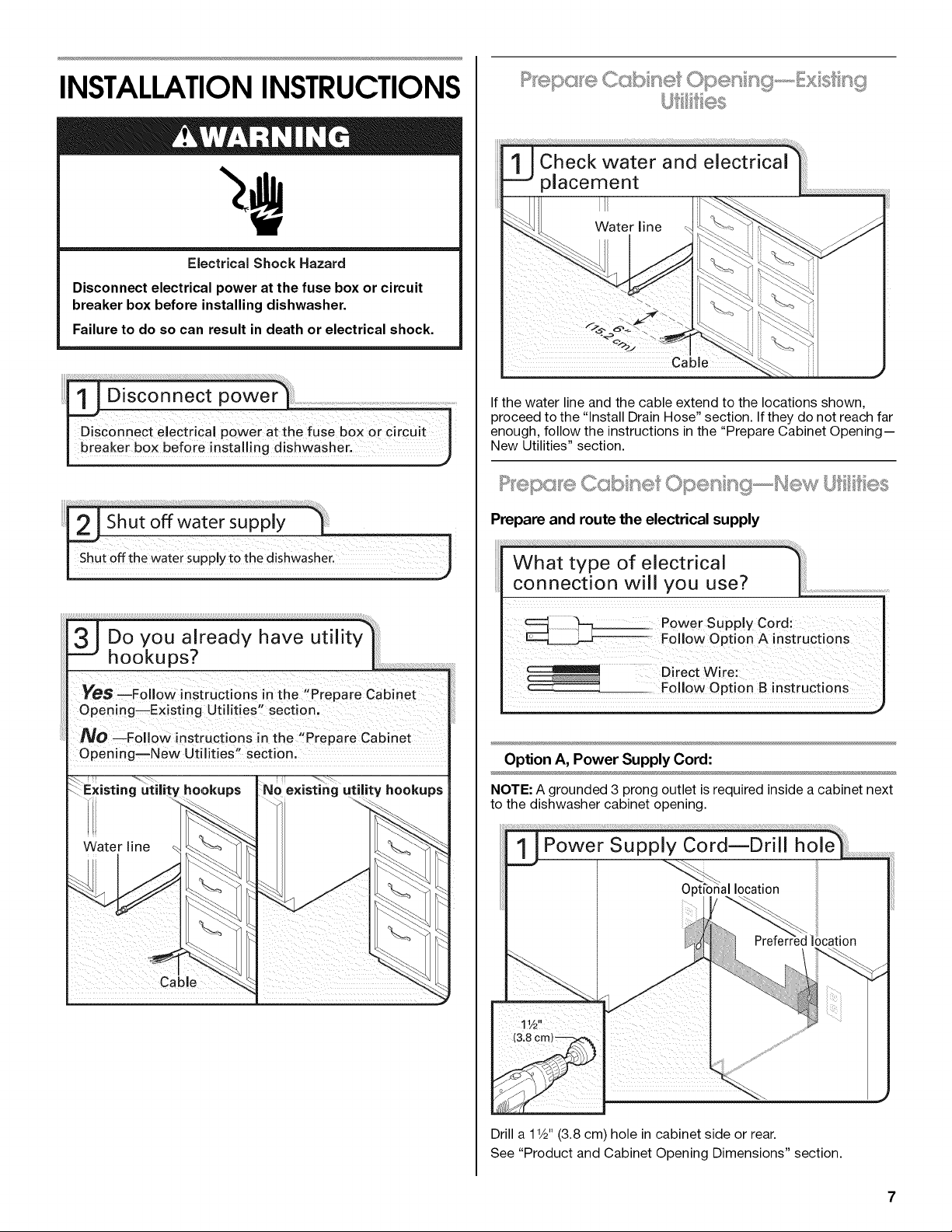

Electrical Shock Hazard

Disconnect electrical power at the fuse box or circuit

breaker box before installing dishwasher.

Failure to do so can result in death or electrical shock.

[ Disconnect electrical p0wer at th e fuse bo x o[ CirCu!t [

! breaker box before !nstalling d!Shwasher" J

III

Water line

If the water line and the cable extend to the locations shown,

proceed to the "Install Drain Hose" section. If they do not reach far

enough, follow the instructions in the "Prepare Cabinet Opening--

New Utilities" section.

Prepare and route the electrical supply

31 Do you already have utility_:

-'-" hookups?

Ye,S _Follow instructions in the ,,Prepare Cabinet

Opening-Existing Utilities" section,

No--Follow instructions in the ,,Prepare Cabinet

Open!ngmNew Utilities" section,

ity hookups

: Power Supply Cord:

F01low Option A instructions

Option A, Power Supply Cord:

NOTE: A grounded 3 prong outlet is required inside a cabinet next

to the dishwasher cabinet opening.

Power Supply Cord_Drill

"_O_p_al location

Drill a 1W' (3.8 cm) hole in cabinet side or rear.

See "Product and Cabinet Opening Dimensions" section.

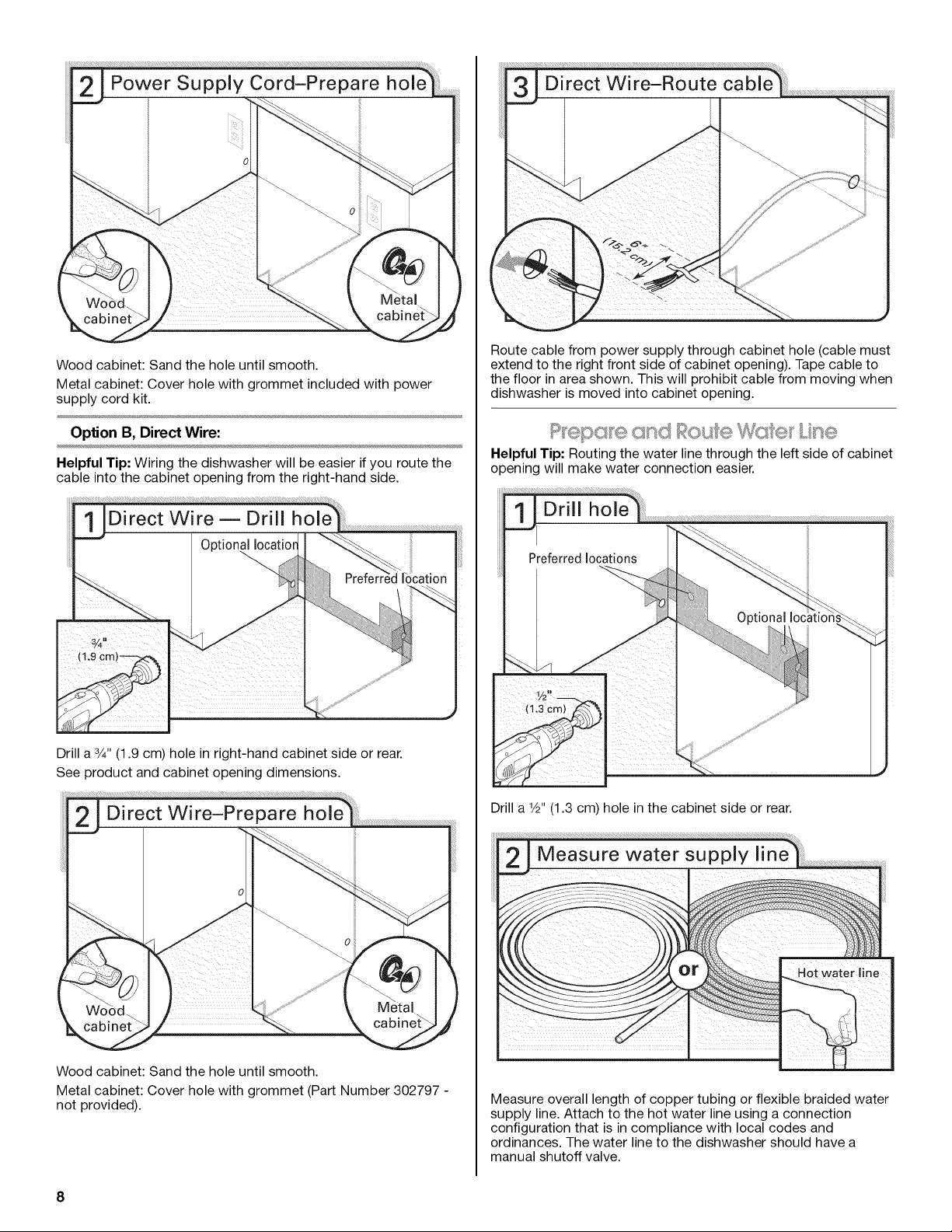

Woodcabinet:Sandtheholeuntilsmooth.

Metalcabinet:Coverholewithgrommetincludedwithpower

supplycordkit.

Option B, Direct Wire:

Helpful Tip: Wiring the dishwasher will be easier if you route the

cable into the cabinet opening from the right-hand side.

Drill a 3/4"(1.9 cm) hole in right-hand cabinet side or rear.

See product and cabinet opening dimensions.

Route cable from power supply through cabinet hole (cable must

extend to the right front side of cabinet opening). Tape cable to

the floor in area shown. This will prohibit cable from moving when

dishwasher is moved into cabinet opening.

Helpful Tip: Routing the water line through the left side of cabinet

opening will make water connection easier.

Wood cabinet: Sand the hole until smooth.

Metal cabinet: Cover hole with grommet (Part Number 302797 -

not provided).

8

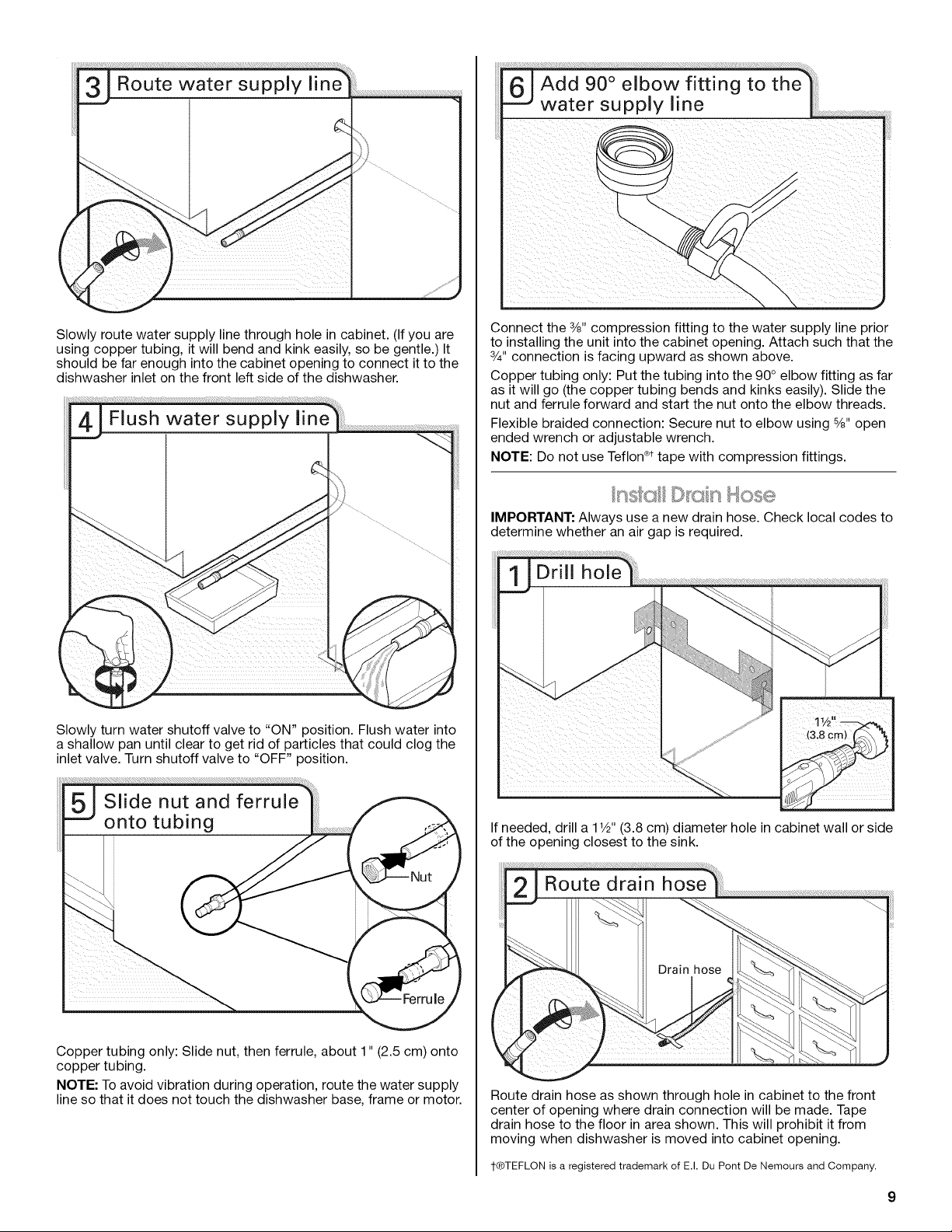

Drill a Y2"(1.3 cm) hole in the cabinet side or rear.

Measure overall length of copper tubing or flexible braided water

supply line. Attach to the hot water line using a connection

configuration that is in compliance with local codes and

ordinances. The water line to the dishwasher should have a

manual shutoff valve.

Route water supply

JAdd 90 ° elbow fitting to the']

water supply line

Slowly route water supply line through hole in cabinet. (If you are

using copper tubing, it will bend and kink easily, so be gentle.) It

should be far enough into the cabinet opening to connect it to the

dishwasher inlet on the front left side of the dishwasher.

Slowly turn water shutoff valve to "ON" position. Flush water into

a shallow pan until clear to get rid of particles that could clog the

inlet valve. Turn shutoff valve to "OFF" position.

Connect the 3/8"compression fitting to the water supply line prior

to installing the unit into the cabinet opening. Attach such that the

3/4"connection is facing upward as shown above.

Copper tubing only: Put the tubing into the 90° elbow fitting as far

as it will go (the copper tubing bends and kinks easily). Slide the

nut and ferrule forward and start the nut onto the elbow threads.

Flexible braided connection: Secure nut to elbow using 5/8"open

ended wrench or adjustable wrench.

NOTE: Do not use Teflon ®ttape with compression fittings.

IMPORTANT: Always use a new drain hose. Check local codes to

determine whether an air gap is required.

Copper tubing only: Slide nut, then ferrule, about 1" (2.5 cm) onto

copper tubing.

NOTE: To avoid vibration during operation, route the water supply

line so that it does not touch the dishwasher base, frame or motor.

If needed, drill a 1V2"(3.8 cm) diameter hole in cabinet wall or side

of the opening closest to the sink.

Route drain hose as shown through hole in cabinet to the front

center of opening where drain connection will be made. Tape

drain hose to the floor in area shown. This will prohibit it from

moving when dishwasher is moved into cabinet opening.

t®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

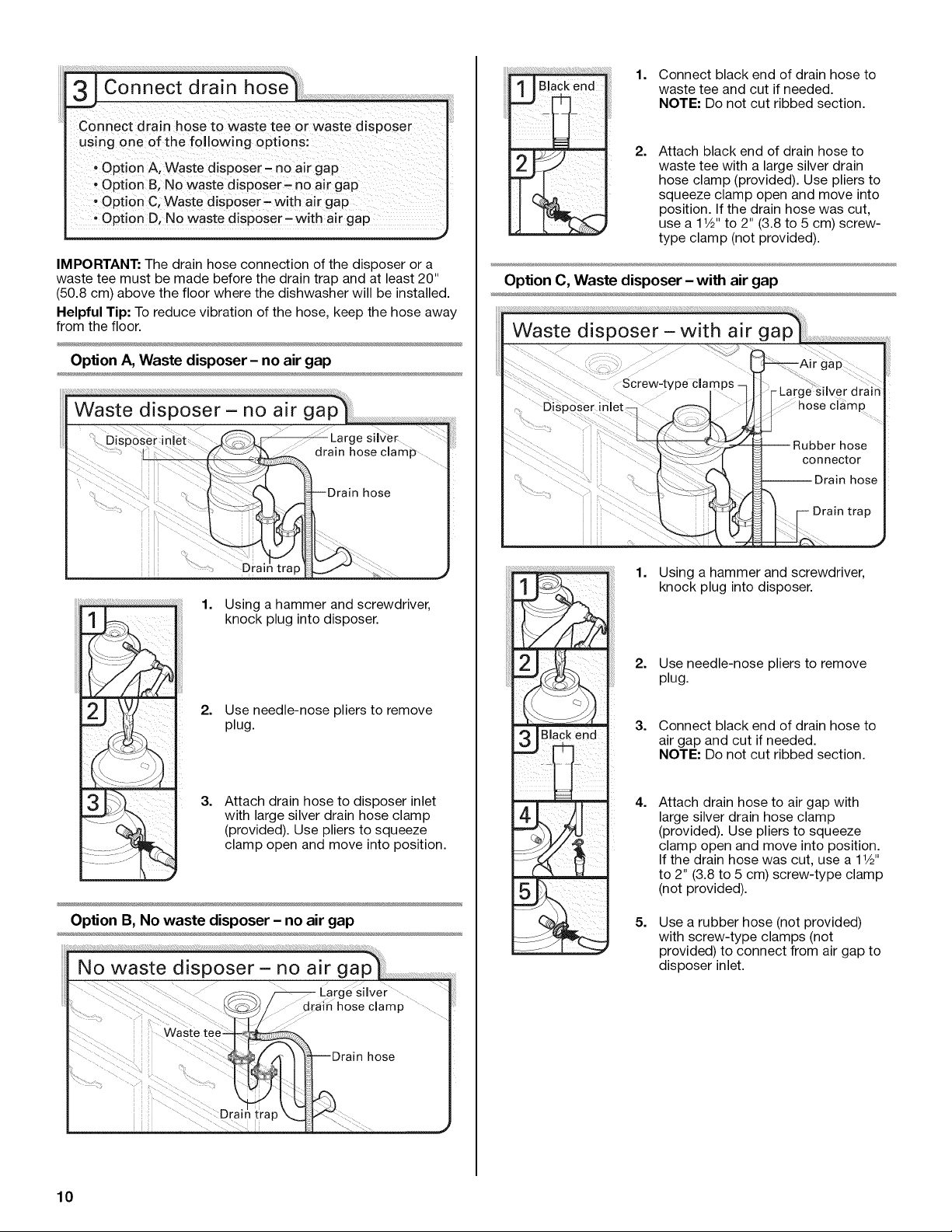

C'_nnect drain hose to waste te e or waste aispo;e I

using thefo low ng 0pt!

i opti0n A: waste dispoSe [ # n

Ta poser-no air gap

IMPORTANT: The drain hose connection of the disposer or a

waste tee must be made before the drain trap and at least 20"

(50.8 cm) above the floor where the dishwasher will be installed.

Helpful Tip: To reduce vibration of the hose, keep the hose away

from the floor.

Option A, Waste disposer - no air gap

1. Connect black end of drain hose to

waste tee and cut if needed.

NOTE: Do not cut ribbed section.

2. Attach black end of drain hose to

waste tee with a large silver drain

hose clamp (provided). Use pliers to

squeeze clamp open and move into

position. If the drain hose was cut,

use a 11/2"to 2" (3.8 to 5 cm) screw-

type clamp (not provided).

Option C, Waste disposer - with air gap

Drain trap

1. Using a hammer and screwdriver,

knock plug into disposer.

2. Use needle-nose pliers to remove

plug.

3.

Attach drain hose to disposer inlet

with large silver drain hose clamp

(provided). Use pliers to squeeze

clamp open and move into position.

Option B, No waste disposer - no air gap

1. Using a hammer and screwdriver,

knock plug into disposer.

2. Use needle-nose pliers to remove

plug.

3. Connect black end of drain hose to

air gap and cut if needed.

NOTE: Do not cut ribbed section.

4=

Attach drain hose to air gap with

large silver drain hose clamp

(provided). Use pliers to squeeze

clamp open and move into position.

If the drain hose was cut, use a 11/2"

to 2" (3.8 to 5 cm) screw-type clamp

(not provided).

5=

Use a rubber hose (not provided)

with screw-type clamps (not

provided) to connect from air gap to

disposer inlet.

10

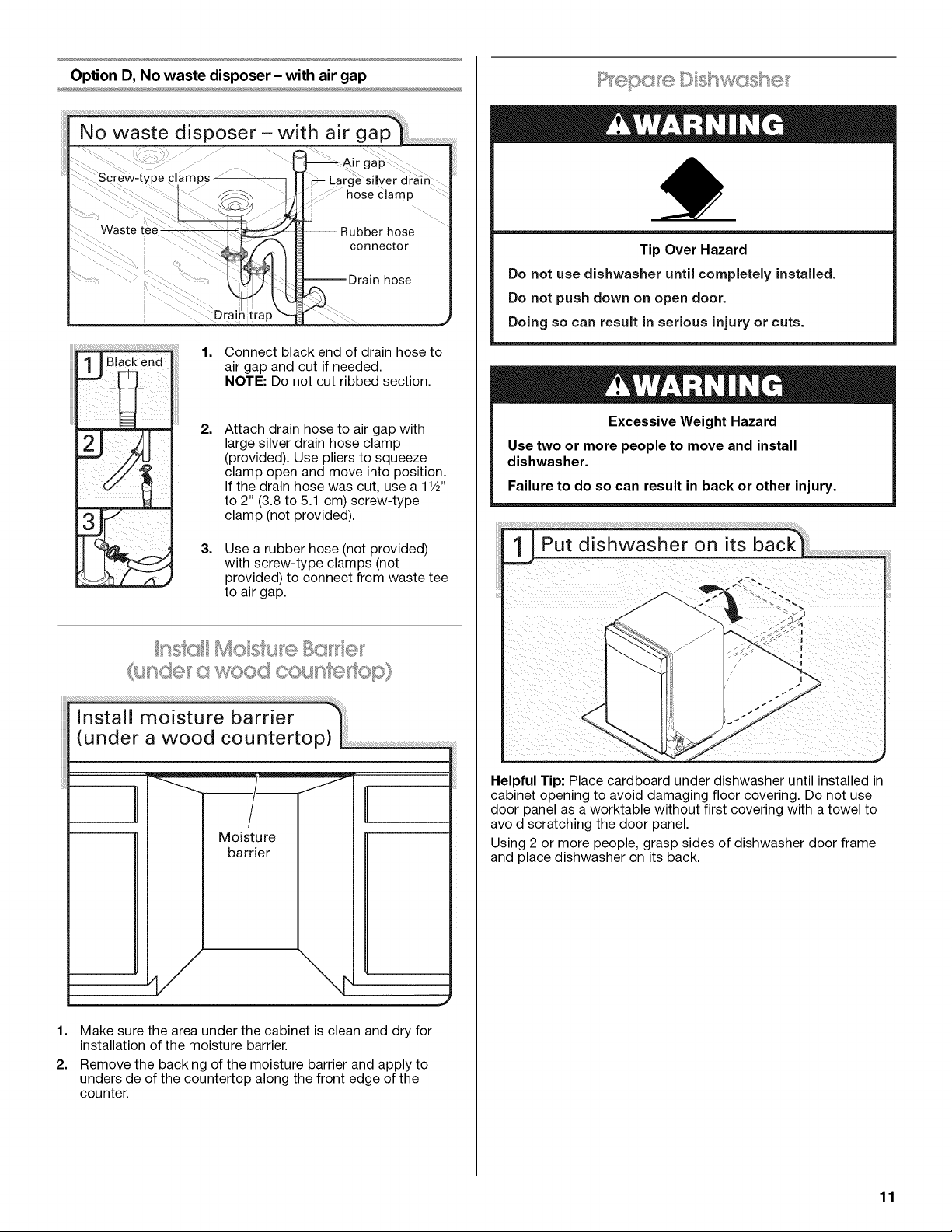

Option D, No waste disposer - with air gap

!;!;___;i i;A¸!ii!!i;;;;;ii;¸;i; ; i¸_:;I;i_!;;;!;ii_ii;;;,

Connect black end of drain hose to

air gap and cut if needed.

NOTE: Do not cut ribbed section.

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

3.3

Attach drain hose to air gap with

large silver drain hose clamp

(provided). Use pliers to squeeze

2.

clamp open and move into position.

If the drain hose was cut, use a 1W'

to 2" (3.8 to 5.1 cm) screw-type

clamp (not provided).

Use a rubber hose (not provided)

with screw-type clamps (not

provided) to connect from waste tee

to air gap.

l_ _ _ _ 1/¸ _

nde ' a od count®dop

Moisture

barrier

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

<

Helpful Tip: Place cardboard under dishwasher until installed in

cabinet opening to avoid damaging floor covering. Do not use

door panel as a worktable without first covering with a towel to

avoid scratching the door panel.

Using 2 or more people, grasp sides of dishwasher door frame

and place dishwasher on its back.

1=

Make sure the area under the cabinet is clean and dry for

installation of the moisture barrier.

2.

Remove the backing of the moisture barrier and apply to

underside of the countertop along the front edge of the

counter.

11

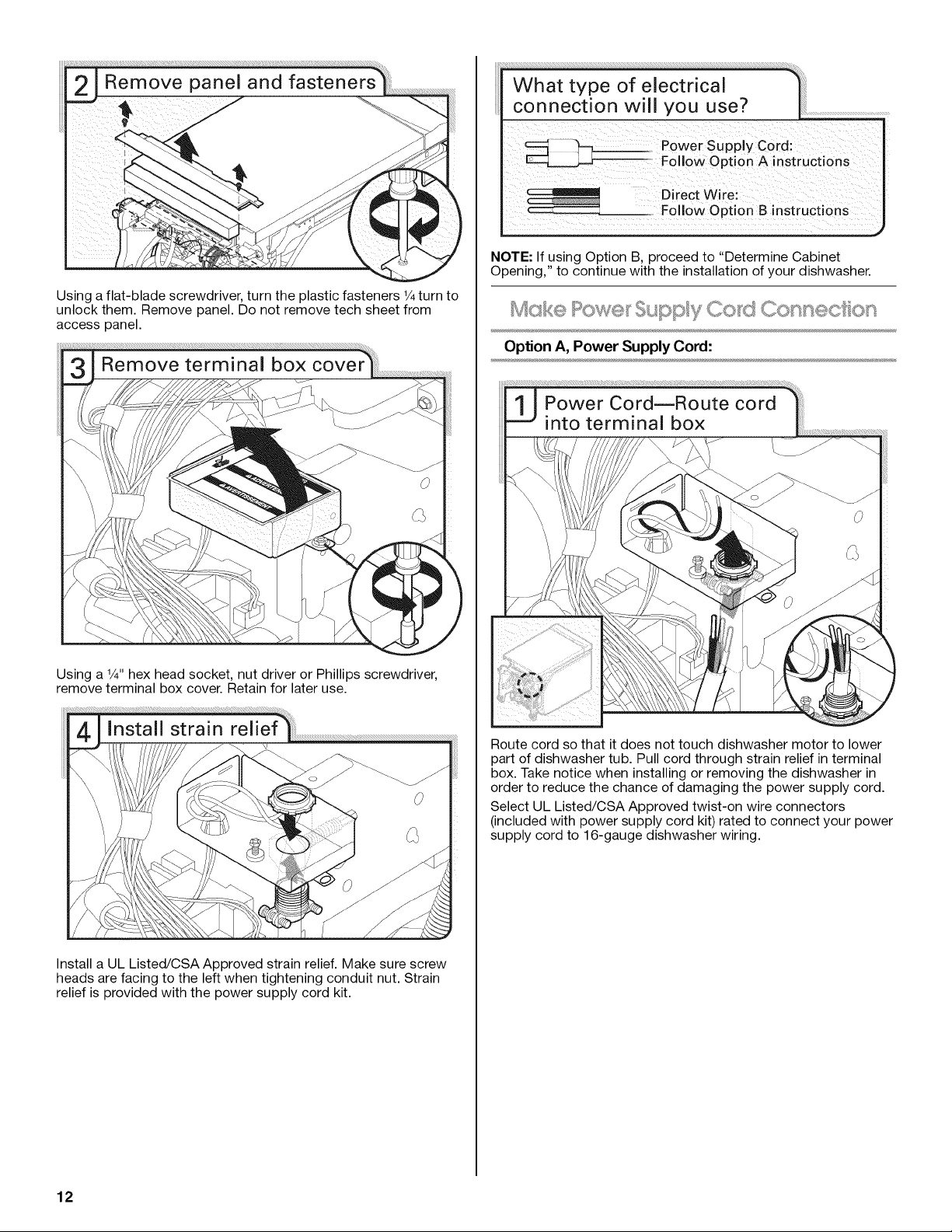

Using a flat-blade screwdriver, turn the plastic fasteners 1/4turn to

unlock them. Remove panel. Do not remove tech sheet from

access panel.

connection will you use? [

Power Supply Cord:

Follow Option A instructions

Direct Wi re:

Follow Option B instructions

NOTE: If using Option B, proceed to "Determine Cabinet

Opening," to continue with the installation of your dishwasher.

Option A, Power Supply Cord:

Using a 1/4"hex head socket, nut driver or Phillips screwdriver,

remove terminal box cover. Retain for later use.

Install a UL Listed/CSA Approved strain relief. Make sure screw

heads are facing to the left when tightening conduit nut. Strain

relief isprovided with the power supply cord kit.

Route cord so that it does not touch dishwasher motor to lower

part of dishwasher tub. Pull cord through strain relief interminal

box. Take notice when installing or removing the dishwasher in

order to reduce the chance of damaging the power supply cord.

Select UL Listed/CSA Approved twist-on wire connectors

(included with power supply cord kit) rated to connect your power

supply cord to 16-gauge dishwasher wiring.

12

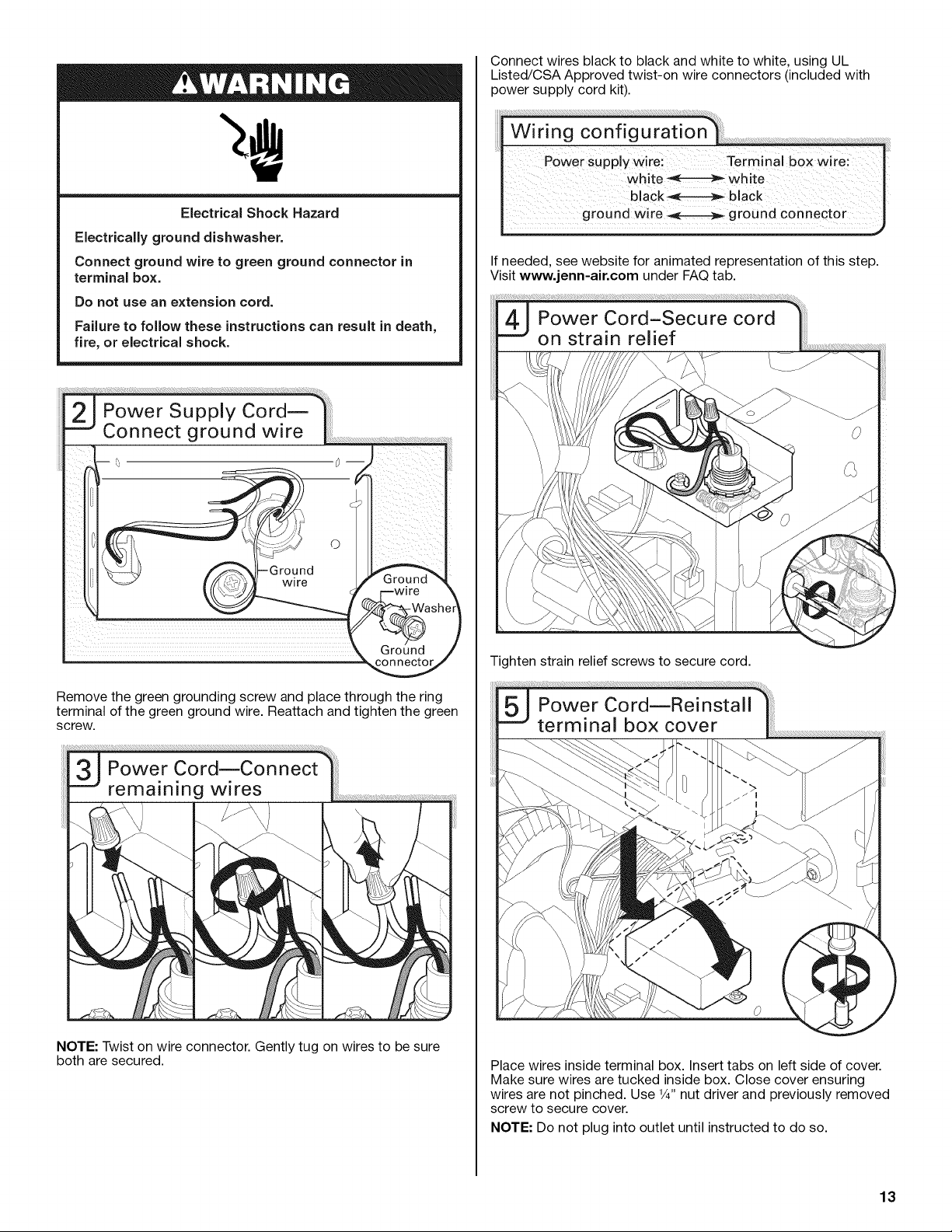

Electrical Shock Hazard

ElectricMly ground dishwasher.

Connect ground wire to green ground connector in

terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Connect wires black to black and white to white, using UL

Listed/CSA Approved twist-on wire connectors (included with

power supply cord kit).

If needed, see website for animated representation of this step.

Visit www.jenn-air.com under FAQ tab.

,1 _ i ¸¸¸¸¸¸//

e -

_ashe

Ground r )

Remove the green grounding screw and place through the ring

terminal of the green ground wire. Reattach and tighten the green

screw.

Power CordmConnect

remaining wires

Tighten strain relief screws to secure cord.

NOTE: Twist on wire connector. Gently tug on wires to be sure

both are secured.

Place wires inside terminal box. Insert tabs on left side of cover.

Make sure wires are tucked inside box. Close cover ensuring

wires are not pinched. Use 1/4"nut driver and previously removed

screw to secure cover.

NOTE: Do not plug into outlet until instructed to do so.

13

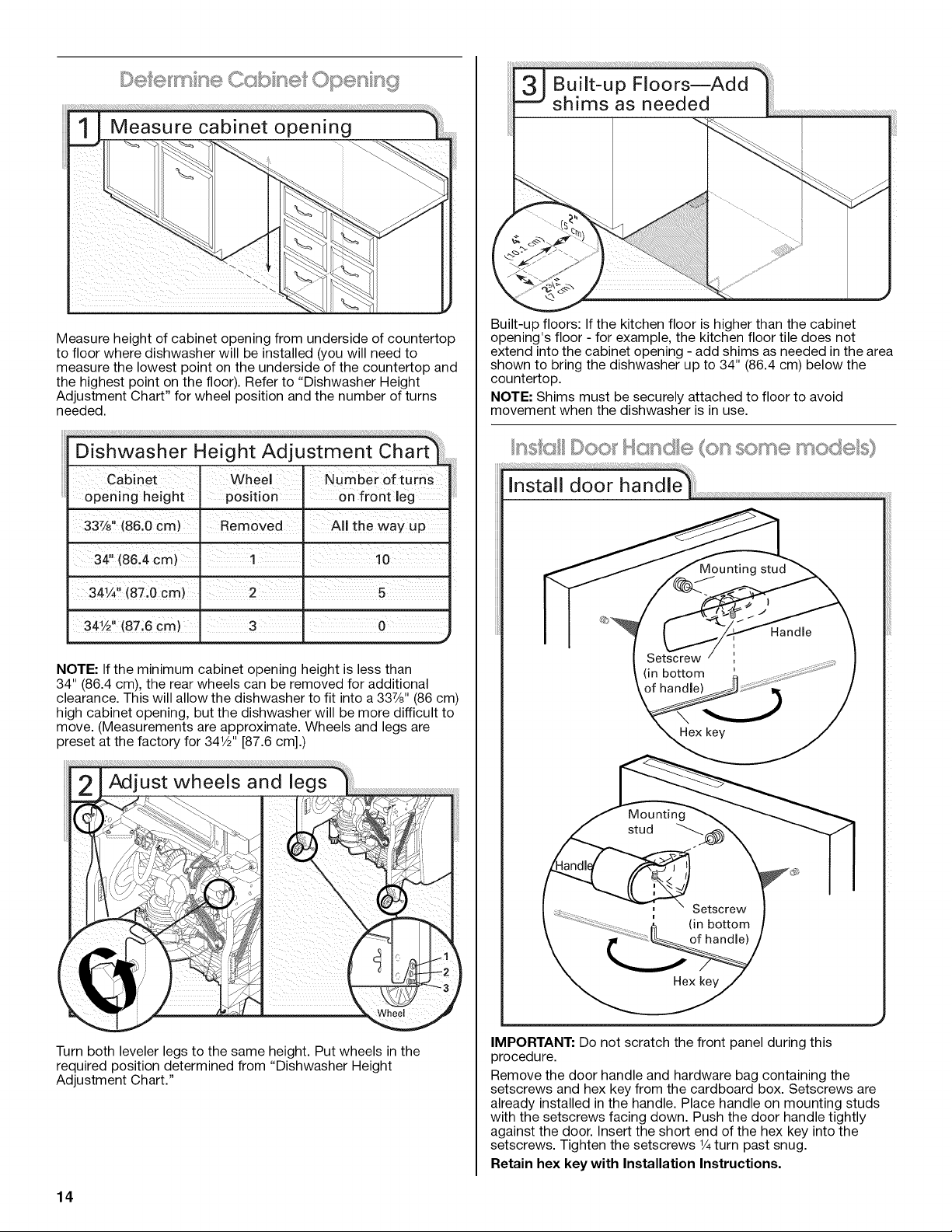

Measure height of cabinet opening from underside of countertop

to floor where dishwasher will be installed (you will need to

measure the lowest point on the underside of the countertop and

the highest point on the floor). Refer to "Dishwasher Height

Adjustment Chart" for wheel position and the number of turns

needed.

Dishwasher Height Adjustment Chart

Cab net whee Number of turns

opening height position on front leg

337/8(86",0cm) Removed I AIItheway .........

34" (86.4 cm) i 1 10

341/4" 87 n,-,,_

( .O..,,,! I 2 , 5

NOTE: If the minimum cabinet opening height is less than

34" (86.4 cm), the rear wheels can be removed for additional

clearance. This will allow the dishwasher to fit into a 337/8'' (86 cm)

high cabinet opening, but the dishwasher will be more difficult to

move. (Measurements are approximate. Wheels and legs are

preset at the factory for 341/2" [87.6 cm].)

Built-up floors: If the kitchen floor is higher than the cabinet

opening's floor - for example, the kitchen floor tile does not

extend into the cabinet opening - add shims as needed in the area

shown to bring the dishwasher up to 34" (86.4 cm) below the

countertop.

NOTE: Shims must be securely attached to floor to avoid

movement when the dishwasher is in use.

Turn both leveler legs to the same height. Put wheels in the

required position determined from "Dishwasher Height

Adjustment Chart."

14

Mounting

stud

, Setscrew

i

(in bottom

of handle)

Hex key

IMPORTANT: Do not scratch the front panel during this

procedure.

Remove the door handle and hardware bag containing the

setscrews and hex key from the cardboard box. Setscrews are

already installed in the handle. Place handle on mounting studs

with the setscrews facing down. Push the door handle tightly

against the door. Insert the short end of the hex key into the

setscrews. Tighten the setscrews 1/4turn past snug.

Retain hex key with Installation Instructions.

C xSO

(Mo s®/S oB36©©£WX,

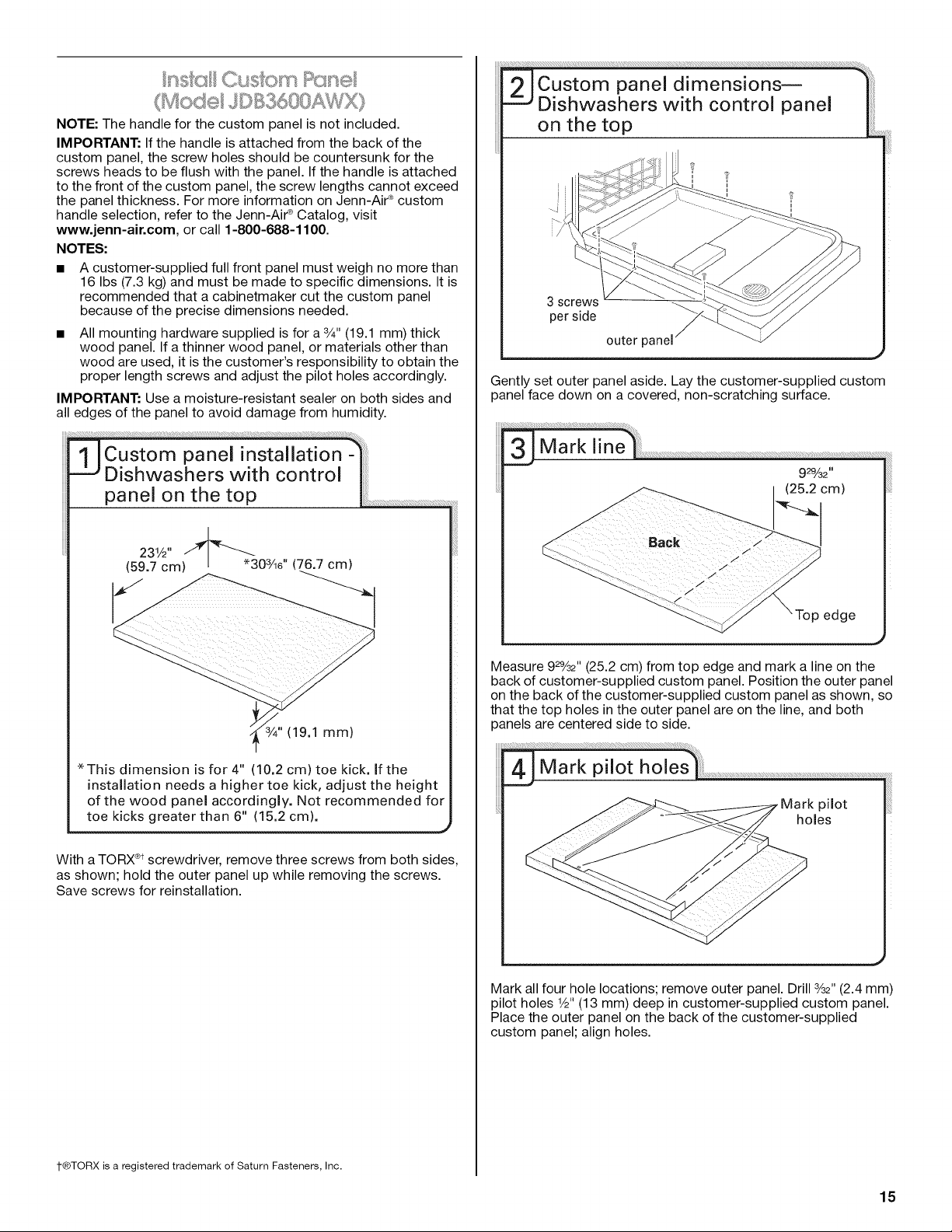

NOTE: The handle for the custom panel is not included.

IMPORTANT: If the handle is attached from the back of the

custom panel, the screw holes should be countersunk for the

screws heads to be flush with the panel. If the handle is attached

to the front of the custom panel, the screw lengths cannot exceed

the panel thickness. For more information on Jenn-Air ®custom

handle selection, refer to the Jenn-Air _ Catalog, visit

www.jenn-air.com, or call 1-800-688-1100.

NOTES:

A customer-supplied full front panel must weigh no more than

16 Ibs (7.3 kg) and must be made to specific dimensions. It is

recommended that a cabinetmaker cut the custom panel

because of the precise dimensions needed.

All mounting hardware supplied is for a 3/4"(19.1 mm) thick

wood panel. If a thinner wood panel, or materials other than

wood are used, it is the customer's responsibility to obtain the

proper length screws and adjust the pilot holes accordingly.

IMPORTANT: Use a moisture-resistant sealer on both sides and

all edges of the panel to avoid damage from humidity.

11 Custom panel installation

---:JDishwashers with control |

panel on the top

.....[

3 screws

per side

outer pane

Gently set outer panel aside. Lay the customer-supplied custom

panel face down on a covered, non-scratching surface.

929/32"

(25.2 cm)

(59.7 cm) I 303Ae'' (76.7 cm)

" (19.1 mm)

*This dimension is for 4" (10.2 cm) toe kick. If the

installation needs a higher toe kick, adjust the height

of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

With a TORX®tscrewdriver, remove three screws from both sides,

as shown; hold the outer panel up while removing the screws.

Save screws for reinstallation.

J

op edge

Measure 92%2"(25.2 cm) from top edge and mark a line on the

back of customer-supplied custom panel. Position the outer panel

on the back of the customer-supplied custom panel as shown, so

that the top holes in the outer panel are on the line, and both

panels are centered side to side.

pilot

holes

Mark all four hole locations; remove outer panel. Drill 3/32"(2.4 mm)

pilot holes V_" (13 mm) deep in customer-supplied custom panel.

Place the outer panel on the back of the customer-supplied

custom panel; align holes.

t®TORX is a registered trademark of Saturn Fasteners, Inc.

15

Loading...

Loading...