Page 1

www.dexpress.com DIMENSION EXPRESS Fax on Demand (775) 833-3600

This Data Sheet Includes Information On

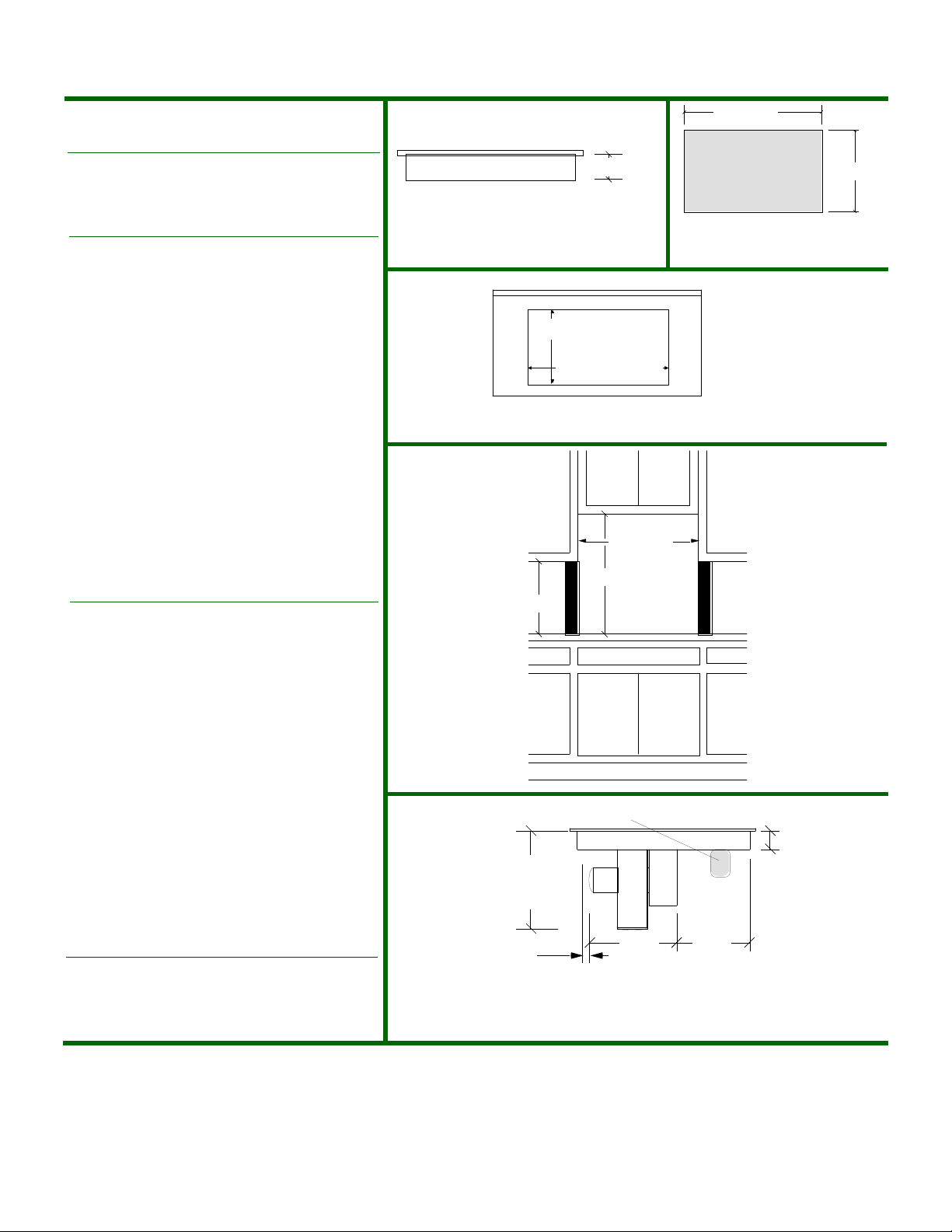

29 3/4"

Jenn-Air

• Product Model Number (s): •

Radiant 30" Downdraft Cooktops:

see below

CVE3401Q, CVE3401B and CVE3401W

Side View (not to scale)

• Dimensions (Actual Size) •

Overall width:

Overall depth:

Distance from top of counter to bottom of unit:

Cut-Out width:

Cut-Out depth:

28 7/8"

21 1/8"

29 3/4"

22"

see below

Min. spacing from cooktop edge to nearest

vertical combustible wall to the RIGHT:

6"

21 1/8"

28 7/8"

Overall Dimensions

Top View (not to scale)

Cut-Out Dimensions

Countertop View

(not to scale)

Min. spacing from cooktop edge to nearest

vertical combustible wall to the LEFT:

6"

Min. spacing from cooktop edge to nearest

vertical combustible wall to the REAR:

Minimum spacing to front edge of counter:

0"

2"

Minimum distance between cooktop

and cabinet directly above:

Minimum width of cabinet directly above:

Maximum depth of cabinets directly

above and adjacent:

30"

30"

13"

Cabinet Requirements

Wall View

(not to scale)

30"

Minimum distance between countertop

and adjacent cabinet above:

18"

• Additional Information •

• Cabinetry over cooktop : 30' minimum clearance

between the top of the cooking surface and the bottom

of an unprotected wood or metal cabinet. 24" minimum

when bottom of wood or metal cabinet is protected by

not less than 1/4" flame retardant millboard covered

with not less than no. 28 MSG sheet steel, 0.015"

stainless steel, 0.024" aluminum or copper.

30"

18"

Minimum horizontal

clearance between the

edge of the appliance

and combustible

construction extending

from the cooking

surface to 18" above

the cooking surface is

6" (see solid areas).

• To eliminate the hazard of reaching over heated

surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage

is to be provided, the hazard can be reduced by

installing a range hood that projects horizontally a

minimum of 5" beyond the bottom of the cabinets.

• Countertop must be supported within 3" of cutout.

Grease container

• Radius corners of cutout and file to insure smooth

edges and prevent corner cracking (1/4" radius).

• Blower can be swiveled 90°.

See page 2-3 for additional information

Subject to change without notice. This system is designed to

be updated daily if necessary. Dimension Express is not

responsible for use of superseded, voided, or outdated data

sheets. Because of the difficulty or impracticability of determining actual damages, liability of Dimension Express shall

not exceed $50.00.

Copyright © Dimension Express, 2000.

• NEVER reuse Data Sheets. Data Sheets are subject to change without • Call Dimension Express if you have any questions at (775) 833-3633 •

notice. Dimension Express is a FREE service bureau and is updated daily, • Always refer to a current Code at a Glance or manufacturer directory •

it makes far more sense to spend the time necessary to request new Data • Data Sheet codes change on the first of odd numbered months at 12:01am •

Sheets for each project, as opposed to the problems, time, costs, and risks

associated with reusing old Data Sheets.

321

Provide 2" min. cabinet

clearance to motor for

cooling purpose. 6"

recomended for servicing.

17 1/2"

Minimum

clearance

required

12 1/2"

BN155.15 • A321B149C150 • 31469 • 000905 • 04628 • 43720

12 1/2"

4 5/8"

Front View

of Cooktop and

Attached Blower

(not to scale)

22"

Page 2

www.dexpress.com

DIMENSION EXPRESS

Fax on Demand (775) 833-3600

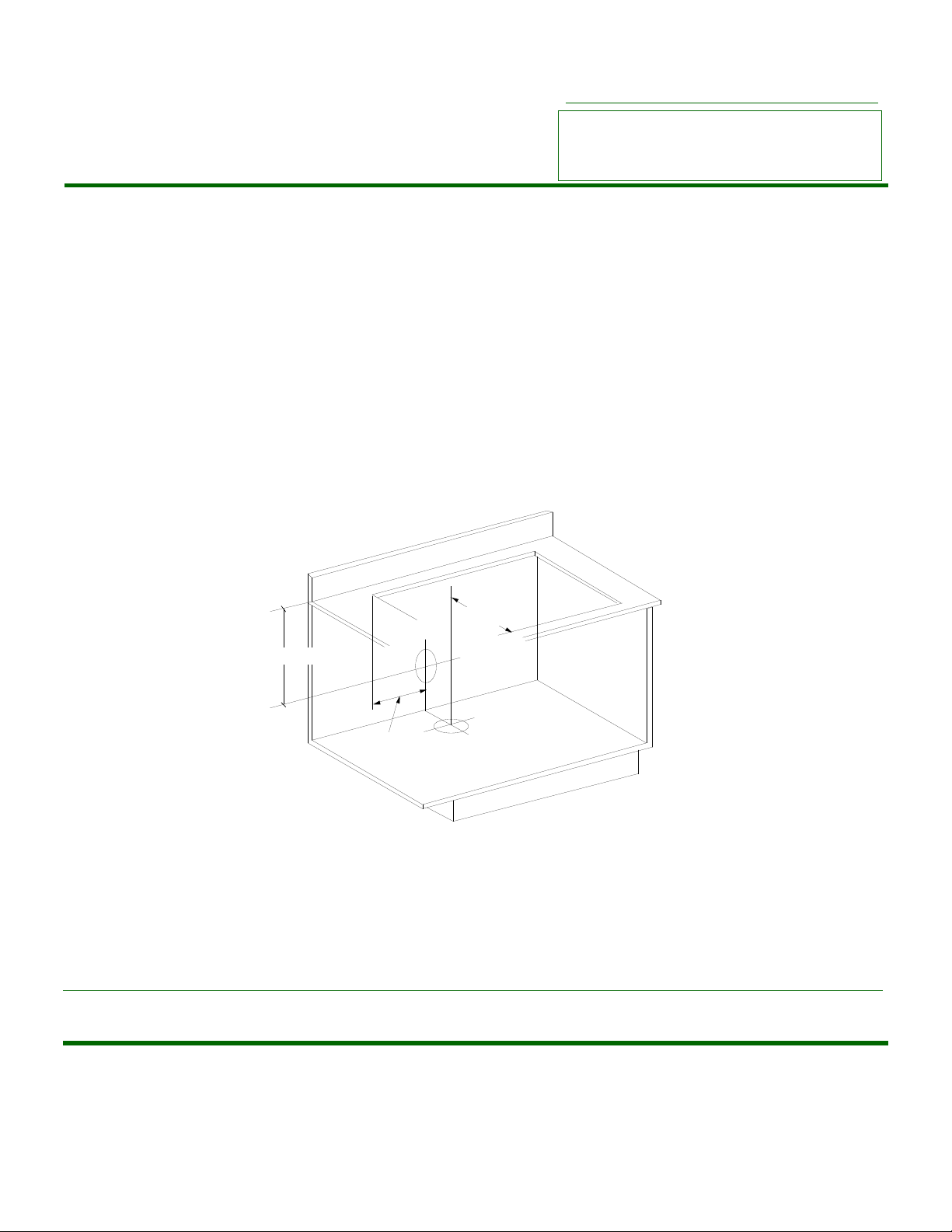

Additional Information:

• Electric supply: 120/240 or 120/208 VAC, 60Hz(Load 33.5 amps @

120/240VAC). 35 amp grounded circuit is required, Power cord is NOT

supplied.

• Duct requirements: See page 3 for ducting information and below for

location.

• Under counter access must be provided to remove and empty

grease container(s).

Duct locations

(not to scale)

Page 2

This Data Sheet Includes Information On

Jenn-Air

• Product Model Number (s): •

Radiant 30" Downdraft Cooktops:

CVE3401Q, CVE3401B and CVE3401W

6 3/8"

16 1/2"

10"

Top of counter to centerline of back duct location: 16 1/2"

Left edge of cutout to centerline of back and bottom duct locations: 10"

Front edge of cutout to centerline of bottom duct location: 6 3/8"

Subject to change without notice. This system is designed to be updated daily if necessary. Dimension Express is not responsible for use of superseded, voided, or

outdated data sheets. Because of the difficulty or impracticability of determining actual damages, liability of Dimension Express shall not exceed $50.00.

Copyright © Dimension Express, 2000.

• NEVER reuse Data Sheets. Data Sheets are subject to change without • Call Dimension Express if you have any questions at (775) 833-3633 •

notice. Dimension Express is a FREE service bureau and is updated daily, • Always refer to a current Code at a Glance or manufacturer directory •

it makes far more sense to spend the time necessary to request new Data • Data Sheet codes change on the first of odd numbered months at 12:01am •

Sheets for each project, as opposed to the problems, time, costs, and risks

associated with reusing old Data Sheets.

BN155.15 • A321B149C150 • 31469 • 000905 • 04628 • 43720

149

Page 3

www.dexpress.com

DIMENSION EXPRESS

Fax on Demand (775) 833-3600

Additional Information:

Ducting Installation Guidelines

Page 3

This Data Sheet Includes Information On

Jenn-Air

• Product Model Number (s): •

Radiant 30" Downdraft Cooktops:

CVE3401Q, CVE3401B and CVE3401W

Unit is rated at a maximum of 60 feet of straight duct, 300CFM of

"make-up" is required. The blower has 2 range settings; Low range

is used when equivalent duct length is up to 30 feet and high range

is used when equivalent duct length is between 31 and 60 feet.

1. Use 6" diameter round or 3 1/4" x 10" rectangular only, except

for equivalent duct lengths of 10 feet or less that vent straight out

the back of the cooktop and directly through the wall. Equivalent

duct lengths of 10 feet or less can use 5" round duct. A transition

from 5" round duct is necessary when connecting to 6" round or

3 1/4" x 10" duct.

2. Do not use 5" elbows except in a 5" system. Instead use a 5" to

6" transition followed by a 6" elbow, or a 5" to 3 1/4" x 10" elbow

transition.

3. Use quality metal duct of at least 26 gauge galvanized or 24 gauge

aluminum. Inferior quality pipe fittings can cause up to twice the

restriction and is a poor value. 6" diameter PVC sewer pipe can be

used for under slab installations. Local codes may require a heavier

gauge material or restrict PVC. Check your local codes.

4. Distance between adjacent fittings (elbows, transitions etc.)

should be at least 18". The farther the better. Closer distance

promotes turbulence which reduces airflow.

5. The number of downstream elbows or transitions should be

limited to three. The initial 5" to 6" straight transition, if used, need

not be counted in this number.

6. Handmade crimps are likely to cause restrictions.

7. If an alternate wall or roof cap is used, be certain duct size is not

reduced, and there is a backdraft damper. It is best to use listed caps

to be certain of proper performance.

8. Thermal breaks: In areas of extreme cold weather, it may be

necessary to provide a short length of nonmetallic duct as close to

the wall as possible, to prevent conduction along the metal duct.

9. High altitude installations: It is advisable to reduce allowable duct

run by 20%.

10. In Canada, the installation must conform with local codes.

11. Elbows, wall caps and other fittings are shown below with their

equivalent straight duct length. Each fitting value must be added to

the amount of straight duct length used, to determine overall straight

duct equivalent length (60 feet maximum).

12. When using flexible duct multiply length of flexible duct by 2.

Duct Equivalents

Equivalent

Length

5 feet

5 feet

12 feet

0 feet

0 feet

0 feet

2 feet

Subject to change without notice. This system is designed to be updated daily if necessary. Dimension Express is not responsible for use of superseded, voided, or

outdated data sheets. Because of the difficulty or impracticability of determining actual damages, liability of Dimension Express shall not exceed $50.00.

Copyright © Dimension Express, 2000.

• NEVER reuse Data Sheets. Data Sheets are subject to change without • Call Dimension Express if you have any questions at (775) 833-3633 •

notice. Dimension Express is a FREE service bureau and is updated daily, • Always refer to a current Code at a Glance or manufacturer directory •

it makes far more sense to spend the time necessary to request new Data • Data Sheet codes change on the first of odd numbered months at 12:01am •

Sheets for each project, as opposed to the problems, time, costs, and risks

associated with reusing old Data Sheets.

Duct

Fitting

6"

90° Elbow

3 1/4" x 10"

Elbow

3 1/4" x 10"

Flat Elbow

5" and 6"

Wall Caps

3 1/4" x 10"

Wall Cap

10" x 10"

Roof Jack

5" and 6"

Thermal

Break

Part

Number

5": A405

6": A406

A403

Legh: 5950

JA: 701943

5": 708786

6": 715557

Part

Number

A456

A496

A496

A463

A463

A495

Duct

Fitting

6"

45° Elbow

5" to 6"

Transition

6" to

3 1/4" x 10"

90° Elbow

3 1/4" x 10"

to 6"

90° Elbow

6" to

3 1/4" x 10"

Transition

3 1/4" x 10"

to 6"

Transition

5" to

3 1/4" x 10"

90° Elbow

Equivalent

Length

2 1/2 feet

Air flow this

1 foot

5 feet

9 feet

1 foot

4 1/2 feet

6 feet

BN155.15 • A321B149C150 • 31469 • 000905 • 04628 • 43720

direction NOT

recommended

Air flow this

direction NOT

recommended

Air Flow

Air Flow

Air Flow

Air Flow

Air Flow

Air Flow

150

Loading...

Loading...