Page 1

Jeen

U N IVE RSAL

Ourt

,o/..lmnxrrta/."

MODEL CJ.5

MODEL

CJ.6

Page 2

Y-

Jeep.

UNIVERSAL

4.WHEEI DRIVE

Model CJ-5

Model

Owner's

Willys Mofors,

lotEDo l, oHto, u.5. A,

Fom OM-1002-R3

Copyrighr

CJ-6

Mqnusl

Inc.

1960

Pdnr.d in u. s. a.

Page 3

Dear Owner

I

.JEEP'

UNIVERSAL

MODEL CJ.5

v;

Welcome to the

pl€dge

many thousands

to ensure that

of

you.

you

which

Owner's Identifr cation Card.

It desdibes the services which

furnish as

to

Card and also the 1000-mile Inspection Coupon.

carefully

controls, and corect

ours€lwes to serve

Your

'Jeep'

satisfactory service.

continued satisfaction and will be

providine

in

You

Read

explain any

Have

Our fi.st

receive f.om

will

has a 1000-mile InspectioD

your

part

you.

gesture

so that

family oI

of other

vehicle

p.operly

Owner's S€rvice Policy caietully and completely.

points

dealer filI out both

has been thorcughly tested

piope.

the

of his sales contract with

that arc not

of service is this owner's

you

operation

satisfied

you

with satisfaction as we

Willys

maintained it

Your Willys

your

will be familiar

owners throughout our fifty-

'Jeep' dealei

maiotenance for

dealer an Owner's Se.vice Policy

Coupon attached, and an

your

clear to

your

you!

of

vehicle

'Jeep'

give you

will

glad

to cooperate with

your

Willys

you.

you.

Owner's ldentification

with the instruments,

vehicle.

'Jeep'

and

is

interested

'Jeep'

'Jeep'

Ask

manual.

owners. We

have the

inspected

many miles

in

vehicle.

dealer

your

will

deal€r

Readit

.JEEP'

UNTVERSAL

MODEL CJ.6

Page 4

IABTE O] CONTENTS

MANUFACIURER'S

The only

sold is that

recommended by the Autooobile

"This

OHIO, U.S.A.

by us,

normal

being timited 10

thereof, includine

supplied by the

(90)

purchaser

(6100

us with transportation

tion shall disclose

this warranty being

pressed

part,

assume

our vehicles.

shau

Willys Service Station

Manufacturer.

been subject to

The

liability

or trade accessory which

NOTE

times to revise, modify, discontinu€

vehicles,

or

it

the

Warranty under

of the

is to certify

to be fiee

use

days after

or before such

Km.),

implied and of all othei

or

and we

fo.

us any

have been

Manufacturer makes no warranty

for any defect

-Willys

or any

Selle!,

Manufacturer, being the Standard

that we,

warant each

f.om

and seryice,

making

all equipment oi trade accessories

vehicle manufactuler, which

making delivery

vhichevei

to our satisfaction to have been

er?lessly in lieu

neither assume

other liability

This warranly

.epaired or altered outside

to affect its stability

oisuse,

Motors,

part

or

incurriDg

which new Willys Motor Vehicles

Manufacturer's Association,

WILLYS MoToRS,INc

new motor vehicle manufactured

defects

in metal or other

in material and workmanship under

our obligation under thjs

good

at our factory any

of such vehicle to the

vehicle has been driven'1000

event shall first occur, be

charees

in

neslisence or

cannot be discow€red

parts

any

prepaid,

nor

shall not apply to aDy

way so as,

any

Inc., reserves the

thereof,

liability

WARRANTY

TOLEDO,

,

Warranty

part

(except

shall, within

returned to

and which

of

other var.anties

all

obligations or liabilities

authorize

in connection with

or reliability,

accid€nt."

o! change any

without

or

any other

in

the

against,

material

WILLYS

obligation

our examina-

thus detective;

person

the sale

vebicle which

of an Authorized

judgment

nor

which

nor assumes anv

in

by

right at any

notice; and,

part,

any

ordinarv

MOTORS,

models

the Purctraser.

to

Waranty

parts

or

tiles)

ninetv

original

miles

ex-

on our

of the

has

device

factorv

INC'

time

of

without

are

and

to

of

or

its

MANUFACTURER'S

SPECIFICATIONS

GETTING ACQUAINTED WITH YOUR

WARRANTY

. .. 6

rJeepr

VEHICIE

GENERAL INFORMATION.. ...,. ,

INSTRUMENTS. ........9

SWITCHES

OPERATING YOUR

AND CONTROLS.. . . . . . . . ......11

'Jeep'

VEHICLE

BREAK IN. 13

DRIVING THE

OPERATION

OF 4-WHEEL DRIVE:

'JEEP'

VEHICLE.... ..

. , , 13

r......

.. .. .

DRIVING TECHNIQUES IN 4-WHEEL DRItrE..

tUBRICATING YOUR'Jeep'

ENGINE LUBRICATION.:.

VEHICLE

.... 22

LUBRICATION CHART........,

SERVICE MILEAGE CHART.......

MAINTAININC

YOUR

'Jeep'

VEHICIE

POWER PLANT.....

cooLING SYSTEM..,.....

ELECTRICAL SYSTEM.

WIRINGDIAGRAM,.....

FUEL SYSTEM..

. - . . . . . . . . .

DRIVING COMPONENTS...

EXTRA

EMERGENCY

EQUIPMENT.,.

CHART.....

. ,

,.

..,.. ., .64

.. . . .........

Page

4

7

. . 16

. . 19

23

.29

30

35

38

39

.....4s

.47

....7s

'Jeeo'

APPROVED

SPECIAL

EOU|PMENI...........i7

Page 5

Tyte

Number ol C) iinders

Bore.

Strolre

Piston Disphcem€nt

Compr€ssion

Standard

High Altitude

Compr*ion Pressure .

Ho.sepower

Hors€power

Torqle

Ratio:

(BraLe

(sAE)

(Maximuh

cJ.6

Fuel Tank

Withont heat€r

With h€ater.

v€hicle weisht

cross

Weights approximat€:

Siip?ing

Curb

For.anvas

For canvas

For hard top model, add.

half

top

full-top mod€I, add

(opt.l

at 4000

.. . . .

at 2000.pr.)

(GWVI:

model, ddd

SPECIFICATIONS

3\"

1\'

rpn.) . .

.72

r5_63

al'

101"

43\6'

67"

l3srj'

r55r'

7r%'

U.S,

\at1sat.

cJs

2163 2223

ga1

1031

151

t7

72

15,63

cJ6

3 t7

21

GETTING

The follovins

tion about

The first section vill acquaibt

designations

The second

important break in

The thi.d section

tions as

The fourth section

syst€ms and components and

minor oaintenance

Prope. lubiication

lub cated

of lubricants, as

condition. You should

at an

your

and serial

section describes

vell as

periodic

the r€commended frequencies

at

Autho.ized Willys Dealer's

ACQUAINTED WITH

IJEEP'

GENERAI.

pases,

'Jeep' vehicle.

given

divided into four s€ctions,

numbers,

period.

covers lublicating

setricins requilements.

explains

procedurcs.

is most impo.tant. Your

in the third section,

periodically

VEHICLE

INFORMATION

you

instruments, and

proper

function

the

also

des$ib€s minor adjustments

have it

S€rvice Department.

When ext€nsive adjustments and lepai.s

peiformed

vork

your

Authorized Willys Dealer's

techniciaDs a.e

by a competent automotive repair

Service Depa.tment

familiar

wjth

your

'Jeep'

.epair recommendations.

All

information

the

recommendations

iDg and

se.vicing

given

in this owDer's nanual

that should be used as a

your'Jeep'

vehicle.

YOUR

contain informa'

with

specificalions, model

conlrols.

operation

proc€dur€s

to

lub.icated and inspected

se€m

vehicle

guide

includins thc all

and recommenda-

-

your

of

rJeep'

'Jeep'

vehicle

with the corftct

maintain

it in first class

necessary,

techniciar. At

aDd with all

consists of factory

prop€rly

lor

vehicle's

and

should be

srades

have the

the service

factory

operat,

Page 6

The vehicle

stamped

plate

the hood on the Ieft

vehicle.

Drefix

dieit

Model CJ-6

575,18-00000.

For

vehicle serial

on

is located

Model CJ's

57548

serial

ready rcIe.ence,

serial

a metal

on the dash

followed

number. The

is

57748.

number here:

VEHICTE

number is

Plate.

side

will

bY a

prefix

For examPle:

recoid

5ERIAT NUMBER

This

under

of

the

have a

five-

for

Yo'lr

I

INSTRUMENTS

The opelational instruments

conveniently

can be easily seen on the instru

panel.

nent

warnine

function of

inadvance,

grouped

Each

indicates

lights

the vehicle and warns,

when something serious

olthe

where they

gauges

a critical

ard

are

is

lion

lights

casionalty

the engine is

breakdowns and exp€nsive repairs.

wro11g. KnowiDg

soins

of these

and observing them oc

gaug€s

while d.iving or while

running can

func-

.he

and warnnrg

prevent

The eneine

stamDed

on the

at tde front

serial

water

of the

F4.134 eneine used;n

will hava a Drefix

number,

by a sii'dieit

s;rial

4J-000000.

sedal

you

JeeP'

dealer

number.

reference,

number

receive

Veh;cle

and

Put

Place.

can

If

lost,

or any

rcPlace

here:

For ready

engine

When

your

new

number.

key

convenient

.hould become

vehicle

locksmith

from this

ENGINE

number

PumP

eneine

both

SERIAI

ls

Do3s

The

models

4J followed

thus:

record

Your

KEYS

to

keys

the

record

Lt rn a

Your

lrour

comPetent

the

the

sare

--keys

'JeeP

keys

AND

NUMBER

tOCKs

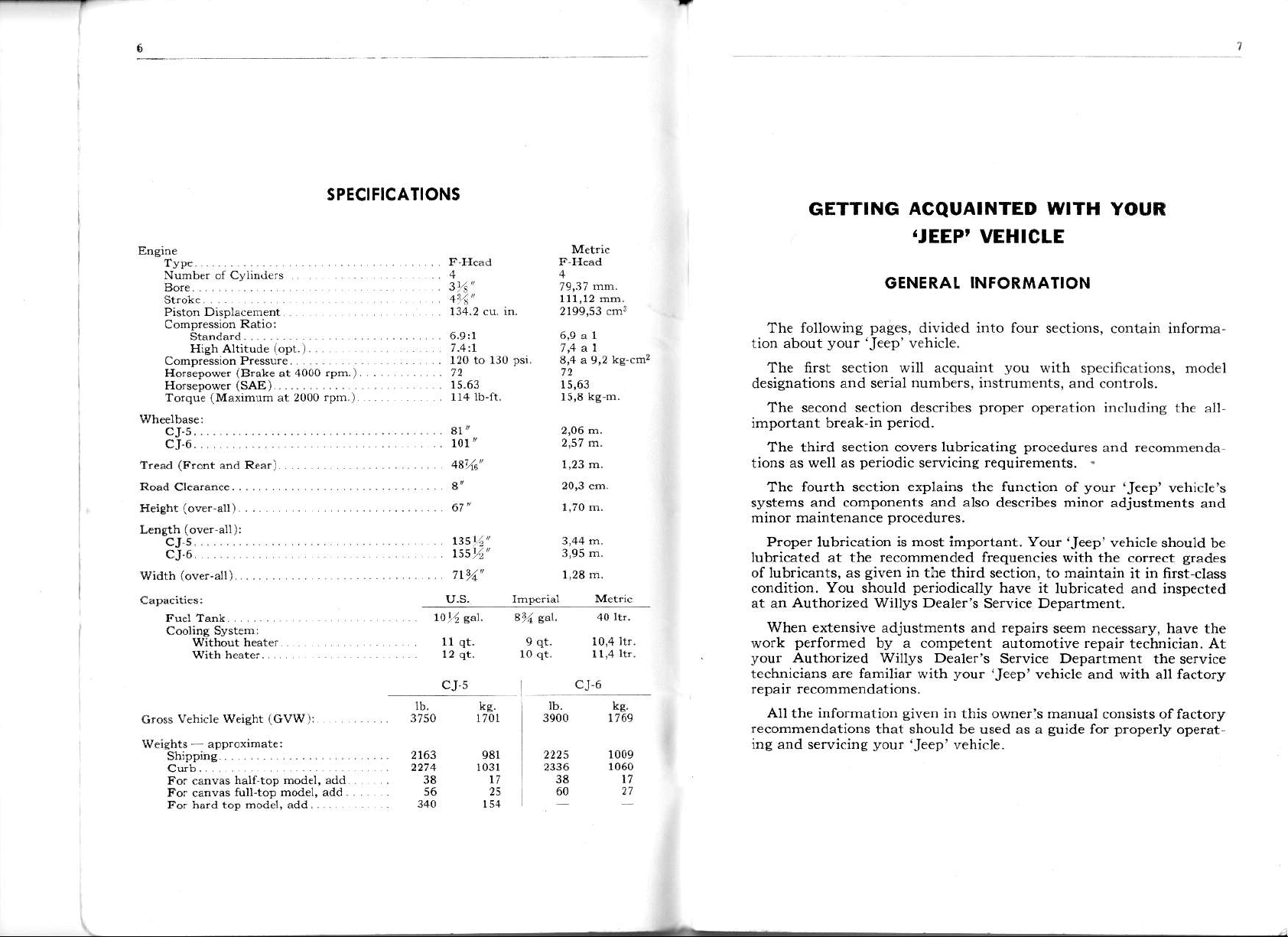

FIG. 1 INSTRUMENTS

SPEEDOMETER

The speedom€ter sweep hand

irdicat€s vehicle speed in miles

hour. The odometer registers ac indicates

,.OIL"

A rubl red

indicate when the e.sine oil is not

pumped

b€ing

to reach the

cation. When the ienition key is

turned on but the engine is not

running,

running

lamp will light to

at sumcient

places

or when the ensine is

at

that oeed

idle

speed, this light

per

WARNING

pressure

lubri

cumulated mitease

right

hand numeral

LIGHT

\till shov red

anything

the ensine

sp€ed,

mediately, for

cated and

shut the eDeine

6

7

travelled.

tenths of

is wrong. Ifit

is running

will burn itself out

of the odometer

a mile.

without neanins

lights

above idle

it isnot

beirs lubri-

The

when

oF im,

in a

Page 7

A ruby-red

indicate that

gen€rato.

ing the

key is turned

not runnine,

.unnine at

show

is not

battery.

idle speed,

red without

..AMP"

lamp will

for some

properly recharg'

When the

or1 but the

or vhen

reason

the engine

this light

meaning

WARNING

light

the

ignition

engine

will

any

to

thing is wrong.

engrne

as

will soo!

is

is

LIGHT

is running above

the charei'rg

have

soon as

comes

ins,

rect the failure.

Possible

so

on and stays

promptly

lights when

Ilit

ci.cuit

the battery

o.

dead.

If this light

on while driv-

detelmine

th€

idle sPeed,

checked

cor-

and

SWITCHES

AND

CONTROI.S

This

eause

is in the

fuel

will drop

mark when

turned

The temDeratufe

tempeEture

the

cooling

the

of the

(hot)

H

running

is

may soon

gate.

The

is that some

ing

antifreeze

€vaporated

a broken

If the

A ruby'red

headlishis

warns

shiline

The

is locat€d

up

The

sisnals

ti;n sienals

tu.n

fuel tank.

back

the

It may

off.

svstem.

gauge

zone,

dangerously

quit.

usual

in the

or leaked

radiator

"amp"

sre

that

inro itr.

sisnal

tuln

on the steering

position of the switch

right turn;

a

is sienalled,

indicates

to

tenit;on switch

of the solution

swings

it rneans

Stop

cause of

warning

light

on tictt U..m

your lights

how

The

Lhe E

take a

gauge

If the

far itto

the engrne

and

of the

radiator

out

heater hose.

or

lieht comes

HEADLIGHT

glows

or oncon.;ng

eves

TURN

indicator

the

a left

turn

the

green

.FUEL"

much

pointer

(emPty)

moment

.TEMP"

registers

needle

the

hot and

'nvestl

overtreat

water

has

through

wher

a"d

may

SIGNAL

switch

colum!

lever

do$n

Pos'

When a

lieht

js

in

or

BEAM

the

be

GAUGE

for the

isnition

The

meanins anything

vehicle

gauge

point€r

is driven

switch

may

to

is

over

GAUGE

the same

on at

fan bett

the

trouble

the

it has been

CAUTION.

.adiator cap

i.jury

ble

hot water. Never add

engine has

the

engine

the

IND]CATOR

driwers.

is

ssrl'h

indrcaro'

When the dimmer

push"d on"e

ha'k o low oPam

time,

has broken.

is, don't drive

corrected

Always

slowly to avoid

from escapins

to cool

rhe headlishls \^.ill

lishl urll

INDICATOR

wlren the

flash.

will

Dleted

;oins straiqht ahead.

i"ncitLi"g

lights

back

snaps

and

s''tcr'

as the

to centered

the

iever automatically

.ecord when

turned

again

fluctuate without

is wrone

roughterrar.

it may

or the engine

remove the

water

overheated;

first.

off

eo

turn

vehicle

will tu.n

the

as the

mean

Whateve.

on until

Possi

steam

when

allow

switch

anc

is

com

is

a8air,

the

off the

Position

on

or

rn'

seli

TGNITION

The ignition

and starting motor

switch ar€ integral.

located on the

the.ight

Turn

(clockwise)

right

ignition

When the

dash, below ard to

of the instrument

the key to the

to

and oank the

engine starts, iDmediately release the key

loaded to

automatically r€turn to

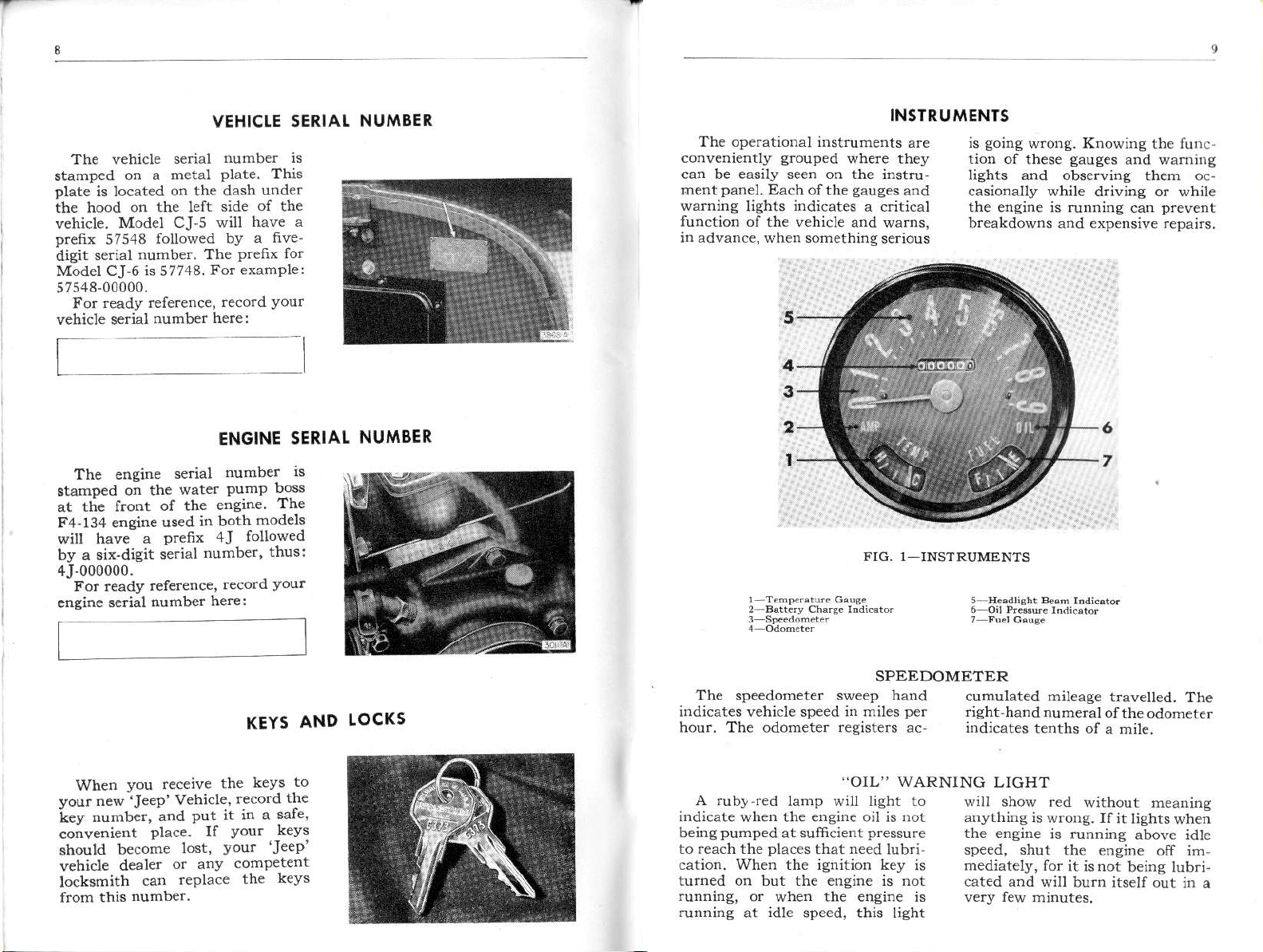

FIO.

2-VEHICLE

AND

This switch is

cluster.

extreme

connect the

eDsine.

as it is spring

CONTROLS

STARTER

the

the key to

rvhen the engi.e

the

and othe.

engine is not running,

key

clockwise)

SWITCH

position.

"on"

To

supply electric

batte.y to operate

to the ext.eDe

the

accessories

position.

Avoid

"start"

is runnine.

curent from

the heater

when the

turn

(counter

teft

tuoing

positioD

the

Page 8

LIGHT SWITCH

the

is the

control

The Iielt switch, No. 4,

pluflge.

knob is

type.

pushed

When

no lights are ]it.

in,

Pulling it out half way ope.ates

parking

the

lights and all the way

SHIFT LE\,ERS

The

"$hiftins

pattem"

ta$mission shift lever

figure 3 for

in

mission

and

the 3'speed

ffgure 4 for

the

of

is

shown

trans.

optional

the

HAND BRAKE

The manually operated brake

control is located uDder

of

of

hand

instrument

the

the steering column.

brake

panel

first depress the foot

the edse

to the left

To set the

HEATER CONTROLS

Check all controls

eration and turn

for

ch€cking

blower control speeds.

Thc air control knob whe'

atl the way out,

gives

air travel thrcugh the

and the amount

far

how

ture control

crease

(l€ft

the

pulled

k

the air flow heat output,

tum the ai. cont.ol

for ftee op-

air control knob

pulled

maximum

the

heater coils

of

heat depends

knob) tempera-

out. To in-

(center

knob)

on

out the

cluster light

parking

4-speed transmission. S€e

for operation of th€ transfer case

shiftine

brak€, then

brake control

handle

headlights. The instrument

is on when either

or the headlights

lights

levers.

pull

out

handle. Turn the

slightly and

on the

push

the

are 50

page

14

hand

it in to

which controls the blower speeds.

notch

One

and second

right for

to the

low speed

notch for high speed.

Pulline out defrcstff control

(right

knob) direcb warm air

throush the two deto€ters to the

wiDdshield. For Su'n'ler DrieirC

-Pull

out

air control

(cent€t

krob) only half way for maximum

fresh air to driver's compartmert.

OPER,ATING YOUR

By

takine a few reasonable

cautions

of

vehicle an opportunitv

"break

the wo.king

vehicle will be

The

vehicl€ ale

limits are maintained

Therefore

should be observed to

a0 Dph.

Carbon monoxide isa

lr

It

gasoline

.

.

.

the fille.

stick registeis

during the first few miles

driviDg and by

in", operatio!

parts

of

greatly

parts

[6s

no

hrs

is iD the exlaust fumes

odor. no laste. no color.

engines. Never

your

of

precision

certain speed

warm uP,

lah.l.

.0to300miles

MAKING

Fill

th€ radiato..

Put

sasoline

Fill

the oil reservoir

pipe

in

the tank.

until the oil indicator

FULL.

&GP

IN

-

mph.

The cmnkcase is filled

During

Be sure to have

dealer irspecr

at the end of 1000 miles

km.l

in a ctosed

the doors $ide

as the eneine is runnins.

READY

Give the vehicle a

.

See that

.

pre

your

of

BREAK

60 oph.

facto.y

viscosity for the

PROPER,

siving

properly

to

and life

your

'{Jeep'

ioproved.

This special oil

new

fitted.

'Jeep'

Close

th.oughout.

limits

"break

in"

at s00 miles

with engine oil of the

recommended

Section.

km.l of operation

not

do

km.]

[s00

CARBON

deadly

sas.

of all

sta.t an

indication of overheatins

component of the

vehrcle

vehicle

11.600

MONOXIDE

ensine

open

the engi'e.

lons

OPERATION

THE !'EHICLE

tlroush

Lubrica p.oper pressure.

See

lubrication

in the Lubrication

VEHICIE

kph.l.300 to

I80

L?h.l800

[95

with oil of

"break-in"

should be

kh.]

[800

in the Lubrication

the frrst 1000 miles

be alert for

vehicle.

usaee.

Keep then open

covering all the items

Sectior.

lires

all

See Ti.e

800

[1300

to 1200 miles

[2000

the

and rcplaced

vismsity

your

your

garage.

befde starti;g

cohplete

have the

Pressure.

mil€s

km.l

km.]

at the

proper

p€riod.

drained

U600

any

in

any

'Jeer"

'Jeep

Always

wide a;

Put

.

lever, Fie.

Place the

high shifr

gear

the fansmission

2, No. 14, in neutal.

transfer case low

lever. No. 8. ;n

or in lhe rear

disen8age the fronr

placing

th€ forward

.

fourth of

also open

.

the shift

position.

Pull

the choke

the way out.

Place the key

the thiottle sfigntly.

lever,

STARTING THE

searshift

and

direcl richr "

position

and lhe starter, Release

axle drive by

No.

7, in

cont.ol one-

This will

in the isnition

ENGINE

lock, No. 5,

right,

closins the ignition

Tu.n

.

the isnition key

and

turD

it to the

and hotd it there ro opdate

pressure

key when engine

Should the engine

.

at once,

pull

out and again

starts'.

fail to

the

choke all tlle wqy

press

tie starting

switch. When the engine

set the

operating

choke control at the

po6ition

and as the en-

circuit.

,,hard

on

start

starts,

best

Page 9

ginc

warms

the way in. Do

choke out as fuel

STARTING

Release the

.

Dcpress the clutch

.

Move the transmission

.

shift leve. to th€

figues 3

axte and traosfer case shift

front

levers are not uscd

vchicle is driv€n

in rcar wheel drive.)

D.press

.

pcdal gradually

timc slowly

pcdal.

Allolr the vehicle

.

mcrtum

lcngth!), ther

and depr€ss the clutch

tor

atlhe-same

Mo!€ tne shift

.

to

DcFcss the foot

gredually

llowly release the clutch

ramc

(29-32

cclerato! and depressing the clutch

pedal

ncxt higher

thc

Shift to

.

way at

tm./ttr.), releasins

before

push

up,

THE VEHICLE

and

the

relcase

(two

moment.

and at the same

'tigh"

about

moving

thc choke

not run with the

is wasted and

hand bmke,

pedal.

position.

first

(Note

4.

on the hishway

foot

and

or thrce v€hicle

rel€ase

accele.ator

that the

when the

acccleratoi

at the same

the clutch

gain

to

the accelera-

p.omptly

lever

speed

speed

18 to

shift lever.

the

if set.

sear

See

mo-

pedal

position.

pedal

time

pedal.

in

20 mph

the ac'

STOPPING

Rclease the foot accelerator.

.

Appty

.

vehiclc is

t1le foot brake

nearly

and thm depress the

practic€

Th€

of appltns the brakes

intermittently ratler tlan

coDstant

pressu.e

a sta.dstill

at

clutch

will

until the

pedal.

with

result in

CHANGING

lower

pedal.

quick-

lcwer

speed, in-

Depress the

.

Mov€ the

.

into the

ly

clutch

gearshift

ncxt

all

tlle

the engine

Should

.

th€ Emergeocy Chart.

see

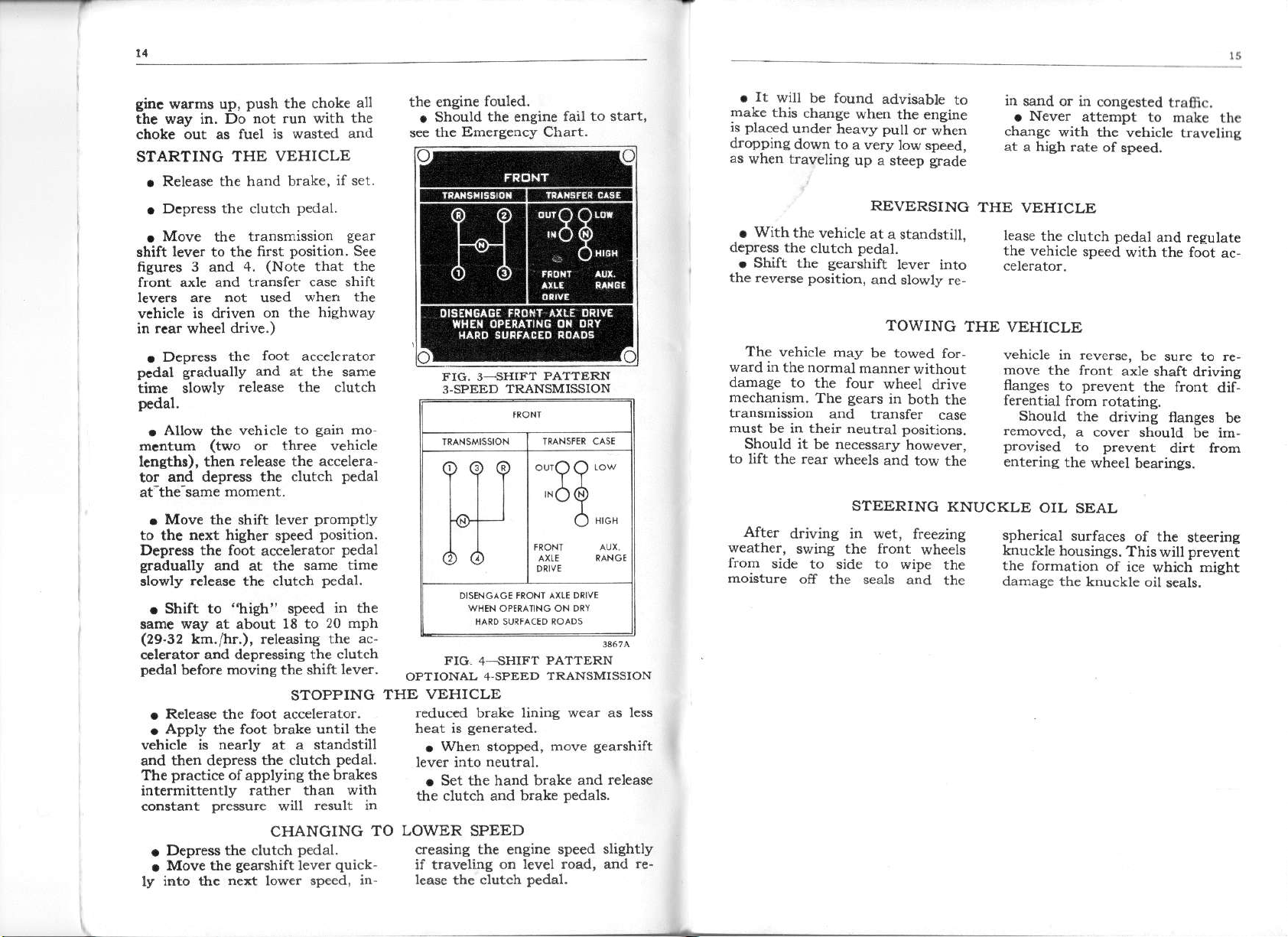

FIC. 3-SIIIFT

3.SPEED

FtG

4

OPTIONA! 4 SPEED

THE VEHICLE

reduc€d brake linine wear as lcss

When stopped, move

.

lever into

S€t the hand brake

.

the clutch and b.ake

TO LOWER SPEED

creasing th€ engiDe speed

if t.aveling

lease

the

clutch

fouled.

the engine

ARANSMISSION

fail to start,

PATTERN

*.ee

^dd

d

-SHIFA

neutral.

on tevel road, and

PAAAERN

ARANSMISSION

and release

pedats.

pedal.

gearshift

slightly

r€-

It

.

will

make

placed

's

dropping

as

when traveling

With

.

deFess the

Shift the

.

the reverse position,

The

ward in

dMage

mechanism.

transmissioD

must

Should it

to lift

be found

this

chanee

under

down to

the vehicle

vehicle

the normal

to the fou.

be in their neutral positions.

.ear

the

when

heavy

a very

up a steep

clutch

pedal.

gearshift

may

mannerwithout

gearc

The

and transfer

necessary

be

wheets and tow rhe

STEERING

After

weather,

from

moistu.e

driving in wet,

swirg the front

side

to side to wipe

otr

the seals and

advisable

the engine

pull

low spe€d,

or

to

when

grade

REVERSING

at

a staDdstill.

lever into

and stowty re-

TOWING

be towed for-

wheel drive

in

both the

case

however,

KNUCKLE

f.eezing

wheels

the

the

in

s.and or in

Never

.

change

at a high rate

with the wehiclc

THE VEHICLE

lease

the clutch

the

vehicle speed

THE !'EHICLE

vehicle in reverse,

move

femoved,

provised

the front

tlanges

ferential

Should

entering

to

OIL

spherical

knuckle

housings.

the formation

damase

the knuckle oil

congestcd

attempt

of sp€€d.

pedal

with the foot

axle

prevent

from rotatins.

the

drivine nanges

a cover

to

the

wheel bearings.

should be lm,

prevent

SEAL

surfaces

of the

This wilt

of ice

tra6c.

to make

and

be sure to !€,

shaft driving

the flont

dirt from

thc

travcling

regulate

ac

dif,

b€

steerins

prevent

which might

seals.

Page 10

To shilt frcrn

2-whael-drive

to

acc€lerator,

move

and

to the

auxiliary-range

hish

front axle

ifth€ vehicle

the

forwa.d

(rear) position before the

drive can

4-wheel-drive

front'axle

(out)

levei

WHEN TO USE

Use 4-wheel

additional

for difficult

ing

provide

fo.

You should

when

are

by the

surfaced

should

tractive

needed under

longed

ha.d-surfaced

ally caus€

shiftins

condition

low speed

industrial and

greater

required than can

standa.d

normal drivins

For

not be used.

effort

use of 4'wheel

out

drive

traction and

.oads, 4-wheel

temporary

is

terrain and

asricultural

only use 4-wheel

traction

transmission

WI{EN NOT

it

P.ovides

such conditions

roads may occasion-

of 4 wheel d

caus€d

let up

be disensased

The additional

on the

is moving,

drive lever

Position.

must be in

to

Provide

lowe.

and

be

Provided

on

drive

difficulty

we. This

build-uP

Power

Power

is

Pulling

by a

The

sear

us€.

drive

TO USE

hard-

drive

Pro

to

low

not

on

in

-'?o*-

'"o

4'WHEEL

gear.

road when

$ow. Us€

rolling

imptements. Use

mud, sand,

2 wheel-drivc

job.

4.WHEEL

of torsional stress

train

variatioDs

differeDt load

drive

several

su

DRI\E

4 wh€el drive

Use

it to

and

and

in tirc diameterc

rclieve tnis buitd-up,

To

the vehicle

feet

Domentarily to allow

ace

I

o',""

need it. Use it

vou

get

heavy trailers

pullins

for

and wherever

traction

DRI\E

results from

conditions.

or dfive otr the

agricultural

it on

won't do the

iD the

reverse for

in

10032

otr the

in

ice, hitts,

normal

drive

normal

uoder

simply

hard

the

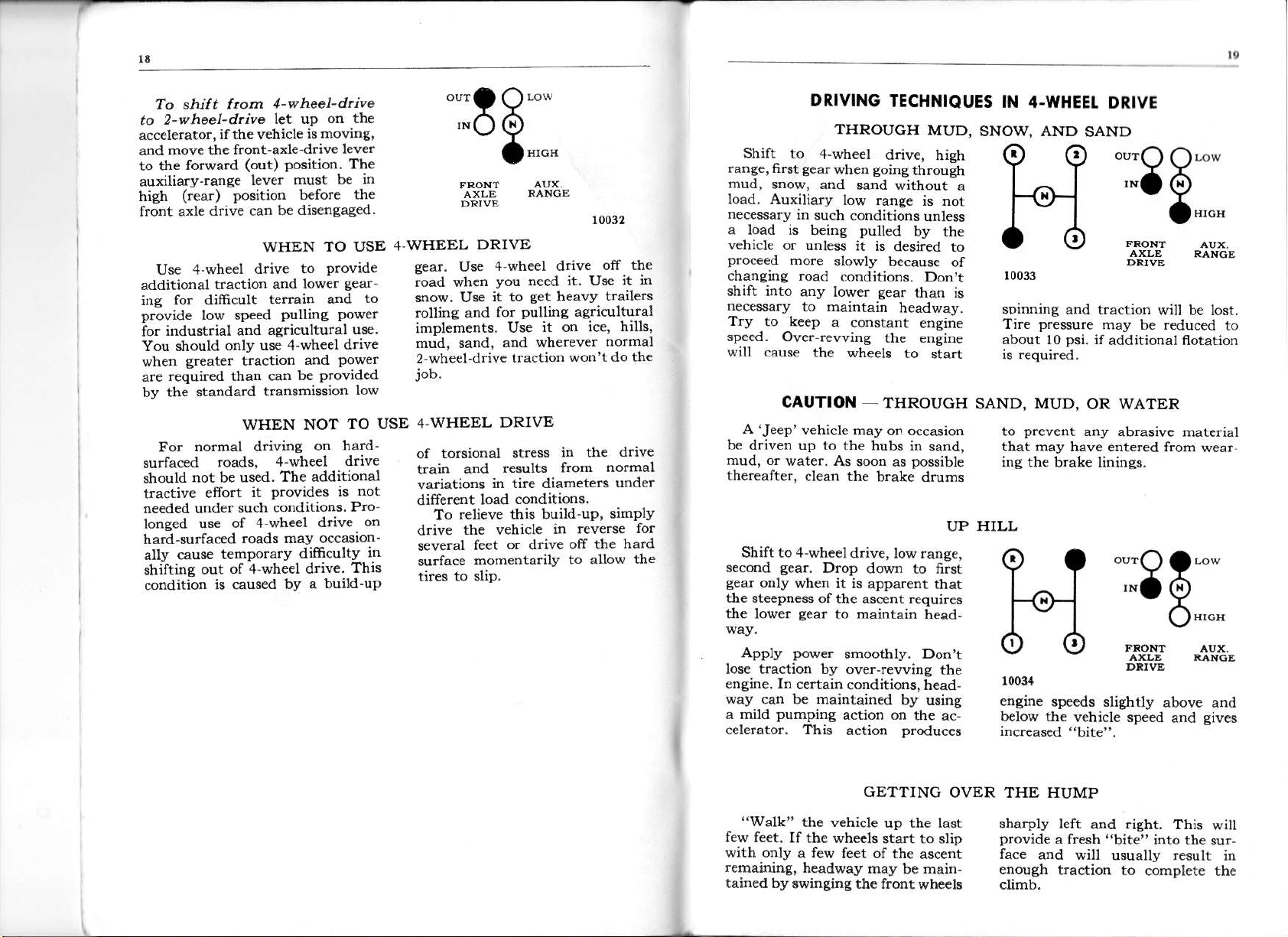

DRIVING

THROUGH

Shift to

range, first

mud,

snow, and

load. Auxiliary

necessary

a load is being

vehicle

proceed

changins road

shift into

necessary

Try

to kcep

speed. Over

will cause

A'Jeep'vehicle

be

driven up to the

mud, oi

thereafter.

Shift to 4-wheel

second

g€ar

only

tie st€cpness ofthe

the lowe.

4-wheel

gea.wheD

in

or unless

more

low rans€

such conditions

slowly

coDditions.

aDy lower

to oaintain

a constant

rewing

the wheels

CAUTION

water. As

clean the

Drop

sea..

when it is

to

sear

TECHNIQUES

MUD,

diive, hish

goine

sand without

pulled

it is

throush

is not

unless

by the

desired to

because

gear

Don't

than is

headway.

ensine

the engine

to

sta.t

of

IN 4.WHEEI.

SNOW. AND

a

sDinning

Tire

about l0

THROUGH SAND, MUD,

may

on occasion

hubs in sand,

sooD as

d.ive, low range,

asc€nt requires

maintain

possible

b.ake drums

dow! to first

apparent that

head-

UP

to

that

ing

HI

LL

9?

SAND

10033

and traction

p.essure

psi.

OR WATER

prev€nt

may

the brake linings.

any

have eDtered from

l-o-l

DRIVE

o,rr.)

a\,"*

,"-

6

a*"

may be reduc€d

il

additional flotation

will be lost.

abrasive material

."Q?--

*o

Q

o"*"

to

wear

Apply power

lose traction by

ensine. ID

way

a mitd

c€lerator. This

"Walk"

few feet.

with only a few

remaining,

tain€d by

certain conditions,

can be maintained

pumpins

the vehicle

If the whecls

headway

swinging the front

smoothly. Don't

ovei-rewing

head-

action on

action

by using

the ac

produces

GETTING

up the last

start to slip

feet of the

may

ascent

be

wheels

main-

dd

tle

OVER THE HUMP

10034

ergine

below t}le

sharply left

provide

face

enough

climb.

speeds slightly

a fresh

and witt

traction to

vehicle speed

.isht.

aDd

"bite"

into the

usually

comPlete the

above and

gives

and

This

will

su.-

result

in

Page 11

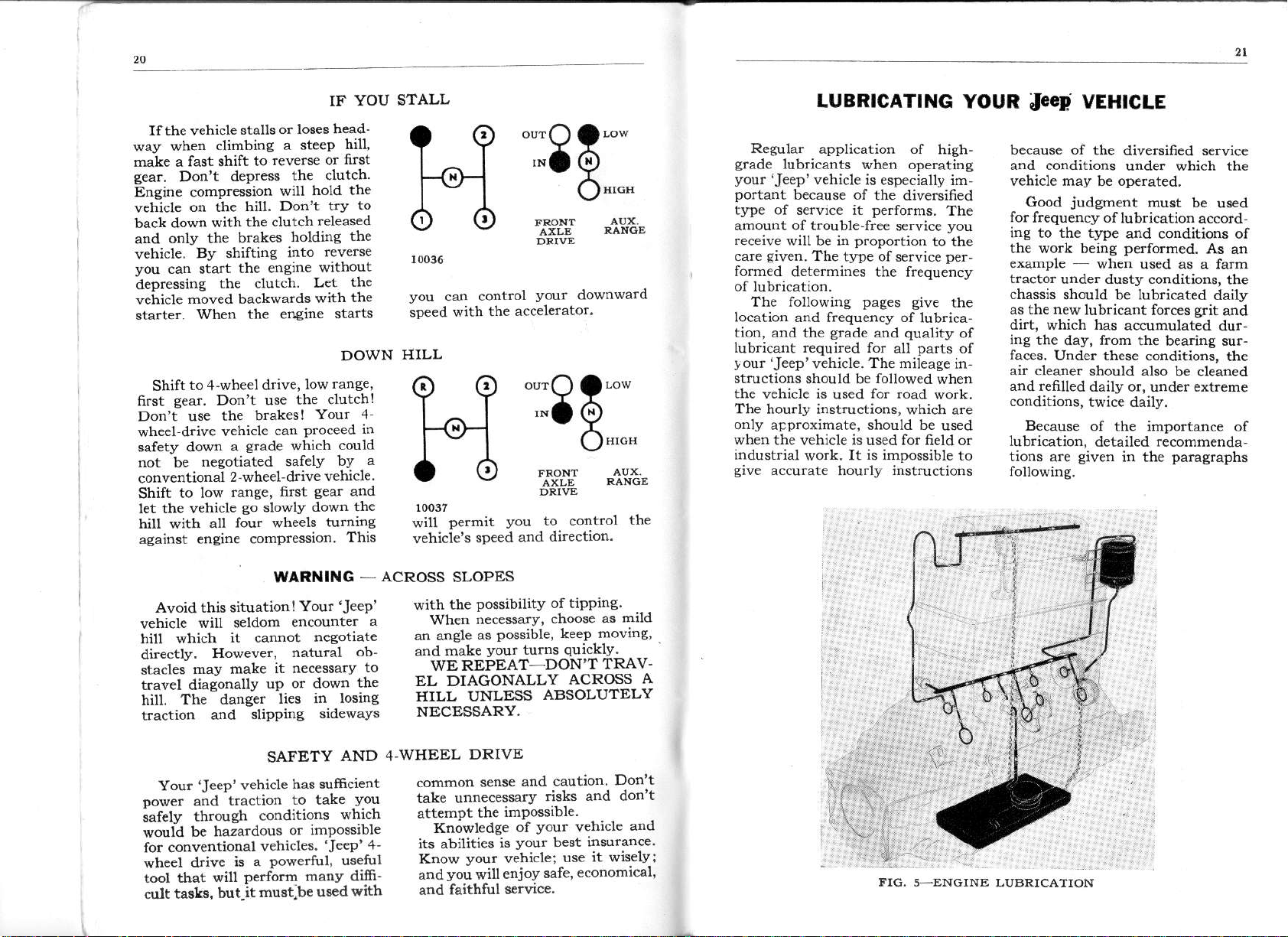

Ifthe vehicle

when

way

male a fast shift to

gear.

vehicle

back dowr

vehicle.

Dont depress

Ensine compression

on the

only the

and

you

can start

depressing

vehicle

starte!.

6rst

Don't use

wheel

safety down

lot be

conventional

Shift

let the vehicle

hiu with

agaiost

moved backwards

to,1 wheel drive,

Shift

gear.

drive vehicl€

to low

stalls

climbing

hill. Don't

the clutch

with

brakes

shifting

By

the engire

the clutch-

WheD

engine compression.

the el}gine starts

Don't use

brakes!

the

a

srade

negotiated safely

2 wheel drive

ranse,

so

all fou. wheels

or loses

a steeP

reverse or

the

wiu

holdins

into

low

the

can

Proceed

whicb

first

slowly

YOU

IF

head-

hi[,

first

clutch

hold the

try

released

the

reverse

without

the

Let

the

with

DOWN

ranse.

clutchl

Your 4

could

by

vehicle

and

sea.

the

down

turnins

This

to

STALL

LUBRICATING

YOUR

JEED

VEHICLE

.'.oo--

??

ro-1

,".

Q

o*""

oo

10036

your

you

speed

can control

the accetetator,

with

downwarcl

HILL

."'a

9?

in

a

tG

^a

?--

ri)

6.".

Jd

1003t

permit

will

vehicle's

you

speed and

to control

direction.

the

Regular

srade

your

'Jeep'

portant

tl.pe

amount of trouble free

.eceive

care

eiven.

foroed

The following

iocation

tion,

and the

lubricait required for

rJeep'

our

I

structions should

the vehicle is

The

hou.ly instructions,

oDly

approrimate, should be

wheD

industrial

give

accurate hourly instluctions

application of

lubricants

vehicle is

because of

of

service it

will be in

The

determines the frequency

ard fr€quency of lubrica-

vehicle. The mileage

the vehicle

work.

when operating

especially im

the diversined

perfo.ms.

service

proportion

t].pe of seNice

pages give

grade

be

used

is

It is impossible

quality

and

all

followed

for road

which are

used for field or

parts

high-

The

you

to the

per-

the

of

of

in

when

work.

used

to

because of

aDd conditions

vehicle may be operated.

Good

for

frequency of

iog to the type

the work beins

example

tractor

chassis

as the new

dirt, which has

ing

the day, from the

faces.

air creare.

and refilled

conditions,

Because

lubrication,

tions are

followine.

the diversified service

unde. which the

judgment

when

unde. dusty conditions,

should be lubdcated

lubricant fotces

Under these conditions,

should also be cleaned

daily or, under extreme

twice daily.

of the importance of

detailed recommenda

given

must be

lubrication accord

and conditions of

performed.

used as a farm

accumulated dur

bearing su.-

in the

used

As an

the

daily

grit

and

the

paragraphs

Avoid this situation!

vehicle

hill which

directly.

stacles

travel diagonally

hill.

traction

wiII seldoo

it cannot

However,

may make

The danger

and

slipPing

uP or down

SAFETY

Your

Dower

safely

vould be hazardous

for

wheel

tool that

cult tasks,

and

throush

cooventional

&ive

vehicle

'Jeep'

traction

conditions

vehicles 'JeeP'

a

is

Powerful,

perform many difi-

will

but-it

must be

WARNING -

Your

encounte.

natural

it necessary

lies

'JeeP'

nesotiate

obthe

in losing

sideways

AND 4'WHEEL

has sufficient

to take

or impossible

vou

which

useful

used with

ACROSS

a

to

4'

SLOPES

with the

When

an anele

and make

possibility of tiPPing.

necessarv,

as

Possible,

your

tums

WE REPEAT'-DON'T

EL DIAGONALLY

HILL UNLESS

ABSOLUTELY

NECESSARY.

DRIVE

and caution

common

tak€ unnecessary

attemPt

Knowledee

its

Know

andyou will

and

sense

imPo€sible.

the

of

you!

your

is

vehicle;

enjoy

abilities

faithful service.

risks and don't

your

safe,

choose

as mild

keep moving,

quickly.

TRAV-

ACROSS

Don't

vehicle

best insurance

it viselyi

use

economicat'

A

and

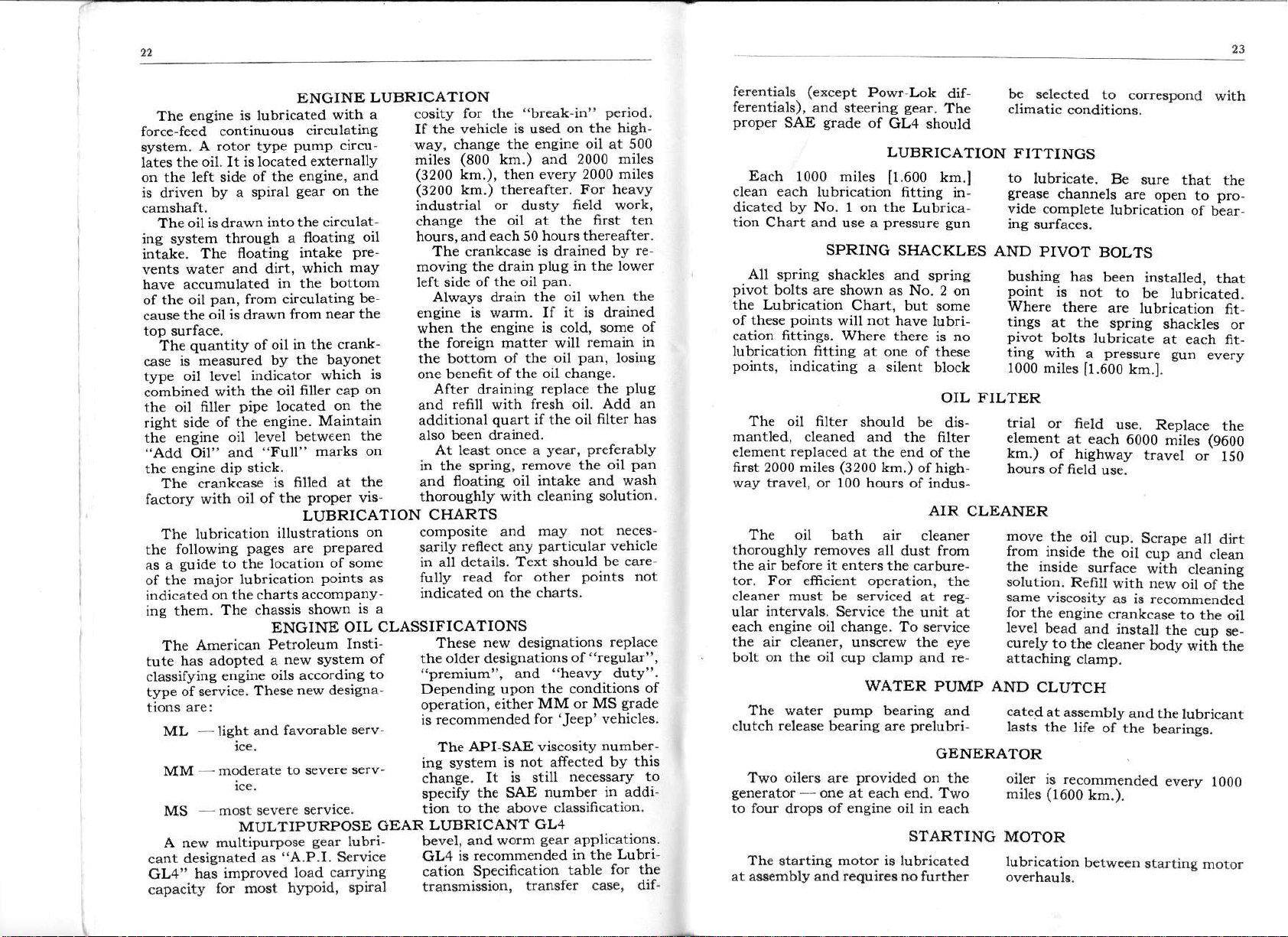

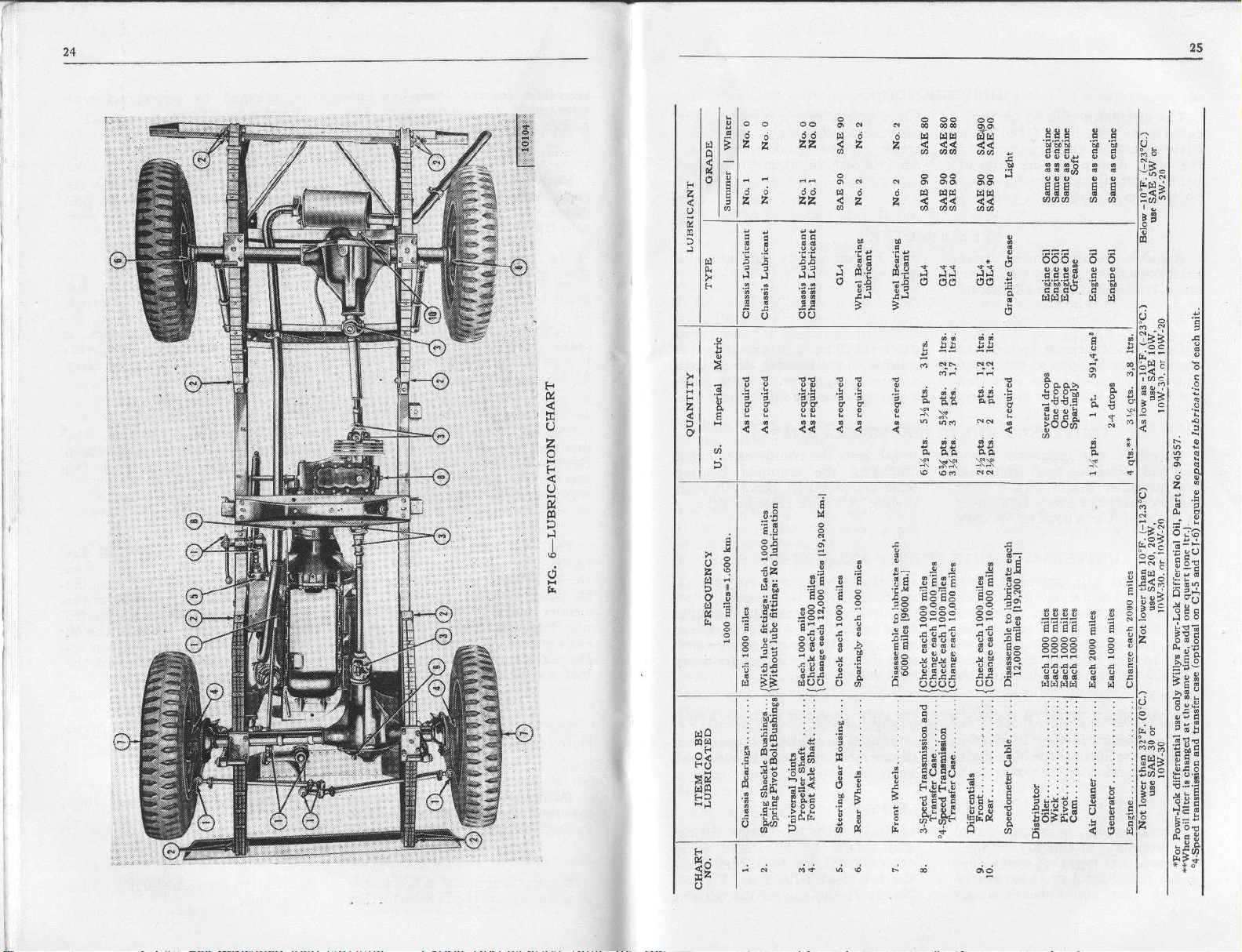

FIO, s-ENGINE LUBRICAAION

Page 12

22

ENGINE

The en{ine

forcc-feed- continuous

svstem.

t;tes the oil. It is located

on the left side

is

&iven

camshaft.

The oil

ine system

iniake.

wat€r and dirt,

vents

have accumulated

of the oil

caus€ the

roD surfacr.

the au€ntitv

is measu;ed

case

tlT€ oil level

combined

the oil

risht side

rhe eneine oil level

Oil"

"Add

enq;ne diD slick.

rhe

The- crankiase

factory

The lubrication

the followins

as a euide

ol th;

indicated;n

ing them.

The

has adopted a

tute

claslifyins

twe ois&ici.

are:

tions

ML - Iisht and favorable

MM -mod€mre

MS

is

lubricated

A rotor

is

The

;il is

fiIle.

with

major

American

(ype

of the eogine, and

spiral

by a

drawn

pan,

with

of rhi engine.

The chassis

into the

lhrough a

floatine intake

from circulating

drawn

of oil in the crank-

indicato. which

the oil

oiDe

and

"Full"

oil of the

pages

to the

lubr;cation

lhe charts

Petroleum Insti

e;sine

rnese

-ice.

most severe

Pump

gear

in the bottom

from

by the bayonet

located

betw(en

filled at the

is

illustratioDs

are

location

ENGINE

new system

oils accord;ng

new desiena

to severe

MULTIPURPOSE

A new multipurpose

A.P.I. S€rvice

cant desienared

GI-a' has

capacity

as

improved

for;ost

load caryins

hypoid, spirat

LUBRICATION

with a

circutating

circu

exlernallv

on the

circulat

floating

$hich

filler caP on

marks on

proper

LUBRICATION

a.companv

shown

o;l hours, and

pre-

may

be'

near the

is

the and

or

Mainrain

lhe slso

vis

on composite

prepared

of some

points

as

is a

OIL CLASSIFICATIONS

of

to

serv.

s€rv-

servrce.

GEAR

tub.i bevel,

eear

cositv for

If the vehicle

wav change

miles

(3200

(3200

industrial

chanee

The crankcase

moving the drain

left side of

Alwavs drain

eneine

when

rhe foreisn

lhe bo(tom

one benefit

Afte.

addirional

At teast once a

in the spr;ne,

and

thorouehlv

CI{ARTS

salily

in all details. Text should

fullv

indicated

These new desi$ations

the older designations

premium".

Depending

operation,

recommended

rs

The

:^^,

irE";..

"p."&

tion to the above

LIJBRICANT

GL4

cation

trans'nission,

the

"break-in"

is used on the high'

(800

km

km

rhe ensine is cold. some

refill

been drained

fioaring oil intake and

renect anv

the engine

kln ) and

everv 2000 miles

then

),

thereafter.

)

or

the oil at the fr.st ten

is wsrm. If it is drained

read for olh€r

dusty

each 50 hou

the oil

maner

of

the

of

the

draining

with

quarl

remove the oil

with cleaning solution

and mav

on lhe charls

field wo.k,

rs

is

drained

plug

in the lower

pan.

the oil when

will

oil

oil change.

replace the

fresh oil Add

if the oil

vear,

particular

of

healv dutv

and

upon the condirions

for

or MS

'JeeP

€ithet MM

API-SAE viscosity

system

is not affected

r. i" still

tt'" Sls

number io addi-

necessatv

ctassification.

GL4

and worm

is recommended

Specificalion

applications.

sear

in the Lubri

table

transfer

Period.

oil

al 500

2000 miles

For heavv

thereafter.

bv re

the

of

remain in

pan.

Iosins

plug

an

6lter has

prefetablv

pan

wash

not n€ces-

vehicle

be cate'

points not

replace

"resular"'

grade

vehicles

number-

bY lhis

for th€

case' dif-

of

to

ferentiats

ferentials),

proper

Each 1000 miles

clean each lubricati@

dicated by No. 1 on the

tion Chart and use a

All

pivot

the Lubrication

of thes€

cation fittings. Where there

lub.ication frtting at one of

points,

(exccpt

and

SAE

steering

grade

Powr Lok

sear.

of

GL4 should

LUBRICATION

[1.600

fitting in-

Lubrica,

pressure

SPRING SHACKLES

spring shackles and

bolts are shown as No.

points

indicatins

Chart, but

rot

will

a silent

have lubri-

dif-

The

km.l

sun

spring

2 on

some

is no

these

block

b€ selected

climatic

to

conditions.

corespond

FITTINGS

to

lubdcate.

grease

vid€

AND

channels

complete

PIVOT

bushins has

point

is Dot

Where

tings

at th€

pivot

bolte tub.icate

there

Be sure

are oDen

lubricatlon

BOLTS

been

to

are

spring

ting with a pressure

1000

miles

[1.600

km.].

with

that the

to l)ro-

of bear-

installed,

that

b€ lubricated.

tub.ication

shackles

fit,

or

at each fit-

guD

every

OIL FILTER

The oil filter

mantled,

element replaced

firut 2000 miles

vay travel, or 100 hours

cleaned aDd the filter

should

at

(3200

the

end of the

km.)

be dis-

ofhigh

of indus-

trial

or field

elemcnt

km.) of

at

each 6000

hishway

u*.

Replace

miles

t.avel

(9600

or

the

150

AIR CLEANER

The oil bath ai.

thoroughly

the

air before

tor. For efficient ope.ation,

clean€r must be selviced

ular inteNals. SeNice the

each engine oil charge. To

the air clean€r, unscrew the eye

on th€ oil

bolt

removes

it

ente.s the carbure-

cup clamp

all

dust

cleaner

from

the

at reg

unit at

service

re

and

move

the

from

inside

the iDside

solutior.

same

for

level

curely

attaching

Refill

vrscosity

the engine

bead

to the

oil cup.

the oil

eurface

and insta)t

cleaner

clamp.

Scrape

cup

with

with new

as is recommended

crankcase

bodv

a

and clea,

cleanine

oit of th;

to the

the

cuD

witL the

dirt

oi1

s€_

.

The water

.elease

clutch

WATER PUMP AND

pump

b€a.ine are

bearing

pfelubri-

and

cated

lasts

CLUTCH

at assembly

the life

and the

of the

lubdcant

bearings.

GENERATOR

Two oilels

generator

to four drops of engine oil in each

The

--

starting

at a$embly and

provided

are

one at each €nd. Two

oD the

STARTING

motor is

requir$ no

lubricated

furthcr

oiler

is recommended

m']es (1600

MOTOR

lubrication

km.).

be8reen

every

1000

stating motor

Page 13

21

?5

tl

tl

tl

tl

tl

tl

l"l

lEl

7

I

I

cd

3^ . 333 C3

E5

J-6

:2

"

Ei :-

"

E a I

i:

i:

,"i .i Be'.,5 F

j-

Hca oJd

. ,: ii

,\

iza

uu

E53_

;:; F E

t 3

g

?

6

ij

;;

1:.

-li-

a

.h--

3t-z

t!l

t€ x! E z

ct I e

z

F

!

r

_r I

i

'.i

El

e,6 ; i

F

d

8i

;2 t ! i-

:C

s,F

s

E

i:

;!:

':?

q

i3

:E

: *6

q

.9.

8-* 5--

"

a

iE :

E

lEr

;

Eli

jjj

i

::

g!6

d

";<i;3;Fr

r !.i

t

3

E ;J

i ;E

;

F

€

t

b

a

tE+E ;€

:;a;

!i;i

ii

;E

ic;5

:

:.:

q.E

i!

, i.i Ei

: ;i;t i

f

r*fF E

rl

i

!'l

;:

Ei

,; iill

ir

;5i:

EiEi

iE

**

3

€

b

3

t

?

6

!

,i

r

E

i i

F

:

i

E

ts

d

,l;!

:lt

!l

i

li

IE

il

: nc

3 t:

:;

i'

!i

6l^

,13

l'^;

l;-;

z

el:

;13

,5lz

t:l

iil

l!l

i!l

!l

l;

l3 sl

ld Sl

i:.gl

la' el

gl

lj

l:i.l

i!!:l

ril

t;

g:l

ij

5*rl

|

t0,sl

t:€51

l;ril

t:E:l

l3:El

l!€:l

t!E;l

gI

IT€

l€:?l

/.tE Fl

li;:l

ld.!l

lF:"1

ll

Page 14

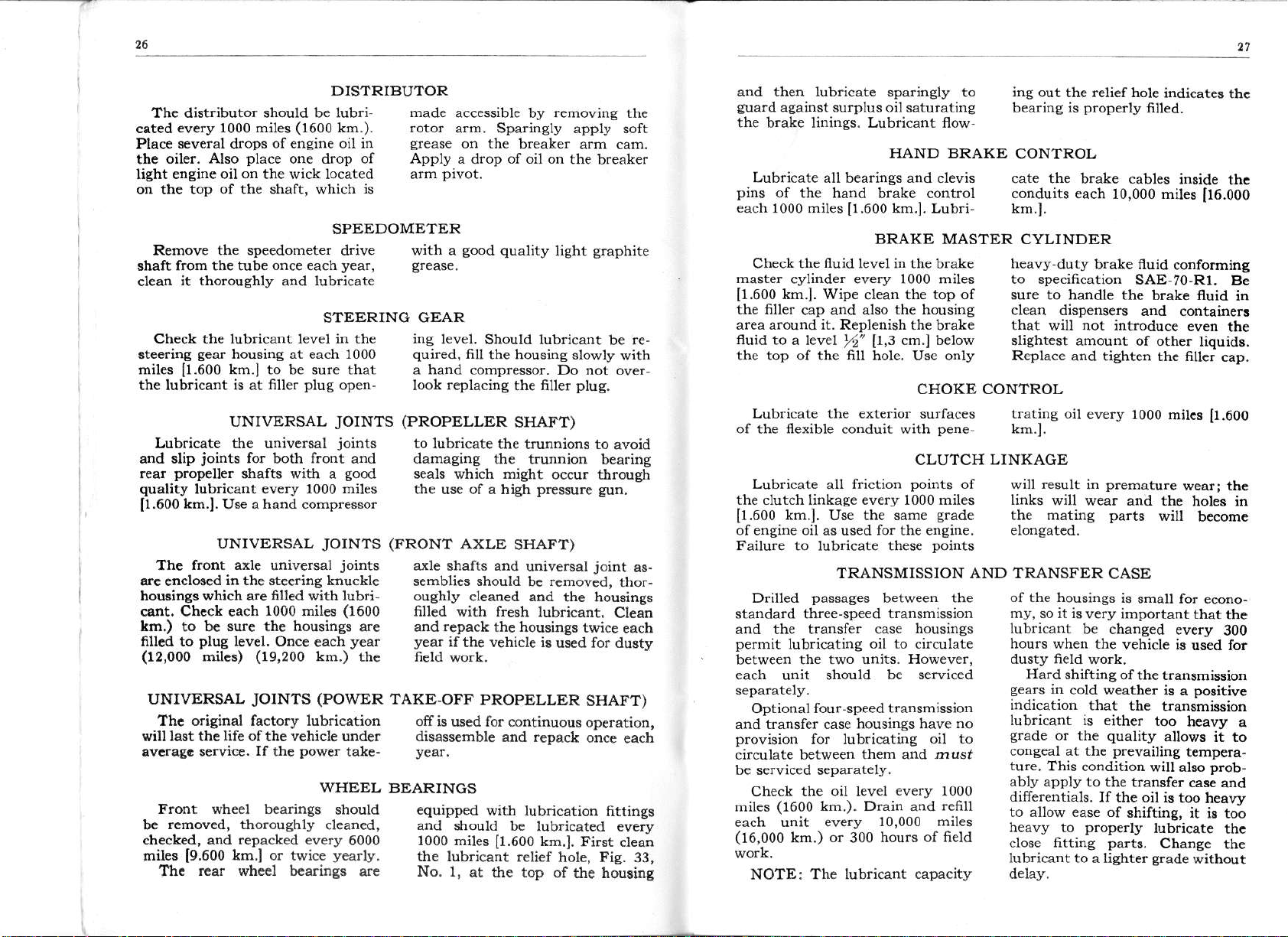

DISTRIBUTOR

The distributor should be lubri

evely 1000 miles

cated

aeveral

Place

oiler. Also

the

drops

light ensine oil

on thc top

of

place

on

the shaft, which

(1600

of engine oil in

one drop of Apply a drop ofoil on

the wick located aim

km.). rotor

made

srease

is

SPEEDOMETER

Remove the speedomete. drive with a

shaft from the tub€

it thoroushly

clean

once each

and

year, grease.

lubricate

STEERINC GEAR

Check the tubricant lewel in the ins

steerins

miles

the lubdcant is at

gear

11.600

housing at each 1000

km.l to be sure that a hand compressor.

fi1le.

UNI\ERSAL

Lubdcate the univcrsal

and slip

rcar

quality

11.600

joints

propeller

lubricant

km.l.

Use

for both f.ont and damaging

shafts with a

every 1000 Diles

a hand compressor

UNIVERSAL

front axle

Thc

arc cnclosed

housings which are

cant. Check cach

km.)

fillcd to

(12,000

bc surc the housings

to

plug

mile!)

UNIVERSAL

universal

in the steering lnuckle

6lled

1000 mil€s

l€vel. Once

(19,200

JOINTS

plus

open- look replacing the filler

JOINTS

joints

good

JOINTS

joiDts

with lubri oushly

(1600

are aDd

year year

each

km.) the field

(POWER

quired,

(PROPELLER

to lubricate

seals which might

the use of a high

(FRONT

axle shafts and

semblies should

TAKE-OFF

Thc original factory lubrication otris

will lsst thc

avcrsg. servic€.

Front whe€l b€arings

removed, tnoroughly

be

ch€cked, and repacked e!€ry

miles

The rcar whccl bearings

lifc

[9.600

ofthe v€hicl€ under disass€Dbl€

power

If

tnc

take-

WHEEL

BEARINGS

should equipped

cleaned,

6000 1000 miles

km.l or twice

yearb..

are No. 1,

accessible by

removing

a!m. Sparingly apply soft

on the

breake. arm cam.

pivot.

sood

quality

lisht

level. Should lubricant

fill

the housine stowly

SHAFT)

tl|e tunnions to

tle trunDion bearing

occur through

pressure guD.

AXLE

SHAFT)

unive.sal

r€moved,

be

cleaned and the

filled with fr€sh

.epack

lubricant.

the housings

if the vehicle i5

wo.k.

PROPELLER

used for continuous

and repack

year.

with tubrication

and should be

the lublicant

et tlle top

lubdcated ev€rv

km.].

[1.600

relief

of the howing

the

the breaker

e.aphite

.e-

be

with

Do not over

plug.

avoid

joint

as-

thor-

housines

Clea;

twice

each

used for dusty

SHAFT)

opcmtion,

onc€

cach

frttings

Fi'st cha;r

hol€, Fis. 33,

and then lubricate sparingly

gua.d

asainst surplus oil saturating

the brake linings. Llbricant flow

HAND ERAKE

Lubricate all bea

pins

of

each 1000 miles

the haod brake control

ngs

[1.600

and clevis

km.]. Lubri-

BRAKE MASTER CYLINDER

Check the

master

11.600

the filter

area around it. Replenish the

fluid

to a leyel

fluid

level in the brake

cylinder every 1000 miles

km.l. Wipe

cap and abo

ctean the top of

the housiDe

rZ"

lr,3

cm.) be\ow

bmke

the top of the fiII hole. Use only

CHOKE CONTROL

Lubricate the exterior su

of the flexible conduit with

aces

pene'

CLUTCH LINKAGE

Lubricate

the clutch linkage every 1000 miles

[1.600

ofengire oil as used fo. the engine.

Failu.e

km.]. Use the same

to lub.icate these

all

friction

points

grade

points

of

TRANSMISSION AND TRANSFER

Drilled

standard three-speed transmission

and the t.ansfe.

permit

between the

each

Optional four-speed transmission

and transfer case housings

provbion

cirolate between them and

be serviced separately.

Check the oil level

m es

each unit every

(16,000

NOTE: The lubricant

passases

lubricatine

two units- Howewer,

unit should

for lub.icating

(1600 km.). Drain

or

km.)

between the

case housiflgs

oil to circulate

be seNiced

10,000 miles

hours of field

300

have no

every

and

capacity

oil to

musl

1000

rcfitl

to

ing

out the relief hole

properly

bearing

is

indicat€s

filled.

CONTROL

cate the b.ake cables

inside

*"n 1o'ooo miles

ffin"

heaa'1,

will result in

links

the mating

of the housings

my,

lubricant

hours when the

dusty field work.

geals

indication

lub cant is eithcr

srade

congeal at the

ture.

ably

ditrerentials.

to attow ease of

beavy to

close fitting

lubricant to a lighter

delay.

duty b.ake fluid

to specification

su.e to handle the

clean dispeft.rs

conforming

SAE-70,R1.

brake fluid

and

containe$

that will not introduce

slightest a.rnount of other

Replace

and tighten thc fille.

oit

every 1000

mircs

lntinc

premature

will wear and

parts

CASE

it is

so

vcry important

be changed

Eard shifting

in

cold weather

that the

or the

quality

p.evailing

This condition

apply to the transfer

If the oil is

properly

parts.

the holes in

will

is

small fo! €cono-

every

vehicle is

of the transmis€ioD

is a

trarsmission

too

allo,i's

will also

too heaw

shifting, it

lubricate

Change

grade

thc

thc

[16.000

even

the

liquids.

cap.

11.600

wear;

thc

bccome

that

the

300

used for

pGitivc

hcavy

it to

tempera-

prob-

caae

and

ir too

thc

the

without

Be

in

a

Page 15

level in the

Check

thc

tial housings

Ir.600

km.l to be sure

irbricant is at

plugopenings.

Some

every

not mix ditrercnt

vehicles

ditrerential

housins

km.l. Do

locking

ment). Lockine

plate

brass

under

?

screw

distinsuish

Ordinary

stamPed

one

heads

(Fig.27, item 17)

it from standard

lubricants

The vehicle

be lubricated.

leaves are

lasting

designed

coated

special lubricant

to last

every

1000

that

the level of

Draib

10,000

mil€s

refill each

and

POWR-LOK

equipped with

ate

(optional

ditrerential

with the

of the

gear

musf

ngs should

sp

At assembly

with a

the life

DIFFERENTIALS

difreren-

Dites

the

the filler

116,000

of lubricants.

or light

the

ditr€rentials).

steam,

flushing.

tYPeE

DIFFERENTIAL

be used

equip-

lEe a

Use

ential

letter

cover

to

dif

Do not flush the Powr

ferential.

vents

not

SPRlNGS

springs.

mixture

tendency

from between

long-

which

not

the

is

of the

flushing

hoLrsins

only Willys

(except

kerGene,

in the locking

Oil, Part

The use

of any

Spraying

of oil and

to wash

light

Use

Do

kind is not

the spring

to clcan

oil

on Powr-Lok

not use water,

or

easoline

ditrerential.

Powr Lok

No. 94557,

of

cl€aning

with the usual

ketosene

this lubricant

eneine oil

out

for

Ditrer-

furnish-

Lok dif'

sol

recom-

has a

leaves.

F

E

o

:.^

F !!

E

E.; E

si

iv

b;

b

.9;

F

Z

o

gu

>

i

p

Check

nor housing

Use

POWER

Check

lubrication

lubricant

the oil level

oil of the

TAKE.OFF

the lubdcant

at

in the

each lubrication.

at

job,

filter

glade

same

maintaioine

plug

level Should

level

GOVERNOR

gove.- the

in

used

SHAFT

AND

at each

the

ensine

housing at each

PULLEY

power

the

quendv,

hours.

300

Drain and

DRIVE HOUSINGS

take-o$ be used

change

refill the

ensine

the

oil change'

lubricant each

fre-

U

>

v

A

;*:

433

",9-

"EE

,bE€

:i

:i'

E

36I

E

I

a

6

9;a

.!

-

6

o

tt

i

o

I

;

E

Page 16

3t30

MAINTAINING

ProDer maintenance

'Jeep'-vehicle

qiven

a

tion and

miles

Such

careful

by

to locate and

faults that

Prompt

thus discovered

holdins

and

I1.600

an inspection

road

a competent

down

costly delays

Your 'Jeep'

best

For

p€ndability,

a tune-up

in the sp.ins

Proper

include

Clean

.

terminals,

cable

connection

right side

front eDgine

Remove th€ spark

.

them

electrqles

thoroughly

Check valwe

.

Remove

inspcct the

and

Adjust ihe

mm.l

sap.

check

.

demands

thorough service

lubrication

km.l of operation

test

and

se.vice

analyze any

may have developed

correction

will

maintenaoce

vehicle dealer

performance

the engine

yearly, preferably

twice

and

tune-up

following:

the

and tight€n

the battery

and

sround

of tlle

support.

.030/

to

t}te distdbutor

points

tne isnition

POWER

PERIODIC

of

You.

that it be

inspec

at €ach 1000

consists

examiDation

of minor faults

go

in operation.

should

fall.

proceduie

strap

engine at the

plugs,

and sPace

10,76

clearance

contact

to.020"

ADJUSTING

of a

technician

small

far toward

expense

ENGINE

and de-

should

the battery

ground

on the

clean

mm

l

Points.

timing. See

YOUR

INSPECTION

is

TUNE-UP

havc

the

gap.

See

caP

10,51

:FED

VEHICLE

PIANT

vitally interested

vehicle and

regularly insp€ct

him

dealers'

the advantage

specifications

as

regularly sent

The follo\rins

methods

ments and also

maintenance

major rcpai. work be

consult

"Electrical

.

screen

.

.

to run until

s€t tlle

so the

.

idle screw so

idle smootlly.

satisfactorily

definitely

consult

Carburetor

and should

less the unit

VALVE LASH

s€rvice technicians

well as bulletins

of making minor adjust

you.

Clean

and check the

Remove and

Sta.t tne

throttle adjustins

engine will

Adjust the carburetot

Should

the engine

t.aced

your

pay you

it will

of complete

cove.ins the

out

paragraphs outline

suggest

ope.ations.

'Jeep'

Section."

the fuel

clean the

engine and

thoroughly

that the ensine

and

to the carburetor,

'Jeep'

service

not be undertaken

is thoroughly

your

in

to

it. Many

factory

v€hicle

which are

the factory.

by

P.ev€ntive

Should

n€cessary,

vehicle

idle at 600

fail to

the tlouble

vehicle

is

dealer.

pump filt€.

fuel line con

allow

waim, tnen

low

perform

dealer'

specialized

'Jeep'

have

have

venti

screw,

rpft.

spced

will

un

under'

The

CHECKING

checked

Adjust

1

Then

wise

der is ready

To dete.min€

9o befo.e

timing gear

notins

top

it

is

valve

in

the inlet

cylinde.

rotate

until the

top center

the

center ma.k

timins

the following manner:

valve lash

to .026'

the craDkshaft

piston

for

the intale

this,

cover. figure

distance

and

may

of No.

(.6604

in

No. 1 cylin-

stroke.

estimate the

position

between the

th€ 5' mark,

FIG.

VALVE

be

mm.).

clock-

on the

8,

by

8 {IL PUMP

TIMING

and

aligD the notch

pulley

drive

With

the

tioD,

I rocker

the

After

lash to the

Should

it is

'Jeep'

crankshaft in

valve tiDidg

arm is

end of the valve

checking, reset

the timing

advisable to

vehicle dealer.

with the

is correct if No.

just

cor.ect

oD the fan

position.

9o

tight against

stem.

clearance.

be incor.ect,

consult

posi-

this

the valve

you.

The

should

intake

care in

Us€

the

that

usins

by

that

sure

against

tash on €xhaust

be set

valves

at 016"

at .018'

(.406

makins this

measu.enents

feele.

sauges

a.e

and

the taPPets

lowest surface

the

valves

mm),

(

rnm.).

46

adjustment

accurate

making

are restng

of the

FIG. ?_TIMING

MARKS

oil

pump

relief

is

valve

The

a

Pressure

trcls the oaximum

The minimum

plovided

which con

plessu.e

oil

pr€ssure

safe

OIL

with

at

is

r? R.ri.f

PUMP

20

mph.

(.a3

of

v,lvc Prunia!

pounds (1.4

(56

km./h.) and

ke./sq.

600

The oil

cm.) at the idte

rpm.

pump

kg./sq.

drive

cn.) at 3s

pounds

6

speed

shaft drives

Page 17

33

FIG. 9 END

SECAIONAL

VIEW OF ENGINE

27-verve

FIC IO SIDE SICTIONAL

Tarp4 Adjulring s.r.s

VIEW

OF ENGINE

Page 18

pump

the

both

Fie. L Should

See

re;ve the

to

the distributor

move

fully not€ the

to ellow reinstallatioo

turbing

use care that

end

r€ctty

the ignition

w}len th€

of the

distdbutor

meshed

the distdbutor.

and

it be

oil

PumP,

position of

pump

drivins

tlle

with the

necessary

first re'

aod

cap

the rotot

without

timing

reinstaued,

is

key on

shaft

slot

carc'

dis-

the

cor-

is

on the

end

of the

pump

thc installation

ignition

the

must be

camshaft

distributor

with the

original

Should

th€ igrition

timing,

correctlv

gear

dlivirs

distributor

position.

it b€

timing,

shaft.

without

the

m$hed

to allow

key a'd

necessary

ref€r

To make

disturbing

ge€r

PumP

with the

mesh of the

in th€

rotor

reset

to

page 4l

to

slot

rubber engine

The

which are

side

attached

rail brackets

and

Dort Dlate. Prev€nt

inotioi

sidcwisc and

No. 24,

with two

of th€

remain o! top

tnc circulation

scre€n and

tem

ventilation

tion

Anv vaDors

..'iiea - nt"

bumed

is shown

valve

claritvi

DosiEion

;ith

horizontal

of tne engine,

vertical

Th€

floating

oil intake,

is attached

3cr€ws.

float and

screen

ofthe

of

Once €ach

year

tube

The crankcase

provides thorough.

which

sludge

of

or exhausted

is shol*n

it

its connectine

in the

the crarkcase

in

the

Fig. 11.

in

out

is shown

whereas

position.

to the

The

water

remove

and

ventilation

reduces

it is

ENCINE

moutltmgs,

to

to the

sup"

frame

the

fore-and_aft

free

allow

vet

oscillation

FLOATING

figure

crankcas€

constructron

tt to

cause

preventing

oil,

clean

and

the

dirt.

float'

thor_

CRANKCASE

sys-

Positive

lorma-

crankcase

manifold

This

Note that

of

Position

in a

tubing

are

and

syst€m

the

for

vertical

instelled

in a

MOUNTINGS

which

source.

A loos€ engine

ctutch chatter

INTAKE

OlL

oughly with

9'

fluid.

install a

noat support

case.

air

seriously

IIENTILATION

Be sure that

cap

Always

When

inc valves,

valve and

the valve

the

oD€rat€

s€at,

6

make the

neut.alizes

KeeP the

vibration

mountings

may causc

high fuel l€vel

or

a suitable

when replacing, bc

gasket between t]te

new

and tle eneine

A leak at this

to

enter

atrecting

oil suction

tne

th€ oil

point

the oil

good

sasket

is in

keep the cap

tuning

the engin€

remove

it thoroughly.

clean

is blocked

veDtilating

and

it will

ensi&

system

should

the

be

idle satisfactorilv

at the

tight.

vib.ation,

cleaning

sure to

crank-

will atlow

line,

prc$ure.

filter tube

condition.

locked

o.

srind-

control

the

carbon'

with

will

valve

impo$iblc

in

se_

not

fail

to

FIG. 1I

The

nushed

for

aDd fatl at the

the antifreeze. Always

cooling system

ing

should

cooling system

twice a

preferably

leaks,

antifreeze. A corrosion

b€ used ir the

leaks before install

CRANKCASE

coouNG

year

time of chaosins

should

and checked

in

the spring

correct

cooling syg

any

inhibitor

VENTILAfINO

be

sYslEM

tem to

.ust

antifreeze wilt

inhibitor.

draiDed

inhibito.

prevent

and scale. A

When

iD the sp ng,

should be

SYSTEM

the formation

contam

the antifreeze

quality-brand

of

a corosion

is

a corrosion

added with the

RADI ATOR

Maint€nance

If

sists of keepins

radiator

free from rust

radiator f.ee

terior of the radiator

cleaned

for leaks each 1000

kn.l

vehicle. If the

to

tion, this

1000 miles or

and

of normal

coDsiderable off-the-.oad

ofthe

the exterior of

core

clean,

and scale, and

from leaks.

the radiator

r€hicle

interval

30 days,

radiator

interior

the

The €x

core

should b€

insDected

miles

service oi

is

subjected

should

opera

be each

whichev€r

con,

the

the

11.600

ttre

inte.val

blowine out

occurs

Cleaning

should be

with

water stream

rear of

spection

the radiato..

is not

accumulatioD of

foreign natedal

fac€s

closing

the radiator

fore

rest.ict

can

the core openings. Examine

carefully for leaks

and

after cle€ning.

fir€t.

p€rformed

air €tream or

di.ected from

A visual

sumcient as

particles

small

on

the cor€ sur

cooling without

by

the

in-

the

of

b€-

Page 19

RADIATOR

pressure

The

vent loss of coolant by ewaporatlon.

It should never be

nonpressure tYPe.

cap, which

the cooling system

[0,492

more

sliehtly

ture. Vacuum in the

relieved bv a valve

which opds at % to

u,u/u

To

cap wheD the

peratuft

cloth

turn

turn

lease) stop is

cap in this

sure

maintairc

kg-cm?] makes the

emcient

higher opetating

kg-cm!t

remove

over the

counterclockwise

until the

is released. Then,

vacuum,

the

is high or boiling,

position

hetF to

cap

rcplaced bY

The

pressure in

up to 7

permitting

bv

radiator

in the

psi.

L

radiator

ensine coolant

pressure

(pressure

fi.st

reached. KeeP

until

DRAINING

Two drain cock

to completely

systeD.

to

use carc

opened. One drain

When &ainilg

guard

asainst

that both

are

drain the

freezins damage.

is located

pre

Pressure

Psi

engine

tempera-

cap

[0,0ss

pressure

tem

Place

and

cap

about

all

Pres

cap

Push

THE COOLING SYSTEM

provided

coolins

the system,

cocks are

THERMOSTAT

A

thermostat,

i$ located in the

of the cytinder

top

quick

wsrming

overcooling

oDeration.

The valvc

ai app.oxim'tely

fully ope'ed at