Page 1

s

sarl

MADD

n

IIn

echnologie

sttrr

s

EEaassyy &

uccttii

u

S

allii

S

a

o

n ff

o

n

n

o

o

M

M

n

& rraappiidd ggaauuggiinngg

A

A

orr

o

D

D

D

D

u

see

u

s

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 2

Contents

Content ....................................................................................................................... 3

Warranty ..................................................................................................................... 3

Gauging method by tracer dilution ................................................................................. 4

Principle .................................................................................................................. 4

Cooking salt as tracer .............................................................................................. 4

First steps with the SalinoMADD .................................................................................. 5

Replacing dry cells .................................................................................................... 5

Power on the unit ..................................................................................................... 5

Functions of the sensor touches ............................................................................... 5

Main menu ............................................................................................................... 6

Working in multimetre mode .......................................................................................... 7

Calibration of the probe ................................................................................................ 7

Cleaning of the probe ................................................................................................ 7

Preparation of the calibration .................................................................................... 7

Calibration ............................................................................................................... 8

Preparing doses for calibration .................................................................................. 9

2

Programming the gauging site ..................................................................................... 10

Selection of the site ............................................................................................... 10

Selecting intervals .................................................................................................. 10

Choice of the meteorological situation ...................................................................... 11

Introduction of the water level ................................................................................. 11

Quantity of injected salt .......................................................................................... 11

Distance to point of injection ................................................................................... 11

End of data inputs .................................................................................................. 11

Gauging acquisition on site .......................................................................................... 12

Before starting the acquisition ................................................................................ 12

Beginning of data acquisition ................................................................................... 12

End of data acquisition ............................................................................................ 12

Display of the results ............................................................................................. 13

End of acquisition due to errors ............................................................................... 13

Tips for practical use .................................................................................................. 14

Technical characteristics ............................................................................................ 15

SALINOMADD software .............................................................................................. 16

Software possibilities ............................................................................................. 16

Practical software use ............................................................................................ 16

Installation of the SalinoMADD software .................................................................. 16

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 3

3

Dear customer,

Thank you for purchasing this device SalinoMADD. This gauging device allows you to measure the flow of rivers

very fast and easily according to the tracer dilution method.

The SalinoMADD is shipped in a sturdy carrying case. It is strongly recommended to always replace the device,

the probe and accessories into this suitcase, which will ensure the best protection. Although it was designed

for use in difficult conditions, it is a piece of precision equipment that must be protected from impact. Handled

with a minimum of precautions, SalinoMADD will help you for long time!

In order to best use your new system, please read this manual and observe the manipulations described below.

CCoonntteenntt

Upon delivery of a device SalinoMADD, the package contains the following materiel:

• A carrying case in polypropylene with rubber-foam inserts

• A SalinoMADD measuring unit with 4 alkaline batteries 1,5V

• A probe for water salinity and temperature with 10 meters cable and connector

• A straight calibrated measure for 100ml.

• 5 doses of 20 ml calibration solution

• A CD “SalinoMADD” containing

o The software SalinoMADD

o This instruction manual

o A notice about the gauging method

o A demo video of a gauging with SalinoMADD

• A serial cable for the communication between SalinoMADD and a PC

The device is delivered ready to use and calibrated.

WWaarrrraannttyy

The device is delivered with a factory warranty for one year from the date of the invoice. Repairs are made in our

workshop; no further benefit can be taken into account without written confirmation of MADD

is understood that this warranty is available only if the device SalinoMADD was used in conditions for which it

was expected, as described below. Any other manipulation should be done at risk and peri of the user.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Technologies

. It

Page 4

4

GGaauuggiinngg mmeetthhoodd bbyy ttrraacceerr ddiilluuttiioonn

The device SalinoMADD uses the tracer dilution method to determine the stream flow of the measured

watercourse.

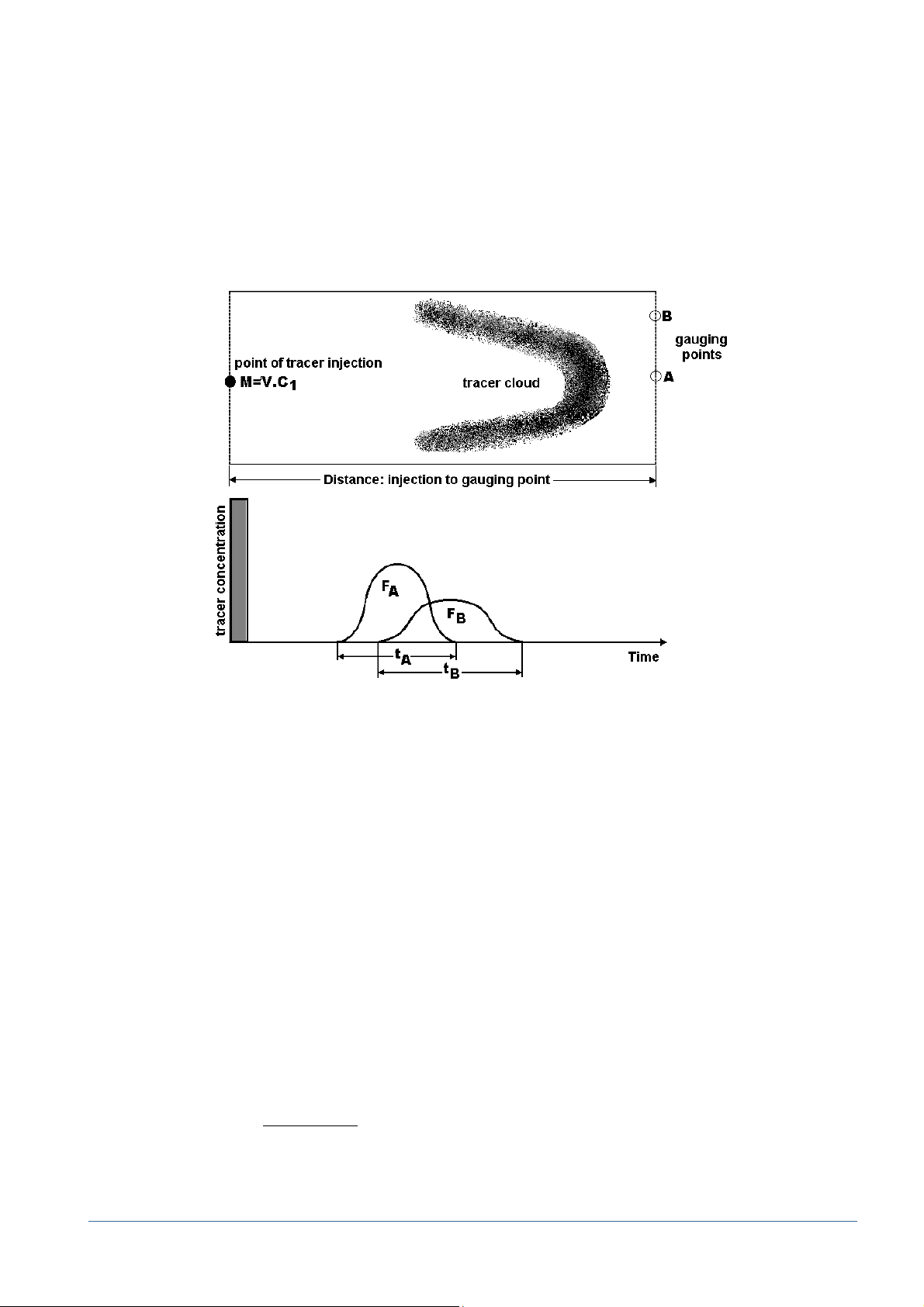

Principle

The main principle of this method consists to inject into a watercourse a concentrated solution of tracer.

Downstream, at a distance large enough from the injection point for a good mix with the river water, the tracer

concentration is measured during the passage of the tracer could. This dilution is a function of flow rate,

assumed constant along the section concerned during the measurement time.

The following conditions are necessary for the application of the dilution method:

• The flow of the river should remain roughly constant during the measurement;

• The tracer must pass totally through the gauging sector;

• At the measuring point, the mixture should be such that at each point of the section of the river must

spend the same amount of tracer.

According to the above conditions, this method is especially adapted in case of low depths, very high speed or in

presence of turbulences that does not guarantee a stable speed, like rivers or streams. As against, it is not

suitable for measuring flow in concrete channels which does not permit the mixing of the water.

Cooking salt as tracer

The cooking salt, sodium chloride (NaCl), is an ideal tracer: it is very easy to find, cheap and has a high degree of

dilution in water. Furthermore, it is not harmful to the fauna and flora at the concentrations used and it is few

absorbed by vegetation and materials of the bed of the river. Finally, it is very easy to measure its concentration

with a conductivity probe.

M

In this case, the operator injects into the river a known mass of salt

Downstream, is placed a conductivity probe that will measure the electrical conductivity of water throughout

T

the duration

dissolved salt concentration. The concentration curve can therefore be deduced in function of time

Q

is then obtained by integrating the concentration over time:

of passage of the cloud of salt. A linear relationship exists between the conductivity of water and

Q

: flow of the water course [l/s]

M

: mass of the injected tracer [mg]

C

: water salinity at time t [mg/l]

t

C

: basic water salinity [mg/l]

0

T

: duration of gauging [s]

diluted in a volume of water of the river.

C

. The flow

t

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 5

5

FFiirrsstt sstteeppss wwiitthh tthhee SSaalliinnooMMAADDDD

Replacing dry cells

The batteries are accessible on the back of the device.

Unscrew the two screws of the battery cover, remove

the old batteries and replace the 4 alkaline dry cells

respecting polarity as indicated inside the housing.

Close the lid.

A set of new cells has a voltage of 6V. This voltage is

displayed in the main menu. When this voltage downs

below 3V, it is necessary to change the batteries. The

autonomy is approximately 30 hours in normal use

with one set of alkaline manganese batteries, type.

AAA, AM3, LR6, Mignon, UM3 etc.

Power on the unit

To switch on the SalinoMADD, just press the button .

At this time the display on right for 2 seconds. It contains also the

software version, useful for eventual future updating.

Functions of the sensor touches

SalinoMADD possess four function buttons disposed on the front panel:

Switch on the unit.

Confirm the chosen parameters displayed.

Go to the next option. Increase numerical values step by step at the

programming of gauging sites.

Back to the last option. Return to the main menu.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 6

6

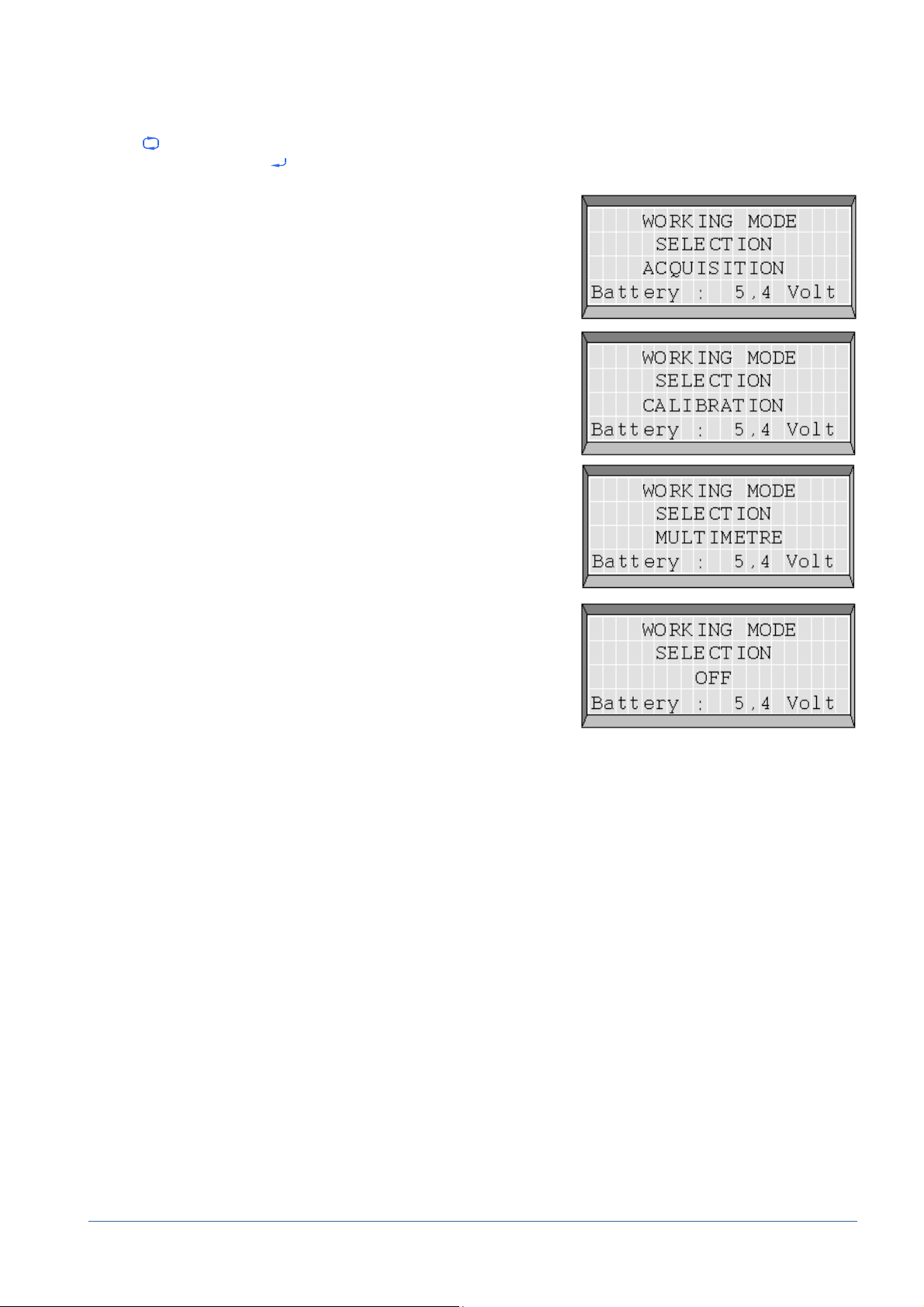

Main menu

Two seconds after the start (see above), the main menu ACQUISITION appears automatically. With help of the

button

off the device. The button

• ACQUISITION mode: This mode permits to launch a gauging

• CALIBRATION mode: The calibration of the probe can be done in

• MULTIMETRE mode: Mode used to do continuous measurements.

• END mode: This permits to switch off the device.

Above illustrations shows that the battery power is always clearly displayed in order to prevent starting

operation with nearly empty cells

, it permits the selection between the 3 functions as illustrated below. The fourth function switches

confirms the function selected.

acquisition and to introduce data for a gauging site.

this mode in order to correct eventual deviations of the salinity

measurement.

It displays salinity in milligrams of salt per litre of water, the

water temperature in °C as well as the conductivity in μS. per

cm.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 7

7

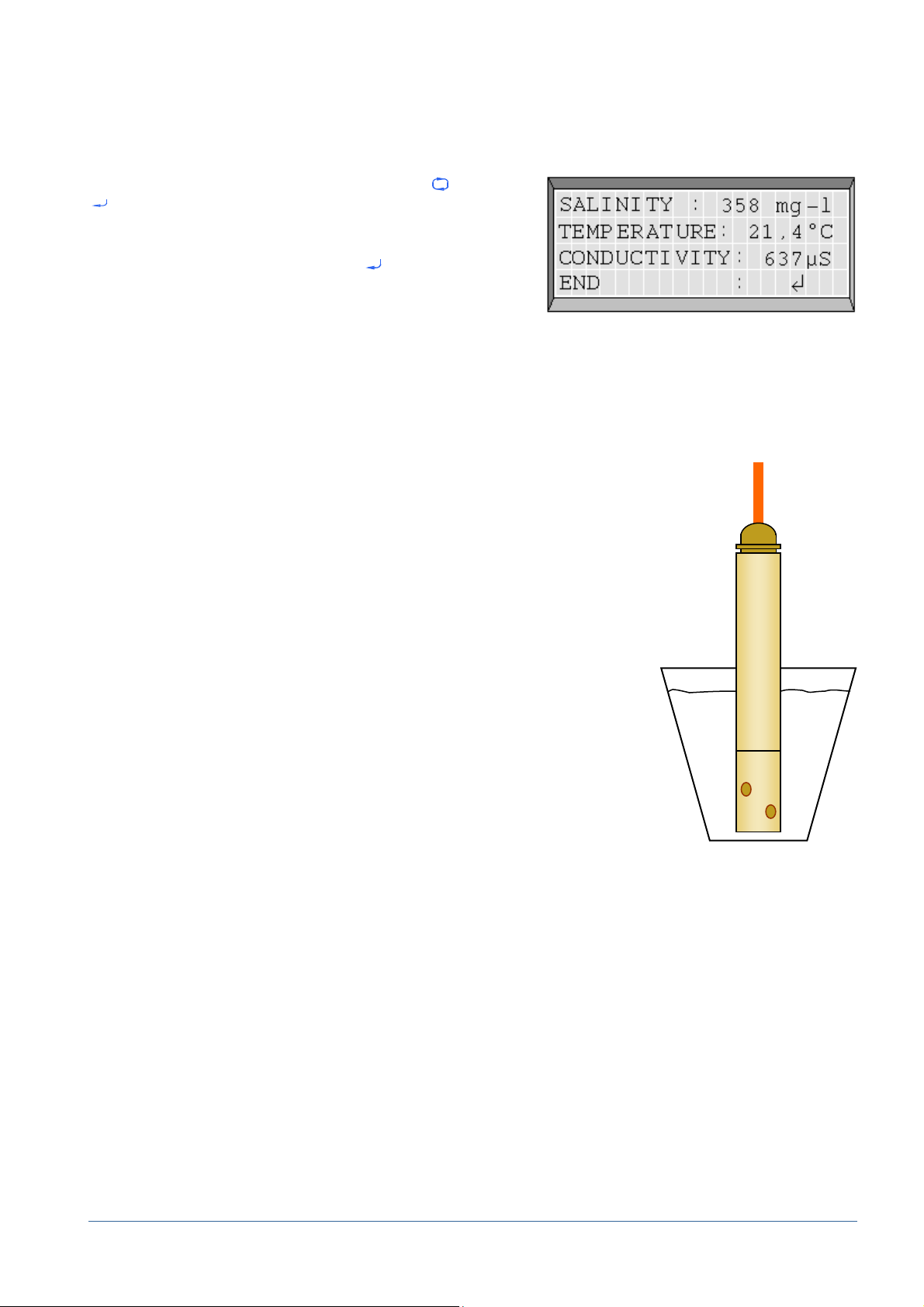

WWoorrkkiinngg iinn mmuullttiimmeettrree mmooddee

The multimetre mode is used for punctual measurements of water quality. The probe must be connected to the

SalinoMADD before switching it on.

On MAIN MENU select MULTIMETRE with touch

. At this moment the instrument measures continuously

salinity, temperature and the conductivity of the water.

To return to the MAIN MENU, press . In this mode, the

device will automatically switch off after about 4 minutes.

and press

CCaalliibbrraattiioonn ooff tthhee pprroobbee

Cleaning of the probe

Ensure that the probe is clean before starting calibration. Clear the electrodes from calcareous deposits using

a specific cleaning agent (Durgol, cleaning vinegar etc.).

In this goal, pour cleaning agent into a recipient up to the level necessary for

complete immersion of the probe's glass part which should remain in the

cleaning liquid for about 20 minutes. Rinse the probe thoroughly in order to

clear off completely the cleaning liquid, let it dry and then place it into

previously prepared half-litre of pure water.

Preparation of the calibration

Following preparation is necessary before calibrating the probe for salinity

gauging.

1. With the 100 ml calibrated tube prepare 2 doses i.e. 200 ml of

demineralized water with a conductivity not exceeding 10 μS (or a

resistivity of minimum 100'000 Ω)

2. Pour this water into a cleaned 1 litre plastic measure. For maximum

measurement accuracy, it is also possible to weigh the water i.e.

200 g of demineralized water.

3. Immerse the probe in this water and connect it to the SalinoMADD,

which must be switched off beforehand.

Before starting the calibration, the probe should have the waters temperature, which can be checked by putting

the device in MULTIMETRE mode. Ensure that the temperature remains stable. Once all parameters meet these

conditions, the calibration can be launch. Only few seconds are necessary.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 8

Calibration

8

In the MAIN MENU, select CALIBRATION with touch

points: at 0 mg/l, at 1200 mg/l, at 825 mg/l and at 426 mg/l.

The message displayed here refers to instructions on previous page.

The following display appears about 5 seconds later. If everything has

been put into place, press

The first calibration step is the determination of the zero point. It is

obtained using pure water as reference. While CALIBRATION OFFSET

is on display, 16 measurements are done. The average of these

measurements finishes the zero calibration which is saved

provisionally

When this display appears, pour 20 ml of calibration liquid into pure

water and use probe to stir it well in order to get a homogenous

mixture. At this moment the solution contains 1200 mg of salt per

liter of water. Press

The second calibration step does 16 measurements as well.

While these are being carried out, CALIBRATION 1200 mg/l stays on

display.

At the end of the display, the average value of the 16 measurements

is saved provisionally.

The next step permits to do the third point of the calibration.

Adding 100 ml of pure water into the 0,2 liter solution, the salinity

reaches 825 mg per liter.

The display indicates the procedure in course showing CALIBRATION

825 mg/l.

At the end, the average value of 16 measurements is saved and the

SalinoMADD continues to the next phase.

The calibration of the fourth and last point is done by adding 300 ml of

pure water into the beaker, that raises the salinity to 425,8 mg per

litre.

Stir well to ensure homogenous solution and press ↵.

The display taking into account the variations shows now

CALIBRATION 426 mg/l. Having saved the average value of 16

measurements, the SalinoMADD passes to the final phase of

calibration.

.

and press

. The calibration is done in the following 4

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 9

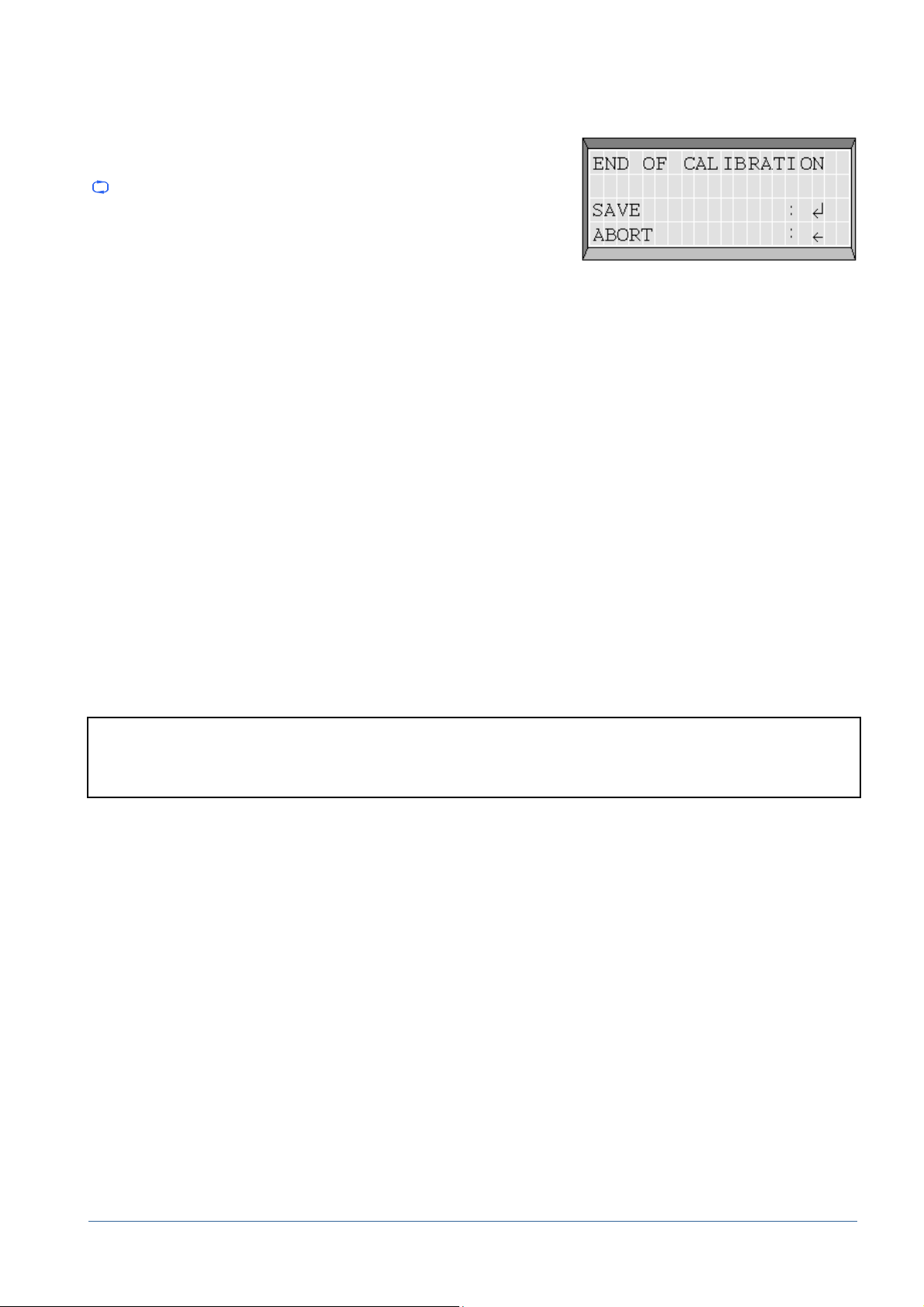

The SalinoMADD will automatically calculate the precise values of the 4 measured calibration points. It will

furthermore determine the curve's non-linearity and calculate necessary corrections. All these parameters are

saved provisionally and the screen passes on to the following display.

This display specifies the end of the calibration of the salinity. At this

moment is still possible to abort the calibration procedure by pressing

If the calibration is ok, confirm by pressing ↵. This will store the

calibration data and these will be maintained even during the exchange

of batteries.

Either command SAVE or ABORT will return to MAIN MENU.

Preparing doses for calibration

Although your SalinoMADD supplier can supply calibration doses, it is useful to be in a position to prepare own

doses, particularly when salt other than chloride sodium is chosen.

The necessary material

• A precision scales with 0,1 g graduations, accuracy < 0,1 %.

• A glass measure with volume scales, accuracy < 0,1 %.

• A number of small plastic bottles with a content of at least 20 ml each

• A pipette or syringe 20 cc accurately calibrated

• An adequate quantity of salt for water flow gauging

• 1 liter of demineralised water with a conductivity not exceeding 10 μS/cm or a resistivity of at least

100'000 ohms.

The preparation of doses

• Weigh out precisely 13,2 g of salt and pour it into a glass.

• Add demineralised water to make up 1 liter of solution

• Stir it well in order to obtain a homogenous solution

• Using a pipette, transfer the solution into small plastic bottles by doses of 20 ml

9

Each dose will contain:

water, which results:

Then:

264 mg / 220 ml * 1000 = 1200 milligrams of salt per litre

(13,2 g / 1000 ml) * 20 ml = 264 milligrams of salt

, added into 200 ml of pure

200+20=220 ml of water containing 264 milligrams of salt

.

.

WARNING

The gauging accuracy depends on the precision of the calibration, which depends on the precision of the

preparation of calibration doses described above. A deviation of only 0,1 gram from the required weight of salt

results in a gauging error of 0,75 %. A deviation of 10 ml from the required volume of water results in a gauging

error of 1 %.

Under certain circumstances and for practical reasons, smaller or bigger doses of calibration liquid may be

needed, but the quantity of salt will always have to be proportional to the total quantity of solution, e.g. : 6,6

grams of salt for 0,5 litre solution or 26,4 g of salt into 2 litres solution. Or if you want to use 10 grams of

salt, you have to add pure water up to a total of 757,5 ml of solution.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 10

10

PPrrooggrraammmmiinngg tthhee ggaauuggiinngg ssiittee

Selection of the site

The SalinoMADD may contain up to 15 pre-programmed sites. This programming is usually carried out at home,

although it can be done anywhere by means of a laptop.

Make sure the SalinoMADD is switched off and then connect the

probe. Having switched on the unit and selected ACQUISITION mode

the display shows the name of the first programmed site.

Here are the options you can select:

Next site

Previous site

Accept the displayed site

If this site has been already gauged, the result will be displayed here

or a ? will appear if gauging was not complete and if no result could be

obtained. By choosing a site previously gauged, the measurements

data will be replaced upon Start by the new gauging data.

If a site has not been pre-programmed, it is always possible to

register a site number on site. In this case, having confirmed the

gauging site, a site number for further reference can be registered.

The numeral chosen with the cursor can be stepped up by pressing

touch

and the cursor can be moved to the next numeral pressing

.

If no site number is desired, just leave the number 0000 (pressing 4x

). A registered site number cannot be erased nor altered.

Selecting intervals

After the selection of a gauging site, the display shown at right will appear. You can select the desired interval

between measurements by pressing touch .

Choosing the interval between 1, 2, 4, 8, 16, or 32 seconds is

directly related with the laps of time the salt cloud needs to

completely pass by the gauging site. The total disposable memory for

one gauging site being 955 measurements, the interval may allow

data acquisition during ¼ hour, ½ hour, 1 hour, 2 hours, 4 ¼ or 8 ½

hours.

It is important to adapt the interval to the characteristics of the water course:

• If the watercourse is rapid and turbulent, the injected tracer will be quickly uniformly mixed and this will

permit a fast gauging with an injection of the tracer at a short distance from the gauging area. In this case

a shorter interval is chosen.

• If the water flow is high, the distance of the tracer injection point from the gauging area will be long and

the time for the tracer cloud to pass by the gauging site will be longer. The interval will have to be longer

as well. Experience in gauging with tracers will make the choice of sites and gauging parameters easier.

NB: All operations to select values like the increment of digits, the quittance of option or the confirmation of

menus are always done with help of the 3 touches of the front panel and their explanation will therefore no

longer be repeated.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 11

11

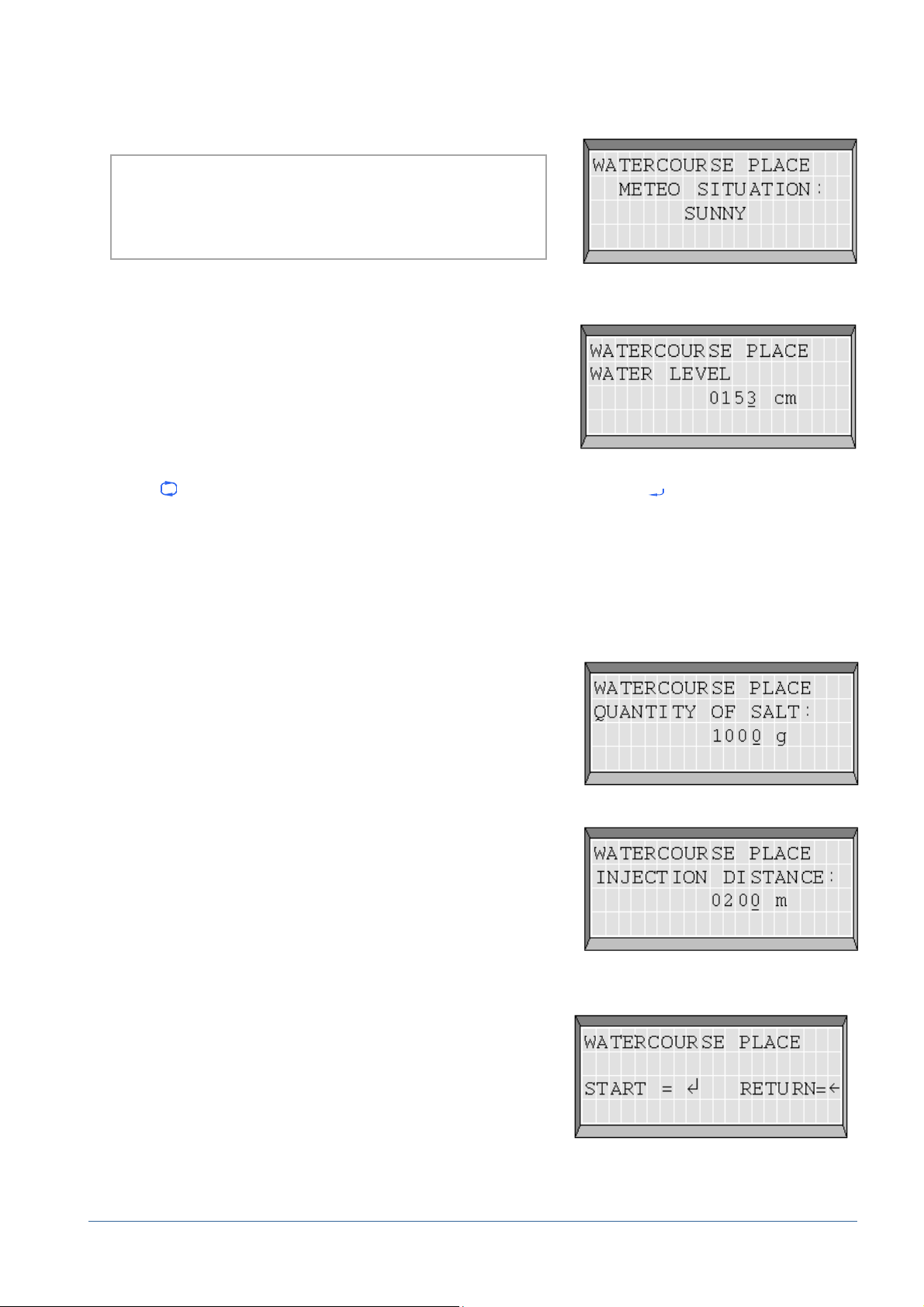

Choice of the meteorological situation

The SalinoMADD contains a number of meteorological situations among which you will choose the appropriate

setting corresponding to the situation at the time of measurement.

Sunny Rainy Snow

Overcast Rain & hail Cloudy

Rain & wind Cold & frost Stormy

Nice & hot Strong rain

Introduction of the water level

Having selected one of above listed meteorological situations, you can

enter the water level of the water course to be gauged. The water

level measured on site permits to correlate measured water flow with

the water level. After a number of measurements at different heights,

it will be possible to establish a formula or at least a relationship

between measured water level and water flow.

Start by selecting the unit in mm, cm or meters before stepping up numbers up to the desired value by pressing

the touch

value is complete.

. The first digit chosen, go on to the next one by pressing touch and so on until the desired

Quantity of injected salt

The next step is the introduction of the salt quantity that will be injected into the water course for the gauging.

The recommended quantity of 2 to 12 grams per litre/second of water flow depends on the distance to the

injection point necessary for a good mixture. The longer the distance, the bigger the tracer dilution and then the

smaller the increase in salinity in the gauging area.

To obtain good results, this instrument requires a salinity increase of

10% or at least 15 milligrams per litre compared with the natural

salinity of the water course.

This quantity of injected salt should be known with precision because it

is an important factor for the water flow calculation.

The SalinoMADD accepts values from 1g to 1000kg.

Distance to point of injection

This distance depends on the nature and the length of the water

course the salt cloud has to travel though until it is evenly spread over

its entire section. The more the water course is turbulent, the faster

mixture and dilution are achieved and the shorter the distance to

point of injection, like in a mountain torrent. In case of a canalized

water course nearly straight or with reservoirs, the flow will be

slower, the distance to point of salt injection will be greater and more

salt will be required.

This distance is recorded for information only since it does not enter into the water flow calculation.

End of data inputs

All necessary data inputs having been recorded in the SalinoMADD,

the acquisition can go on.

The data has been safely stored and the unit will restart and return

to its initial state within a few seconds.

.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 12

12

GGaauuggiinngg aaccqquuiissiittiioonn oonn ssiittee

Before starting the acquisition

Before launching the acquisition, select the site and its indications (see above).

Make sure that the probe has reached the water's temperature before starting the data acquisition. The water

salinity is directly dependent on the water temperature which is measured to correct the salinity and thus bring

it to a standard 20° C. Just use the MULTIMETRE mode to control the temperature stability.

Beginning of data acquisition

After the START of the acquisition, the SalinoMADD begins the

measurements according to the programmed interval. At each

measurement, salinity and water temperature values are displayed

on screen. These measurements are checked to detect the arrival of

the salt cloud.

For correct operation, the device should do at least 100

measurements before the arrival of the salt cloud.

Then both following situations may appear:

th

• The first one occurs when the salt cloud arrives between the 100

case, the device records the initial salinity before the arrival of the salt cloud. It will also record the

memory address of the start. It then continues recording the data.

• The second situation appears when more than 240 measurements having been recorded and that the salt

cloud has not arrived yet. In this case, the SalinoMADD, in order to prevent wasting memory space, will

delete the oldest measurements and record the new ones. As soon as the salt cloud is detected, the

memory address of the start and initial salinity are memorized and the data acquisition continues normally.

and the 240th measurement. In this

As soon as the salt cloud has been detected, the display shown here

appears. Instead of the now useless temperature indication, the

initial salinity IS is displayed. At the end of the acquisition procedure,

the salinity should have reached again this initial value. The value on

the left (M .Nr = 468) indicates the number of measurements

already recorded while the value on the right (REM = 487) shows the

number of remaining measurements. Current date and time are

shown on the fourth line.

End of data acquisition

During the rest of the procedure, the SalinoMADD will try to detect the end of the salt cloud. The operator will

follow the evolution as well. When the water salinity come back to its initial value, the display will normally say

END OF CLOUD - STOP:

can stop the procedure as indicated on the display. If not, he will

await the end of the salt cloud before stopping. The SalinoMADD

does not switch off automatically unless the memory of the site in

question is exhausted. At this moment or when pressing touch

the memory address of the end the cloud, the values of the initial,

maximum and final salinity and the exact time at the end of the

gauging are recorded in the memory of the site. At the end of the

measuring procedure, the results are displayed.

. The operator will ensure that the salinity has dropped to its initial value. If so he

,

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 13

Display of the results

The procedure having run normally, the module having detected the

beginning and the end of the salt cloud, it will now, upon pressing

touch

moment of the display END OF CLOUD the measurement of salinity

has reached its initial value, we may take it for granted that all the

injected salt has passed though the gauging area. We may then

graphically check the quality of the salt dilution on the PC with help

of the SALINOMADD software and eventually correct the points of

beginning and end of salt cloud.

It may happen that the SalinoMADD does not detect the end of the

cloud and thus the operator should interrupt manually the

procedure. In this case the display says MANUAL STOP, ESTIMATED

FLOW. The estimated value should in fact be correct because the

beginning of the cloud had been detected correctly by the module and

the end by the operator.

When the memory of a site is full, the device displays MEMORY

EXHAUSTED. Various raisons can be the cause:

• The length of the salt cloud has exhausted the memory size.

• The SalinoMADD has not detected the end of the salt cloud and

• The end of the cloud has detected, but the 100 preliminary

In any case, check the gauging curve in the graph and decide if the gauging is good or not.

, display the data as shown here at the right. If at the

the operator did not stop it.

measurements had not been recorded.

13

End of acquisition due to errors

If the SalinoMADD has not been in position to collect a sufficient

amount of parameters for the calculation of water flow, it will explain

it on the screen.

In this case, it may be necessary to repeat the gauging procedure.

The operator, who is equipped with a laptop with SALINOMADD

software, can check the gauging curve on site and therefore leaves

the site with the assurance of perfect gauging results.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 14

14

TTiippss ffoorr pprraaccttiiccaall uussee

• Prepare, whenever possible, gauging site programming in advance. It makes the actual data acquisition

work much easier.

• Upon arrival at the measurement site, place immediately the probe into the water. It will then reach fast

the water temperature.

• Try to position the probe in a place where the water course is not too turbulent. Always avoid the

phenomenon of cavitation around the probe. It can perturb the measurements and cause air bubbles

between the probe's electrodes.

• Do not connect the probe to the SalinoMADD when switched on. If this happens however, the SalinoMADD

may be blocked and can not be switched on again. It is then necessary to remove the alkaline batteries for

a moment and put them back in place again. In this case, recorded data, date and time are lost. The unit is

still in working condition but names of sites, localities and operators can always be introduced later at the

office.

• Don’t forget that the SalinoMADD must record at least 100 measurements prior to the arrival of the salt

cloud. The time needed for these measurements is proportional to the gauging intervals as shown below:

INTERVAL RECORDING BEFORE CLOUD ARRIVES

1 second 1 minute 40 seconds

2 seconds 3 minutes 20 seconds

4 seconds 6 minutes 40 seconds

8 seconds 13 minutes 20 seconds

16 seconds 26 minutes 40 seconds

32 seconds 53 minutes 20 seconds

• It is preferable to dilute the salt in water taken from the river to be gauged and then inject the total mixed

solution at once into the water course (max. 300 g of salt per litre). Avoid not yet dissolved salt to sink to

the bottom of the riverbed.

• The most important point for successful gauging is in fact the good dissolution and mixture of the salt in

the water course. Some turbulences caused by a few stones or tiny waterfalls favours the mixing process.

In a straight and flat riverbed or a canal placing some stones can help the mix.

• Small side streams of the water course and basins may slow down part of the current which does not

favour the mixing process.

• A higher speed of the current is a positive factor for the mixing process and a rapid passage of the salt

cloud favours the measuring since the threshold of natural salinity varies very little.

• Gauging in tunnels, straight canals with a current speed of 1 meter/second gives good results even at long

distances (e.g. more than 3000 m) from point of salt injection.

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 15

15

TTeecchhnniiccaall cchhaarraacctteerriissttiiccss

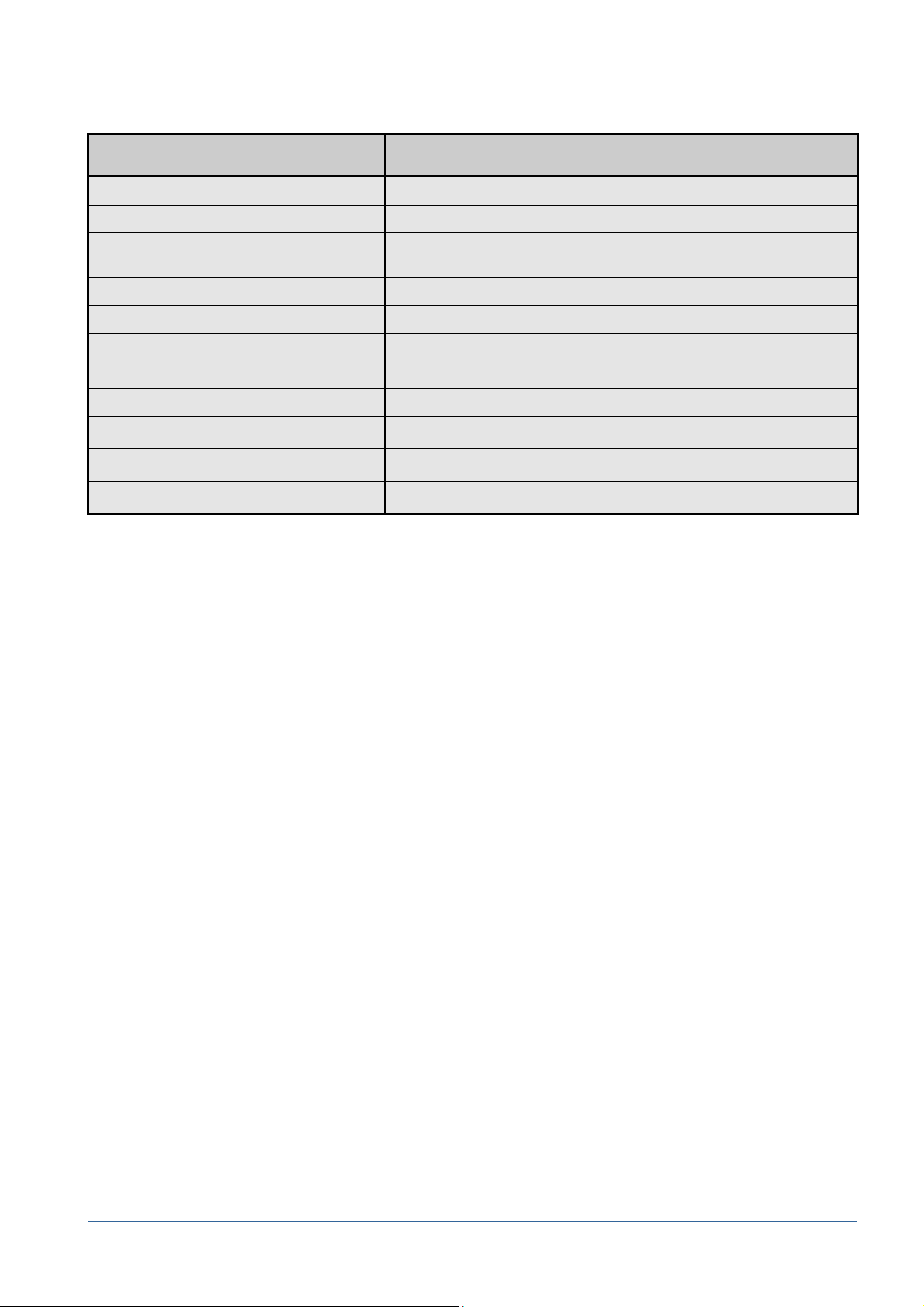

PARAMETRES VALUES

Power supply

Autonomy Approx. 30 hours in normal conditions

Measuring range of salinity Salinity : 0 to 2000 mg/l

Sensitivity of salinity 1 mg/l

Precision of salinity

Ratio conductivity/salinity

Measuring range of temperature

Precision of temperature

Cable length of the probe 10 metres

Weight of the device with probe 1,570 kg

Total weight of the suitcase 2,700 kg

4 alkaline cells 1.5V, type AAA, AM3, LR6, UM3, MIGNON

Conductivity : 0 to 3600 μS/cm

± 1 % max.

1.780 μS/mg/l

0 to 40 °C

± 0.2° C

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Page 16

16

SSAALLIINNOOMMAADDDD ssooffttwwaarree

Software possibilities

The main purpose of this software is to evaluate the acquired gauging data as graphs on PC or laptop. It

presents a clear picture of the acquisition quality.

Functions of the software:

• Preparing, by group of 15, the parameters of the gauging sites.

• Upload into the SalinoMADD a group of 15 gauging sites.

• Setting date and time.

• Reading on site data recordings and saving them.

• Visualization of the gauging graph for each site.

• Eventual modification of major parameters of measuring sites.

• Subsequent calculation of water flow in accordance with the part of curve taken into account.

• Saving processed data files.

• Exporting formatted data for use in spreadsheets.

• Printing gauging card with graphs.

Practical software use

The SALINOMADD software running under Windows® is a very easy to use tool which does not require any

special know-how. It includes online help explaining the functions in details and at any time. All commands are

clearly defined on the touches for graphic functions - just click on them with the mouse.

Installation of the SalinoMADD software

1. Insert the installation CD in your CD drive.

2. Select the language you wish to use and then follow the on-screen installation instructions.

3. If the launch of the application is not automatic, please launch it manually:

Click on Start, select Run…, type D:\Autorun\AUTO-G.exe and click OK

Warning:

When you transfer the data from SalinoMADD to PC, or when you store the site programming from PC to

SalinoMADD or during time setting, don't switch on SalinoMADD !

MADD

Technologies sàrl

Tel: +41 24 445 31 16 – Fax: +41 24 445 21 23 – Email: info@madd.ch – www.madd.ch

– Avenue des Sports 42 – CH-1400 Yverdon-les-Bains – Switzerland

Loading...

Loading...