Page 1

OPERATOR'S MANUAL

MOBILE ELEVATING WORK PLATFORM

S1530E, S1930E, S2032E, S2046E,

S2632E, S2646E, S3246E, S4046E, S4550E

EN - 9831/3200 ISSUE 3 - 09/2017

THIS MANUAL SHOULD ALWAYS STAY WITH THE MACHINE

Page 2

Page 3

Foreword

The Operator's Manual

You and others can be killed or seriously injured

if you operate or maintain the machine without

first studying the Operator's Manual. You must

understand and follow the instructions in the

Operator's Manual. If you do not understand

anything, ask your employer or JCB dealer to

explain it.

OPERATOR'S

MANUAL

MOBILE ELEVATING WORK PLATFORM

S1530E, S1930E, S2032E,

S2046E, S2632E, S2646E,

S3246E, S4046E, S4550E

Do not operate the machine without an Operator's

Manual, or if there is anything on the machine you

do not understand.

Treat the Operator's Manual as part of the machine.

Keep it clean and in good condition. Replace the

Operator's Manual immediately if it is lost, damaged

or becomes unreadable.

Machine Delivery and Installation

Even if you have operated this type of equipment

before, it is very important that your new machines

operations and functions are explained to you by

a JCB Dealer Representative following delivery of

your new machine.

Following the installation you will know how to gain

maximum productivity and performance from your

new product.

Please contact your local JCB dealer if the

Installation Form (included in this manual) has not

yet been completed with you.

Your local JCB Dealer is

EN - 9831/3200 - ISSUE 3 - 09/2017

This manual contains original instructions, verified by

the manufacturer (or their authorized representative).

Copyright 2017 © JCB SERVICE

All rights reserved. No part of this publication may

be reproduced, stored in a retrieval system, or

transmitted in any form or by any other means,

electronic, mechanical, photocopying or otherwise,

without prior permission from JCB SERVICE.

www.jcb.com

Page 4

Notes:

9831/3200-3

Page 5

Table of Contents

Contents Page No.

Acronyms Glossary ........................................................................................................................................ iv

Introduction

About this Manual

Model and Serial Number ..................................................................................................................... 1

Using the Manual .................................................................................................................................. 1

Left-Hand Side, Right-Hand Side ......................................................................................................... 1

Cross References ................................................................................................................................. 2

Location of Manual ............................................................................................................................... 2

Safety

Safety - Yours and Others .................................................................................................................... 3

Safety Warnings .................................................................................................................................... 3

General Safety ...................................................................................................................................... 4

Clothing and Personal Protective Equipment (PPE) ............................................................................ 4

About the Product

Introduction

General .................................................................................................................................................. 5

Name and Address of the Manufacturer .............................................................................................. 5

Product Compliance .............................................................................................................................. 5

Description

General .................................................................................................................................................. 6

Intended Use ......................................................................................................................................... 6

Log Moving/Object Handling ................................................................................................................. 6

Danger Zone ......................................................................................................................................... 6

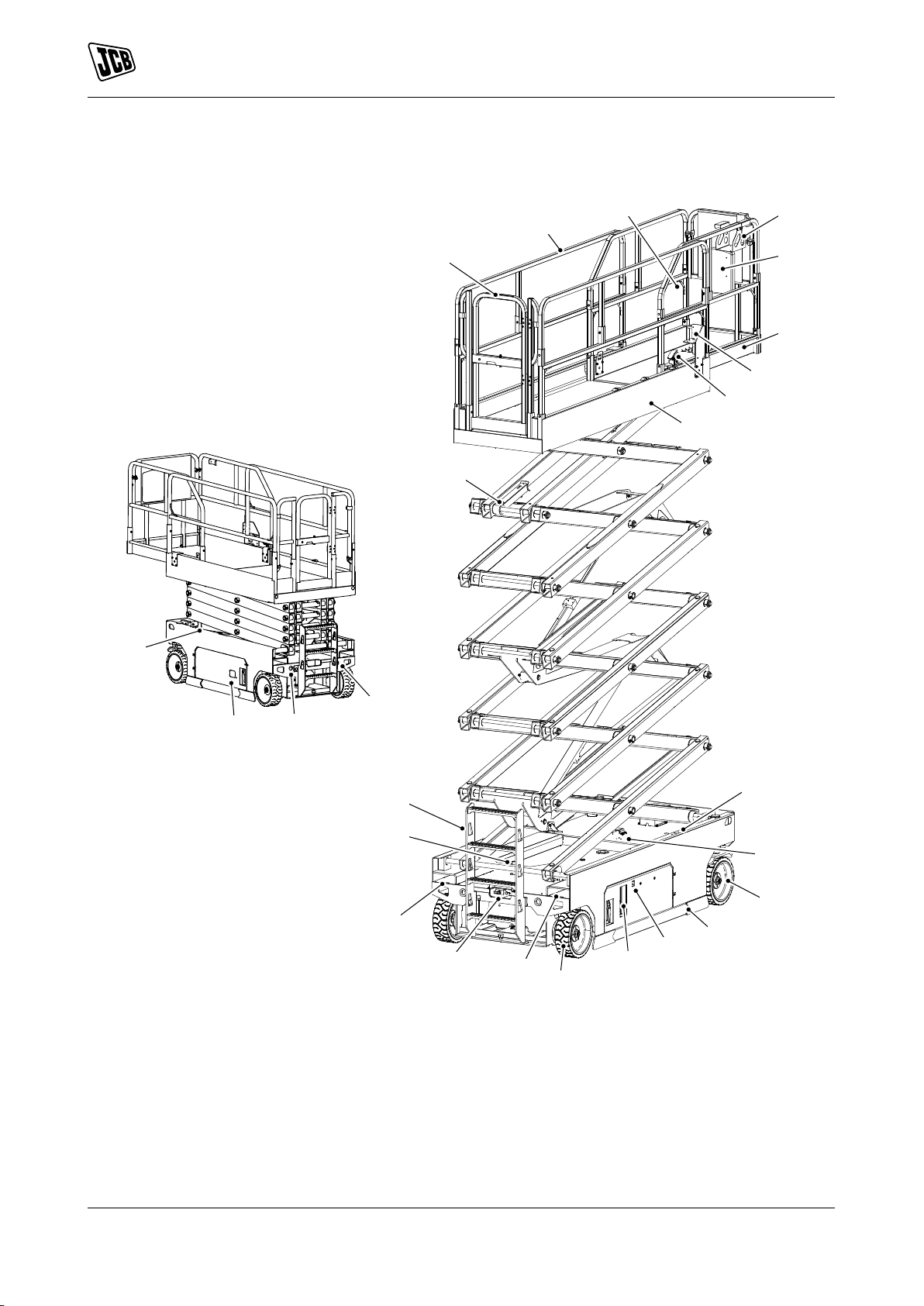

Main Component Locations .................................................................................................................. 7

Product and Component Identification

Machine ................................................................................................................................................. 9

Safety Labels

General ................................................................................................................................................ 10

Safety Label Identification ................................................................................................................... 10

Operation

Introduction

General ................................................................................................................................................ 15

Operating Safety

General ................................................................................................................................................ 16

Worksite Safety ................................................................................................................................... 17

Risk Assessment ................................................................................................................................ 17

Walk-Around Inspection

General ................................................................................................................................................ 19

Entering and Leaving the Operator Station

General ................................................................................................................................................ 20

Battery Isolator

General ................................................................................................................................................ 22

Stopping and Parking

General ................................................................................................................................................ 24

Getting the Machine Moving

General ................................................................................................................................................ 25

Slopes

General ................................................................................................................................................ 26

i 9831/3200-3 i

Page 6

Table of Contents

Driving on Slopes ............................................................................................................................... 26

Driving the Machine

General ................................................................................................................................................ 28

Operating Levers/Pedals

Control Layouts ................................................................................................................................... 29

Working with the Platform

General ................................................................................................................................................ 32

Extending and Retracting the Platform ............................................................................................... 35

Folding and Unfolding the Guardrails ................................................................................................. 35

Moving a Disabled Machine

General ................................................................................................................................................ 37

Lifting the Machine

General ................................................................................................................................................ 39

Transporting the Machine

General ................................................................................................................................................ 41

Loading the Machine onto the Transporting Vehicle/Trailer ............................................................... 41

Operating Environment

General ................................................................................................................................................ 43

Preservation and Storage

Storage

General ................................................................................................................................................ 45

Take out of Storage ............................................................................................................................ 45

Maintenance

Introduction

General ................................................................................................................................................ 47

Owner/Operator Support ..................................................................................................................... 47

Service/Maintenance Agreements ...................................................................................................... 48

Obtaining Spare Parts ........................................................................................................................ 48

Maintenance Safety

General ................................................................................................................................................ 49

Fluids and Lubricants ......................................................................................................................... 49

Batteries .............................................................................................................................................. 51

Maintenance Schedules

General ................................................................................................................................................ 55

How to Use the Maintenance Schedules ........................................................................................... 55

Maintenance Intervals ......................................................................................................................... 55

Pre-start Cold Checks, Service Points and Fluid Levels .................................................................... 56

Functional Tests and Final Inspection ................................................................................................ 57

Maintenance Positions

General ................................................................................................................................................ 58

Service Points

General ................................................................................................................................................ 61

Access Apertures

General ................................................................................................................................................ 63

Battery Cover ...................................................................................................................................... 63

Hydraulic Compartment Cover ........................................................................................................... 63

Body and Framework

General ............................................................................................................................................... 65

Safety Equipment

Check (Operation) ............................................................................................................................... 66

ii 9831/3200-3 ii

Page 7

Table of Contents

Brakes

Park Brake .......................................................................................................................................... 68

Steering System

General ............................................................................................................................................... 69

Tyres

General ............................................................................................................................................... 70

Hydraulic System

General ............................................................................................................................................... 71

Oil ........................................................................................................................................................ 74

Electrical System

General ............................................................................................................................................... 75

Battery ................................................................................................................................................. 75

Battery Isolator ................................................................................................................................... 80

Fuses .................................................................................................................................................. 80

Relays ................................................................................................................................................. 81

Technical Data

Introduction

General ................................................................................................................................................ 83

Static Dimensions

Dimensions .......................................................................................................................................... 84

Weights ............................................................................................................................................... 87

Performance Dimensions

Driving Performance ........................................................................................................................... 90

Noise Emissions

Noise Data .......................................................................................................................................... 94

Vibration Emissions

Vibration Data ..................................................................................................................................... 95

Fluids, Lubricants and Capacities

General ................................................................................................................................................ 96

Electrical System

General ................................................................................................................................................ 97

Fuses .................................................................................................................................................. 97

Hydraulic System

General ................................................................................................................................................ 99

Wheels and Tyres

General .............................................................................................................................................. 100

Fault-Finding

General .............................................................................................................................................. 101

Declaration of Conformity

General .............................................................................................................................................. 103

Data ................................................................................................................................................... 103

Warranty Information

Service Record Sheet ....................................................................................................................... 105

iii 9831/3200-3 iii

Page 8

Acronyms Glossary

AC Alternating Current

LCD Liquid Crystal Display

LED Light Emitting Diode

MECU Machine Electronic Control Unit

PPE Personal Protective Equipment

RCBO Residual current Circuit Breaker with Over current protection

USB Universal Serial Bus

Table of Contents

iv 9831/3200-3 iv

Page 9

About this Manual

Introduction

About this Manual

Model and Serial Number

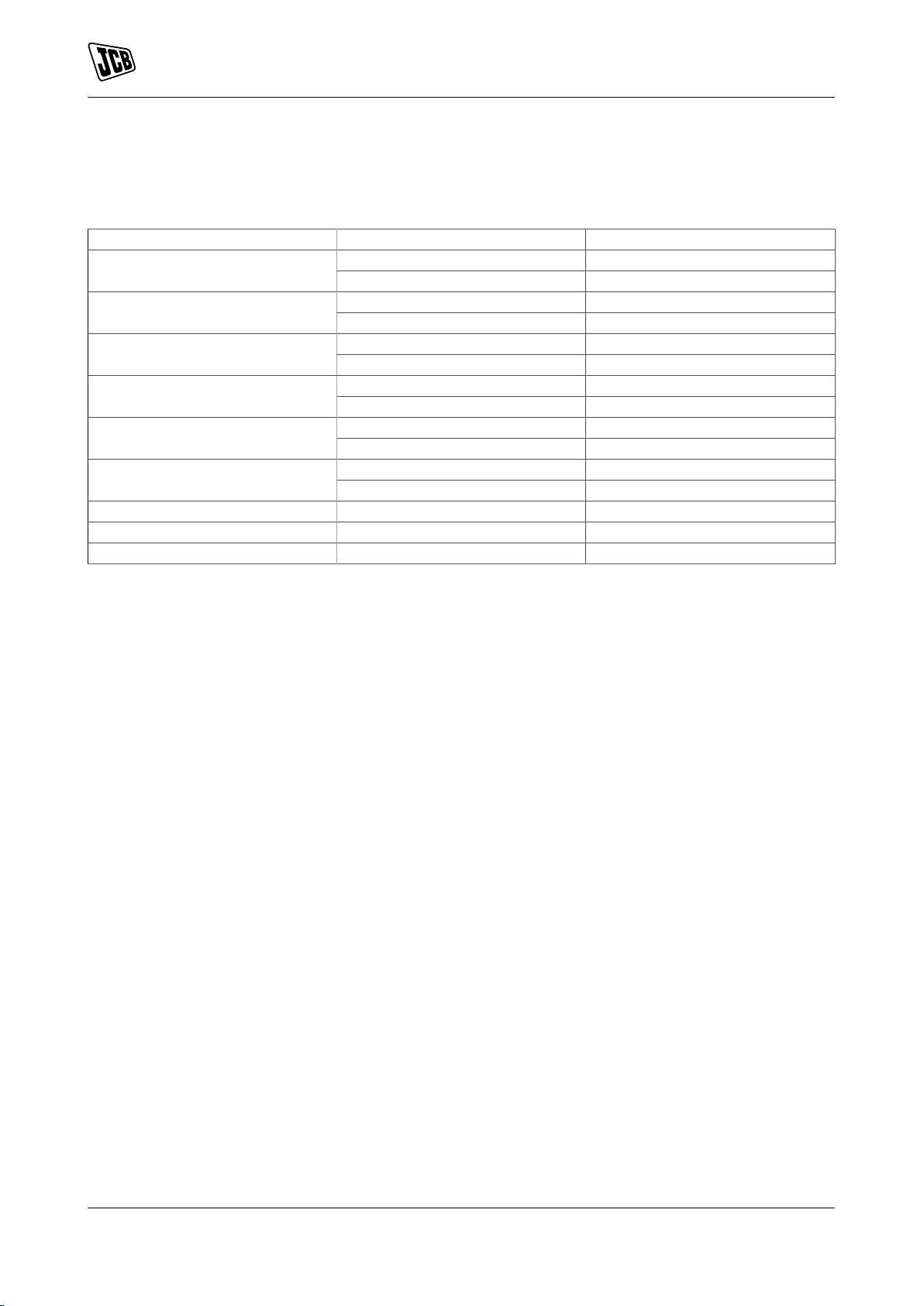

This manual provides information for the following model(s) in the JCB machine range:

Model From: To:

2532501 2537500S1530E

2671002 2672000

2532501 2537500S1930E

2671002 2672000

2532501 2537500S2032E

2671002 2672000

2532501 2537500S2046E

2671002 2672000

2532501 2537500S2632E

2671002 2672000

2532501 2537500S2646E

2671002 2672000

S3246E 2532501 2537500

S4046E 2532501 2537500

S4550E 2533185 2537500

Introduction

Using the Manual

This operator's manual is arranged to give you a good understanding of the machine and its safe operation.

It also contains maintenance and technical data.

Read this manual from the front to the back before you use the machine for the first time, even if you have used

machines of a similar/same type before as the technical specification, systems and controls of the machine

may have changed. Particular attention must be given to all the safety aspects of operating and maintaining

the machine.

If there is anything you are not sure about, ask your JCB dealer or employer. Do not guess, you or others could

be killed or seriously injured.

The general and specific warnings in this section are repeated throughout the manual. Read all the safety

statements regularly, so you do not forget them. Remember that the best operators are the safest operators.

The illustrations in this manual are for guidance only. Where the machines are different, the text and or the

illustration will specify.

The manufacturer's policy is one of continuous improvement. The right to change the specification of the

machine without notice is reserved. No responsibility will be accepted for discrepancies which may occur

between specifications of the machine and the descriptions contained in this manual.

All of the optional equipment included in this manual may not be available in all territories

Left-Hand Side, Right-Hand Side

In this manual, 'left' and 'right' mean your left and right when you are stood in the platform facing the operator's

manual storage case.

1 9831/3200-3 1

Page 10

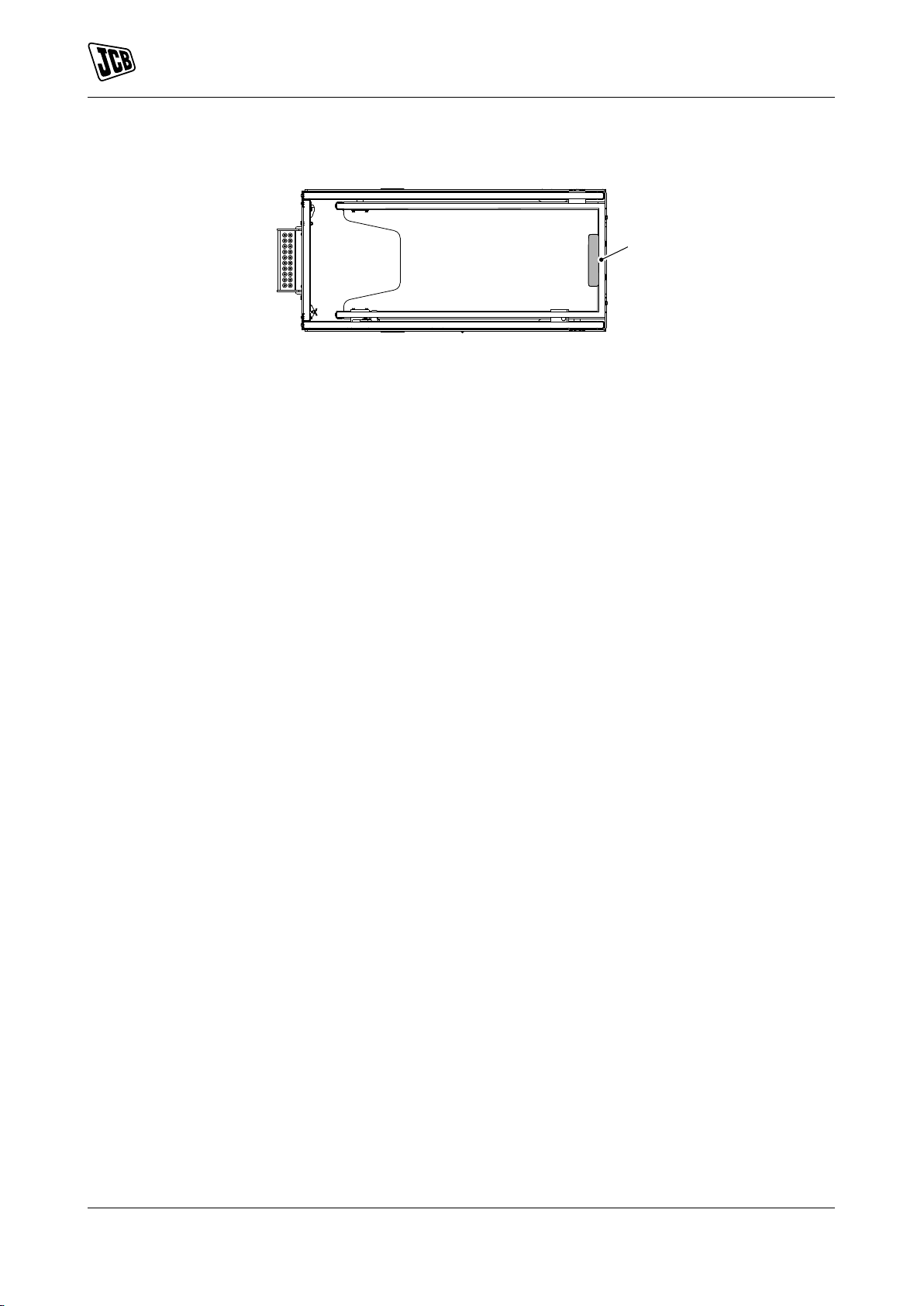

Introduction

A

B

C

About this Manual

Figure 1.

A Left B Right

C Operator's manual storage case

Cross References

In this manual, cross references are made by presenting the subject title in blue (electronic copy only). The

number of the page upon which the subject begins is indicated within the brackets. For example: Refer to:

Cross References (Page 2).

Location of Manual

The operator's manual is located in a storage case at one end of the platform. The manual should always be

returned to its case after use. Refer to: Main Component Locations (Page 7).

2 9831/3200-3 2

Page 11

Introduction

Safety

Safety

Safety - Yours and Others

All machinery can be hazardous. When a machine is correctly operated and maintained, it is a safe machine

to work with. When it is carelessly operated or poorly maintained it can become a danger to you (the operator)

and others.

In this manual and on the machine you will find warning messages, read and understand them. They inform

you of potential hazards and how to avoid them. If you do not fully understand the warning messages, ask your

employer or JCB dealer to explain them.

Safety is not just a matter of responding to the warnings. All the time you are working on or with the machine

you must be thinking of what hazards there might be and how to avoid them.

Do not work with the machine until you are sure that you can control it.

Do not start any work until you are sure that you and those around you will be safe.

If you are not sure of anything, about the machine or the work, ask someone who knows. Do not assume

anything.

Remember:

• Be careful

• Be alert

• Be safe.

Safety Warnings

In this manual and on the machine, there are safety notices. Each notice starts with a signal word. The signal

word meanings are given below.

The signal word 'DANGER' indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

The signal word 'WARNING' indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

The signal word 'CAUTION' indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

The signal word 'Notice' indicates a hazardous situation which, if not avoided, could result in machine damage.

The safety alert system (shown) also helps to identify important safety messages in this manual and on the

machine. When you see this symbol, be alert, your safety is involved, carefully read the message that follows,

and inform other operators.

Figure 2. The safety alert system

3 9831/3200-3 3

Page 12

Introduction

Safety

General Safety

Training

To operate the machine safely you must know the machine and have the skill to use it. You must abide by

all relevant laws, health and safety regulations that apply to the country you are operating in. The operator's

manual instructs you on the machine, its controls and its safe operation; it is not a training manual. If you are a

new operator, get yourself trained in the skills of using a machine before trying to work with it. If you don't, you

will not do your job well, and you will be a danger to yourself and others. In some markets and for work on certain

jobsites you may be required to have been trained and assessed in accordance with an operator competence

scheme. Make sure that you and your machine comply with relevant local laws and jobsite requirements - it

is your responsibility.

Care and Alertness

All the time you are working with or on the machine, take care and stay alert. Always be careful. Always be

alert for hazards.

Clothing

You can be injured if you do not wear the correct clothing. Loose clothing can get caught in the machinery.

Keep cuffs fastened. Do not wear a necktie or scarf. Keep long hair restrained. Remove rings, watches and

personal jewellery.

Alcohol and Drugs

It is extremely dangerous to operate machinery when under the influence of alcohol or drugs. Do not consume

alcoholic drinks or take drugs before or while operating the machine or attachments. Be aware of medicines

which can cause drowsiness.

Feeling Unwell

Do not attempt to operate the machine if you are feeling unwell. By doing so you could be a danger to yourself

and those you work with.

Mobile Phones

Switch off your mobile phone before entering an area with a potentially explosive atmosphere. Sparks in such

an area could cause an explosion or fire resulting in death or serious injury.

Lifting Equipment

You can be injured if you use incorrect or faulty lifting equipment. You must identify the weight of the item to

be lifted then choose lifting equipment that is strong enough and suitable for the job. Make sure that lifting

equipment is in good condition and complies with all local regulations.

Raised Machine

Never position yourself or any part of your body inside the raised scissor pack which is not correctly supported.

If the machine moves unexpectedly you could become trapped and suffer serious injury or be killed.

Lightning

Lightning can kill you. Do not use the machine if there is lightning in your area.

Machine Modifications

This machine is manufactured in compliance with prevailing legislative requirements. It must not be altered in

any way which could affect or invalidate its compliance. For advice consult your JCB dealer.

Clothing and Personal Protective Equipment (PPE)

Do not wear loose clothing or jewellery that can get caught on controls or moving parts. Wear protective clothing

and personal safety equipment issued or called for by the job conditions, local regulations or as specified by

your employer.

4 9831/3200-3 4

Page 13

About the Product

Introduction

About the Product

Introduction

General

Before you start using the machine, you must know how the machine operates. Use this part of the manual

to identify each control lever, switch, gauge, button and pedal. Do not guess, if there is anything you do not

understand, ask your JCB dealer.

Name and Address of the Manufacturer

JCB Access Limited, Lakeside Works, Rocester, Uttoxeter, United Kingdom, ST14 5JP

Product Compliance

Your JCB product was designed to comply with the laws and regulations applicable at the time of its manufacture

for the market in which it was first sold. In many markets, laws and regulations exist that require the owner to

maintain the product at a level of compliance relevant to the product when first produced. Even in the absence

of defined requirements for the product owner, JCB recommend that the product compliance be maintained

to ensure safety of the operator and exposed persons and to ensure the correct environmental performance.

Your product must not be altered in any way which could affect or invalidate any of these requirements. For

advice consult your JCB dealer.

For its compliance as a new product, your JCB and some of its components may bear approval numbers

and marking's, and may have been supplied with a Declaration/Certificate of Conformity. These marking's and

documents are relevant only for the country/region in which the product was first sold to the extent that the

laws and regulations required them.

Re-sales and import/export of products across territories with different laws and regulations can cause new

requirements to become relevant for which the product was not originally designed or specified. In some cases,

pre owned products irrespective of their age are considered new for the purposes of compliance and may be

required to meet the latest requirements which could present an insurmountable barrier to their sale/use.

Despite the presence of any compliance related marking's on the product and components, you should not

assume that compliance in a new market will be possible. In many cases it is the person responsible for import

of a pre owned product into a market that becomes responsible for compliance and who is also considered

the manufacturer.

JCB may be unable to support any product compliance related enquiry for a product which has been moved out

of the legislative country/region where it was first sold, and in particular where a product specification change

or additional certification would have been required in order for the product to be in compliance.

5 9831/3200-3 5

Page 14

About the Product

Description

Description

General

This machine is a self propelled aerial work platform on the top of an elevating scissor arm mechanism.

Intended Use

The machine is intended to lift the personnel with their tools and position them at a level of working height.

The machine can be used to reach areas located above machinery or equipment positioned at ground level

by use of the extending platform.

The machine is intended to be used in normal conditions for the applications and in the environmental conditions

as described in this manual. Use in any other way not described in the manual is considered contrary to intended

use of this machine.

The machine is not intended for use in mining and quarrying applications, in demolition activities, forestry, any

use underground, or in any kind of explosive atmosphere. This is not an exhaustive list. For any activity not

described here, it is recommended that a risk assessment must be done prior to operation.

If the machine is to be used in applications where there is a high silica concentration, risk due to materials

containing asbestos or similar hazards, additional protective measures such as the use of PPE (Personal

Protective Equipment) may be required.

The machine should not be operated by any person who does not have an appropriate level of qualification,

training or experience of use of this type of machine.

Prior to use of the machine, its suitability (size, performance, specification etc.) should be considered with

regards to the intended application and any relevant hazards that may exist. Contact your JCB dealer for

support in determining the appropriate JCB machine, attachment and any optional equipment that is suitable

for the application and environment.

Log Moving/Object Handling

Do not use the machine to move or handle logs or other objects. You could cause serious injury to yourself

and damage to the machine. Do not use the machine as a crane. Do not overload the platform with tools or

equipment. Refer to: Technical Data (Page 83). For more information, contact your JCB dealer.

Danger Zone

The danger zone is any zone within and/or around the machinery in which a person is subject to a risk to their

health or safety. During operation of the machine, keep all persons out of the danger zone. Persons in the

danger zone could be injured.

Before you do a maintenance task, make the product safe. Refer to: Maintenance Positions (Page 58).

6 9831/3200-3 6

Page 15

Main Component Locations

K

W

U

T

S

R

K

L

M

N

Q

P

S

V

F

J

G

H

A

B

C

D

E

X

Y

Z

About the Product

Description

Figure 3.

A Gate B Guardrail

C Harness fastening point D Platform control panel

E Operator's Manual F Platform extension

G AC (Alternating Current) Power socket (option) H Extension platform pedal

J Main platform K Warning lights

L Tilt sensor M Front wheel (steering)

N Pot hole protection plate P MECU (Machine Electronic Control Unit) display

Q Ground controller R Rear wheel

S Lift point/forklift position T Manual release valve and emergency lowering

U Pot hole activation plungers V Ladder

W Safety strut X Battery charger

7 9831/3200-3 7

handle

Page 16

Y Charging plug Z Power to platform plug

About the Product

Description

8 9831/3200-3 8

Page 17

Product and Component Identification

A

Machine

Your machine has an identification plate as shown. Refer to Figure 4.

Figure 4.

About the Product

Product and Component Identification

A Machine identification plate location

Figure 5. Machine Identification Plate

9 9831/3200-3 9

Page 18

About the Product

F

F

E

G

H

J

J

A

B

D

C

E

Safety Labels

Safety Labels

General

WARNING Safety labels on the machine warn you of particular hazards. You can be injured if you do not

obey the safety instructions shown.

The safety labels are strategically placed around the machine to remind you of possible hazards.

If you need eye-glasses for reading, make sure you wear them when reading the safety labels. Do not overstretch or put yourself in dangerous positions to read the safety labels. If you do not understand the hazard

shown on the safety label, then refer to Safety Label Identification.

Keep all of the safety labels clean and readable. Replace a lost or damaged safety label. Make sure the

replacement parts include the safety labels where necessary. Each safety label has a part number printed on

it, use this number to order a new safety label from your JCB dealer.

Safety Label Identification

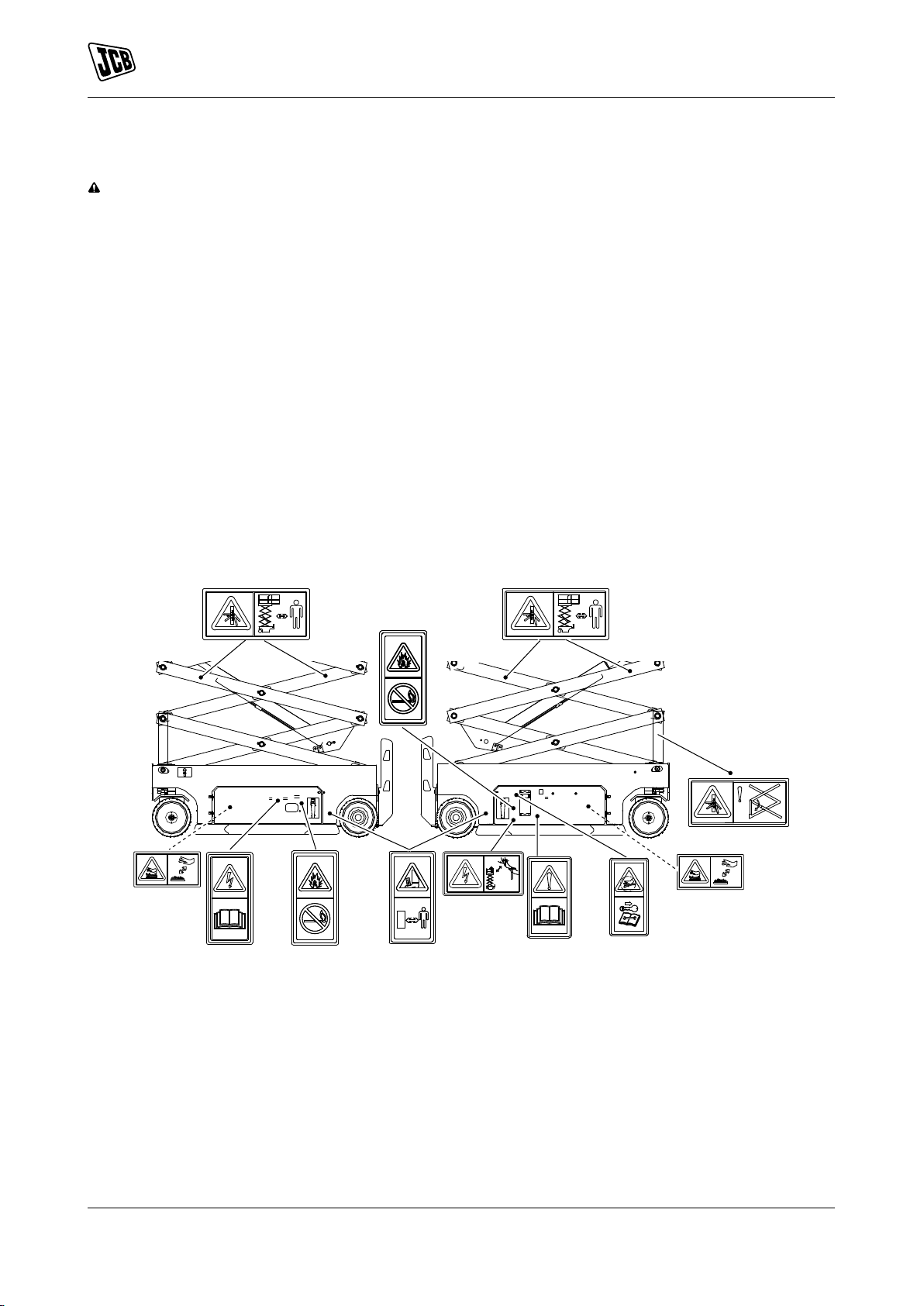

For: S1530E, S1930E .............................................................................................................. Page 10

For: S2032E, S2632E, S4550E ............................................................................................... Page 12

For: S2046E, S2646E, S3246E, S4046E ................................................................................. Page 13

(For: S1530E, S1930E)

Figure 6.

10 9831/3200-3 10

Page 19

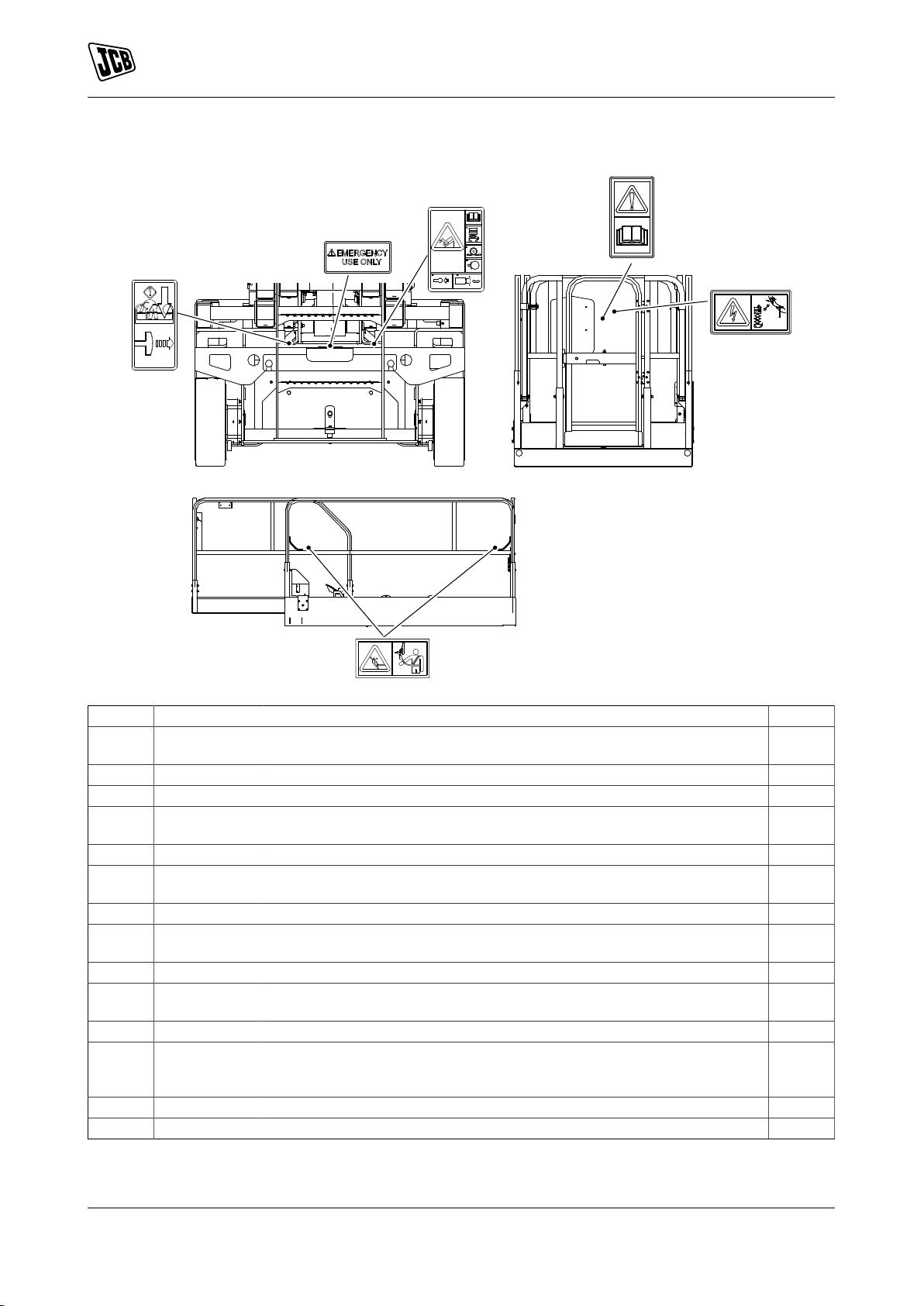

Figure 7.

P

B

K

L

M

R

About the Product

Safety Labels

Table 1. Safety Labels

Item Part No. Description Qty.

A 400/G0761 Crush hazard (to feet). Keep a safe distance. The attachment may roll

forward when released.

B 400/D2107 Electrical hazard. Stay a safe distance away from power lines. 2

C 817/70092 Warning. Read the Operator’s Manual before you operate the machine. 1

D 400/G0762 Pressure hazard. Stop the machine, remove the ignition key and consult

service manual before carrying out any servicing and maintenance work.

E 400/G0767 Explosion hazard. Remove the sources of ignition. 2

F 400/D0831 Warning. Crush hazard. Keep a safe distance from scissor pack/

G 400/G6092 Electrical hazard. Read operator’s manual. 1

H 400/D2141 Warning. Engage safety strut before carrying out maintenance within the

J 332/P7128 Burns to fingers and hands. Stay a safe distance away. 2

K 400/G3529 Warning. Emergency descent control. Pull lever to lower the platform in

L 400/D2576 Warning. Item for emergency use only. 2

M 400/D2979 Warning. Danger of uncontrolled machine movement. Platform to be in

P 400/D1430 Wear safety harness. 4

R 400/G0705 Warning. Read operator’s manual before operating machine. 1

mechanism.

scissor pack.

the event that the operator is incapacitated.

fully lowered position. Use wheel chocks. To release brakes, push valve

and pump lever.

4

1

4

1

1

1

11 9831/3200-3 11

Page 20

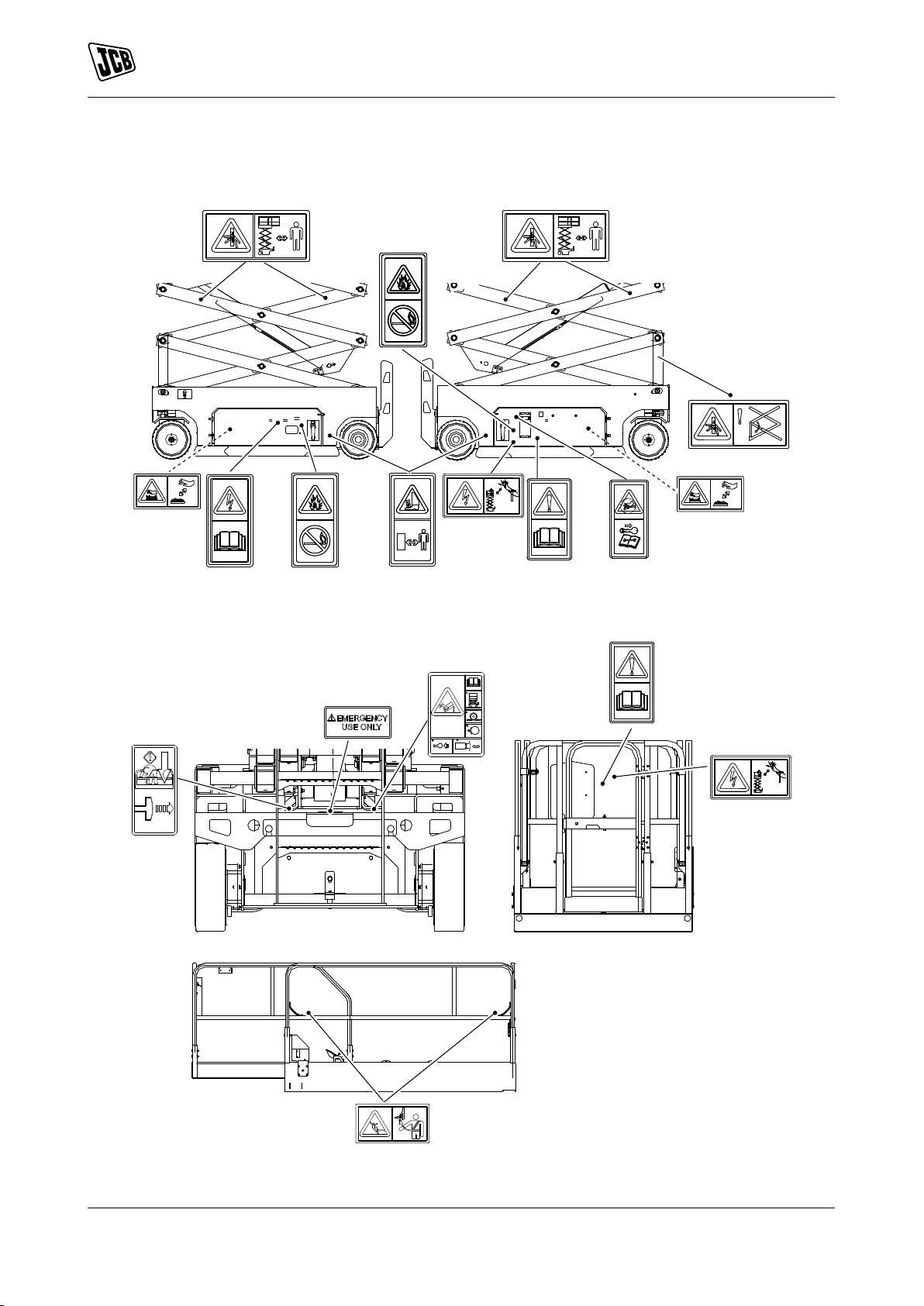

(For: S2032E, S2632E, S4550E)

F

F

E

G

H

J

J

A

B

D

C

E

P

B

K

L

M

R

About the Product

Safety Labels

Figure 8.

Figure 9.

12 9831/3200-3 12

Page 21

About the Product

F

F

E

G

H

J

J

A

B

D

C

E

Safety Labels

Table 2. Safety Labels

Item Part No. Description Qty.

A 332/P7135 Crush hazard (to feet). Keep a safe distance. The attachment may roll

forward when released.

B 400/D2107 Electrical hazard. Stay a safe distance away from power lines. 2

C 817/70092 Warning. Read the Operator’s Manual before you operate the machine. 1

D 817/70002 Pressure hazard. Stop the engine, remove the starter key and consult the

Service Manual before you complete any service or maintenance work.

E 817/70042 Explosion hazard. Remove sources of ignition. 2

F 400/D0831 Warning. Crush hazard. Keep a safe distance from scissor pack/

mechanism.

G 817/70032 Electrical hazard. Read the Operator’s Manual. 1

H 400/D2141 Warning. Engage safety strut before carrying out maintenance within the

scissor pack.

J 332/P7128 Burns to fingers and hands. Stay a safe distance away. 2

K 400/G3529 Warning. Emergency descent control. Pull lever to lower the platform in

the event that the operator is incapacitated.

L 400/D2576 Warning. Item for emergency use only. 2

M 400/D2979 Warning. Danger of uncontrolled machine movement. Platform to be in

fully lowered position. Use wheel chocks. To release brakes, push valve

and pump lever.

P 400/D1430 Wear safety harness. 4

R 400/G0705 Warning. Read operator’s manual before operating machine. 1

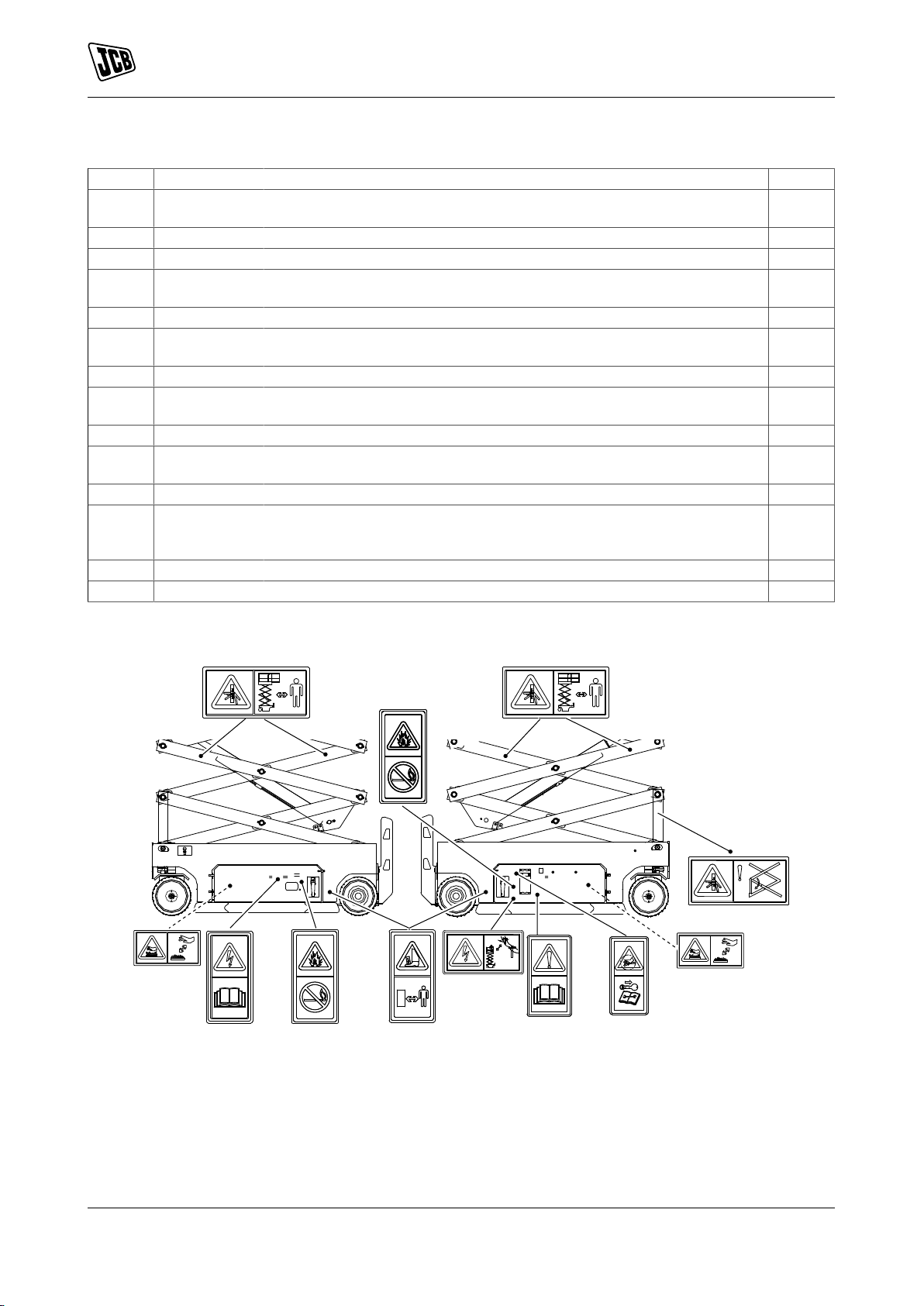

(For: S2046E, S2646E, S3246E, S4046E)

4

1

4

1

1

1

Figure 10.

13 9831/3200-3 13

Page 22

Figure 11.

P

B

K

L

M

R

About the Product

Safety Labels

Table 3. Safety Labels

Item Part No. Description Qty.

A 332/P7135 Crush hazard (to feet). Keep a safe distance. The attachment may roll

forward when released.

B 400/D2107 Electrical hazard. Stay a safe distance away from power lines. 2

C 817/70092 Warning. Read the Operator’s Manual before you operate the machine. 2

D 817/70002 Pressure hazard. Stop the engine, remove the starter key and consult the

Service Manual before you complete any service or maintenance work.

E 817/70042 Explosion hazard. Remove sources of ignition. 2

F 400/D0831 Warning. Crush hazard. Keep a safe distance from scissor pack/

G 817/70032 Electrical hazard. Read the Operator’s Manual. 1

H 400/D2141 Warning. Engage safety strut before carrying out maintenance within the

J 332/P7128 Burns to fingers and hands. Stay a safe distance away. 2

K 400/G3529 Warning. Emergency descent control. Pull lever to lower the platform in

L 400/D2576 Warning. Item for emergency use only. 2

M 400/D2979 Warning. Danger of uncontrolled machine movement. Platform to be in

P 400/D1430 Wear safety harness. 4

mechanism.

scissor pack.

the event that the operator is incapacitated.

fully lowered position. Use wheel chocks. To release brakes, push valve

and pump lever.

4

1

4

1

1

1

14 9831/3200-3 14

Page 23

Operation

Introduction

Operation

Introduction

General

The aim of this part of the manual is to guide the operator step-by-step through the task of learning how to

operate the machine efficiently and safely. Read the Operation section through from beginning to end.

The operator must always be aware of events happening in or around the machine. Safety must always be the

most important factor when you operate the machine.

When you understand the operating controls, gauges and switches, practice using them. Drive the machine in

an open space, clear of people. Get to know the 'feel' of the machine and its driving controls.

Do not rush the job of learning, make sure you fully understand everything in the Operation section. Take your

time and work efficiently and safely.

Remember:

• Be careful.

• Be alert.

• Be safe.

15 9831/3200-3 15

Page 24

Operation

Operating Safety

Operating Safety

General

Training

Make sure that you have had adequate training and that you are confident in your ability to operate the machine

safely before you use it. Practice using the machine and its attachments until you are completely familiar with

the controls and what they do. With a careful, well trained and experienced operator, your machine is a safe

and efficient machine. With an inexperienced or careless operator, it can be dangerous. Do not put your life,

or the lives of others, at risk by using the machine irresponsibly. Before you start to work, tell your colleagues

what you will be doing and where you will be working. On a busy site, use a signalman.

Before doing any job not covered in this manual, find out the correct procedure. Your local JCB distributor will

be glad to advise you.

Machine Condition

A defective machine can injure you or others. Do not operate a machine which is defective or has missing

parts. Make sure the maintenance procedures in this manual are completed before using the machine.

Machine Limits

Operating the machine beyond its design limits can damage the machine, it can also be dangerous. Do

not operate the machine outside its limits. Do not try to upgrade the machine performance with unapproved

modifications or additional equipment.

Communications

Bad communications can cause accidents. Keep people around you informed of what you will be doing. If you

will be working with other people, make sure any hand signals that may be used are understood by everybody.

Worksites can be noisy, do not rely on spoken commands.

Parking

An incorrectly parked machine can move without an operator. Follow the instructions in the Operator's Manual

to park the machine correctly.

Banks and Trenches

Banked material and trenches can collapse. Do not work or drive too close to banks and trenches where there

is danger of collapse.

Safety Barriers

Unguarded machines in public places can be dangerous. In public places, or where your visibility is reduced,

place barriers around the work area to keep people away.

Sparks

Explosions and fire can be caused by sparks from the electrical system. Do not use the machine in closed

areas where there is flammable material, vapour or dust.

Regulations

Obey all laws, worksite and local regulations which affect you and your machine.

Electrical Power Cables

You could be electrocuted or badly burned if you get the machine or its attachments too close to electrical

power cables.

You are strongly advised to make sure that the safety arrangements on site comply with the local laws and

regulations concerning work near electric power lines.

Before you start using the machine, check with your electricity supplier if there are any buried power cables

on the site.

There is a minimum clearance required for working beneath overhead power cables. You must obtain details

from your local electricity supplier.

Machine Safety

Stop work at once if a fault develops. Abnormal sounds and smells can be signs of trouble. Examine and repair

before resuming work.

16 9831/3200-3 16

Page 25

Operation

Operating Safety

Travelling at High Speeds

Travelling at high speeds can cause accidents. Always travel at a safe speed to suit working conditions.

Confined Areas

Pay extra attention to proximity hazards when operating in confined areas. Proximity hazards include buildings,

traffic and bystanders.

Safe Working Loads

Overloading the machine can damage it and make it unstable. Study the specifications in the Operator's Manual

before using the machine.

Lightning

If there is lightning, stay away from the machine and do not use the machine. If you are on the machine, exit

the machine and get to safety. Do not attempt to mount or enter the machine.

If the machine is struck by lightning do not use the machine until it has been checked for damage and

malfunction by trained personnel.

Worksite Safety

"Workplace Inspection" will help operators to determine whether the workplace is suitable for operation.

Operators must inspect the workplace before they move machines there. It is the operator's responsibility to

understand and keep in mind the hazards in the workplace, He/she shall pay attention and avoid these problems

when move, install and operate the machine. Check for hazards such as but not limited to:

• Drop-offs, or potholes including those concealed by water mud, etc.

• Slopes.

• Bumps and floor obstructions.

• Debris.

• Over head obstructions and electrical conductors.

• Hazardous locations and atmospheres.

• Inadequate surface and support to withstand all load forces imposed by the platform in all operating

configurations.

• Wind and weather conditions.

• Presence of unauthorized persons.

• Other possible unsafe conditions.

Risk Assessment

It is the responsibility of the competent people that plan the work and operate the machine to make a judgement

about the safe use of the machine, they must take into account the specific application and conditions of use

at the time.

It is essential that a risk assessment of the work to be done is completed and that the operator obeys any

safety precautions that the assessment identifies.

If you are unsure of the suitability of the machine for a specific task, contact your JCB dealer who will be

pleased to advise you.

The following considerations are intended as suggestions of some of the factors to be taken into account when

a risk assessment is made. Other factors may need to be considered.

A good risk assessment depends on the training and experience of the operator. Do not put your life or the

lives of others at risk.

Personnel

• Are all persons who will take part in the operation sufficiently trained, experienced and competent? Are

they fit and sufficiently rested? A sick or tired operator is a dangerous operator.

• Is supervision needed? Is the supervisor sufficiently trained and experienced?

17 9831/3200-3 17

Page 26

Operation

Operating Safety

• As well as the machine operator, are any assistants or lookouts needed?

The Machine

• Is it in good working order?

• Have any reported defects been corrected?

• Have the daily checks been carried out?

• Are the tyres in good condition?

• Is the battery sufficiently charged to complete the job?

Working Area

• Is it level?

• Is the ground solid? Will it support the weight of the machine when loaded?

• How rough is the ground? Are there any sharp projections which could cause damage, particularly to

the tyres?

• Are there any obstacles or hazards in the area, for example, debris, excavations, manhole covers, power

lines?

• Is the space sufficient for safe manoeuvring?

• Are any other machines or persons likely to be in or to enter the area while operations are in progress?

The Route to be Travelled

• How solid is the ground, will it provide sufficient traction and braking? Soft ground will affect the stability

of the machine and this must be taken into account.

• How steep are any slopes, up/down/across? A cross slope is particularly hazardous, is it possible to detour

to avoid them?

Weather

• How windy is it? High wind will adversely affect the stability of a loaded machine.

• Is it raining or is rain likely? The ground that was solid and smooth when dry will become uneven and

slippery when wet, and it will not give the same conditions for traction, steering or braking.

Emergency Plan

Make sure that emergency rescue plan is in place and understood by those involved when operating the

machine from platform controller at height.

18 9831/3200-3 18

Page 27

Operation

Walk-Around Inspection

Walk-Around Inspection

General

The following checks must be made each time you return to the machine after leaving it for any period of time.

We advise you also to stop the machine occasionally during long work sessions and do the checks again.

All these checks concern the serviceability of the machine. Some concern your safety. Get your service engineer

to check and correct any defects.

1. Check for cleanliness.

1.1. Remove dirt and debris, especially from around the linkages, rams, pivot points.

1.2. Make sure the platform floor and handrails are clean and dry.

1.3. Clean all of the safety and instructional labels. Replace any label that is missing or cannot be read.

2. Check for damage.

2.1. Examine the machine generally for damaged and missing parts.

2.2. Make sure that all of the fasteners and pivot pins are correctly installed.

2.3. Check the operation of the platform side rails.

2.4. Check the condition of the tyres.

2.5. Check for leaks

3. Make sure that all of the access panels are closed correctly.

3.1. If access panels are installed with locks, we recommend that you lock them to prevent theft or

tampering.

4. Check the operation of all controls.

5. Check the operator's manual is in good condition and is kept in the operator's manual storage compartment.

6. Check the level of the hydraulic fluid and for leaks.

7. Check the visual condition of the batteries, cables and wiring.

8. Check the operation of the safety equipment.

Refer to: Check (Operation) (Page 66).

19 9831/3200-3 19

Page 28

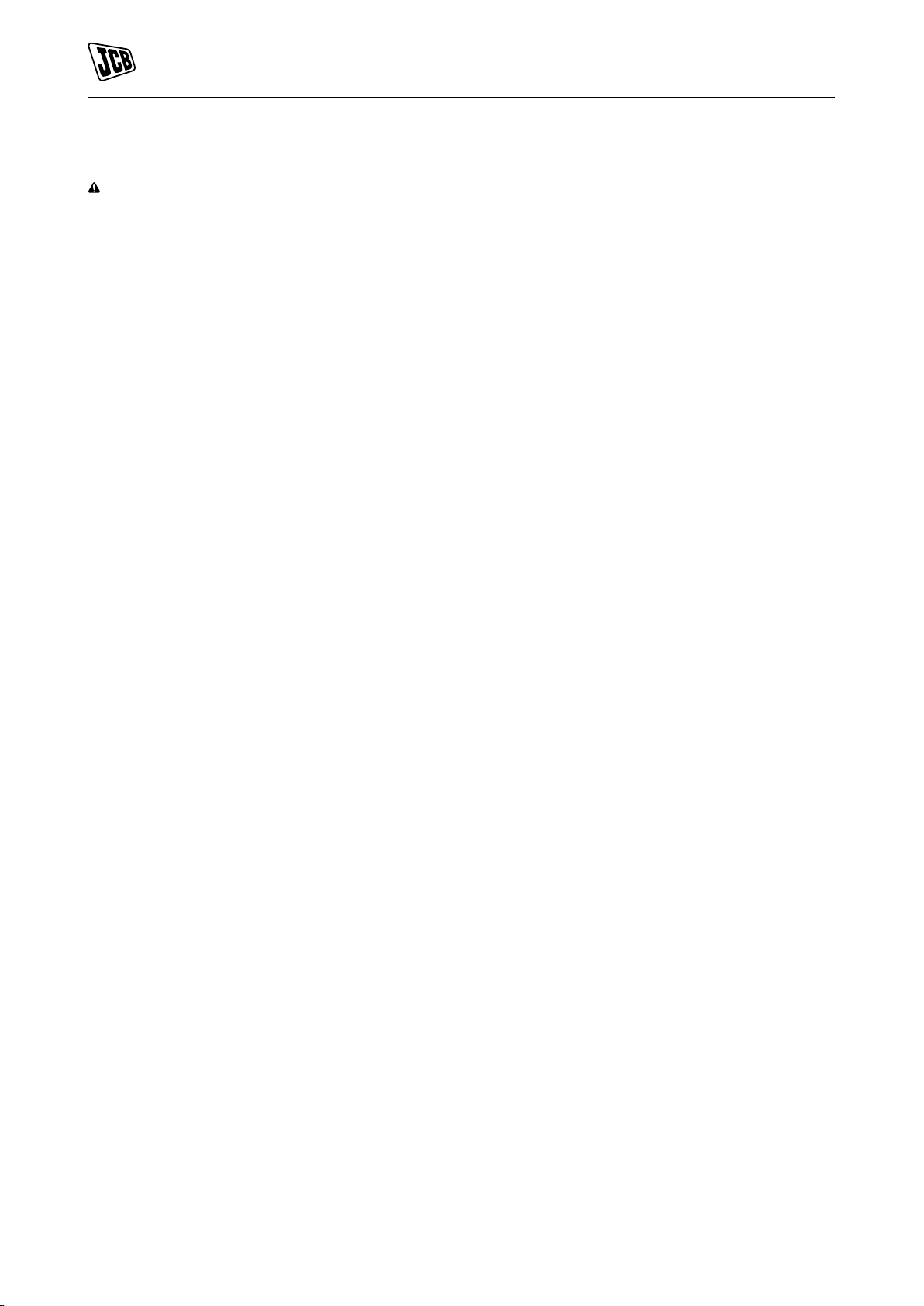

Operation

Entering and Leaving the Operator Station

Entering and Leaving the Operator Station

General

CAUTION If the guardrails have been folded down, use extreme caution when entering and leaving the

operator station. Do not operate the controls from the platform when the guard rails are folded.

CAUTION Entering or leaving the operator station must only be made where steps and handrails are

provided. Always face the machine when entering and leaving. Make sure the step(s), handrails and your

boot soles are clean and dry. Do not jump from the machine. Do not use the machine controls as handholds,

use the handrails.

Make sure the machine is stopped, correctly parked and fully stowed before entering or leaving the platform.

Refer to: Stopping and Parking (Page 24).

When entering and leaving the platform always maintain three points of contact with the guardrails and step.

Do not use the machine controls as handholds.

Entering the Platform

1. Hold the two guardrails, then use the steps to climb up to the platform. Refer to Figure 12.

2. Depress the lever and open the platform door.

3. Step into the platform.

4. Close the platform door and make sure it latches correctly.

Leaving the Platform

1. Park the machine on solid (slabbed or paved), level ground.

2. Depress the lever and open the platform door.

3. Hold both of the guardrails and step backwards out of the platform onto the steps.

4. Close the platform door and make sure it latches correctly.

5. Use the steps to climb down backwards onto the ground.

20 9831/3200-3 20

Page 29

Figure 12.

A

Operation

Entering and Leaving the Operator Station

A Lever

21 9831/3200-3 21

Page 30

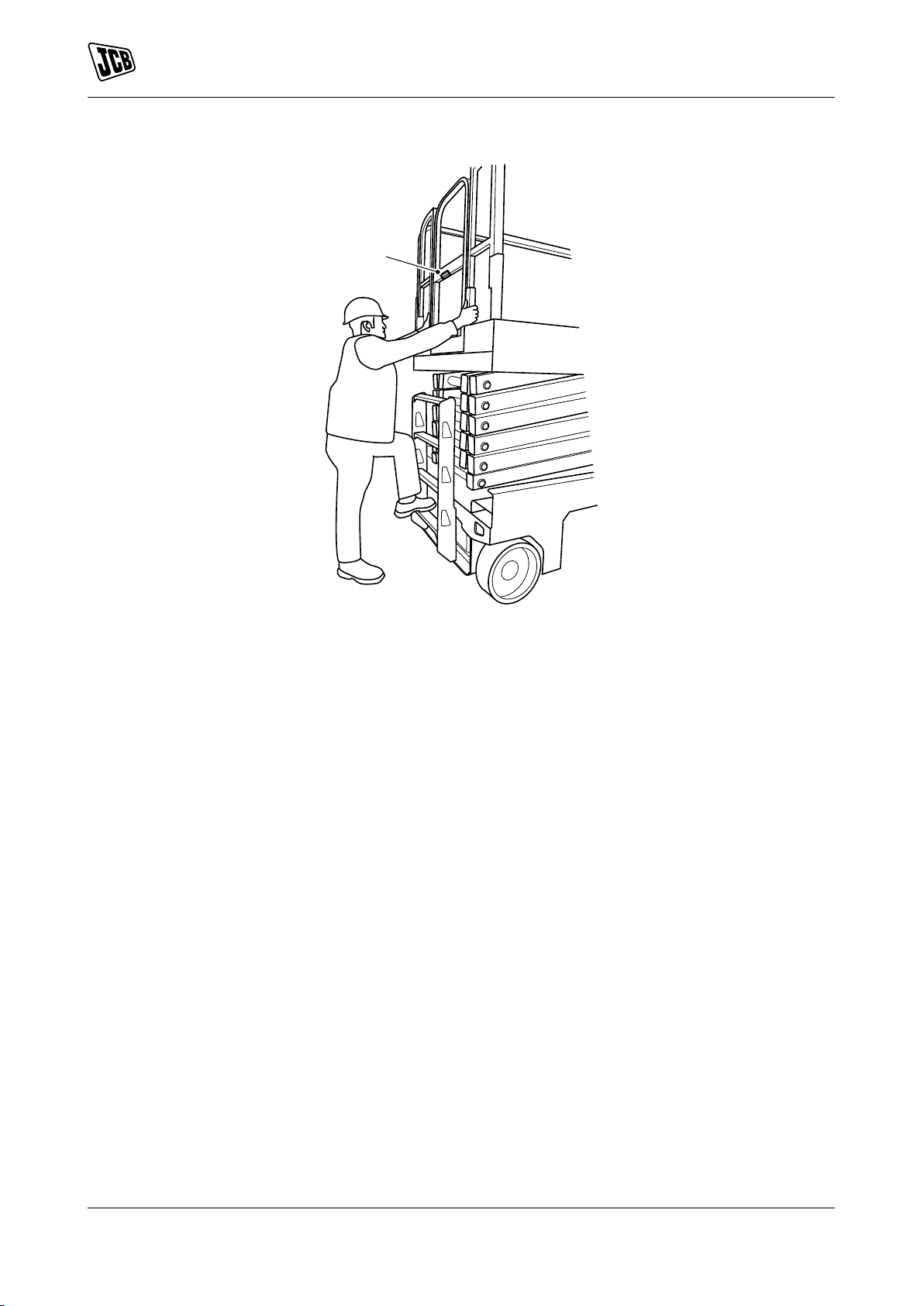

Battery Isolator

A

General

WARNING The batteries remain live even when the isolator key is removed.

Disconnect the Machine Electrics:

1. Turn the key switch to the off position.

2. Get access to the battery isolator.

Refer to: Access Apertures (Page 63).

3. Disconnect the battery isolator by pulling handle. Refer to Figure 13.

Connect the Machine Electrics:

1. Make sure the key switch is at off position.

2. Connect the battery isolator.

Figure 13. Lead Acid Battery

Operation

Battery Isolator

A Battery isolator

22 9831/3200-3 22

Page 31

A

A Battery isolator

Operation

Battery Isolator

Figure 14. Lithium Iron Phosphate Battery

23 9831/3200-3 23

Page 32

Operation

Stopping and Parking

Stopping and Parking

General

This machine has brakes installed on the rear wheels only. The brakes installed on this machine are park brake

only, there are no dynamic brakes installed.

The brake will release automatically during travel, the brake will not release during lifting.

1. Select a safe place to stop where the ground is firm and level such as slabbed or paved surface, where

the machine will not cause an obstruction and away from heavy traffic.

2. Lower the platform.

3. Turn the key switch to the off position. Remove the key to avoid unauthorized use.

3.1. Before switching off the machine check the battery level. If necessary, put the machine on charge to

ensure that the battery is fully charged for the next time the machine is used.

Brake Operational Limits

The machine brakes are capable of stopping the machine at its maximum speed on the maximum gradients

as stated in this manual.

It is recommended that the machine is not parked or left unattended on slopes greater than those specified

in this manual. It is the responsibility of the operator to assess the ground and atmospheric conditions before

using or parking the machine on gradients.

The machine must be immediately taken out of service until corrected if the brakes do not operate within

specifications or performance requirements as defined in this manual or any other in-service, periodic or postmaintenance brake verification.

24 9831/3200-3 24

Page 33

Operation

Getting the Machine Moving

Getting the Machine Moving

General

WARNING Watch for obstructions around machine and overhead when driving. Check clearance above, to

sides, at bottom of machine when lifting or lowering the platform.

WARNING Keep hands and arms out of the path of the scissor arms when lowering the platform.

WARNING Do not use the platform controller to release the platform when it is stuck, snagged or caught.

In this case, use the ground controller only when there are no persons on the platform.

CAUTION Do not raise platform with the guardrails folded down. The guardrails must be in their upright

positions and properly secured when raising the platform.

Raising and Lowering the Platform

Refer to: Operating Levers/Pedals (Page 29).

Operation from the Ground

1. Turn the key switch to ground control.

2. Make sure the ground and platform emergency stop buttons are pulled out.

3. Move the platform raising/lowering toggle switch either up or down. Move up to raise the platform. Move

down to lower the platform.

4. When lowering the platform the platform will stop part way down for safety. Release the toggle switch

and check there are no obstructions in the scissors. Move the toggle switch down again to fully lower the

platform. There is an intentional delay periods of 3 seconds after the stop and 1.5 seconds after the toggle

switch is pressed during lowering.

Operation from the Platform

1. Turn the key switch to platform control.

2. Make sure the ground and platform emergency stop buttons are pulled out.

3. Press the raise/lower mode button on the platform controller. The button should illuminate.

4. Press and hold the enable switch.

5. Move the joystick forwards or backwards. Check the arrow colours on the joystick with the operating

direction. Move forwards to lower the platform. Move backwards to raise the platform.

Operation in Raised Position

The automatic pothole protection system will fold down and drive speed is reduced when the platform raised.

25 9831/3200-3 25

Page 34

Operation

B

A

Slopes

Slopes

General

WARNING Make sure that you have been trained and are familiar with the use of machines on slopes, and

understand the adverse affects that slopes and site conditions can have on stability. Never use the machine

on a slope if you do not understand the recommended practices for the use of machines in such applications.

There are a number of factors which can adversely affect the stability of the machine and the safety of the

machine and operator when used on a slope.

It is essential that a risk assessment of the work to be done is completed and that the operator complies with

any safety precautions that the assessment identifies.

Driving on Slopes

WARNING If the tilt indicator warning light/alarm is activated while driving with platform raised, lower the

platform and drive to a smooth firm level surface.

While driving on slopes with the platform fully stowed make sure that the front/back and side slope does not

exceed the rated gradient for the machine. Refer to: Performance Dimensions (Page 90).

Figure 15.

A Front/back slope B Side slope

While driving on slopes with the platform raised make sure that front/back slope and side slope does not exceed

the angles specified.

Front/back slope 3°

Side slope 1.5°

26 9831/3200-3 26

Page 35

Figure 16.

B

A

A Front/back slope B Side slope

Operation

Slopes

27 9831/3200-3 27

Page 36

Operation

Driving the Machine

Driving the Machine

General

Operation from the Ground

1. Drive and steer functions are not available on the ground controller.

Operation from the Platform

Machine travel speed is restricted when the platform is raised.

1. Turn the key switch to platform control.

Refer to: Control Layouts (Page 29).

2. Make sure the ground and platform emergency stop buttons are pulled out.

3. Press the drive mode button. The button should illuminate. Always check that the machine is in the correct

mode before moving the joystick.

4. Press and hold the enable switch.

5. Slowly move the joystick forwards or backwards. Move forwards to move the machine forwards. Move

backwards to move the machine backwards.

Drive Speed

There are two drive speeds available when the machine is stationary. Press the speed button to switch between

high speed and low speed. When the light is illuminated slow speed is enabled. When the light is extinguished

high speed is enabled. Slow speed is activated when the platform is raised. Always check that the machine is

in the correct drive speed before moving the joystick, especially after lowering the platform.

Steering

Press and hold the enable switch. Press the steering switch left or right to change the steering direction of

the steering wheels.

28 9831/3200-3 28

Page 37

Operation

E

F

AA

B

C

D

Operating Levers/Pedals

Operating Levers/Pedals

Control Layouts

CAUTION Keep the machine controls clean and dry. Your hands and feet could slide off slippery controls.

If that happens you could lose control of the machine.

Ground Controller

WARNING Do not operate the machine with the ground controller when there are personnel in the platform

except in an emergency.

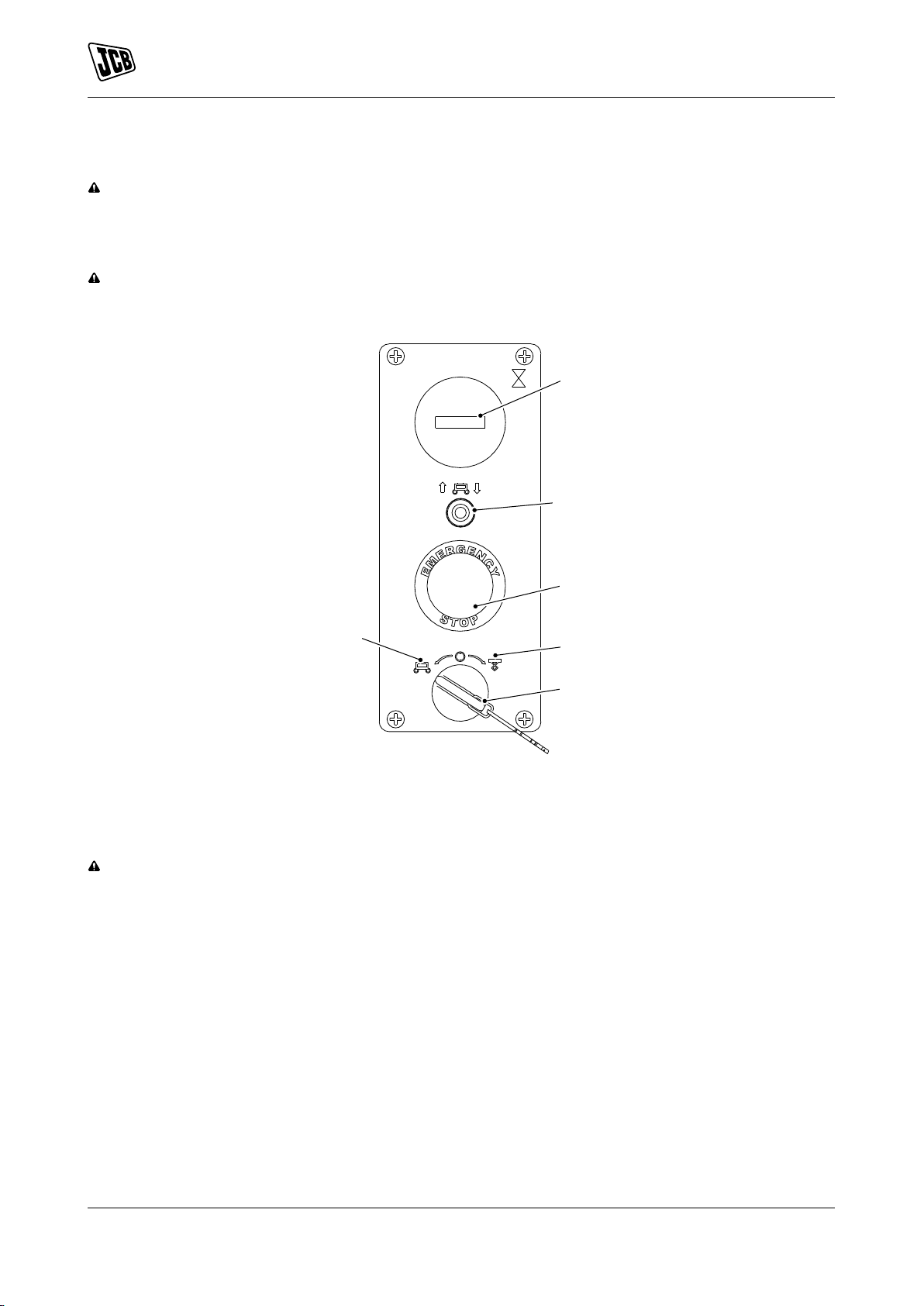

Figure 17.

A Ground control position B Platform control position

C Key switch D Platform raising/lowering toggle switch

E Emergency stop switch F Hourmeter

Platform Controller

WARNING Do not drive the machine with the platform raised except on smooth, firm and level surface free

of obstructions and pot holes.

29 9831/3200-3 29

Page 38

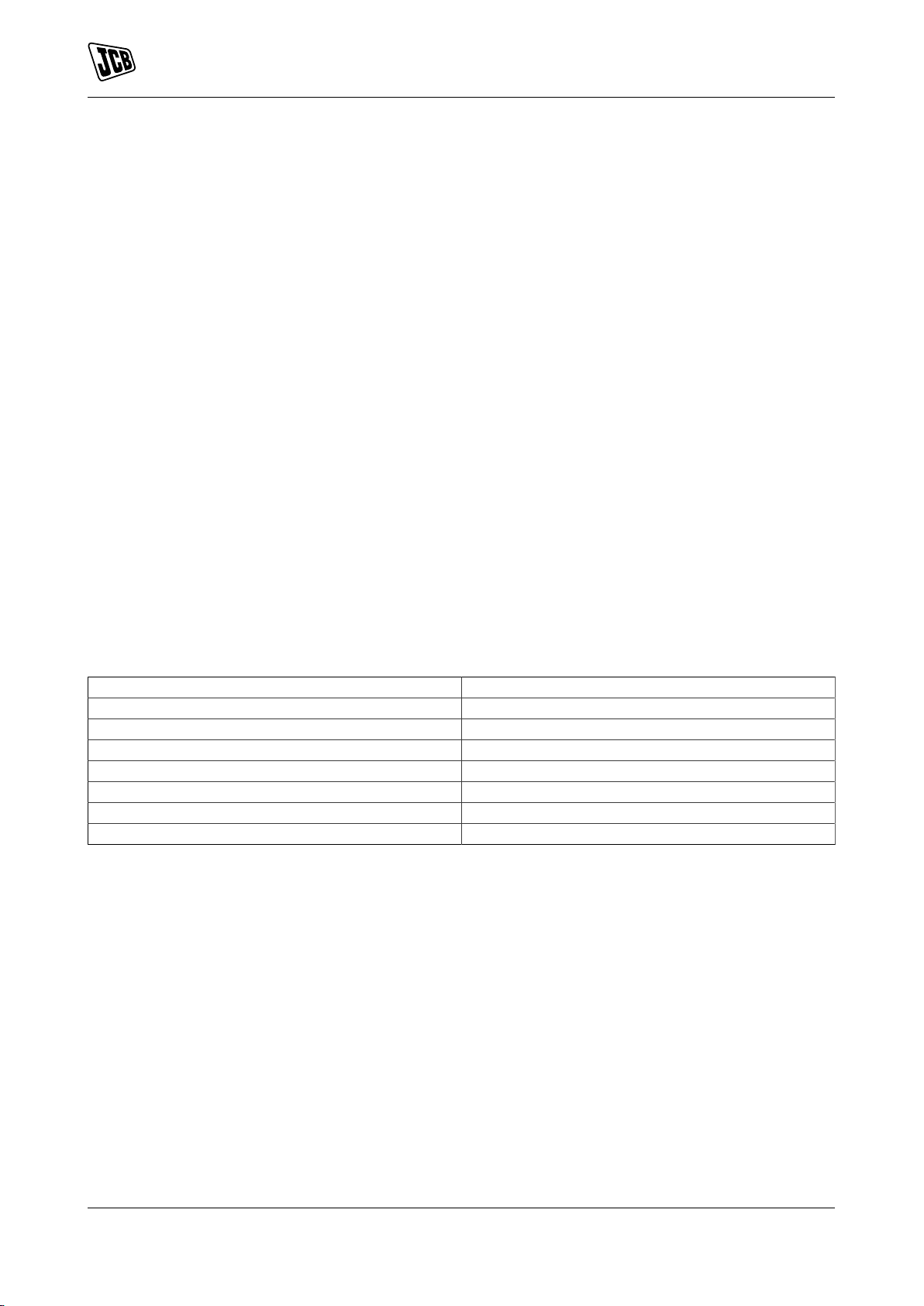

Figure 18.

EMERGENCY

S

T

O

P

A

B

C

D

E

F

G

H

J

K

Operation

Operating Levers/Pedals

A Emergency stop switch B Joystick (forwards/backwards)

C Turn left switch D Turn right switch

E Safety trigger/enable switch F Raise/lower mode

G Drive mode H Display

J Horn button K Speed button

The platform control lever is installed on a portable bracket that can be moved around the platform. The platform

controller can be fitted to the ground controller to suit the operation.

30 9831/3200-3 30

Page 39

Figure 19.

Operation

Operating Levers/Pedals

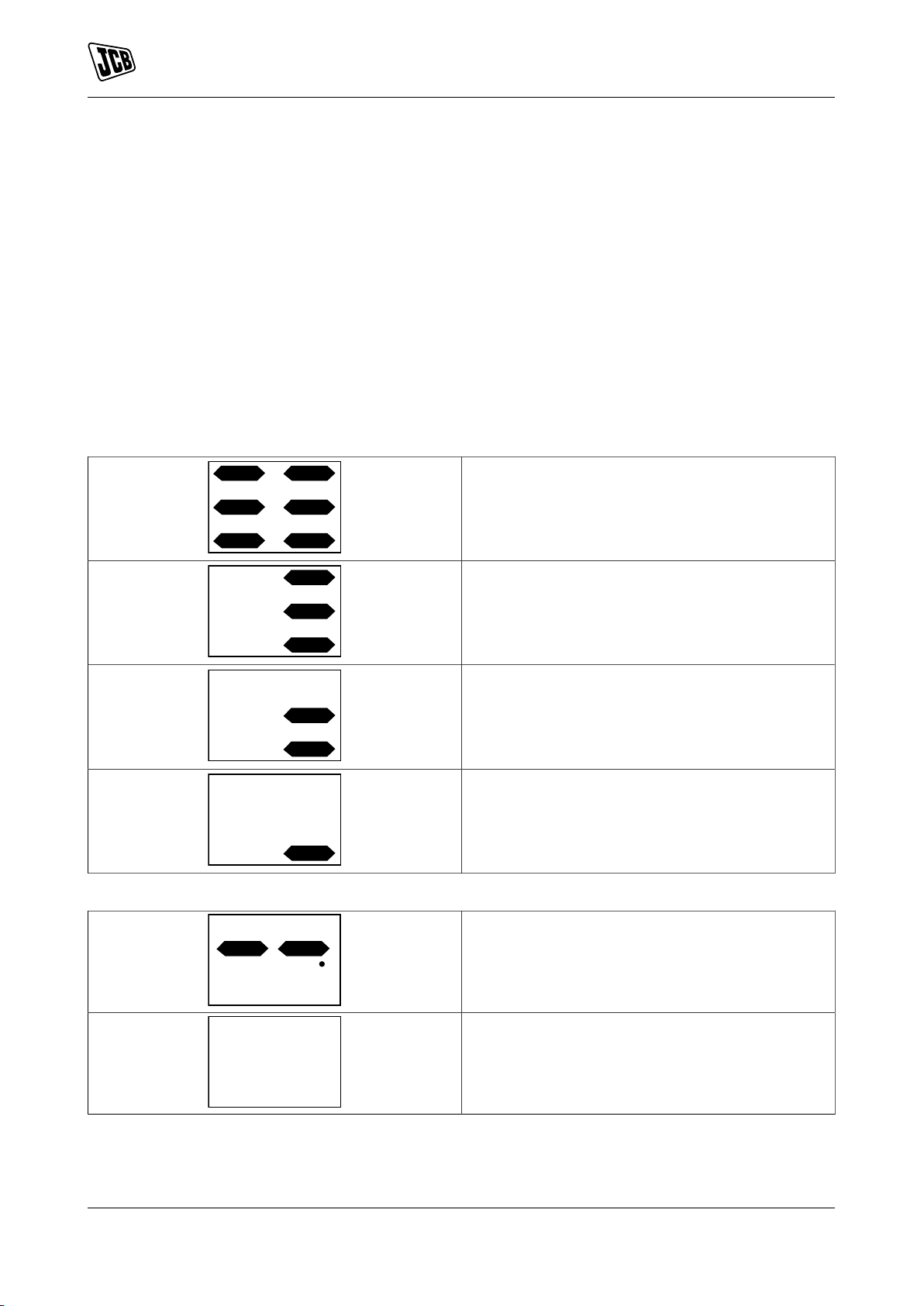

Platform Controller Display

The display is used to show the battery level and error codes. Refer to: Check (Electrolyte Level)

(Page 77). Refer to Figure 18.

Refer to: Fault-Finding (Page 101).

31 9831/3200-3 31

Page 40

Operation

Working with the Platform

Working with the Platform

General

Trip and Fall Hazards

• Prior to operation, make sure that all operator door and guard rails are fastened and secured in their

proper position.

• It is recommended that all persons in the platform wear full body harnesses with a short lanyard attached

to an authorised lanyard anchor point while operating this machine. For further information refer to JCB

dealer.

• Keep both feet firmly on the platform floor at all times. Never position ladders, boxes, steps, planks or

other similar items on unit to provide additional reach for any purpose.

• Never use the scissor arm assembly to gain accesses to or leave the platform.

• Keep your footwear and the platform floor clean of oil, mud and slippery substances.

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any energized (exposed or insulated) parts according

to the Minimum Approach Distance. Refer to Table 4.

• Allow for machine movement and electrical line swaying.

• Maintain a clearance of at least 3m between any part of the machine and its occupants, their tools, and

their equipment from any electrical line or apparatus carrying up to 50,000 volts. One foot additional

clearance is required for every additional 30,000 volts or less.

• The minimum approach distance may be reduced if insulating barriers are installed to prevent contact,

and the barriers are rated for the voltage of the line being guarded. These barriers shall not be part of

(or attached to) the machine. The minimum approach distance shall be reduced to a distance within the

designed working dimensions of the insulating barrier. This determination shall be made by a qualified

person in accordance with the employer, local, or governmental requirements for work practices near

energized equipment.

Table 4. Minimum Approach Distance

Voltage Range Minimum Approach Distance

0 to 300 V Caution!

300V to 50 KV 3m/10ft

50KV to 200KV 5m/15ft

200KV to 350KV 6m/20ft

350KV to 500KV 8m/25ft

500KV to 750KV 11m/35ft

750KV to 1000KV 14m/45ft

Tipping Hazards

• Make sure that the ground conditions are adequate to support the maximum tire load indicated on the tire

load decals located on the chassis adjacent to each wheel. Do not travel on unsupported surfaces.

• The user must be familiar with the driving surface before driving. Do not exceed the allowable sideslope

and grade while driving.

• Do not raise the platform or drive with platform raised while on or near a sloping, uneven, or soft surface.

Make sure that the machine is positioned on the level, solid (slabbed or paved) ground before elevating

platform or driving with the platform in the elevated position.

• Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces.

• Never exceed the maximum work load as specified on the platform. Keep all loads within the confines of

the platform. Evenly distribute the load across the platform, or the machine could become unstable.

• Do not operate the machine when wind conditions exceed the limit.

• Never attempt to use the machine as a crane. Do not tie-off machine to any adjacent structure. Never

attach wire, cable, or any similar item to platform.

• If the platform or scissor pack becomes stuck or snagged on an adjacent or overhead structure, do not

try to free the machine until all personnel are removed from the platform.

• Do not push or pull from the platform against any adjacent or overhead structures.

• Do not cover platform sides or carry large surface area items in the platform when operating outdoors.

The addition of such items increases the exposed wind area of the machine.

32 9831/3200-3 32

Page 41

Operation

A

B

C

D

H

G

F

E

Working with the Platform

• Do not increase platform size with unauthorised deck extensions or attachments.

• Do not raise the platform with the access apertures open. Keep the access apertures closed whilst the

platform is raised.

• If the scissor arm or platform is caught so that one or more wheels are off the ground, all the persons

and tools must be removed before attempting to free the machine. Use a crane, forklift truck, or other

appropriate equipment to stabilise the machine and remove the personnel.

Crushing and Collision Hazards

• Approved head protection must be worn by all operating and ground personnel.

• Keep hand and limbs out of the scissor arm assembly during operation and when raised unless safety

strut installed.

• Watch for obstructions around machine and overhead when driving. Check clearance above, to sides, at

bottom of machine when lifting or lowering the platform.

• Always post a lookout when driving in areas where vision is obstructed.

• Keep non-operating personnel at least 1.8m away from machine during all operations.

• Under all travel conditions, the operator must limit travel speed according to conditions of ground surface,

congestion, visibility, slope, location of personnel, and other factors.

• Be aware of stopping distances in all drive speeds.

• Exercise extreme caution at all times to prevent obstacles from striking or interfering with operating

controls and persons in the platform.

• Ensure that operators of other overhead and floor level machines are aware of the aerial work platform's

presence. Disconnect power to overhead cranes. Barricade floor area if necessary.

• Do not operate over ground personnel. Warn personnel not to work, stand, or walk under a raised platform.

Position barricades on floor as necessary.

Platform Information Decals

The decals are located at the backboard of the platform.

Figure 20.

A Machine model B Indoor rating

C Maximum wind speed D Outdoor rating

E Maximum wind speed F Maximum manual force

G Maximum manual force H Maximum platform height

33 9831/3200-3 33

Page 42

Operation

J

K

L

M

A

B

A

D

C

E

F

H

G

K

J

Working with the Platform

Figure 21.

J Weight distribution on the extended platform K Weight distribution on the extended platform

L Weight distribution on the retracted platform M Weight distribution on the retracted platform

Figure 22.

A Not suitable for outdoor use

The decals are located at the entry point of the platform.

Figure 23.

A Indoor rating (at 0m/s wind speed) B Weight distribution on the extended platform

C Weight distribution on the retracted platform D Outdoor Rating (at 12.5m/s wind speed)

E Weight distribution on the extended platform F Weight distribution on the retracted platform

G Maximum manual force H Wind speed

34 9831/3200-3 34

Page 43

Working with the Platform

A

B

A

J Maximum manual force K Wind speed

Figure 24.

A Not suitable for outdoor use

Extending and Retracting the Platform

WARNING Do not exceed the maximum rated load stated on the platform.

WARNING Do not stand on the extension platform while it is moving or not fixed.

CAUTION Do not lower the platform without completely retracting the platform extension.

Operation

Make sure that platform door is latched correctly before extending or retracting the platform.

There are three fixing positions for the extending platform

1. Press the pedal.

2. Hold and push the extension platform guard rail.

3. Release the pedal when the rail is in one of the three fixing positions. Make sure that it is engaged correctly.

Figure 25.

A Pedal B Fixing positions

4. Press the pedal and pull the extended guardrail to retract the platform.

Folding and Unfolding the Guardrails

CAUTION If the guardrails have been folded down, use extreme caution when entering and leaving the

operator station. Do not operate the controls from the platform when the guard rails are folded.

Fold the guardrails in order as shown. Refer to Figure 26.

1. To fold down each of guardrail, remove the lock pin for that guardrail.

35 9831/3200-3 35

Page 44

Operation

1

2

3

4

5

6

Working with the Platform

2. Take a firm hold on the top of the guardrail, carefully lower it until it is fully folded. Follow the sequence

of folding order

For unfolding the guardrails, follow the reverse sequence of folding order. Make sure that each lock pin is

installed when guardrails are unfolded.

Figure 26.

36 9831/3200-3 36

Page 45

Operation

A

Moving a Disabled Machine

Moving a Disabled Machine

General

Notice: Following any incident, thoroughly inspect the machine. Do not raise the platform until you are sure

that all damage has been repaired and that all controls are operating correctly. Test all functions first from

the ground controller, then from the platform controller.

WARNING Do not use the platform controller to release the platform when it is stuck, snagged or caught.

In this case, use the ground controller only when there are no persons on the platform.

If the machine becomes disabled, the machine must be made safe, lifted onto a transporter and moved to a

location where it can be repaired.

Towing, winching or pushing the machine without following the correct procedure will damage parts of the

hydraulic system. If possible, repair the disabled machine where it stands.

Lower the Platform (Emergency Operation)

The lowering alarm does not sound while lowering but if the machine is switched on the fault alarm will sound

due to lowering without electrical controls. Lowering may continue.

To lower the platform in emergency conditions:

1. Pull out the emergency lowering lever. Refer to Figure 27.

2. Release the lever to stop the operation.

Figure 27.

A Emergency lowering lever

Brake Release Function

1. Put blocks at the front and rear of all four wheels. Make sure they are securely in place.

2. The release valve is at the back of the chassis.

3. Push in the black brake release handle to close the brake valve and trap the brake pressure. Refer to

Figure 28.

4. Firmly pump the red brake release handle as required to release the brake. Refer to Figure 28.

5. Pull the black handle out after the machine is recovered to re-apply the brakes.

37 9831/3200-3 37

Page 46

Moving a Disabled Machine

A

B

Figure 28.

A Black brake release handle B Red brake release handle

Operation

38 9831/3200-3 38

Page 47

Operation

A

Lifting the Machine

Lifting the Machine

General

Lifting by Forklift

Do not lift the machine from the side. Lifting the machine from the side may cause machine damage.

1. Make the machine safe with the platform lowered.

2. Check the extension platform, controller and chassis parts are correctly secured.

3. Remove any loose items from the machine.

4. Keep the machine in the lowered position while lifting with the forklift.

5. Use the forklift slots at the ladder side at the end of the machine.

5.1. Align the forks with the forklift slots at the end of the machine.

5.2. Drive the forklift forwards until the forks carriage almost touches the ladder

5.3. When lifting the machine rotate the forks back slightly to ensure the machine will not slide off the forks.

Travel with the machine at the specified distance from the ground.

Length/Dimension/Distance: 0.4m

5.4. Level the forks before landing the machine.

Figure 29.

A Forklift slots

Lifting by Hoist

1. Make the machine safe with the platform lowered.

2. Check the extension platform, controller and chassis parts are correctly secured.

3. Remove any loose items from the machine.

4. Use the correct length of hoisting rope to prevent damage to the platform base and guardrail.

5. Make sure the hoist rigging is in the correct position. Adjust the hoist rigging to prevent machine damage

and keep the machine in the level position.

39 9831/3200-3 39

Page 48

Figure 30.

X

Y

Operation

Lifting the Machine

X X axis distance Y Y axis distance

5.1. You must consider the location of the centre of gravity on the machine, when you lift the machine.

Refer to Table 5.

Table 5. Location of the Centre of Gravity

Machine Model X axis Y axis

S1530E 620mm 511mm

S1930E 604mm 540mm

S2032E 955mm 625mm

S2632E 956mm 672mm

S2046E 801mm 530mm

S2646E 806mm 570mm

S3246E 808mm 638mm

S4046E 815mm 676mm

S4550E 1,058mm 754mm

40 9831/3200-3 40

Page 49

Operation

Transporting the Machine

Transporting the Machine

General

WARNING The safe transit of the load is the responsibility of the transport contractor and driver. Any

machine, attachments or parts that may move during transit must be adequately secured.

CAUTION Before moving the machine onto the trailer, make sure that the trailer and ramp are free from

oil, grease and ice. Remove oil, grease and ice from the machine tyres. Make sure the machine will not

foul on the ramp angle.

Check the condition of the transport vehicle before the machine is loaded on to its trailer.

Make sure that the transport trailer is suitable for the dimensions and weight of your machine. Refer to: Static

Dimensions (Page 84).

Before transporting the machine make sure you will be obeying the local rules and laws regarding machine

transportation of all the areas that the machine will be carried through.

Loading the Machine onto the Transporting Vehicle/Trailer

Make sure that platform controller is correctly secured. Secure the platform controller to the guardrail at the

mounting position provided in the front right corner of the platform. Insert a bolt through the controller cradle

into the threaded hole provided.

Lifting the Machine onto the Transporting Vehicle/Trailer

1. Turn the machine off and remove the key.

2. Remove any loose items from the machine.

3. Place the blocks at the front and rear of the trailer wheels.

4. Lift the machine on to the trailer.

5. Put blocks at the front and rear of all four wheels. Make sure they are securely in place.

6. Measure the maximum height of the machine from the ground. Make sure the truck driver knows the

clearance height before he drives away.

7. If required remove the lock pins from all four corners of the platform and fold the guardrails.

8. Secure the machine to the trailer bed with suitable chains. Use the tie down points indicated by the safety

decals.

41 9831/3200-3 41

Page 50

Figure 31.

A

Operation

Transporting the Machine

A Lock pin

Driving the Machine onto the Transporting Vehicle/Trailer

1. Put the blocks at the front and rear of the trailer wheels.

2. Lower the ramps and check for suitability.

Refer to: Performance Dimensions (Page 90).

3. Check the condition and security of the trailer side rails to make sure that the machine cannot be driven

off the trailer.

4. Drive the machine onto the trailer and position it taking into account the load distribution.

5. Put blocks at the front and rear of all four wheels. Make sure they are secure in place.

6. Turn the machine off and remove the key.

7. Remove any loose items from the machine.

8. Measure the maximum height of the machine from the ground. Make sure the truck driver knows the

clearance height before he drives away.

9. If required remove the lock pins from all four corners of the platform and fold the guardrails.

10. Secure the machine to the trailer bed with suitable chains. Use the tie down points indicated by the decals.

42 9831/3200-3 42

Page 51

Operation

Operating Environment

Operating Environment

General

For: Lead Acid Battery ............................................................................................................. Page 43