Page 1

1

Page 2

2

JCBD-JS2

PENDULUM JIGSAW

JCB is a byword around the world for quality, innovation and success.

With the application of stringent design parameters and utilising high

performance, modern materials and manufacturing processes, your

JCB product has been developed for optimum functionality and

practical application.

Used for the purposes for which it is intended, and with careful

maintenance, as outlined in this User Guide, your JCB product will

give years of satisfactory service.

Please read all of these safety and operating instructions

carefully before using this jigsaw. Please pay particular

attention to all of the sections of this User Guide that

carry warning symbols and notices.

Contents page

Product specification 3

Pack contents 3

Electrical safety 4

Safety instructions 5-6

Parts identification 7

Fitting the blade 8

Fitting the rip fence guide 9

Adjusting the cutting angle 9

Fitting the anti-splinter insert 10

Fitting the anti-scratch base plate 10

Using the blade guard 11

Fitting the vacuum adaptor 11

Setting the pendulum action 11

Variable speed selector 12

Operating the trigger switch 12

Using the jigsaw 13

Cleaning and maintenance 14

Service and repair 14

Environmental protection 14

Guarantee 15

Page 3

PRODUCT SPECIFICATION

Model number JCBD-JS2

Rated voltage 230VAC 50Hz

Input power 710 watts

No load variable speed 400 - 3200 strokes per minute

Pendulum action 4 stage

Mitre cutting 0 - 45o (Left and right)

Maximum cutting depth Wood - 80 mm

Steel - 10 mm

Aluminium - 30 mm

3

A - weighted sound pressure level Lp = 87.4 dB (A)

A - weighted sound power level Lw = 100. 4 dB (A)

Weighted root mean square vibration: 4.1 m/sec

PACK CONTENTS

Jigsaw JCBD-JS2

Parallel fence guide

Vacuum adaptor

Anti scratch base plate (fitted to base plate)

2 x wood cutting jigsaw blades (coloured black)

2 x metal cutting jigsaw blades (coloured red)

2

Anti splinter base plate insert

Hexagonal key

Carry case

Page 4

ELECTRICAL SAFETY

4

Warning: Read these safety instructions carefully

before connecting the jigsaw to the mains supply.

Make sure that the voltage of the electricity supply

is the same as that indicated on the rating plate on

the jigsaw.

This jigsaw may be fitted with a non-rewireable plug. If it becomes

necessary to change the fuse in the plug, the fuse cover must be

refitted. If the fuse cover is lost or damaged, the plug must not be

used until a suitable replacement is fitted. If the plug has to be

changed because it is not suitable for your socket, or becomes

damaged, it should be cut off and an appropriate plug fitted,

following the wiring instructions shown below. The plug that is

removed must be disposed of safely. Insertion into a 13 amp socket

could cause an electrical hazard.

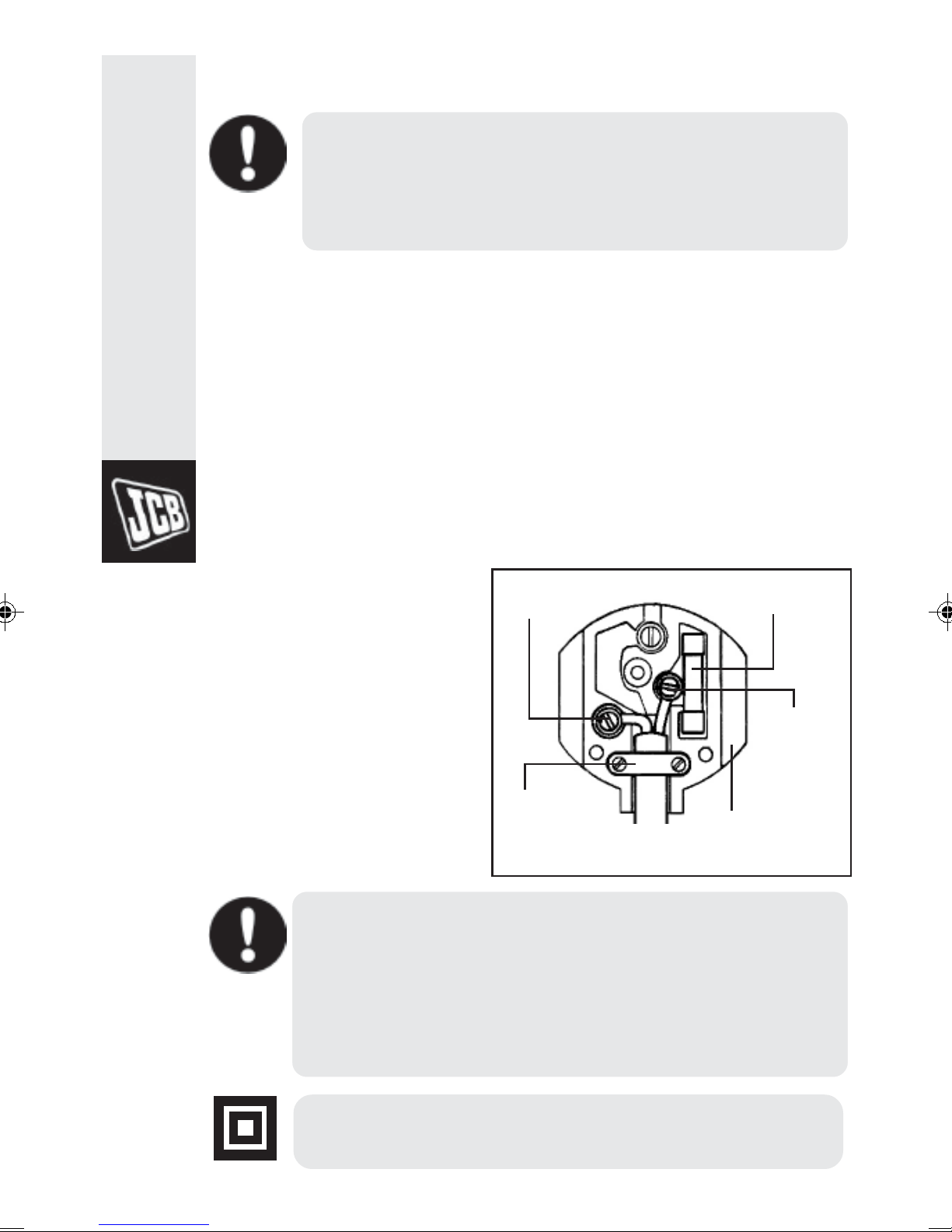

The wires in the mains lead are coloured in accordance with

the following code:- Blue = neutral; Brown = live.

If the colours of the wires in

the mains lead of the jigsaw,

do not correspond with the

markings on the terminals

Connect Blue

to N (neutral)

Fit the

recommended

fuse

of your plug, proceed as

follows.

The blue wire must be

connected to the terminal

marked N, or coloured black.

The brown wire must be

connected to the terminal

marked L, or coloured red.

Warning: No connection should be made to the Earth

terminal of the plug. A 5 amp fuse must be fitted.

This jigsaw is designed to operate on 230VAC 50 Hz.

Connecting it to any other power source may cause

damage to the tool. Do not allow this jigsaw to be

exposed to rain, or moisture.

This symbol indicates that this tool is Double

Insulated and does not require an Earth connection.

Make sure that

the outer sheath

of the cable is

held by the clamp

Connect

Brown to

L (live)

Mains plug made

to BS1363/A

requirements

Page 5

SAFETY INSTRUCTIONS

Warning: When using this jigsaw, basic safety

precautions, including the following should be

observed to reduce the risk of fire, electric shock

and personal injury. Make sure that you have read

all of these instructions before using the jigsaw.

Keep this user guide in a safe place for future

reference.

KEEP WORK AREA CLEAN - Cluttered work areas invite

accidents and injuries.

CONSIDER WORK AREA ENVIRONMENT - Do not expose power

tools to rain. Do not use power tools in damp, or wet locations.

Keep work area well lit. Never use power tools where there is a risk

of fire, or explosion.

KEEP CHILDREN AWAY - Do not allow children to touch the tools.

Visitors should be kept away from the work area.

STORE IDLE TOOLS - When not in use, all tools should be stored

in a dry, secure place out of the reach of children.

DO NOT FORCE THE TOOL - It will perform better and more

safely at the level for which it was designed.

USE THE RIGHT TOOL - Do not force small tools to do the job of

a heavy duty tool, or use for purposes for which they were not

intended.

DRESS PROPERLY - Do not wear loose clothing, or jewellerythat

can be caught in moving parts. Tie back long hair.

SAFETY GLASSES - Use safety glasses, and if appropriate, use dust

masks.

PROTECT YOUR EARS - Wear ear protectors.

DO NOT OVERREACH - Keep proper footing and balance at all

times.

SECURE THE WORK - Use clamps, or vices to hold the

workpiece. It is safer and it frees both hands to operate the tool.

MAINTAIN YOUR TOOLS - Keep the accessories sharp and clean.

Keep all handles and grips dry and clean.

DISCONNECT TOOLS - Disconnect all tools from the mains

supply when not in use, or when making adjustments etc.

REPAIRS - Have the tool repaired by a qualified person.

STAY ALERT - Watch what you are doing. Use common sense and

caution. Never operate tools when you are tired.

DO NOT ABUSE THE MAINS LEAD - Never carry the tool by the

mains lead, or pull it to disconnect it from the mains socket. Keep

the mains lead away from heat, oil and sharp edges.

AVOID UNINTENTIONAL STARTING - Never carry a plugged in

tool with a finger on the switch and ensure that the tool is switched

off when plugging in to the mains supply.

5

Page 6

6

SAFETY INSTRUCTIONS continued

Warning: Before operating this jigsaw make sure that

you have read and fully understand all of these extra

safety precautions. These safety precautions must be

observed when operating the jigsaw. Ensure that the

jigsaw is unplugged from the mains supply before

fitting, or removing the blade, or making any other

adjustments.

Make sure that the hexagonal key has been removed from the

blade securing cup head screws before switching the jigsaw on.

Remove all nails and metal objects from the workpiece before

starting to cut.

The jigsaw blade will continue to run for a few seconds after the

jigsaw is switched off. Always wait until the blade has completely

stopped before putting the jigsaw down.

Make sure that the jigsaw blade is securely and tightly fitted and

that the blade guard is in place before switching on.

Hold the jigsaw firmly and apply the base plate to the workpiece,

without engaging the blade, before switching on.

Make sure that the cutting path of the jigsaw is free of obstacles,

both above and below the cutting surface.

Do not work with the jigsaw above your head, or on overhead

applications.

If the blade becomes jammed, switch off immediately and

disconnect from the mains supply before clearing the obstruction.

Use only sharp and undamaged jigsaw blades. Always replace

blunt, bent, cracked, or damaged saw blades.

When cutting, the base plate must be flat on the work surface.

Make sure that the mains lead is kept to the rear of the work

area, away from the blade.

Never place your hand or fingers in front of the jigsaw blade when

cutting.

Page 7

PARTS IDENTIFICATION

1

6

13

12

34

2

7

5

6

11

14 15 16

17

1 Variable speed selector

2 On/Off trigger switch

3 Lock-On button

4 Handle

5 Mains cable

6 Cooling vents

7 Dust extraction port

8 Base plate adjustment

9 Base plate screw

7

910

8

18

10 Anti-scratch base plate cover

11 Parallel fence guide fixing screws

12 Blade guard

13 Pendulum adjustment lever

14 Hexagonal key

15 Anti-splinter insert

16 Dust extraction port adaptor

17 Parallel fence guide

18 Carrying/storage case

Page 8

8

FITTING THE BLADE

Warning: Ensure that the jigsaw is disconnected

from the mains supply before fitting, or removing the

blade, or making adjustments to the base plate, the

blade support roller, or the parallel fence guide.

To fit the blade to the jigsaw, proceed as follows.

1. Slide the blade guard to the upper position.

2. Loosen the two cup headed blade securing screws, using the

hexagonal key provided. Access to the two blade securing

screws can be gained through the slots in the front of the

blade guard.

3. Make sure that the blade teeth are facing forwards.

4. Push the blade shank as far as it will go into the blade

locating clip.

5. Slightly tighten the two blade securing screws alternately, to

position the blade.

5. Ensure that the blade is straight.

6. Fully tighten the two blade securing screws.

7. Push the blade guard down to the lower position.

If replacement blades are needed, standard plane, parallel

shank, 90 mm saw length blades are generally available from

most good DIY/tool stores.

Blade

securing

screws

Blade

guard

Blade

locating

clip

Warning: Use only sharp and undamaged jigsaw

blades. Do not use blunt, bent, cracked, or damaged

blades.

Page 9

FITTING THE PARALLEL FENCE GUIDE

The parallel fence guide helps you to cut in a straight line,

parallel to the edge of the workpiece. To fit and adjust the

parallel fence guide, proceed as follows.

1. Loosen the parallel fence guide locking screws.

2. Push the parallel fence guide through the locating slots.

3. Set the width required and tighten the locking screws.

When cutting, ensure that the parallel fence guide is resting

against the edge of the workpiece.The parallel fence guide can

be fitted to either side of the base plate.

Parallel fence

guide locking

screws

Parallel fence guide

9

ADJUSTING THE CUTTING ANGLE

To allow you to achieve angle cuts, the base plate can be tilted to

any angle up to of 45 on either side.

To adjust the cutting angle proceed as follows.

1. Make sure that the jigsaw is disconnected from the mains supply.

2. Raise the blade guard to the upper position.

3. Loosen the base plate adjusting screw.

4. Set the base plate at the required angle.

5. Retighten the base plate adjusting screw.

6. Make a test cut on a scrap of material to ensure that the

correct angle has been set.

Base plate

adjusting

screw

Page 10

FITTING THE ANTI-SPLINTER

10

INSERT

The-anti splinter insert should be fitted to the base plate when cutting

wood. The insert can only be used when the base plate is in the 90

position. To fit the insert, press it upwards from below, into the recess

provided in the base plate. To remove the insert push it down and out

of the base plate.

Anti-splinter

insert

Antisplinter

insert

FITTING THE ANTI-SCRATCH

BASE PLATE COVER

The anti-scratch base plate cover is supplied to prevent damage to

the surface of delicate, or fragile materials. To fit it, place it over the

metal base plate and push firmly until it snaps into place. To remove

the cover, carefully lever out the end clips.

Base

plate

Base plate

cover

End clips

Page 11

USING THE BLADE GUARD

Warning: Ensure that the blade guard is in the lower

position when operating the jigsaw. If the base plate

is positioned to make an angle cut make sure that the

base plate is in the lowest possible position. Do not

use the jigsaw without the blade guard.

FITTING THE DUST EXTRACTION

PORT ADAPTOR

The jigsaw is supplied with a dust extraction port and a dust

extraction port adaptor. It may be necessary to fit the adaptor

before connecting to a

vacuum cleaner.

The adaptor has a bayonet

fitting. Push the adaptor into

the dust extraction port and

twist it to secure it. The dust

extraction will be most

efficient when the blade

guard is in the lower

position.

Twist

Adaptor

Push

Dust

extraction

port

11

SETTING THE PENDULUM ACTION

The 4 stage, pendulum action is designed to give the most efficient

cutting action in a variety of materials.

To set the pendulum action, rotate the

adjuster to the desired setting. When the

correct setting is selected, the blade

achieves maximum penetration on the

upward cutting stroke and is lifted back,

away from the material, on the downward

non-cutting stroke. This gives improved

quality of cut, and longer blade life. The

table below shows the recommended

settings.

Position Wood Metal Plastic

III Fast cuts - PVC

II Thick wood - Fibreglass

Acrylic

I Plywood Aluminium -

Chipboard Non-ferrous -

0 Thin wood Sheet metal -

Fine cuts

Page 12

VARIABLE SPEED SELECTOR

12

The variable speed selector dial is used to control the speed at

which the saw operates. This is known as the blade stroke rate. To

pre-select the required blade stroke rate, turn the selector

dial to the relevant number. A low number gives a low stroke rate

and a high number gives a high stroke rate. The stroke rate should

be adjusted according to the material being cut. The table below

shows some recommended settings. It should only be used as a

guide. Make a test cut on a scrap of material to ensure that the

correct stroke rate has been selected.

Material Setting

Wood 5 - 6

Metal 2 - 3

Aluminium 3 - 5

PVC 3 - 4

Variable speed

selector dial

OPERATING THE TRIGGER SWITCH

To switch the jigsaw on, fully squeeze the ON/OFF trigger switch.

To switch the jigsaw off, release the trigger switch. If continuous

operation is required, the trigger switch can be locked in the ON

position. To lock the switch ON, squeeze the trigger switch, press

the lock-on button and release the trigger switch. To release the

lock-on button squeeze the trigger switch and then release it.

Make sure that you release the lock-on button before

disconnecting from the mains supply. Before plugging the jigsaw

into the mains supply, make sure that the trigger switch is in the

OFF position.

Switch in Off position Switch in locked-On position

Page 13

USING THE JIGSAW

Warning: Make sure your cutting line is free of nails

before cutting. Do not cut hollow pipes. Do not cut

wood thicker than 80mm, steel thicker than 10mm, or

aluminium thicker than 30mm. Make sure that you

have adequate clearance for the blade beneath the

material. Make sure the blade is not touching the

material when you first operate the trigger switch.

Do not remove the jigsaw from the workpiece until

the blade has stopped moving. The blade and the

material will be hot when cutting is finished.

CUTTING METCUTTING MET

CUTTING MET

CUTTING METCUTTING MET

The jigsaw will cut light gauge ferrous sheet and non-ferrous

metals such as copper, brass and aluminium. Cutting metal will

take longer than cutting any other material and you should not

force the blade into the metal as this will shorten the life of the

blade and may damage the material that you are cutting.

Where possible you should clamp the workpiece to a backing

sheet such as plywood, or other soft material. Then cut both

the metal and the backing piece together. Make sure that you

have selected the correct metal cutting jigsaw blade for the job.

It is advisable to spread a thin film of oil along the cutting line

before starting to cut.

ALAL

AL

ALAL

13

CUTTING LCUTTING L

CUTTING L

CUTTING LCUTTING L

The blades of the jigsaw cut on the upstroke. Any splintering of

the material will therefore occur on the upper face nearest the

base plate. When sawing thin wood or plastic laminates, use a

fine tooth metal cutting blade and cut from the back surface of

the material. To further minimize the risk of chipping the edges,

clamp a piece of scrap wood, or hardboard to both sides of the

material and cut through the complete assembly.

POCKET CUTTINGPOCKET CUTTING

POCKET CUTTING

POCKET CUTTINGPOCKET CUTTING

To make a cut which is not on the edge of the material, first

mark clearly the start point for the cut you wish to make. Drill a

10mm hole in the material and lower the blade through the

hole until the base is flat against the workpiece. Now cut in the

normal way.

AMINAAMINA

AMINA

AMINAAMINA

TESTES

TES

TESTES

Page 14

14

CLEANING AND MAINTENANCE

Warning: Make sure that the jigsaw is switched off

and disconnected from the mains supply before

starting any cleaning, or maintenance procedures.

After use, clean all dust and wood chippings from the jigsaw.

Clean all of the ventilation slots on the motor housing. The

blade locating clip and support roller should be kept clean and

lightly oiled at regular intervals. Keep the handle clean and free

from oil and grease. Resin and glue on the blade causes poor

cutting results. Clean the blade after use. Make sure that the

base plate is free from dirt and grease. There are no user

servicable parts inside this jigsaw. Refer to qualified service

personnel if internal maintenance is required. Always store the

jigsaw in the carrying case. If replacement blades are needed,

standard plane, parallel shank, 90 mm saw length blades are

generally available from most good DIY/tool stores.

SERVICE AND REPAIR

Should the jigsaw require repair during the guarantee period,

please return it to the place of purchase. You will need to

provide proof of purchase to obtain a free of charge repair or

replacement. If the jigsaw should require repair after the

guarantee has expired, please contact the Customer Help Line

on 0845 602 1381.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of

them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and

disposed of in a manner which is compatible with

the environment.

Page 15

GUARANTEE

This product is guaranteed for twelve months from the date of

original purchase. Any defect that arises due to faulty materials,

or workmanship will be repaired free of charge, where possible,

during this period by the dealer from whom you purchased it.

The guarantee is subject to the following provisions:

The guarantee is only valid within the boundaries of the country

of purchase.

The product must be correctly assembled and operated in

accordance with the instructions contained in this User Guide.

The guarantee does not cover accidental damage, misuse, or

consumable items such as jigsaw blades.

The guarantee will be rendered invalid if the product is resold, or

has been damaged by inexpert repair.

15

The manufacturer disclaims any liability for incidental, or

consequential damages.

The guarantee is in addition to and does not diminish your

statutory, or legal rights.

Customer Help Line number: 0845 602 1381

IDS-JS2-REV4-JUN02

Page 16

Loading...

Loading...