Page 1

Important! It is essential that you read the instructions in this manual before assembling,

maintaining and operating this machine.

Subject to technical modifications.

Keep the instruction for future reference.

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

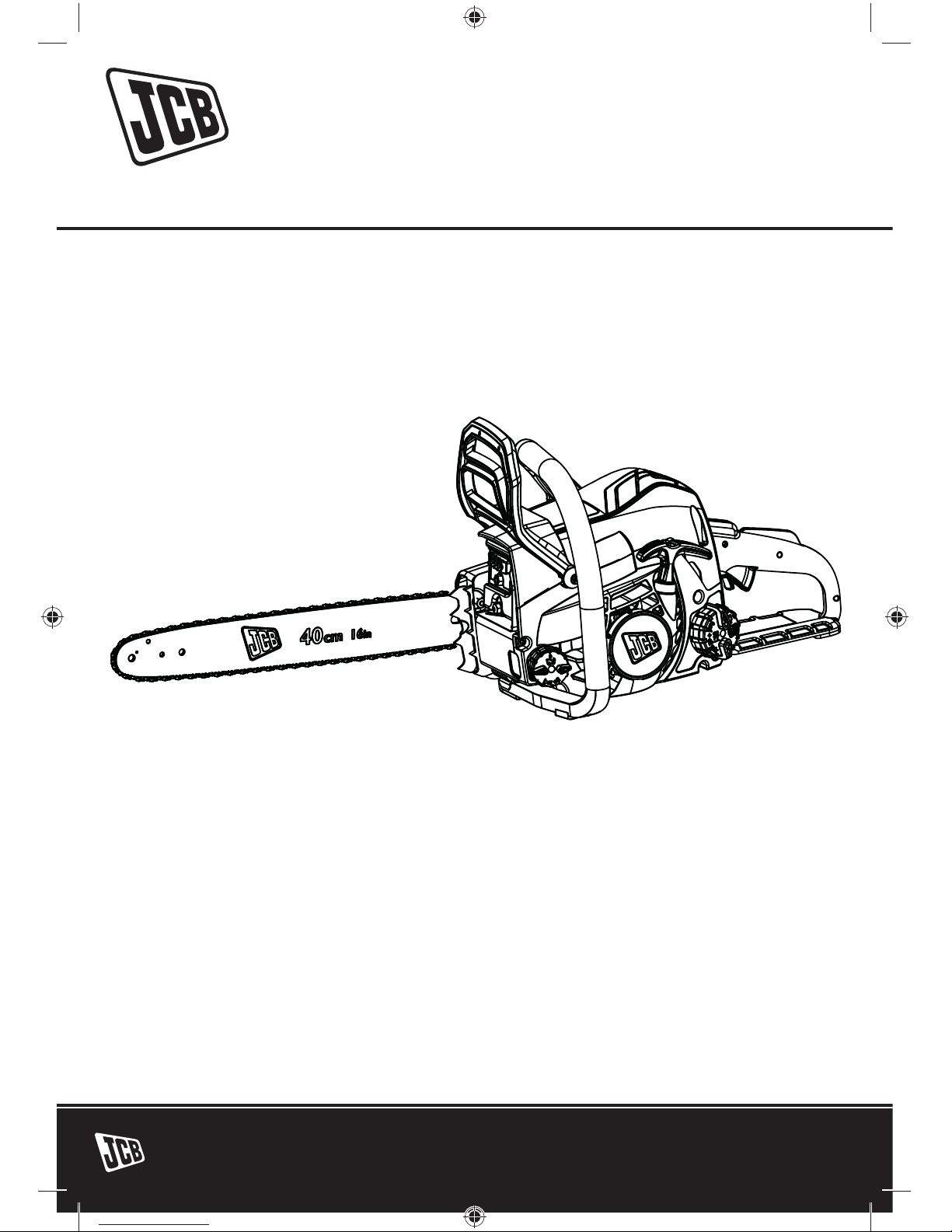

SAFETY AND OPERATING MANUAL

ORIGINAL INSTRUCTIONS

CHAINSAW

JCB-CS38

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 1JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 1 12/3/2010 5:57:34 PM12/3/2010 5:57:34 PM

Page 2

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

GENERAL SAFETY RULES

INTENDED USE

The chainsaw is designed for cutting branches, trunks, logs and beams. It is only

designed to cut wood and to be used outdoors.

Do not use the chainsaw for other purposes not listed above.The chainsaw is not to

be used for professional tree services. It is not to be used by children or by persons

not wearing adequate personal protective equipment and clothing.

For safe operation, read and understand all instructions before using the chainsaw.

Follow all safety instructions. Failure to follow all safety instructions listed below can

result in serious personal injury.

Know your tool. Read the operator’s manual carefully. Learn the saw’s

applications and limitations as well as the specific potential hazards related to the

tool. We recommend you attend a professional training course to increase your

awareness and proficiency in all chainsaw operations.

Kickback may occur when the nose or tip of the guide bar touches an object, or

when the wood closes in and pinches the saw chain in the cut. Tip contact in some

cases may cause a lightning-fast reverse reaction, kicking the guide bar up and

back toward the operator. Pinching the saw chain along the top of the guide bar

may push the guide bar rapidly back toward the operator. Either of these reactions

may cause you to lose control of the saw, which could result in serious personal

injury. Do not rely exclusively upon the safety devices built into the saw. As a

chainsaw user, you should take every step to keep your cutting jobs free from

accident and injury.

With a basic understanding of kickback, you can reduce or eliminate the element

of surprise. Sudden surprise contributes to accidents.

Keep a good firm grip on the saw with both hands when the engine is running.

Place your right hand on the rear handle and your left hand on the front handle with

your thumbs and fingers encircling the chainsaw handles. A firm grip together with

a stiff left arm will help you maintain control of the saw if kickback occurs.

Make sure that the area in which you are cutting is free from obstructions. Do not

let the nose of the guide bar contact a log, branch, fence or any other obstruction

that could be hit while you are operating the saw.

Always cut with the engine running at full speed. Fully squeeze the throttle trigger

and maintain a steady cutting speed.

Do not overreach or cut above chest height.

Follow the manufacturer’s sharpening and maintenance instructions for the saw

chain.

Only use replacement bars and chains specified by the manufacturer or the

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 2JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 2 12/3/2010 5:58:23 PM12/3/2010 5:58:23 PM

Page 3

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

equivalent.

Do not operate a chainsaw with one hand. Serious injury to the operator, helpers,

bystanders may result from one-handed operation. A chainsaw is intended for twohanded use.

Do not operate a chainsaw when you are exhausted. Fatigue causes

carelessness. Be more cautious before rest periods and towards the end of your

shift. Never operate a chainsaw when under the influence of medication, drugs or

alcohol.

Use safety footwear. Do not wear loose clothing. Wear protective gloves and

clothing, and eye, hearing and head protection devices.

Heavy protective clothing may increase operator fatigue, which could lead to

heat stroke. During hot and humid weather, heavy work should be scheduled for

early morning or late afternoon hours when temperatures are cooler.

Do not stand on any unstable surface while using the chainsaw, such as ladders,

scaffolds, trees, etc. Always keep a sound and firm footing.

Use caution when handling fuel. Move the chainsaw at least 10 m from the fuelling

point before starting the engine.

Do not allow other persons to be near the chainsaw when starting or cutting

with the chainsaw. Keep bystanders and animals out of the work area.

Do not start cutting until you have a clear work area, secure footing and a

planned retreat path from the falling tree.

Keep all parts of your body away from the saw chain when the engine is running.

Always carry the chainsaw with the engine stopped and the brake engaged,

the guide bar and saw chain to the rear and the silencer away from your body. When

transporting the chainsaw, use the appropriate guide bar scabbard.

Do not operate a chainsaw that is damaged, improperly adjusted or not completely

and securely assembled. Be sure that the saw chain stops moving when the throttle

control trigger is released.

Shut off the engine before setting the chainsaw down. Do not leave the engine

running unattended. As an additional safety precaution, apply the chain brake prior

to setting down the saw.

Use extreme caution when cutting small-size brush and saplings because

slender material may catch the saw chain and be whipped toward you or pull you

off balance.

When cutting a limb that is under tension, be alert for spring back so that you will

not be struck when the tension in the wood fibres is released.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 3JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 3 12/3/2010 5:58:25 PM12/3/2010 5:58:25 PM

Page 4

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Keep the handles dry, clean, and free of lubricant or fuel mixture.

Beware of carbon monoxide poisoning. Operate the chainsaw only in well-

ventilated areas.

Do not climb a tree to use the chainsaw, unless you have been specifically

trained to do so.

Do not operate the chainsaw from a ladder; this is extremely dangerous.

All chainsaw service, other than the items listed in the instruction manual and all

maintenance should be performed by competent chainsaw service personnel. (For

example, if improper tools are used to remove the flywheel or if an improper tool

is used to hold the flywheel in order to remove the clutch, structural damage to the

flywheel could occur and subsequently could cause the flywheel to burst.)

Always have a fire extinguisher available when using a chainsaw.

Use only the replacement guide bars and low kickback chains specified for

the saw.

Do not adapt the powerhead to a bow guide or use it to power any attachments

or devices not listed for the saw.

The petrol-powered saw is intended for infrequent use by homeowners, cottagers

and campers, and for such general applications as clearing, pruning, cutting

firewood, etc. It is not intended for prolonged use. Prolonged periods of operation

can cause circulatory (white finger) problems in the user’s hands due to vibration.

For such use, it may be appropriate to use a saw having an anti-vibration feature.

Save these instructions. Refer to them frequently and use to instruct other users.

If you loan someone the tool, loan them these instructions also.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 4JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 4 12/3/2010 5:58:25 PM12/3/2010 5:58:25 PM

Page 5

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

ADDITIONAL SAFETY RULES FOR YOUR CHAINSAW

Do not cut vines and/or small underbrush (a diameter of less than 3 in.).

Silencer surfaces are very hot during and immediately after operation of the

chainsaw; keep all body parts away from the silencer. Serious burns may occur if

contact is made with the silencer.

Always hold the chainsaw with both hands when the engine is running. Use

a firm grip with thumbs and fingers encircling the chainsaw handles.

Never let anyone use the chainsaw who has not received adequate

instructions in its proper use. This applies to rentals as well as privately-owned

saws.

Before you start the engine, make sure the saw chain is not contacting any

object.

Wear snug-fitting clothing. Always wear heavy, long trousers, boots and gloves.

Do not wear jewellery, shorts, sandals or go barefoot. Loose clothing could be

drawn into the engine or catch the chain or underbrush. Wear overalls, jeans or

chaps made of cut-resistant material or that contain cut-resistant inserts. Secure

hair so that it is above shoulder length.

WARNING

Wear safety clothing which is designed for chainsaw operators.

Wear non-slip safety footwear and heavy-duty gloves to improve your grip and

to protect your hands.

Wear eye protection which is marked to comply with BS EN166, as well as

hearing and head protection, when operating this equipment.

Keep bystanders and animals out of the work area. Do not allow other persons

to be nearby during starting or cutting with the chainsaw.

Note: The size of the work area depends on the job being performed as well as

the size of the tree or work piece involved. For example, felling a tree requires a

larger work area than making other cuts (i.e. bucking cuts, etc.).

Follow the sharpening and maintenance instructions for the saw chain.

Never operate a chainsaw that is damaged, improperly adjusted or has been

modified (particularly guards or safety devices), or is not completely and

securely assembled. Be sure that the saw chain stops moving when the throttle

control trigger is released. If the saw chain moves at idle speed, the carburettor

may need adjusting. If the saw chain still moves at idle speed after adjustment has

been made, contact an authorized service centre for adjustment and discontinue

use until the repair is made.

Do not smoke during refueling.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 5JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 5 12/3/2010 5:58:27 PM12/3/2010 5:58:27 PM

Page 6

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

To reduce the risk of fire and burn injury, handle fuel with care. It is highly

flammable.

Mix and store fuel in a container approved for petrol.

Mix fuel outdoors where there are no risks from sparks or flames.

Select bare ground, stop the engine, and allow it to cool before refuelling.

Loosen the fuel cap slowly to release any pressure and to keep fuel from escaping

around the cap.

Tighten the fuel cap securely after refuelling.

Wipe spilled fuel from the unit. Move 10 m away from refuelling site before starting

engine.

NEVER attempt to burn off spilled fuel under any circumstances.

The product is very noisy when operating. To prevent long term hearing damage,

wear hearing protection and keep other persons at least 15 m away from the work

area. Operating similar tools nearby increases risk of injury.

Use of hearing protection reduces the ability to hear warnings (shouts or alarms). The

operator must pay extra attention to what is happening around the work area.

Kickback is a dangerous reaction that can lead to serious injury. Do not rely

only on the safety devices provided with the saw. As a chainsaw user, you must take

special safety precautions to help keep your cutting jobs free from accident or injury.

Additional risks

Even when using the chainsaw as intended, there still remains additional risk of harm

which cannot be fully prevented. The following list of potential hazards should be read

and understood. You should pay extra attention and care to these items to reduce the

risk of injury.

Contact with exposed cutting teeth and saw chain.

Access to rotating parts (the saw chain).

Unexpected, abrupt movement (kickback) of the guide bar.

Flying chain parts (thrown off or broken).

Flying material (cut from the work piece).

Inhalation of saw dust and particles or emissions from the petrol engine.

Skin contact with petrol / oil.

Loss of hearing if no hearing protective equipment is worn during use.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 6JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 6 12/3/2010 5:58:27 PM12/3/2010 5:58:27 PM

Page 7

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

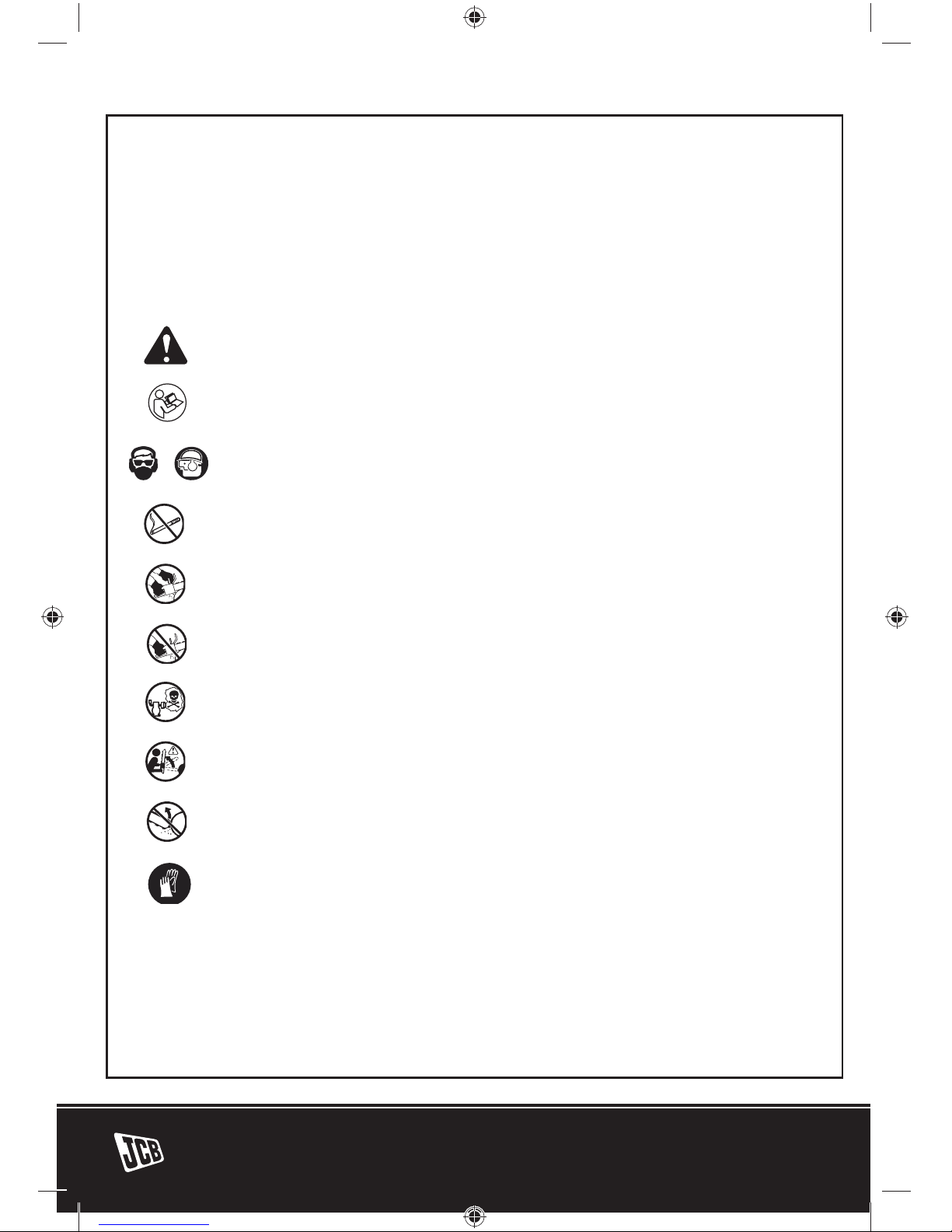

SYMBOLS

Thank you for your purchase.

The chainsaw has been engineered and manufactured to a high standard for

dependability, ease of operation, and operator safety. If properly cared for, it will give

years of rugged, trouble-free performance.

Important: Some of the following symbols may be used on the tool. Please learn

the meaning. Proper interpretation of the symbols will allow better and safer operation of the tool.

Indicates danger, warning or caution. It means “Attention! Your safety is

involved.”

Read the operation manual and follow all warnings and safety

instructions.

Wear eye, ear and head protection.

Do not smoke.

Hold and operate properly with both hands.

Do not operate with one hand only.

Engines produce carbon monoxide which is odorless and poisonous. Do

not operate in enclosed area.

Beware of kickback.

Avoid bar nose contact.

Wear non-slip, heavy-duty protective gloves when handling the saw.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 7JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 7 12/3/2010 5:58:27 PM12/3/2010 5:58:27 PM

Page 8

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Use unleaded petrol intended for motor vehicle use with an octane rating

of 91 ([R+M]/2) or higher. The product is powered by 2-stroke cycle

engine and requires pre-mixing petrol and 2-stroke lubricant.

Keep all bystanders and animals at least 15 m away.

Add bar and chain oil each time you add fuel to the saw.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 8JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 8 12/3/2010 5:58:27 PM12/3/2010 5:58:27 PM

Page 9

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

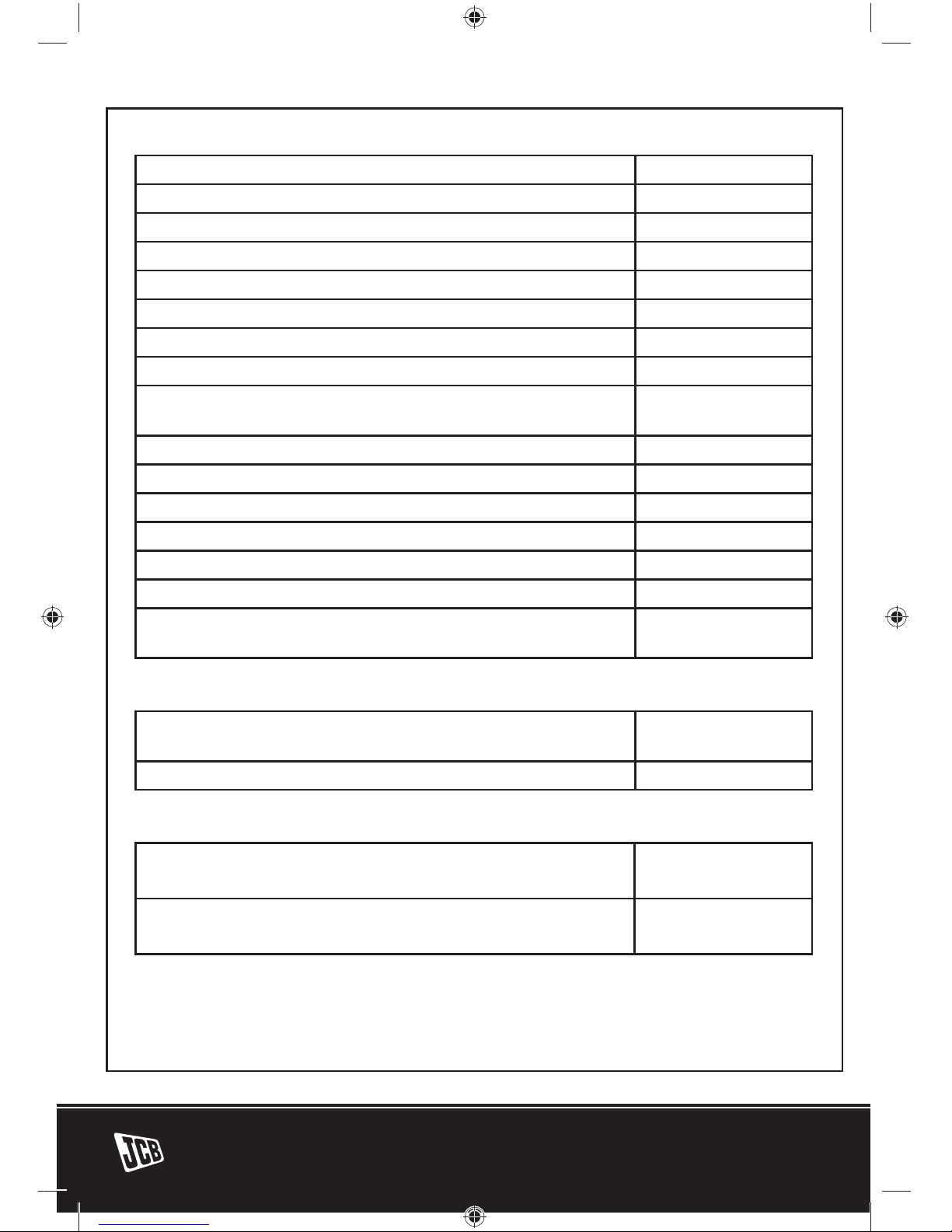

TECHNICAL DATA

SPECIFICATIONS

Weight - no bar, chain, fuel [kg or (lb)] 4.7 or (10.36)

Weight - with bar and chain, no fuel [kg or (lb)] 5.4 or (11.90)

Fuel tank volume [cm

3

or (L)] 340 or (0.34)

Lubricant tank volume [cm

3

or (L)] 192 or (0.192)

Bar length [cm or (inch)] 40 or (16)

Usable cutting length [cm or (inch)] 37 or (14.57)

Chain pitch [mm or (inch)] 9.53 or (0.375)

Chain gauge [mm or (inch)] 1.27 or (0.05)

Chain type 3/8" low profi le full

complement

Drive sprocket 6 teeth x 3/8"

Engine displacement [cm

3

or (L)] 42 or (0.042)

Maximum engine power (ISO 7293) (kW) 1.7

Maximum engine speed with attachment (r/min) 11,000

Maximum engine speed with attachment (r/min) (reference) 12,500

Idling engine speed (r/min) 2,600-3,600

Specifi c fuel consumption at maximum engine power [g/

kW.h or (L/kW.h)]

426 or (0.587)

NOISE INFORMATION (ISO 22868)

Sound pressure level LpAav:101dB(A),

KpA=3 dB(A)

Sound power level dB(A) 112

VIBRATION INFORMATION (ISO 22867)

Front handle Carlton / Oregon

8.2 m/s2, K=1.5

Rear handle Carlton / Oregon

7.7 m/s2, K=1.5

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 9JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 9 12/3/2010 5:58:28 PM12/3/2010 5:58:28 PM

Page 10

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

BAR AND CHAIN

(Carlton guide bar only use with Carlton saw chain; Oregon guide bar only use with

Oregon saw chain)

Guide bar (Carlton)

Carlton part number

Colour

16-10W-N156-MHC

Black

Chain (Carlton)

Carlton part number N1C-BL-56E B

Guide bar (Oregon)

Oregon part number

Colour

160 SDEA 041

Black

Chain (Oregon)

Oregon part number 91P-56P

CERTIFICATION / COMPLIANCE

Full CE approval includes:

Safety

EMC

Noise

Vibration

Yes

Yes

Yes

Yes

Emission compliance EU stage 2

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 10JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 10 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 11

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

COMPONENT LIST AND ASSEMBL Y

1. Starter grip

2. Trigger release

3. Throttle trigger

4. Starter housing

5. Chain lubricant cap

6. Rear handle

7. Engine cover

8. Front handle

9. Front hand guard/chain brake

10. Clutch cover

11. Chain tension dial

12. Clutch cover lock knob

13. Primer bulb

14. Ignition switch

15. Choke lever

16. Fuel cap

17. Flats on drive links

18. Brake position - chainsaw brake

19. Run position - chainsaw brake

20. Silencer

21. Start position

22. Run position

23. Kickbar danger zone

24. Clean the chain brake

25. Idle speed screw “T”

26. Pull

27. Push

28. Rotational kickback

29. Proper hand grip position

30. Improper grip

31. Proper grip

32. Chain line

33. Thumbs on underside of handle bar

34. Straight arm

35. Planned line of fall

36. 135 degree from planned line of fall

37. Path of safe retreat

38. Hinge - 5 cm or 1/10 diameter

39. Back cut

40. Notch approximately 1/3 diameter of

the trunk

41. Hinge

42. Wedge

43. Vertical cut

44. Lodge section

45. Horizontal cut

46. Kickback

47. Log supported at one end

48. Finishing cut

49. Load

50. 1st cut 1/3 diameter

51. Log supported at both ends

52. Overbucking

53. Underbucking

54. Second cut

55. Cut limbs one at a time and leave

support limbs under tree until log is

cut

56. Springpole

57. Chain drive links

58. Cutters

59. Chain rotation

60. Bar groove

61. Adjusting pin

62. Chain tension pin hole

63. Sprocket

64. Rotate clutch cover knob clockwise

to secure

65. Loosen chain

66. Tighten chain

67. Raker (depth gauge) clearance

68. Inspect drive sprocket

69. Gullet

70. Heel

71. Rivet hole

72. Top plate

73. Cutting corner

74. Side plate

COMPONENT LIST

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 11JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 11 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 12

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

ASSEMBLY

Packing list

Chainsaw

Scabbard

Combination wrench

2-cycle engine lubricant

Gift box

Operator’s manual

Unpacking

Carefully remove the product and any accessories from the box. Make sure that

all items listed in the packing list are included.

Inspect the product carefully to make sure no breakage or damage occurred

during shipping.

Do not discard the packing material until you have carefully inspected and

satisfactorily operated the product.

If any parts are damaged or missing, please call your service centre for assistance.

Note: The chainsaw has been factory tested. It is normal to find some slight lubri-

cant residue on the saw.

75. Depth gauge

76. Toe

77. Left hand cutters

78. Right hand cutters

79. Top plate filing angle

80. Correct

81. Less than 30 degree

82. More than 30 degree

83. Incorrect

84. Side plate filing angle

85. Hook

86. Backward slope

87. Depth gauge jointer

88. Flat file

89. Restore original shape by rounding

the front

90. Lubricating hole

91. Air filter

92. Chain brake

93. Post

94. Starter cover

95. Clean engine fins

96. Clean flywheel fins

97. Fuel filter

98. Deflector

99. Deflector retaining nut

100. Spark arrestor

101. Bumper spike bar

102. Bolt & nut

103. Gasket

104. T25 T orx Screwdriver

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 12JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 12 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 13

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

WARNING

If any parts are damaged or missing, do not operate the tool until the parts are replaced.

Failure to heed this warning could result in serious personal injury.

WARNING

Do not attempt to modify the product or create accessories not recommended for

use with the product. Any such alteration or modification is misuse and could result in

hazardous condition leading to possible serious personal injury.

WARNING

Before first use, it is essential that you ensure the bar and chain have not become

loose in transit. Never operate a chainsaw with incorrectly adjusted chains. Failure to

follow these steps could result in severe personal injury.

ADJUSTING THE CHAIN TENSION

See Figures 2-3, 37, 42-45.

WARNING

Never touch or adjust the chain while the motor is running. The saw chain is very sharp.

Always wear protective gloves when performing maintenance on the chain.

1. Stop the engine before setting the chain tension.

2. Slightly loosen the clutch cover lock knob by pressing in and rotating counter

clockwise (Figure 37).

3. Turn the chain tension dial clockwise to tension the chain (Figure 44).

Note: A cold chain is correctly tensioned when there is no slack on the underside

of the guide bar, the chain is snug, and it can be turned by hand without binding.

4. Re-tension the chain whenever the fl ats on the drive links hang out of the bar

groove (Figure 3).

Note: During normal saw operation, the temperature of the chain increases. The

drive links of a correctly tensioned warm chain will hang approximately 1.2 mm out

of the bar groove. The tip of the combination wrench can be used as a guide to help

determine the correct warm chain tension.

Note: New chains tend to stretch; check the chain tension frequently and tension

as required. This applies for a NEW tool.

5. Lift the tip of the guide bar up to check for sag (Figure 43).

6. Release the tip of the guide bar and turn the chain tension dial clockwise. Repeat

this process until the sag does not exist.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 13JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 13 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 14

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

7. Hold the tip of the guide bar up and tighten the clutch cover lock knob securely.

The chain is correctly tensioned when there is no sag on the underside of the

guide bar, the chain is snug, but it can be turned by hand without binding. Ensure

that the chain brake is not set.

Note: If chain is too tight, it will not rotate. Loosen the clutch cover lock knob by

pressing in and slightly rotating counter clockwise, then rotate the chain tension

dial counter clockwise. Lift the tip of the guide bar up and re-tighten the clutch

cover lock knob securely. Ensure that the chain will rotate without binding.

CAUTION

A chain tensioned while warm may be too tight upon cooling.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 14JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 14 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 15

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

OPERATING INSTRUCTIONS

WARNING

Do not allow familiarity with this product to make you careless. Remember that a

careless fraction of a second is sufficient to inflict serious injury.

WARNING

Always wear safety goggles or safety glasses with side shields when operating

power tools. Failure to do so could result in objects being thrown into your eyes

resulting in possible serious injury.

WARNING

Do not use any attachments or accessories not recommended by the manufacturer

of this product. The use of attachments or accessories not recommended can result

in serious personal injury.

WARNING

Wear eye protection which is marked to comply with EN 166, as well as hearing and

head protection, when operating this equipment. Failure to heed this warning could

result in serious personal injury.

WARNING

Exposure to vibrations through prolonged use of petrol-powered hand tools could

cause blood vessel or nerve damage in the fingers, hands and joints of people

prone to circulation disorders or abnormal swellings. Prolonged use in cold weather

has been linked to blood vessel damage in otherwise healthy people. If symptoms

such as numbness, pain, loss of strength, change in skin color or texture or loss

of feeling occur in fingers, hands or joints, discontinue use of this tool and seek

medical attention. An anti-vibration system does not guarantee the avoidance of

these problems. Users who operate power tools on a continual and regular basis

must monitor closely their physical condition and the condition of this tool.

FUELING AND REFUELING

WARNING

Always shut off engine before fuelling. Never add fuel to a machine with a running

or hot engine. Move at least 10 m from refuelling site before starting the engine. DO

NOT SMOKE! Failure to heed this warning could result in serious personal injury.

WARNING

Check for fuel leaks. If found, correct them before using the saw to prevent fire or

burn injury.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 15JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 15 12/3/2010 5:58:29 PM12/3/2010 5:58:29 PM

Page 16

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Fuel is highly flammable. Always handle with care.

Always refuel outdoors where there are no sparks and flames. Do not inhale fuel

vapors.

Do not let petrol or lubricant come in contact with your skin. If comes in contact with

your skin, wash immediately with soap and plenty of water.

Keep petrol and lubricant away from your eyes. If petrol or lubricant comes in

contact with your eyes, wash them immediately with clean water. If irritation sill

exists, see a doctor immediately.

Clean up spilled petrol immediately.

TO MIX THE FUEL

The product is powered by a 2-cycle engine and requires pre-mixing petrol with

2-cycle lubricant. Pre-mix unleaded petrol and 2-cycle engine lubricant in a clean

container approved for petrol.

The engine is certified to operate on unleaded petrol intended for automotive use

with an octane rating of 91 or higher.

Do not use any type of pre-mixed petrol/lubricant from fuel service stations, such

as the pre-mixed petrol/lubricant intended for use in mopeds, motorcycles, etc.

Use high quality 2-cycle self-mixing lubricant for air-cooled engines. Do not use

automotive lubricant or 2-cycle outboard lubricant.

Mix 2% lubricant into the petrol. This is a 50:1 ratio.

1 l + 20 ml =

2 l + 40 ml =

3 l + 60 ml = 50:1 (2%)

4 l + 80 ml =

5 l + 100 ml =

Mix the fuel thoroughly each time before fueling.

Mix in small quantities. Do not mix quantities more than the amount to use in a 30-

day period. A 2-cycle lubricant containing a fuel stabilizer is recommended.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 16JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 16 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 17

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Note: Fuel system damage or performance problems resulting from the use of

an oxygenated fuel containing more than the percentage of oxygen stated previously are not covered under warranty.

TO FILL THE TANK

See Figure 5.

1. Clean surface around the fuel cap to prevent contamination.

2. Loosen the fuel cap slowly.

3. Carefully pour the fuel mixture into the tank. Do not spill.

4. Prior to replacing the fuel cap, clean and inspect the gasket.

5. Immediately replace and tighten the fuel cap. Wipe up any fuel spillage.

Note: It is normal for smoke to emit from a new engine during and after first use.

ADDING BAR AND CHAIN LUBRICANT

See Figure 6.

The bar and chain lubricant is designed for chains and chain oilers, and is formulated

to perform over a wide temperature range with no dilution required. The chainsaw

should use approximately one tank of lubricant per tank of fuel.

Note: Do not use dirty, used or otherwise contaminated lubricants. Damage may

occur to the lubricant pump, bar or chain.

Carefully pour the bar and chain lubricant into the lubricant tank.

Fill the lubricant tank every time you fuel the engine.

OPERATING THE CHAIN BRAKE

See Figures 7-8.

Check the operating condition of the chain brake prior to each use.

Engage the chain brake by rotating your left hand around the front handle, allowing

the back of your hand to push the chain brake lever/hand guard toward the bar

while the chain is rotating rapidly. Be sure to maintain both hands on the saw

handles at all times.

Reset the chain brake back into the “Run” position by grasping the top of the chain

brake lever/hand guard and pulling toward the front handle until you hear a click.

WARNING

If the chain brake does not stop the chain immediately, or if the chain brake will not

stay in the “Run” position without assistance, take the saw to an authorised service

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 17JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 17 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 18

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

centre for repair.

STARTING AND STOPPING ENGINE

See Figures 7-14.

WARNING

Keep your body to the left of the chain line. Never straddle the saw or chain, or lean

past over the chain line.

Place the chainsaw on level ground and ensure that no objects or obstructions are

within the immediate vicinity that could come in contact with the bar and chain.

Hold the front handle firmly with your left hand and put your right foot onto the base

of the rear handle.

TO START A COLD ENGINE

1. Turn on the ignition switch.

2. Make sure the chain brake is in the “Run” position by pulling back on the lever/

hand guard.

3. Fully press and release the primer bulb at least 10 times.

4. Pull choke lever all the way out to “Start” position.

5. When the temperature is above 10°C, pull the starter grip until the engine attempts

to start, but no more than 3 times. When the temperature is below 10°C, pull the

starter grip until the engine attempts to start, but no more than 5 times.

6. Push choke lever to “Run” position. Pull starter grip until engine runs.

Note: Allow the saw to run in this position 15-30 seconds, depending upon the

temperature.

7. Depress the trigger release and squeeze and release the throttle trigger to return

the engine to idle after a total run time of at least 30 seconds.

Note: Failure to release partial throttle when chain brake lever is in the “Brake”

position will result in serious damage to the unit. Never squeeze and hold the throttle trigger while the chain brake is in the “Brake” position.

TO START A WARM ENGINE

1. Turn on the ignition switch.

2. Make sure the chain brake is in the “Run” position by pulling back on the lever/

hand guard.

3. Keep choke lever on “Run” position.

4. Pull starter grip until engine runs, but no more than 5 times. If engine does not start

after 5 pulls, use cold engine starting procedure.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 18JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 18 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 19

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

5. Squeeze and release the throttle trigger to return the engine to idle.

TO STOP THE ENGINE

1. Release the throttle trigger and let the engine return to idle.

2. To stop the engine, move the ignition switch to the “Stop” (0) position. Do not put

the chainsaw on the ground when the chain is still moving. For additional safety , set

the chain brake when the saw is not in use.

3. In the event that the ignition switch will not stop the saw, pull the choke lever out

to the fully extended position “Full choke” and engage the chain brake to stop the

engine. If the ignition switch will not stop the saw when set to the “Stop” position,

have the ignition switch repaired before using the chainsaw again to prevent unsafe

conditions or serious injury.

Note: After using the saw , always relieve tank pressure by loosening then re-tightening the chain lubricant and fuel caps. Allow the engine to cool before storing.

ADJUSTING IDLE SPEED

See Figure 15.

If the engine starts, runs and accelerates, but will not idle, turn the idle speed screw

“T” clockwise to increase idle speed to 2600~3600 rpm.

If the chain turns at idle, turn the idle speed screw “T” counter clockwise to reduce

the idle RPM and stop the chain movement. If the saw chain still moves at idle

speed, contact an authorised service centre for adjustment and discontinue use

until the repair is made.

WARNING

THE SAW CHAIN SHOULD NEVER TURN AT IDLE. Serious personal injury may

result from the saw chain turning at idle.

PULL AND PUSH

See Figure 16.

The reaction force of the saw is always opposite to the direction the chain is moving.

The operator must be ready to control the PULL when cutting on the bottom edge of

the bar and the PUSH when cutting along the top edge.

KICKBACK PRECAUTIONS

See Figures 17-18.

Rotational kickback occurs when the moving chain contacts an object at the Kickback

Danger Zone of the guide bar. The result is a lightning-fast reverse reaction, which

kicks the guide bar up and back towards the operator. This reaction can cause loss of

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 19JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 19 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 20

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

control, which can result in serious injury.

PREPARING FOR CUTTING

PROPER GRIP ON HANDLES

See Figure 19.

Wear non-slip gloves for maximum grip and protection.

Hold the saw firmly with both hands. Always keep your left hand on the front handle

and your right hand on the rear handle so that your body is to the left of the chain

line.

WARNING

Never use a left-handed (cross-handed) grip or any stance that would place your body

or arm across the chain line.

Maintain a proper grip on the saw whenever the engine is running. The fingers

should encircle the handle and the thumb wrapped under the handlebar. This grip

is least likely to be broken by a kickback or other sudden reaction of the saw. Any

grip in which the thumb and fingers are on the same side of the handle is dangerous

because a slight kick of the saw can cause loss of control.

WARNING

See Figure 20.

DO NOT operate the throttle trigger with your left hand and hold the front handle with

your right hand. Never allow any part of your body to be in the chain line while operating

a saw.

PROPER CUTTING STANCE

See Figure 21.

Balance your weight with both feet on solid ground.

Keep left arm with elbow locked in a “straight arm” position to withstand any kickback

force.

Keep your body to the left of the chain line.

Keep your thumb on the underside of the handlebar.

WORK AREA PRECAUTIONS

See Figure 22.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 20JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 20 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 21

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Cut only wood or materials made from wood.

Never allow children to operate the saw. Do not allow persons to use this chainsaw

who have not read the operator’s manual or received adequate instructions for the

safe and proper use of the chainsaw.

Keep helpers, bystanders, children and animals at a SAFE DISTANCE from the

cutting area. During felling operations, the safe distance should be at least twice

the height of the largest trees in the felling area. During bucking operations, keep a

minimum distance of 5 m between workers.

Always cut with both feet on solid ground to prevent being pulled off balance.

Do not cut above chest height as a saw held higher is difficult to control against

kickback forces.

Do not fell trees near electrical wires or buildings. Leave this operation for

professionals.

Cut only when visibility and light are adequate for you to see clearly.

BASIC OPERATING / CUTTING PROCEDURES

Practise cutting a few small logs using the following technique to get the “feel” of using

the saw before you begin a major sawing operation.

1. Take the proper stance in front of the wood with the saw idling.

2. Accelerate the engine to full throttle just before entering the cut by squeezing the

throttle trigger.

3. Begin cutting with the saw against the log.

4. Keep the engine at full throttle the entire time you are cutting.

5. Allow the chain to cut for you; exert only light downward pressure. Forcing the cut

could result in damage to the bar, chain or engine.

6. Release the throttle trigger as soon as the cut is completed, allowing the engine to

idle. Running the saw at full throttle without a cutting load can result in unnecessary

wear to the chain, bar and engine.

7. Do not put pressure on the saw at the end of the cut as this may cause the saw to

drop in an unsafe manner.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 21JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 21 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 22

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

DO NOT FELL TREES IN HAZARDOUS CONDITIONS

WARNING

Do not fell trees during periods of high wind or heavy rain. Wait until the hazardous

weather has ended. When felling a tree, it is important that you heed the following

warnings to prevent possible serious injury.

Do not cut down trees having extreme lean or large trees with rotten limbs, loose bark

or hollow trunks. Have these trees pushed or dragged down with heavy equipment,

then cut them up.

Do not cut trees near electrical wires or buildings.

Check the tree for damaged or dead branches that could fall and hit you during

felling.

Periodically glance at the top of the tree during the back cut to ensure the tree is

going to fall in the desired direction.

If the tree starts to fall in the wrong direction, or if the saw gets caught or hung up

during the fall, leave the saw and save yourself!

PROPER PROCEDURE FOR TREE FELLING

See Figures 23-26.

1. Pick your escape route (or routes in case the intended route is blocked). Clear the

immediate area around the tree and make sure there are no obstructions in your

planned path of retreat. Clear the path of safe retreat approximately 135° from the

planned line of fall.

2. Consider the force and direction of the wind, the lean and balance of the tree, and

the location of large limbs. These things infl uence the direction in which the tree will

fall. Do not try to fell a tree along a line different from its natural line of fall.

3. Cut a notch about 1/3 the diameter of the trunk in the side of the tree. Make the

notch cuts so they intersect at a right angle to the line of fall. This notch should be

cleaned out to leave a straight line. To keep the weight of the wood off the saw,

always make the lower cut of the notch before the upper cut.

4. Make the back cut level and horizontal, and at a minimum of 2 in. above the

horizontal cut of the notch.

Note: Never cut through to the notch. Always leave a band of wood between the

notch and back cut (approximately 2 in. or 1/10 the diameter of the tree). This is

called a “hinge” or “hinge wood.” It controls the fall of the tree and prevents slipping

or twisting or shoot back of the tree off the stump.

5. On large diameter trees, stop the back cut before it is deep enough for the tree to

either fall or settle back on the stump. Then insert soft wooden or plastic wedges

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 22JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 22 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 23

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

into the cut so they do not touch the chain. Drive wedges in, little by little, to help

jack the tree over.

6. As the tree starts to fall, stop the chainsaw and put it down immediately. Retreat

along the cleared path, but watch the action in case something falls your way.

WARNING

Never cut through to the notch when making a back cut. The hinge controls the fall of

the tree; this is the section of wood between the notch and back cut.

REMOVING BUTTRESS ROOTS

See Figure 27.

A buttress root is a large root extending from the trunk of the tree above the ground.

Remove large buttress roots prior to felling. Make the horizontal cut into the buttress

first, followed by the vertical cut. Remove the resulting loose section from the work area.

Follow the correct tree felling procedure after you have removed the large buttress

roots.

BUCKING

See Figure 28.

Bucking is the term used for cutting a felled tree to the desired log length.

Cut only one log at a time.

Support small logs on a saw horse or another log while bucking.

Keep a clear cutting area. Make sure that no objects can contact the guide bar nose

and chain during cutting; this can cause kickback.

During bucking operations, stand on the uphill side so that the cut-off section of the

log cannot roll over you.

Sometimes it is impossible to avoid pinching (with just standard cutting techniques)

or difficult to predict which way a log will settle when cut.

BUCKING WITH A WEDGE

See Figure 29.

If the wood diameter is large enough for you to insert a soft bucking wedge without

touching the chain, you should use the wedge to hold the cut open to prevent pinching.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 23JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 23 12/3/2010 5:58:30 PM12/3/2010 5:58:30 PM

Page 24

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

BUCKING LOGS UNDER STRESS

See Figure 30.

Make the first bucking cut 1/3 of the way through the log and finish with a 2/3 cut on the

opposite side. As you cut the log, it will tend to bend. The saw can become pinched or

hung in the log if you make the first cut deeper than 1/3 of the diameter of the log.

Give special attention to logs under stress to prevent the bar and chain from pinching.

OVERBUCKING

See Figure 31.

Begin on the top side of the log with the bottom of the saw against the log; exert light

downward pressure. Note that the saw will tend to pull away from you.

UNDERBUCKING

See Figure 32.

Begin on the underside of the log with the top of the saw against the log; exert light

upward pressure. During underbucking, the saw will tend to push back at you. Be

prepared for this reaction and hold the saw firmly to maintain control.

BRANCH TRIMMING AND PRUNING

See Figures 33-34.

Work slowly, keeping both hands on the saw with a firm grip. Maintain secure footing

and balance.

Keep the tree between you and the chain while limbing.

Do not cut from a ladder. This is extremely dangerous. Leave this operation for

professionals.

Do not cut above chest height. A saw held higher than chest height is difficult to

control against kickback.

WARNING

Never climb into a tree to limb or prune. Do not stand on ladders, platforms, a log or in

any position which can cause you to lose your balance or control of the saw.

When pruning trees, it is important not to make the flush cut next to the main limb or

trunk until you have cut off the limb further out to reduce the weight. This prevents

stripping the bark from the main member.

Underbuck the branch 1/3 through for your first cut.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 24JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 24 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 25

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Overbuck the branch to drop it.

Finish by cutting smoothly and neatly against the main member so the bark will grow

back to seal the wound.

WARNING

If the limbs to be pruned are above chest height, hire a professional to perform the

pruning.

CUTTING SPRINGPOLES

See Figure 35.

A springpole is any log, branch, rooted stump or sapling which is bent under tension by

other wood so that it springs back if the wood holding it is cut or removed. On a felled

tree, a rooted stump has a high potential of springing back to the upright position during

the bucking cut to separate the log from the stump. Watch out for springpoles — they

are dangerous.

WARNING

Springpoles are dangerous and could strike the operator, causing the operator to lose

control of the chainsaw. This could result in severe or fatal injury to the operator.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 25JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 25 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 26

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

MAINTENANCE

WARNING

When servicing, use only identical replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING

Always wear safety goggles or safety glasses with side shields during power tool

operation or when blowing dust. If operation is dusty, also wear a dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, grease, etc.

WARNING

Do not at any time let brake fluids, petrol, petroleum-based products, penetrating

lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal injury.

LUBRICATION

All of the bearings in this product are lubricated with a sufficient amount of high grade

lubricant for the life of the unit under normal operating conditions. Therefore, no further

lubrication is required.

REPLACING THE GUIDE BAR AND CHAIN

See Figures 36-45.

DANGER

Never start the engine before installing the guide bar, chain, clutch cover and clutch

drum. Without all these parts in place, the clutch can fly off or explode, exposing the

user to possible serious injury.

WARNING

To avoid serious personal injury, read and understand all the safety instructions in this

section.

Always place the switch in the “Stop” (0) position before you work on the saw.

Make sure the chain brake is not set by pulling the chain brake lever/hand guard

towards the front handle to the “Run” position.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 26JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 26 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 27

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Note: When replacing the guide bar and chain, always use the specified bar and

chain.

Wear gloves when handling the chain and bar. These components are sharp and

may contain burrs.

1. Press in on the clutch cover lock knob and rotate counter clockwise until the

clutch cover can be removed.

2. Remove the bar and chain from the mounting surface.

3. Remove the old chain from the bar.

4. Lay out the new saw chain in a loop and straighten any links. The cutters should

face in the direction of chain rotation. If they face backwards, turn the loop over.

5. Place the chain drive links into the bar groove as shown.

6. Position the chain so there is a loop at the back of the bar.

7. Hold the chain in position on the bar and place the loop around the sprocket.

8. Fit the bar fl ush against the mounting surface so that the bar studs are in the

long slot of the bar.

9. Replace the clutch cover ensuring that the adjusting pin in the clutch cover is in

the bar chain tensioning pin hole.

10. Replace the clutch cover and rotate clutch cover lock knob just enough to hold

the cover in position.

Note: The bar must be free to move for tension adjustment.

11. Remove all slack from the chain by rotating the chain tension dial clockwise

until the chain seats snugly against the bar with the drive links in the bar groove.

12. Lift the tip of the guide bar up to check for sag.

13. Release the tip of the guide bar and turn the chain tension dial clockwise.

Repeat this process until sag does not exist.

14. Hold the tip of the guide bar up and tighten the clutch cover lock knob securely.

The chain is correctly tensioned when there is no sag on the underside of the

guide bar, the chain is snug, but it can be turned by hand without binding.

Ensure that the chain brake is not set.

Note: If chain is too tight, it will not rotate. Loosen the clutch cover lock knob by

pressing in and slightly rotating counter clockwise, then rotate the chain tension

dial counter clockwise. Lift the tip of the guide bar up and re-tighten the clutch

cover lock knob securely. Ensure that the chain will rotate without binding.

CHAIN MAINTENANCE

See Figures 45-47.

Check that the switch is in the “Stop” (0) position before you work on the saw.

Use only a low-kickback chain on this saw. This fast-cutting chain provides

kickback reduction when properly maintained.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 27JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 27 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 28

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

For smooth and fast cutting, maintain the chain properly. The chain requires

sharpening when the wood chips are small and powdery. The chain must be

forced through the wood during cutting or the chain will cut to one side. During

maintenance of the chain, consider the following:

Improper filing angle of the side plate can increase the risk of severe kickback.

Raker (depth gauge) clearance.

Too low increases the potential for kickback.

Not low enough decreases cutting ability.

If the cutter teeth hit hard objects such as nails and stones, or are abraded

by mud or sand on the wood, have an authorised service centre sharpen the

chain.

Note: Inspect the drive sprocket for wear or damage when replacing the chain.

If signs of wear or damage are present in the areas indicated, have the drive

sprocket replaced by an authorised service centre.

Note: If you do not fully understand the correct procedure for sharpening the

chain after reading the instructions that follow, have the saw chain sharpened by

an authorised service centre or replace with a recommended low-kickback chain.

SHARPENING THE CUTTERS

See Figures 48-51.

Be careful to file all cutters to the specified angles and to the same length, as fast

cutting can only be obtained when all cutters are uniform.

WARNING

The saw chain is very sharp. Always wear protective gloves when performing

maintenance to the chain to prevent serious personal injury.

1. Tension the chain prior to sharpening.

2. Use a 5/32 in. (4 mm) diameter round fi le and holder. Do all of your fi ling at the

midpoint of the bar.

3. Keep the fi le level with the top plate of the tooth. Do not let the fi le dip or rock.

4. Use light but fi rm pressure. Stroke towards the front corner of the tooth.

5. Lift the fi le away from the chain tooth on each return stroke.

6. Put a few fi rm strokes on every tooth. File all left hand cutters in one direction.

Then move to the other side and fi le the right hand cutters in the opposite direction.

7. Remove fi lings from the fi le with a wire brush.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 28JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 28 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 29

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Note: A dull or improperly sharpened chain can cause excessive engine speed

during cutting, which may result in severe engine damage.

WARNING

Improper chain sharpening increases the potential of kickback.

WARNING

Failure to replace or repair a damaged chain can cause serious injury.

TOP PLATE FILE ANGLE

See Figure 52.

CORRECT 30° – file holders are marked with guide marks to align file properly to

produce correct top plate angle.

LESS THAN 30° – for cross cutting.

MORE THAN 30° – feathered edge dulls quickly.

SIDE PLATE ANGLE

See Figure 53.

CORRECT 80° – produced automatically if you use the correct diameter file in the

file holder.

HOOK – “grabs” and dulls quickly; increases the potential of kickback. Results from

using a file with a diameter too small or a file held too low.

BACKWARD SLOPE – needs too much feed pressure; causes excessive wear to

the bar and chain. Results from using a file with a diameter too large or file held

too high.

MAINTAINING DEPTH GAUGE CLEARANCE

See Figures 54-56.

Maintain the depth gauge at a clearance of 0.64 mm. Use a depth gauge tool for

checking the depth gauge clearances.

Every time the chain is filed, check the depth gauge clearance.

Use a flat file and a depth gauge jointer to lower all gauges uniformly. Use a 0.64

mm depth gauge jointer. After lowering each depth gauge, restore original shape

by rounding the front. Be careful not to damage adjoining drive links with the edge

of the file.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 29JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 29 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 30

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Depth gauges must be adjusted with the flat file in the same direction the adjoining

cutter was filed with the round file. Use care not to contact cutter face with flat file

when adjusting depth gauges.

MAINTAINING THE GUIDE BAR

See Figure 57.

Check that the switch is in the “Stop” (0) position on the saw.

In every week of use, turn over the guide bar on the saw to distribute the wear for

maximum bar life. The bar should be cleaned every day of use and checked for

wear and damage. Feathering or burring of the bar rails is a normal process of bar

wear. Such faults should be smoothed with a file as soon as they occur.

A bar with any of the following faults should be replaced:

Wear inside the bar rails that permits the chain to lay over sideways

Bent guide bar

Cracked or broken rails

Spread rails

Lubricate guide bar sprockets weekly. Using a grease syringe, lubricate weekly in

the lubricating hole. Turn the guide bar and check that the lubrication holes and

chain groove are free from impurities.

CLEANING THE AIR FILTER

See Figures 58-59.

1. Activate the chain brake.

2. Remove the two screws holding the engine cover.

3. Lift the front of the engine cover past chain brake lever.

4. Lift the back of the engine cover past the handle.

5. Before removing the air fi lter from the carburettor, blow or brush as much loose dirt

and sawdust from around the carburettor and chamber as possible.

Note: Make sure to pull the choke rod out to keep the carburettor from being contaminated.

6. Lift the air fi lter off the air fi lter base.

7. Choose one of the following cleaning options:

To lightly clean, tap the filter against a smooth, flat surface to dislodge most saw

dust and dirt particles.

After every 5 hours of operation, clean in warm soapy water, rinse and let dry

completely. Replace with a new filter after every 25 hours of use.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 30JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 30 12/3/2010 5:58:31 PM12/3/2010 5:58:31 PM

Page 31

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Note: An alternate method is to clean the filter with compressed air. Always

wear eye protection to avoid eye injury.

8. Reinstall the air fi lter .

Note: If you use an air hose for drying, blow through both sides of filter.

Note: Make sure the air filter is correctly replaced before re-assembly. Never run

the engine without the air filter, serious damage could result.

CLEANING THE STARTER UNIT

See Figure 60.

Use a brush to keep the cooling vents of the starter assembly free and clean of debris.

ADJUSTING THE CARBURETTOR

See Figure 61.

Before adjusting the carburettor:

1. Use a brush to clean the starter cover vents.

2. Clean the air fi lter .

3. Allow the engine to warm up prior to adjustment of engine idle speed.

WARNING

Weather conditions and altitude may affect carburetion. Do not allow bystanders close

to the chainsaw while adjusting the carburettor.

Idle Speed Adjustment - The idle speed adjustment controls how much the throttle

valve stays open when the throttle trigger is released. To adjust:

Turn idle speed screw “T” clockwise to increase idle speed.

Turn idle speed screw “T” counter clockwise to decrease idle speed.

WARNING

THE SAW CHAIN SHOULD NEVER TURN AT IDLE. Serious personal injury may result

from the saw chain turning at idle.

CLEANING THE ENGINE

See Figures 58, 62-64.

Clean the engine fins and flywheel fins with a brush periodically . Dangerous overheating

of the engine may occur due to impurities on the engine.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 31JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 31 12/3/2010 5:58:48 PM12/3/2010 5:58:48 PM

Page 32

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

WARNING

Never run the saw without all the parts, including the clutch cover and starter housing,

securely in place.

Because parts can fracture and pose a danger of thrown objects, leave repairs of the

flywheel and clutch to factory trained authorised service centre personnel.

1. Remove the screws and engine cover as described previously.

2. Clean the engine fi ns.

3. Lift the chain brake over the post.

4. Lay the chainsaw on its side with the bar and chain on the ground.

5. Remove the chain lubricant and fuel caps.

6. Remove the three screws that hold the starter housing in place.

7. Lift off the starter cover and set aside.

8. Replace chain lubricant and fuel caps to prevent contamination during cleaning.

9. Clean the fl ywheel fi ns.

10. Replace the starter housing. Reinstall screws and secure.

1 1. Replace the chain lubricant and fuel caps.

12. Replace the engine cover. Reinstall screws and secure.

13. Replace the chain brake on the post.

Note: Check to ensure that the air filter is in the proper position before reinstalling

the engine cover.

Note: If you notice power loss with the petrol-powered tool, the exhaust port and

silencer may be blocked with carbon deposits. These deposits may need to be

removed to restore performance. We highly recommend that only qualified service

technicians perform this service.

CHECKING THE FUEL FILTER

See Figure 65.

Check the fuel filter periodically. Replace it if contaminated or damaged.

REPLACING THE SPARK PLUG

See Figure 66.

This engine uses a Champion RCJ4 or RCJ6Y or NGK BPMR7A with .025 in. electrode

gap. Use an exact replacement and replace every 50 hours or more frequently, if

necessary.

1. Remove the spark plug lead by carefully rotating back and forth whilst gently pulling

upwards.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 32JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 32 12/3/2010 5:58:48 PM12/3/2010 5:58:48 PM

Page 33

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

2. Loosen the spark plug by turning it counter clockwise with a wrench.

3. Remove the spark plug.

4. Hand thread the new spark plug, turning it clockwise. Tighten securely with wrench.

Note: Be careful not to cross-thread the spark plug. Cross-threading will seriously

damage the engine.

5. Re-attach the spark plug lead by pressing fi rmly onto the top of spark plug.

INSPECTING / CLEANING THE SPARK ARRESTOR SCREEN

See Figure 67.

The silencer is equipped with a spark arrestor screen. A faulty spark arrestor screen

can create fire hazard. Through normal use, the screen can become dirty and should

be inspected weekly and cleaned as required. Always keep the silencer and spark

arrestor on the saw in good condition.

WARNING

Silencer surfaces are very hot during and after operation of the chainsaw. To avoid

serious personal injury, keep all body parts away from the silencer.

1. Allow the silencer to cool.

2. Remove the defl ector retaining nut.

3. Remove the defl ector to access the spark arrestor screen and gasket.

4. If dirty , clean the spark arrestor screen with a small wire brush. Replace the screen

and gasket if they are cracked or otherwise deteriorated. Reinstall the retaining nut

to obtain a replacement spark arrestor, contact your service centre.

INSPECTING AND CLEANING THE CHAIN BRAKE

See Figure 68.

Always keep the chain brake mechanism clean by lightly brushing the linkage free

from dirt.

Always test the chain brake performance after cleaning.

WARNING

Even with daily cleaning of the mechanism, the dependability of a chain brake to

perform under field conditions cannot be certified.

STORING THE PRODUCT

Clean all foreign material from the product. Store it in a well-ventilated place that

is inaccessible to children. Keep away from corrosive agents such as garden

chemicals and de-icing salts.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 33JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 33 12/3/2010 5:58:48 PM12/3/2010 5:58:48 PM

Page 34

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Observe local regulations for the safe storage and handling of petrol.

WHEN STORING 1 MONTH OR LONGER

1. Drain all fuel from tank into a container approved for petrol.

2. Run the engine until it stops. This will remove all fuel-lubricant mix that could

become stale and leave varnish and gum in the fuel system.

3. Squeeze primer bulb several times to purge fuel from carburettor.

4. Drain all bar and chain lubricant from tank into a container approved for lubricant.

5. Always place the scabbard over the guide bar and chain before transporting or

storing the unit.

M

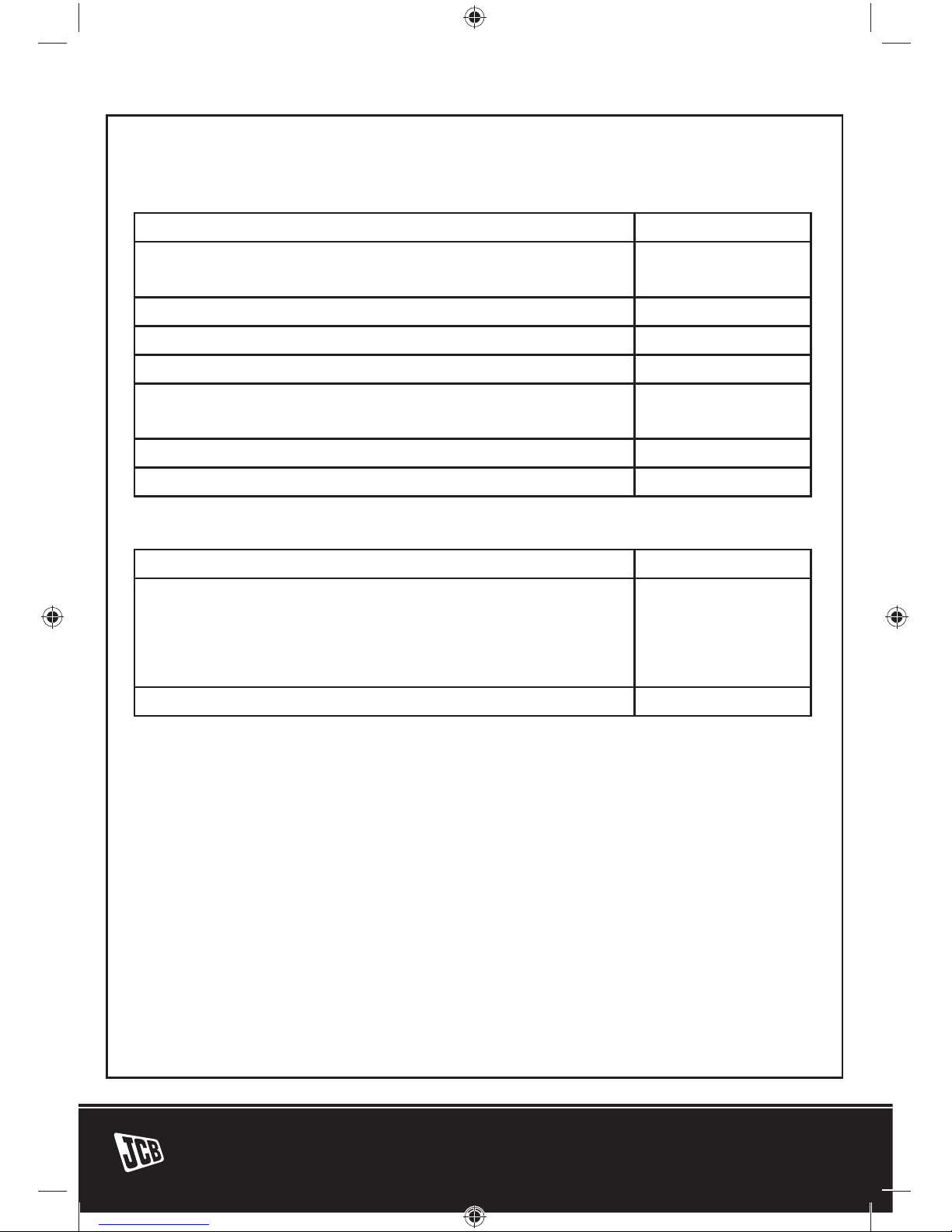

MAINTENANCE SCHEDULE

Check Frequency

Fuel mixture level Before each use

Bar lubrication Before each use

Chain tension Before each use

Chain sharpness Before each use

For damaged parts Before each use

For loose fasteners Before each use

For loose parts Before each use

Chain brake function Before each use

For fuel leaks Before each use

Inspect and clean Frequency

Bar Before each use

Complete saw After each use

Air filter Every 5 hours*

Chain brake Every 5 hours*

Replace spark plug Yearly

Replace fuel filter Yearly

* Hours of operation

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 34JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 34 12/3/2010 5:58:49 PM12/3/2010 5:58:49 PM

Page 35

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

PROBLEM SOLVING

If these solutions do not solve the problem, contact your authorised service dealer.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start. No spark.

Clean or replace spark plug.

Reset spark plug gap.

Engine is flooded.

With the ignition switch Off,

remove spark plug.

Move choke lever to “Run”

position (pushed in completely)

and pull starter grip 15 to 20

times. This will clear excess fuel

from engine.

Clean and reinstall spark plug.

Set ignition switch to “Run” ( l )

position.

Push and fully release primer

bulb 10 times.

Pull starter grip three times with

choke lever at

“Run” position.

If engine does not start, move

choke lever to

“Full choke”

position and repeat normal

starting procedure.

If engine still fails to start,

repeat procedure with a new

spark plug.

Engine starts but

will not accelerate

properly.

Carburettor requires

“L”

(Low jet) adjustment.

Contact an authorised service

centre for carburettor adjustment.

Engine starts, then

dies.

Carburettor requires

“L”

(Low jet) adjustment.

Contact an authorised service

centre for carburettor adjustment.

Engine starts but

will not run properly

at high speed.

Carburettor requires

“H”

(High jet) adjustment.

Contact an authorised service

centre for carburettor adjustment.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 35JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 35 12/3/2010 5:58:49 PM12/3/2010 5:58:49 PM

Page 36

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Engine does not

reach full speed and/

or emits excessive

smoke.

Lubricant / fuel mixture

incorrect.

Use fresh fuel and the correct

2-cycle lubricant mix ratio.

Air filter dirty. Clean air filter.

Spark arrestor screen

dirty.

Clean spark arrestor screen.

Carburettor requires

“H”

(High jet) adjustment.

Contact an authorised service

centre for carburettor adjustment.

Engine starts,

runs and

accelerates but

will not idle.

Chain turns at

idle.

Carburettor requires

adjustment to idle

speed.

Turn idle speed screw

“T”

clockwise to increase speed.

Turn idle speed screw

“T” counter

clockwise to decrease speed.

Air leak in the intake

system.

Contact an authorised service

centre for a rebuild kit.

Bar and chain

running hot and

smoking.

Chain lubricant tank

empty.

Lubricant tank should be filled

every time fuel tank is filled.

Chain tension is too

tight.

Tension chain.

Oiler is not functioning.

Run at half throttle 30 to 45

seconds.

Stop saw and check for lubricant

dripping from guide bar.

If lubricant is present, the chain

may be dull or bar may be

damaged.

If no lubricant is present, contact

an authorised service centre.

Engine starts and

runs, but chain is

not rotating.

Chain brake is

engaged.

Release chain brake.

Chain tension is too

tight.

Tension chain.

Guide bar and chain

assembled incorrectly.

Replace the guide bar and chain.

Guide bar and/or chain

are damaged.

Inspect guide bar and chain for

damage.

Drive sprocket teeth

damaged.

Contact an authorised service

centre for drive sprocket

replacement.

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 36JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 36 12/3/2010 5:58:49 PM12/3/2010 5:58:49 PM

Page 37

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

WARRANTY STATEMENT

CUTTING EDGE CONSTRUCTION TECHNOLOGY IN YOUR HANDS

In 1945, JCB began producing construction equipment. Today, we build the world’s

number one diggers, each one the product of our unswerving focus on innovation,

quality and engineering. JCB power tools are built to give you the same world beating

standards of performance. The same innovation, to always get the job done better,

the same quality, to never let you down, the same engineering heritage and expertise

that you can trust 100%.

JCB power tools are guaranteed against manufacturing defects for a period of 3

years (with registration) from the date of purchase. If your JCB power tool becomes

defective within this warranty period, we guarantee to:

Replace or repair all defective parts, free of charge, or

Repair products free of charge, or

Replace the unit with a new or re-conditioned unit, free of charge.

REGISTER NOW FOR YOUR EXTENDED JCB WARRANTY

With the extended 3 year warranty, JCB offers you additional protection which

extends far beyond the legally required periods and warranty conditions.

This service is available to you at no cost if you register your new JCB outdoor product

within 30 days of the purchase date.

All you need to do in order to receive this JCB service: register your machine online

at JCBDIY.COM

Our JCB service is only available within the U.K. & Ireland on Tel: 0845 600 5526

LIMITED WARRANTY

JCB warrants this outdoor product to be free of defects in material or workmanship

for 24 months from the date of purchase by the original purchaser, subject to the

limitations below. Please keep your invoice as proof of date of purchase.

This warranty is only applicable where the product is used for personal and

non-commercial purposes. This warranty does not cover damage or liability caused

by/due to misuse, abuse, accidental or intentional acts by user, improper handling,

unreasonable use, negligence, failure by end user to follow operating procedures

outlined in the user’s manual, attempted repair by non-qualifi ed professional,

unauthorized repair, modifi cation, or use of accessories and/or attachments not

specifi cally recommended by authorized party.

This warranty does not cover spark plugs, leaf collection bags, chainsaw chains &

chain bar, brush cutter blades, line trimmer heads, nylon cable or any part which

ordinary wear and tear results in required replacement during warranty period. Unless

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 37JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 37 12/3/2010 5:58:49 PM12/3/2010 5:58:49 PM

Page 38

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

specifi cally provided under applicable law, this warranty does not cover transportation

cost of consumable items.

This limited warranty is void if the product’s original identifi cation (trade mark, serial

number, etc.) markings have been defaced, altered or removed or if product is not

purchased from an authorized reseller or if product is sold AS IS and/or WITH ALL

FAULTS.

Subject to all applicable local regulations, the provisions of this limited warranty

are in lieu of any other written warranty, whether express or implied, written or oral,

including any warranty of MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL WE BE LIABLE FOR SPECIAL, INCIDENTAL,

CONSEQUENTIAL DAMAGES. OUR MAXIMUM LIABILITY SHALL NOT EXCEED

THE ACTUAL PURCHASE PRICE PAID BY YOU FOR THE PRODUCT.

This warranty is valid only in the U.K. & Ireland

WARRANTY CLAIMS

For guarantee claims, please contact JCB Customer Services. You will need to

submit proof of purchase in the form of a valid receipt that displays date and place of

purchase.

JCB CUSTOMER SERVICES 0845 600 5526

JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 38JCB-CS38_960488008-01_Manual_final_ OEM licence.indd 38 12/3/2010 5:58:49 PM12/3/2010 5:58:49 PM

Page 39

SL7 1TB

Customer Helpline 0845 600 5526 Monday to Friday 09.00 to 17.00

www.JCBdiy.com

Name: JCB - Chestnut House

Address: Chestnut Avenue, Chandlers Ford, Eastleigh, Hants, SO53 3LE - United

Kingdom.

Name: Simon Del-Nevo (Director of Outdoor Power Equipment)

Company name: Techtronic Industries Europe, Middle East and Africa

Address: Medina House, Field House Lane, Marlow, Bucks. SL7 1TB - United Kingdom

Herewith we declare that the product

Category .........................................................................CHAINSAW for cutting wood

Model ...........................................................................................................JCB-CS38

Serial number..........................................................................See product rating label

Year of Construction ................................................................See product rating label

• is in conformity with the relevant provisions of the Machinery Directive (2006/42/EC)

• is in conformity with the provisions of the following other EC-Directives

EMC Directive (2004/108/EC),

Noise Emission Directive (2000/14/EC amended by 2005/88/EC), and

Gas Emission Directive (2004/26/EC).

And furthermore, we declare that

• the following (parts/clauses of) European harmonised standards have been used

EN ISO 11681-1:2008, EN ISO 22867:2008

EN ISO 22868:2008, EN ISO 14982:2009, EN ISO 3744:2009

Notifi ed body, 0905 Intertek Deutschland GmbH, Nikolaus-Otto-Str. 13, 70771

Leinfelden-Echterdingen has carried out EC type approval, and the certifi cate No. is.

Measured sound power level 101 dB (A)

Guaranteed sound power level 112 Lwa dB (A)

Conformity assessment method to Annex V/ Directive 2000/14/EC

Place, date: Hong Kong, 20/11/2010 Signature: Andrew John Eyre

(BEng, CEng, MIET)