Page 1

POWER TOOL

INSTRUCTION & USER MANUAL

EN

IM-18AG-EN

JCB-18AG

Original Instructions

Page 2

2

JCB-18AG

Instruction & User Manual

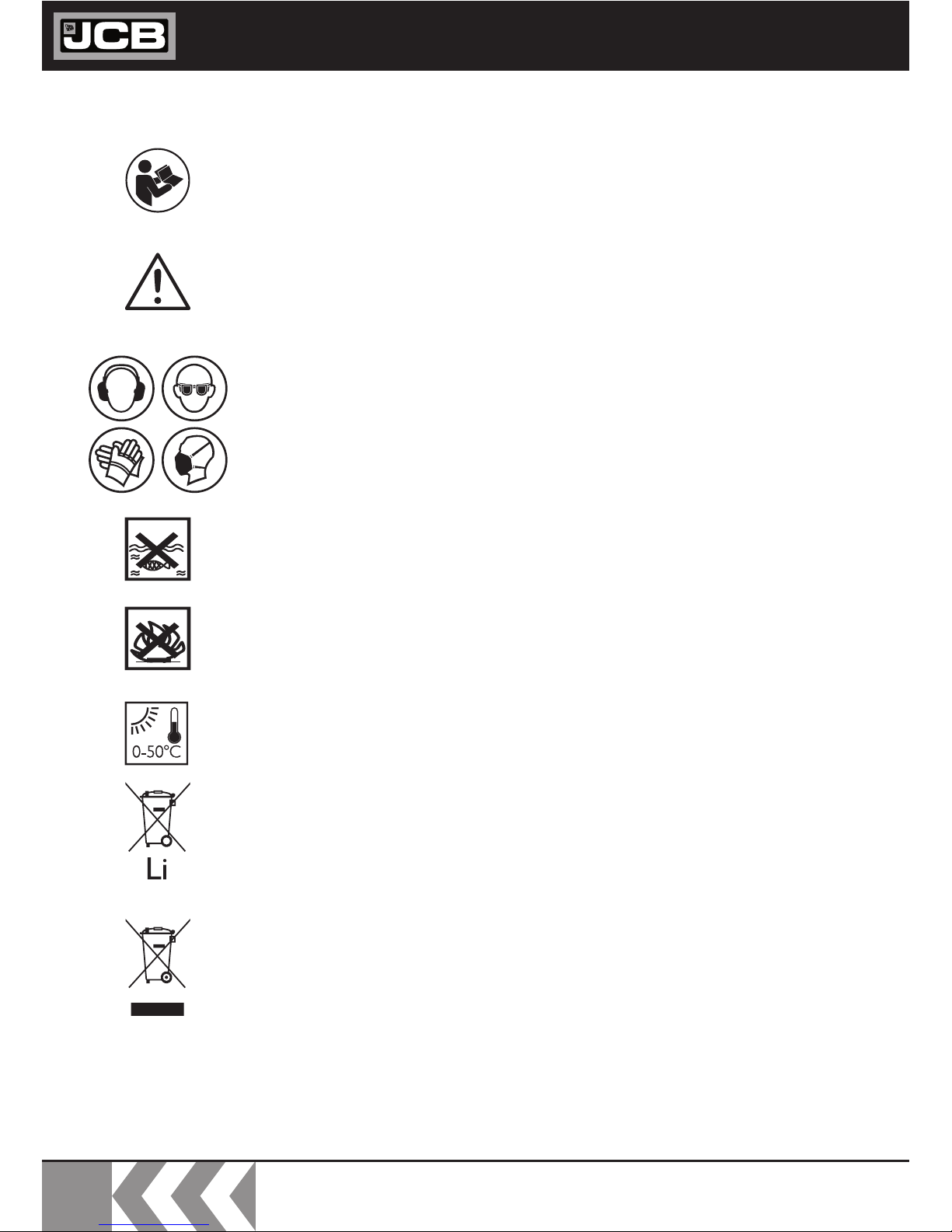

GENERAL WARNINGS & DISPOSAL

To reduce the risk of injury, the user must read the instruction manual.

The device must not be exposed to rain or immersed in water.

Do not allow any part of the device to come into contact with flames, or to

catch fire.

Do not dispose of batteries in household waste. Return exhausted batteries

to a local collection or recycling point.

This product has been marked with a symbol relating to removing electric and

electronic waste. The product should not be discarded with household waste

but must be returned to a collection system which conforms to the European

Directive 2012/19/EU. It will then be recycled or dismantled in order to

reduce the impact on the environment. Electric and electronic equipment can

be hazardous for the environment and for human health since they contain

hazardous substances.

This symbol is used throughout this manual to warn the user about potential

risks. Please read & understand these sections before using the device.

Personal Protective Equipment (P.P.E.), such as ear defenders, eye protection,

safety gloves and a dust mask, must be worn during the operation of the

device.

Do not expose battery pack or tool to fire or excessive temperatures above

130°C.

The month and year of manufacture can be found within the product serial number e.g.

MMYYPPPAXXXXX. Where production month (MM) and production year (YY) are included.

Page 3

3

JCB-18AG

Instruction & User Manual

Contents

GENERAL POWER TOOL SAFETY WARNINGS 4

1. Work area safety 4

2. Electrical safety 4

3. Personal safety 4

4. Power tool use and care 5

5. Battery tool use and care 5

6. Service 6

TOOL SPECIFIC SAFETY WARNINGS 6

Additional Safety Rules For Grinders 6

Kickback And Related Warnings 8

CHARGER SAFETY 10

COMPONENT LIST 12

TOOL TECHNICAL DATA 13

NOISE INFORMATION 13

VIBRATION INFORMATION 14

OPERATING INSTRUCTIONS 15

Intended Use 15

Battery 15

Handle 16

Guard 16

Grinding Wheel Assembly 16

Power Switch 16

Surface Grinding 16

Edge Grinding (Cutting) 17

Surface Finishing 17

Maintenance 18

Transport and Storage 19

WARRANTY STATEMENT 20

Conditions 20

Terms 20

EC DECLARATION OF CONFORMITY 22

Page 4

4

JCB-18AG

Instruction & User Manual

Read all safety warnings, instructions and

specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

injury. Save all warnings and instructions for

future reference.

WARNING!

The term “power tool” in the warnings refers to

your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

m Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

m Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or

fumes.

m Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2. Electrical safety

m Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

m Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body

is earthed or grounded.

m Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

m Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep the cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of

electric shock.

m When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

m If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3. Personal safety

m Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication. A moment

of inattention while operating power tools may

result in serious personal injury.

m Use personal protective equipment.

Always wear eye protection. Protective

equipment such as a dust mask, non-skid safety

shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal

injuries.

m Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger on

the switch or energising power tools that have

the switch on invites accidents.

GENERAL POWER TOOL SAFETY WARNINGS

Page 5

5

JCB-18AG

Instruction & User Manual

m Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

m Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

m Dress properly. Do not wear loose

clothing or jewellery. Keep your hair and

clothing away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

m If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

m Do not let familiarity gained from

frequent use of tools allow you to become

complacent and ignore tool safety

principles. A careless action can cause severe

injury within a fraction of a second.

4. Power tool use and care

m Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was designed.

m Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch is

dangerous and must be repaired.

m Disconnect the plug from the power

source and/or remove the battery pack,

if detachable, from the power tool before

making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

m Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

m Maintain power tools and accessories.

Check for misalignment or binding of

moving parts, breakage of parts and any

other condition that may affect the power

tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

m Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier

to control.

m Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

m Keep handles and grasping surfaces

dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not

allow for safe handling and control of the tool in

unexpected situations.

5. Battery tool use and care

m Recharge only with the charger specified

by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of

fire when used with another battery pack.

m Use power tools only with specifically

designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

Page 6

6

JCB-18AG

Instruction & User Manual

m When battery pack is not in use, keep it

away from other metal objects, like paper

clips, coins, keys, nails, screws or other

small metal objects, that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

m Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

If contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

m Do not use a battery pack or tool that is

damaged or modified. Damaged or modified

batteries may exhibit unpredictable behaviour

resulting in fire, explosion or risk of injury.

m Do not expose a battery pack or tool to

fire or excessive temperature. Exposure

to fire or temperature above 130 °C may cause

explosion.

m Follow all charging instructions and do

not charge the battery pack or tool

outside the temperature range specified

in the instructions. Charging improperly or

at temperatures outside the specified range may

damage the battery and increase the risk of fire.

6. Service

m Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

m Never service damaged battery packs.

Service of battery packs should only be

performed by the manufacturer or authorized

service providers.

Page 7

7

JCB-18AG

Instruction & User Manual

TOOL SPECIFIC SAFETY WARNINGS

m Wear ear protectors. Exposure to noise

can cause hearing loss.

m Wear eye protection. Wear goggles

to prevent eyes from exposure to flying

particles.

m Wear dust mask. Take protective

measures against inhalation of dust. Some

materials can contain toxic materials. Also

work with dust/ chip extraction when

connectable.

Additional Safety Rules For

Grinders

m This power tool is intended to

function as a grinder tool. Read

all safety warnings, instructions,

illustrations and specifications

provided with this power tool. Failure

to follow all instructions listed below may

result in electric shock, fire and/or serious

injury.

m Operation such as polishing is not

recommended to be performed with

this power tools. Operation for which the

power tool was not designed may create a

hazard and casue personal injury.

m Do not use accessories which

are not specifically designed

and recommended by the tool

manufacturer. Just because the accessory

can be attached to your power tool, it does

not assure safe operation.

m The rated speed of the accessory

must be at least equal to the

maximum speed marked on the

power tool. Accessories running faster

than their rated speed can break and fly

apart.

m The outside diameter and the

thickness of your accessory must be

within the capacity rating of your

power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

m Threaded mounting of accessories

must match the grinder spindle

thread. For accessories mounted

by flanges, the arbour hole of the

accessory must fit the locating

diameter of the flange. Accessories that

do not match the mounting hardware of the

power tool will run out of balance, vibrate

excessively and may cause loss of control.

m Do not use a damaged accessory.

Before each use inspect the accessory

such as abrasive wheels for chips

and cracks, backing pad for cracks,

tear or excess wear, wire brush for

loose or cracked wires. If power tool

or accessory is dropped, inspect for

damage or install an undamaged

accessory. After inspecting and

installing an accessory, position

yourself and bystanders away from

the plane of the rotating accessory

and run the power tool at maximum

no-load speed for one minute.

Damaged accessories will normally break

apart during this test time.

Page 8

8

JCB-18AG

Instruction & User Manual

m Wear personal protective equipment.

Depending on application, use

face shield, safety goggles or safety

glasses. As appropriate, wear dust

mask, hearing protectors, gloves

and workshop apron capable of

stopping small abrasive or workpiece

fragments. The eye protection must be

capable of stopping flying debris generated

by various operations . The dust mask

or respirator must be capable of filtrating

particles generated by your operation.

Prolonged exposure to high intensity noise

may cause hearing loss.

m Keep bystanders a safe distance away

from work area. Anyone entering

the work area must wear personal

protective equipment. Fragments of

workpiece or of a broken accessory may fly

away and cause injury beyond immediate

area of operation.

m Hold the power tool by insulated

gripping surfaces only, when

performing an operation where the

cutting tool may contact hidden

wiring. Contact with a “live” wire will also

make exposed metal parts of the power

tool “live” and could give the operator an

electric shock.

m Never lay the power tool down until

the accessory has come to a complete

stop. The spinning accessory may grab the

surface and pull the power tool out of your

control.

m Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory could

snag your clothing, pulling the accessory into

your body.

m Regularly clean the power tool’s

air vents. The motor’s fan will draw

the dust inside the housing and excessive

accumulation of powdered metal may cause

electrical hazards.

m Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

m Do not use accessories that require

liquid coolants. Using water or other

liquid coolants may result in electrocution or

shock.

Kickback And Related Warnings

m Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching

or snagging causes rapid stalling of the

rotating accessory which in turn causes

the uncontrolled power tool to be forced

in the direction opposite of the accessory’s

rotation at the point of the binding.

m For example, if an abrasive wheel is

snagged or pinched by the workpiece,

the edge of the wheel that is entering into

the pinch point can dig into the surface of

the material causing the wheel to climb

out or kick out. The wheel may either

jump toward or away from the operator,

depending on direction of the wheel’s

movement at the point of pinching.

Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking proper

precautions as given below.

Page 9

9

JCB-18AG

Instruction & User Manual

m Maintain a firm grip on the power

tool and position your body and

arm to allow you to resist kickback

forces. Always use auxiliary handle, if

provided, for maximum control over

kickback or torque reaction during

start-up. The operator can control torque

reactions or kickback forces, if proper

precautions are taken.

m Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

m Do not position your body in the

area where power tool will move if

kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s

movement at the point of snagging.

m Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and

cause loss of control or kickback.

m Do not attach a saw chain

woodcarving blade or toothed saw

blade. Such blades create frequent

kickback and loss of control.

Page 10

10

JCB-18AG

Instruction & User Manual

m To reduce risk of injury, only charge

JCB rechargable batteries. The

charger and battery packs are specifically

designed to work together. Other types of

batteries may burst causing fire and personal

injury.

m Do not allow any liquid to get inside

the charger. Electric shock may result.

m Do not expose the charger to rain or

snow.

m Under certain conditions with the

charger plugged into the power

supply, the exposed charging contacts

inside the charger can be shorted by

foreign materials. Foreign materials of a

conductive nature such as, but not limited

to, steel, wool, aluminium foil or any buildup

of metallic particles should be kept away

from charger cavities.

m Always unplug the charger from

the power supply when there is no

battery in the cavity.

m Unplug the charger from the power

supply before attempting to clean.

m Do not operate the charger with a

damaged cord or plug. Have them

replaced immediately.

m The charger is designed to operate

on standard 230V household

electrical power. Do not attempt to

use it on any other voltage.

m This appliance can be used by

children aged from 8 years and above

and persons with reduced physical,

sensory or mental capabilities or

lack of experience and knowledge

if they have been given supervision

or instruction concerning use of

the appliance in a safe way and

understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be

made by children without supervision.

m If the supply cord is damaged, it must

be replaced by the manufacturer, its

service agent or similarly qualified

persons in order to avoid a hazard.

CHARGER SAFETY

Read all safety warnings, instructions

and specifications provided with the

charger. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious injury. Save all warnings

and instructions for future reference.

WARNING!

Page 11

11

JCB-18AG

Instruction & User Manual

Page 12

12

JCB-18AG

Instruction & User Manual

COMPONENT LIST

5

6

1.

ON/ OFF SWITCH

2.

SIDE HANDLE

3.

SPINDLE LOCK

4.

GUARD

5.

LOCKING NUT

6.

GRINDING DISC

7.

LOWER PLATE

8.

CHARGER*

9.

BATTERY PACK* - PLEASE REFER TO TABLE ON

PAGE 11 FOR BATTERY INFORMATION

10.

BATTERY TEST BUTTON AND CHARGE

INDICATOR*

7

3

2

1

4

*If applicable

8

12

13

Battery size shown for

illustrative purposes only

Page 13

13

JCB-18AG

Instruction & User Manual

TOOL TECHNICAL DATA

NOISE INFORMATION

Rated Voltage

18V d.c.

No Load Speed

n: 8000/min

Sanding Disc Diameter

115mm

Product Weight (Body only, w/o battery)

2.59 kg

A-Weighted Sound Pressure (LpA)

76.1 dB(A)

A-Weighted Sound Power (LwA)

87.1 dB(A)

KpA & KwA

3 dB(A)

Wear ear protection when sound pressure is over 80 dB(A)

Battery

Code

Battery

Size

Voltage

Battery

Capacity

Charge Time

(Fast Charger: JCB-18VFC)

Charge Time

(Super Fast Charger: JCB-18SFC)

JCB-20LI Small 18V 2.0Ah 50 mins 30 mins

JCB-30LI Large 18V 3.0Ah 80 mins 45 mins

JCB-40LI Large 18V 4.0Ah 100 mins 60 mins

JCB-50LI Large 18V 5.0Ah 120 mins 75 mins

Times given as a guide only. Battery charge and discharge times dependant on age, usage and condition.

Charger Code Input Power Output

JCB-18VFC 220 - 240V ~ 50-60Hz 70W 2.4A

JCB-18SFC 220 - 240V ~ 50-60Hz 105W 4.0A

LITHIUM ION BATTERY TECHNICAL DATA

CHARGER TECHNICAL DATA

Page 14

14

JCB-18AG

Instruction & User Manual

The vibration emission value of the power

tool is tested under EN 60745-1 and EN

60745-2-3, and can vary during operation

depending on the following usage conditions:

WARNING!

m How the tool is used and the materials

being cut or drilled.

m The tool being in good condition and well

maintained.

m Using the correct accessory for the tool and

ensuring it is sharp and in good condition.

m The tightness of the grip on the handles and

if any anti-vibration accessories are used.

m The tool being used as intended by its

design and these instructions.

m The declared vibration total value may also

be used in a preliminary assessment of

exposure.

THIS TOOL MAY CAUSE HAND-ARM

VIBRATION SYNDROME IF USAGE IS

NOT ADEQUATELY MANAGED.

To be accurate, an estimation of exposure

level in the actual conditions of use should

also take account of all parts of the operating

cycle. These include times when the tool is

switched off and when it is running idle but

not actually doing work. This may significantly

reduce the total exposure level over the

working period, helping to minimize your

vibration exposure risk.

WARNING!

m ALWAYS use sharp chisels, drills and blades.

m Maintain this tool in accordance with these

instructions and keep well lubricated (where

appropriate).

m If the tool is to be used regularly then invest

in anti-vibration accessories.

m Avoid using tools in temperatures of 10

°

C

or less.

m Plan your work schedule to spread any high

vibration tool use across a number of days.

VIBRATION INFORMATION

Vibration total values (triax vector sum) determined according to EN 60745-1 and

EN 60745-2-3

Vibration Emission

Value (ah)

Main Handle

2.9 ms

-2

Auxillary Handle

2.4 ms

-2

Uncertainty (K)

1.5 ms

-2

Page 15

15

JCB-18AG

Instruction & User Manual

OPERATING INSTRUCTIONS

Intended Use

This angle grinder is intended for grinding, edge

grinding (cutting) and surface finishing of metal,

stone and ceramic objects and surfaces.

The tool must not be modified or used for

any other purposes than the ones described in

these instructions.

Battery

Make sure the power switch is not pressed

in when inserting or replacing the battery.

NOTE

m Do not force the battery when

connecting it, use moderate pressure.

An incorrectly connected battery can

damage the battery terminals or the battery

socket on the tool.

m Use the button on the battery to check the

charging status; 4 red LEDs indicates fully

charged, where 1 indicates low battery

status.

Charging The Battery

After charging for the first time, ensure the

battery is completely discharged before

placing on charge again. Repeat this charging

and discharging cycle 4 to 5 times to ensure

battery is correctly conditioned.

WARNING!

m Place the battery charger on a level and

stable surface. Plug the charger into a 230 V

power point.

m Connect the battery to the charger so that it

clicks into place.

m Refer to the Battery Charge Level table

below for battery charger status as indicated

by LED lights.

m Unplug the charger from the power point

and remove the battery from the charger.

Battery Charge Level

Red

LED

Green

LED

Battery Charge Status

Charger is connected to

mains power

Connected battery is

charging

Connected battery is fully

charged

Connected battery has a

charging fault

Charger is outside correct

operating temperature

range (<0˚C / >40˚C)

If the LEDs on the charger do not come on

when charging:

m Check that the charger’s mains adaptor is

properly plugged into the power point and

that the charger is switched on

m Check that the battery is correctly inserted

in the charger

Connecting the battery

m Connect the battery to the battery socket

on the tool so that it clicks into place.

Removing the battery

m Press the battery release button and remove

the battery from the tool.

Page 16

16

JCB-18AG

Instruction & User Manual

Handle

m For work safety and convenience use the

auxiliary handle. This can be mounted on

the left or right side, or on the top of the

machine. Choose the position that provides

the most comfortable and safest handling

Guard

m Fit the guard as shown in the illustration.

Adjust the clamping force of the locking arm

by tightening the hex screw out or in when

the locking arm is unloaded.

Grinding Wheel Assembly

m Place the inner flange disc over the spindle

with the locking edges facing down and

make sure that the disc and spindle’s edges

mate. The flange disc must not rotate freely,

but must follow the rotation of the spindle.

m Place the grinding or cut-off disc on the

inner flange disc and align the hole against

the shoulder.

m Fit the outer flange disc and tighten with the

tightening key. Press and hold in the button

for the spindle lock to prevent the spindle

from rotating during tightening.

m After fitting or replacing the disc, the grinder

should be test-run at a low speed for a

few minutes, without the disc being placed

against an object. If the disc is damaged it

must be replaced immediately.

Disassembling the grinding wheel can be

performed in inverse order.

NOTE

Power Switch

Ensure the self-locking button is loosened

and the switch is in the ‘off’ position before

the power is turned on.

NOTE

m On: Press and push the power switch

forward to start the tool, then press down

the switch to lock.

m Having the switch in the lock position will

mean you don’t have to hold the switch

whilst using the tool.

m Off: Press and push the power switch

backwardso stop the tool.

Using the pressure release function of the

power switch gives you added safety. Letting

go will make the tool stop itself.

NOTE

Surface Grinding

m Allow the tool to reach full speed before

touching the tool to the work surface.

m Apply minimum pressure to the work

surface, allowing the tool to operate at high

speed. Grinding rate is greatest when the

tool is at high speed.

m Maintain a 20-30 degree angle between the

tool and work surface.

m Continuously move the tool in a forward

and back motion to avoid creating gouges in

the work surface.

m Remove the tool from the work surface

before turning it tool off. Allow the tool to

stop rotating before laying it down.

Page 17

17

JCB-18AG

Instruction & User Manual

Edge Grinding (Cutting)

Wheels used for cutting and edge grinding

may break if they bend or twist while the

tool is being used to do cut-off work or deep

grinding.

WARNING!

m Allow the tool to reach full speed before

touching the tool to the work surface.

m Apply minimum pressure to the work

surface, allowing the tool to operate at high

speed. Grinding rate is greatest when the

tool is at high speed.

m Position yourself so that the open-underside

of the wheel is facing away from you.

m Once a cut has begun and a notch is

established in the workpiece, do not change

the angle of the cut. Changing the angle of

the cut will cause the wheel to bend and

may cause wheel breakage. Edge grinding

wheels are not designed to withstand side

pressures caused by bending.

m Remove the tool from the work surface

before turning it tool off. Allow the tool to

stop rotating before laying it down.

Do not use edge grinding/ cutting wheels for

surface grinding applications. These wheels

are not designed for side pressures encoun-

tered with surface grinding - wheel breakage

and injury may result.

WARNING!

Surface Finishing with Sanding

Flap Discs

m Allow the tool to reach full speed before

touching the tool to the work surface.

m Apply minimum pressure to the work

surface, allowing the tool to operate at high

speed. Grinding rate is greatest when the

tool is at high speed.

m Maintain a 5-10 degree angle between the

tool and work surface

m Continuously move the tool in a forward

and back motion to avoid creating gouges in

the work surface.

m Remove the tool from the work surface

before turning it tool off. Allow the tool to

stop rotating before laying it down.

Proper guard must be reinstated for grinding

wheel, sanding flap disc, wire brush or wire

wheel applications after sanding applications

are complete.

WARNING!

Maintenance

Switch off the tool and disconnect the power

(remove battery/unplug) before cleaning and

maintenance. This helps avoid the risk of

electric shocks and accidental starting.

WARNING!

m Wipe the tool with a dry or damp cloth.

Do not use a wet cloth. Do not use

detergent that contains solvent or

corrosive, abrasive additives. This risks

damaging the surfaces of the tool.

m Clear the tool vents and the accessory

mount of dust and dirt after each use.

Do not clean ventilation holes by

inserting sharp objects in them, such

as screwdrivers and other similar

objects.

Page 18

18

JCB-18AG

Instruction & User Manual

m Stubborn contamination in areas hard to

access can be removed with compressed air

(max 3. bar).

m Regularly check all fasteners, screws and

bolts to make sure that they are tight.

Tighten any loose screws immediately or

serious injury could occur.

Never open the tool. The tool has no

internal parts that the user can service or

repair. Never try to repair the tool yourself.

Take to an authorised service centre.

WARNING!

Transport and Storage

m If the tool will remain unused for any length

of time, it should be stored in the original

packaging.

m Store the tool in a dry, frost-free, well

ventilated place with a temperature of no

more than 40°C.

m Keep all tools out of the reach of children.

m Always switch off the tool and disconnect it

from the power supply (remove the battery/

unplug the power cord) before transport.

m Always carry the tool using the purpose-

designed handle.

m Ensure that the tool is not at risk of tipping

over or exposed to excessive vibration and

shocks during transport, especially if the tool

will be transported by car or other vehicle.

Page 19

19

JCB-18AG

Instruction & User Manual

Page 20

20

JCB-18AG

Instruction & User Manual

WARRANTY STATEMENT

JCB Power Tools are guaranteed against manufacturing defects

for up to 5 years (extra charges may apply) from date of purchase

by simply registering your product online within 30 days. Proof of

purchase required. This does not affect your statutory rights.

To register your JCB Power Tool, please visit: jcb-tools.com

Online registration is required to receive a warranty certificate to activate your standard 3 year

warranty. You will be given the option to extend to a 5 Year Warranty (extra charges may apply).

Registration is only available online via www.jcb-tools.com. You will need your original sales

receipt, the model number and the serial number (if applicable) of your product. Kits comprising

of two or more tools are excluded from single registration and must registered individually for full

warranty cover.

Upon successful registration, a warranty certificate will be available to download, print or save as

a PDF document. The relevant warranty certificate together with the original sales receipt will be

required in the event of any claim within the warranty period..

Should you choose not to register your product within 30 days of purchase, your statutory

consumer rights will not be affected. You will need the original sales receipt as proof of purchase in

the event of a warranty claim.

Warranty cover commences from the date of purchase on the retail sales receipt and is valid only

for JCB Tools products purchased within the UK bearing the CE mark and a visible serial number.

In the unlikely event your JCB Power Tool is subject to a manufacturing fault within the warranty

period, JCB Tools may repair the product by replacing defective parts free of charge at our

discretion. In the event parts are irreplaceable JCB Tools may replace your product free of

charge. The original product will remain the property of JCB Tools in this situation.

The above repair or replacement of products will be undertaken providing that:

m The product has been subject to fair wear and tear only.

m The product has not been subject to accidental or cosmetic damage.

Page 21

21

JCB-18AG

Instruction & User Manual

m The product has not been misused and has been used only in accordance with the instruction

manual provided.

m The product has not been subject to overload or insufficient servicing and maintenance.

m The product has not been subject to any abnormal environmental conditions or inappropriate

operating conditions.

m Repairs have not been attempted by an unauthorised person and no modifications have been

made to the product.

m Repairs have not been undertaken using non-genuine spare parts.

JCB Power Tools used for Hire Fleets or as part of B2B and Service Contracts are not covered by

these terms and conditions.

JCB Tools standard 3 Year and extended 5 Year Warranties excludes the following

(where relevant):

m Components normally subject to wear such as carbon brushes.

m Batteries, Chucks and Chargers.

m Accessories and consumable items.

m Cases and tool storage products.

If your product develops a fault within 30 days of purchase, return it to the retailer where it was

purchased together with your sales receipt. If a product develops a fault after 30 days a warranty

claim must be submitted.

If you have a warranty claim please take your product, original sales receipt and if applicable,

a copy of your extended warranty certificate to your place of purchase or nearest JCB Tools

retailer.

If you wish to send your product to us directly, please call us on 03308380257 to arrange

warranty claim or repair. Delivery and repair charges may apply at our discretion should the

warranty claim be invalid for any of the reasons illustrated above. In the event charges are not

accepted the product will be retained by JCB Tools and remain the property of JCB Tools.

The information on both your sales receipt and your extended warranty certificate must match.

JCB TOOLS WILL NOT BE LIABLE FOR ANY INJURIES OR CONSEQUENTIAL DAMAGES

RESULTING FROM USE OF THIS PRODUCT.

Page 22

22

JCB-18AG

Instruction & User Manual

EC DECLARATION OF CONFORMITY

We,

JCB Tools

Declare that the product:

Description

18V Lithium-Ion Angle Grinder

Type

JCB-18AG

Function

Grinding and Surface Finishing

Complies with the following Directives;

EC Machinery Directive

2006/42/EC

EC Electromagnetic Compatibility Directive

2014/30/EU

RoHS Directive

2011/65/EU

Standards conform to

EN 55014-1:2006+A1+A2

EN 55014-2:2015

EN 55014-1:2017

EN 60745-1:2009+A11

EN 60745-2-3:2011+A2+A11+A12+A13

The person authorized to compile the technical file:

Date: 20/09/2018

Signature:

Name/ title: Mya Yee Lwin / Quality Assurance Manager

Address: JCB Tools, 55 Romsey Industrial Estate, Romsey, SO51 0HR, UK.

Company REG: 11062222

Page 23

23

JCB-18AG

Instruction & User Manual

Loading...

Loading...