Page 1

BACKHOE LOADER

Gross power: 63kW (85hp) – 74.2kW (100hp) Maximum dig depth: 4m – 6.14m Maximum shovel capacity: 1.0m3 – 1.3m

|

3CX/4CX ECO

3

Page 2

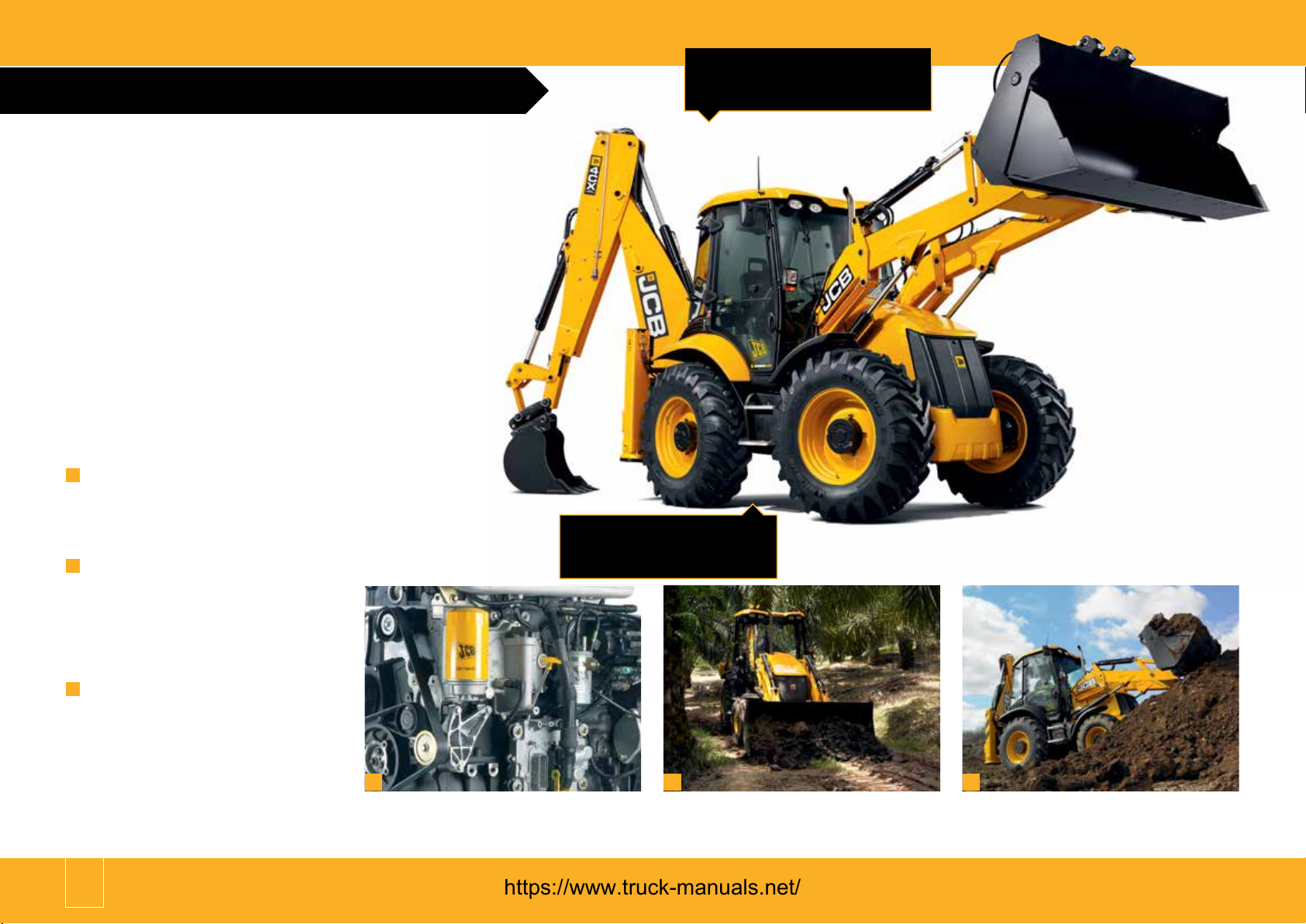

COST OF OWNERSHIP AND EFFICIENCY.

THE LATEST 3CX AND 4CX BACKHOES DON’T

JUST PROVIDE YOU WITH THE POWER TO

GET THINGS DONE; THEY ALSO OFFER YOU

COUNTLESS FEATURES TO ENSURE THAT

PERFORMANCE IS EFFICIENT, AND

OWNERSHIP COSTS ARE REDUCED.

JCB pioneered the backhoe loader in 1953.

Since then, we’ve remained the market

leader, inventing features like 4WD and

An efficient drivetrain.

1

By producing high levels of power and torque

even at engine speeds as low as 1,200rpm,

DIESELMAX can provide fuel-efficient matching of

transmission and hydraulics.

2

JCB EcoRoad technology is designed to provide

the highest efficiency and productivity levels possible

when roading. Featuring JCB’s patented TorqueLock

technology (the world’s first lock-up torque

converter fitted to a backhoe loader), EcoRoad

actually reduces fuel consumption by up to 25%

whilst increasing speed by up to 10%, and working

area by up to 10%.

the side-shift chassis.

As the market leader, JCB sells around half of

all the world’s backhoe loaders.

3

At the loader end of our ECO machines, thanks

to EcoLoad along with high lift capacities and

breakout forces, and of course the outstanding

DIESELMAX engine, you can count on lifting and

shifting more, faster - these are the most efficient

loaders in their class.

3CX/4CX ECO BACKHOE LOADER2

1

2

3

Page 3

Residual benefits.

4

Our DIESELMAX engine can run on lower-grade

fuels, which makes the 3CX and 4CX easily resalable

across different territories. This, of course, boosts

residuals.

A JCB 3CX or 4CX is a great asset in many respects,

not least financially – huge global demand, plus

legendary productivity, plus superb build quality

equals maximum resale value.

COST OF OWNERSHIP AND EFFICIENCY

Added efficiency.

5

JCB’s efficient design philosophy looks at every

aspect of our machines, applying innovative

technologies to squeeze the absolute maximum out

of every drop of fuel and making the 3CX and 4CX

ECO our most efficient backhoes ever.

The result of these innovations is that in typical

roading, loading, excavating and idle cycles our

backhoe loaders deliver an average fuel saving of up

to 16%, plus lower emissions and noise levels.

6

High back-off brakes reduce viscous drag during

roading and rehandling, which in turn improves

economy by up to 2%.

4 65

33CX/4CX ECO BACKHOE LOADER

Page 4

QUALITY, RELIABILITY AND DURABILITY.

THE LATEST JCB 3CX AND 4CX ECO MACHINES ARE

DESIGNED FOR HARD WORK. THEY’RE MADE USING

ONLY THE VERY FINEST MATERIALS AND PROCESSES,

WHICH ARE TESTED, TRIED AND PROVEN TO EXCEL.

THEY’RE ALSO PROTECTED FROM THE INEVITABLE

RIGOURS OF SITE LIFE.

Damage limitation.

1

To stop the 3CX or 4CX’s kingpost hoses from

snagging and sustaining damage, we enclose them

in a flexible, robust guide.

2

The steering ram on the 3CX is protected from

impact damage whilst loading, because it’s mounted

1 2

behind the front axle.

4 3CX/4CX ECO BACKHOE LOADER

3

To protect boom and dipper hoses from the

perils of trenchwork, we’ve enclosed them inside the

rear structures of the machine.

4

The clam rams on our 3CX and 4CX machines

are ultra-reliable because they’re protected from

debris when loading by optional JCB clam shovel

ram guards.

5

To safeguard from impact damage on site,

the 3CX and 4CX are now available with rear

light guards.

43 5

Page 5

Built to last.

6

For added rigidity – and to protect hoses from

damage – a 3CX or 4CX has flat plate-depressed

loader arms, while cat tail welds reduce stress

concentrations.

7

The plastic fuel tank on the 3CX and 4CX is

completely rustproof for ultimate fuel injection

system protection.

8

The single-piece composite cab floor on these

backhoes is also rustproof, and has moulded water

channels.

9

JCB’s robot welded single-piece chassis

maximises strength and minimises weight.

Tested to the limits.

QUALITY, RELIABILITY, DURABILITY

6

10

All the materials with which we construct our

backhoe loaders are tested to the very max. By

exposing those materials to extreme temperatures,

chemicals, salt, oil and light, we know they’ll survive

the most hostile conditions.

11

To prove the durability of our

DIESELMAX

engines, we’ve tested them for 110,000 hours in 70

different machines across the toughest applications

and environments.

The axles and transmissions of JCB 3CXs and 4CXs

are built for a 12,000-hour life, with the heavyweight

axles designed to withstand massive shock loads. The

rear axle alone has a static load rating of 25,000kg,

and a dynamic load rating of 12,500kg.

7 8

9

10

10

11

3CX/4CX ECO BACKHOE LOADER

5

Page 6

PRODUCTIVITY AND PERFORMANCE.

JCB BACKHOES HAVE ALWAYS LED THE

WAY IN POWER AND PERFORMANCE,

AND OUR LATEST 3CX AND 4CX MODELS

ARE NO EXCEPTION. IN EVERY RESPECT

– FROM DIGGING TO LIFTING AND

MANOEUVRING – THESE MACHINES

WILL MAXIMISE YOUR PRODUCTIVITY.

A productive drivetrain.

1

Choose from three engines to suit your

requirements – with 63kW, 68.6kW and 74.2kW

options, you can balance ultra efficiency against

ultimate performance.

2

To give your 3CX or 4CX even greater

traction and performance, as well as reduced

tyre wear, opt for our automatic limited slip

differential traction control.

For enhanced loading performance and

smoother gear changes, we offer a 6-speed

gearbox with low ratio first and second gears.

With a 160-litre fuel tank, the 3CX and

4CX ECO machines are designed to do

a huge amount of work between refills.

Innovative hydraulics.

3

EcoLoad also features a Hydraulic Speed

Control (HSC) switch which – combined with

high torque at low engine speed from our

DIESELMAX engine – gives more tractive effort,

faster cycle times, excellent pushing power and

hill climbing performance.

6 3CX/4CX ECO BACKHOE LOADER

1 2

3

Page 7

Digging further.

A 3CX or 4CX ECO’s 4-ram self-levelling loader

automatically adjusts the shovel on both raise and

lower cycles without any need for manual

adjustment. It also provides unhindered front shovel

visibility, especially when loading at height.

The JCB return-to-dig feature means operators can

quickly reset the shovel to dig.

4

To ensure an extra 1.2m dig depth and reach

– and to minimise repositioning – the 3CX and 4CX

are fitted with our inner box design Extradig feature.

Both the 3CX and 4CX ECO boast high ground

clearances of up to 370mm, together with 20°

departure angles. This means operators can work

easily on steep slopes and uneven ground at

maximum productivity.

PRODUCTIVITY AND PERFORMANCE

4

JCB 4CX:

the ultimate backhoe loader.

5

Boasting unparalleled power, peformance and

versatility, the JCB 4CX ECO is the ideal machine

for just about any application, from road-building to

house-building, waste recycling and landscaping.

6

The 4CX ECO’s large optional 1.3m³ shovel

capacity along with 3 steering modes provide

exceptional on-site productivity.

5 6 6

Four-wheel steer Two-wheel steer Crab-steer mode

73CX/4CX ECO BACKHOE LOADER

Page 8

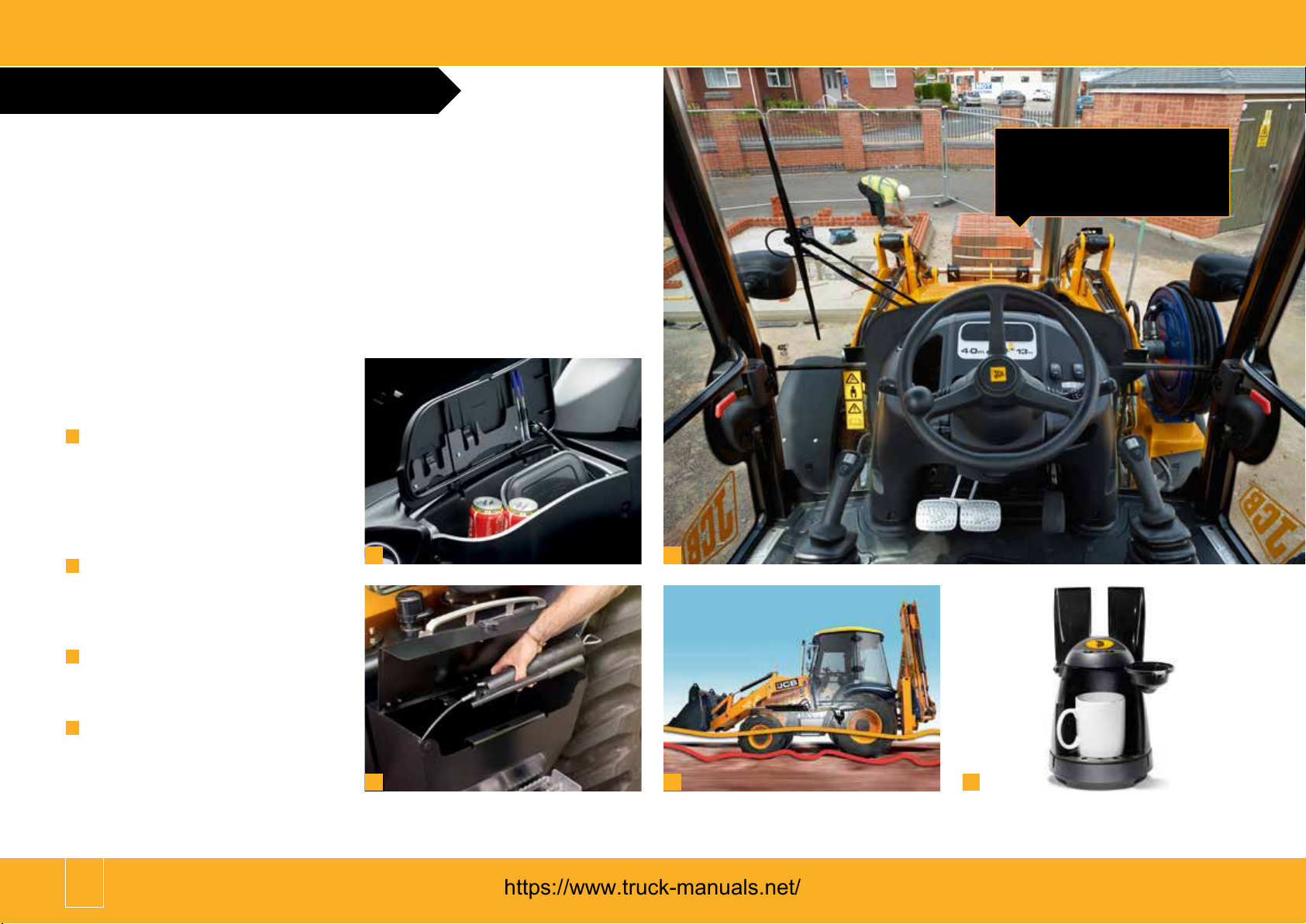

COMFORT AND EASE OF USE.

IN ORDER TO HELP YOU REAP THE MAXIMUM

BENEFIT OF THE 3CX AND 4CX’S SUPERIOR

PERFORMANCE, WE’VE DESIGNED THESE MACHINES

TO BE ALL-DAY COMFY, ERGONOMIC AND EXTREMELY

INTUITIVE FOR OPERATORS TO USE.

A great place to work.

All our ECO backhoes have low noise levels, with

our 63kW (85hp) engine model offering the

quietest operation.

1

To help operators get to work quickly and safely,

our optional heated front screen/heated mirrors

remove any built-up frost and ice without the need

to climb across the machine on cold mornings. A cab

pre-heating option can be set to warm the cab

automatically without starting the engine.

2

There’s storage aplenty in our 3CX and 4CX

cabs; work tools are easy to carry, the cab

environment is well-organised and, on A/C models,

there’s an in-cab cool box for food and drinks.

2

JCB’s single piece glass provides optimum

visibility across the work area of a 3CX or

4CX ECO, while our narrow front bonnet

allows extra visibility to the front shovel

and wheels.

1

3

For added comfort and reduced material spillage,

JCB’s SmoothRide System minimises bounce

during travel.

4

Exclusive to JCB backhoe loader,

integrated a hot drinks machine option into the cab to

provide you with a delicious cup of hot tea or coffee

throughout the day.

8 3CX/4CX ECO BACKHOE LOADER

we have

3 42

Page 9

COMFORT AND EASE OF USE

Maximum manoeuvrability.

5

JCB’s new improved Powerslide features a

larger hydraulic ram, which produces more power

to reposition the excavator quickly and effortlessly.

The 3CX and 4CX have optional LSD to stop

wheelspin in difficult ground conditions, inturn

reducing tyre wear.

6

5

Efficient, safe stopping power requires minimal

pedal effort because of the 3CX and 4CX ECO’s

power brakes.

7

JCB X (Diagonal)

Slew

left

Boom

raise

ISO +

Dipper out

Slew

left

Dipper in

SAE +

Boom lower

Slew

left

Boom raise

9

Boom

lower

Slew

right

Slew

right

Slew

right

Dipper

Bucket

Bucket

crowd

Bucket

crowd

out

crowd

Boom lower

Boom raise

Dipper out

Dipper in

Bucket

dump

Dipper

in

Bucket

dump

Bucket

dump

Always in control.

7

The EcoDig system is controlled by a two-

position rocker switch on the main console in the

cab. This control offers the operator a choice

between an ECO mode, maximum efficiency and

digging potential mode, or Lo mode, an ultimate

machine control for fine grading, lifting and delicate

groundworks profiling applications.

8

JCB’s ergonomic seat-mounted excavator-style

controls (a standard-fit on our Easy and Advance Easy

Control machines) make for great manoeuvrability,

fingertip control and supreme comfort.

9

So that operators feel right at home in the

3CX/4CX ECO, we fit a traditional manual control

system as standard, with a choice of three control

patterns – JCB X, SAE+ and ISO+.

With joystick-controlled loader operations on

Advanced EasyControl, it’s comfortable, logical and

easy to control the loader end of a 3CX or 4CX.

6

8

93CX/4CX ECO BACKHOE LOADER

Page 10

SECURITY AND SERVICEABILITY.

AS THE WORLD’S NUMBER ONE BACKHOES,

THE 3CX AND 4CX ARE BLESSED WITH SUPREME

POWER AND PRODUCTIVITY. TO BALANCE ALL THAT

PERFORMANCE AND DESIRABILITY, THERE’S SAFETY,

SECURITY AND SERVICEABILITY APLENTY TOO.

Safe and secure.

1

A stabiliser warning system* lets 3CX and 4CX

operators know if the stabilisers aren’t fully retracted

when the machine is on the move.

2

The 3CX and 4CX ECO are safe machines to

1

get in and out of, with large anti-slip steps of an open

grille design to stop material build-up.

3

2

10

3CX/4CX ECO BACKHOE LOADER

3

To keep operators safe even when using

powered attachments, we fit an impact-protected

rear screen* to these backhoes. This also makes glass

replacement easy.

4

There’s a large lockable toolbox onboard for

safe storage.

5

Punctures are a fact of life on site, which is

why the 3CX and 4CX feature optional liquid fill

tyres for a fast repair.

* Optional

4 5

Page 11

Safety.

6

An optional JCB keypad immobiliser adds to

machine protection and allows the operator to key in

a sequence of numbers to activate the starting of the

machine. An alternative option to this is the unique

JCB key featuring a built-in circuit chip – each

backhoe loader can only be started by its’ own,

unique key.

SECURITY AND SERVICEABILITY

Serviceability.

To save more time and effort, these backhoes are

designed to offer grouped single-side servicing.

7

Our one-piece bonnet is easy to lift, and there’s

no need to remove extra side panels.

8

Refuelling of a 3CX or 4CX can be done from

ground level.

We’ve got a patented rear stabiliser wear pad design,

with fast and simple adjustment.

9

JCB LiveLink telematics can provide an array of

information to optimise fleet management and

machine reliability.

7

6

8

9

113CX/4CX ECO BACKHOE LOADER

Page 12

THE OPTIONS LIST.

A BACKHOE LOADER IS, BY ITS VERY NATURE,

A HIGHLY VERSATILE MACHINE, BUT OUR OPTIONAL

EXTRAS MAKE IT ALL THE MORE SO, ALLOWING

YOU TO TAILOR YOUR 3CX OR 4CX TO A HUGE

ARRAY OF DIFFERENT APPLICATIONS.

6-in-1 shovel.

1

Equip your 3CX or 4CX with one of these and

you can dig, doze, load, grab, grade and backfill

without having to switch attachments.

Front bumper protection bars.

2

The 3CX can be equipped with front protection

bars, protecting the bonnet and front grill from

damage when loading into lorries and trailers.

Excavator lifting kit.

3

This lifting kit means you can use a 3CX or 4CX

ECO’s excavator arm as a crane for object handling.

Optional hose burst check valve (HBCV) on the boom,

together with an audio warning alarm, are available.

design reduces the potential for on-site damage and

protects the hose when it’s not being used.

Handheld tools and the excavator can be operated

simultaneously for increased productivity; this also

removes the need for separate powerpacks –

traditionally a theft risk. The hose reel meets EHTMA

Class C tool operation standards and features low

back pressures, 138 bar pressure and

a 20 l/min flow rate.

Hydraulic thumb.

5

This feature increases the versatility of your 3CX

or 4CX because its profiled edge is ideal for handling

round objects and awkward materials – logs, pipes or

scrap metal, for example.

Dozing

Grabbing Grading

1

1

Digging

Loading

Backfilling

3

4

Hose reel.

4

The unique ability of a JCB backhoe to provide

an independent hydraulic circuit for handheld tools is

nothing new. But our 9m hose reel option means

you get even greater working radius, while the reel

12 3CX/4CX ECO BACKHOE LOADER

2 5

Page 13

THE OPTIONS LIST

Powerslide.

6

JCB Powerslide hydraulically sideshifts the backhoe

for less effort and reduces the change of any site

damage to tarmac or paved surfaces, making it ideal

for the utilities sector.

Combined hammer and

bi-directional unit.

7

Increasing attachment compatibility and versatility,

this brand new option provides both low-flow and

high-flow hydraulic power, with low back pressure

maintaining optimum flow to the attachment. The

circuit operates independently of the extending

dipper and is capable of operating a wide range of

single and double acting attachments. Hammer only,

or hammer and bi-directional options are available.

Knuckleboom.

8

T

he 4CX ECO features a knuckleboom option

(4CN) which has a 30° articulation angle between the

boom and dipper giving a working envelope of 240°.

This allows you to dig in areas simply not possible with

a conventional backhoe, such as around objects like

tress, telegraph poles or lamp posts; parallel alongside

a road while keeping the machine on the road; or

even towards the front of the machine.

Hydraulic quickhitch.

9

Our latest quickhitch makes attachment changing

quick, safe and compliant with both current and

future legislation.

Integral shovel street pads.

10

This new option prevents ground damage and,

therefore, costly repairs.

6

7 8 10

9

3CX/4CX ECO BACKHOE LOADER

13

Page 14

LIVELINK, WORK SMARTER.

LIVELINK IS AN INNOVATIVE SOFTWARE

SYSTEM THAT LETS YOU MANAGE JCB

MACHINES REMOTELY – ONLINE, BY

EMAIL OR BY MOBILE PHONE. ACCESS

EVERYTHING FROM MACHINE ALERTS

TO HISTORY INFORMATION, WITH ALL

DATA STORED AT A SECURE CENTRE.

Maintenance benefits

Manage machine maintenance easily –

accurate hours monitoring and service alerts

improve maintenance planning, while

real-time location data helps you manage

your fleet. Critical machine alerts and

maintenance history records are also available.

Productivity and cost benefits

You can monitor and manage your machines

fuel level throughout the day using the analysis

function. Livelink has a comprehensive

reporting tool allowing you to manage your

machines up time and utilisation to get the

most of your machine.

Security benefits

Livelink’s real-time geofencing alerts tell you

when machines move out of predetermined

zones, and real-time curfew alerts inform you

of unauthorised usage, straight to your mobile

phone. Further benefits include real-time

location information, and LiveLink has its own

internal battery and aerial.

Note: LiveLink features are model dependent, check machine specifications.

14 3CX/4CX ECO BACKHOE LOADER

Page 15

VALUE ADDED.

JCB’S WORLDWIDE CUSTOMER SUPPORT IS FIRST CLASS.

WHATEVER YOU NEED AND WHEREVER YOU ARE, WE’LL BE

AVAILABLE QUICKLY AND EFFICIENTLY TO HELP MAKE SURE

YOUR MACHINERY IS PERFORMING TO ITS FULL POTENTIAL.

1

Our Technical Support Service provides instant

access to factory expertise, day or night, while our

Finance and Insurance teams are always on hand to

provide fast, flexible, competitive quotes.

2

The global network of JCB Parts Centres is

another model of efficiency; with 15 regional bases,

we can deliver around 95% of all parts anywhere in

the world within 24 hours. Our genuine JCB parts

are designed to work in perfect harmony with your

machine for optimum performance and productivity.

2

3

JCB Assetcare offers comprehensive extended

warranties and service agreements, as well as

service-only or repair and maintenance contracts.

Irrespective of what you opt for, our maintenance

teams around the world charge competitive labour

rates, and offer non-obligation quotations as well as

fast, efficient insurance repair work.

31

Manufacturing Facilities

Dealers

Parts Distribution Centres

153CX/4CX ECO BACKHOE LOADER

Page 16

SPECIFICATION

A

K

SPECIFICATION

STATIC DIMENSIONS

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

G

F

E

D

J

K

Dimensions in mm 3CX Eco

A Total travel length

B Axle centreline distance

C Slew centre to rear axle centre distance

D Stabiliser feet clearance

E Kingpost clearance

F Steering wheel centre height

G Cab roof height

H Total travel clearance

5.62 5.62 5.62 5.91 5.91 5.91 5.91 5.91 5.91 7.53

2.17 2.17 2.17 2.22 2.22 2.22 2.22 2.22 2.22 2.32

1.36 1.36 1.36 1.36 1.36 1.36 1.36 1.36 1.36 1.20

0.37 0.37 0.37 0.33 0.33 0.34 0.34 0.34 0.34 0.41

0.52 0.52 0.52 0.48 0.48 0.50 0.50 0.50 0.50 0.50

1.94 1.94 1.94 1.86 1.86 1.88 1.88 1.88 1.88 1.88

3.03 3.03 3.03 2.98 2.98 3.03 3.03 3.03 3.03 3.03

3.61 3.61 3.61 3.48 3.56 3.54 3.62 3.97 3.97 3.91

B

A

Sitemaster

3CX Eco

C

3CX Eco

Contractor

J Rear frame width 2.35 2.24* 2.35 2.24* 2.35 2.24*

K Shovel width 2.35 2.23* 2.35 2.23* 2.35 2.23*

K Shovel width - option

- - - - - - - -

* Narrow option

H

G

F

D

3CX Eco

Super

J

3CX Eco

Super Sitemaster

4CX

4CX

Sitemaster

4CX

Super

B

4CX Super

Sitemaster

C

H

E

4CN

2.24 2.24 2.36 2.36 2.36 2.36 2.36

2.23 2.23 2.33 2.33 2.33 2.33 2.33

2.44 2.44 2.44 2.44

-

GROUND LINE ANGLES

Machine model

L Approach angle

L

N

M

M Interference angle/ramp to ground plane

N Departure angle

degrees

degrees

degrees

3CX, 3CX Sitemaster,

3CX Sitemaster

66° 74° 74°

120° 118° 118°

20° 19° 19°

3CX Super,

3CX Super Sitemaster

4CX All models

Page 17

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

SPECIFICATION

SPECIFICATION

ENGINE (Stage II / Stage IIIb)

Model

Engine standard Stage IIIb Stage IIIb Stage IIIb Stage IIIb

Manufacturer JCB JCB JCB JCB

Aspiration Turbocharged Turbocharged

Displacement litre 4.4 4.4 4.4 4.4

No. of cylinders 4 4 4 4

Bore mm 103 103 103 103

Stroke mm 132 132 132 132

Rated engine rpm 2200 2200 2200 2200

Power ratings

Rated ISO 14396 (SAE J1995 Gross) kW 63 68.6 74.2 74.2

Maximum torque

Max. torque rpm Nm 320/362 400/408 425/440 425/440

Max. torque rpm rpm 1200 1400 1500 1300

TRANSMISSION

Model 2WS 63kW 2WS 68.6kW 2WS 74.2kW AWS 68.6kW AWS 74.2kW

Manufacturer JCB JCB JCB JCB JCB JCB JCB JCB JCB JCB

Type Syncroshuttle Syncroshuttle Powershift Autoshift Powershift Autoshift Syncroshuttle Powershift Powershift Autoshift

Gear selction Manual Manual Powershift Powershift Powershift Powershift Manual Powershift Powershift Powershift

Torquelock N/A N/A Optional Optional Standard Optional N/A Optional Standard Optional

Gear 1 6.2 6.2 5.4 5.1 5.4 5.1 5.7 4.9 5.0 4.9

Gear 2 10.0 10.0 10.0 8.6 10.0 8.6 9.1 8.6 9.3 8.1

Gear 3 21.3 21.3 22.5 11.6 22.5 11.6 19.6 19.8 21.5 11

Gear 4 39.8 39.8 38.3 18.7 38.3 18.7 37.1 37.1 38.1 17.7

Gear 5 - - - 31.3 - 31.1 - - - 29.6

Gear 6 - - - 38.3 - 38.3 - - - 38.1

3CX Eco,

Sitemaster

Stage II / Stage IIIb Stage II / Stage IIIb Stage II / Stage IIIb Stage II / Stage IIIb

3CX Eco,

Sitemaster, Super

Super Sitemaster

3CX Eco

,

Contractor

Turbocharged &

Intercooled

4CX

All models

Turbocharged &

Intercooled

ELECTRICAL AND INSTRUMENTATION

Gauges Tachometer, engine coolant temp, fuel level, hourmeter, clock

Warning system

Battery 900 CCA/110 A/hr

Pre-wire Radio speakers (cab), beacon (all)

Horn Controlled from both front and rear

Alternator 95 amp standard

Front working lights 4 adjustable

Rear working lights 4 adjustable

ENGINE SUPPORT SYSTEM

Fuel type Diesel

Fuel filter Replaceable cartridge plus water/sediment separator prefilter

Air cleaner Dual, dry element type, with self cleaning internal air intake precleaner

Oil filter and lubrication Full flow, spin-on type filter

Cooling system Hot climate specification, pressurised 1.0 bar suction fan. Pressurised recovery tank with integral filler neck

Audible and visual system. Engine oil, water in fuel, transmission oil temperature and

pressure, park brake, air cleaner, alternator

OPERATING WEIGHTS

Machine model 3CX

Fixed dipper kg 7702 - - 7999 - 8178 - 8394 - -

Extended dipper kg 8102 8102 8102 8399 8399 8578 8578 8794 8794 8846

Measured with 6-in-1, 600mm bucket, full fuel tank and operator

Actual weight will vary depending on machine options.

3CX

Sitemaster

3CX

Contractor

3CX

Super

3CX

Super Sitemaster

4CX

4CX

Sitemaster

4CX

Super

4CX

Super Sitemaster

4CN

Page 18

SPECIFICATION

SPECIFICATION

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

FRONT AXLE

Model 3CX 2WD

Type Flame cut bar

Limited slip - - - Option

Axle ratings kg kg kg kg

Static load rating 16500 16500 25000 25000

Dynamic load rating 8300 8300 12500 12500

Oscillation angle 16° 16° 16° 16°

REAR AXLE

Model

Type

Limited slip Option Option Option

Axle ratings kg kg kg

Static load rating 25000 25000 25000

Dynamic load rating 12500 12500 12500

STEERING

Model

Axles Steer drive Steer drive

Steering turns - lock to lock 23⁄4 23⁄4 23⁄4

Kerb – kerb turning circle - unbraked

Loader clearance circle

Kerb – kerb turning circle - braked 6.9 8.0 8.0

Loader clearance circle - braked 9.5 9.5 9.5

(Depending on tyre size, ground conditions etc.)

SERVICE CAPACITIES

Model 3CX All models 4CX All models

Cooling system

Fuel tank

Engine oil with filter

Gearbox with filter

Rear axle

Front drive axle

Hydraulic system incl. tank

3CX, 3CX Contractor,

3CX Sitemaster

JCB epicyclic hub reduction with

torque proportional

3CX, 3CX Contractor,

3CX Sitemaster

-

unbraked 10.4 11.15 10.7

3CX 4WD,

3CX Sitemaster,

3CX Contractor

JCB steer drive with

torque proportiona

3CX Super Sitemaster

JCB 4WD steer drive with

torque proportional

m m m

8.1 9.35 9.1

ltr

ltr

ltr 15 15

ltr 16 16

ltr 16 16

ltr 16 16

ltr

3CX Super, 3CX

Super Sitemaster

JCB 4WD steer drive

with torque proportio

l

3CX Super,

3CX Super Sitemaster

18.5 18.5

160 160

117 117

3CX Super,

JCB epicyclic hub reduction

with torque proportional

All models

JCB epicyclic hub reduction with

torque proportional

All models

Steer drive

4CX

All models

4CX

4CX

OPTIONAL ACCESSORIES

Key/keypad immobiliser, Sitemaster, Michelin or Goodyear Brands of tyres with a selection of traction/industrial tread in a crossply/ radial

construction, Powershift/Autoshift transmissions, JCB TorqueLock, JCB Powerslide, Standard excavator buckets (300mm to 900mm), Deep

profile excavator buckets (300mm to 940mm), Ditching buckets, General purpose/6-in-1 front shovels, Manual/ hydraulic front quickhitch,

Manual/hydraulic rear quickhitch, 3/8" loader arm pipework/5/8" loader arm pipework, Hammer/ bi-directional pipework, Hand held tool circuit,

9m hose reel, Excavator lifting kits for EN474 and non-EN474 territories, Loader/ excavator HBCV’s, Electric refuelling pump, Heated front

screen, Heated mirrors, Reverse alarm, Coffee machine, Grid heaters, Eberspacher cold start kits, Front bumper protection, Fire extinguisher,

Fuel tank guards, Air suspension seat, Seat headrest, Biodegradeable oil, Black/yellow trim kits, Instrument panel vandal guard, Different size front

counterweights, Stabiliser streetpads, Shovel streetpads, Rear light guards, Lubricity filter, Shovel clam ram guards, Dual pattern controls (ISO/SAE

changeover), Extendable steer column, Air conditioning, SRS.

HYDRAULIC SYSTEM - 3CX

3CX, 3CX Super,

Pump flows* 3CX, 3CX Sitemaster

Open centre systems

(Gear pumps) @ 1750 rpm

Manual Control (Gear pump)

Pump 1 58 63 65

Pump 2 & 3

EasyControl

Pump 1 - 63 65

Pump 2 & 3

Closed centre systems

(Piston pump) @ 2200 rpm

Advanced EasyControl

System relief pressure

*Optimum flow **Territory specific

HYDRAULIC SYSTEM - 4CX

Pump flows*

Open centre systems

(Gear pumps) @ 1700 rpm

Manual Control (Gear pump)

Pump 1 & 3 82 80

Pump 2

EasyControl

Pump 1 & 3 82 80

Pump 2** 73 64

Closed centre systems

(Piston pump) @ 2200 rpm

Advanced EasyControl

System relief pressure

*Optimum flow **Territory specific

l/min l/min l/min

71 81 89

- 81 89

l/min l/min l/min

- 165 (32.3) 165 (32.3)

bar (lbf/sq in) bar (lbf/sq in) bar (lbf/sq in)

251 (3650) 251 (3650) 251 (3650)

4CX** 4CX**

l/min l/min

73 64

l/min l/min

165 165

bar (lbf/sq in) bar (lbf/sq in)

251 (3650) 251 (3650)

3CX Sitemaster,

3CX Super Sitemaster,

3CX Contractor

3CX Contractor**

Page 19

LOADER DIMENSIONS

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

SPECIFICATION

SPECIFICATION

P

S

R

Q

3CX, 3CX Contractor,

3CX Sitemaster

GP shovel 6-in-1 shovel GP shovel 6-in-1 shovel GP shovel 6-in-1 shovel GP shovel 6-in-1 shovel

M Dump height m 2.74 2.72 2.64 2.64 2.69 2.69 2.69 2.69

N Load over height m 3.23 3.20 3.16 3.13 3.21 3.18 3.21 3.18

O Loader hinge pin height m 3.45 3.45 3.41 3.41 3.46 3.46 3.46 3.46

P Pin forward reach m 0.36 0.36 0.47 0.47 0.41 0.41 0.41 0.41

Q Reach at ground (toe plate horizontal) m 1.42 1.37 1.52 1.50 1.42 1.39 1.42 1.39

R Max. reach at full height m 1.20 1.15 1.26 1.22 1.21 1.17 1.21 1.17

S Reach at full height fully dumped m 0.83 0.78 0.88 0.82 0.82 0.76 0.82 0.76

T Dig depth m 0.07 0.10 0.18 0.23 0.14 0.18 0.14 0.18

U Roll back at ground degrees 45° 45° 45° 45° 45° 45° 45° 45°

V Dump angle degrees 43° 43° 44° 44° 45° 45° 45° 45°

Jaw opening width m - 0.95 - 0.95 - 0.95 - 0.95

V

O

N

M

U

T

3CX Super, 3CX Super

Sitemaster

4CX, 4CX Super 4CX All models

P

S

R

Q

V

O

N

M

U

T

LOADER PERFORMANCE

Model 3CX

GP shovel 6-in-1 shovel 6-in-1 shovel GP shovel 6-in-1 shovel GP shovel 6-in-1 shovel GP shovel 6-in-1 shovel

Loader breakout – shovel kgf 6170 6531 6590 6227 6531 6227 6590 6227 6590

Loader breakout – arms kgf 4942 4732 5730 5936 4732 5936 5730 5936 5730

Rated operating capacity 7’4”* kgf 3479 3229 4378 4638 3229 – – – –

Rated operating capacity 7’8”* kgf 3439 3169 – – 3169 – – – –

Rated operating capacity kg – – – – – 4638 4378 4638 4378

Clamping force kgf – 2940 2945 – 2940 – 2945 – 2945

*Rated operating capacity as determined according to ISO 14397: 2007

3CX Super,

3CX Super Sitemaster

3CX Super

3CX Sitemaster,

3CX Contractor

(Standard lift)

4CX, 4CX Super 4CX All models

Page 20

SPECIFICATION

SPECIFICATION

LOADER ATTACHMENTS – Forklift Performance Data

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

forks

Y

Z

W

X

4CX All models

Quickhitch mounted

forks

Y

Z

W

X

3CX, 3CX Contractor, 3CX Sitemaster

6-in-1 shovel mounted

forks

W Forks – tine length m 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1

Forks – tine width m 0.08 0.08 0.08 0.08 0.08 0.08 0.08 0.08

X Forks reach at ground level m 2.66 2.03 2.78 2.18 2.68 2.13 2.68 2.13

Y Forks reach at full height m 2.25 1.72 2.38 1.81 2.30 1.76 2.30 1.76

Z Forks lift height – max m 2.92 3.27 2.85 3.23 2.90 3.28 2.90 3.28

Fork spacing – min m 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2

Fork spacing – max m 2.17 1.03 2.17 1.03 2.17 1.03 2.17 1.03

SWL @ 500mm load centres kg 1000 2000 1000 2000 1000 2000 1000 2000

Quickhitch mounted

forks

3CX Super, 3CX Super Sitemaster

6-in-1 shovel mounted

forks

Quickhitch mounted

forks

4CX Super, 4CX Sitemaster

4CX Super Sitemaster

6-in-1 shovel

mounted forks

Quickhitch mounted

forks

6-in-1 shovel mounted

LOADER ATTACHMENTS – Direct Mount

Capacity SAE

G.P. Shovel 6-in-1

Width mm (ft-in) Rated m³ Struck Rated m³ Struck

2235 (7-4) 1.0 0.83 1.0 0.76

2350 (7-8) 1.1 0.91 1.2 1.02

2350 (7-8) 4CX model only 1.3 1.19 1.2 1.02

2440 (8-0) 4CX model only - - 1.3 1.19

3CX All models

4CX

4CX Super

4CX Sitemaster

4CX Super Sitemaster

Page 21

BACKHOE DIMENSIONS

E

H

C

A

B

C

D

J

G

F

A

J

E

H

C

F

D

C

B

G

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

SPECIFICATION

SPECIFICATION

3CX

C

E

C

E

H

3CX, 3CX Sitemaster,

3CX Contractor

3CX Super

3CX Super,

3CX Super Sitemaster

4CX

4CX,

4CX Sitemaster

4CX Super, 4CX

Super Sitemaster

H

Standard Dipper Extradig Standard Dipper Extradig Standard Dipper Extradig Standard Dipper Standard Dipper

A SAE max dig depth m

SAE 2ft flat bottom m

Maximum dig depth with deep profile bucket m

B Reach – ground level to rear wheel centre m

C Reach – ground level to slew centre m

D Reach – at full height to slew centret m

E Side reach – to centre line of machine m

F SAE operating height m

G Maximum loadover height m

SAE loadover height m

H Total kingpost travel m 1.16 1.16 1.05 1.05 1.16 1.16 1.16 –

Ext – 5.46 – 5.58 – 5.53 6.14 –

Ret 4.24 4.24 4.37 4.37 4.32 4.32 4.98 4.85

Ext – 5.43 – 5.55 – 5.50 6.11 –

Ret 4.21 4.21 4.34 4.34 4.29 4.29 4.93 4.82

Ext – 5.97 – 5.93 – 5.88 6.51 –

Ret 4.75 4.75 4.72 4.72 4.67 4.67 5.35 5.19

Ext – 7.87 – 7.88 – 7.88 8.44 –

Ret 6.72 6.72 6.74 6.74 6.74 6.74 7.35 7.13

Ext – 6.52 – 6.54 – 6.54 7.10 –

Ret 5.37 5.37 5.40 5.40 5.40 5.40 6.01 5.93

Ext – 3.66 – 3.75 – 3.75 4.47 –

Ret 2.74 2.74 2.82 2.82 2.82 2.82 3.43 3.26

Ext – 7.09 – 7.09 – 7.16 7.71 –

Ret 5.94 5.94 5.94 5.94 6.02 6.02 6.69 5.93

Ext – 6.35 – 6.20 – 6.26 6.52 –

Ret 5.53 5.53 5.39 5.39 5.45 5.45 5.89 5.82

Ext – 4.72 – 4.67 – 4.73 5.03 –

Ret 3.84 3.84 3.78 3.78 3.84 3.84 4.06 4.60

Ext – 4.32 – 4.22 – 4.28 4.55 –

Ret 3.4 3.4 3.33 3.33 3.39 3.39 3.58 –

Narrow rear frame option m 1.05 1.05 – – – – – –

J Bucket rotation Speed 201° 201° 201° 201° 201° 201° 201° 201°

4CN

Page 22

SPECIFICATION

SPECIFICATION

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

BACKHOE PERFORMANCE

Bucket tearout kgf

Dipper tearout kgf

Lift capacity of bucket pivot at full reach kg

* Heavy Lift excavator

3CX, 3CX Sitemaster,

3CX Super, 3CX Super Sitemaster

3CX Contractor 4CX 4CX, 4CX Sitemaster

4CX Super,

4CX Super Sitemaster

4CN

Standard Dipper Extradig Extradig Standard Dipper Extradig Standard Dipper Standard Dipper

Speed 5431 5385 5385 5431 5385 5387 6047

Power 6324 6228 6228 6324 6228 6230 6929

Ext – 2255 2255/ 2729* – 2729 2675 –

Ret 3217 3225 3225/ 3903* 3893 3903 3722 3893

Ext – 719 719/ 1082* – 1082 1199 –

Ret 1584 1451 1451/ 1885* 2046 1885 1556 1733

BACKHOE ATTACHMENTS – Standard Profile Bucket

3CX & 4CX All models

Width* Capacity SAE Weight (+ Teeth)

mm Rated m³ Struck m

3

kg Teeth

229 0.04 0.03 95 0

305 † 0.06 0.05 102 3

DITCHING BUCKETS

3CX All models 4CX All models

Width* Capacity SAE Weight Capacity SAE Weight

mm Rated m³ Struck m

3

kg Rated m³ Struck m

3

1525 0.22 0.155 150 0.22 0.16 150

1830 0.26 0.186 172 0.26 0.19 172

356 † 0.075 0.06 105 3

400 † 0.09 0.07 109 3

457 † 0.12 0.09 116 3

610 † 0.17 0.13 140 4

800 † 0.24 0.17 162 5

950 † 0.30 0.21 198 5

TAPERED BUCKETS –

Width* Capacity SAE

mm Rated m³ Struck m

381–1676 0.07 0.06 30 2

305–1067 0.12 0.10 60 2

3CX & 4CX All models

3

Angle degrees Teeth

* Including sidecutters. Width less sidecutters deduct 25mm.

† Available with additional wear strips to give added strength and rigidity.

BACKHOE ATTACHMENTS – Standard Profile Bucket

3CX All models 4CX All models

Width* Capacity SAE Weight (+ Teeth) Capacity SAE Weight (+ Teeth)

mm Rated m³ Struck m

3

kg Teeth Rated m³ Struck m

3

kg Teeth

305 0.09 0.07 102 3 0.09 0.07 102 3

356 0.11 0.09 117 3 0.11 0.09 117 1

457 0.16 0.13 122 3 0.16 0.13 122 3

610 0.23 0.18 142 4 0.23 0.18 142 4

800 0.30 0.24 163 5 0.30 0.24 163 5

950 0.38 † 0.30 183 5 0.38 0.30 183 5

1100 0.48 † 0.34 203 6 0.48 0.34 203 6

* Including sidecutters. Width less sidecutters deduct 25mm (1in).

† Capacity in cu.yd.

kg

Page 23

TM320 Telescopic Wheeled loading shovel

3CX/4CX ECO Backhoe loader

SPECIFICATION

SPECIFICATION

233CX/4CX ECO BACKHOE LOADER

Page 24

ONE COMPANY, OVER 300 MACHINES.

Your nearest JCB dealer

9999/5756 11/13 Issue 1 (T2/T3)

3CX/4CX Eco Backhoe Loader

Gross power: 63kW (85hp) – 74.2kW (100hp) Maximum dig depth: 4m – 6.14m

Maximum shovel capacity: 1.0m3 – 1.3m

3

JCB Sales Limited, Rocester, Staffordshire, United Kingdom ST14 5JP.

Tel: +44 (0)1889 590312 Email: salesinfo@jcb.com

Download the very latest information on this product range at: www.jcb.com

©2009 JCB Sales. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic,

mechanical, photocopying or otherwise, without prior permission from JCB Sales. All references in this publication to operating weights, sizes, capacities and other performance

measurements are provided for guidance only and may vary dependant upon the exact specification of machine. They should not therefore be relied upon in relation to suitability

for a particular application. Guidance and advice should always be sought from your JCB Dealer. JCB reserves the right to change specifications without notice. Illustrations and

specifications shown may include optional equipment and accessories. The JCB logo is a registered trademark of J C Bamford Excavators Ltd.

www.carbonbalancedpaper.com

unique print number

Loading...

Loading...