Page 1

M9500 MONITOR LOUDSPEAKERS

OWNERS MANUAL

M9500

Page 2

GENERAL SYSTEM DESCRIPTION

The JBL M9500 monitor loudspeaker system represents a

refinement of the principles that have guided JBL’s high-level

monitor system design over the last thirty years.

In keeping with contemporary monitoring practice, the system

is essentially of two-way design. A horn-compression driver

section covers the frequency range from 650Hz to20kHz.

Located above and below the high-frequency section are

mirror-imaged low-frequency transducers in ported enclosures.

The stereo pair of loudspeakers exhibits both vertical and

horizontal symmetry for effective “point source” radiation and

for accurate stereophonic imaging. All transducers make use of

shielded neodymium magnets, and the systems can be used in

proximity to video monitors with no interference.

The M9500 system uses stand-alone dividing networks that

facilitate various electronic options, including bi-wiring, triwiring, and biamplification. The networks are designed around

the finest components available and make use of dc bias on

the capacitors for greater linearity.

A single M9500 system is capable of producing sine wave output levels of 110 dB Lp at one meter with extremely low

distortion. In terms of wide band program, this translates into

levels of 120 dB Lp for the stereo pair at normal listening

distances of 2 and 3 meters.

The enclosures are made of thick sections of mediumdensity fiberboard, liberally braced, and have an attractive,

scuff-resistant finish.

Unpacking and Inspection

The complete M9500 system is shipped in eight containers, as

detailed below:

2 — Lower low-frequency enclosures

2 — High-frequency/horn enclosures

2 — Upper low-frequency enclosures

1 — Dividing networks (2 networks in one package,

including 6 hook-up cables and 4 9-volt batteries)

1 — Low-frequency grilles

(4 in one package)

Make sure that you have all containers. Unpack them carefully

and inform your JBL dealer of any sign of damage. It is

recommended that you save the packaging for future use.

Page 3

A

HF

HF

LF1

LF2

R

0

B

R

B

R

Input

Biamp

Norm

B

+

–

To M9500

I

B

HF

HF

LF1

LF2

R

0

B

R

B

R

Input

Biamp

Norm

B

+

–

To M9500

C

HF

HF

LF1

LF2

R

0

B

R

B

R

Input

Biamp

Norm

B

+

–

To M9500

System Setup

The M9500 systems are modular, each consisting of a stack of

three separate enclosures. The larger of the bass enclosures

are placed at the bottom, and the high-frequency/horn modules

stack on top and are aligned by the screws that protrude on

the bass section. The smaller bass modules are placed on top

of the high-frequency modules and are similarly aligned.

We recommend that you do not assemble the M9500 systems

until you have determined their best location in your listening

room or control room. In general, the listening angle for best

stereo imaging should be in the range from 45 to 60 degrees

and the loudspeakers should be placed no closer than about 25

or 30 cm (10" or 12") from the wall behind them. Sidewalls

should be somewhat farther away, and the loudspeakers

should be toed inward toward the primary listening position.

The room itself should be quiet, well-damped, and free of

obvious flutter echoes or standing waves.

Connect the loudspeakers to the networks using the cables

provided. Note that there are different cables for highfrequency and low-frequency hookup; they cannot be

intermixed. For positive contact, insert the Speakon

connectors and turn them one-eighth turn clockwise.

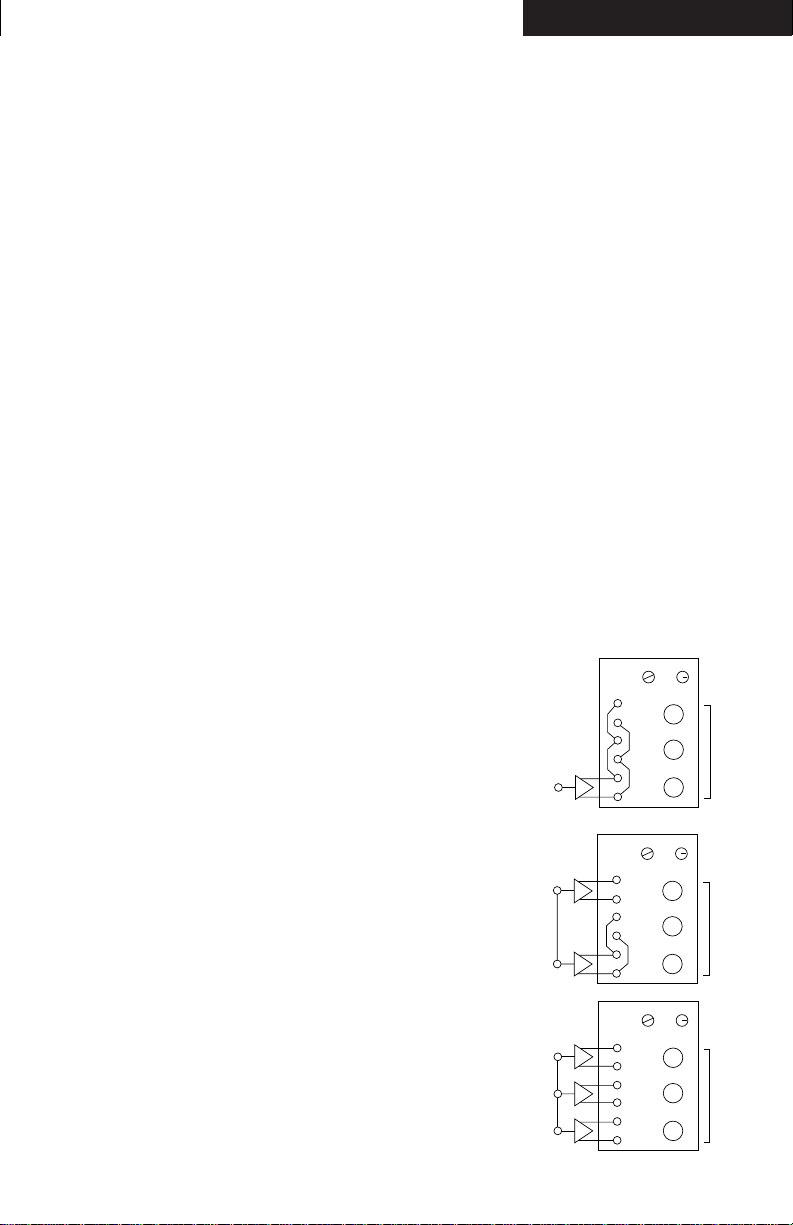

Electronic Options

Your next concern is the amplifier/ loudspeaker operating mode.

The various hookup options are shown in Figure 1. We will

describe each of these options:

Option A, single full-range amplifier. This mode of operation

requires a relatively large, high-quality amplifier capable of

delivering up to 800 watts per channel into 4-ohms. Note that

all sections of the network are connected in parallel with the

straps provided.

Option B, bi-wiring. In this mode, identical power amplifier

sections are fed full-range program; one amplifier is connected

to the high-frequency portion of the system, and the other is

fed to the low frequency sections in parallel. Many users will

use a large stereo amplifier to drive the low- frequency

sections and a smaller one for the high-frequency sections.

Make sure that the stereo amplifier used for the paralleled

low-frequency sections can deliver the necessary power into

4 ohms.

Option C, tri-wiring. This mode of operation is similar to B,

but with each low-frequency section driven by its own

amplifier. In this case, each low-frequency amplifier section will

look into 8 ohms.

Figure 1. Electronic hookup

options; views of the rear

panel of the dividing

network. A, single full-range

amplification; B, bi-wiring

with two amplifiers; C, triwiring with three amplifiers;

and D, biamplification with

external electronic dividing

®

network and separate highand low-frequency

amplifiers.

Page 4

Option D, biamplification. This mode of operation requires a

LF1

LF2

R

B

R

Input

B

To M950

D

HF

HF

LF1

LF2

R

0

B

R

B

R

Input

Biamp

Norm

B

+

–

To M9500

HF out

LF out

Electronic dividing

network

(650 Hz crossover)

,,

,,

,

,

,

,

,,

,

,,,

,,,

,,,

,

,,

,,,

,,,,,

,,,,,

,,,

Silver plated pole piece

Front cover

Diecast aluminum housing

Serpentine phone plug

Aquaplas-dusted

titanium diaphragm

Foam acoustic pad

Top plate

Neodymium magnet

Return circuit

Screen

Throat

Threaded mounting holes

,,,,

,,,,

,,

,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

Aluminum shorted turn

Copper shorted turn

Cooling vent (1 of 3)

Neodymium magnet

Return circuit

Edgewood aluminum

ribbon voice coil

Centering spider

Diecast frame/

magnet chassis

Fiberglas/Aquaplas

composite cone

Foam compliance

dedicated electronic dividing network crossing over at 650 Hz.

We recommend the JBL DX-1 with internal compensation

made for the M9500 system. If this mode is used, make sure

that the screwdriver adjustment on the back of each network

is set in the “biamp” position.

High-frequency trim switches on the

back of the networks provide three settings (zero, plus, and minus) so that the systems can be

trimmed for the acoustical characteristics of the listening

space.

Regardless of the operating mode you choose, we recommend

that only the finest hookup wire be used between the amplifiers and dividing networks. We recommend that the wire size

be no smaller than 3.3 square millimeter cross-section (#12

AWG). The inputs to the networks can accommodate spade

lugs, pins, bare wire, or individual banana connectors.

The internal 9-volt battery that is used to bias the capacitors

will normally last at least 5 years. You may test it by pressing

the gold logo on the front of the network. If the LED on the

front of the network illuminates, the battery is functional and

need not be replaced.

The

Transducers

Figure 2. Cutaway view of

JBL 475Nd high-frequency

compression driver. Note

the curved (equalized) paths

from the diaphragm to the

driver's output.

Figure 3. Cutaway view of

JBL 1400Nd low-frequency

transducer. Note both

aluminum and copper

shorting rings.

Page 5

The JBL model 475Nd compression driver used in the M9500

has a smooth titanium dome 101 millimeters in diameter that

has been lightly coated with Aquaplas™ damping compound.

Its aluminum ribbon voice coil operates in a magnetic flux field

of 1.65 tesla (16,500 gauss). Mid-band efficiency is 20%, while

at the peak value of driver impedance it is in excess of 50%.

The driver uses JBL’s Coherent Wave™ phasing plug, which

provides equalized path lengths from all sections of the

diaphragm to the driver's output. The driver is mounted on the

H9500 horn, a design used only in this system that provides

smooth loading down to 500 Hz and exhibits consistent

horizontal dispersion over its operating range.

There are two JBL model 1400Nd low-frequency transducers

in each loudspeaker system. A single 1400Nd is capable

of handling instantaneous input signals of 600 watts,

corresponding to a midband peak output of 118 dB Lp at a

distance of one meter. The transducer’s second and third

harmonic distortion have been reduced through the use of

JBL’s traditional aluminum shorting ring at the base of the pole

piece, as well as through the use of a copper shorting ring on

the top plate adjacent to the voice coil. The transducers make

use of JBL’s Vented Gap Cooling™ in which forced air,

generated by cone motion, removes heat produced by the

voice coil. Each driver is mounted in its own ported enclosure,

and the two enclosures are “stagger tuned” to provide

smoother and more extended low-frequency response.

Cutaway views of the high-frequency and low-frequency

transducers are shown in Figures 2 and 3.

Typical System Performance Measurements

The high-frequency response of the M9500 system was carefully established by making a series of measurements over

frontal angles of 60° in both vertical and horizontal planes. This

allows for optimal listening over a wide area. The frequency

response averaged over the 60° horizontal and vertical angles,

measured from 200 Hz to 20 kHz, is shown in Figure 4. Here,

the network High Frequency trim is set in its zero position.

The slight downward trend was incorporated, based on

extensive listening tests to contemporary pop/rock and

classical recordings.

+10

dB

0

–10

–20

Relative level (dB)

–30

2345678910

1.5 2 3 4 5 6 7 8 9

100

10 1.5 2 23456789

1000

10 1.5

10000

Figure 4. Averaged frontal

angle response (60°,

horizontal and vertical) of

M9500 from 200 Hz to 20

kHz.

Page 6

The directivity index (DI) of the H9500 horn is shown in Figure

100dB

10 Ω

2345678910

1.5 2 3 4 5 6 7 8 9

100

10 1.5 2 23456789

1000

10 1.5

10000

Anecmoil

Ground

Plane

M9500

4.3V @ 1.5 m

HF @ "0"

96dB

2345678910

1.5 2 3 4 5 6 7 8 9

100

10 1.5 2 23456789

1000

10 1.5

10000

M9500

Distortion

3.0V @ 1 m

Distortion Raised 20dB

Solid = Second Harm.

Dash = Third Harm.

5. The smoothly rising DI is a consequence of the gradual

narrowing of the vertical dispersion angle above 2 kHz and

contributes to the overall flatness of the high-frequency

response of the system.

20

10

0

Directivity Index, DI (dB)

Frequency (Hz)

100

10

1

20000100005000200010005002001005020

Overall system on-axis pressure response and impedance are

shown in Figure 6. The contributions of the paralleled lowfrequency sections and the high-frequency section are shown

individually along with their acoustical summation. The overall

slopes in the crossover region are a combination of electrical

(network) and acoustical response.

Figure 5. Plot directivity

index (DI) and directivity

factor (Q) of the H9500.

Directivity Factor, Q

Figure 6. On-axis response

of M9500. Individual

contributions of paralleled

low-frequency transducers

and high-frequency section

are shown, along with their

summation. The impedance

curve is also given, showing

a minimum value of 3 ohms

in the 100 Hz range.

The second and third harmonic distortion of the system is

shown in Figure 7. Here, the system is driven with sine wave

input to produce an output of 96 dB Lp at a distance of 1

meter. An output of 96 dB with a sine wave input corresponds

to extremely high system output with wide band program

material. Distortion curves have been raised 20 dB, and the values seen here lie well below 1% for the lowest frequencies up

to 4.5 khz, reaching a value of only 1.6% at 10 kHz. Not many

loudspeakers can demonstrate such low levels of distortion as

shown here.

Figure 7. Second and third

harmonic distortion for

fundamental of 96 dB Lp at

a distance of 1 meter.

(Distortion raised 20 dB)

Page 7

Care and Maintenance of the System

Your M9500 monitors should give years of trouble-free service.

Normally, the only routine maintenance will be cleaning. The

grilles may be cleaned of dust gently with a vacuum cleaner

using a brush attachment. If there should be stains on the

grille, a soft bristle brush moistened with a dilute mixture of

water and dishwashing detergent may be used. The same

mixture may be used for cleaning the enclosure finish itself

if it has become smudged.

As mentioned before, the 9-volt batteries in the dividing networks will last perhaps as long as their normal shelf life. You

may expect them to last at least 5 years. If the LED no longer

lights, remove the acrylic door on the front of the network and

replace them.

System Specifications

Acoustic and Electrical Specifications:

Sensitivity:

Rated Impedance (LF parallel):

Minimum Impedance:

Frequency Response:

Crossover Frequency:

System Polarity:

EIA (positive voltage to red terminal

produced outward cone motion)

System Components and Physical Specifications:

Low-Frequency Transducer:

High-Frequency Transducer:

Horn Assembly:

Dividing Network:

Enclosure Volumes:

78 liters (2.8 cu ft) 35 Hz tuning (upper LF)

115 liters (4.1 cu ft) 28 Hz tuning (lower LF)

System Dimensions:

140 mm H x 330 mm W x 403 mm D

(55"H x 15.13"W x 15.88"D)

Total depth including horn 521 mm (20.5")

Weight:

38.2 kg (84 lbs) upper LF

54.5 kg (120 lbs) lower LF

37.3 kg (82 lbs) horn assembly

95 dB for 2.83 V @ 1 meter

4 Ohms

3.0 Ohms @ 100 Hz

35 Hz to 20 kHz (half space)

650 Hz

1400 Nd

475 Nd

H9500

N9500

Page 8

JBL continually strives to improve its products. New materials, production methods and design refinements are introduced into existing

models without notice as a routine expression of our design philosophy.

For this reason, JBL M9500 Series Loudspeakers may differ in some

respect from their published specifications and descriptions, but will

always equal or exceed the original specifications unless otherwise

stated.

JBL Consumer Products, Inc.

80 Crossways Park West

Woodbury, NY 11797

8500 Balboa Blvd.

Northridge, CA 91329

800 645 7484

Printed in USA on recycled paper 9/95

Part No. JBLM9500M

Loading...

Loading...