Page 1

Installation Manual

Intellivox ADC-V90 & ADC-H90 models

(Part Nos. 576125, 577125, 577135, 576126, 577126 and 577136)

EN 54 -24

Page 2

JBL Professional® Intellivox ADC Installation Manual

EC DECLARATION OF CONFORMITY

13

This document confirms that the product manufactured by Duran Audio BV and described hereafter is in conformity with

the following directive(s) and meets the requirements of the following standard(s):

Applicable directive(s) LVD 2006/95/EC (see note 1)

Applicable standard(s) Not applicable Provided options Not applicable

Product details:

Construction product description

Product model/type

Document references:

Datasheet(s)

Other references Not applicable

Manufacturer:

Name Duran Audio BV

Address

Web www.duran-audio.com

Authorized by G. Duran - General manager

Place and date of issue Zaltbommel – September 25, 2015

Loudspeaker for voice alarm systems for fire detection and fire alarm systems for

buildings

ADC-V90

ADC-H90

201509/V90_2.3 (ADC-V90 datasheet)

201509/H90_2.3 (ADC-H90 datasheet)

Koxkampseweg 10

5301 KK Zaltbommel

The Netherlands

Signature

Notes:

1. Only if connected in accordance with the manufacturer’s instructions to mains operated audio equipment with safety

properties according to the relevant harmonized standards.

2

201509/ADCIM

Page 3

JBL Professional® Intellivox ADC Installation Manual

Declaration of Performance

According to Construction Products Regulation (CPR) 305/2011

No: 2014-001

1. Unique identification code of the product-type:

ADC-V90

ADC-H90

2. Type, batch or serial number or any other element allowing identification of the construction product

as required pursuant to Article 11(4):

Each product has a unique serial number specified on the product label

3. Intended use or uses of the construction product, in accordance with the applicable harmonised

technical specification, as foreseen by the manufacturer:

Construction product Loudspeaker for voice alarm systems for fire detection and fire

alarm systems for buildings

Intended use Fire safety

Harmonised technical specification EN 54-24:2008

Fire detection and fire alarm systems

Part 24: Components of voice alarm systems - Loudspeakers

Provided options Type B

4. Name, registered trade name or registered trade mark and contact address of the manufacturer as

required pursuant to Article 11(5):

Name Duran Audio BV

Address Koxkampseweg 10

5301 KK Zaltbommel

The Netherlands

Web www.duran-audio.com

Branding/Trade name Models are sold under both AXYS & JBL brand names

201509/ADCIM

3

Page 4

JBL Professional® Intellivox ADC Installation Manual

5. Where applicable, name and contact address of the authorised representative whose mandate covers

the tasks specified in Article 12(2):

Not applicable

6. System or systems of assessment and verification of constancy of performance of the construction

product as set out in Annex V:

System 1

7. Declaration of performance concerning a construction product covered by a harmonised standard:

Notified body details:

Name Scientific and Research Centre for Fire Protection

named after Józef Tuliszkowski - National Research Institute

Identification CNBOP-PIB-1438

Address

Nadwislanska 213 Street

05-420 Józefów

Poland

Web

www.cnbop.pl

EC certificate of conformity 1438/CPD/0306

ITT report No. 5136/BA/11

8. Declaration of performance concerning a construction product for which a European Technical

Assessment has been issued:

Not applicable

4

201509/ADCIM

Page 5

JBL Professional® Intellivox ADC Installation Manual

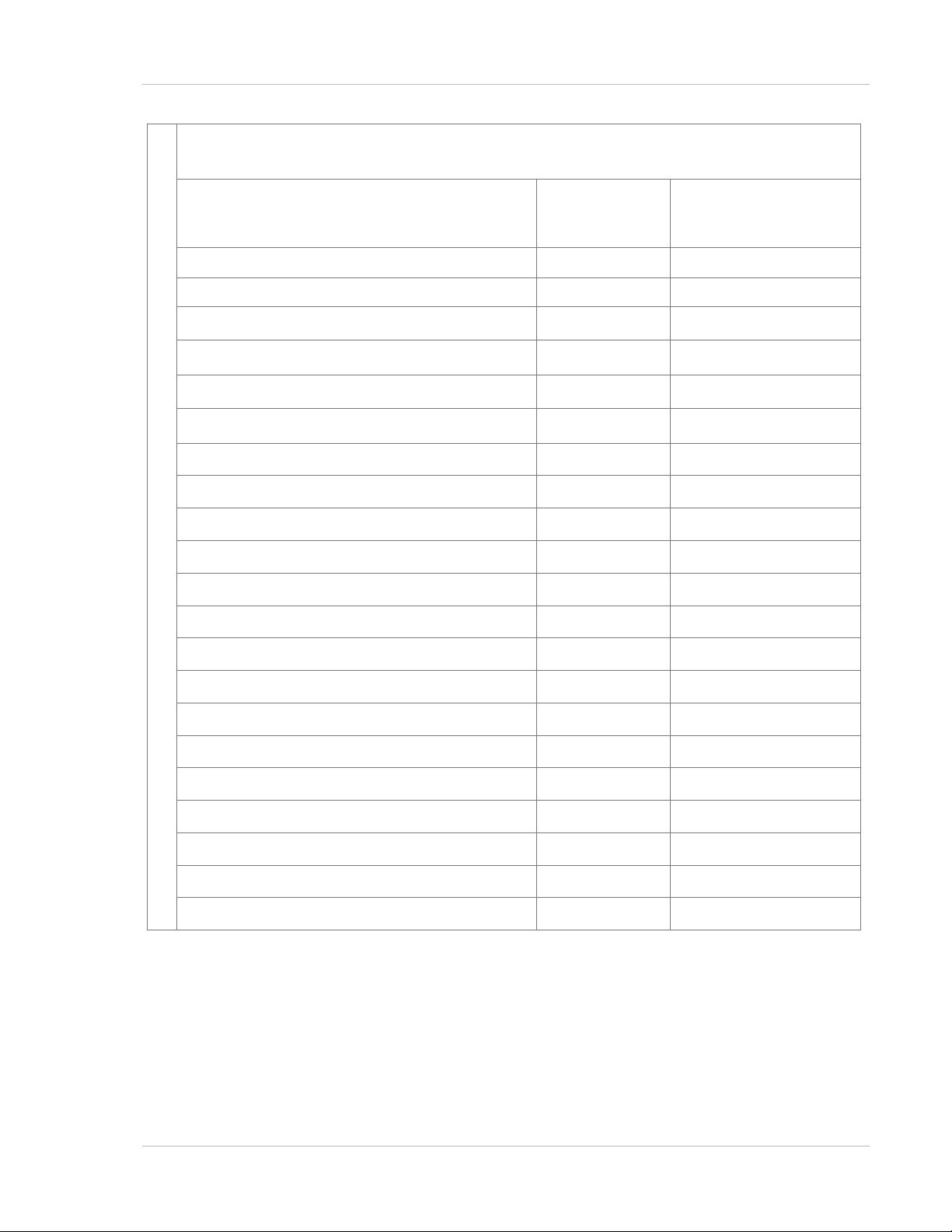

9. Declared performance:

Essential characteristics Performance Harmonised technical

specification

EN 54-24:2008 - Type B

Frequency response limit Passed Section 4.2

Reproducibility Passed Section 5.2

Rated impedance Passed Section 5.3

Horizontal and vertical coverage angles

Maximum sound pressure level

Passed Section 5.4

Passed Section 5.5

Durability Passed Section 4.3

Construction Passed Section 4.4

Marking and data Passed Section 4.5

Rated noise power (durability) Passed Section 5.6

Enclosure protection Passed Section 5.18

Dry heat (operational) Passed Section 5.7

Dry heat (endurance) Passed Section 5.8

Cold (operational) Passed Section 5.9

Damp heat, cyclic (operational) Passed Section 5.10

Damp heat, steady state (endurance) Passed Section 5.11

Damp heat, cyclic (endurance) Passed Section 5.12

Sulfur dioxide corrosion (endurance) Passed Section 5.13

Shock (operational) Not applicable Section 5.14

Impact (operational) Passed Section 5.15

Vibration, sinusoidal (operational) Passed Section 5.16

Vibration, sinusoidal (endurance) Passed Section 5.17

201509/ADCIM

5

Page 6

JBL Professional® Intellivox ADC Installation Manual

10. The performance of the product identified in points 1 and 2 is in conformity with the declared

performance in point 9.

This declaration of performance is issued under the sole responsibility of the manufacturer identified

in point 4.

Signed for and on behalf of the manufacturer by:

Name and function G. Duran - General manager

Place and date of issue Zaltbommel - September 25, 2015

Signature

6

201509/ADCIM

Page 7

JBL Professional® Intellivox ADC Installation Manual

USER’S NOTICE AND DISCLAIMER

No part of this manual including the software

described in it may be reproduced, transmitted,

transcribed, stored in a database system or

translated without the express written permission

of JBL Professional.

Documentation kept by the end user for back-up

purposes is excluded from the above.

All products and corporate names mentioned

in this manual may be registered trademarks or

copyrights of their respective companies. They

are used here for indicative purposes only.

The information contained in this manual has

been carefully checked for accuracy; however no

guarantee is given with respect to its correctness.

JBL Professional accepts no responsibility or

liability for any errors or inaccuracies that may

appear in this manual or the products and

software described in it.

Specifications and information contained in

this manual are subject to change at any time

without notice.

© 2015 JBL Professional. All rights reserved.

201509/ADCIM

7

Page 8

JBL Professional® Intellivox ADC Installation Manual

This page has been left blank intentionally

8

201509/ADCIM

Page 9

JBL Professional® Intellivox ADC Installation Manual

TABLE OF CONTENTS

EC declaration of conformity............................2

Declaration of Performance ..........................3-6

User’s Notice and disclaimer............................7

1. Important Safety Instructions ....................... 10

2. Introduction ..................................... 11

Applicable models and variants....................11

What’s in the packaging .........................12

3. Installation Guide................................. 13

Preparing For Installation ........................13

Intellivox ADC Connections .......................13

Mechanical Installation ..........................14

Acoustic Centre ................................14

Mounting Options ...........................15-16

Mounting Procedure ............................17

Wiring Details .................................18

Tap Setting ...................................18

Correction EQ and High-Pass Filter .................19

Securing The Front Grill..........................19

Pilot Tone Indicator .............................20

Speaker Protection .............................20

4. Appendices ......................................21

Appendix 1 - Optional Accessories .................21

201509/ADCIM

9

Page 10

1. IMPORTANT SAFETY INSTRUCTIONS

JBL Professional® Intellivox ADC Installation Manual

This symbol is intended to alert you to the

presence of uninsulated dangerous voltages

within the product’s enclosure that may be

of sufficient magnitude to constitute a risk of

electric shock.

This symbol is used throughout this manual

and is intended to alert you to the presence of

important instructions.

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such as radiators,

heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

9) Only use attachments/accessories specified by the

manufacturer.

10) Use only with the cart, stand, tripod, bracket

or table specified by the manufacturer, or sold

with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to

avoid injury from tip-over.

11) Refer servicing to qualified service personnel. Servicing

is required when the apparatus has been damaged in any

way, liquid has been spilled or objects have fallen into the

apparatus, the apparatus does not operate normally, or

has been dropped.

Warning -The installer should ensure that

the mechanical mounting method employed

should be capable of supporting four times

the weight of the unit (i.e., with a safety factor of 4).

Always use both of the brackets provided with the unit.

10

201509/ADCIM

Page 11

JBL Professional® Intellivox ADC Installation Manual

2. INTRODUCTION

This manual describes the recommended installation

procedure for the JBL Intellivox ADC range of loudspeakers.

The ADC range are compact 100 V/70 V line units intended

for use in a wide variety of Public Address and Voice

Alarm (PA/VA) systems. They are particularly suitable for

installation in reverberant spaces such as railway and bus

stations, airports, places of worship, shopping centres,

etc., where high quality speech reproduction is required.

The JBL Intellivox ADC device is a loudspeaker type known

as passive loudspeaker array, in which multiple drive units

are mounted in the housing at specific spacings. In addition

to the drivers, the Intellivox ADC housing contains a set of

passive filters. When properly applied, the Intellivox ADC

device is capable of achieving a constant SPL for mid-band

frequencies over the listening area, whilst minimizing the

‘spill’ to other areas.

Other key features include:

• Pilot tone indication

• Protection (glass + thermal fuse and ceramic

terminal block)

APPLICABLE MODELS, AND VARIANTS

The Intellivox ADC range is available in two versions:

• Model V90 – for vertical mounting

(Part Nos. 576125, 577125 and 577135)

• Model H90 – for horizontal mounting

(Part Nos. 576126, 577126 and 577136)

This manual is applicable to both models. However, some

factors arising from the two models’ different physical

configurations result in some sections of the manual text

being strictly applicable to only the V90 or the H90. These

sections are clearly indicated.

Apart from the passive filters, the two models are both

electrically identical and can use the same mounting

brackets. However their effective areas of coverage are

very different, and the decision as to which is specified in

a particular installation will be dictated by the specifics of

the building or space.

fig.1.1 Model V90 – for vertical mounting

• EQ correction and high-pass filter

This manual covers:

• Wiring and connection details

• Mechanical installation of the loudspeaker

Please note that a full range of optional mounting brackets

and connection coverboxes are available.

Please refer to our website for further details.

201509/ADCIM

fig.1.2 Model H90 – for horizontal mounting

11

Page 12

JBL Professional® Intellivox ADC Installation Manual

WHAT’S IN THE PACKAGING

In addition to the loudspeaker itself, each unit is packed with the following items:

• Installation manual (this document)

• ADC Datasheet

• Box containing:

REF ITEM QTY USE

A Mounting brackets 2 Speaker mounting

B 30 mm hex-headed screws with washers and wall plugs 4

C M5 x 12 mm pan-head screws with shakeproof washers 8

D

A B

M4 x 10 mm round-head screws with star

retaining washers (inc. hex key)

C D

4 Grill security screws

Mounting bracket fixings

(wall)

Mounting bracket fixings

(loudspeaker)

fig.2 Box contents

12

201509/ADCIM

Page 13

JBL Professional® Intellivox ADC Installation Manual

3. INSTALLATION GUIDE

PREPARING FOR INSTALLATION

Before starting to install the Intellivox ADC loudspeaker, a

number of points should be considered.

• It is assumed that the installation site has been the subject

of an extensive DDA investigation or optimisation prior to

the actual install. (DDA = Digital Directivity Analysis, the

JBL proprietary simulation software for these products*).

This procedure will have identified the optimum physical

location for the Intellivox ADC, to accurately achieve the

desired acoustic coverage. In particular, the “acoustic

centre” position in terms of height above the finished

floor, and any mechanical mounting angles will have

been specified. The installer should confirm that he/she

has this information.

• Unless specified otherwise by the sound system designer,

the Intellivox ADC Model V90 should be installed at a

position exactly perpendicular to the listening plane

(i.e. vertical if the floor is horizontal). Unlike conventional

loudspeaker systems, minor mechanical misalignment

may lead to degraded coverage and intelligibility. Ensure

(by use of a levelling device such as a spirit level) that

the surface to which the Intellivox is to be attached is

absolutely vertical and that both mounting bracket

positions are in the same plane. This restriction does

not apply to the Model H90, which is intended to be

tilted downwards.

INTELLIVOX ADC CONNECTIONS

The Intellivox ADC range loudspeakers are designed to

be connected to 100 V or 70 V line speaker distribution

systems. They are not intended to be used with amplifiers

which are designed to drive only low-impedance (i.e. 4 - 8

ohms) loudspeakers. However, such amplifiers may be used

if intermediate 100 V/70 V line transformers are connected

between the amplifier outputs and the loudspeakers.

Suitable power amplifiers for use with the Intellivox ADC

range include the JBL AXYS PB-400 and PB-800 models.

In most situations, installation will be simplified by

running the speaker cables to the intended location before

attempting to mechanically mount the Intellivox speakers.

If the loudspeaker is being used as part of a Voice Alarm

application, it is likely that fire-resistant (pyro) cable will

be required; local regulations covering these requirements

should always be checked and followed.

The cable entry gland at the rear of the ADC models can

accept cable with a maximum diameter of 13.5 mm.

Ensure that the cable being installed does not exceed this.

Wiring details can be found on page 14.

*Authorized electro-acoustic consultants or ‘build & design’ sound contractors can apply for a DDA License free of charge. This license

can be obtained through our website www.jblpro.com

For further information please refer to the Help files and manual with the DDA software.

201509/ADCIM

13

Page 14

MECHANICAL INSTALLATION

Reference point for

acoustical mounting

height - V90

Acoustic Centre

Mounting an Intellivox ADC loudspeaker is a straight-

forward procedure, but it is essential to understand

that the precise mounting location is extremely critical.

The correct mounting location is defined as part of the

acoustical design process and the installer should make

sure that he/she has this information before commencing

to mount the Intellivox ADC.

MODEL V90 ONLY

JBL Professional® Intellivox ADC Installation Manual

fig.3 Sticker showing acoustic centre and unit orientation

The correct operational height defined by the system

designer is the height of the Intellivox ADC’s acoustic

centre (reference point). This point does not necessarily

coincide with the position of any particular physical

component on the unit. The location of the speaker’s

acoustic centre is marked by the centre of the yellow

sticker on the front face of the unit at the time of

shipping, and it is this position that must correspond

to the operational height defined in the design process.

The vertical position of the acoustic centre of the Model

V90 is towards the top of the unit, as indicated by the

yellow sticker (see fig.3). The horizontal position is on

the vertical centre line.

When calculating the positions for the mountings (see

below), the distance from the acoustic centre to the

top or bottom of the loudspeaker (whichever is being

used as the reference datum) should be measured and

then allowed for when marking the mounting positions.

The specification sheet supplied with each loudspeaker

includes a mechanical drawing clearly showing the

mounting position locations.

Because of the tightly-controlled vertical radiation

pattern of the V90, a small deviation from the calculated

acoustical mounting height or vertical mounting

angle may cause severe degradation of the expected

performance.

Note also that the yellow sticker indicates which way is

“up”; ensure that this orientation is observed.

The V90 will normally be mounted perpendicular to

the listening plane, i.e. vertically when the floor is a

conventional horizontal plane. However, if the DDA

investigation has specified a downward angle for some

reason, this angle must be adhered to in the mounting

process. This is likely to necessitate the use of spacers

on the upper mounting bracket.

14

fig.4.1 Acoustic centre reference point for V90

201509/ADCIM

Page 15

JBL Professional® Intellivox ADC Installation Manual

Reference point for

acoustical mounting

position - H90

MODEL H90 ONLY

The location of the acoustic centre of the Model H90 is

in the centre of the unit, both horizontally and vertically.

This is indicated by the yellow sticker on the front grill.

The H90 should be mounted accurately so that

its acoustic centre is at the position identified by the

site survey.

The arrangement of drivers in the H90 differs from the

V90; for this reason, a different set of measurements

needs to be accurately made. For the H90, the critical

aspects of the mounting position are that the horizontal

(long) axis of the enclosure should be precisley

horizontal, and that if the H90 is not being mounted

against a wall (i.e., suspended from a pole or similar

arrangement), the azimuth angle – the angle about the

enclosure’s central vertical axis – should also be exactly

that specified by the DDA survey. Further to these

criticalities, the angle of rotation about the horizontal

axis should also be carefully checked to ensure that the

“downwards” radiating angle of the unit is correct.

fig.4.2 Acoustic centre reference point for H90

A

H90

B

C

(A) Width = The position of the acoustic centre on the

horizontal plane

(B) The angle of rotation around the horizontal axis

(C) Azimuth = The angle of rotation around the vertical axis

fig.4.3 H90 further mounting information

MOUNTING OPTIONS

Intellivox ADC models have two attachment points at the

rear of the enclosure; the loudspeaker should be mounted

using these points. Each point consists of four M5 threaded

inserts and only the screws supplied with the original

mounting hardware should be used.

Cavity walls can sometimes be problematical when high-

power loudspeakers are mounted on them. The internal

wall cavity may resonate at one or more frequencies,

degrading the audio performance significantly. Installers

are advised to insert rockwool or similar sound-absorbing

material into the cavity in the vicinity of the loudspeaker

when mounting an Intellivox on a wall of this type.

201509/ADCIM

An Intellivox Accessories brochure, which includes a full

range of optional brackets for various situations can be

downloaded from http://www.jblpro.com

fig.5.1 - Standard bracket dimensions in mm

15

Page 16

MODEL V90 ONLY

JBL Professional® Intellivox ADC Installation Manual

Model V90 only: There are three options for mounting

the Intellivox ADC Model V90:

1. The first (and most often used) method is to use the

standard mounting brackets supplied with the unit.

Dimensions of the bracket are shown in fig.5.1.

The standard brackets allow mounting of the Intellivox

ADC Model V90 on a straight wall or on a curved surface

(e.g., a pillar) with a gap of 25 mm (1.0”) between the

rear of the enclosure and the wall.

The mounting procedure is given on page 13 under

“Mounting Procedure”.

2. A second method is to mount the Model V90 using

(optional) swivel brackets which allow the plane of the

column’s vertical radiating axis to be at an angle other

than 90 degrees to the wall. In this case two swivel

brackets are needed. The horizontal angle of the swivel

brackets can be secured by the hexagonal nut. The

swivel brackets are mounted to the rear of the enclosure

by the four M5 pan head screws instead of the standard

brackets. Two versions of swivel brackets are available,

permitting the Intellivox to be rotated through 45 or 90

degrees either way respectively. Refer to page 17 for

ordering information.

fig.5.2 Direction of rotation

when using optional

swivel brackets with

the V90

3. The third method is to mount the column within a

recess in the wall or dedicated mounting panel so

that the front of the unit is flush. This is a specialised

mounting situation which will be encountered only

rarely. Access to the rear of the unit will still be required

for the cables. Because of the proximity of the unit to

the walls, particular attention should be paid to the

avoidance of acoustic resonances (see page 11).

MODEL H90 ONLY

Model H90 only: Unlike the V90, considerable flexibility

exists in the mounting possibilities of the H90. The H90

is not specifically designed to be mounted on a vertical

(or angled) wall. The method of mounting employed

in a particular installation will be primarily dictated by

the downwards angle at which the H90 needs to be

mounted to achieve the coverage calculated during the

DDA analysis.

16

Custom mounting hardware may be required to achieve

the correct mounting angle. Small mounting angles

may be realised using the standard mounting brackets

(supplied) in conjunction with suitable spacers.

The standard mounting brackets supplied with the unit

may be employed if the Model H90 is to be fixed “flat”

onto a vertical wall.

Note that the provided locking mechanism of the

optional hinges and swivel brackets is not suitable for

the standard (horizontal) mounting method.

201509/ADCIM

Page 17

JBL Professional® Intellivox ADC Installation Manual

MOUNTING PROCEDURE

The general procedure for mounting the Intellivox ADC

Models V90 or H90 using the standard brackets is described

below. It is assumed that cabling for connection to the

100 V/70 V line system has been run to the loudspeaker

location.

Proceed as follows:

1. Use of the wall plugs and hexagon head screws

supplied is recommended. If using other types, ensure

that the “across-flats” head size does not exceed 11.5

mm (0.45”).

2. Mark and drill the holes (8 mm) for the wall plugs. For the

V90 use the two holes with the slots running vertically as

reference. For H-90 use the slotted hole in the centre of

the bracket as reference.

3. Insert the plugs and screws into the holes. Tighten

the screws with a spanner, but stop with a few mm of

screw shaft visible between the head and the wall.

4. Check that it is possible to slide a bracket over the

heads.

5. Check that the chosen mounting points will position

the column in the correct vertical angle specified by

the acoustic design (in the case of the Model V90, this

is usually exactly perpendicular to the listening area).

Use spacers on one or both brackets if necessary.

6. Attach the brackets to the rear of the loudspeaker

using the M5 x 12 pan-head screws and shakeproof

washers supplied. The 10 mm diameter holes allow

screwdriver access to the screw heads.

7. Remove the front grill from the loudspeaker by gently

lifting it at the locations of the ‘snap-on’ fittings which

hold it in place. Remove the protective foam. Unscrew

the four self-tapping screws securing the connector

compartment cover and remove the cover.

H90

fig.7 - Connector cover location

V90

8. Lift the loudspeaker and slide the brackets over the

heads of the hex-head screws protruding from the wall,

and at the same time feed the speaker cable through

the cable entry gland at the rear and into the connector

compartment so that it is free and accessible from the

front. Tighten the rear gland, leaving sufficient free

cable to connect to the terminal block.

Ensure that the gland fits tightly around the

cable jacket. The enclosure protection, as

well as the LF SPL response, will deteriorate in case of

a leaky enclosure.

9. Firmly fasten the screws securing the brackets to the

wall with the spanner. Re-check the verticality (or other

angle if specified) with a spirit level or similar levelling

device.

fig.6 - Bracket attachment

201509/ADCIM

10. The loudspeaker connections should now be made –

see section on Wiring Details on page 14.

17

Page 18

JBL Professional® Intellivox ADC Installation Manual

WIRING DETAILS

When the Intellivox ADC has been mounted in the

correct position, it may be connected up. Connection is

straightforward; having passed the cable through the

gland, connect the speaker feed to the ‘100 V’ and ‘0’

terminals of the ceramic connection block.

Always ensure that the amplifier is powered

down before wiring the loudspeaker. If the

audio suddenly becomes live there is a

strong risk of electric shock.

The third terminal, marked with an Earth (Ground) symbol,

allows a separate earthing connection to be made to the

loudspeaker. This provides a low impedance circuit to earth

from the metalwork of the enclosure, as often required by

safety regulations. If the loudspeaker enclosure is mounted

on a support that offers a low impedance connection to the

safety ground, the earth terminal of the ceramic connection

block can be directly wired to the mounting support as

indicated in fig.8.1. If a safety ground connection is

not available in the vicinity of the mounting location,

the wiring scheme as indicated in fig.8.2 can be used.

Note that the application dependent safety regulations

should be consulted in order to determine the proper

grounding scheme.

TAP SETTING

The internal 100 V/70 V transformer’s primary tapping

should be set according to the power requirements of the

installation. This figure will have been determined at the

time of site analysis; see also the Maximum SPL figures in

the specifications table on the data sheet.

The tapping is set by means of an internal switch that is

located behind the inspection plate as indicated in fig.9.2

(Model V90) and fig.9.3 (Model H90). This switch has three

positions, labelled 100 W, 50 W and 25 W. These figures

relate to the speaker use on a 100 V line system, lower

powers are available from a 70 V line system.

The table below summarises the output powers:

Tap Switch

setting

100 V line system 70 V line system

100 W 100 50

50 W 50 25

25 W 25 12.5

fig.9.1 - Tap settings

Max. output power (W)

100 V

Brown

0

Blue

Green/yellow

fig.8.1 - Wiring details A

100 V

Brown

0

Blue

Green/yellow

fig.8.2 - Wiring details B

18

100 V-/70 V-line feed

(2-core cable)

To safety earth

100 V-/70 V-line feed

(3-core cable)

fig.9.2 - Switch locations (Model V90)

fig.9.3 - Switch locations (Model H90)

201509/ADCIM

Page 19

JBL Professional® Intellivox ADC Installation Manual

CORRECTION EQ AND HIGH-PASS FILTER

Many building PA systems will include some provision

for equalisation (EQ) adjustment at the signal processing

stage, or within the power amplifier (as with the JBL AXYS

PB-400 and PB-800 amplifiers). Adjusting EQ to achieve

maximum system intelligibility is a normal part of the

commissioning process, though it should be noted that

measured intelligibility will be greatly affected by several

other factors not immediately under the designer’s control,

such as reverberation time and ambient noise levels. If

external EQ adjustment is not available, it may be desirable

in some applications to modify the frequency response of the

loudspeaker itself.

The frequency response can be altered by means of two

switches labelled ‘EQ’ and ‘HPF’. These switches are located

behind the inspection plate as indicated in fig.9.2 (Model

V90) and fig.9.3 (Model H90).

The EQ switch has two positions. The EQ is disabled if the

switch is in the ‘Flat’ position. The mid-cut EQ correction

is indicated in fig.10.1 (Model V90) respectively fig.10.3

(Model H90). The factory default setting is with EQ enabled

(flattest SPL versus frequency response). If the EQ is

disabled the maximum achievable SPL is somewhat higher,

at the expense of a SPL response that is less flat.

Note that this does not apply to the integral

load monitoring of the JBL AXYS PB-400/PB-800

Industry Amplifiers; these amplifiers do not use a

DC signal for load monitoring purposes.

fig.10.1 - V90 correction EQ

fig.10.2 - V90 high-pass filter

The HPF (high-pass filter) switch also has two positions.

The high-pass filter is disabled if the switch is in the ‘Flat’

position. The frequency response of the high-pass filter

is indicated in fig.10.2 (Model V90) respectively fig.10.4

(Model H90). The filter response is slightly dependent on

the tap setting, the curves are valid for the 100 W tap. The

factory default setting is with the high-pass filter enabled,

this setting is most suitable for voice applications.

Note that the high-pass filter might have to be disabled in

case of 3rd-party line monitoring applications that make

use of a DC signal. DC will be blocked by a series capacitor

if the high-pass filter is enabled.

If the monitoring system uses an end-of-line unit, and DC

input to the loudspeaker should be blocked, the high-pass

filter should be enabled. If the monitoring system is to be

used in conjunction with the loudspeaker(s), without endof-line unit, the high-pass filter should be disabled.

201509/ADCIM

fig.10.3 - H90 correction EQ

fig.10.4 - H90 high-pass filter

SECURING THE FRONT GRILL

Option 1. After making the connections and setting the

power tapping, the front grill may be replaced. Do not

replace the protective foam! Align the four locating spigots

with the four larger holes in the back of the grill frame and

push the grill back on, ensuring that all four spigots locate

positively with the retaining clips within the holes.

Option 2. The front grill may be secured more permanently

with the (supplied) M4 security screws. These need to be

fitted one at a time before replacing the grill.

19

Page 20

HOLE FOR

SECURITY SCREW

REAR OF

GRILL

LOCATING HOLE

WITH RETAINING CLIP

fig.11 - Securing the front grill

M4 TAPPED HOLE

LOCATING SPIGOT

FRONT OF

SPEAKER

Insert a screw through the larger hole in the corner of

the grill rear flange by feeding it from the inside of the

flange, so that the thread of the screw protrudes from the

rear of the grill. Push a retaining washer (supplied with

the screws) over the screw thread, and up against the

metalwork to retain the screw in position. Repeat for the

other three corners.

Push the grill into place using the locating spigots as

previously described. Insert the hex key supplied through

holes in the grill itself to tighten the security screws into

the M4 tapped holes.

JBL Professional® Intellivox ADC Installation Manual

SPEAKER PROTECTION

In a PA/VA system, it is important that the failure of a single

loudspeaker does not incapacitate the rest of the system.

The ADC range of speakers incorporate three protection

systems to prevent this.

1. The glass fuse is designed to protect against excessive

current being drawn by the unit. The fuse is a standard

20 mm diameter 1 A anti-surge type. Only replace this

with a fuse of the same type and rating. In the event of

the fuse needing replacement, remove the protective

cap from the fuseholder. The fuse can be removed from

the holder by inserting a small screwdriver or similar

through the holes in the top of the holder. Refer to

fig.12.1 (Model V90) and fig.12.2 (Model H90).

2. ADC units also incorporate a separate thermal fuse in

series with the 100 V/70 V input. This is intended as

fail-safe device, which goes open-circuit if the internal

temperature becomes excessive, such as would occur

in the event of a fire. Thus a local fire which damages

a single speaker on a system does not cause other

speakers elsewhere to fail, as the damaged unit is

removed from the speaker circuit.

PILOT-TONE INDICATOR

In many PA/VA systems, a high-frequency pilot-tone is

continuously fed to the loudspeakers for load monitoring

purposes. This permits load and cable integrity to be

constantly verified. A LED is fitted to the front panel of the

ADC range of speakers, which illuminates on detection of

a pilot-tone. The LED is visible with the grill installed, and

is a useful check that the system is operational.

The JBL AXYS PB-400 and PB-800 amplifiers include

a suitable pilot-tone generator; other manufacturers’

equipment may also be suitable. The pilot-tone should

be in the frequency range 20 to 23 kHz, and of at least 6

Vrms amplitude (note that this level is not dependant on

the tap setting, the detection process is most sensitive for

frequencies around 21 kHz) for the LED to illuminate. Pilottones of other frequencies and/or levels may be used if the

fault monitoring system demands them; the illumination of

the LED is not essential for such a system to operate correctly.

3. A ceramic connector ensures that the terminal will not

melt in a fire situation and short out the audio line.

fig.12.1 - Fuse location (Model V90)

fig.12.2 - Fuse location (Model H90)

20

201509/ADCIM

Page 21

JBL Professional® Intellivox ADC Installation Manual

4. APPENDICES

OPTIONAL ACCESSORIES

Listed below are some optional accessories which may be

required for a particular installation.

DESCRIPTION ORDER CODE

Intellivox wall bracket set (2 pcs), 25 mm, RAL 9007 802227

Intellivox hinge bracket 90°, RAL 9007 802005

Intellivox swivel bracket 90°, RAL 9007 806668

Intellivox swivel bracket 45°, RAL 9007 806678

Intellivox wall bracket set (2 pcs), 25 mm, RAL 9010 802225

Intellivox wall bracket set (2 pcs), 35 mm, RAL 9010 802235

Intellivox wall bracket set (2 pcs), 60 mm, RAL 9010 802260

Intellivox hinge bracket 90°, RAL 9010 802000

Intellivox swivel bracket 90°, RAL 9010 806608

Intellivox swivel bracket 45°, RAL 9010 806618

Small hinge set (2 pcs) 806602

201509/ADCIM

21

Page 22

JBL Professional® Intellivox ADC Installation Manual

This page has been left blank intentionally

22

201509/ADCIM

Page 23

JBL Professional® Intellivox ADC Installation Manual

This page has been left blank intentionally

201509/ADCIM

23

Page 24

JBL Professional

8500 Balboa Boulevard

Northridge, CA 91329 U.S.A.

© Copyright 2015 JBL Professional

www.jblpro.com

Loading...

Loading...