Page 1

car audio

power amplifier

owner’s manual

THANK YOU

for purchasing a JBL A6000GTi or A3000GTi amplifier.

For warranty support, please register your purchase at www.jbl.com.

Select Car Audio, then click on Support, and then click on Product Registration.

Also, please retain your original purchase receipt and packing crate

in case you must ship your unit back for service.

Page 2

INSTALLATION

WARNING: Playing loud music

in an automobile can hinder your

ability to hear traffic and permanently

damage your hearing. We recommend

listening at low or moderate levels

while driving your car. JBL accepts

no liability for hearing loss, bodily injury

or property damage resulting from the

use or misuse of this product.

IMPORTANT: To get the best

performance from your JBL A6000GTi or

A3000GTi amplifier, we strongly

recommend that installation be entrusted to a qualified professional. Although

these instructions explain how to install

JBL amplifiers in a

general sense, they do not show

specific installation methods that may

be required for your particular vehicle.

If you do not have the necessary tools

or experience, do not attempt the

installation yourself. Instead, please ask

your authorized JBL car audio dealer

about professional installation.

INSTALLATION

WARNINGS AND TIPS

• Always wear protective eyewear

when using tools.

• Turn off all audio components and

other electrical devices before you

start. Disconnect the (–) negative lead

from your vehicle’s battery.

• Check clearances on both sides of

a planned mounting surface before

drilling holes or installing screws.

Remember – the screws can extend

behind the surface.

• At the installation sites, locate

and make a note of all fuel lines,

hydraulic brake lines, vacuum lines,

and electrical wiring. Use extreme

caution when cutting or drilling in and

around these areas.

• Before drilling or cutting holes, use

a utility knife to remove unwanted

fabric or vinyl to keep material from

snagging in a drill bit.

• When routing cables, keep inputsignal cables away from power

cables and speaker wires. Use

grommets when passing cables

through the vehicle’s inner walls.

• When making connections, observe

the amplifier’s polarity markings.

Make sure that each connection

is clean and properly secured. Use

the shortest ground wire possible

to minimize resistance and avoid

noise problems.

• If the amplifier’s fuse must be

replaced, use only the same type

and rating as that of the original.

Do not substitute another kind.

CHOOSING A

MOUNTING LOCATION

The JBL A6000GTi and A3000GTi

amplifiers are big! Conventional mounting locations under driver or passenger

seats will not accommodate either

amplifier. Mount the amplifier in the

vehicle’s trunk or cargo area, but never

mount the amplifier in the engine compartment, outside the vehicle or

in any location where it may get wet.

When choosing a location, make sure

the site’s underlying structure is strong

enough to support the amplifier’s

weight and drilled holes for mounting

bolts. Also, verify that there will be adequate ventilation around the amplifier,

so that airflow to its internal fans will

not be blocked and the unit can

properly cool itself.

WARNING: To avoid personal injury and

possible product damage, we strongly

urge you to enlist additional help in

unpacking and moving the

JBL A6000GTi or A3000GTi amplifier

to a desired mounting location.

PARTS LIST

Each amplifier is packed with the following parts:

• Four (4) 1/2" x 3" socket-head cap

screws and T-nuts.

• One (1) Remote Level Control with

mounting hardware

• One (1) 15' RJ11 Cable for Remote

Level Control

• One (1) Logo Badge

• One (1) Set of Performance Graphs

• One (1) Owner’s Manual

• One (1) Warranty Registration

Instruction Card

MOUNTING THE

AMPLIFIER

We strongly recommend first mounting

a piece of wood or Medium Density

Fiberboard (MDF) to the vehicle, and

then mounting the amplifier to the

board. The amplifier is large and heavy

and must be mounted using all four

screws and T-nuts provided. Using

the amplifier as a template, mark the

location of the mounting holes on the

mounting surface, drill pilot holes, and

securely attach the amplifier to the

mounting surface with the provided

screws and T-nuts. Make sure the

amplifier does not pinch or smash

power cables, speaker wires, input

cables or any of the vehicle’s wiring.

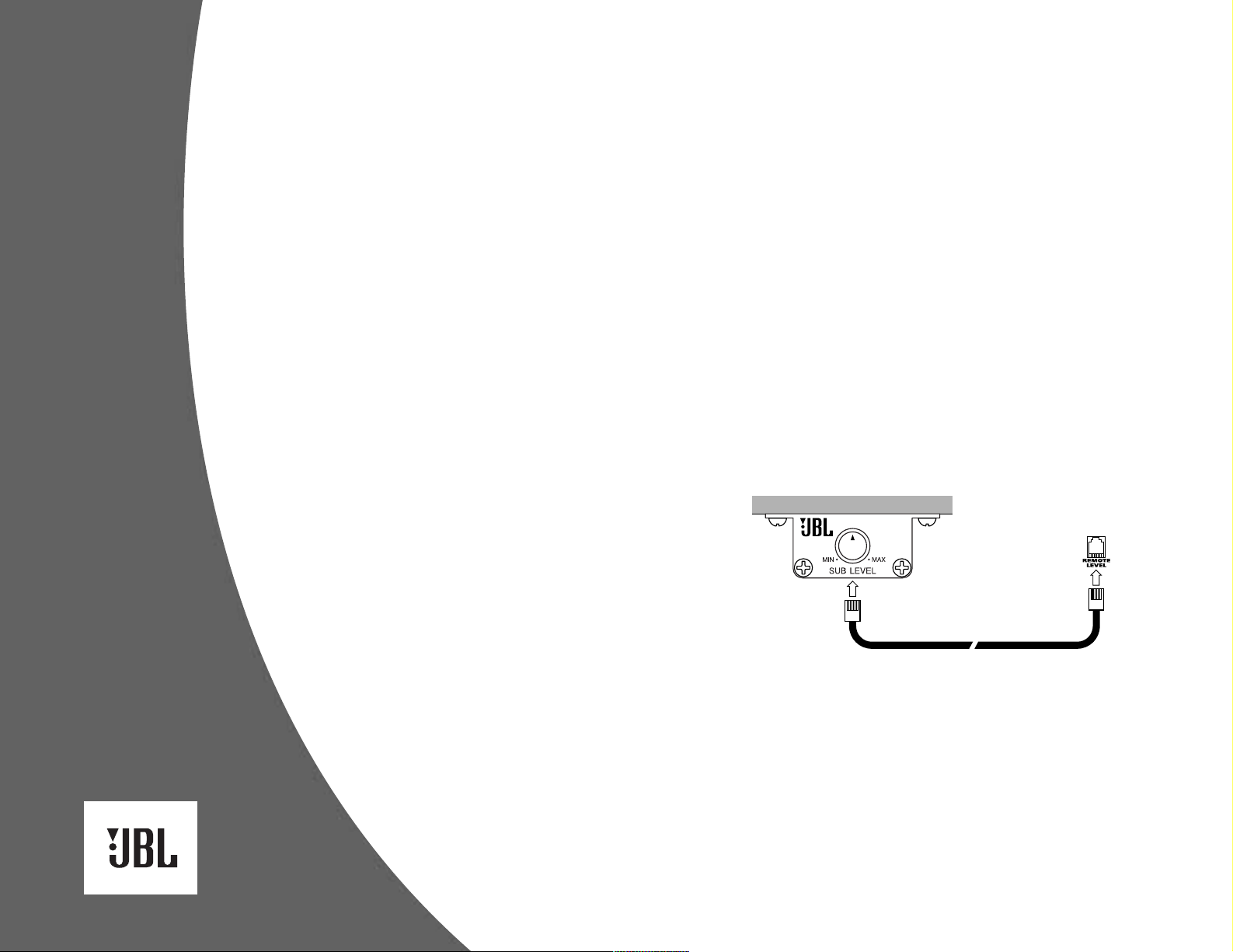

Install the Remote Level Control in a

convenient location in or under the

dashboard. The control may be

removed from its housing for custom

installation. Using the enclosed RJ11

cable, connect the control to the

amplifier, as shown in Figure 1.

2

A6000GTi/A3000GTi

(on input panel)

RJ11 Cable

RJ45 connector

RJ45 connector on back

Figure 1. Connecting the Remote Level

Control.

Once the amplifier is mounted, peel the

backing from the adhesive (on the back

of the logo badge) and attach the badge

in the appropriate orientation.

Page 3

DESIGNING A SPEAKER SYSTEM FOR THE GTI AMPLIFIER

NOTE: Although the JBL A6000GTi or

A3000GTi amplifier will drive a system

made up of any subwoofers, we

recommend using JBL GTi subwoofers

with GTi amplifiers.

Both the JBL A6000GTi and A3000GTi

amplifiers provide RMS power that

exceeds the RMS power-handling

rating of nearly every subwoofer

available. To use this amplifier

optimally, you should design a speaker

system made up of several identical

speakers, so that the power delivered

by the amplifier will be shared equally

among the speakers.

The JBL A6000GTi and A3000GTi

amplifiers support a wide range of

impedances, and any speaker system

with a total or equivalent impedance of

1 to 4 ohms will extract full power from

either amplifier. In order to connect

multiple woofers to the A6000GTi or

A3000GTi, you’ll need to connect your

speakers in series, parallel or seriesparallel. We’ve included diagrams for

each connection scheme and a pair of

formulas, which will help you.

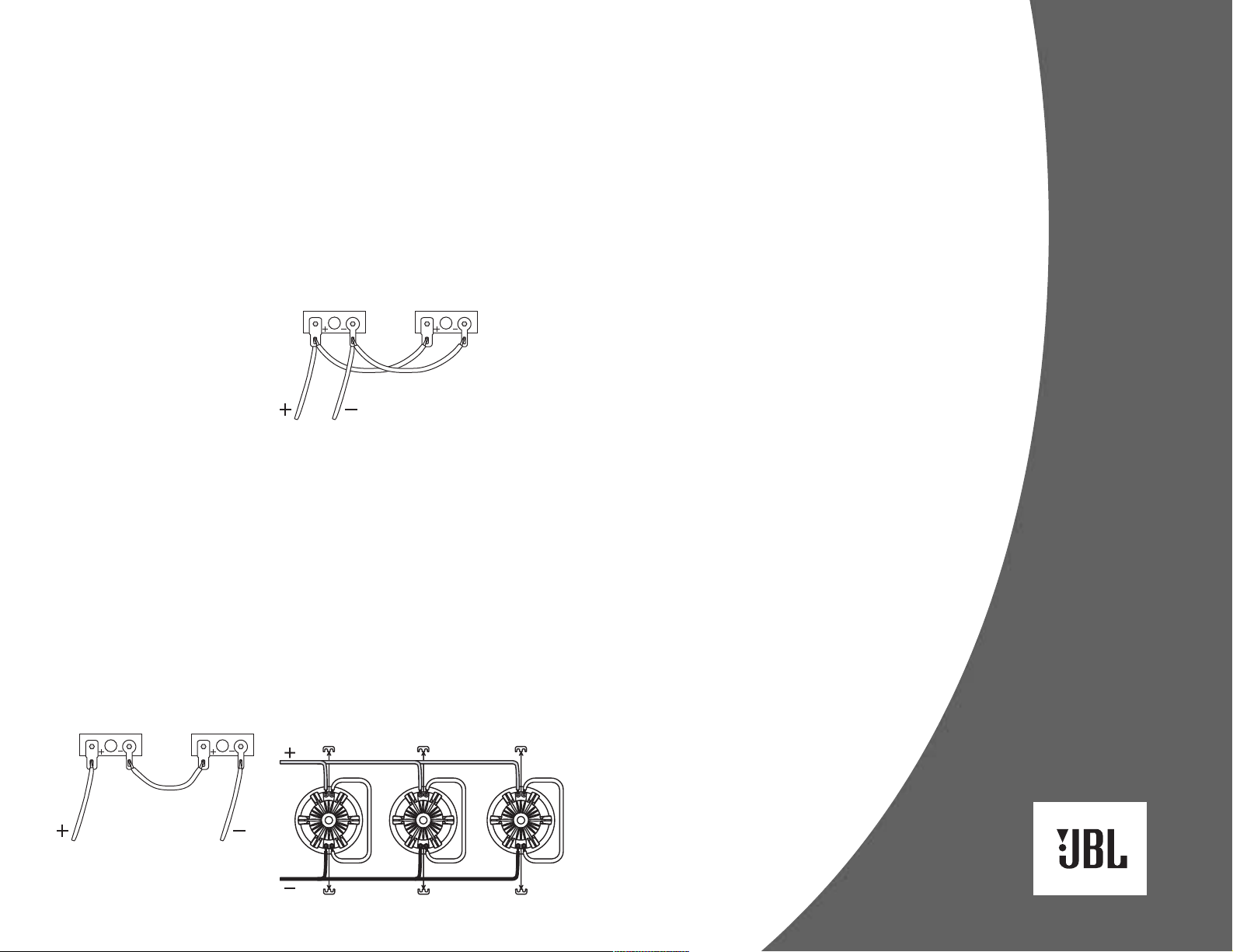

SERIES CONNECTIONS

The formula for determining the total

impedance of the two woofers connected in series is:

Z

total

= Z1+ Z2+ Z3...

Where Z

total

is the total impedance of

all woofers connected in series. Z

1

, Z

2

and Z3(and so on) are the nominal

impedance ratings of the individual

speakers. The total impedance of the

voice coils shown in Figure 2 is 8 ohms.

Figure 2. Series connection of two

4-ohm voice coils yields a total

impedance of 8 ohms.

PARALLEL CONNECTIONS

The formula for determining the

equivalent impedance of the voice coils

connected in parallel is:

Z

equivalent

= 1/(1/Z1+ 1/Z2+ 1/Z3…)

Where Z

equivalent

is the equivalent

impedance of the coils connected in

parallel. Z

1

, Z2and Z3(and so on) are

the nominal impedance ratings of the

individual speakers. The equivalent

impedance of the voice coils shown in

Figure 3 is 2 ohms.

Figure 3. Parallel connection of two

4-ohm voice coils yields a total

impedance of 2 ohms.

DUAL VOICE-COIL

CONNECTIONS

Dual voice-coil subwoofers, such as

JBL’s GTi series, may be connected

in series, as shown in Figure 2;

in parallel, as shown in Figure 3; or in

series-parallel, as shown in Figure 4.

Figure 4. Series-parallel connections

of three W15GTi subwoofers (with a

voice coil impedance of 6 ohms) yields

a total series impedance of 12 ohms

for each subwoofer, and an equivalent

parallel impedance of 4 ohms for all

three subwoofers.

To determine the impedance of a

system of three W15GTi (dual voicecoil) subwoofers connected in seriesparallel, use the series connection

formula to determine the impedance

of each subwoofer with its voice coils

connected in series. Then insert the

calculated value into the parallel

connection formula to determine the

equivalent impedance for the three subwoofers connected in parallel.

NOTE: Each W15GTi voice coil has an

impedance of 6 ohms.

For example, in Figure 4, each woofer

will have an impedance of 12 ohms, by

Z

total

= Z1+ Z2= 6 + 6 = 12

and the three woofers connected

in parallel will have an equivalent

impedance of 4 ohms, by

Z

equivalent

= 1/(1/Z1+ 1/Z2+ 1/Z3)

= 1/(1/12 + 1/12 + 1/12)

= 1/(3/12)

= 12/3 = 4

NOTE: All subwoofers connected to an

amplifier in a system must be identical

and, if they are dual voice-coil subwoofers, their coils must be wired identically. Do not connect the coils of one

subwoofer together in series and

another in parallel, since doing so will

cause uneven power distribution,

potential damage to the speakers, and

poor overall performance.

ABOUT SPEAKER

POWER HANDLING

The RMS power handling rating of

a speaker indicates the amount of

power it will handle continuously.

Although designing a subwoofer

system by considering the RMS rating

will ultimately provide you with the

most reliable system, your speakers

may be able to handle more power,

depending on what kind of music is

being reproduced.

For music with extended bass notes

(e.g., bass music, hip-hop or techno),

you should design a speaker system

based on the RMS power handling of

your speakers. For music with sharp

transient bass notes (e.g., rock,

country or jazz), the RMS power

handling rating is conservative, and you

can count on your speakers being able

to handle more power than the RMS

rating.

The total power output of your

amplifier will be divided among the

speakers connected to it. For example,

if you are using an A6000GTi and three

W15GTi subwoofers, each subwoofer

will receive 2,000 watts.

It’s important to choose a system of

subwoofers that will handle all of the

power. To determine how much total

power your speaker system will

handle, simply multiply the RMS power

handling rating of one of your speakers

by the total number of speakers that

will be connected.

3

4 ohms 4 ohms

4 ohms 4 ohms

Remove

Terminal Jumper

Red

Black

Remove

Terminal Jumper

Page 4

4

SUPPLYING POWER TO THE GTI AMPLIFIER

POWER IN IS

POWER OUT

In order to get full power out of your

amplifier, you must provide full power to

your amplifier. That’s a basic rule

of physics. The A6000GTi amplifier

can draw nearly 800 amperes when

reproducing sine waves at full output.

Both JBL A6000GTi and A3000GTi amplifiers can quickly exhaust the

factory-installed charging system of

any vehicle on the road today. With this

much available amplifier power, you will

need to beef up your vehicle’s

electrical system to satisfy the

amplifier’s current demands. We

recommend adding at least two

12-volt batteries, connected in

parallel with cold-cranking capacities

of at least 600 amperes each, to the

factory-installed charging system.

HOW YOUR CHARGING

SYSTEM WORKS

The battery’s job is to start your

vehicle. Running the electrical

accessories is the alternator’s job.

The battery isn’t designed to be a

continuous source of power. It is a

renewable source and is charged by

the alternator when the engine runs.

Battery charging can only occur when

the current demand from the electrical

accessories is less than the total current output capacity of the alternator.

PROGRAM MATERIAL

AND CURRENT DEMAND

Music is a combination of loud and

soft sounds, with varying durations

and rhythms that present unique

current demands during amplification.

For example, it may take full power

to reproduce the sound of a kick

drum. The peak power demand doesn’t

last very long, but it is repeated over

and over.

If your charging system can’t provide all

the power your amplifier needs on

a continuous basis, it still may be

adequate. During the sound of the

kick drum, the battery can provide

the extra current that’s necessary,

and between kick drum beats, the alternator will put some of the energy back

into the battery.

However, depending on the current rating of the alternator, the amplifier’s

maximum output power, the music

content, and the charging system’s

capability, the alternator may not be

able to keep up over time. In that case,

you’ll need to install a somewhat larger

alternator for more current, or adjust

your driving and listening habits, to give

the alternator time to catch up with the

amplifier’s current demand.

Few stock batteries can provide the

current required to reproduce even

short-duration musical peaks. Adding

a pair of batteries with cold-cranking

capacities of 600 amperes will provide

extra current for short music bursts, but

reserve power may still be

depleted over longer music intervals.

Adding more batteries will provide more

reserve power and current, but no matter how many are installed, the alternator will still have to recharge them all.

If you plan to use the A6000GTi or

A3000GTi in SPL competition, the charging system requirements will be much

greater than those for normal music listening. Be prepared to add additional

batteries and alternators to provide

continuous current required for continuous duty.

See your authorized JBL car audio

dealer for help in designing and

installing an upgraded charging

system to support your GTi amplifier.

Page 5

5

MAKING THE CONNECTIONS

POWER CONNECTIONS

Use 0-gauge cable to connect the

amplifier’s GND– terminal directly to

the vehicle’s chassis (see Figure 5).

Scrape off all paint from the metal area

for a good, clean ground connection.

Make sure the ground wire is as short

as possible and is connected to metal

on the vehicle’s body. Do not connect

the GND – cable to the frame of the

vehicle. It is isolated from the chassis

using rubber shims and will not provide

an adequate ground. Instead, use the

trunk’s floor or cargo area as a suitable

location. Do not connect the GND –

cable to the battery’s negative (–)

terminal.

Figure 5. Power wiring

diagram for the JBL A6000GTi

amplifier. The A3000GTi is

wired in a similar way.

Use 0-gauge cable to connect the

BATT+ terminal directly to the vehicle’s

battery. If the battery is located in the

engine compartment and the BATT+

cable must be routed through the

firewall or any metal obstruction, install

a wafer-type (ANN) fuse with a current

rating of at least 500 amperes and an

appropriate fuse holder

within 18" of the vehicle’s battery

(see Figure 5).

Connect the source unit’s remote

turn-on lead to the REMOTE terminal on

the amplifier (see Figure 5). Use

any convenient gauge wire for the

connection.

The amplifier’s internal neon lights

require a separate switched power

connection with at least a 2-ampere current capacity. If desired, install a switch

to turn on the neon lights or a relay triggered by a circuit in the vehicle (e.g.,

door switch, trunk pin switch or other

turn-on source). If you want the amplifier’s neon to light when the

amplifier is on, connect the LIGHTING

terminal to a relay triggered by the radio’s

remote turn-on lead (see Figure 5).

IMPORTANT: Do not connect a jumper

directly between the REMOTE and

LIGHTING terminals. Doing so may burn

out the remote turn-on circuits

in your source unit.

SIGNAL CONNECTIONS

Use high-quality twisted-pair RCA audio

cables to connect your source unit’s

main stereo or subwoofer RCA output

jacks to the amplifier’s L/R INPUT jacks.

For a single subwoofer output, use an

RCA “Y” adapter to

connect its signal to both input jacks.

As a convenience, each JBL A6000GTi

or A3000GTi amplifier is also equipped

with a set of PASS-THRU L/R RCA audio

jacks. They will pass incoming audio

signals unaltered, and you can use

them to send stereo audio signals to

other components in your system.

REMOTE LEVEL

CONTROL/ACCESSORY

GAUGE OUTPUTS

The A6000GTi and A3000GTi use an

RJ45 connector to output control

signals for the Remote Level Control

and accessory gauges. Use the 15'

RJ11 cable to connect the control to the

amplifier. For accessory gauges, use

the pinouts in Figure 6 to make custom

cables with materials found

at most electronics supply stores or

home centers.

For gauges, varying voltages are output

on selected RJ45 pins to indicate

voltage, current and temperature.

For battery voltage, linear scale (pin 1):

2 volts = 8 volts at the battery

4.5 volts = 18 volts at the battery

For temperature, linear scale (pin 2):

0 volts = –10 degrees Celsius

5 volts = 110 degrees Celsius

For current, linear scale (pin 3):

0 volts = 0 amperes current draw

5 volts = 800 amperes current draw

Also, you can connect a power meter

using the pins for battery voltage and

current. Be sure to use a power meter

that multiplies the incoming voltage and

current signals (i.e., P = E x I) to convert

the data to watts.

SPDT Relay

(or other

turn-on

signal)

A6000GTi

Power Terminals

+12 V

Ground

87 87a85

ncno

86 30

Chassis

Ground

(Bare Metal)

0-gauge0-gauge

Remote Turn-On

Batteries

ANN-Type Fuse

(500 A or more)

Source Unit

18 "

Ground (also use for acc. gauges) = 8

81

No Connection = 7

Remote Level Control = 6

Remote Level Control = 5 4 = Remote Level Control

3 = Current (to acc. ampere meter)

2 = Temperature (to acc. temp. gauge)

1 = Battery Voltage (to acc. volt meter)

RJ45 Connector

(GTi Input Panel)

Figure 6. Pinouts for the REMOTE LEVEL RJ45 connector on the

A6000GTi or A3000GTi amplifier.

CONNECTING

THE SPEAKERS

IMPORTANT: As a safety feature and

due to the high output voltage

capability of the A6000GTi and

A3000GTi amplifiers, the SPEAKER

OUTPUTS are equipped with a cover

that must be in place in order for

the amplifier to operate. When the

cover is removed, the amplifier will

turn off and speaker connections

can be made safely.

Page 6

6

MAKING THE CONNECTIONS

A6000GTi SPEAKER

CONNECTIONS

The A6000GTi is a 2-channel amplifier

designed to drive subwoofers only.

The left and right input signals are combined inside the amplifier to

provide a mono output signal, no

matter which output mode is selected.

The A6000GTi can be connected to

two independent speaker systems in

2-channel mode. It can be connected to

a combination of subwoofers

configured as a single load with its

channels bridged or connected in

parallel. Bridged channels will provide

high output voltage for driving loads

with a nominal impedance of 2 to 4

ohms. Connecting the channels in

parallel will provide the high current

necessary to drive loads of 1 to 2 ohms.

Included below are three application

diagrams that will help you plan

your A6000GTi installation. Figures 7

through 9 show how to configure the

JBL A6000GTi subwoofer amplifier for

bridged-mono, parallel-mono and

2-channel operation (see Setting Up the

GTi Amplifier).

IMPORTANT: If the nominal impedance

of the speaker system is close to 2

ohms, you may try both bridged and

parallel configurations to determine

which one performs better. Remember

to set the output mode switch to the

appropriate setting when changing

configurations.

NOTE: For simplicity, Figures 7 through

9 do not show power, remote and input

connections (see page 5).

A6000GTi Amplifier

(partial output panel)

Subwoofer

System

2 to 4

ohms

Subwoofer

System

2 to 4

ohms

Set Output Mode

to 2CH/BR

(on input panel)

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

A6000GTi Amplifier

(partial output panel)

Set Output Mode

to PARALLEL

(on input panel)

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

Subwoofer

System

2 ohms

or less

jumper

A6000GTi Amplifier

(partial output panel)

Set Output Mode

to 2CH/BR

(on input panel)

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

Subwoofer

System

2 ohms

or more

Figure 7. The JBL A6000GTi

subwoofer amplifier is set

to bridged mode to drive a

subwoofer system. Only use

this mode when the nominal

equivalent or total impedance

of the speaker system is

2 ohms or greater.

Figure 9. The JBL A6000GTi

subwoofer amplifier is set

to 2-channel mode to drive

a pair of subwoofers or

subwoofer systems with

nominal equivalent or total

impedances of 2 to 4 ohms.

Figure 8. The JBL A6000GTi

subwoofer amplifier is set

to parallel mode to drive a

subwoofer system. Only

use this mode when the

nominal equivalent or total

impedance of the speaker

system is less than 2 ohms.

NOTE: A jumper is added

between the + terminals.

Page 7

7

MAKING THE CONNECTIONS

A3000GTI SPEAKER

CONNECTIONS

Included below are three application

diagrams that will help you plan your

A3000GTi installation. Figures 10

through 12 show how to configure

the JBL A3000GTi amplifier for

bridged-mono, parallel-mono and

2-channel operation (also see

Setting Up the GTi Amplifier).

NOTE: For simplicity, Figures 10 through

12 do not show power, remote and input

connections (see page 5).

A3000GTi Amplifier

(partial output panel)

2 to 4

ohms

2 to 4

ohms

L Speaker

System

R Speaker

System

Set Output Mode

to STEREO

(on input panel)

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

A3000GTi Amplifier

(partial output panel)

Set Output Mode

to PARALLEL

(on input panel)

Subwoofer

System

2 ohms

or less

jumper

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

A3000GTi Amplifier

(partial output panel)

Set Output Mode

to BRIDGE

(on input panel)

Subwoofer

System

2 ohms

or more

See “Setting The Crossover”

on Page 8

to Adjust Crossover Controls

Figure 10. The JBL A3000GTi

amplifier is set to bridged

mode to drive a subwoofer

system. Only use this mode

when the nominal equivalent

or total impedance of the

speaker system is 2 ohms

or greater.

Figure 12. The JBL A3000GTi

amplifier is set to stereo

mode to drive a pair of fullrange speaker systems with

nominal equivalent or total

impedances of 2 to 4 ohms.

Figure 11. The JBL A3000GTi

amplifier is set to parallel

mode to drive a subwoofer

system. Only use this mode

when the nominal equivalent

or total impedance of the

speaker system is less than

2 ohms.

NOTE: A jumper is added

between the + terminals.

OUTPUT LOAD SWITCH

The Output Load switch is used to

optimize amplifier performance when

driving a full-range signal. Set the

switch according to the nominal impedance of the load: Use the 4-ohm mode

when driving loads with a nominal

impedance greater than 2 ohms and the

2-ohm mode when driving loads with a

nominal impedance of 2 ohms or less.

Page 8

8

SETTING UP THE GTI AMPLIFIER

SETTING INPUT

SENSITIVITY

NOTE: You can use the supplied

REMOTE LEVEL control to fine-tune

the input sensitivity or to adjust the

level of the bass according to the

program material after the amplifier’s

LEVEL control has been set properly.

Connect the remote module’s attached

cable to the REMOTE LEVEL (RJ45) jack

on the amplifier’s input panel. Start with

the REMOTE LEVEL Control in its maximum (clockwise) position.

1. Initially, turn the amplifier’s LEVEL

control to the minimum (clockwise)

position.

2. Reconnect the (–) negative lead to

your vehicle’s battery. Apply power

to the audio system and play a

favorite music track.

3. Increase the source unit’s volume

control to the maximum listening

position. Slowly turn the amplifier’s

LEVEL control counterclockwise and

observe the I/OPT and E/OPT LEDs

(on the amplifier’s top).

• In the bridged or 2-channel mode,

at the ideal setting, the E/OPT LED

should flash on musical peaks to

indicate the amplifier is producing

maximum voltage. If the I/OPT LED

flashes in bridged mode, this

indicates the speaker system’s

impedance is lower than 2 ohms

and the amplifier should be

configured in the parallel mode.

• In the parallel mode, at the ideal

setting, the I/OPT LED should

flash on musical peaks to indicate

that the amplifier is producing maximum current.

If either the I/OPT or E/OPT LED is

on steadily, the amplifier is being

overdriven and your speakers may

be in jeopardy. Turn the LEVEL

control back slightly until the I/OPT or

E/OPT LED flashes on musical peaks.

SETTING PHASE

1. Initially set the PHASE control to 0°.

Play a favorite audio track that has

significant bass output.

2. Continue listening to the music and

have another person slowly adjust

the PHASE control towards 180° and

back to 0° again.

3. Repeat Step 2 as needed until you

find a setting that produces the most

mid-bass output.

NOTE: For applications using multiple

GTi amplifiers where the highest SPL

is desired at a single point in the

vehicle (i.e., SPL competition), adjust

the PHASE controls on all amplifiers

so all speakers are in phase at the

microphone position. This will provide the highest SPL when measured

with an SPL meter.

SETTING DBO

DBO (or Dynamic Bass Optimizer) is

a 12dB/octave high-pass filter with variable frequency (20Hz to 80Hz)

and variable boost (0 to +12dB) at

the cutoff frequency.

NOTE: During DBO adjustment, you can

audition the effect by setting the DBO

switch to OFF and then back to ON.

NOTE: The A3000GTi can be used

to drive a pair of stereo mid-bass

speakers. In this case, use the DBO

to set the high-pass filter (from 20Hz to

80Hz) and use the crossover to set the

low-pass filter (from 80Hz to 320Hz).

For a vented box where a subwoofer

is prone to overexcursion below the

tuned frequency, set DBO to ON and set

the DBO HP FREQ control 10Hz below

the box’s resonant (tuned)

frequency (e.g., 30Hz for a vented

box tuned to 40Hz). Power typically

wasted in this region will now be

conserved and instead be available

for frequencies the enclosure can

reproduce. Use the DBO BOOST

control to boost the bass at the set

frequency by as much as 12dB, as

shown in Figure 13.

For a sealed enclosure, use DBO to

enhance the middle of the bass region.

Set DBO to ON, and then set the DBO

HP FREQ control to 35Hz to 40Hz. Adjust

the DBO BOOST control for a big and

full bass sound. Alternatively, for a

tighter-sounding bass, set the DBO HP

FREQ control between 45Hz to 50Hz and

also adjust the DBO BOOST control

according to your preference.

For an infinite baffle application,

set DBO to ON, and then set the

HP FREQ control to the speaker’s Fs

value (to keep the subwoofer from

trying to create bass below the

resonant frequency). Adjust the DBO

BOOST control according to your taste.

–9

–6

–3

0

–12

20 80

Freq. (Hz)

dB

DBO HP FREQ Control

(adjusts cut-off

frequency)

–6

0

6

12

–12

20 80

Freq. (Hz)

dB

DBO BOOST Control

(adjusts boost amount

at cut-off frequency)

HP FREQ

20Hz80Hz

BOOST

MAX MIN

Figure 13. Frequency response curves

show typical DBO control ranges for

the JBL A6000GTi or A3000GTi amplifier.

SETTING THE CROSSOVER

IMPORTANT: If you plan to use the

A3000GTi to drive full-range speakers,

set the crossover mode switch to FLAT

and skip to the next section, “Setting

Input Sensitivity.”

1. Depending on your system plan,

set the A3000GTi’s crossover mode

switch to LP (low-pass) or HP (highpass). The A6000GTi is a low-pass

amplifier only, designed to drive

subwoofers. No crossover switch

is provided.

2. The crossover slope has two

settings: 12 (dB per octave) or

24 (dB per octave). Select the

slope that best suits your taste, but

consider that a steeper low-pass

filter will make the subwoofers

sound less directional (since more

midrange will be filtered from the

signal). A steeper high-pass filter will

reduce a small speaker’s

unnecessary cone excursion at

the lowest frequencies, which

will increase power handling

and reduce distortion.

3. Set the A3000GTi’s HP FREQ control

to allow the speakers to make

as much bass as possible while

minimizing distortion caused by

small speakers trying to reproduce

the lowest frequencies. The best

setting is one where the speakers

produce crisp, clear impact without

being overdriven.

4. For either amplifier, set the LP FREQ

control so vocal information is not

reproduced by the subwoofers, and

the subwoofers’ sound blends with

the sound of the midrange speakers

without any missing information.

NOTE: The LP FREQ control can be

set to any frequency between 32Hz

and 320Hz.

Page 9

9

SETTING UP THE GTI AMPLIFIER

REPLACING THE FUSE

OR NEON TUBES

The JBL A6000/A3000GTi amplifier

is equipped with an internal fuse, a

20-inch neon tube and two 6-inch neon

tubes. Should the fuse or a neon tube

fail, perform the following steps

to replace the part:

NOTE: For neon tube replacement, see

your authorized JBL car audio dealer to

purchase new StreetGlow

®

neon tubes

in 6- or 20-inch sizes.

NOTE: Although the following

steps discuss and illustrate how

to disassemble a JBL A6000GTi,

the disassembly procedure for a

JBL A3000GTi is similar.

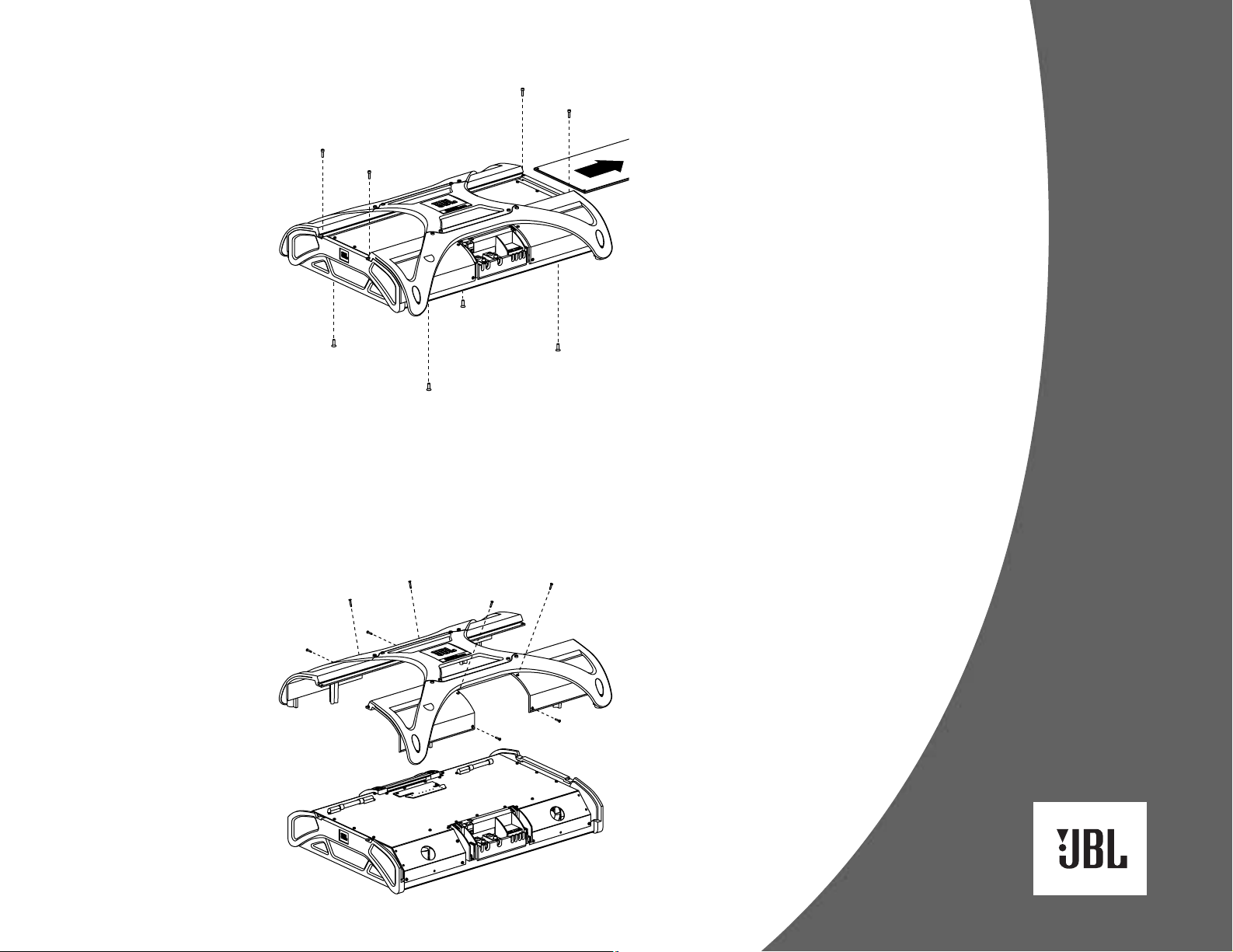

1. Disconnect and unmount the

amplifier from the vehicle. On a

soft surface, turn the amplifier over

to view the bottom. Using a T-25

screwdriver, remove the four large

Torx-head screws along the bottom

edges and set them aside (see

Figure 14).

2. Turn the amplifier over to view the

top. Using a 5 ⁄32-inch Allen wrench,

remove the four cap screws on the

clear cover and set them aside (see

Figure 14).

3. Slide the clear cover off and set it

aside (see Figure 14).

Figure 14. Removing bottom screws and

the clear cover from the A6000GTi

amplifier. NOTE: Do not remove the logo

badge assembly.

4. Using a T-15 screwdriver, remove the

four Torx-head screws around the

output panel and set them aside (see

Figure 15).

5. Repeat Step 4 for the input panel

(see Figure 15).

6. Remove the cover and set it aside

(see Figure 15).

Figure 15. Removing the input and

output screws and the cover from the

A6000GTi amplifier.

Page 10

10

SETTING UP THE GTI AMPLIFIER

7. Using a T-15 screwdriver, remove the

two Torx-head screws on the display

board and set them aside

(see Figure 16 below). Disconnect

the ribbon cable from display board.

8. Using a T-15 screwdriver, remove the

16 Torx-head screws on the

perforated shield and set them aside

(see Figure 16).

Figure 16. Removing the fuse from the

A6000GTi amplifier.

9. Using a small flat-blade screwdriver,

disconnect the wiring for the neon

tubes.

10. Remove the perforated shield and

set it aside.

11. Replace the fuse or a neon tube as

follows:

• To replace the fuse on the ampli-

fier circuit board (see Figure 16),

use a 7 ⁄ 16-inch hex-socket driver

to remove the two fuse nuts and

then discard the failed fuse. Fasten

the replacement fuse

in place using the two fuse nuts.

• To replace a neon tube (see Figure

17), use a T-15 screwdriver and pliers to remove the two

Torx-head screws, nuts and

washers on the two clamps that

hold each neon tube in place.

Remove the failed neon tube

and unscrew its wires.

On the replacement neon tube, clip off

the cigarette lighter adapter. Then strip

the wires and screw the ends to the

connector. Refasten the two clamps

with hardware in place around the

neon tube. If needed, repeat this procedure for another failed neon tube.

Figure 17. Neon tube locations on the

A6000GTi amplifier.

12. Reassemble the amplifier in reverse

order, as discussed in Steps 1

through 10.

Failed

Fuse

20" Neon Tube

(under shield)

6" Neon Tubes

Page 11

11

TROUBLESHOOTING

SYMPTOM LIKELY CAUSE SOLUTION

No audio No voltage at power Check BATT+, REMOTE and

(Power LED is off) or remote terminal GND – terminals with VOM for

blown fuse or poor connection

Internal fuse blown Replace internal fuse

(incorrect power (see Replacing the Fuse

connections) or Neon Tubes section)

No audio Low or high voltage Check BATT+ terminal with

(Power LED at power terminal VOM for voltage between

is flashing) 10 and 16 Vdc; if not within

limits, check vehicle’s

electrical system

No audio Direct current on Disconnect cable from

(Power and speaker output(s) REMOTE terminal; if Fault LED

Fault LEDs is still on, contact local JBL

are on) service center

No audio Internal amplifier Check for blocked vents

(Power and temperature is over or whether the ambient

Thermal LEDs 85° C temperature is above 85° C

are on)

Distorted audio Amplifier’s gain is Properly adjust the

(I OPT and/or set to High LEVEL control (see

E OPT LED[s] Setting Input

are on more Sensitivity section)

than off)

Distorted audio Defective source unit Try new source unit

(I OPT and/or

E OPT LED[s] Shorted speaker Disconnect wires from

work correctly) wires SPEAKER OUTPUTS and

check for shorts between

wires, or between a wire and

the vehicle’s chassis

Music lacks Speakers are out Check speaker connections

“punch” of phase (see sections on speaker

connections)

Wrong output mode Verify output mode setting

(see Making the Connections

section)

Neon tubes do No voltage to neon tubes Check LIGHTING

not light for +12 Vdc terminal with VOM

Neon tubes are dead Replace neon tubes

(see Replacing the Fuse

or Neon Tubes section)

3000 Watts Parallel Bridge

Thermal

CH 1

CH 2

Signal -18 dB -9 dB E Opt I Opt

Power

Fault

A3000GTi

6000 Watts Parallel Bridge

Power

Thermal

Signal -18 dB -9 dB E Opt I Opt Fault

A6000GTi

Figure 18. Display indicates Power Output and Protection status.

Page 12

Declaration of Conformity

We, Harman Consumer Group International

2, route de Tours

72500 Chateau-du-Loir

France

declare in own responsibility that the products

described in this owner’s manual are in compliance

with technical standards:

EN 55013:2001

EN 55020:2002

Emmanuel Millot

Harman Consumer Group International

Chateau-du-Loir, France 05/04

JBL Consumer Products

250 Crossways Park Drive, Woodbury, NY 11797 USA

© 2004 Harman International Industries, Incorporated

JBL and Crown are registered trademarks of

Harman International Industries, Incorporated.

Part No. GTIAMPOM4/04

www.jbl.com

Features, specifications and appearance are subject to change without notice.

Loading...

Loading...