JBL 2490-H Brochure

Professional Series

Key Features:

200 watts continuous program

above 250 Hz

Optimized phasing plug design

for low distortion, smooth

response, and wide bandwidth

100 mm (4 in), .08 mm (.003 in)

thickness, titanium diaphragm

76 mm (3 in) throat exit diameter

100 mm (4 in) edgewound

voice coil

The Model 2490H is a unique addition to JBL’s family of professional

quality compression drivers. The

design goal was to provide very high

level sound pressure at low distortion

over the bandwidth of 250 Hz to

above 3 kHz. Extensive computer

modeling, including finite element

analysis and boundary element

analysis, were used to optimize the

magnetic structure, phasing plug,

and diaphragm. This application of

advanced technology has produced a

smaller, lighter weight compression

driver with better performance than

previous high-power midrange

transducers.

A new phasing plug was developed

with an optimized two slit configuration A five-to-one compression ratio

produces very low distortion and

smooth, wide bandwidth response.

The new diaphragm design includes

JBL’s exclusive three-dimensional diamond pattern surround’ tuned to

reduce fatigue inducing stresses in the

membrane and support structure.

Precision engineering and manufacturing processes provide controlled

normal and suspension resonance

modes. The diaphragm and suspension use 3 mil pure titanium for

high stiffness and freedom from

breakup modes.

A long voice coil design using high

temperature voice coil former

material and adhesives enable the

2490 to handle high power levels

over extended periods of time.

¹U.S. Patent #4,324,312. Foreign patent pending.

2490H

Midrange

Compression Driver

2490H Midrange Compression Driver

Architectural Specifications:

The compression driver shall consist of a ferrite magnetic structure

with all magnetic assembly parts machined from cast or extruded

billet stock. The phasing plug shall be assembled of concentric horns

to minimize phase cancellations. The diaphragm shall be .08 mm

(.003 in) pure titanium pneumatically drawn to shape. Frequency

response shall be controlled through the use of a three dimensional

suspension structure. The voice coil shall be edgewound aluminum

ribbon of not less than 100 mm (4 in) diameter, operating in a

magnetic field of not less than 1.5 T (15,000 gauss).

Performance specifications of a typical production unit shall be as

follows: Measured sensitivity with a 45 mW input on a 76 mm (3 in)

plane wave tube, averaged from 300 Hz to 4 kHz, shall be at least 123

dB SPL. Measured sensitivity with a 1 W input at 1 m distance on axis

from the mouth of a horn with a Q of 20 averaged in the 2 kHz octave

band shall be at least 114 dB SPL. As an indication of electromechanical conversion efficiency, the Bl factor shall be at least 18 Tesla meters.

Frequency response, measured on a terminated tube, shall be flat

within ± 1 dB from 250 Hz to 2.5 kHz. Nominal impedance shall be 8

ohms and power capacity shall be at least 200 watts normal speech or

music program material.

The compression driver shall be the JBL Model 2490. Other drivers

will be considered for equivalency provided that submitted data from

a recognized independent test laboratory verify that the above performance specifictions are met

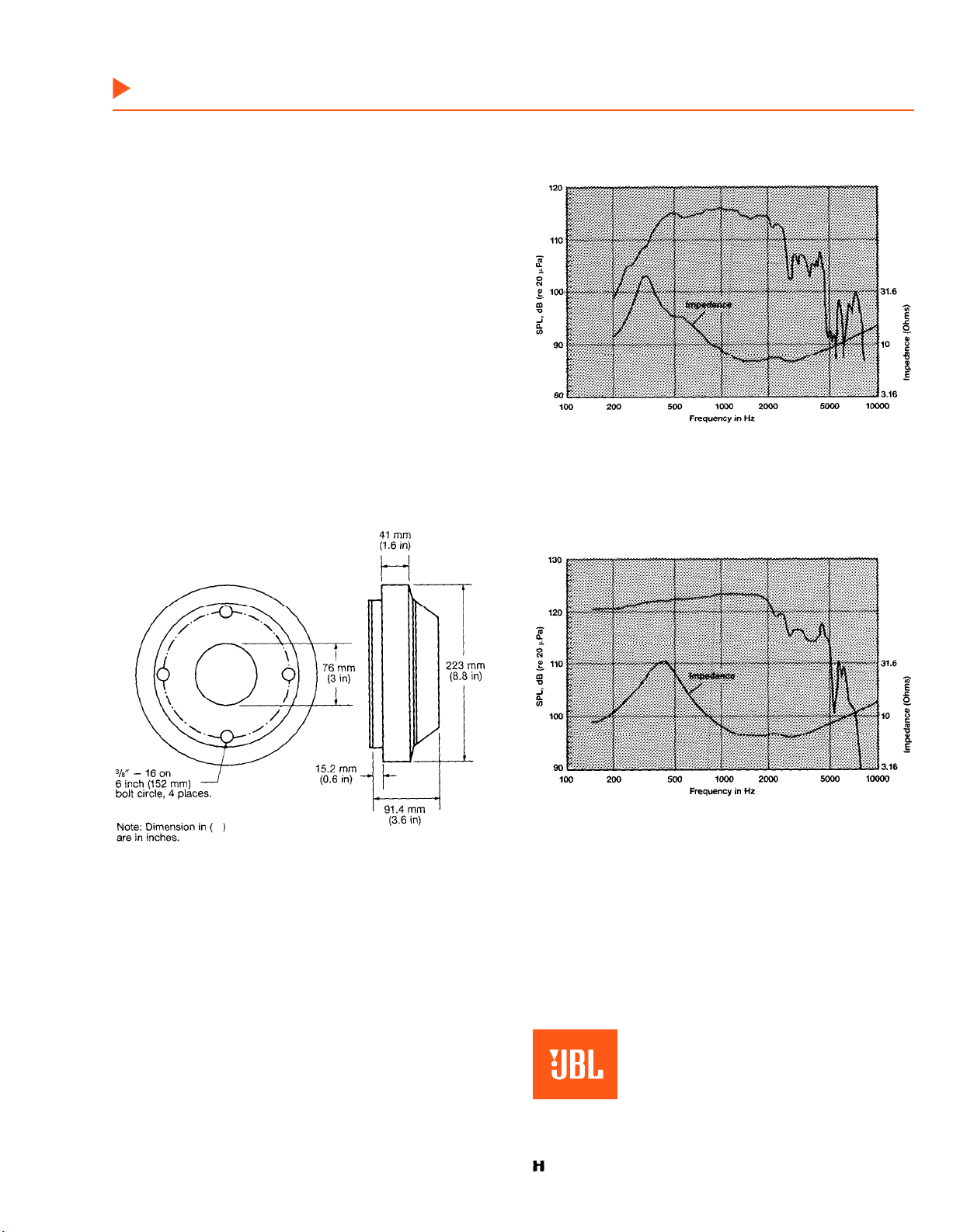

Response on JBL 2393 Bi-Radial® Horn

Frequency response of the 2490H coupled to a JBL 2393 Bi-Radial

Horn, measured on-axis at a distance of 1 meter with a l-watt

(2.83 V rms) input in a reflection free environment, with impedance

vs. frequency curve.

Response on Plane-Wave Terminated Tube

®

Frequency response and impedance modulus of model 2490H

coupled to a 76 mm (3 in) diameter terminated plane wave tube

This is the power response of the transducer. (0.6 V rms input).

JBL Professional

8500 Balboa Boulevard, P.O. Box 2200

Northridge, California 91329 U.S.A.

A Harman International Company

10/94 10M

P1149

Loading...

Loading...