JBL 2426-H, 2426-J Brochure

Professional Series

Key Features:

25 mm (1 in) horn throat diameter

Alternate 1 3/8” - 18 screw mounting

70 watts continuous program at

800 Hz

100 watts continuous program

above 1.2 kHz

44 mm (1¾ in) pure titanium

diaphragm

Patented diamond-pattern

diaphragm suspension

44 mm (1¾ in) edgewound

aluminum ribbon wire voice coil

Copper-plated pole piece for

reduced inductance and increased

high-frequency output

The model 2426H is a professional

quality high frequency compression

driver which incorporates JBL’s

titanium diamond diaphragm. This

titanium diamond structure combines

the ruggedness of phenolic and

composite-type diaphragms with the

outstanding frequency response of

fragile aluminum and exotic metal

diaphragms.

JBL’s exclusive suspension1, con-

sisting of a three-dimensional dia-

mond pattern, reduces bending

stresses in the diaphragm support

structure. The depth of the diamond

pattern is closely controlled to

provide predictable frequencies for

the 2nd and 3rd normal resonance

modes and for the basic suspension

resonance.

The mathematically determined

phasing plug consists of concentric

exponential horns to minimize phase

cancellations. Phasing plug, throat exit

tube and diaphragm assemblies are

identical to the previous model.

All cast parts and tolerances are held

to the same levels traditionally associated with JBL designs. Additionally the

press-fit assembly and interlocking

parts assure greater resistance to the

mechanical shock. Diaphragm assemblies are rim centered rather than pin

mounted, for instant interchangeability and ease of field service.

Mounting is provided for standard

25 mm (1 in) three bolt pattern.

The front snout may be removed

(unscrewed) to allow standard 1 3/8” -

18 screw mounting. Through holes for

1

U. S. Patent 4,324,312

2426H/J

Compression Driver

Specifications:

Throat Diameter: 25 mm (1 in)

Nominal Impedance: 2426H - 8 ohms

Minimum Impedance:

D.C. Resistance:

Power Capacity1:

Sensitivity:

Nominal Efficiency: 25% (800 Hz to 2.5 kHz)

Frequency Range:

Recommended Crossover4: 800 Hz or higher, 12 dB/octave slope minimun

Diaphragm: 0.05 mm (0.002 in) pure titanium

Voice Coil Diameter: 44 mm (1% in)

Voice Coil Material: Edgewound aluminum ribbon

Flux Density: 1.8 T (18,000 gauss)

Bl Factor: 6.3 N/A(H)

Positive voltage to black terminal gives diaphragm motion toward phasing plug

MOUNTING INFORMATION:

Mounting:

Dimensions:

l

Continuous program is defined as 3 dB greater than continuous pink noise and is a conservative expression of the

transducer’s ability to handle normal speech and music program material. Continuous pink noise power ratings are rested

with pink noise input having a 6 dB crest factor for two hours duration, per AES standard.

2

Sensitivity measured on-axis in the far field with 2.83 V rms at 8 ohms or 4.0 V rms at 16 ohms and referred to 1 meter

distance calculated by inverse square law. Listed sound pressure level (SPL re 20 uPa) represents an average from

1 kHz to 4 kHz.

3

As specified by recognized standards organizations, JBL plane wave tube measurements represent the SPL in a 25 mm

diameter terminated tube, using a 1 mW input signal (0.126 V rms into 16 ohms, 0.089 V rms into 8 ohms) swept from

800 Hz to 2.5 kHz. The sensitivity with a 1 W input would he 30 dB greater.

4

A 2426 can be used to 500 Hz; however, power capacity will be reduced to 20 W continuous program in the region between

500 Hz and 800 Hz.

JBL continually engages in research related to product improvement. New materials, production methods, and design

refinements are introduced into existing products without notice as a routine expression of that philosophy. For this

reason, any current JBL product may differ in some respect from its published description, but will always equal or

exceed rhe original design specifications unless otherwise stated.

Net Weight:

2426J - 16 ohms

5 ohms (H), 9 ohms (J) @ 5 kHz

3.3 ohms (H), 6.5 ohms (J) ± 10% @ 25°C

70 W continuous program above 800 Hz

100 W continuous Program above 1.2 kHz

107 dB SPL, 1 W @ 1 m, JBL 2344A horn

110 dB SPL, 1 W @ 1 m, JBL 2370A horn

117 dB SPL, 1 mW on plane wave tubes

500 Hz to 20 kHz

9.3 N/A (J)

Three ¼-20 threaded holes, 120° apart on 57.2 mm

(2¼ in) diameter

Front snout may be removed (unscrewed) to expose

standard 1 3/8 in -18 screw threads

149 mm (5 7/8 in) diameter

104 mm (4 1/8 in) depth

4.3 kg (9½ lb)

2

2

2426H/J Compression Driver

external attachment points are also provided. A machined

ring of copper surrounds the pole piece to counteract the

inductance of the voice coi1 at high frequencies. After

manufacture, the frequency response of each driver is

tested for conformity to rigid performance standards.

The 2426H is offered in an 8 ohm impedance, and

the otherwise identical 2426J is offered in a 16 ohm

impedance.

Architectural

The compression driver shall consist of a ferrite magnetic structure.

All magnetic assembly parts shall be machined from cast or extruded

billet stock. The phasing plug shall be assembled of concentric horns

to minimize phase cancellations, and it shall be further coupled to a

tapered throat. Driver mounting shall consist of a removable snout

incorporating standard 25mm (1 in) three bolt pattern and fitted with

three external attachment points. The snout shall be removable to

allow the use of 1 3/8" - 18 screw-thread attachment.

The diaphragm shall be 0.05 mm (0.002 in) pure titanium pneumat-

ically drawn to shape. High frequency response shall be controlled

through the use of a three-dimensional suspension structure. The

voice coil shall be edgewound aluminum ribbon of not less than 44

mm (1¾ in) in diameter, operating in a magnetic field of not less than

1.8 tesla (18,000 gauss). An impedance controlling ring shall be affixed

to the pole piece in order to increase efficiency at high frequencies.

Performance specifications of a typical production unit shall be as

follows: Measured sensitivity with a 1 m W input on a 25 mm (1 in) ter-

minated tube, averaged from 800 Hz to 2.5 kHz, shall be at least 117

dB SPL. Measured sensitivity with a 1 W input at 1 m distance on-axis

from the mouth of a horn with a Q of 6.3, averaged in the 2 kHz octave

band, shall be at least 110 dB SPL. As an indication of electromechanical conversion efficiency, the Bl factor shall be at least 6.3 (9.3) newtons per ampere. Frequency response, measured on a terminated

tube, shall be flat within ± 1 dB from 800 Hz to 3.3 kHz, with a 6 dB/

octave rolloff above that point. Nominal impedance shall be 8 [16]

ohms and power capacity shall be at least 70 watts normal speech or

music program material.

The compression driver shall be JBL Model 2426 H [J]. Other

drivers will be considered for equivalency provided that submitted

data from a recognized independent test laboratory verify that the

above performance specifications are met.

Specifications:

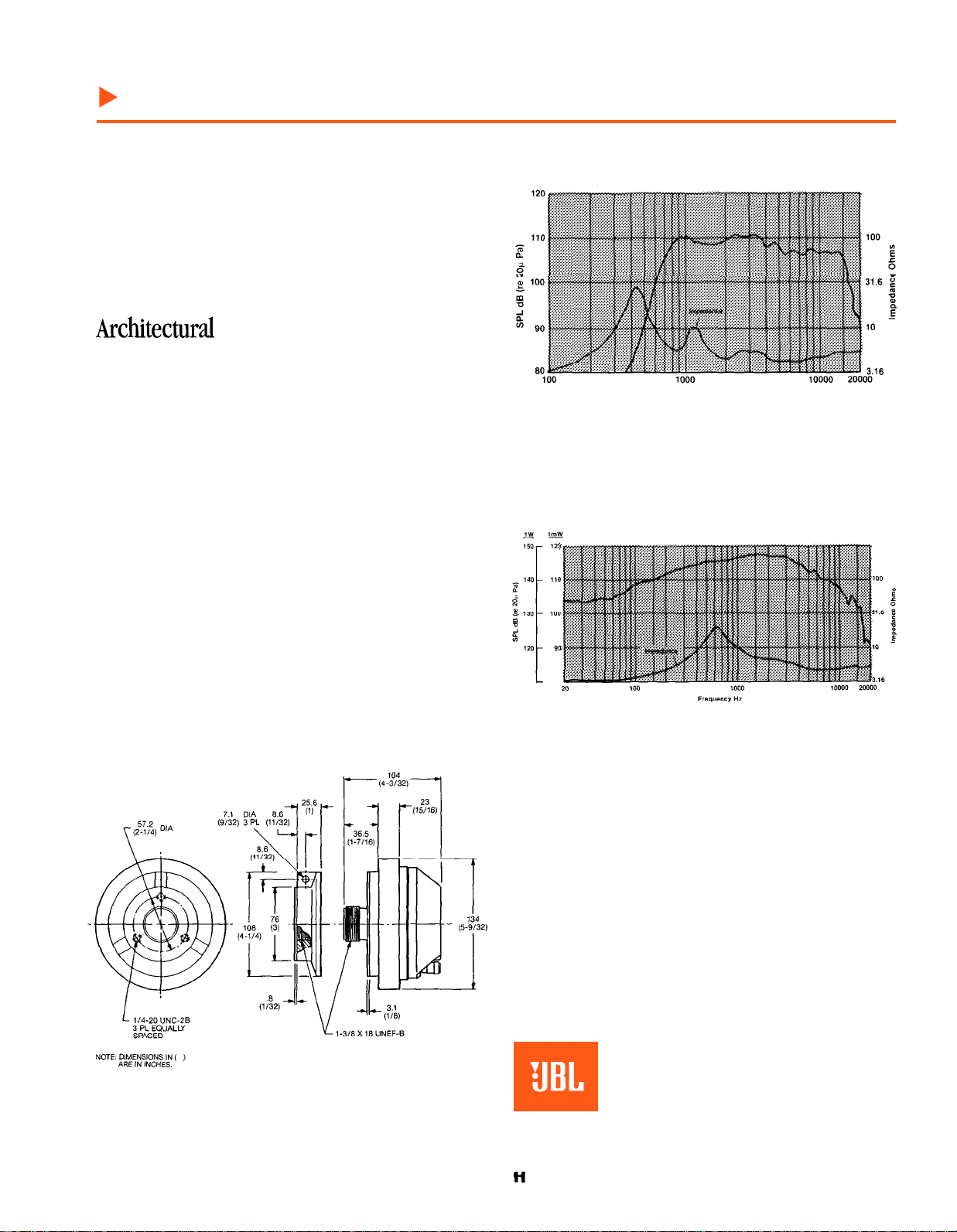

Response on JBL 2370 Flat-Front Bi-Radial® Horn

Frequency Hz

Frequency response of the 2426H coupled to a JBL 2370 Flat-Front BiRadial® horn, measured on-axis at a distance of 1 meter with a 1 watt

(2.83 V RMS) input in a reflection-free environment, with impedance

vs. frequency curve. The increased high-frequency output is due to

the horn design’s increasing directivity in the vertical plan.

Response on Plane-Wave Terminated Tube

Frequency response and impedance modulus of Model 2426H

coupled to a 25 mm (1 in) diameter terminated plane-wave tube.

This is the power response of the transducer, and is the frequent)

response that will be obtained on a true full-bandwidth constantdirectivity horn design, such as JBL’s 2360 series of Constant

Coverage Bi-Radial® Horns.

JBL Professional

8500 Balboa Boulevard, PO. Box 2200

Northridge, California 91329 U.S.A.

fi

A Harman International Company

SS2426

10/94 10M

P1055

Loading...

Loading...