Professional Series

Key Features:

Bi-Radial® Constant-Coverage

horn design

Constant 100° x 100° dispersion

from 3 kHz to 20 kHz

40 watts continuous program

3 kHz to 21.5 kHz response

Annular-ring diaphragm ferrite

motor structure

44 mm (1

aluminum ribbon voice coil

105 dB sensitivity, 1 W, 1 m (3.3 ft)

3/4

in) edgewound

2404H

Ultra-High

Frequency Transducer

Designed for use as an ultra-high

frequency driver in multi-element,

full range loudspeaker systems, the

JBL Model 2404H delivers an un-

matched combination of wide, tightly

controlled dispersion, extended frequency response, high power capacity, and high efficiency

One key to this outstanding performance lies in the unique geometry of

the driver’s Bi-Radial horn¹ Developed with the aid of the latest computer design and analysis techniques, the

horn provides constant coverage from

its recommended crossover point of

3 kHz to beyond 20 kHz. The Bi-Radial

compound flare configuration maintains precise control of the horn’s

wide 100° x 100° coverage angle, and

the horn’s rapid flare rate dramatically

reduces second harmonic distortion.

The uniform coverage of the horn is

illustrated by the detailed polar data

and the isobar (constant sound pressure) contours included in this specification sheet. The polar curves of the

2404 exhibit soft-edge pattern characteristics, due to the gradual drop-off of

level with increasing off-axis angle.

Specifications:

Nominal Impedance:

Minimum Impedance: 7.2 ohms @ 3 kHz

Power Capacity¹:

Sensitivitya:

Frequency Response ( ± 3 dB):

Usable Frequency Range ( - 10 dB):

Coverage Angles:

(Flange mounting holes on top and bottom)

(Flange mounting holes on right and left)

(Averaged over 3.15 kHz to 20 kHz)

(Averaged over 3.15 kHz to 20 kHz)

(With minimum 12 dB/octave slope)

Magnetic Assembly Weight:

Positive voltage to black terminal gives forward diaphragm motion

¹Continuous program power is defined as 3 dB greater than continuous sine wave power and is a conservative expression of

the transducer’s ability to handle normal speech and music program material. Below 2 kHz the input power should be

limited to 5 watts (6.3 V RMS) or less.

²Axial level, 2.83 V RMS input, averaged over 3 kHz to 20 kHz.

³These dimensions apply to front mounting of the 2404 assembly, Rear mounting is not recommended due to the possible

interference with the wide angular coverage pattern of the horn.

Horizontal Angle:

Vertical Angle:

Directivity Factor (Q):

Directivity Index (Di):

Recommended Crossover:

Diaphragm:

Diaphragm Diameter:

Voice Coil Diameter:

Voice Coil Material: Edgewound aluminum ribbon

Flux Density:

Force Factor (B1):

Dimensions:

Flange Height:

Flange Width:

Depths³:

Overall: 128 mm (5 in)

Behind Baffle:

In Front of Baffle:

Baffle Cutout Diameters:

Net Weight:

Shipping Weight:

8 ohms

40 watts continuous program at 3 kHz or higher,

12 dB/octave slope

105 dB SPL (1 W, 1 m)

4 kHz to 19 kHz

3 kHz to 21.5 kHz

(Included angle between 6 dB down points, rated

over 3.15 kHz to 20 kHz)

100 ( + 47, - 10)°

100 ( + 42, - 14)°

6.8 (+ 1.5, - 2.3)

8.3 (+ 0.9, - 1.8)

3 kHz or higher

0.05 mm (0.002 in) Aluminum alloy

44 mm (1¾ in)

44 mm (1¾ in)

1.9 kg (4.1 lb)

1.75 T (17,500 gauss)

5.25 N/A

130 mm (5.12 in)

130 mm (5.12 in)

96 mm (3.76 in)

32 mm (1.25 in)

122 mm (4

2.27 kg (5 lb)

2.72 kg (6 lb)

51/64

in)

2404H Ultra-High Frequency Transducer

The coverage pattern of the Bi-Radial horn provides

precise pattern control and excellent frequency response

even at extreme oblique off-axis angles (off-axis both

horizontally and vertically). This behavior is illustrated in

this specification sheet with polar data taken at an oblique

angle of 45° in addition to the usual horizontal and vertical polar curves. Additional data on the directional characteristics of the 2404 is illustrated in 10 kHz octave bandwidth isobar contours. These contours represent the

sound pressure distribution in the front hemisphere of

the horn. The contours show the excellent symmetrical

soft-edge coverage that the Bi-Radial horn provides.

Coupled to the horn is a constant area phasing plug and

an annular ring diaphragm ferrite motor structure.

The phasing plug maintains constant phase and amplitude. The annular voice coil diaphragm is pneumatically

formed of fatigue-resistant aluminum and utilizes an optimally constructed voice coil former and the latest in high

temperature adhesive technology to substantially increase

the driver’s power capacity. A ferrite magnetic structure

provides a high flux level for extended response and maximum efficiency while maintaining traditional JBL

tolerances in assembly and manufacture.

1 Patent No. 4,308,932. Further information on the Bi-Radial horns can be found in a paper

by D. Smith, D Keele, and J Eargle, Improvements in Monitor Loudspeaker Systems, presented at the 69th Convention of the Audio Engineering Society (May 1981). AES Preprint

1784 (F-4) available from JBL Professional.

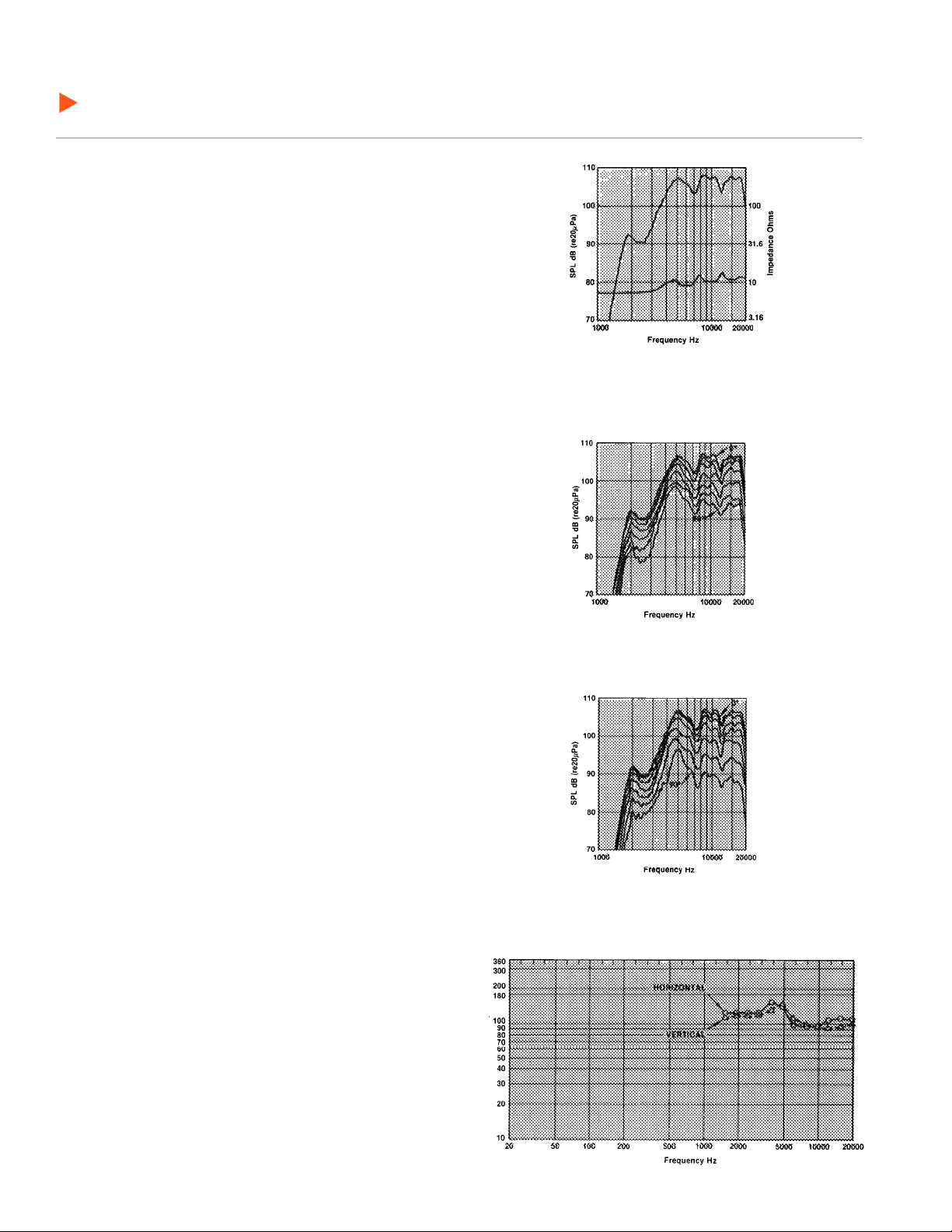

Frequency response and impedance.

Frequency response of the 2404, measured on axis at a distance of

1 meter with 1 watt (2.83 V RMS) applied, in a reflection-free environment, with impedance vs frequency curve. Unit free standing

(without baffle).

Architectural Specifications:

The transducer shall have a measured sensitivity (SPL at 1 m with a

1 W input swept from 3 kHz to 20 kHz) of a least 105 dB on axis. Onaxis frequency response measured under free field conditions at a distance of 1 m (3.3 ft) or more shall extend from 3 kHz to 20 kHz.

Horizontal and vertical dispersion shall be a constant 100° x 100°

from 3 kHz to 20 kHz when measured at the 6 dB down points relative

to on-axis frequency response characteristics using

pink noise as the signal source. Nominal impedance shall be 8 ohms

and power capacity shall be at least 40 watts normal program material.

The transducer shall have a maximum flange size of 130 mm x 130

mm (5.12 in x 5.12 in) and a depth of 128 mm (5 in) and weigh not less

than 11 kg (5 lb). The horn shall be injection molded structural foam

polycarbonate.

All magnetic assembly parts shall be machined from cast or

extruded billet stock.

Voice coil diameter shall be 44 mm (13¾ in), operating in a magnetic

field whose flux density measures at least 1.75 tesla (17,500 gauss).

Voice coil wire shall be aluminum, milled to a ribbon then wound by

hand on its edge and mated to an anodized aluminum diaphragm.

The transducer shall be JBL Model 2404H.

JBL continually engages in research related to product improvement. New materials, production methods, and design refinements are introduced into existing products without

notice as a routine expression of that philosophy. For this reason, any current JBL product

may differ in home respect from its published description, but will always equal or exceed

the original design specifications unless otherwise stated.

1/3

-octave band

Horizontal off-axis response.

Horizontal off-axis response taken at 15 degree intervals out to 90

degrees off axis.

Vertical off-axis response.

Vertical off-axis response taken at 15 degree intervals out to 90

degrees off axis.

Beamwidth ( - 6 dB) vs Frequency.

Loading...

Loading...