Page 1

Automatic Soldering Irons

for Automation

Ref. TRA245-A / TRA470-A

www.jbctools.com

Page 2

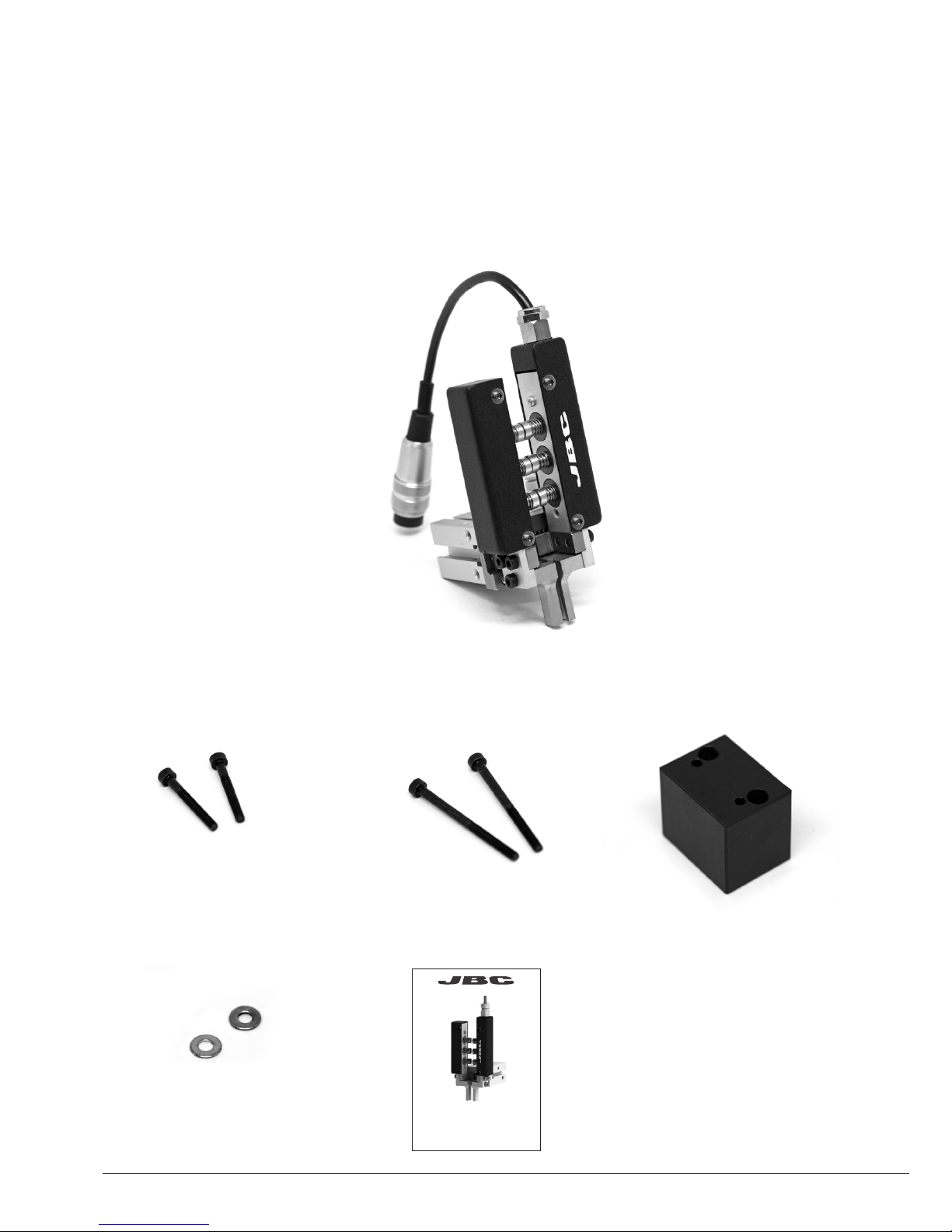

Packing List

The following items should be included for TRA245:

Insulator Clamp ..............1 unit

Ref. 0 021512

Screws

DIN 912 M3X40 .............. 2 units

Ref. 00 21514

Soldering Iron

for Automation .............. 1 unit

Ref. T RA245-A

Works with R245 cartridges

Screws

DIN 912 M3X25 .............. 2 units

Ref. 0001392

Manual ......................... 1 unit

Ref. 0 021282

Washers

DIN 125 Ø3,2 ............ 2 units

Ref. 0242404

Either TRA245 or TRA470 are included.

2

Ref. TR245-A / TR470-A

Automatic Soldering Irons

for Automation

www.jbctools.com

Page 3

Screws

DIN 912 M3x12 .......... 2 units

Ref. 0926733

Screws

DIN 912 M3x25 ........... 2 units

Re f. 00 21511

Insulator Clamp ..............1 unit

Ref. 0 021513

Washers

DIN 125 Ø3,2 ............ 2 units

Ref. 0242404

Soldering Iron

for Automation .............. 1 unit

Ref. TR A470-A

Works with R470 cartridges

The following items should be included for TRA470:

www.jbctools.com

3

Manual ............................ 1 unit

Ref. 0 021282

Ref. TR245-A / TR470-A

Automatic Soldering Irons

for Automation

www.jbctools.com

Page 4

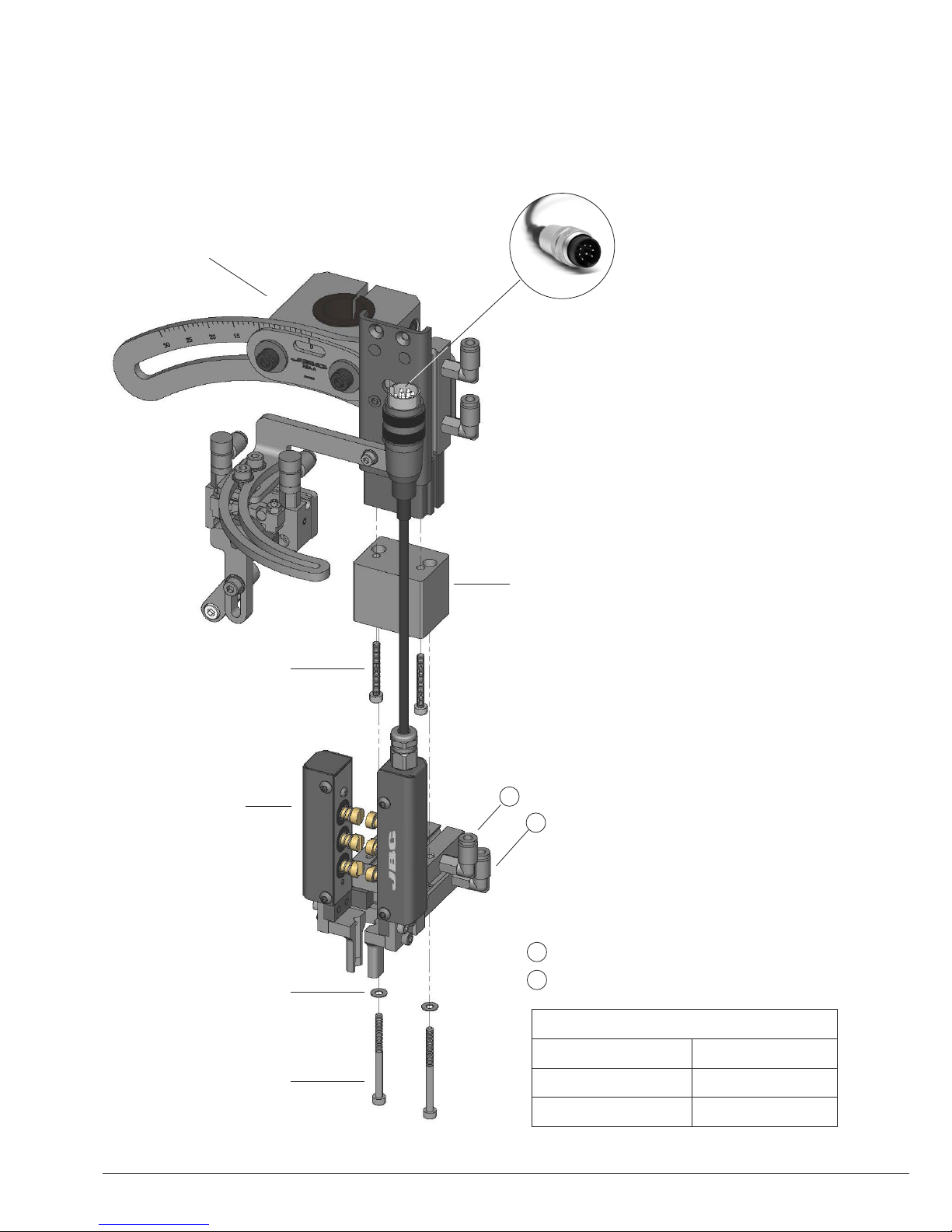

A

B

Assembly

Screws

Ref. 0 021514

Washers

Ref. 024240 4

Automatic

Soldering Iron

Ref. TRA245-A

Screws

Ref. 0001392

Connection to UCR245

using Tool Cable

Ref. 00 2140 3

Gripper Actuator

Fluid Air

Applicable tubing Ø4mm

Operating pressure 0,15 to 0,7 MPa

A Air tube connection to fix cartridges

B Air tube connection to release car tridges

Soldering Head for Automation*

Ref. RBA-A

*Not included, sold separately

TRA245

Insulator Clamp

Ref. 0 021512

It is mandatory to have the electrical

Insulator Clamp assembled for proper

tool working.

Don’t remove the Insulator Clamp.

4

Page 5

Screws

Ref. 0 021511

Washers

Ref. 024240 4

Screws

Ref. 0926733

Automatic

Soldering Iron

Ref. TRA470 -A

A

B

Connection to UCR470

using Tool Cable

Ref. 00 2140 3

Gripper Actuator

Fluid Air

Applicable tubing Ø4mm

Operating pressure 0,15 to 0,7 MPa

A Air tube connection to fix cartridges

B Air tube connection to release car tridges

Soldering Head for Automation*

Ref. RBA-A

*Not included, sold separately

TRA470

Insulator Clamp

Ref. 0 021513

It is mandatory to have the electrical

Insulator Clamp assembled for proper

tool working.

Don’t remove the Insulator Clamp.

www.jbctools.com

5

Page 6

122,1

4,807

~166

~6,535

68,4

2,693

53,5

2,106

40,6

1,598

28

1,102

8,6

0,339

30

1,181

29,8

1,173

15,8

0,622

2x

3,4

2x0,134

21

0,827

15,8

0,622

Working point

TRA245-A

Dimensions

mm

(in)

6

Page 7

138,1

5,437

~166

~6,535

68,4

2,693

69,5

2,736

56,6

2,228

12

0,472

8,6

0,339

30

1,181

29,8

1,173

15,8

0,622

21

0,827

15,8

0,622

2x

3,4

2x0,134

Working point

TRA470-A

mm

(in)

www.jbctools.com

7

Page 8

Inserting Cartridges

The Automatic Soldering Iron for TRA is directed towards the cartridge. Once in position its

valve must be activated.

JBC recommends bi-stable valves to prevent the cartridges from falling out in case of an

emergency stop or power cut.

When using the Automatic Cartridge Stand CS2R, you have to activate its valve to open the

gripper and to release the cartridge before making any movement.

Gripper Actuator

TRA

CS2R*

Soldering

Irons

Cartridge Range Control Unit Cartridge Stand

R245 R470 UCR245 UCR470 CS2R245 CS2R470

TRA245

TRA470

RBA, SFR, GSFR and CLMR are compatible with R245 and R470 ranges.

*Not included, sold separately

Compatibility

8

Page 9

Accessories

Solder Feeder

for Automation*

Ref. SFR-A

Guide Kit

for Automation*

Ref. GSFR

Soldering Head for Automation*

Ref. RBA-A

Automatic

Soldering Iron

Ref. T RA245-A

TR A470-A

Automatic Cartridge Stand*

Ref. CS2R245-A

CS2R470-A

*Not included, sold separately

www.jbctools.com

9

Page 10

*Not included, sold separately

Work Place Example

Solder Feeder*

Ref. SFR-A

Automatic Tip

Cleaner*

Ref. CLMR-A

Soldering Head*

Ref. RBA-A

Automatic Soldering Iron

Ref. TRA245-A

TR A470-A

Automatic Cartridge Stand*

Ref. CS2R245-A

CS2R470-A

Control Unit*

Ref. UCR245-5A

UCR470- 5A

Guide Kit*

Ref. GSFR

10

Page 11

Maintenance

- Before carrying out maintenance, always unplug the tool.

- Use a damp cloth to clean the tool. Alcohol can only be used to clean the metal parts.

- Periodically check that the metal parts of the tool are clean so the control unit can detect the tool

status.

- Periodically check all cables and tube connections.

- Maintain tip surface clean and tinned prior to storage in order to avoid tip oxidation.

Rusty and dirty surfaces reduce heat transfer to the solder joint.

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

- Under normal operating conditions, the air gripper lifespan is 10 million cycles. It is recommended

to replace it at the end of its lifespan.

It is imperative to follow safety guidelines to prevent electric shock,

injury, fire or explosion.

- Do not use the soldering iron for any purpose other than soldering or rework. Incorrect use may

cause fire.

- The teperature of accessible surfaces may remain high after the unit is turned off.

Handle with care.

- Do not leave the appliance unattended when it is on.

- Be sure that the power supply is disconnected before changing any spare part.

- Allow the cartridges to cool down before changing them.

- Heat can cause inflamable products to ignite even when not visible.

- Avoid flux coming into contact with skin or eyes to prevent irritation.

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

Safety

www.jbctools.com

11

Page 12

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Manual in other languages available on our website

www.jbctools.com

Warranty

JBC’s two-year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear or misuse.

In case of any manufacturing defect, the equipment

must be returned, postage paid, to the dealer where

it was purchased.

0021282-0618-V01

Specifications

TRA245-A

- Net Weight: 316 g (0.69 lb)

- Dimensions: 122.1 x 68.4 x 52.6 mm (4.807 x 2.693 x 2.111 in)

TRA470 -A

- Net Weight: 318 g (0.70 lb)

- Dimensions: 138.1 x 68.4 x 52.6 mm (5.437 x 2.693 x 2.111 in)

Complies with CE standards.

ESD protected.

Loading...

Loading...