Jbc RMSE-2QE, RMSE-1QE, RMSE-9QE User Manual

www.jbctools.com

INSTRUCTION MANUAL

Complete Rework Station

with Electric Pump

Ref. RMSE-QE

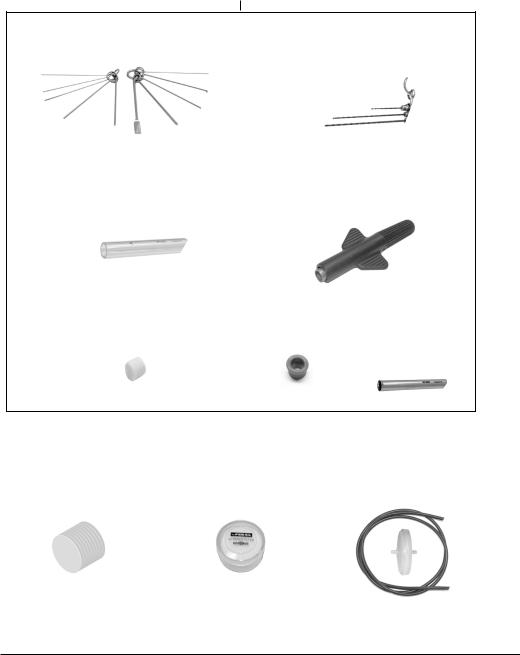

Packing List

The following items are included:

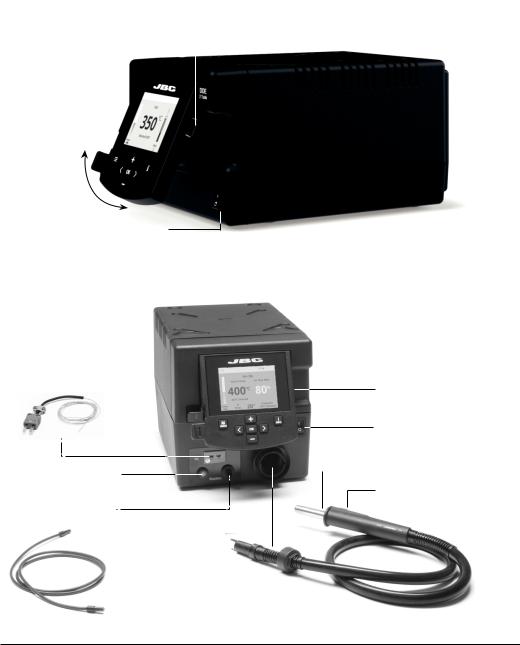

JTSE Control |

|

DDE Control Unit .......... |

1 unit Electric Desoldering |

|

Unit .................................... |

1 unit |

Ref. DDE-1C (120V) |

Module ............................. |

1 unit |

Ref. JTSE-1A (100V - 120V) |

DDE-2C (230V) |

Ref. MSE-A |

|

|

JTSE-2A (230V) |

|

DDE-9C (100V) |

|

|

Stand ................................ |

1 unit Stand ................................ |

1 unit |

Stand ............................... |

1 unit |

Ref. JT-SE |

Ref. AD-SE |

|

Ref. DR-SE |

|

Heater hose set ............ |

1 unit |

General Purpose |

|

Desoldering Iron ........... |

1 unit |

Ref. JT-T1A (100V / 120V) |

Handle .............................. |

1 unit |

Ref. DR560-A |

|

|

JT-T2A (230V) |

|

Ref. T245-A |

|

C560003 already inserted |

|

2

|

|

|

|

|

www.jbctools.com |

|

|

|

|

JT Accessory set |

|

|

|

|

|

Ref. 0012332 |

|

|

|

|

|

||

Extractor stand ............. 1 unit |

|

Extractors |

Tripod |

||

Ref. 0008752 |

|

Ref. E2184 |

Ref. T2050 |

||

|

|

|

|

E2064 |

(Ø 39mm) |

|

|

|

|

E2052 |

T2250 |

|

|

|

|

||

|

|

|

|

|

(Ø 85mm) |

|

|

|

|

Protectors |

Suction Tube |

|

|

|

|

Ref. P2220 |

Ref. 0932330 |

|

|

|

|

P2230 |

|

|

|

|

|

P2235 |

|

|

|

|

|

P4000 |

|

|

|

|

|

P4010 |

|

ESD Tip Cleaner ........... 1 unit |

|

Suction Cups |

Nozzles |

||

Ref. CL8499 |

|

Ref. 0930110 |

Ref. JN2015 (x1) |

||

|

|

|

|

Ø 10 - 0934050 (x3) |

JN2012 (x1) |

|

|

|

|

Ø 4.7 - 0934070 (x1) |

JN2020 (x1) |

|

|

|

|

|

|

Sponge ............................ |

1 unit |

Metal Brush ................... |

1 unit |

Sponge ............................ |

1 unit |

Ref. S0354 |

|

Ref. CL6217 |

|

Ref. CL6210 |

|

3

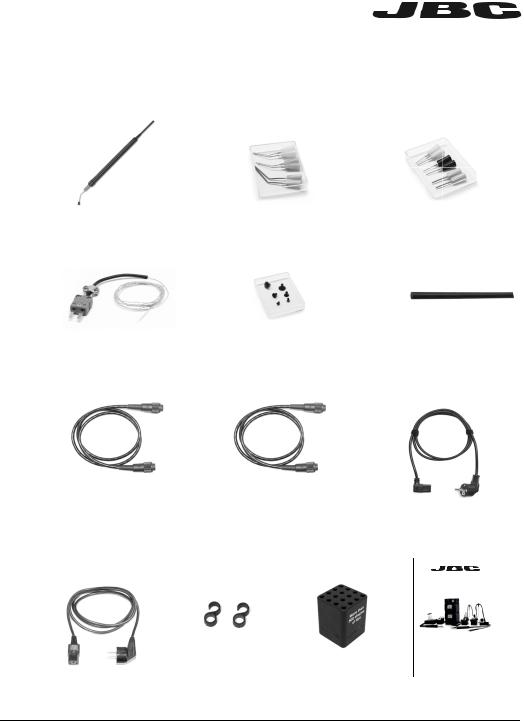

DR560 Accessories

Ref. 0022819

Tip cleaning set ................................. |

1 unit |

Long Tip Cleaning set ..................... |

1 unit |

Ref. 0965970 |

|

Ref. 0965760 |

|

Glass solder collector ..................... |

1 unit |

Spanner ............................................. |

1 unit |

Ref. 0812620 |

|

Ref. 0780550 |

|

Filter Box ................. |

1 unit |

Internal gasket .............. |

1 unit |

Metal solder |

|

Ref. 0780840 |

|

Ref. 0019208 |

|

collector ................... |

1 unit |

It contains 10 filters |

|

It contains 2 gaskets |

|

Ref. 0812630 |

|

Cotton Filter ................... |

1 unit |

Filter Box .......................... |

1 unit |

Suction Filter |

..................1 unit |

Ref. 0781046 |

|

Ref. 0005966 |

|

Ref. 0821830 |

|

It contains 10 filters |

|

It contains 50 filters |

|

|

|

4

www.jbctools.com

Pick & Place ................... |

1 unit |

Bent Needles Set ......... |

1 unit |

Straight Needles Set ... 1 unit |

Ref. T260-A |

|

Ref. 0861660 |

|

Ref. 0901546 |

Thermocouple |

|

Cups Set ......................... |

1 unit |

Cleaning stick |

................1 unit |

Type K .............................. |

1 unit |

Ref. 0940163 |

|

Ref. 0786640 |

|

Ref. PH218 |

|

|

|

|

|

Stand Cable ................. |

2 units |

Module Cable ................ |

1 unit |

Power cord |

|

Ref. 0011283 |

|

Ref. 0014874 |

|

For DDE ........................... |

1 unit |

|

|

|

|

Ref. 0013671 (100/120V) |

|

|

|

|

|

0010569 (230V) |

|

Power cord |

|

Union |

|

Cartridge |

Manual ................. |

1 unit |

For JTSE ................. |

1 unit |

Flanges ..... |

1 unit |

holder .............. |

1 unit Ref. 0023140 |

|

Ref. 0009417 (100V/120V) |

Ref. 0011356 |

Ref. SCH-A |

|

|

||

0009401 (230V) |

|

|

|

|

|

|

www.jbctools.com

INSTRUCTION MANUAL

Complete Rework Station

with Electric Pump

Ref. RMSE-QE

5

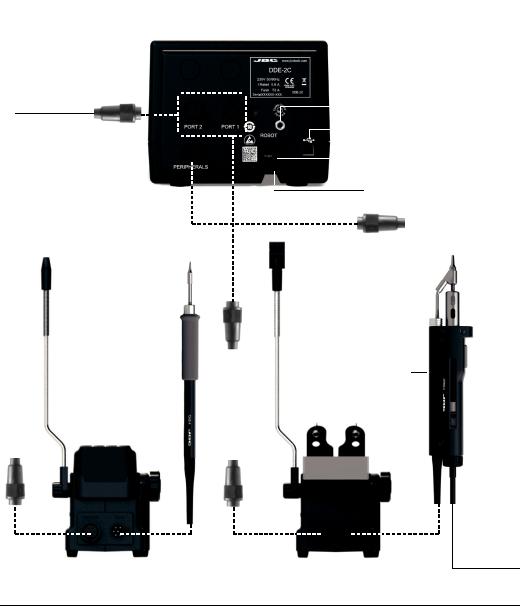

Connections

Work simultaneously with up to 2 tools and join each station port with 1 module + 1 pedal (Peripherals).

Stand Cable

Ref. 0011283 |

|

|

Equipotential connection |

||

|

|

||||

|

|

|

|

USB-B connector |

|

|

|

|

|

||

|

|

|

|

RJ12 connector for Robot |

|

|

|

|

|

||

|

|

|

|

Power Socket |

|

|

|

|

|

|

|

General |

|

|

|

Purpose |

|

|

|

|

|

|

|

Handle |

|

|

Desoldering Iron |

|

|

||

Ref. T245-A |

|

|

Ref. DR560-A |

|

|

|

|

Stand |

Stand |

Ref. AD-SE |

Ref. DR-SE |

6

www.jbctools.com

JTSE Connection

Stand

Ref. JT-SE

Auxiliar connector

Equipotential connector

USB connector

Robot RS232 connector

Power Socket Fuse

To Pedal

Ref. P-005* or P-405*

*Not included

Module Cable

Ref. 0014874

Electric Desoldering Module

Ref. MSE-A

To another peripheral

To Pedal

Ref. P-005* or P-405*

*Not included

7

DDE Features

2,8” Color TFT screen |

|

USB-A connector |

||

|

|

|

|

|

|

|

|

|

|

Tilt the display for easy reading

Main switch

JTSE Features

Thermocouple type K

Ref. PH218

USB-A connector

Main Switch

Heating element

Activates the suction pump

Hot Air button

Suction Tube (On / Off) For tripods and extractors

Heater Hose set

Ref. JT-T1A (100V/120V)

JT-T2A (230V)

8

www.jbctools.com

DDE Work Screen

The DDE offers an intuitive user interface which provides quick access to station parameters.

Default PIN: 0105

Status bar |

|

|

|

|

|

|

|

17:14 |

|

|

|

|

|

|

|

|

|

|

Tool |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power |

|

|

|

|

|

T245470 |

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

35080ºC |

|

|

|

|

|

|

in use |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

indicator |

|

|

|

|

|

|

|

|

|

Temp. Levels |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

250 350 380 |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

Power |

|

Port |

|

|

|

|

|

|

|

||||||||||

Displayed if |

45% |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

||||||||||||

temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

levels are |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

activated |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Station |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Information |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Change |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

port |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

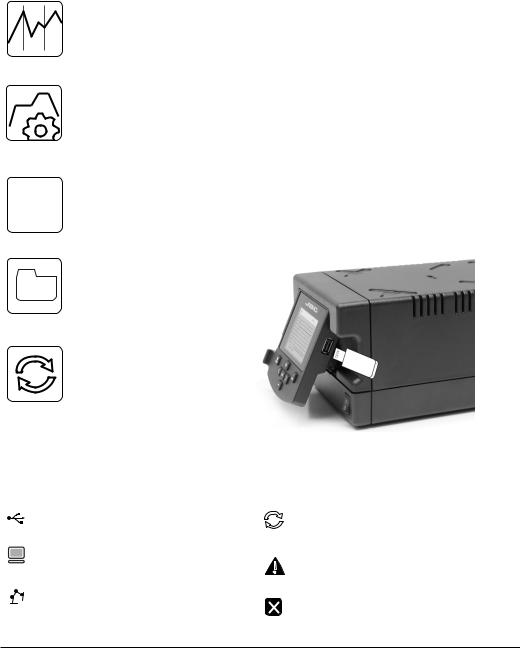

Menu Options

Set the station |

Set the tool |

|

Display the hours |

parameters |

parameters |

|

worked in each cycle |

Station |

Tools |

Counters |

|

Consult / modify the |

|

|

|

links of the peripherals |

It is possible to |

|

Allows you to carry |

connected to the |

choose the language |

|

out an overall station |

station with the port |

from a list. |

|

reset restoring all the |

they are connected to. |

|

|

parameters to their |

Peripherals |

Language |

Reset |

default values. |

9

Advanced functionalities

It provides detailed graphics of tip temperature and power delivery in real time during solder joint formation for analysis purposes. This helps you decide how to adjust your process or which tip to use to obtain the best quality soldering.

Graphics

|

Designed to avoid thermal shock when soldering Ceramic Chip components like |

|

MLCC, this new and unique feature allows controlling the heating ramp up rate of the |

|

tool to gradually increase the temperature of the |

|

component through all the phases of the soldering process. Up to 25 fully confi gurable |

Profiles |

soldering profi les can be stored. |

The first system to optimize traceability in soldering

JBC Net - Get greater quality and control in your production

- Manage your whole soldering process remotely in real time

Export graphics

Insert a USB flash drive into the USB-A connector to save your

soldering process in csv format.

Files

Station update

Download the JBC Update File from

www.jbctools.com/software.html

Insert the USB flash drive with the

Update file downloadedto the station.

System notifications

The following icons will be displayed on the screen’s status bar.

USB fl ash drive is connected. |

Station software update. |

|

Press INFO to start the process. |

Station is controlled by a PC. |

Warning. |

|

Press INFO for failure description. |

Station is controlled by a robot. |

Error. |

|

Press INFO for failure description, |

|

the type of error and how to proceed. |

10

Loading...

Loading...