Page 1

www.jbctools.com

TE

PRECISION

HOT AIR STATION

Page 2

JT / PRECISON HOT-AIR

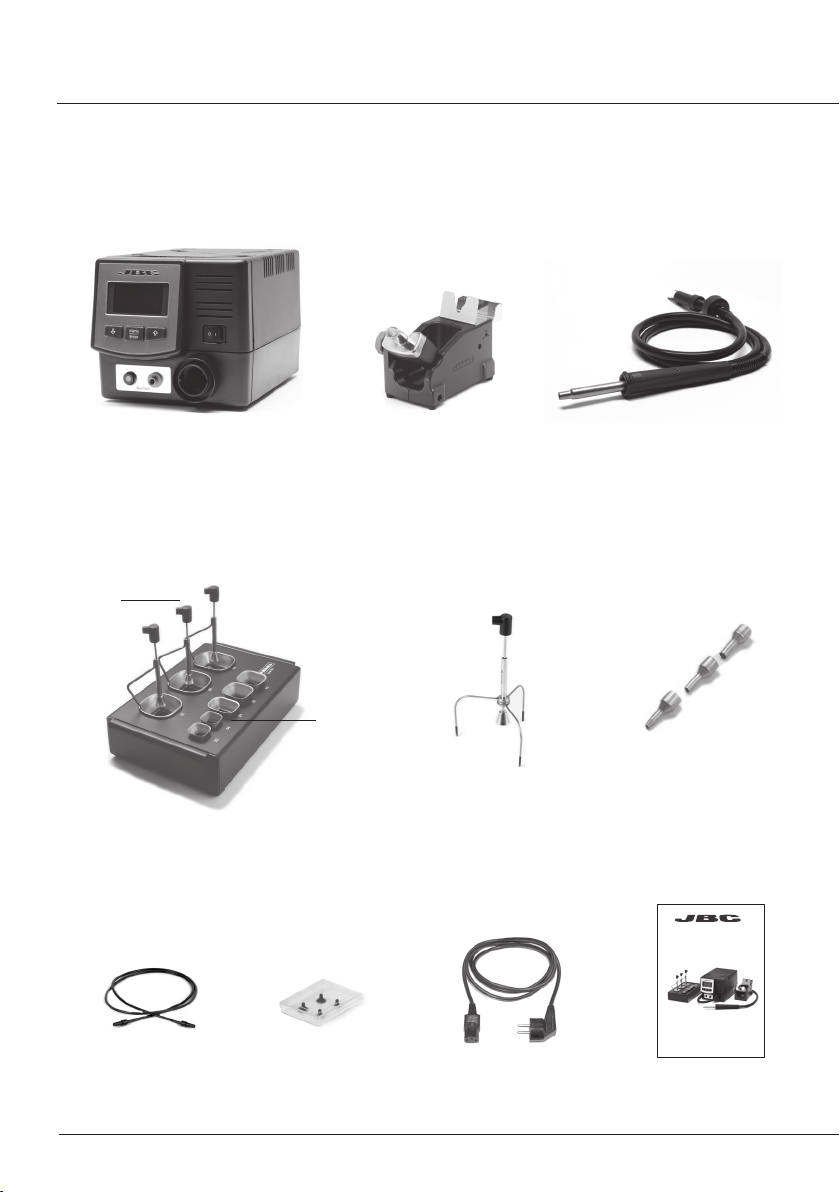

CONTROL UNIT TE-SA

0008752

EXTRACTOR STAND *

Extractor

E2184

E2064

E2052

Protector

P2220 (32)

P2230 (48)

P2235 (24)

P400 0 (44)

P4010 (60)

STAND

T2050 ø20

T2250 ø40

TRIPOD*

TE-TB

(100V / 120V / 230V)

HEATING SET

TN9209 ø3

TN9208 ø4

TN9080 ø5

NOZZLE

0932330

SUCTION TUBE *

0930110

SUCTION CUPS *

POWER CORD

* These accessories not supplied with TE-2QB / TE-1QB / TE-9QB stations

2

www.jbctools.c om

TE

PRECISION

HOT AIR STATION

Page 3

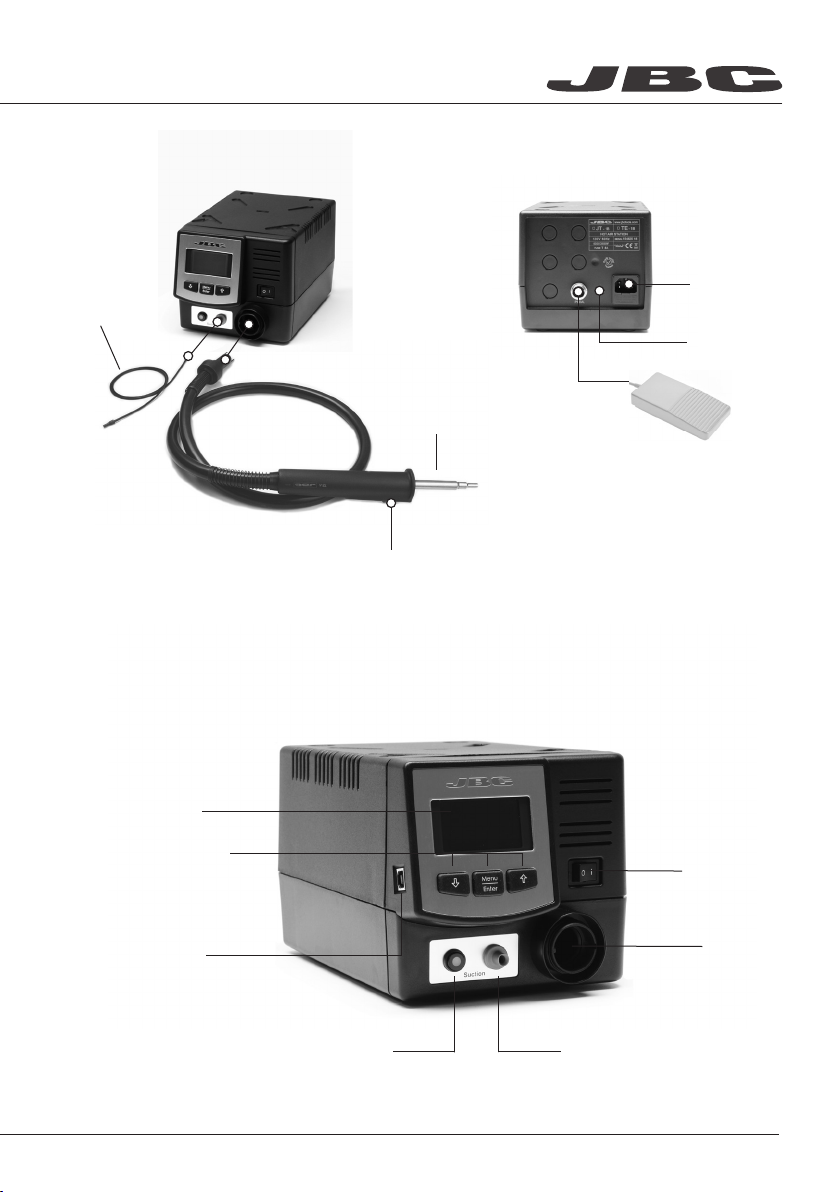

INSTALLATION

Suction

Tube

Connectable tools:

JT-T2A / JT-T1A

TE-TB

DESCRIPTION

Heating element

Hot Air switch

(ON / OFF)

Power cord

socket

Equipotencial

connection

Pedal 0964551

(NOT INCLUDED)

(ON / OFF hot air)

Display

Function keys

USB connector to PC:

- Update station software

- Create graphs of the soldering process

- Manage and monitor parameters via PC

Activation of

suction pump

Main switch

Vacuum inlet for tripods

and extractors

Heater inlet

3

Page 4

CONTROL SCREEN / MANUAL MODE

Time to stop 45 seconds

Tem p ºC

Air %

Current temperature

Selected temperature

Decrease & move down

400

400ºC Select

Power 70%

Access Menu

&

Confirm Selection

PRESS Key 2 seconds

to access Menu

CONTROL SCREEN / PROFILE MODE

Pro fi le 8

º

C

Graph of selected profile

80

Tem p ºC

380

Air 100%

Time 125s.

% Instant power supplied to heater

Increase & move up

Selected profile

Current temperature

Selected flow

Remaining time

Decrease profile number

Access Menu

(pess key 2 secondes)

You can switch between operating modes (Manual Mode / Profiles Mode) by pressing the “increase” and

“decrease” keys simultaneously for 2 seconds. (Only if mode profiles is ON)

4

Increase profile number

Page 5

SETTINGS

ORIGINAL PIN: 0105

Mai n me nu

1 Reset settings

2 Station

3

4

Settings

Profile Settings

Counters

Set ti ng s

1

Temp unit Celsius

2 Maximum

3 Minimum temp T OFF

4 Fix temp 4000C

5 Max air 100%

6 Min air 10%

7 Fix air 40%

8 Time to stop 120 sec

9 Beep ON

10 Pop up ON

11 Change PIN

* Selecting Tmin to “T OFF” allows

for blowing at ambient temperature.

temp 4500C

Bac k

1 Station ON hours

2

Works hours 0

3 Works

*

Cou nt er s

cycles 0

Bac k

5 Program version

Exi t

0

Pro fi le s et ti ng s

1 Profiles

2 Edit Profile

3

º

C

Edi t Pr of il e 8

º

C

Copy profile

Exi t

Edi t Pr of il e

Sel ec t

Pro fi le

8

Ste p 4

Tim e 20

Tem p 45 0

Air 100

Exi t

5

Page 6

EDIT PROFILE

This option allows you to edit or create a profile.

First , you must select the profile to edit and then modify the points that make up the profile.

Each profile is composed of 9 points, each point is formed by three parameters:

1. Time (seconds)

2. Temperature (°C / °F)

3. Flow rate (%)

You can delete the last point of the profile by selecting “-----” in the time parameter.

It should be taken into account that the regulation range permitted by the station is between 150°C and

450°C, whereby it is not possible to create temperature ramps between room temperature (Toff) and

150°C.

The station can store up to 25 temperature profiles.

The first three profiles are edited as an example.

COPY PROFILE

This option allows you to copy a profile.

You must select the profile source and the destination profile where it will be copied.

DELETE PROFILE

This option will allow you to delete a profile previously selected.

DESOLDERING PROCEDURE

1. Position suction cup.

6

2. Hot-air melts solder. 3. IC pops up automatically.

Page 7

MAINTENANCE

REPLACING THE HEATING ELEMENT

Follow this process inverted to re-connect the heating element.

Only perform this operation when the tool is stopped and the heating element set is cold.

1. Untighten screw.

2. Separate the heating element from the heating set’s handle.

3. Connect new heating element, pushing it’s extreme.

4. Insert screw to aviod air-loss witch could reduce the heating element’s lifetime.

0012374

(230V -100V -120V)

Heating element

TE-TB

(100V-120V -230V)

0012697

Handle

CHANGING THE HEATING SET

1. Ensure that the tool is off.

2. Use a wrench to unscrew the connector seal.

Heating set

3. Pull back the seal.

4. Pull connector from socket to disconnect heating set.

5. Follow steps in reverse to connect the heating set.

7

Page 8

TECHNICAL SPECIFICATIONS

- Temperature selection from room temperature to 450°C (850ºF) and cool mode (can be used to blow air at room

temperature).

- Ambient Operating Temperature: 10 to 40ºC (50-104ºF)

- Output Peak Power: 300W.

- Air flow regulation: 5-20 l/min.

- Vacuum: 30% / 228 mmHg / 9 inHg

- TE-2B 230V 50/60Hz. Input fuse 4A.

- TE-1B 120V 50/60Hz. Input fuse 8A.

- TE-9B 100V 50/60Hz. Input fuse 8A.

- Total weight of unit: 2.3Kg (5.1lb)

- Complies with CE standards on electrical safety, electromagnetic compatibility

and ESD protected housing “skin effect”.

- RoHS compliant.

- Equipotential connector and the tool tip are connected to station mains ground supply for ESD protection.

This product should not be

thrown in the garbage.

WARRANTY

JBC’s 2 years warranty guarantees this equipment against all manufacturing defects, covering the replacement of defective parts and

all necessary labour.

Warranty does not cover product wear due to use or mis-use.

In order for the warranty to be valid, equipment must be returned,

postage paid, to the dealer where it was purchased enclosing this

fully filled in, sheet.

SERIAL Nº

STAMP OF DEALER

DATE OF PURCHASE

www.jbctools.com

0012881-0313

Loading...

Loading...