Page 1

English

www.jbctools.com

Precision Hot Air Station

Ref. TE-C

www.jbctools.com

Page 2

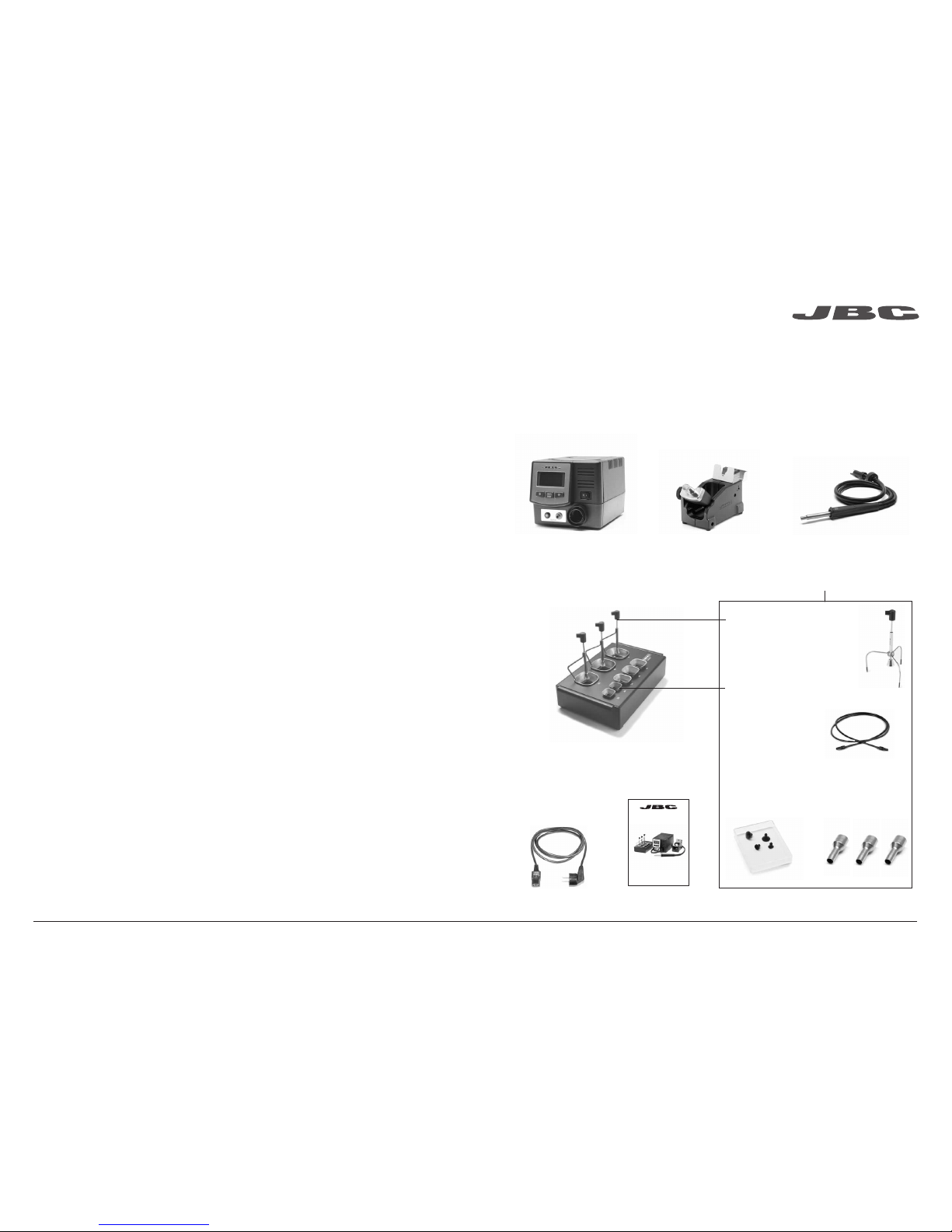

Packing List

The followin g items should be i ncluded:

Accessory set

Ref. 0012332

2 3

Manual .............1 unit

Ref. 0015898

* Not supplie d with TE-QC

www.jbctools.com

Power Cord .....1 unit

Ref. 0009417

(100V/120V)

0009401

(230V)

Precision Hot Air Station

Ref. TE-C

Precisio n Heater

hose set ............................1 u nit

Ref. TE-TB

Stand ..................................1 unit

Ref. TE-SA

JTE Contro l Unit ............1 unit

Ref. JTE-1C

JTE-2C

JTE-9C

Extra ctor desk* ..............................................1 unit

Ref. 0008752

Suction Tube*

Ref. 0932330

Suction Cups*

Ref. 0930110

Ø 10 - 0934050 (x3)

Ø 4.7 - 0934070 (x1)

Extra ctors*

Ref. E2184

E2064

E2052

Protector s*

Ref. P2220

P2230

P2235

P4000

P4010

Tripod*

Ref. T2050

T2250

Nozzles

Ref. TN9209 Ø 3mm

TN9208 Ø 4mm

TN9080 Ø 5m m

2

ww w.jb ct oo ls. co m

3

Page 3

Features

Compatible Nozzles

The TE-TB works with TE nozzles. Find the model that best suits your soldering needs in www.jbctools.com

2

1

4 5

Other connectable tool:

Heater hose set

Ref: JT-TA

Hot Air switch

(On / Off )

Power Socket

Fuse

Equipotentia l

connectio n

To Pedal

Ref. P-005

Press the pedal to start

hot air or rele ase to stop.

Heating

element

Precisio n Heater

Hose set

Ref. TE-TB

Suction Tube

Ref. 0932330

For tripods

and extractors

Activates the

suction pump

USB-B co nnector

Update the station

softwar e from

the JBC website

Suits your work p osition

Adjustable Stand Nozzle Changer

Nozzle ch anger

Ref. Shape Size

TN9209 Straight Ø 3mm

TN9208 Straight Ø 4mm

TN9080 Straight Ø 5mm

TN9787 Bent Ø 3mm

TN9785 Bent Ø 4mm

TN9782 Bent Ø 5mm

Straight Bent

Ø mm Ø mm

4

ww w.jb ct oo ls. co m

5

Page 4

Te mp ºC

Ai r %

Time to stop 45 seconds

Power 70%

400

85

400ºC Select

Operation

Process Control

3. Releasing1. Placing 2. Heating

For small components

(fig. 1 and 2). For large components (fig. 3 an d 4).

6 7

Position the ex tractor with the

appropria te suction cup and

press the suc tion button.

Heat the comp onent by

pressing th e heater button.

The compon ent lifts of f

automatical ly when the

solder mel ts.

Access Menu ( pess key 2 seconds) & Con firm Select ion

Selected te mperature

Current tempe rature

% Instant power su pplied

to heater

You can switch betwe en operating mo des (Manual Mode / Program Mode) by pre ssing the

“increase” a nd “decrease” keys sim ultaneously f or 2 seconds (Onl y when programs mo de is ON).

Manual Mode

We recommend u sing the protector + tri pod We recommend using the extrac tors

Protectors & Extractors

1 2 3 4

Protector s

* Ref. AxB (m m) * Ref. AxB (mm)

P3353 4,3 x 3

48

P2230 15 x 15

P3786 5,2 x 5,2

60

P4010 17 x 17

P3352 5,2 x 7,5 P4005 18 x 29

P3355 5,2 x 9,5 P4030 18,5 x 18,5

P3356 6,2 x 4,2 P1068 18,5 x 24

P3785 7, 2 x 7,2 P26 85 28,5 x 28,5

P3784 8,2 x 8,2 P4085 31,5 x 31,5

P4035 9 x 13 P2672 33 x 46

P4040 9,5 x 19 P4002 50 x 50

P4080 9,5 x 21 P3357 52,5 x 14

32

P2220 10 x 10

P4045 10,5 x 21

P4090 11 x 16

24

P2235 12 x 17

P1249 12 x 23

44

P4000 12,5 x 12,5

P3354 13,2 x 13,2

P4025 13,5 x 21,5

øD

* Referenc e Desk

Tripods

* Ref. øC (mm)

T2050 39

T2250 85

Manua l extrac tor

* Ref. øD (mm)

E2190 7

Extra ctors

* Ref. AxB (mm) * Ref. AxB (mm)

52 E2052 20 X 20 E2124 45 X 45

64 E20 64 20 X 26

80 E2184 24 X 24

E2068 27 X 27

E4020 28,5 X 28,5

E4015 31,5 X 31,5

E2084 33 X 33

E2100 38 X 38

Current air flow

6

ww w.jb ct oo ls. co m

7

Page 5

Ma in m en u

1 Reset settings

2 Station

Settings

3

Program Settings

4

Counters

5 Program version

Ex it

Se tt in gs Pr og ra m Se tt in gs

Ed it P ro gr am

Ed it P ro gr am 8

1

Temp unit Celsius

2 Maximum

temp 4500C

3 Minimum temp T OFF*

4 Fix temp 4000C

5 Temp Adjust 00C

6 Max air 100%

7 Min air 10%

8 Fix air 40%

9 Time to stop 120 sec

10 Beep ON

11 Pop up ON

12 Change PIN

1 Programs

2 Edit program

3

Copy program

4

Delete program

Ba ck

Se le ct

Pr og ra m

St ep 4

Ti me 20

Te mp 45 0

Ai r 10 0

º

C

º

C

8

Ex it

Co un te rs

1 Station ON hours

0

2

Works hours 0

3 Works

cycles 0

Ba ck

Te mp ºC

º

C

Pr og ra m 8

380

Air 100%

Time 125s.

8 9

* Selecting M inimum Temp as

“T OFF”, the air blows at room

temperature.

Menu Screen

Original PIN: 0105

Decrease p rogram

number

Increase program

number

Selected pr ogram

Current temp erature

Selected air flow

Graph of sel ected

program

Remaini ng time

Program Mode

Edit Progr am

This option al lows you to edit or create a program.

First, you must se lect the progra m to edit and then mo dify the points that make up the progr am.

Each progra m is composed of 9 po ints, each point co nsisting of 3 para meters:

1. Time (seconds)

2. Temperature (°C / °F)

3. Flow rate (%)

You can delete the last po int of the program by se lecting “-----” in the time pa rameter.

Remembe r that the regulatio n range permi tted by the station is b etween 150°C and 450°C, so it is

not possibl e to create temperature ramps between ro om temperature ( T O FF ) and 150°C.

The station c an store up to 25 temperature pr ograms.

The first th ree programs are installed as an ex ample.

Copy Progr am

This option al lows you to copy a program.

You must select the pro gram source and its destination (w here it will be co pied).

Delete Program

This option wi ll allow you to delete a prev iously sele cted program.

8

ww w.jb ct oo ls. co m

9

Page 6

Choose the needle and the suction cup that best fits the component and start working as follows:

Maximum working temp: 250ºC (482ºF)

Operati on

1. Suction

Pick & Place

Ref. T260-A

2. Relea se

This tool helps you easily place and remove SMDs of any size thanks to the suction pump.

Pick & Place (not supplied with TE)

Press the button to

start/stop the suction

Once the suction is

activated, cover the

pen hole with your

finger and lift off the

component.

Insert the needle

with the appropriate

cup for a correct

suction process.

Lift your finger

to release the

component in the

appropriate place.

You should

avoid the needle

protruding from the

lower part.

Pick & Place

Ref. T260-A

Straig ht Needles Se t

Ref. 0901546

Bent Need les Set

Ref. 0861660

10 11

Only per form this operation when the element is cold an d the unit is disco nnected from the m ains.

1. Loosen the screw.

2. Pull the he ating element away f rom the handle.

3. Connec t the new heating el ement, ensuri ng it is pushed al l the way in.

4. Tighten the sc rew.

Replacing the Heating Element

1. Ensure that the tool is tur ned off.

2. Use a spann er to unscrew the con necting nut.

3. When att aching the new tub e make sure the rib

lines up with th e groove on the control u nit.

4. Tighten wit h the spanner.

Changing the TE-TB Precision Heater Hose Set

Precisio n Heater

Hose Set

Ref. TE-TB

Heating El ement

Ref. 0012374 (100V - 230V - 120V)

Handle

Ref. 0012697

10

ww w.jb ct oo ls. co m

11

Page 7

Safety

It is imperative to follow safe ty guideli nes to prevent ele ctric

shock, inj ury, fire or expl osion.

- Do not use the uni ts for any purpose other than solde ring or rework. Inc orrect use may c ause fire.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded

before use. When unp lugging it, hold th e plug, not the wire.

- Do not work on ele ctrically li ve parts.

- The tool should be placed in the s tand when not in us e in order to activate the sleep mode.

The s oldering tip, the me tal part of the tool a nd the stand may stil l be hot even when the s tation is

turn ed off. Handle wi th care, includin g when adjustin g the stand positi on.

- Do not leave the ap pliance unat tended when it i s on.

- Do not cover the ven tilation grills. H eat can cause i nflamable products to ignite.

- Use a “non resid ue” classifi ed flux and avoid c ontact with skin or eyes to prevent irritation.

- Be careful with the fumes prod uced when sol dering.

- Keep your work place clean a nd tidy. Wear appropria te protective glasse s and gloves whe n

work ing to avoid person al harm.

- Utmost care mu st be taken with liq uid tin waste which c an cause burn s.

- This appli ance can be use d by children over the a ge of eight and als o persons with re duced

physi cal, sensor y or mental capabilities or la ck of experienc e provided that they have been given

adeq uate superv ision or instru ction concer ning use of the appliance and und erstand the ha zards

involved. Children mus t not play with the app liance.

- Maintenanc e must not be carr ied out by childr en unless sup ervised.

1. Pull off the fuse holder and remove th e

fuse. If nece ssary use a too l to lever it off.

2. Press the new fuse into the fuse ho lder

and replace i t in the station.

Fuse holder

Fuse holder

Fuse

12 13

Maintenance

Before carr ying out mai ntenance or storag e, always allow the equipment to cool.

- Clean the station screen with a g lass cleane r or a damp cloth.

- Use a damp cloth to cl ean the casing a nd the tool. Alcohol can only be use d to clean

the metal pa rts.

- Maintain he ating elemen t clean prior to storage in order to avoid its oxi dation.

Rusty and dirty sur faces redu ce heat transfer.

- Periodica lly check all c ables and tubes.

- Replace a bl own fuse as follows:

- Replace any d efective or dama ged pieces. Us e original JBC s pare parts on ly.

- Repairs sh ould only be performed by a JBC a uthorized techn ical serv ice.

12

ww w.jb ct oo ls. co m

13

Page 8

14 15

Exploded View

TE-1C 120V 50/60Hz. Input fus e 8A. Rated Current 6A. Control Unit m odel: JTE-1C

TE-2C 230V 50/60Hz. Inpu t fuse 4A. Rated Cur rent 3A. Control U nit model: JTE-2C

TE-9C 100V 50/60Hz. Inp ut fuse 8A. Rated Cu rrent 7A. Control Unit mod el: JTE-9C

- Weigh t: 5.2 kg (11.4 lb)

- Dim ensions: 148 x 184 x 140

- Nom inal Power: 300W

- Temperatur e selection: Room te mperature / 150ºC to 450°C (300ºF to 840 ºF)

Cool m ode: T Off. Used to blow ai r at room temperature

- Amb ient Operatin g Temperature: 10 to 40ºC (50-104ºF)

- Idle Temp. Stabilit y: +/-20 ºC (+/-36 º F)

- Air f low regulation: 3-17 SLPM

- USB co nnector station -PC

- P-0 05 Pedal conne ctor

Complies w ith CE standard s

ESD protected hous ing “skin effe ct”

Specifications

14

ww w.jb ct oo ls. co m

15

Page 9

0015898-0215

www.jbctools.com

Warranty

JBC’s 2 year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear due to use

or mis-use.

In order for the warranty to be valid, equipment

must be returned, postage paid, to the dealer

where it was purchased.

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Loading...

Loading...