Page 1

Solder Feeder for Automation

Ref. SFR-A

INSTRUCTION MANUAL

www.jbctools.com

Page 2

Packing List

The following items should be included:

Manual ............................ 1 unit

Ref. 0021348

Allen Key 1,5 mm ......... 1 unit

Ref. 0741610

Reel Support ................. 1 unit

Ref. 0021219

Solder Feeder for

Automation .................... 1 unit

Ref. SFR-A

Communications

Cable 3 m........................ 1 unit

Ref. 0020261

Spanner 10 mm............. 1 unit

Ref. 0017631

Allen Key 2,5 mm ......... 1 unit

Ref. 0012574

Ref. SFR-A

Solder Feeder for Automation

Screws

DIN 912 M4x60.......... 2 units

Ref. 0014954

Screws

DIN 7991 M4x10........ 2 units

Ref. 0490180

Download the Robot Communication Protocol for SFR at www.jbctools.com/jbcsoftware.html

2

www.jbctools.com

INSTRUCTION MANUAL

Page 3

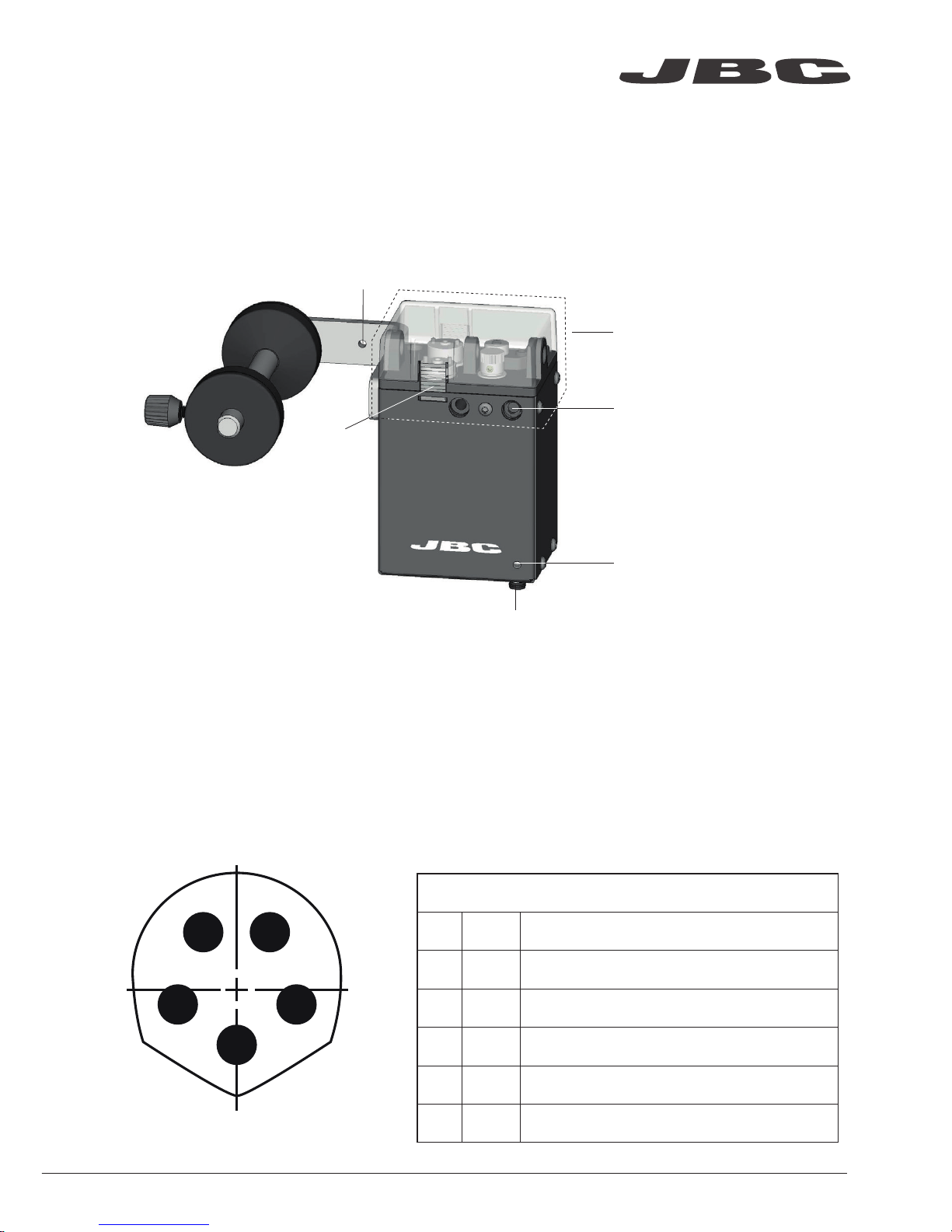

1 3

5

2 4

Front view

SFR Communications Connector

Features

Connection

The Solder Feeder for Automation must be controlled by a Robot/PLC/Computer. JBC developed

RS232 Robot Communication Protocol. (Available at www.jbctools.com/jbcsoftware.html)

The SFR-A can be connected with a five-pins communications cable (Ref. 0020261).

See the table below for a description of Communication Connector pin distribution:

Communications Connector

Pin Color Description

1 Brown

Power supply input:

24Vdc (±5%). 1.5 A current required

2 White Serial input: RS232 RX

3 Blue

Common reference:

GND for RS232, power supply and switch.

4 Black

Switch input:

0V or 24V to start feeding. Leave it open to stop.

5 Grey Serial output: RS232 TX

Communications Connector

LED Indicator:

· Blue: device powered

· Green: device working

· Red blinking: error, no solder wire

or device is blocked

Assembling holes

ESD

Safe Connector

The SFR Solder Feeder works together with one of the different GSFR Guide Kits, available for the various solder

wire diameters, with or without solder wire perforation. GSFR kits are sold separately.

Drag mechanism*

Lid with

push tabs

www.jbctools.com

3

Page 4

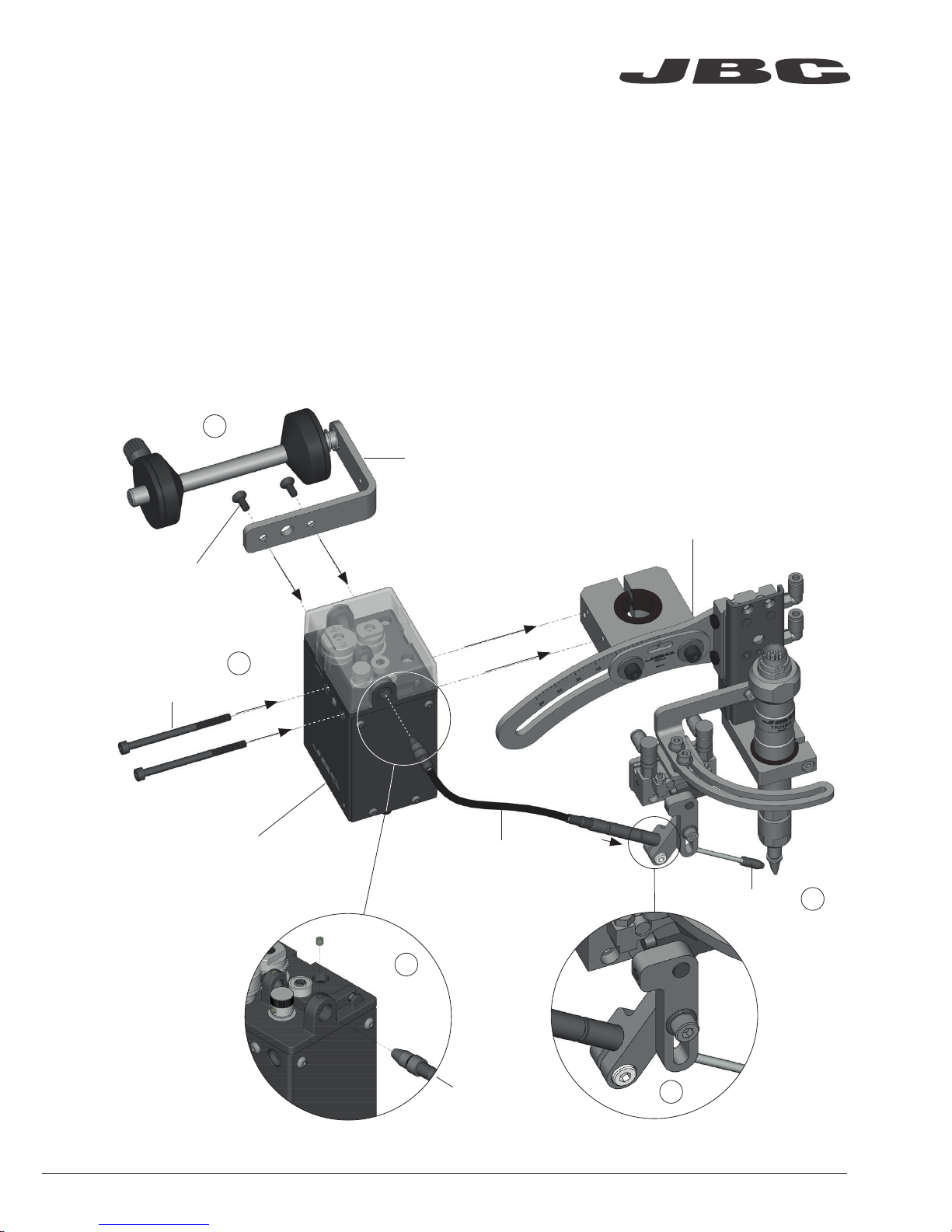

Assembly: GSFR* Wheels to SFR

For this operation, disconnect the device, and dismantle the Cover by pushing the tabs. Use the

allen key and the spanner to assemble the following components.

1. Insert the Intermediate Nozzle until its collar rests against the housing and tighten the screw.

2. Assemble the Guide Wheel and tighten the screw. If you use a Guide Kit without Solder

Wire Perforation assemble the Support Wheel.

3. If you have a Guide Kit with Solder Wire Perforation assemble the Blade first, then mount the

Blade Clamp onto the same axis and tighten the screw. If you use a Guide Kit without Solder

Wire Perforation, assemble the Traction wheel.

Caution: handle the blade carefully to avoid injury.

4. Insert the Inlet Nozzle into the hole and tighten the screw.

1

GSFR* with Solder Wire Perforation GSFR* without Solder Wire Perforation

4

1

2 2

3 3

4

Blade

Blade Clamp

Inlet

Nozzle

Inlet

Nozzle

Guide

wheel

Traction

Wheel

Support

Wheel

Inter.

Nozzle

Inter.

Nozzle

*Not included, sold separately

4

Page 5

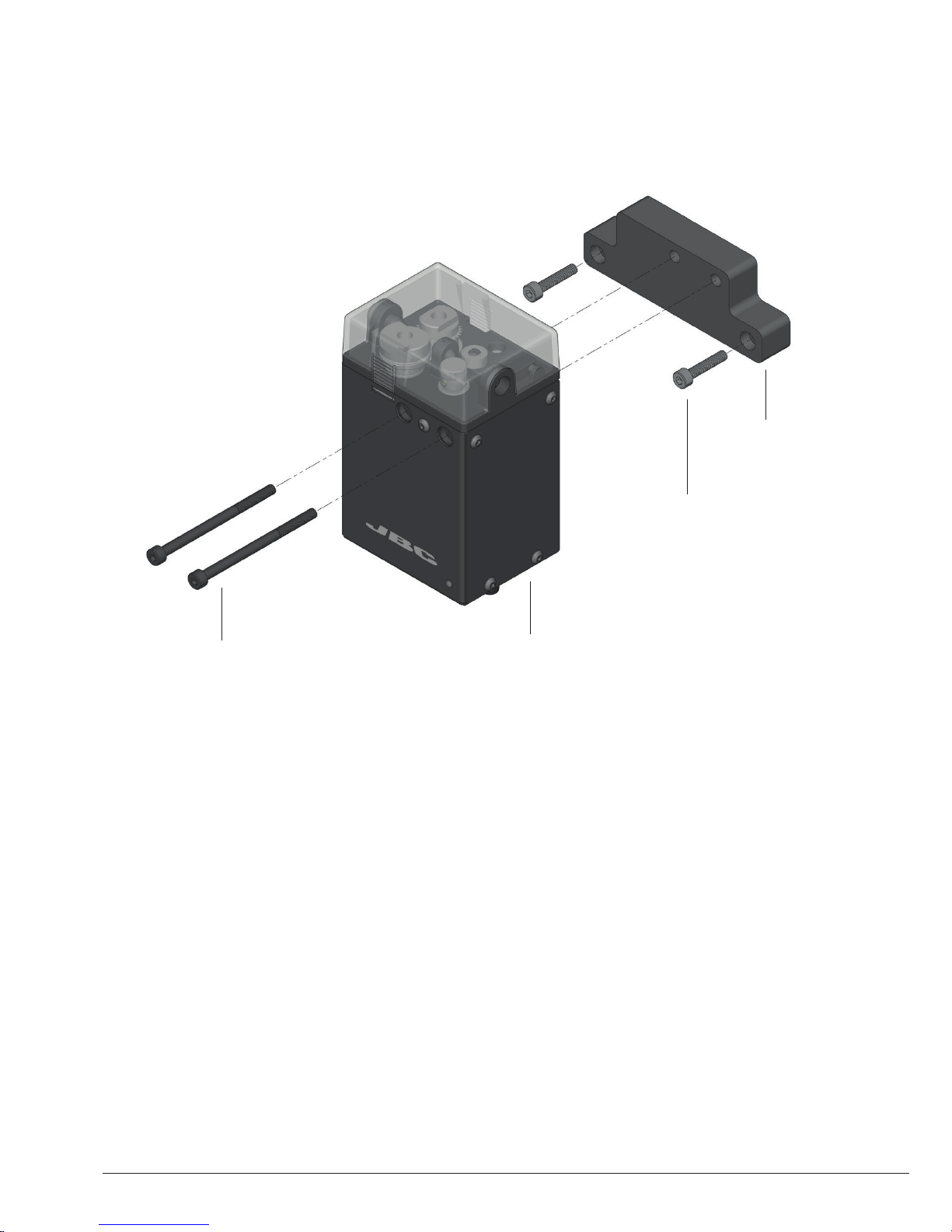

1. Assemble the SFR to the RBA with the screws.

2. Assemble the GSFR Guide Tube to the RBA and tighten the screw.

3. Assemble the Outlet Nozzle onto the Dispensing Tube.

4. Assemble the GSFR Bushing into the SFR hole and tighten the screw.

5. Finally attach the Reel Support to the SFR with its screws.

Assembly: SFR to RBA*

Solder Feeder

for Automation

Ref. SFR-A

GSFR Guide Tube*

Soldering Head

for Automation*

Ref. RBA-A

Reel Support

Ref. 0021219

2

4

5

Screws

Ref. 0014954

Screws

Ref. 0490180

GSFR Bushing*

*Not included, sold separately

Outlet Nozzle*

3

1

www.jbctools.com

5

Page 6

Assembly: SFR independent from RBA*

Screws

Ref. 0014954

Solder Feeder

for Automation

Ref. SFR-A

Insulator*

Ref. 0021713

Screws*

Ref. 0921890

If mounting SFR independently from RBA, the Electrical Insulator is required.

Assemble the Insulator to your device with its screws, followed by the SFR to The insulator with its

screws.

The Electrical Insulator must be assembled for the tool to work properly.

Do not use the SFR without insulator if it is mounted without the RBA.

*Not included, sold separately

6

Page 7

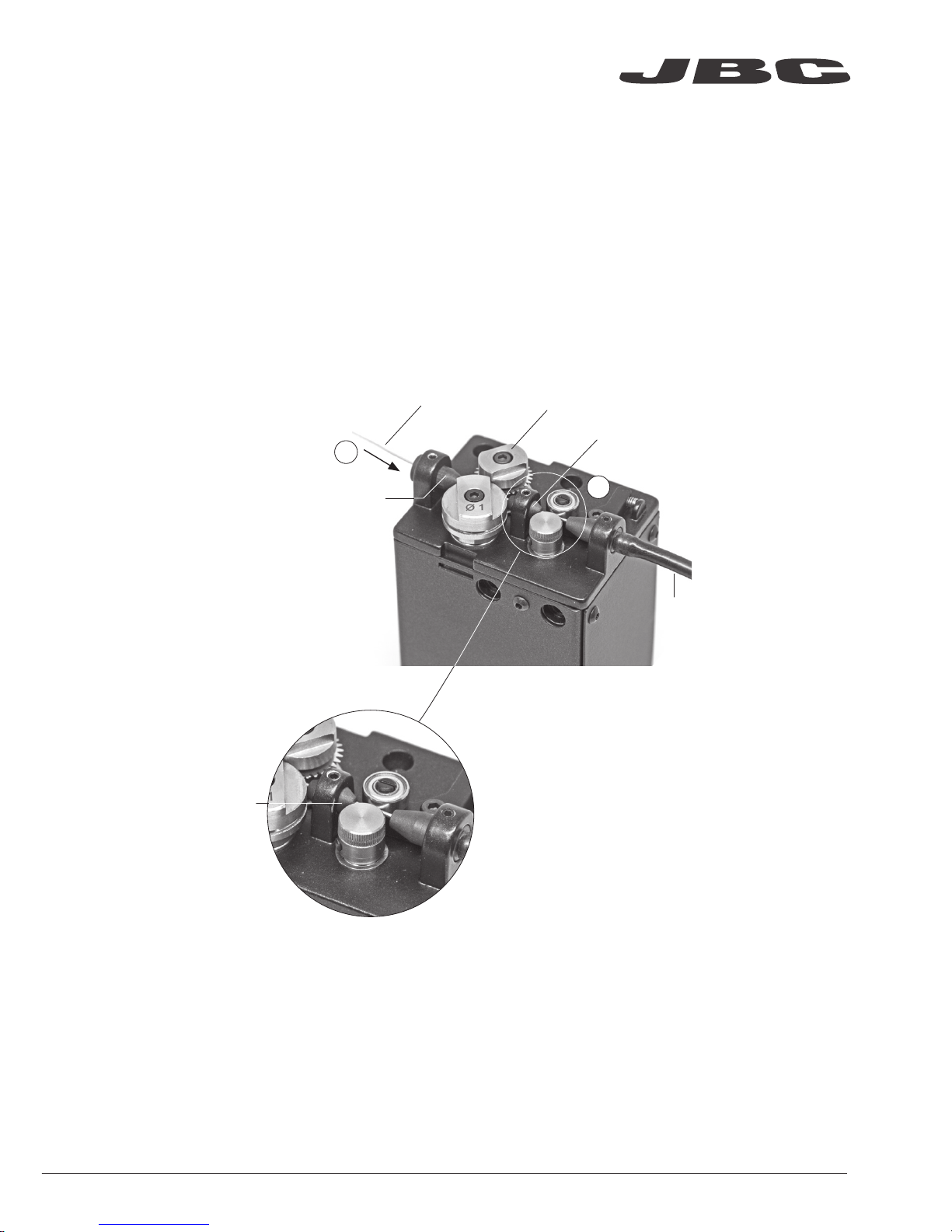

Solder Wire Loading

The GSFR must be assembled previously.

1. Feed the Solder Wire into the Inlet Nozzle until it reaches the wheels.

2. Make sure the wire passes through the Intermediate Nozzle and enters into the Guide Tube.

Wire feeding is controlled by an external controller (Robot/PLC/Computer). See the Robot Communication Protocol for SFR unit at www.jbctools.com/jbcsoftware.htm

Solder Wire

2

1

Wheels

Inlet

Nozzle

Guide

Tub e

Intermediate

Nozzle

Intermediate

Nozzle

www.jbctools.com

7

Page 8

Dimensions

mm

(in)

Solder Wire Reel dimensions: max. lenght 80mm (3.2 in), max. diameter 80mm (3.2 in), max. weight 1 kg (2.2 lb).

8

Page 9

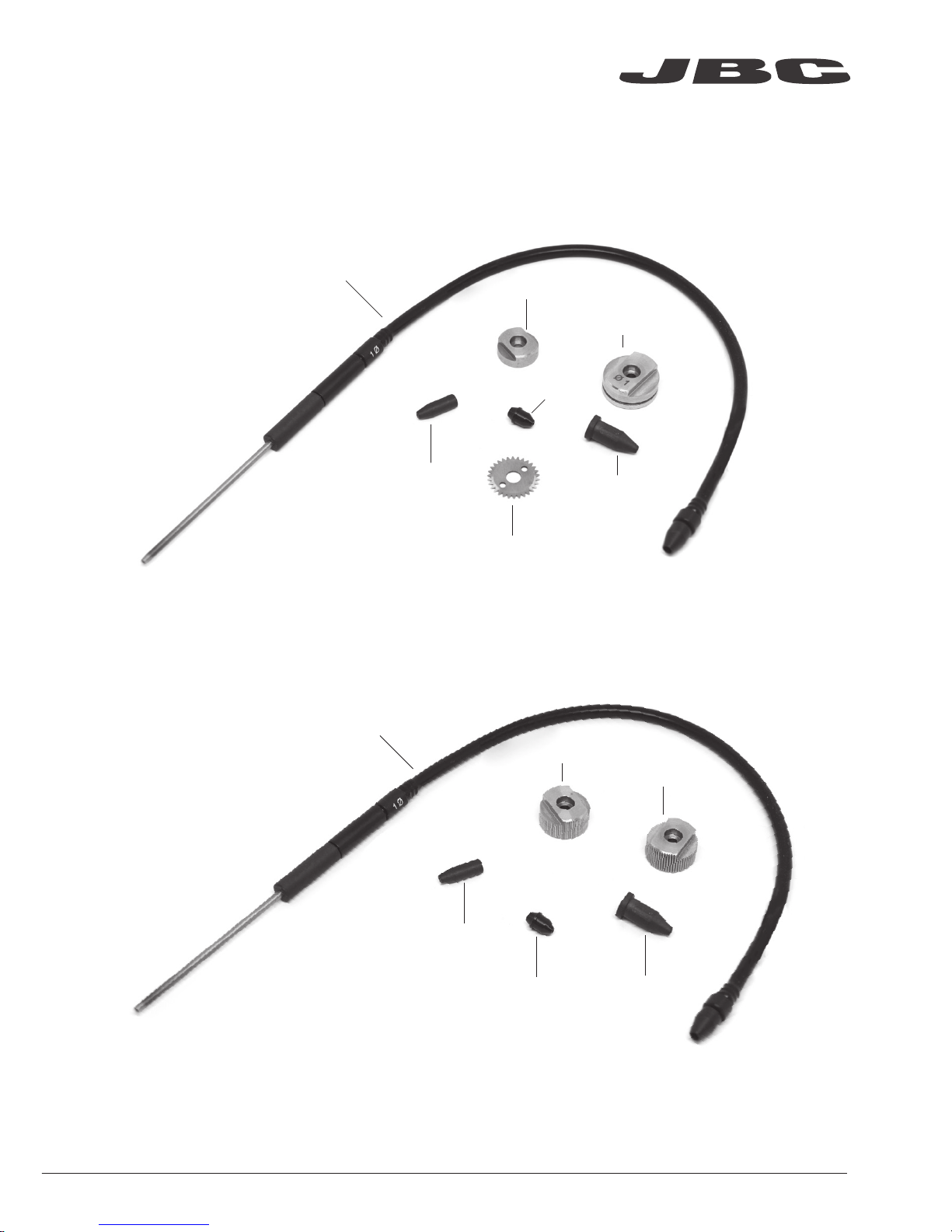

Accessories

Guide Kit for SFR with Solder Wire Perforation

Ref. GSFRXXVXX

Different Guide Kits for different Solder Wire diameters and Tube lengths are available.

More information at www.jbctools.com

Guide Tube

Inlet Nozzle

Guide Wheel

Blade Clamp

Blade

Inter. Nozzle

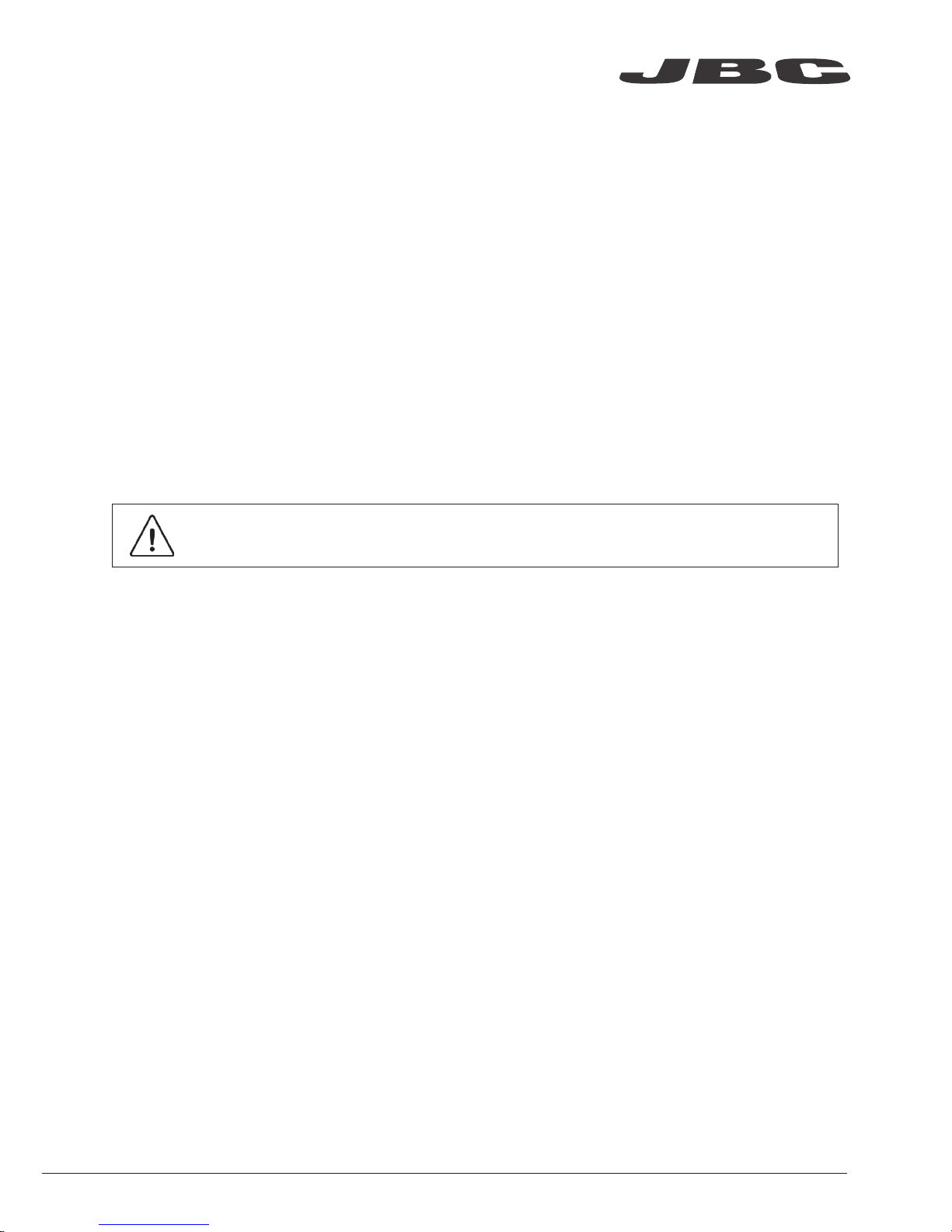

Inlet Nozzle

Traction Wheel

Outlet Nozzle

Support Wheel

Inter. Nozzle

Guide Tube

Outlet Nozzle

Guide Kit for SFR without Solder Wire Perforation

Ref. GSFRXXDXX

www.jbctools.com

9

Page 10

*Not included, sold separately

Work Place Example

Solder Feeder

Ref. SFR-A

Tip Cleaner*

Ref. CLMR-A

Soldering Head*

Ref. RBA-A

Soldering Iron*

Ref. TR245-A

TR470-A

TR A245-A

TR A470-A

Automatic Cartridge Stand*

Ref. CS2R245-A

CS2R470-A

Control Unit*

Ref. UCR245-5A

UCR470- 5A

Guide Kit*

Ref. GSFR

10

Page 11

It is imperative to follow safety guidelines to prevent electric shock,

injury, fire or explosion.

- Do not use the device for any other purpose.

- Do not leave the appliance unattended when it is on.

- Be sure that the power supply is disconnected before changing any spare part.

- Avoid flux coming into contact with skin or eyes to prevent irritation.

- Be careful of fumes produced while soldering.

- Keep your workplace clean and tidy. Wear appropriate protective glasses and gloves while

handling any component to avoid personal injury.

- Utmost care must be taken with liquid tin waste which can cause burns.

Safety

- Before carrying out maintenance, always unplug the tool and the device.

- Use a damp cloth to clean the Solder Feeder. Alcohol can only be used to clean the metal parts.

- Periodically check all cables and tube connections.

- Replace any defective or damaged parts. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

Maintenance

www.jbctools.com

11

Page 12

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Manual in other languages available on our website

www.jbctools.com

Warranty

JBC’s two-year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear or misuse.

In case of any manufacturing defect, the equipment

must be returned, postage paid, to the dealer where

it was purchased. Please, register your product

within 30 days of purchase in www.jbctools.com/

productregistration.

0021348-0618-V05

Specifications

- Net Weight: 870 gr (1.92 lb)

- Dimensions: 114 x 66 x 52 mm (4.49 x 2.60 x 2.05 in)

- Spool Capacity: Up to 1 kg (2.20 lb)

- Solder Wire Reel Dimensions: Max. lenght 80mm (3.2 in), max. diameter 80mm(3.2 in)

- Solder Wire Reel Weight: Up to 1kg (2.2 lb)

- Solder Diameter: Depends on the GSFR Kit used

- Max. Speed: 120 mm/s (4.72 in/s)

- Ambient Operating Temp.: 10 - 40 ºC (50 - 104 ºF)

- Connections: M8-5 pin Commmunication Connector

Complies with CE Standards.

ESD safe.

Loading...

Loading...