Page 1

Automatic Solder Feeder

Ref. SF-110VB/SF-210VB

www.jbctools.com

Page 2

Packing List

The following items should be included:

Manual ............................... 1 unit

Ref. 001633

Allen key Ø 1,5 ................ 1 unit

Ref. 0741610

SF Control Unit ............. 1 unit

Ref. SF-1B (100-120V)

SF-2B (230V)

Allen key Ø 2,5 ................ 1 unit

Ref. 0012574

Reel support ................ 1 unit

Ref. 0019301(x1)

0018033 (x1)

0003412 (x2)

Power cable .................... 1 unit

Ref. 0009417 (100V/120V)

0009401 (230V)

Spanner ............................ 1 unit

Ref. 0017631

Guide Set ........................ 1 unit

Ref. GSF10V-B

Automatic Solder Feeder

Ref. SF-B

lock rings

Solder Feed

Handle .............................. 1 unit

Ref. SF280-A

2

www.jbctools.com

Page 3

Power Socket

Fuse

RJ12 connection

for Robot System

RJ12 connection for Station

USB-B connector

Tin wire inlet

Features

Solder

Feed Handle

Ref. SF280-A

Control Unit

Main Switch

Control Screen

www.jbctools.com

3

Page 4

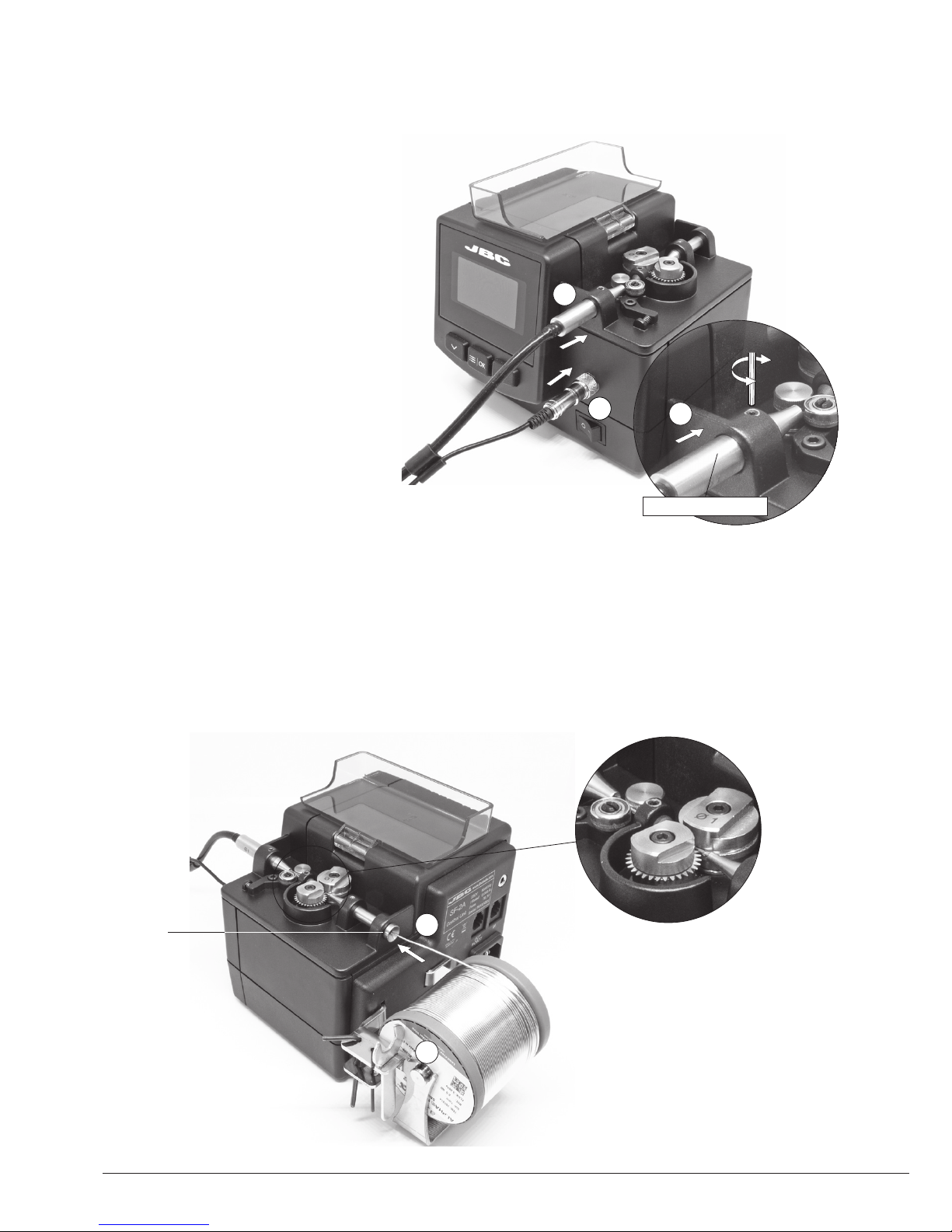

Tool assembly

Connect the tool to the control unit.

1. Push the guide tube to the end

and tighten the screw.

2. Connect the jack.

Load the solder wire

1. Put the reel into its support.

2. Feed the wire into the input nozzle (2) until it reaches the wheels.

1

1

2

Input

nozzle

1

2

3. Use the Tin Reload Process

in Main Menu by pressing

the tool button.

4. Make sure the wire passes

through the nozzle.

inser t to the end

4

Page 5

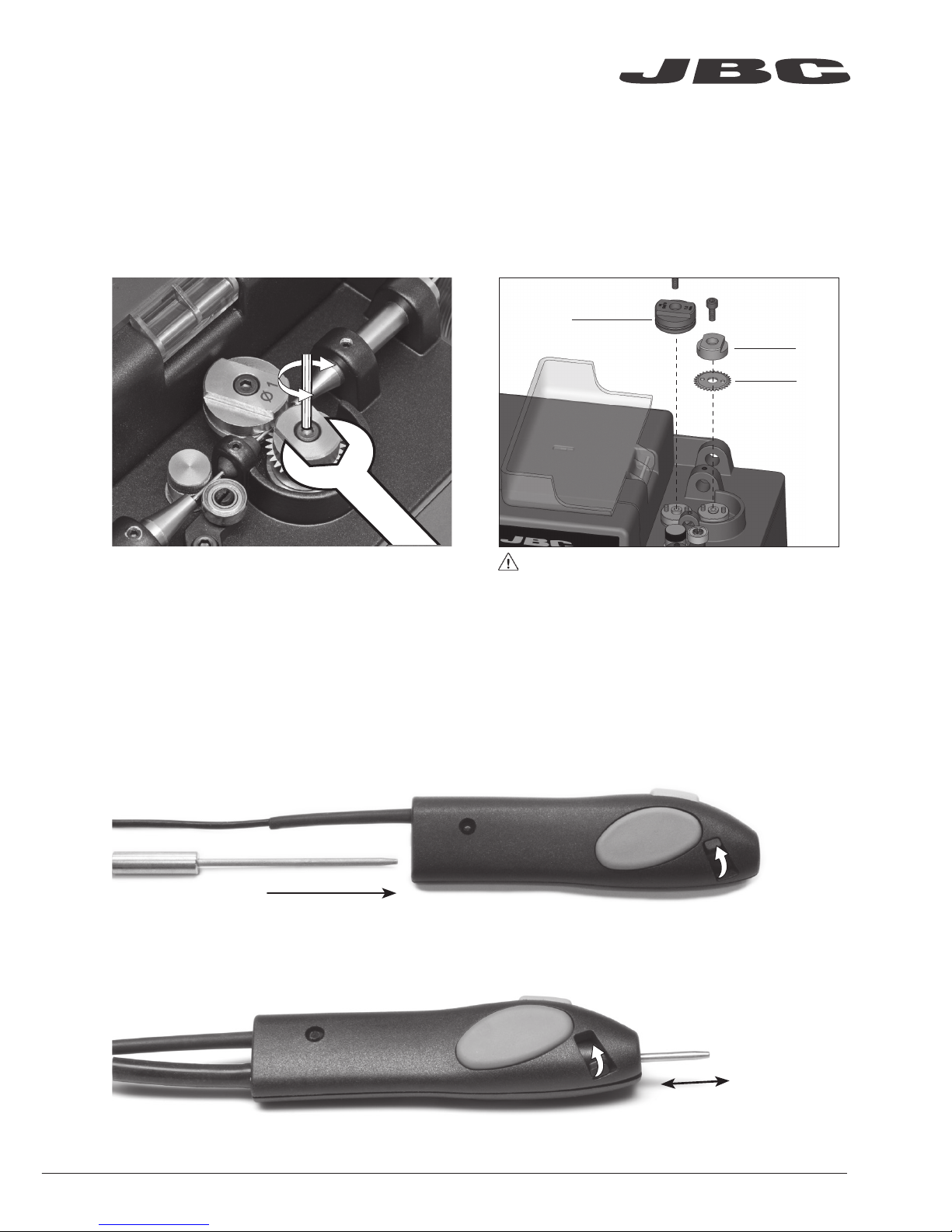

Changing the wheels and the blade

1. Use the a llen key and the spanner to loosen

the screws.

2. Replace the guide wheel and the blade for

the new ones.

Guide

wheel

Blade

clamp

Blade

For this operation, disconnect the unit.

* Handle with care to avoid any cuts with the

blade because it is sharp.

2. You can easily adjust the length of the tube by opening the tube clamp.

Replacing the guide tube

1. Open the guide clamp, take off the guide tube and insert the new one.

For this operation, disconnect the tool from the control unit.

www.jbctools.com

5

Page 6

Back

Setting Program 35

Continuous Mode Discontinuous Mode Program 35

Speed

Length

Length

STEP1 STEP2

Speed

Speed

Supplied: 2.0mm 0:05

40% 40%

mm/s mm

mm

mm/s

mm/s

40.0

1.5

1.5

20.0

20.0

STEP3

Length Speed

mm mm/s

5.0

20.0

STEP 1

STEP 2

STEP 3

Back

Edit Program

mm

mm/s

STEP 1 STEP 2 STEP 3

35

5.0 3.0 1.5

20.0 24.5 20.0

FACTORY 1

1 Program 35

FACTORY 1

2 Program 22

LAB 2

3 Program 35

FACTORY 1

Program Concatenation

Back

Work Screen

Control Process

Choose between continuous, discontinuous and program mode:

Program mode

With the SF you can define up to 35 dynamic programs. In each one you can configure up to 3

steps with different lenght wire and dispensing speed.

Execute them sequentially and cyclically with the ‘Edit Concatenation List’ option.

6

Page 7

Main Menu

5 Tin Reload Process

6 Counters

7 Software Version

1 Reset settings

2

Station settings

3

Tool settings

4 Programs Settings

Exit

1 Length units*

mm

2

Beep Off

3 PIN On

4 Change PIN

1 Mode

Discontinuous

2

Backward Off

Tool Settings

Station Settings

Back

Back

1 Edit Program

2

Delete Program

3

Edit Concatenation List

Program Settings

Ba

ckward Forward

Reload Process

1 Plugged hours

7605

2

Working hours 350

3 Supplied mm 560

4 Work Cycles 75830

Counters

Back

5 Reset partial counters

Press Enter to toggle*

Press enter when finished

Back

5 Station Locket

Off

6

Robot Mode Off

Screen Menu

Original PIN: 0105

Control Process

*switch total and partial

counters

*switch mm and inches

www.jbctools.com

7

Page 8

Solder Wire Ø (mm) With Solder Wire Perforation Solder Wire Ø (mm) Without Solder Wire Perforation

- - 0.5-0.6 GSF05D-B

0.8 GSF08V-B 0.7-0.8 GSF08D-B

1.0 GSF10V-B 0.9 -1.0 GSF10D-B

1.5 GS F15V-B 1. 2-1. 5 GSF15D-B

Accesories

Solder Feed Handle Stand

Ref. SF-SE

It prevents the SF280-A Solder Feed Handle

from rolling away while working.

Different guide sets are available depending on the solder wire used:

8

Page 9

Before carrying out maintenance, always allow

the equipment to cool down.

- Clean the station screen with a glass cleaner

or a damp cloth.

- Use a damp cloth to clean the casing and the

tool. Alcohol can only be used to clean the

metal parts.

- Periodically check all cables and tubes.

Clean periodically

Maintenance

1. Pull off the fuse holder and remove the

fuse. If necessary use a tool to lever it off.

2. Insert the new fuse into the fuse holder

and return it to the station.

- Replace a blown fuse as follows:

- Replace any defective or damaged parts. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

www.jbctools.com

9

Page 10

- Do not use the units for any purpose other than soldering or rework. Incorrect use may cause fire.

- The power cord must be plugged into approved bases. Make sure that it is properly grounded

before use. When unplugging it, hold the plug, not the wire.

- Do not work on electrically live parts.

- The tool should be placed in the stand when not in use.

Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- Do not cover the ventilation grills. Heat can cause inflamable products to ignite.

- Avoid the contact of flux with skin or eyes to prevent irritation.

- Be careful with the fumes produced while soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight as well as persons with reduced

physical, sensory or mental capabilities or lacking experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance.

- Maintenance must not be carried out by children unless supervised.

Safety

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

10

Page 11

产品中有害物质的名称及含量

有害物质含量表

部件名称

有害物质

铅(Pb) 汞(Hg) 镉(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

烙铁头 O O O O O O

手柄 O O O O O O

电源线 O O O O O O

主机 O O O O O O

电源插座 O O O O O O

保险丝 O O O O O O

主开关 O O O O O O

电位连接 X O O O O O

变压器 O O O O O O

线路板 X O O O O O

O 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572 规定的限量要求以下。

X 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572 规定的限量要求。

www.jbctools.com

11

Page 12

Exploded View

12

Page 13

www.jbctools.com

13

Page 14

Notes

14

Page 15

www.jbctools.com

15

Page 16

0021633-0818-V02

Specifications

SF-110VB 100-120V 50/60Hz. Input fuse: 0.2A.

SF-210VB 230V 50/60Hz. Input fuse: 0.125A.

- Net Weight: 1,9 Kg (4.2 lb)

- Dimensions: 150 x 120 x 115 mm (5.9 x 4.8 x 4.6 in)

- Spool capacity up to 1 kg (2.2 Ib)

- Solder diameter Ø0,5-1,5 mm (Ø0.02-0.059 in)

- Max. Wire lenght 250 mm (9.84 in)

- Max. Forward speed 120 mm/s (4.72 in/s)

- Max. Reverse speed 120 mm/s (4.72 in/s)

- Ambient operating temp: 10 - 40 ºC (50 - 104 ºF)

- USB connector station-PC

- Robot connector

Complies with CE standards.

ESD protected.

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Manual in other languages available on our website

www.jbctools.com

Warranty

JBC’s two-year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear or misuse.

In case of any manufacturing defect, the equipment

must be returned, postage paid, to the dealer where

it was purchased. Please, register your product

within 30 days of purchase in www.jbctools.com/

productregistration.

Loading...

Loading...