Page 1

Premium

Complete Rework Station

with Electric Pump

Ref. RMSE-C

Español 35

English 3

Page

www.jbctools.com

Page 2

2

Index

Packing list ......................................................... 3

JT Hot Air station

Features .............................................................. 7

Stand & Nozzle changer ................................ 8

Protectors & Extractors ................................ 10

T260 Pick & Place .......................................... 11

Operation & Process Control with JT ....... 12

JT-TA Replacing the Heating Element ...... 15

JT-TA Changing the Heater Hose Set ...... 15

DDE Control Unit & MSE Module

Features ............................................................ 16

Stands & Tip Cleaner .................................... 18

T245 Changing Cartridges .......................... 20

DR560 Changing Tips .................................. 21

DR560 Changing the Heating Element ... 22

DR560 Tin Deposit Cleaning ...................... 23

DR560 Tip Care .............................................. 24

Desoldering Process DDE & MSE ............. 24

MSE Initial Setup ............................................ 25

MSE Changing the pump filters ................. 25

Operation with DDE ...................................... 26

Process Analysis ............................................ 28

Soldering Net .................................................. 29

Working with robots ...................................... 30

Station Sotware .............................................. 30

Maintenance ..................................................... 31

Safety ................................................................... 32

Specifications .................................................. 33

Exploded View ................................................. 66

Page 3

3

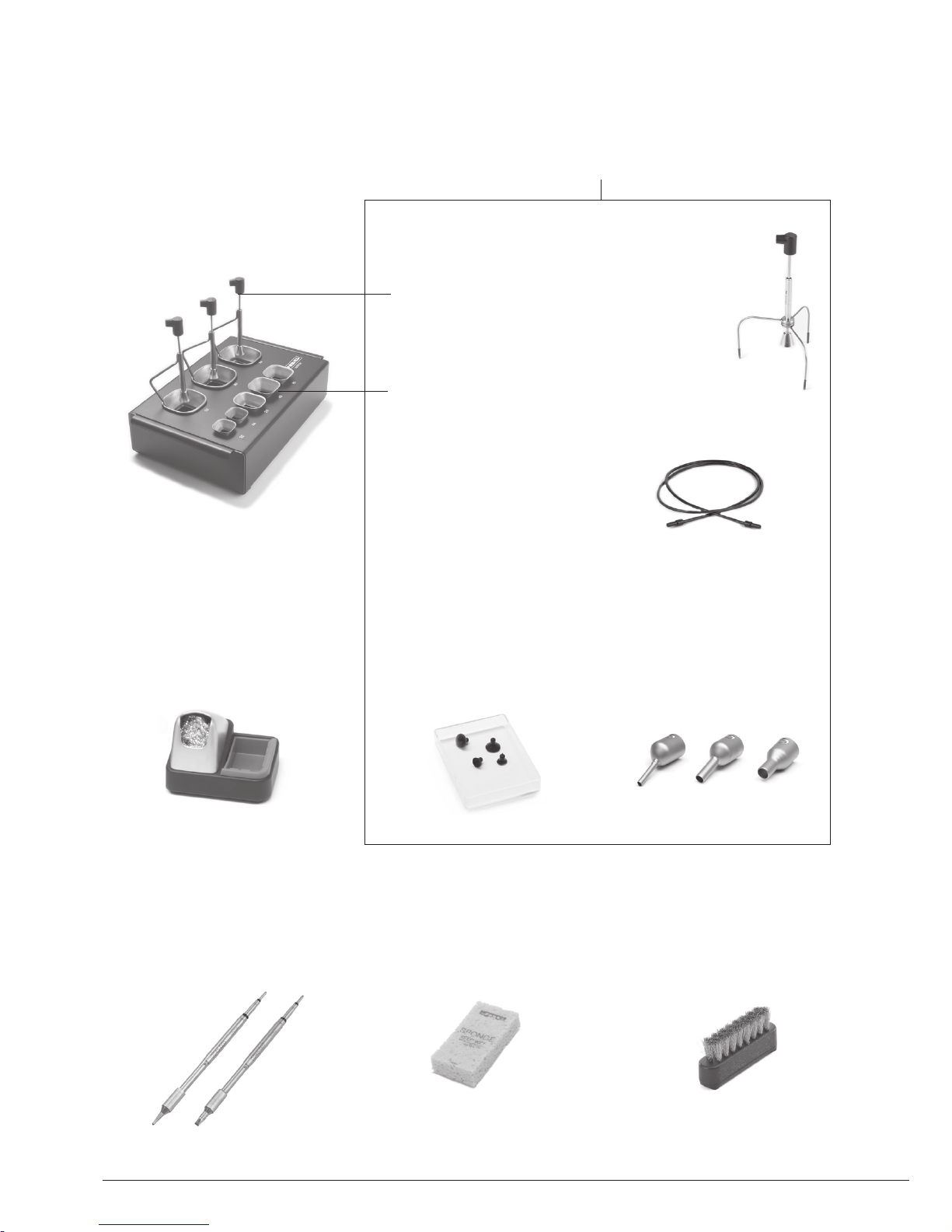

Packing List

The following items should be included:

Stand ................................ 1 unit

Ref. AD-SD

Electric Desoldering

Module ............................ 1 unit

Ref. MSE-A

DDE Control Unit .......... 1 unit

Ref. DDE-1B (120V)

DDE-2B (230V)

DDE-9B (100V)

Desoldering Iron ........... 1 unit

Ref. DR560-A

C560003 already inserted

Stand ............................... 1 unit

Ref. DR-SD

General Purpose

Handle ............................... 1 unit

Ref. T245-A

Heater hose set ............ 1 unit

Ref. JT-T1A (100V / 120V)

JT-T2A (230V)

Stand ................................ 1 unit

Ref. JT-SD

JTE Control Unit ........... 1 unit

Ref. JTE-1D (120V)

JTE-2D (230V)

JTE-9D (100V)

ww w.j b cto o l s .com

Page 4

4

Tip Cleaner ..................... 1 unit

Ref. CL9885

JT Accessory set

Ref. 0012332

Sponge ............................. 1 unit

Ref. S0354

Metal Brush .................... 1 unit

Ref. CL6217

Cartridges ..................... 2 units

Ref. C245903

Ref. C245906

* These accessories are not supplied with JT-2QC / JT-1QC / JT-9QC stations.

Extractor stand* ............ 1 unit

Ref. 0008752

Suction Tube*

Ref. 0932330

Suction Cups*

Ref. 0930110

Ø 10 - 0934050 (x3)

Ø 4.7 - 0934070 (x1)

Extractors*

Ref. E2184

E2064

E2052

Protectors*

Ref. P2220

P2230

P2235

P4000

P4010

Tripod*

Ref. T2050 (Ø 39mm)

T2250 (Ø 85mm)

Nozzles

Ref. JN2015 (x1)

JN2012 (x1)

JN2020 (x1)

Page 5

5

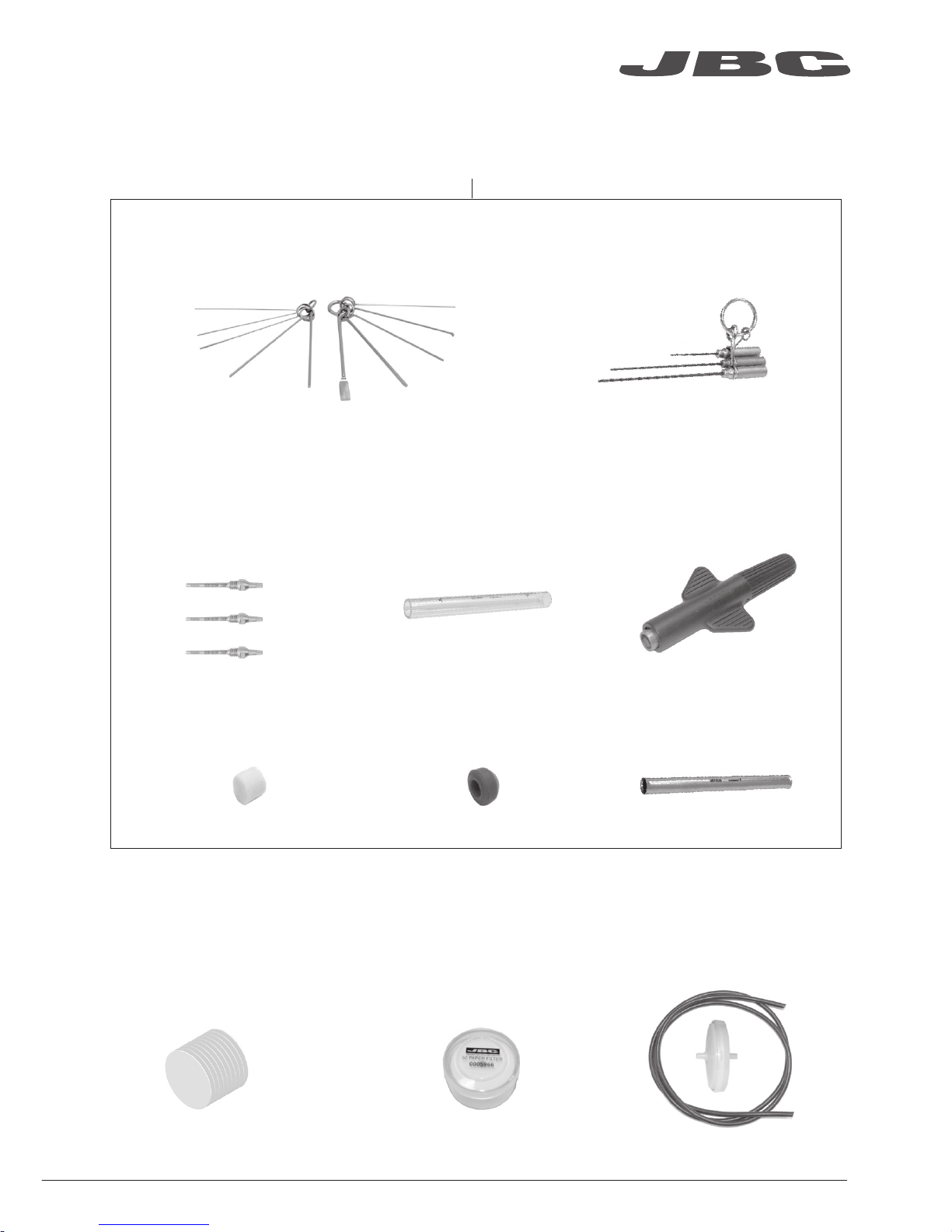

Suction Filter ................... 1 unit

Ref. 0821830

Cotton Filter ................... 1 unit

Ref. 0781046

It contains 10 filters

Filter Box .......................... 1 unit

Ref. 0005966

It contains 50 filters

DR560 Accessories

Ref. 0010211

Internal gasket ............ 2 units

Ref. 0812360

Tip cleaning set .......................................... 1 unit

Ref. 0965970

Spanner ........................... 1 unit

Ref. 0780550

Tin deposit .................... 1 unit

Ref. 0812620

Long Tip Cleaning set ........................... 1 unit

Ref. 0965760

Metal tin diposit ........... 1 unit

Ref. 0812630

Tips ............................. 3 units

Ref. C560005

Ref. C560013

Ref. C560004

Filter Box .................... 1 unit

Ref. 0780840

It contains

10 filters

ww w.j b cto o l s .com

Page 6

6

Manual ...............................1 unit

Ref. 0017357

Premium

Complete Rework Station

with Electric Pump

Ref. RMSE-C

Stand Cable ................. 2 units

Ref. 0011283

Power cords

For DDE ........................... 1 unit

Ref. 0013671 (100/120V)

0010569 (230V)

Module Cable ................. 1 unit

Ref. 0014874

Cleaning stick ................ 1 unit

Ref. 0786640

Pick & Place ................... 1 unit

Ref. T260-A

Straight Needles Set ... 1 unit

Ref. 0901546

Bent Needles Set ......... 1 unit

Ref. 0861660

Cups Set ......................... 1 unit

Ref. 0940163

Union Flanges ............... 1 unit

Ref. 0011356

For JTE ............................. 1 unit

Ref. 0009417 (100V/120V)

0009401 (230V)

www .jbc tool s.c om

Page 7

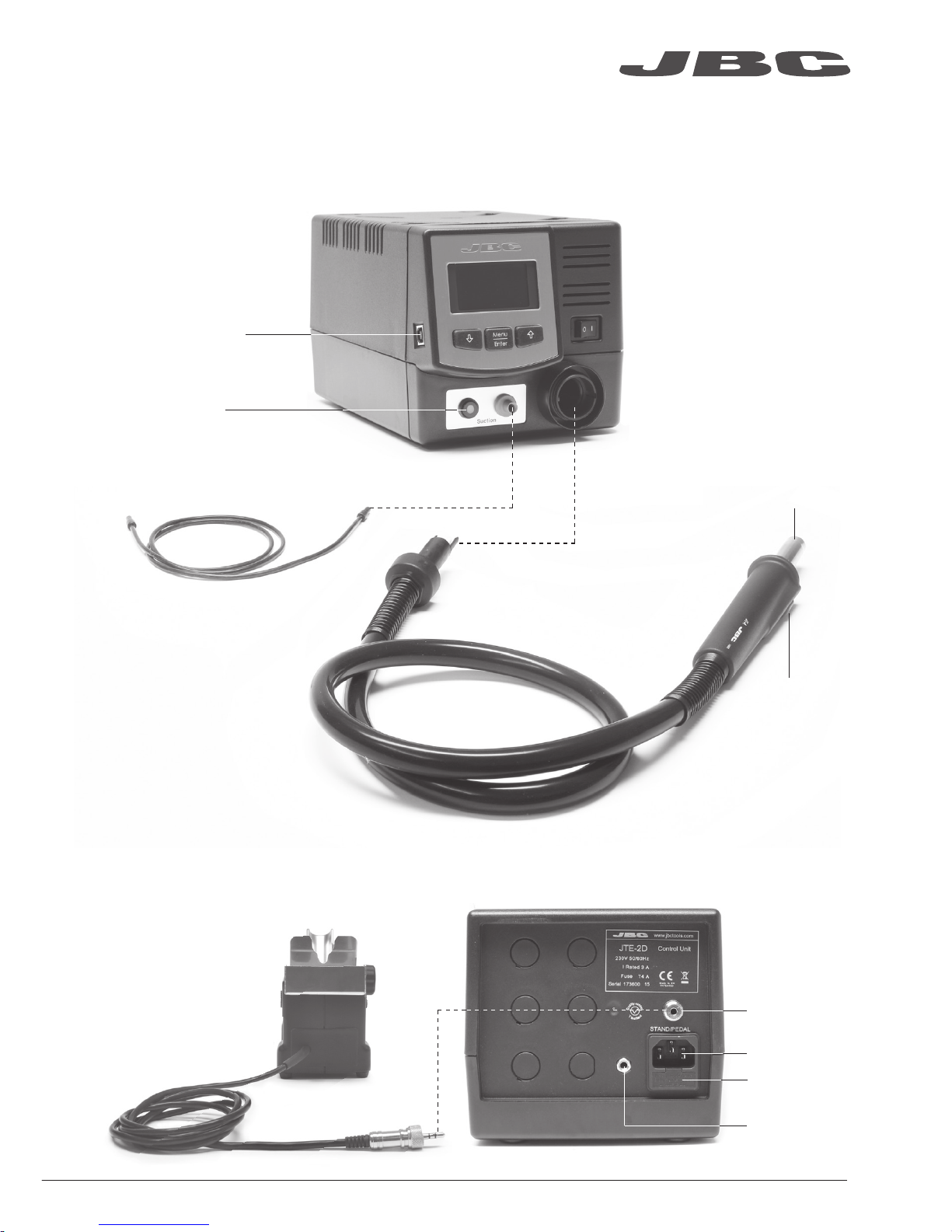

JT Features

7

Another connectable tool:

Precision Heater hose set

Ref: TE-TB

Hot Air button

(On / Off)

Power Socket

Optional:

P-005 Pedal

connection

Fuse

Equipotential

connection

Heating

element

Suction Tube

Ref. 0932330

Heater Hose set

Ref. JT-T1A (100V/120V)

JT-T2A (230V)

Stand

Ref. JT-SD

For tripods

and extractors

Activates the

suction pump

USB-B connector

Update the station

software from

the JBC website

ww w.j b cto o l s .com

Page 8

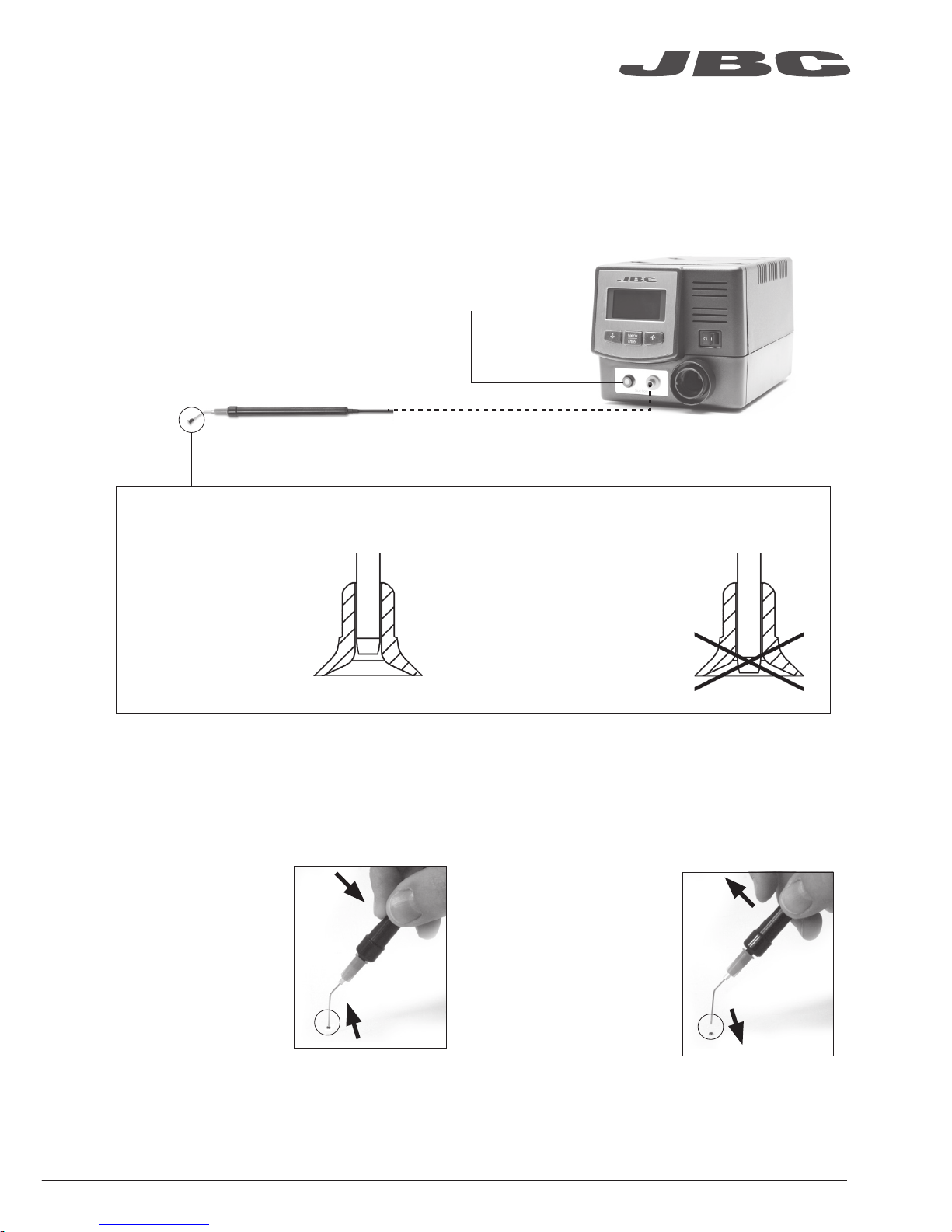

Press

Press

Do not

press

8

1. From the main Menu, select the mode to activate the tool depending on the task.

2. The tool stops blowing hot air when returned to the stand.

Stand + Autostart OFF

Stand + Autostart ON

Pedal*

Adjust the tool holder angle to suit your work position.

Press the start/stop button to

blow hot air.

The tool will start blowing hot

air when it is lifted from the

stand.

Press the Pedal to blow hot

air and release to stop.

*The P-005 Pedal is not

supplied with this station.

See our website.

Adjustable Stand

Operation Modes

Page 9

9

Quick Nozzle Changer

Changing nozzles quickly and safely.

Compatible Nozzles

The JT-TA works with JT nozzles. Find the model that best suits your soldering needs in www.jbctools.com

2

1

In case of a loosely fitting nozzle:

Ref. Shape Size

JN2020 Straight Ø 8mm

JN8417 Straight Ø 10mm

JN2015 Bent Ø 4mm

JN2012 Bent Ø 6mm

JN6633 Bent Ø 8mm

JN7637 Flat 10 x 2mm

JN7638 Flat 20 x 2mm

JN7639 Flat 30 x 2mm

Straight Bent Flat

Ø mm

Ø mm

A x B mm

1. Push the nozzle tab inwards with a

screwdriver or flat-nosed pliers.

2. Insert the nozzle into the JT-TA Heater again.

Turn the tool off

and handle with

care. The heating

element and the

nozzle are still hot.

ww w.j b cto o l s .com

Page 10

10

For small components (fig. 1 and 2). For large components (fig. 3 and 4).

We recommend using the protector + tripod We recommend using the extractors

Protectors & Extractors

1 2 3 4

Protectors

* Ref. AxB (mm) * Ref. AxB (mm)

P3353 4,3 x 3

48

P2230 15 x 15

P3786 5,2 x 5,2

60

P4010 17 x 17

P3352 5,2 x 7,5 P4005 18 x 29

P3355 5,2 x 9,5 P4030 18,5 x 18,5

P3356 6,2 x 4,2 P1068 18,5 x 24

P3785 7,2 x 7,2 P2685 28,5 x 28,5

P3784 8,2 x 8,2 P4085 31,5 x 31,5

P4035 9 x 13 P2672 33 x 46

P4040 9,5 x 19 P4002 50 x 50

P4080 9,5 x 21 P3357 52,5 x 14

32

P2220 10 x 10

P4045 10,5 x 21

P4090 11 x 16

24

P2235 12 x 17

P1249 12 x 23

44

P4000 12,5 x 12,5

P3354 13,2 x 13,2

P4025 13,5 x 21,5

øD

* Reference Desk

Tripods

* Ref. øC (mm)

T2050 39

T2250 85

Manual extractor

* Ref. øD (mm)

E2190 7

Extractors

* Ref. AxB (mm) * Ref. AxB (mm)

52 E2052 20 X 20 E2124 45 X 45

64 E2064 20 X 26

80 E2184 24 X 24

E2068 27 X 27

E4020 28,5 X 28,5

E4015 31,5 X 31,5

E2084 33 X 33

E2100 38 X 38

Page 11

Choose the suction cup that best fits the component (Maximum working temp.: 250ºC / 482ºF):

11

1. Suction 2. Release

This tool helps place and remove SMDs of any size thanks to the suction provided by the station.

T260 Pick & Place

Press the button to

start/stop the suction

Once activated

the suction button,

cover the pen hole

with your finger and

pick the component.

Insert the needle

with the appropriate

cup for a correct

suction process.

Lift your finger

to release the

component on the

appropriate place.

You should avoid the

needle to stick out of

the lower part.

Operation

Pick & Place

Ref. T260-A

ww w.j b cto o l s .com

Page 12

Tem p ºC

Air %

Time to stop 45 seconds

Power 70%

400

85

400ºC Select

12

Operation with JT station

Process Control

3. Releasing1. Placing 2. Heating

Position the extractor with the

appropriate suction cup and

press the suction button.

Heat the component. The component lifts off

automatically when the

solder melts.

Access Menu (pess key 2 seconds) & Confirm Selection

Selected temperature

Current temperature

% Instant power supplied

to heater

You can switch between operating modes (Manual Mode / Program Mode) by pressing the

“increase” and “decrease” keys simultaneously for 2 seconds (Only when programs mode is ON).

Manual Mode

Current air flow

Page 13

Tem p ºC

º

C

Pro gr am 8

380

Air 100%

Time 125s.

13

Decrease program

number

Increase program

number

Selected program

Current temperature

Selected air flow

Graph of selected

program

Remaining time

Program Mode

Program Options

Edit Program

This option allows you to edit or create a program.

First, you must select the program to edit and then modify the points that make up the program.

Each program is composed of 9 points, each point consisting of 3 parameters:

1. Time (seconds)

2. Temperature (°C / °F)

3. Flow rate (%)

You can delete the last point of the program by selecting “-----” in the time parameter.

It should be taken into account that the regulation range permitted by the station is 150-450°C, whereby it is not possible to create temperature ramps between room temperature (Toff) and 150°C.

The station can store up to 25 temperature programs.

The first three programs are edited by JBC as an example.

Copy Program

This option allows you to copy a program.

You must select the program source and its destination (where it will be copied).

Delete Program

This option will allow you to delete a previously selected program.

ww w.j b cto o l s .com

Page 14

Mai n me nu

1 Reset station

2 Station

Settings

3

Program Settings

4

Counters

5 Program version

Exi t

Sta ti on S et ti ng s Pro gr am S et ti ng s

Edi t Pr og ra m

Edi t Pr og ra m 1

1

Temp unit Celsius

2 Maximum

temp 4500C

3 Minimum temp T OFF

4 Fix temp -----

5 Temp Adjust + 00C

6 Max air 100%

7 Min air 10%

8 Fix air -----

1 Programs OFF

2 Edit program

3

Copy program

4

Delete program

Bac k

Sel ec t

Pro gr am

Ste p 1

Tim e 30

Tem p 3 00

Air 10 0

º

C

º

C

1

Exi t

Cou nt er s

1 Station ON hours

0

2

Works hours 0

3 Works

cycles 0

Bac k

9 Time to stop 120 sec

10 Stand/Pedal Stand

Autostart OFF

11 Beep ON

12 Pop up ON

13 Change PIN

14

* Selecting Minimum Temp as

“T OFF”, the air blows at room

temperature.

Menu Screen

Original PIN: 0105

Page 15

15

Only perform this operation when the element is cold and the unit is disconnected from the mains.

1. Loosen the screw.

2. Pull the heating element away from the handle.

3. Connect the new heating element, ensuring its pushed all the way in.

4. Tighten the screw.

JT-TA Replacing the Heating Element

Heating Hose Set

Ref. JT-T1A (100V / 120V)

JT-T2A (230V)

Heating Element

Ref. 0014107 (230V)

0014105 (100V / 120V)

Handle

Ref. JT-A

1. Ensure that the tool is turned off.

2. Use a spanner to unscrew the connecting nut.

3. The tube end of the new heater must be inserted

so that the longitudinal rib fits into the groove.

5. Follow the same steps conversely.

JT-TA Changing the Heater Hose Set

ww w.j b cto o l s .com

Page 16

DDE & MSE Features

16

Stand

Ref. DR-SD

Stand Cable

Ref. 0011283

Work simultaneously with up to 2 tools and join each station port with 1 module + 1 pedal (Peripherals).

Stand

Ref. AD-SD

General

Purpose

Handle

Ref. T245-A

RJ12 connector for Robot

USB-B connector

Equipotential connection

Power Socket

Desoldering Iron

Ref. DR560-A

Cartridge

Ref. C245903

Ref. C245906

Tip

Ref. C560004

Ref. C560005

Ref. C560013

Page 17

17

Suction Filter

Ref. 0821830

Module Cable

Ref. 0014874

USB-A connector

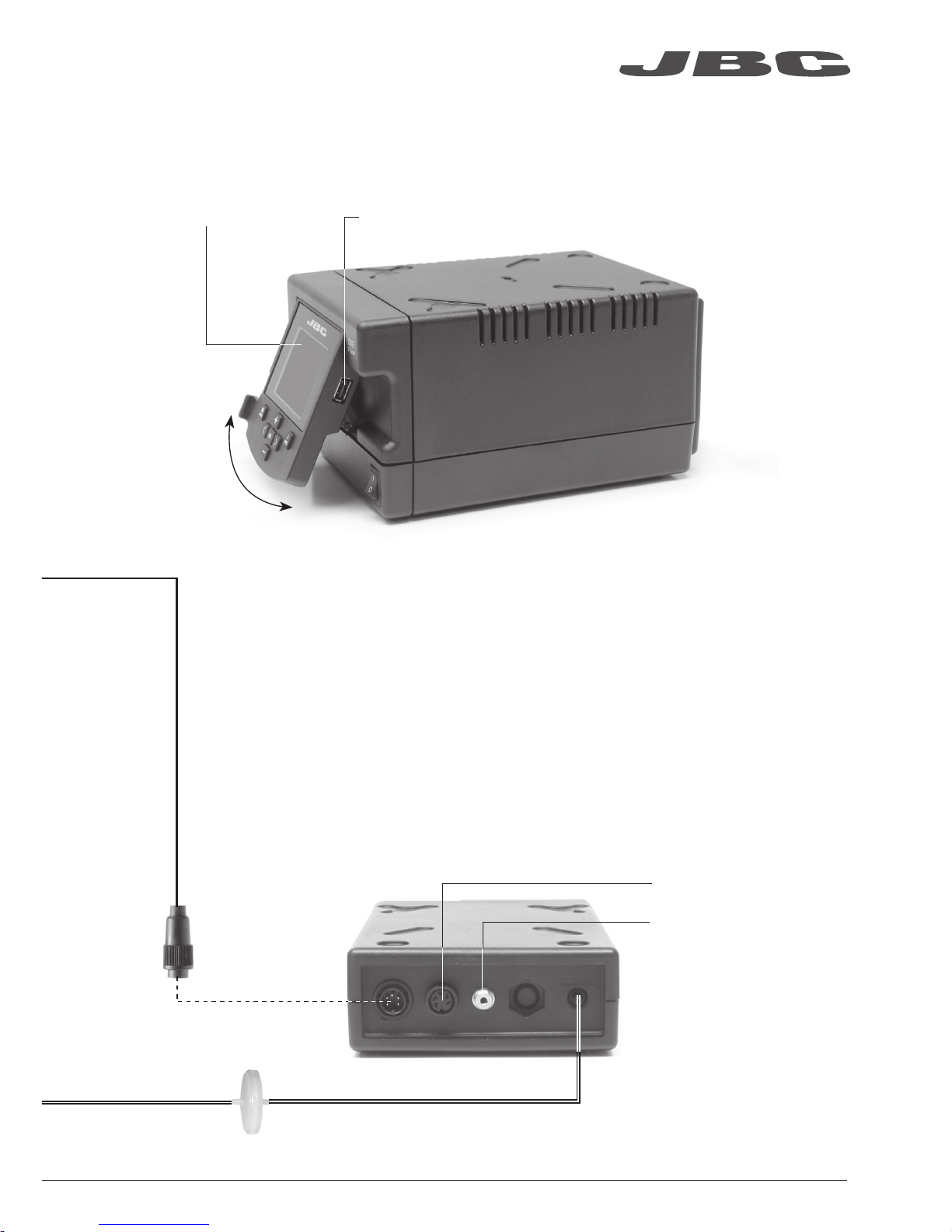

2,8” Color TFT screen

Tilt the display

for easy reading

Electric Desoldering Module

Ref. MSE-A

To another peripheral

To Pedal

Ref. P-005

ww w.j b cto o l s .com

Page 18

Stand

Ref. AD-SD

18

Quick tip changer

Permits switching

cartridges without

interrupting

your work.

Adjustable

tool holder

Suits your

work

position.

Adjustable

cable

collector

Adjustable Stands

Stand

Ref. DR-SD

Quick tip changer

Holding tip system

for easy change.

Cable collector

Keeps working area free of cable.

Page 19

19

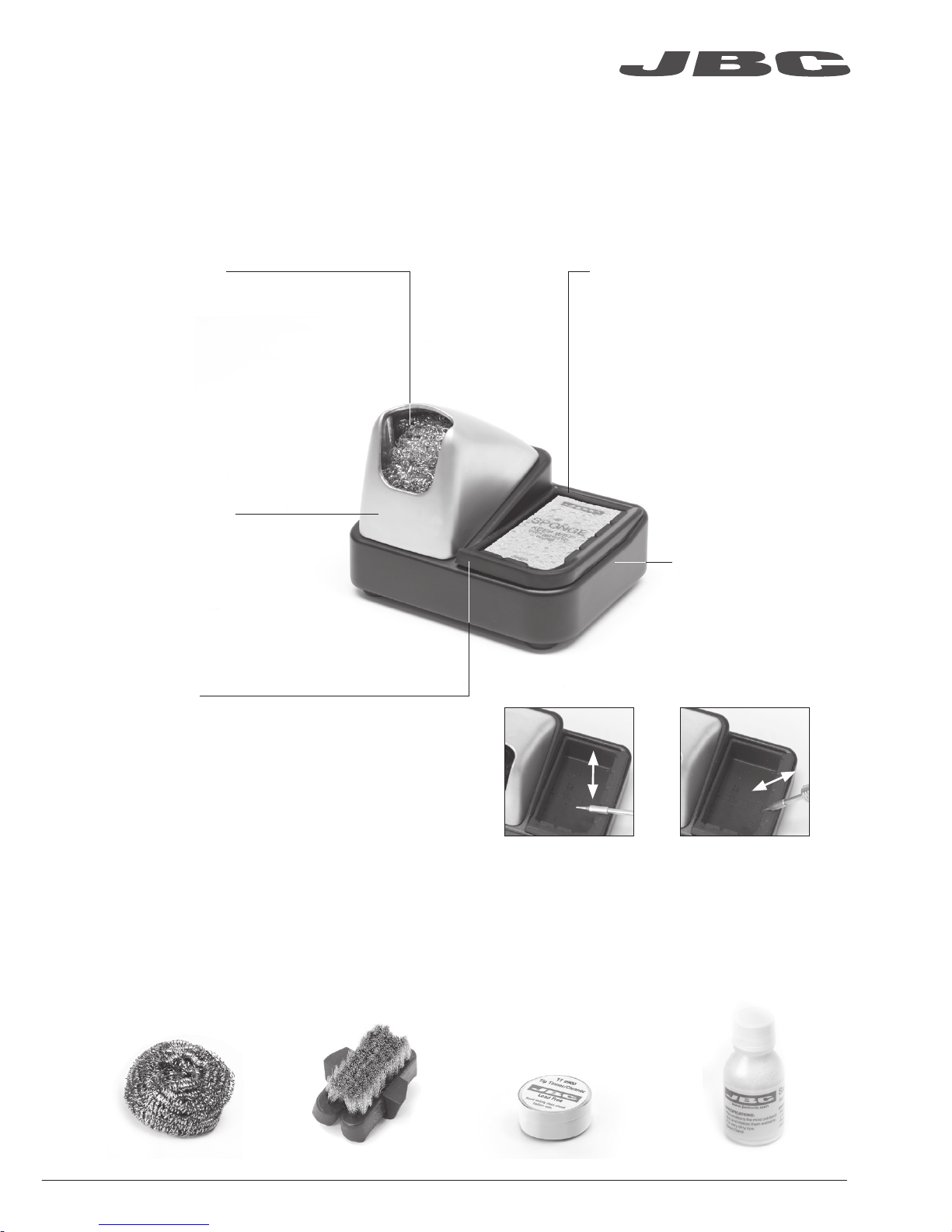

Improve thermal transfer by cleaning the tip after each solder joint.

Tip Cleaner

Optional

Brass wool

Ref. CL6210

Inox wool

Ref. CL6205

Brushes

Ref. CL6220

Tip-tinner

Ref. TT-A

Sand

Ref. CL6211

Splashguard

Non-slip base

Sponge

Ref. S0354

Wiper

Ref. CL0236

Very effective cleaning

method. It leaves a small layer

of solder on the tip to prevent

oxidation between cleaning

and rewetting.

It prevents splashing of

solder particles when

using the brass wool. Heavy weighted non-

slip base for simple-

handed cleaning.

The least harmful cleaning

method. Keep the sponge damp

with distilled water when working

to avoid tip wear.

A temperature resistant receptacle lets

the operator remove excess solder by

gentle tapping or wiping. It can be easily

removed for cleaning.

Tapping: Wiping:

Tap gently to remove

excess solder.

Use the slots to

remove remaining

particles.

ww w.j b cto o l s .com

Page 20

ø 1

ø 3,5

A

B

20

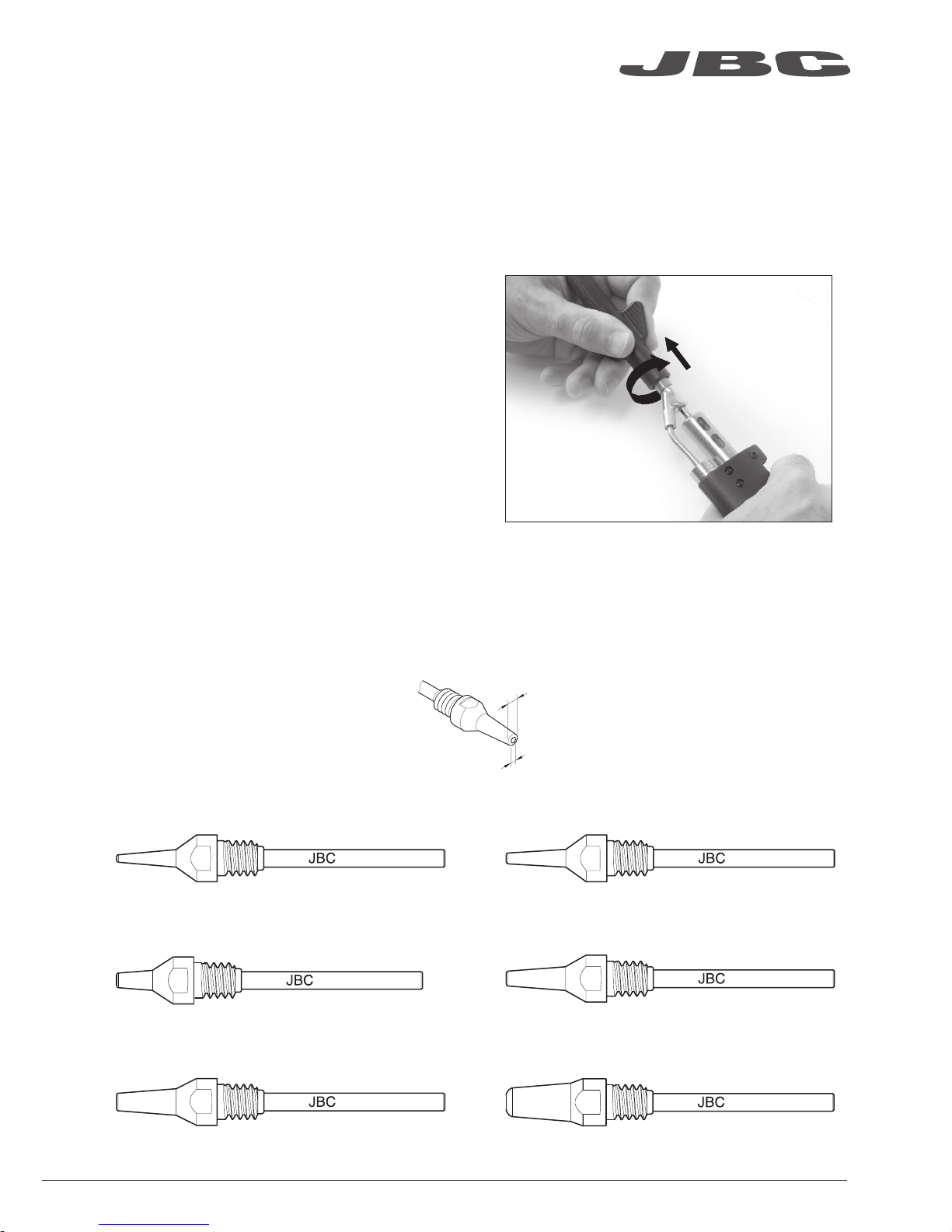

T245 Changing Cartridges

1. Removing 2. Inserting 3. Fixing

Place the handle in the

extractor and pull to

remove the cartridge.

Place the handpiece on top

of the new cartridge and

press down.

Use the holes for fixing the

cartridge* as follows:

A. For straight C210.

B. For curved C210.

C. For curved C245.

D. For straight C245.

*Important

It is essential to insert the cartridges as far as the mark for a proper connection.

B

C

A

D

Compatible cartridges

The T245 handle works with C245 cartridges. Find the model that best suits your soldering needs

in www.jbctools.com

Round Chisel Round bent Bevel Special models

Save time and change cartridges safely without switching the station off.

Mark

Page 21

A ø

B ø

21

DR560 Changing Tips

This operation should be done while the tip is hot, not below 250°C, so that any tin left inside is in

molten state.

250ºC minimum

C560-001

C560-002

C560-003

C560-004

C560-009

C560-014

C560-001 ØA=1,4 ØB=0,6 Ømax. pin=0,4

C560-002 ØA=1,8 ØB=0,8 Ømax. pin=0,6

C560-003 ØA=2,7 ØB=1 Ømax. pin=0,8

C560-004 ØA=3,2 ØB=1,3 Ømax. pin=1,1 C560-009 ØA=5 ØB=1,3 Ømax. pin=1,1

C560-014 ØA=2,5 ØB=0,8 Ømax. pin=0,6

1. Removing

Unscrew the tip using the spanner

supplied.

2. Inserting

Fit the new tip and tighten with the

spanner to make sure it is air tight.

Compatible Tips

The DR560 works with C560 tips. Find the model that best suits your soldering needs in www.jbctools.com

Here are some C560 tips in real size (mm):

ww w.j b cto o l s .com

Page 22

22

DR560 Changing the Heating Element

1. Loosening

The deposit lid needs to be

loosened.

2. Removing

Loosen the screw as shown

and remove the

Heating Element.

3. Placing

Place the new Heating

Element and follow the steps

conversely.

2

1

3

To perform this operation, turn off the station or disconnect the tool.

Important

For a proper connection it is essential to insert the cartridge by lining it up to the mark .

Page 23

23

DR560 Tin Deposit Cleaning

1. Removing the lid

3. Inserting the deposit

Check filter

Lid

Check

internal joint

2. Cleaning

The filter and internal joint must be checked

and replaced if dirty or damaged.

Remove the coil to clean the inside of the

deposit with the stick supplied.

The lid must be removed with the DR560 in

vertical position.

The deposit must be inserted with coil filter in

place, positioned between the 2 lines marked

on the tin deposit.

Then the whole unit must be closed by

screwing the lid.

Marks

ww w.j b cto o l s .com

Page 24

24

Desoldering process

Use a tip with a larger diameter than the pad to achieve maximum aspiration and thermal efficiency.

Place the tip with the

component terminal in the

hole.

After pressing the desoldering key there is a slight delay until the self-contained vacuum pump

stops. This makes sure that the vacuum circuit is completely empty. If any solder remains are left

on a terminal after desoldering it, resolder it with fresh solder and repeat the desoldering operation.

When the solder liquefies,

gently rotate the tip so that

the compo nent terminal can

be lifted off.

Press the vacuum pump

button long enough to remove

the solder.

3. Aspirating1. Placing 2. Rotating

The intake tube should be periodically cleaned by the largest rod.

DR560 Tip Care

Important

DO NOT press the vacuum pump button while tinning the desoldering tip, as the fumes given

off by the flux would quickly block the ducts and the air filter.

Page 25

Peripherals Port 2-DR

17:14

Pedal None

Module None

Module

MSE_a

None

25

MSE Changing the pump filters

- Clean the casing with a damp cloth. Make sure to use a soft cloth when cleaning the front.

- Periodically check all cable and tube connections.

- Keep filters clean to ensure proper solder suction and replace them when necessary.

Spare filters

Ref. 0005966

Cotton filters

Ref. 0781046

Suction filter

Ref. 0821830

O Ring

Ref. 0007717

Filter cover

Ref. 0004710

Important

Do not use sharp

pointed objects

to open the

suction filter.

1. Select the module from the list of

peripheral connections. Remember your first

connection is denoted as “a”, the second

being “b”, etc. (e.g. MSE_a, MSE_b,...)

2. Press Menu or Back to save changes.

Once set up, you can change the module

settings by entering the Peripherals Menu.

MSE Initial Setup

Peripherals

After connecting the electric desoldering module (MSE-A), enter the Peripherals

Menu and select the port which you want to join with the module.

ww w.j b cto o l s .com

Page 26

26

Port

2

T245

17:14

3. Hibernation

Operation

The JBC Exclusive Heating System

Our revolutionary technology is able to recover tip temperature extremely quickly. It means the user

can work at a lower temperature and improve the quality of soldering. The tip temperature is further

reduced thanks to the Sleep and Hibernation modes which increase the tip life by 5.

1. Work 2. Sleep

When the tool is lifted from the

stand the tip will heat up to the

selected temperature.

When the tool is in the stand,

the temperature falls to the

preset Sleep temperature.

After longer periods of

inactivity, the power is cut off

and the tool cools down to

room temperature.

Tools Menu:

· Set Sleep temperature

· Set Sleep delay

(from 0 to 9 min or no Sleep)

· Set Hibernation delay

(from 0 to 60 min or no

hibernation)

Tools Menu: Tools Menu:

Long time in

the stand

· Set temperature limits

· Select temperature levels

350

ºC

Port

2

Power

45%

T245

17:14

Selected 350ºC

Sleep

Tool in the stand

Actual Temp. 180ºC

Delay to hibernation: 29:30

Port

2

T245

17:14

Hibernation

Actual Temp. 25ºC

Page 27

350

ºC

Port

2

Power

45%

Temp. Levels

T245

250 350 380

17:14

27

USB flash drive is connected.

Station is controlled by a PC.

Station is controlled by a robot.

Station software update.

Press INFO to start the process.

Warning.

Press INFO for failure description.

Error. Press INFO for failure description,

the type of error and how to proceed.

System notifications (Status Bar)Menu Options

Station

Information

Power

indicator

Tool

in use

Work Screen

Status bar

The DDE offers an intuitive user interface which provides quick access to station parameters.

Change

port

Displayed if

temperature

levels are

activated

Station Tools Counters

ResetGraphicsPeripherals

Press INFO for each parameter description.

ww w.j b cto o l s .com

Page 28

Port 1 - T245

450

400

350

300

250

150

100

50

200

Power Temp

17:14

28

By pressing Graphics in the main MENU, temperature and power figures in real

time are displayed for each port. This helps you decide which tip to use to obtain

the best quality solder joints.

Process analysis

Export graphics

Insert a USB flash drive into the USB-A

connector to save your soldering process in

csv format.

Graphics

Temperature

Power (%)

See other

port graphic

Page 29

29

Soldering Net

Remotely manage and monitor as many stations as your PC can handle.

Functions:

- Set all the station parameters from your PC.

- Organize groups of stations and set all their parameters at the same time.

- Store specific configurations for later uses.

- Analyze the soldering graphics of the stations on your PC and export them.

1. Download the JBC Manager software and the user manual from www.jbctools.com/manager.html

2. Connect the stations via USB-B connector and the PC will automatically detect them.

3. The notification will be displayed on the station.

any JBC

station

JBC

Manager

software

USB Hub

ww w.j b cto o l s .com

Page 30

30

1. Connect the tool to the station port by means of the CHB-A Converter.

2. Connect your Robot system to the Robot connector (RJ12) of the station.

DB9-RJ12 Adapater available only if necessary (Ref: 0013772).

3. Enable the Robot option in the station settings and the notification will be displayed:

4. Set your Robot’s commands according to the Robot Communication Protocol, available on the

website www.jbctools.com/jbcsoftware-menu-115.html.

Manage and monitor the station using a Robotic system.

Working with Robots

Control

Unit

Robot

Update the station software

1. Download the JBC Update File from

www.jbctools.com/software.html and save

it on a USB flash drive. Preferably one with

no other files.

JBC

Update File

CHB-A

Converter

Ref. CHB-A

2. Insert the USB flash drive to the station.

The icon is diplayed while updating.

RS-232

connection

Page 31

31

Clean periodically

Maintenance

Before carrying out maintenance or storage, always allow the equipment to cool.

- Clean the station screen with a glass cleaner

or a damp cloth.

1. Pull off the fuse holder and remove the

fuse. If necessary use a tool to lever it off.

2. Press the new fuse into the fuse holder

and replace it in the station.

- Use a damp cloth to clean the casing and

the tool. Alcohol can only be used to clean

the metal parts.

- Periodically check that the metal parts of

the tool and stand are clean so that the

station can detect the tool status.

Fuse holder

Fuse holder

- Maintain tip surface clean and tinned prior

to storage in order to avoid tip oxidation.

Rusty and dirty surfaces reduce heat

transfer to the solder joint.

- Periodically check all cables and tubes.

Fuse

- Replace a blown fuse as follows:

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

ww w.j b cto o l s .com

Page 32

32

Safety

- Do not use the units for any purpose other than soldering or rework. Incorrect use may cause fire.

- The power cable must be plugged into approved bases. Make sure that it is properly grounded

before use. When unplugging it, hold the plug, not the wire.

- Do not work on electrically live parts.

- The tool should be placed in the stand when not in use in order to activate the sleep mode.

The soldering tip, the metal part of the tool and the stand may still be hot after the station

is turned off. Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- Do not cover the ventilation grills. Heat can cause inflamable products to ignite.

- Avoid flux coming into contact with skin or eyes to prevent irritation

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight as well as persons with reduced

physical, sensory or mental capabilities or lacking experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance.

- Maintenance must not be carried out by children unless supervised.

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

Page 33

33

Specifications

Complete Rework station with Electric Pump

RMSE-1C / RMSE-2C / RMSE-9C

- Total weight: 16.6 kg (36.6 lb)

- Ambient Operating Temperature: 10 to 40ºC (50-104ºF)

JTE-1D 120V 50/60Hz. Input fuse 8A. Rated current: 6A.

JTE-2D 230V 50/60Hz. Input fuse 4A. Rated current: 3A.

JTE-9D 100V 50/60Hz. Input fuse 8A. Rated current: 7A.

- Weight: 3.9 kg (8.5 lb)

- Dimensions: 148 x 184 x 140

- Nominal Power: 700W

- Temperature selection: Room temperature / 150ºC to 450°C (300ºF to 840ºF)

Cool mode: T Off. Used to blow air at room temperature

- Ambient Operating Temperature: 10 to 40ºC (50-104ºF)

- Air flow regulation: 10-50 SLPM

- Vacuum: 30% / 228 mmHg / 9 inHg

- USB connector station-PC

- P-005 Pedal Connection

DDE-1B 120V 50/60Hz. Input fuse: 4A. Output: 23.5V

DDE-2B 230V 50/60Hz. Input fuse: 2A. Output: 23.5V

DDE-9B 100V 50/60Hz. Input fuse: 5A. Output: 23.5V

- Weight: 4.3 Kg (9.3 lb)

- Dimensions: 148 x 120 x 232 mm

- Output Peak Power: 150W per tool

- Temperature Range: 90-450°C (190-840 ºF)

- Idle Temp. Stability (still air) ±1.5 ºC (±3 ºF)

- Tip to ground resistance: <2 ohms

- Tip to ground voltage: <2mV RMS

- USB-A / USB-B / Peripherals connectors

- RJ12 connector for Robot

MSE-A

- Weight: 1.2 Kg (2.6 lb)

- Dimensions: 145 x 55 x 225 mm

- Vacuum: 75% / 570 mmHg / 22.4 inHg

- Flow rate: 9 SLPM

- P-005 Pedal connection

Complies with CE standards

ESD protected housing “skin effect”

ww w.j b cto o l s .com

Page 34

34

Índice

Composición .................................................... 35

JT Estación de Aire Caliente

Características ................................................39

Soporte ajustable .......................................... 40

Extractor de boquillas ................................. 41

Protectores y extractores ............................ 42

T260 Lápiz posicionador ............................. 43

Funcionamiento y Control del proceso..... 44

JT-TA Reemplazar elemento calefactor.... 47

JT-TA Cambiar el conjunto calefactor........ 47

DDE Unidad de Control y MSE módulo

Características ............................................... 48

Soportes ..........................................................50

Limpiador de Puntas ................................... 51

T245 Cambiar Cartuchos ............................ 52

DR560 Cambiar Puntas ............................... 53

DR560 Cambiar elemento calefactor ...... 54

DR560 Limpiar depósito de estaño ......... 55

DR560 Mantenimiento de las puntas ...... 56

Desoldar con la DDE y el MSE .................. 56

MSE Puesta en marcha ............................... 57

MSE Cambiar los filtros ............................... 57

Funcionamiento ............................................. 58

Pantalla de trabajo ....................................... 59

Análisis del proceso ...................................... 60

Red de Soldadura ......................................... 61

Trabajar con Robots ..................................... 62

Actualizar el Sotware de la estación ........ 62

Mantenimiento ................................................ 63

Seguridad ......................................................... 64

Especificaciones ........................................... 65

Despiece ........................................................... 66

Page 35

35

Stand

Soporte ............... 1 unidad

Ref. AD-SD

Desoldering Iron

Desoldador .................. 1 unidad

Ref. DR560-A

Stand

Soporte .............. 1 unidad

Ref. DR-SD

Heater hose set

Conjunto calefactor ........ 1 ud.

Ref. JT-T1A (100V / 120V)

JT-T2A (230V)

Stand

Soporte ....................... 1 unidad

Ref. JT-SD

JTE Control Unit

Unidad de Control JTE .. 1 ud.

Ref. JTE-1D (120V)

JTE-2D (230V)

JTE-9D (100V)

Electric Desoldering Module

Módulo desoldador

eléctrico ....................... 1 unidad

Ref. MSE-A

DDE Control Unit

Unidad de Control DDE ... 1 ud.

Ref. DDE-1B (120V)

DDE-2B (230V)

DDE-9B (100V)

General Purpose Handle

Mango para aplicaciones

generales ............ 1 unidad

Ref. T245-A

Composición

Los siguientes artículos deberían estar incluidos:

ww w.j b cto o l s .com

Page 36

36

Conjunto de accesorios JT

Ref. 0012332

Cartridges

Cartuchos ............... 2 unidades

Ref. C245903 (x1)

Ref. C245906 (x1)

* Estos accesorios no se suministran con las estaciones JT-2QC / JT-1QC / JT-9QC.

Extractor stand*

Soporte de extractores .... 1ud.

Ref. 0008752

Suction Tube*

Tubo de succión

Ref. 0932330

Suction Cups*

Ventosas

Ref. 0930110

Ø 10 - 0934050 (x3)

Ø 4.7 - 0934070 (x1)

Extractors*

Extractores

Ref. E2184

E2064

E2052

Protectors*

Protectores

Ref. P2220

P2230

P2235

P4000

P4010

Tripod* · Tripode

Ref. T2050 (Ø 39mm)

T2250 (Ø 85mm)

Nozzles

Boquillas

Ref. JN2015 (x1)

JN2012 (x1)

JN2020 (x1)

Tip Cleaner

Limpiador de puntas ....... 1 ud.

Ref. CL9885

Metal Brush

Cepillo metálico ......... 1 unidad

Ref. CL6217

Sponge

Esponja ....................... 1 unidad

Ref. S0354

Page 37

37

Accessorios del DR560

Ref. 0010211

Tip cleaning set

Juego de limpieza de puntas ............... 1 unidad

Ref. 0965970

Long Tip Cleaning set

Juego de limpieza de puntas largo ....... 1 ud.

Ref. 0965760

Tips

Puntas ................. 3 unidades

Ref. C560005 (x1)

Ref. C560013 (x1)

Ref. C560004 (x1)

Tin deposit

Depósito de estaño .........1 ud.

Ref. 0812620

Spanner

Llave ........................... 1 unidad

Ref. 0780550

Filter Box

Caja de filtros ....... 1 unidad

Ref. 0780840

Contiene 10 filtros

Internal gasket

Casquillo junta

interior ................... 2 unidades

Ref. 0812360

Metal tin diposit

Depósito de metal

para estaño ............... 1 unidad

Ref. 0812630

Cotton Filter

Filtros de algodón ... 1 unidad

Ref. 0781046

Contiene 10 filtros

Filter Box

Caja de filtros ............ 1 unidad

Ref. 0005966

Contiene 50 filtros

Suction Filter

Filtro de aspiración ... 1 unidad

Ref. 0821830

ww w.j b cto o l s .com

Page 38

38

Manual ....................... 1 unidad

Ref. 0017357

Cables de red

Para DDE ................... 1 unidad

Ref. 0013671 (100/120V)

0010569 (230V)

Cleaning stick

Bastoncillo de limpieza .. 1 ud.

Ref. 0786640

Pick & Place

Lápiz posicionador ... 1 unidad

Ref. T260-A

Straight Needles Set

Conjunto de

agujas rectas .............. 1 unidad

Ref. 0901546

Bent Needles Set

Conjunto de

agujas dobladas......... 1 unidad

Ref. 0861660

Suction Cup Set

Conjunto de ventosas .... 1 ud.

Ref. 0940163

Premium

Complete Rework Station

with Electric Pump

Ref. RMSE-C

Para JTE ..................... 1 unidad

Ref. 0009417 (100V/120V)

0009401 (230V)

Stand Cable

Cable del soporte ......... 2 uds.

Ref. 0011283

Module Cable

Cable del módulo .... 1 unidad

Ref. 0014874

Union Flanges

Bridas de unión ......... 1 unidad

Ref. 0011356

Contiene 2 bridas

www .jbc tool s.c om

Page 39

JT Características

39

Elemento

calefactor

Suction Tube

Tubo de succión

Ref. 0932330

Heater Hose set

Conjunto calefactor

Ref. JT-T1A (100V - 120V)

JT-T2A (230V)

Para trípodes y

extractores

Activación de

la bomba de

succión

USB-B connector

Actualice el software

de la estación en

www.jbctools.com

Interruptor para

aire caliente

(ON / OFF)Otra herramienta conectable:

Precision Heater hose set

Conjunto calefactor de precisión

Ref: TE-TB

Entrada de red

Fusible

Conexión

equipotencial

Pedal

Ref. P-005

Con el pedal pulsado se

emite aire caliente.

Soporte

Ref. JT-SD

ww w.j b cto o l s .com

Page 40

Pulse Pise

No

pulse

40

1. Desde el menú principal, seleccione el modo de activación de la herramienta en función de la

tarea a desarrollar.

2. La herramienta deja de emitir aire caliente cuando se deja en el soporte.

Soporte + Autostart OFF Soporte + Autostart ON Pedal*

El elemento ajustable del soporte se adapta a su posición de trabajo.

Pulse el interruptor para emitir

aire caliente.

La herramienta se activa

automáticamente cuando se

levanta del soporte.

Use el pedal para el control

del calefactor.

*El pedal P-005 no se incluye

en esta estación.

Consulte nuestra web.

Soporte ajustable

Modos de operación

Page 41

41

Extractor de boquillas

Changing nozzles quickly and safely.

2

1

Boquillas compatibles

El JT-TA funciona con las boquillas JT. Encuentre el modelo que mejor se ajuste a sus necesidades de

trabajo en www.jbctools.com

Para una mejor sujeción de la boquilla:

1. Empuje la lengüeta hacia dentro con la ayuda

de un destornillador o unos alicates planos.

2. Inserte la boquilla en el conjunto calefactor.

Apague la

herramienta

y maneje con

cuidado.

El elemento

calefactor y la

boquilla todavía

están calientes.

Ref. Forma Medida

JN2020 Recta Ø 8mm

JN8417 Recta Ø 10mm

JN2015 Doblada Ø 4mm

JN2012 Doblada Ø 6mm

JN6633 Doblada Ø 8mm

JN7637 Plana 10 x 2mm

JN7638 Plana 20 x 2mm

JN7639 Plana 30 x 2mm

Recta Doblada

Plana

Ø mm Ø mm A x B mm

ww w.j b cto o l s .com

Page 42

42

Para componentes pequeños (fig. 1 y 2) Para componentes grandes (fig. 3 y 4)

Protectores y extractores

Recomendamos usar extractoresRecomendamos usar protector + trípode

1 2 3 4

Protectores

* Ref. AxB (mm) * Ref. AxB (mm)

P3353 4,3 x 3

48

P2230 15 x 15

P3786 5,2 x 5,2

60

P4010 17 x 17

P3352 5,2 x 7,5 P4005 18 x 29

P3355 5,2 x 9,5 P4030 18,5 x 18,5

P3356 6,2 x 4,2 P1068 18,5 x 24

P3785 7,2 x 7,2 P2685 28,5 x 28,5

P3784 8,2 x 8,2 P4085 31,5 x 31,5

P4035 9 x 13 P2672 33 x 46

P4040 9,5 x 19 P4002 50 x 50

P4080 9,5 x 21 P3357 52,5 x 14

32

P2220 10 x 10

P4045 10,5 x 21

P4090 11 x 16

24

P2235 12 x 17

P1249 12 x 23

44

P4000 12,5 x 12,5

P3354 13,2 x 13,2

P4025 13,5 x 21,5

øD

* Referencia del soporte de extractores

Tripodes

* Ref. øC (mm)

T2050 39

T2250 85

Extractor manual

* Ref. øD (mm)

E2190 7

Extractores

* Ref. AxB (mm) * Ref. AxB (mm)

52 E2052 20 X 20 E2124 45 X 45

64 E2064 20 X 26

80 E2184 24 X 24

E2068 27 X 27

E4020 28,5 X 28,5

E4015 31,5 X 31,5

E2084 33 X 33

E2100 38 X 38

Page 43

Elija la ventosa que mejor se adapte al componente (Temp. máxima de trabajo: 250ºC / 482ºF):

43

T260 Lápiz posicionador

Apriete para

iniciar o detener

la succión

Inserte la aguja en la

ventosa apropiada

para una succión

correcta.

Evite que la aguja

sobresalga de la parte

inferior de la ventosa.

Esta herramienta permite colocar y retirar SMDs fácilmente gracias al sistema de succión de la unidad.

1. Succionar

Funcionamiento

2. Soltar

Una vez activado el

botón de succión,

cubra el agujero del

lápiz con el dedo

hasta y recoja el

componente.

Levante el dedo del

agujero para soltar

el componente en el

sitio adecuado.

Pick & Place

Lápiz posicionador

Ref. T260-A

ww w.j b cto o l s .com

Page 44

Tem p ºC

Air %

Time to stop 45 seconds

Power 70%

400

85

400ºC Select

44

Funcionamiento de la JT

Control del proceso

3. Soltar1. Colocar 2. Calentar

Posicione la ventosa y

apriete el botón de succión.

Proyecte aire caliente con el

conjunto calefactor.

El componente se levantará

automáticamente cuando el

estaño se derrita.

Confirme la selección

Para acceder al Menú (apriete 2 segundos)

Temperatura seleccionada

Temperatura actual

% potencia

Puede intercambiar los modos (manual / programa) apretando las teclas “aumentar” o “disminuir”

simultáneamente durante 2 segundos (sólo si el modo programa está activo).

Modo manual

Page 45

Tem p ºC

º

C

Pro gr am 8

380

Air 100%

Time 125s.

45

Disminuir número de

programa

Aumentar número de

programa

Programa seleccionado

Temperatura actual

Caudal seleccionado

Gráfico del programa

seleccionado

Tiempo restante

Modo programa

Opciones de Programa

Edit Program

Esta opción le permite crear o editar un programa. Seleccione un número de programa a editar y

modifique los puntos en función de sus necesidades de trabajo. Cada programa se compone de 9

puntos y cada punto consiste en 3 parámetros:

1. Tiempo (segundos)

2. Temperatura (°C / °F)

3. Caudal de Aire (%)

Puede borrar el último punto del programa seleccionando “-----” en el parámetro Tiempo.

Tenga en cuenta que el rango de temperatura permitido por la estación es 150- 450°C, por lo que

no es posible crear rampas de temperatura entre la temperatura ambiente y los 150°C.

La estación puede almacenar hasta 25 programas de temperatura. Los primeros 3 programas

que muestra la estación han sido editados por JBC a modo de ejemplo.

Copy Program

Esta opción le permite copiar un programa. Seleccione la opción “program source” e indique

el programa que quiere copiar. A continuación seleccione “program destination” e indique el

programa donde será copiado. En el momento de salir (Exit) podrá salvar los cambios.

Delete Program

Esta opción le permite borrar un programa previamente seleccionado.

ww w.j b cto o l s .com

Page 46

Mai n me nu

1 Reset settings

2 Station

Settings

3

Program Settings

4

Counters

5 Program version

Exi t

Set ti ng s Pro gr am S et ti ng s

Edi t Pr og ra m

Edi t Pr og ra m 8

1

Temp unit Celsius

2 Maximum

temp 4500C

3 Minimum temp T OFF*

4 Fix temp 4000C

5 Temp Adjust 00C

6 Max air 100%

7 Min air 10%

8 Fix air 40%

9 Time to stop 120 sec

10 Beep ON

11 Pop up ON

12 Change PIN

1 Programs

2 Edit program

3

Copy program

4

Delete program

Bac k

Sel ec t

Pro gr am

Ste p 4

Tim e 20

Tem p 45 0

Air 10 0

º

C

º

C

8

Exi t

Cou nt er s

1 Station ON hours

0

2

Works hours 0

3 Works

cycles 0

Bac k

46

* Seleccionando “T OFF” en la

Mínima temperatura permite la

emisión de aire ambiente.

Pantallas de Menú

PIN original: 0105

Page 47

47

Heating Hose Set

Conjunto calefactor

Ref. JT-T1A (100V / 120V)

JT-T2A (230V)

Heating Element

Elemento calefactor

Ref. 0014107 (230V)

0014105 (100V / 120V)

Asegúrese que el elemento calefactor está frío y la unidad de control desconectada de la red.

1. Afloje el tornillo.

2. Tire del elemento calefactor y sáquelo del mango.

3. Conecte el nuevo elemento calefactor hasta que encaje lo más adentro posible.

4. Atornille de nuevo.

JT-TA Reemplazar el elemento calefactor

JT Handle

Manguera JT-A

Ref. JT-A

1. Apague la herramienta.

2. Desenrosque la tuerca de conexión con la ayuda de

una llave inglesa.

3. Encaje el extremo del nuevo conjunto calefactor en

la unidad de control.

4. Siga los mismos pasos al revés.

JT-TA Cambiar el conjunto calefactor

ww w.j b cto o l s .com

Page 48

48

Características DDE y MSE

Trabaje simultáneamente con 2 herramientas y enlace cada puerto con 1 módulo + 1 pedal (Peripherals).

Stand

Soporte

Ref. AD-SD

Conector RJ12 para Robot

Conector USB-B

Conexión equipotencial

Toma de correinte

Desoldering Iron

Desoldador

Ref. DR560-A

Cartridge

Cartucho

Ref. C245903

Ref. C245906

Tip

Punta

Ref. C560004

Ref. C560005

Ref. C560013

Stand

Soporte

Ref. DR-SD

Stand Cable

Cable del soporte

Ref. 0011283

General Purpose

Handle

Mango para

aplicaciones generales

Ref. T245-A

Page 49

Electric Desoldering Module

Módulo desoldador eléctrico

Ref. MSE-A

49

A otro

periférico

Al Pedal

Ref. P-005

Conector USB-A

Pantalla color TFT de 2,8”

Incline la pantalla

para una mejor

lectura

Suction Filter

Filtro de succión

Ref. 0821830

Module Cable

Cable del módulo

Ref. 0014874

ww w.j b cto o l s .com

Page 50

50

Cambio rápido

de cartuchos

Cambie cartuchos

sin interrumpir

su trabajo

Soporte de

herramienta

ajustable

Se adapta a

su posición

de trabajo.

Recogecable

ajustable

Soportes ajustables

Stand

Soporte

Ref. DR-SD

Cambio rápido

de puntas

El sistema de

sujeción de puntas

facilita el cambio.

Recogecable

Mantiene el área de trabajo ordenada sin cable

Stand

Soporte

Ref. AD-SD

Page 51

51

Se puede quitar

fácilmente para

su limpieza.

Mejore la transferencia térmica de la punta limpiándola después de cada soldadura.

Limpiador de Puntas

Brass wool

Lana de latón

Ref. CL6210

Protección

anti-salpicaduras Limpiador

Ref. CL0236

Método de limpieza

muy efectivo. Deja una

fina capa de soldadura

en la punta para

prevenir la oxidación

entre la limpieza y la

rehumectación.

Previene las

salpicaduras de

partículas de soldadura.

Para esponja: Para cepillos: Golpeteo: Limpieza: Mantenimiento

Golpe suave

para retirar restos

de soldadura.

Ranuras para

retirar partículas

adheridas.

Base

antideslizante

Sponge

Esponja

Ref. S0354

No es necesario sujetar

la base.

El método de limpieza

más eficaz y menos

dañino. Mantenga la

esponja húmeda con agua

destilada, así evitará el

desgaste de la punta.

Receptáculo resistente a la temperatura para eliminar

el exceso de soldadura golpeteando y limpiando.

Opcional

Inox wool

Lana inoxidable

Ref. CL6205

Brushes

Cepillos de metal

Ref. CL6220

Tip-tinner

Reestañador de puntas

Ref. TT-A

Sand · Arena

Ref. CL6211

ww w.j b cto o l s .com

Page 52

ø 1

ø 3,5

A

B

52

B

C

A

D

Cambiar cartuchos del T245

1. Retirar 2. Insertar 3. Fijar

Coloque el soldador en el

extractor y tire para retirar

el cartucho.

Coloque el mango soldador

en la parte superior del

nuevo cartucho y presione

ligeramente.

Fije el cartucho* utilizando

los agujeros:

A. Para los C210 rectos.

B. Para los C210 curvados.

C. Para los C245 curvados.

D. Para los C245 rectos.

*Importante

Es necesario insertar el cartucho hasta la marca para una conexión correcta.

Marca

Cartuchos compatibles

El mango para soldador T245 funciona con cartuchos C245. Encuentre el modelo que mejor se

adapte a sus necesidades de soldadura en www.jbctools.com

Redondo Cincel

Redondo

curvado

Bisel

Modelos

especiales

Ahorre tiempo cambiando los cartuchos de forma rápida y segura sin apagar la estación.

Page 53

A ø

B ø

53

C560-001

C560-002

C560-003

C560-004

C560-009

C560-014

Cambiar puntas del DR560

Esta operación debe realizarse con la punta caliente (por encima de los 250°C) para que el estaño

de su interior se mantenga fundido.

250ºC mínimo

C560-001 ØA=1,4 ØB=0,6 Ømax. pin=0,4

C560-002 ØA=1,8 ØB=0,8 Ømax. pin=0,6

C560-003 ØA=2,7 ØB=1 Ømax. pin=0,8

C560-004 ØA=3,2 ØB=1,3 Ømax. pin=1,1 C560-009 ØA=5 ØB=1,3 Ømax. pin=1,1

C560-014 ØA=2,5 ØB=0,8 Ømax. pin=0,6

1. Retirar

Desenrosque la punta utilizando la llave

suministrada.

2. Insertar

Coloque la punta nueva y enrósquela

con la llave para asegurarse que queda

hermético.

Puntas compatibles

El DR560 funciona con puntas C560.

Encuentre el modelo que mejor se adapte a sus necesidades de desoldadura en www.jbctools.com

Algunas de las puntas

C560 en tamaño real

(mm):

ww w.j b cto o l s .com

Page 54

54

DR560 Cambiar el elemento calefactor

1. Desenroscar

Desenrosque la tapa del

depósito.

2. Retirar

Afloje el tornillo y retire el

elemento calefactor.

3. Colocar

Coloque el nuevo elemento

calefactor hasta la marca* y

siga los mismos pasos a la

inversa.

2

1

3

Para realizar esta operación apague la estación o desconecte la herramienta.

*Importante

Para una conexión apropiada es necesario insertar el cartucho alineándolo con la marca .

Page 55

55

DR560 Limpieza del depósito de estaño

1. Retirar la tapa

3. Insertar el depósito

Compruebe

el filtro

Tapa

Compruebe la

junta interna

2. Limpiar

El filtro y la junta interna deben supervisarse

para reemplazarlos si fuera necesario, ya sea

por exceso de suciedad o por algún daño.

Retire el espiral para limpiar el interior del

depósito con la baqueta suministrada.

La tapa se debe retirar con el desoldador en

posición vertical.

El depósito se debe insertar con el espiral ya

colocado entre las dos marcas.

Concluya el proceso cerrando el depósito

con la tapa.

Marcas

ww w.j b cto o l s .com

Page 56

56

Proceso de desoldadura

La punta elegida debe tener un diámetro más grande que el pad para conseguir la máxima aspiración

posible y el mejor rendimiento térmico.

Coloque la punta en el

terminal del through-hole

tal y como se muestra.

Tras pulsar el botón del desoldador hay un ligero retraso hasta que la bomba de succión se

detiene. Esto asegura que el conducto de succión está completamente vacío.

Si se quedaran restos de soldadura en algun terminal después de desoldarlo, vuelva a soldarlo

con estaño nuevo y repita el proceso de desoldadura.

Cuando la soldadura se liqüe,

gire la punta con suavidad

para que el terminal del

componente se suelte.

Pulse el botón de la bomba

de succión hasta retirar

por completo los restos de

soldadura.

3. Aspirar1. Colocar 2. Rotar

El conducto de entrada se debe limpiar periódicamente con la baqueta más grande posible.

Mantenimiento de puntas del DR560

Importante

NO pulse el botón de la bomba de succión mientras estaña la punta, ya que los humos produ-

cidos por el flujo bloquearían rápidamente los conductos y el filtro de aire.

Page 57

Peripherals Port 2-DR

17:14

Pedal None

Module None

Module

MSE_a

None

57

Cambiar los filtros de la bomba MSE

Filtros

Ref. 0005966

Cotton filters

Filtros de algodón

Ref. 0781046

Suction filter

Filtro de aspiración

Ref. 0821830

Anillo

Ref. 0007717

Tapa de filtros

Ref. 0004710

- Limpie la carcasa con un paño húmedo. Asegúrese que utiliza un paño suave para el frontal.

- Revise periódicamente los cables y tubos.

- Mantenga los filtros limpios para garantizar una correcta aspiración y reemplácelos si fuera necesario.

1. Seleccione el módulo del listado de

conexiones periféricas. Recuerde que su

primera conexión se indica como “a”, la

segunda como “b”, etc. (MSE_a, MSE_b,...)

2. Pulse Menu o Back para guardar los

cambios. Una vez configurado podrá

modificar cambios desde el menú Peripherals.

Puesta en marcha de la bomba MSE

Peripherals

Tras conectar el módulo desoldador eléctrico (MSE-A), entre en el menú de

Peripherals y seleccione el puerto con el que desee enlazar el módulo.

ww w.j b cto o l s .com

Page 58

58

Port

2

T245

17:14

350

ºC

Port

2

Power

45%

T245

17:14

Selected 350ºC

Sleep

Tool in the stand

Actual Temp. 180ºC

Delay to hibernation: 29:30

Port

2

T245

17:14

Hibernation

Actual Temp. 25ºC

3. Hibernación

Funcionamiento

El exclusivo sistema calefactor de JBC

Nuestra tecnología revolucionaria es capaz de recuperar la temperatura de la punta de forma

extremadamente rápida. Esto significa que el usuario puede trabajar a una temperatura más baja

y mejorar la calidad de la soldadura. Esta temperatura se reduce aún más gracias a los modos de

Sleep e Hibernation que incrementan hasta 5 veces la vida de las puntas.

1. Trabajo 2. Sleep

Al levantar la herramienta

del soporte, la punta se

calienta hasta la temperatura

seleccionada.

Si la herramienta permenece

en el soporte, la temperatura

se reduce a la temperatura

predefinida.

Tras largos períodos de

inactividad (predefinido a

30min), se corta el suministro

de energía y la punta se enfría

hasta temperatura ambiente.

Menú Tools:

· Configure la temperatura

de Sleep

· Configure el tiempo de

retraso de Sleep

(de 0 a 9 min o ninguno)

· Configure el retraso de

Hibernación

(de 0 a 60 min o ninguno)

Menú Tools: Menú Tools:

Períodos

largos en el

soporte

· Configure límites de

temperatura.

· Seleccione niveles de

temperatura.

Page 59

350

ºC

Port

2

Power

45%

Temp. Levels

T245

250 350 380

17:14

59

Station Tools Counters

ResetGraphicsPeripherals

Unidad de memoria USB conectada.

Estación controlada por un PC.

Estación controlada por un robot.

Actualización del software de la estación.

Pulse INFO para iniciar el proceso.

Aviso.

Pulse INFO para la descripción del fallo.

Error. Pulse INFO para la descripción del

fallo, el tipo de error y cómo proceder.

Notificaciones (Barra de estado)

Ayuda de la

estación

Indicador de

potencia

Herramienta

en uso

Pantalla de trabajo

Barra de

estado

La DDE-B presenta una interfaz de usuario intuitiva y ofrece un rápido acceso a los parámetros.

Cambio de

puerto

Se muestra si

los niveles de

temperatura

están activos

Pulse INFO para la descripción de parámetros.

Opciones de Menú

ww w.j b cto o l s .com

Page 60

Port 1 - T245

450

400

350

300

250

150

100

50

200

Power Temp

17:14

60

Graphics

Pulsando sobre Graphics en el menú principal, se muestran las respuestas de

temperatura y potencia en tiempo real de cada puerto. Esto le ayudará a decidir

cuál es la punta más adecuada para obtener la mejor calidad en sus soldaduras.

Análisis del proceso

Exporte gráficos

Inserte una unidad de memoria USB para

guardar su proceso de trabajo en formato csv.

Temperatura

Potencia (%)

Vea el gráfico

del otro puerto

Page 61

61

Red de soldadura

Gestione y monitorice tantas estaciones como soporte su PC.

Funciones:

- Configure todos los parámetros de la estación desde su PC.

- Organice grupos de estaciones y configure todos sus parámetros al mismo tiempo.

- Guarde configuraciones específicas para usos posteriores.

- Analice gráficos del proceso de soldadura de las estaciones desde su PC y expórtelos.

cualquier

estación

JBC

JBC

Manager

software

USB Hub

1. Descargue el software JBC Manager y el manual de usuario de www.jbctools.com/manager.html

2. Conecte las estaciones a través del conector USB-B y el PC las detectará automáticamente.

3. La notificación se mostrará en la estación.

ww w.j b cto o l s .com

Page 62

62

1. Conecte la herramienta a la estación utilizando el convertidor CHB-A (Ref: CHB-A).

2. Conecte su sistema robotizado al conector Robot de la estación (RJ12).

Si lo necesita, el adaptador DB9-RJ12 está disponible (Ref: 0013772).

3. Active la opción de robot en la estación y se mostrará la siguiente notificación:

4. Configure su sistema robotizado según el Protocolo de Comunicación para Robots,

que encontrará en www.jbctools.com/jbcsoftware-menu-115.html.

Gestione y monitorice la estación por medio de un sistema robotizado.

Trabajar con Robots

Unidad

de Control

Robot

Actualice el software de la estación

1. Descargue el archivo de actualización de

www.jbctools. com/software.html

cuando esté disponible y guárdelo en una

unidad de memoria USB (preferentemente

una sin otros archivos).

JBC

Update File

Convertidor

CHB-A

Ref. CHB-A

Conexión

RS-232

2. Inserte la unidad de memoria USB.

La notificación se muestra mientras

se actualiza el software.

Page 63

63

Mantenga limpio

Mantenimiento

Antes de realizar tareas de mantenimiento o almacenar, desconecte el equipo y déjelo enfriar.

1. Tire del portafusible para retirar el fusible.

Si lo precisa, utilice una pequeña palanca.

2. Sustituya el fusible y coloque de nuevo el

portafusibles en su sitio.

- Use un paño húmedo para limpiar la

pantalla del equipo, la carcasa y la

herramienta. Puede utilizar alcohol

solamente en las partes metálicas.

- Compruebe periódicamente que las partes

metálicas de la herramienta y del soporte

están limpias. Así la estación puede

detectar el estado de la herramienta y

activar los modos de Sleep o Hibernation.

Portafusible

Portafusible

- Mantenga la punta limpia y estañada la

para evitar su oxidación. Las superfícies

sucias reducen la transferencia térmica a la

soldadura.

- Revise periódicamente los tubos y cables.

Fusible

- Cambie el fusible fundido de la siguiente manera:

- Cambie cualquier pieza defectuosa o dañada. Utilice solamente recambios originales de JBC.

- Cualquier reparación sólo se podrá realizar por un servicio técnico oficial JBC.

ww w.j b cto o l s .com

Page 64

64

Seguridad

- No utilice el equipo para otros fines que no sea la soldadura o reparación. El uso incorrecto

puede causar fuego.

- El cable de red debe enchufarse en bases homologadas. Asegúrese de que está conectado a

tierra correctamente antes de su uso. Al retirarlo, tire del conector, no del cable.

- No trabaje con tensión.

- La herramienta debe permanecer en el soporte mientras no está en uso con el fin de activar el modo

de Sleep o Hibernación. El cartucho y las partes metálicas de la herramienta o del soporte pueden

estar calientes incluso cuando con la estación apagada. Manipule con cuidado, incluso cuando se

ajusta la posición del soporte.

- No deje el aparato desatendido cuando está en funcionamiento.

- No cubra las rejillas de ventilación. El calor puede causar que los productos inflamables se enciendan.

- Evite el contacto del Flux con la piel o los ojos para prevenir la irritación.

- Tenga cuidado con el humo producido al trabajar.

- Mantenga su lugar de trabajo limpio y ordenado. Use gafas y guantes de protección adecuados.

Así evitará cualquier daño.

- Tenga cuidado con los restos de estaño líquido. En contacto con la piel, puede causar quemaduras.

- Este aparato puede ser utilizado por personas a partir de 8 años y también por aquellas

personas con movilidad reducida o capacidades físicas, sensoriales o mentales limitadas o

con falta de experiencia y conocimientos siempre y cuando reciban supervisión o instrucciones

relativas al uso del aparato de una manera segura y entiendan los riesgos que implica. Los niños

no deben jugar con el aparato.

- Los niños no deberán realizar tareas de mantenimiento sin supervisión.

Es necesario cumplir estas normas de seguridad para prevenir cualquier

choque eléctrico, heridas, fuego o explosiones.

Page 65

65

Complete Rework station with Electric Pump

Estación completa de reparación con bomba eléctrica

RMSE-1C / RMSE-2C / RMSE-9C

- Peso total: 16.6 kg (36.6 lb)

- Temperatura de trabajo ambiente: 10-40ºC (50-104ºF)

JTE-1D 120V 50/60Hz. Fusible de entrada: 8A

JTE-2D 230V 50/60Hz. Fusible de entrada: 4A

JTE-9D 100V 50/60Hz. Fusible de entrada: 8A

- Peso: 5.7 kg (12.6 lb)

- Dimensiones: 148 x 184 x 140

- Potencia nominal: 700W

- Rango de temperatura: Temp. ambiente / 150-450°C (300-840ºF)

Modo frío: T Off. Utilizado para emitir aire en temperatura ambiente.

- Regulación del caudal de aire: 10-50 SLPM

- Vacío: 30% / 228 mmHg / 9 inHg

- Conexión USB estación-PC

- Conector para pedal P-005

DDE-1B 120V 50/60Hz. Fusible de entrada: 4A. Salida: 23.5V

DDE-2B 230V 50/60Hz. Fusible de entrada: 2A. Salida: 23.5V

DDE-9B 100V 50/60Hz. Fusible de entrada: 5A. Salida: 23.5V

- Peso: 4.3 Kg (9.3 lb)

- Dimensiones: 148 x 120 x 232 mm

- Potencia máxima de pico: 150W por herramienta

- Rango de temperatura: 90-450°C (190-840 ºF)

- Estabilidad de temperatura en reposo: ±1.5 ºC (±3 ºF)

- Resistencia punta a tierra: <2 ohms

- Tensión en punta: <2mV RMS

- Conectores USB-A / USB-B / Peripherals (periféricos)

- Conector RJ12 para Robot

MSE-A

- Peso: 0.9 Kg (1.9 lb)

- Dimensiones: 145 x 55 x 225 mm

- Vacío a 6 Bar: 75% / 570 mmHg / 22.4 inHg

- Caudal de aire: 9 SLPM

- Conector para pedal P-005

Cumple con las normativas CE

Seguridad ESD

Especificaciones

ww w.j b cto o l s .com

Page 66

66

Exploded View · Despiece

Page 67

67

ww w.j b cto o l s .com

Page 68

0017357-1216

Warranty

JBC’s 2 year warranty covers

this equipment against all

manufacturing defects, including

the replacement of defective parts

and labour.

Warranty does not cover product

wear or misuse.

In order for the warranty to be

valid, equipment must be returned,

postage paid, to the dealer where

it was purchased.

This product should not be thrown in the garbage.

In accordance with the European directive 2012/19/EU, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Garantía

Esta garantía de 2 años cubre este

equipo contra cualquier defecto

de fabricación, incluyendo la

sustitución de partes defectuosas

y mano de obra.

La garantía no cubre el desgaste

del producto por uso o mal uso.

Para que esta garantía sea válida,

el equipo debe ser devuelto, a

portes pagados, al distribuidor

donde se compró.

Este producto no debe desecharse en la basura.

De acuerdo a la directiva europea 2012/19/UE, los equipos electrónicos al final de su vida se deberán

recoger y trasladar a una planta de reciclaje autorizada.

www.jbctools.com

Loading...

Loading...