Page 1

www.jbctools.com

INSTRUCTION MANUAL

Complete Rework Station

with Electric Pump

Ref. RMSE-QE

Page 2

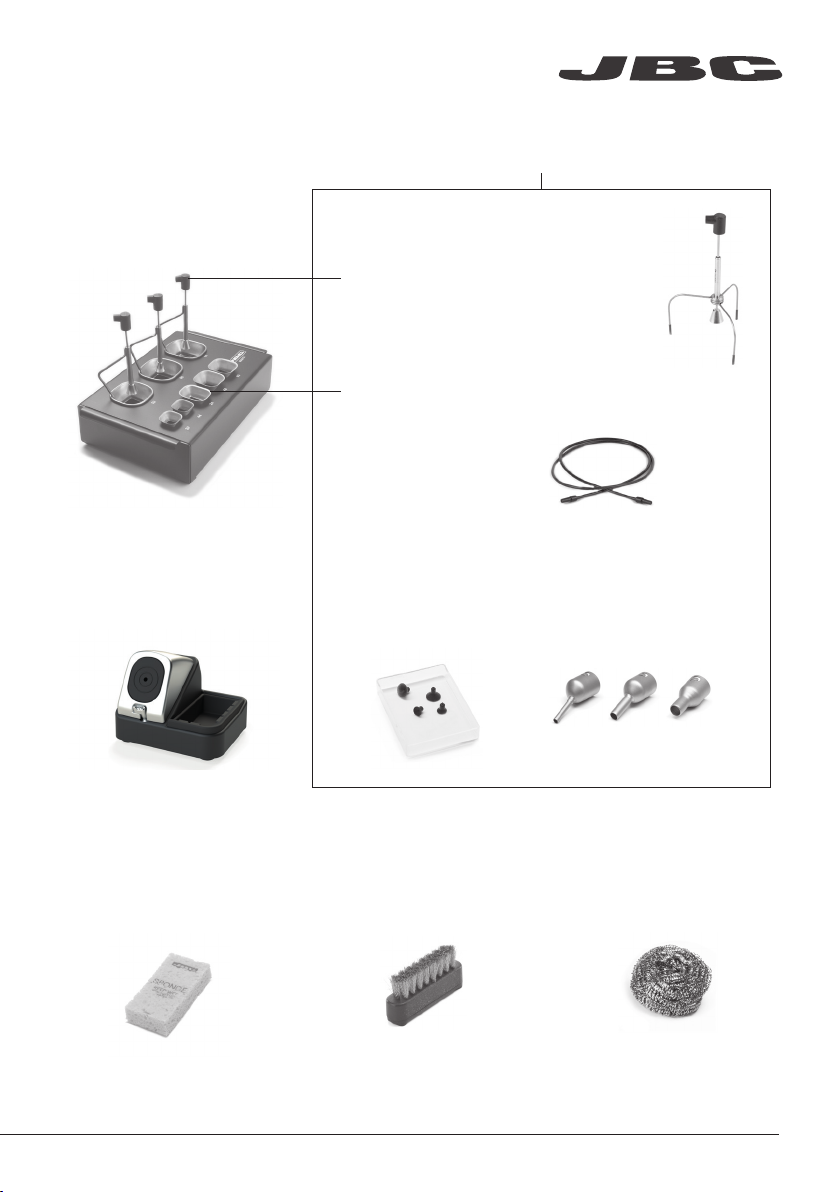

Packing List

The following items are included:

JTSE Control

Unit ....................................1 unit

Ref. JTSE-1A (100V - 120V)

JTSE-2A (230V )

Stand ................................ 1 unit

Re f. J T- SE

DDE Control Unit .......... 1 unit

Ref. DDE-1C (120V)

DDE-2C (230V)

DDE-9C (100V)

Stand ................................ 1 unit

Ref. AD-SE

Electric Desoldering

Module ............................. 1 unit

Ref. MSE-A

Stand ............................... 1 unit

Ref. DR-SE

Heater hose set ............ 1 unit

Ref. JT-T1A (100V / 120V)

JT-T2A (230V )

2

General Purpose

Handle .............................. 1 unit

Ref. T245-A

Desoldering Iron ........... 1 unit

Ref. DR560-A

C560003 already inserted

Page 3

JT Accessory set

Re f. 0 012 332

www.jbctools.com

Extractor stand ............. 1 unit

Ref. 0008752

ESD Tip Cleaner ........... 1 unit

Ref. CL8499

Extractors

Ref. E2184

E2064

E2052

Protectors

Ref. P2220

P2230

P2235

P4000

P4010

Suction Cups

Re f. 093 0110

Ø 10 - 0934050 (x3)

Ø 4.7 - 0934070 (x1)

Trip od

Ref. T2050

(Ø 39mm)

T2250

(Ø 85mm)

Suction Tube

Ref. 0932330

Nozzles

Ref. JN2015 (x1)

JN2012 (x1)

JN2020 (x1)

Sponge ............................ 1 unit

Ref. S0354

Metal Brush ................... 1 unit

Ref . CL6 217

Sponge ............................ 1 unit

Ref. C L6 210

3

Page 4

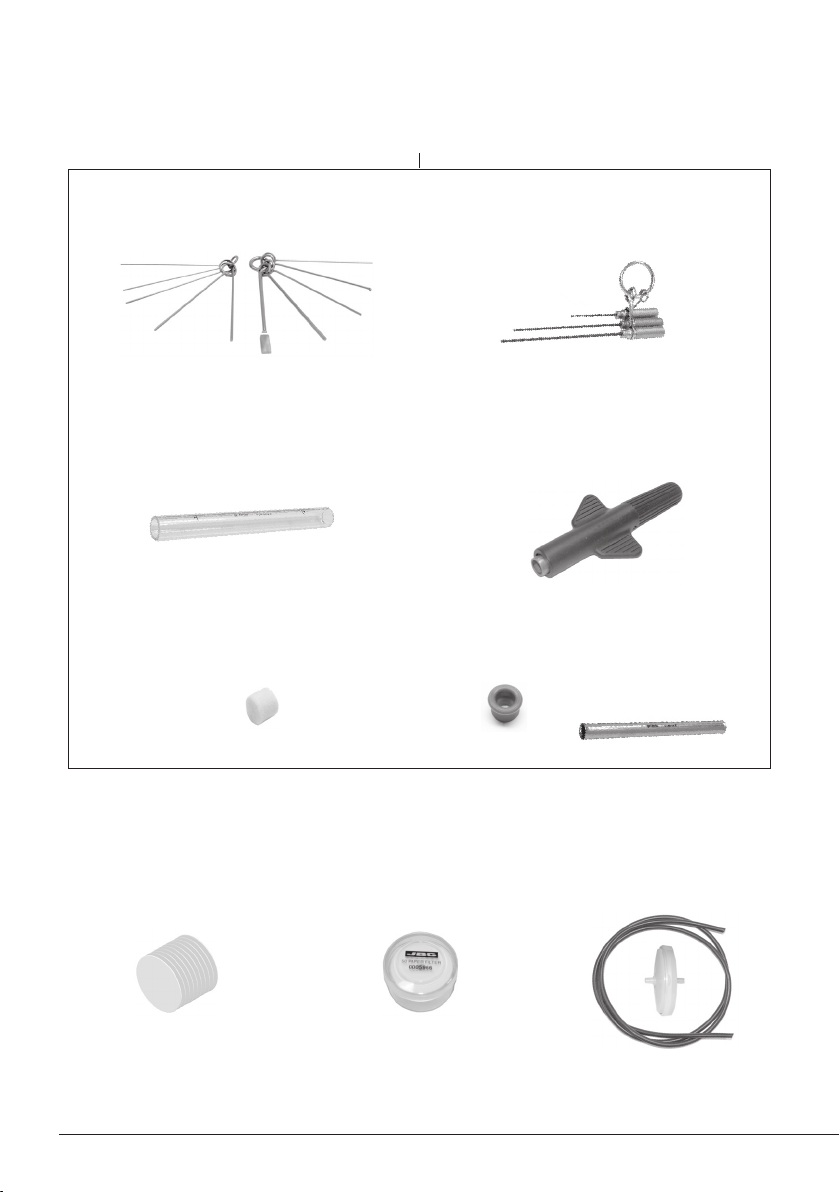

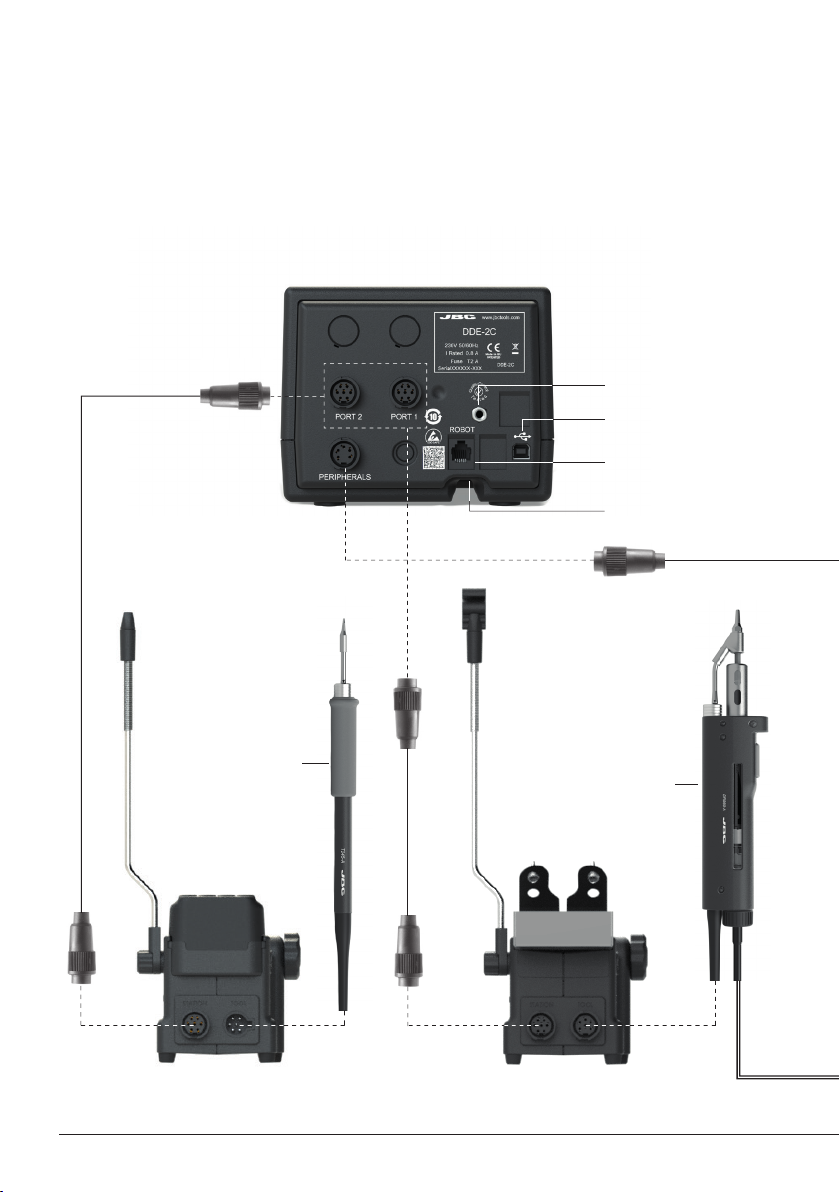

DR560 Accessories

Ref. 002 2819

Tip cleaning set ................................. 1 unit

Ref. 0965970

Glass solder collector ..................... 1 unit

Re f. 0 81262 0

Filter Box ................. 1 unit

Ref. 0780840

It contains 10 filters

Internal gasket .............. 1 unit

Ref. 0019208

It contains 2 gaskets

Long Tip Cleaning set ..................... 1 unit

Ref. 0965760

Spanner ............................................. 1 unit

Ref. 0780550

Metal solder

collector ................... 1 unit

Ref. 0812630

Cotton Filter ................... 1 unit

Ref. 0781046

It contains 10 filters

4

Filter Box .......................... 1 unit

Ref. 0005966

It contains 50 filters

Suction Filter .................. 1 unit

Re f. 08 21830

Page 5

www.jbctools.com

Pick & Place ................... 1 unit

Ref. T260-A

Thermocouple

Typ e K .............................. 1 unit

Ref. PH218

Stand Cable ................. 2 units

Re f. 001128 3

Bent Needles Set ......... 1 unit

Ref. 0861660

Cups Set ......................... 1 unit

Ref. 0940163

Module Cable ................ 1 unit

Ref. 0 014 874

Straight Needles Set ... 1 unit

Re f. 090154 6

Cleaning stick ................ 1 unit

Ref. 0786640

Power cord

For DDE ........................... 1 unit

Ref. 0013671 (100/120V )

0010569 (230V)

Power cord

For JTSE ................. 1 unit

Ref. 0009417 (100V/120V)

0009401 (230V)

Union

Flanges ..... 1 unit

Re f. 00113 5 6

Cartridge

holder .............. 1 unit

Ref. SCH-A

Manual .................1 unit

Ref. 002 314 0

www.jbctools.com

INSTRUCTION MANUAL

Complete Rework Station

with Electric Pump

Ref. RMSE-QE

5

Page 6

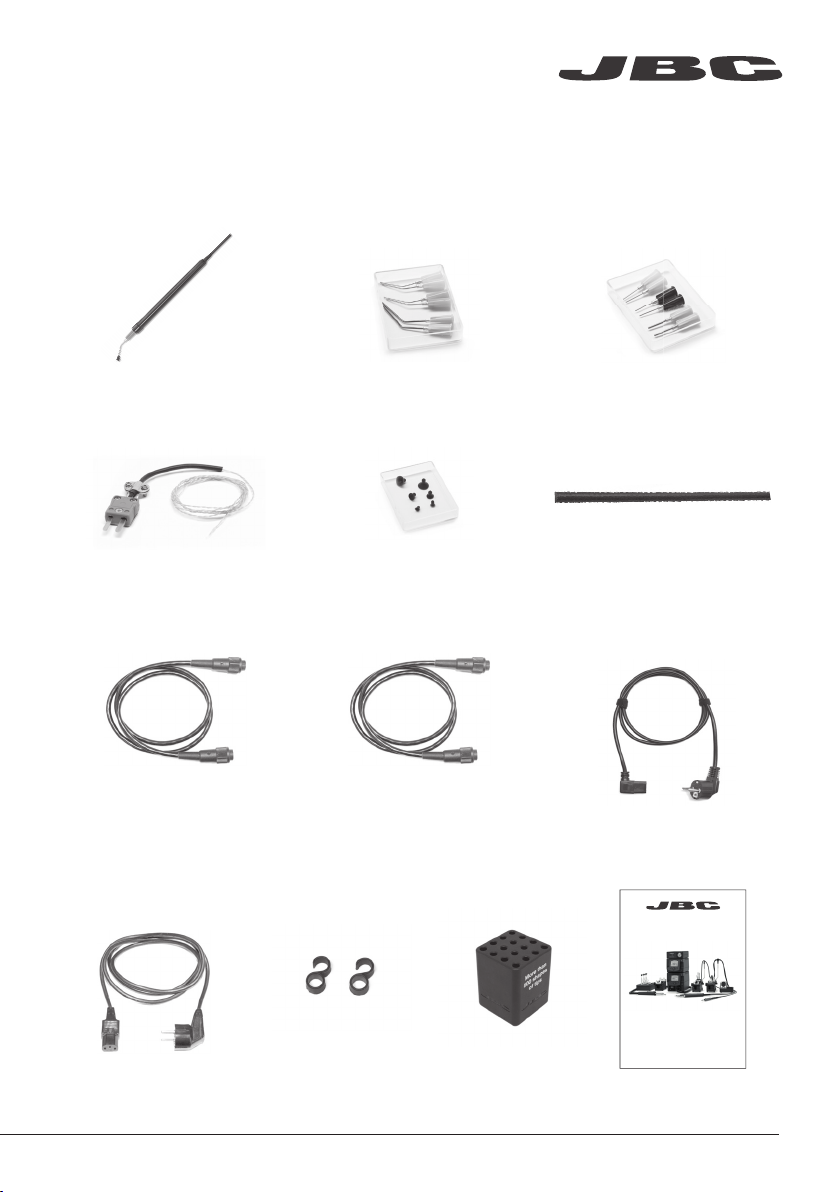

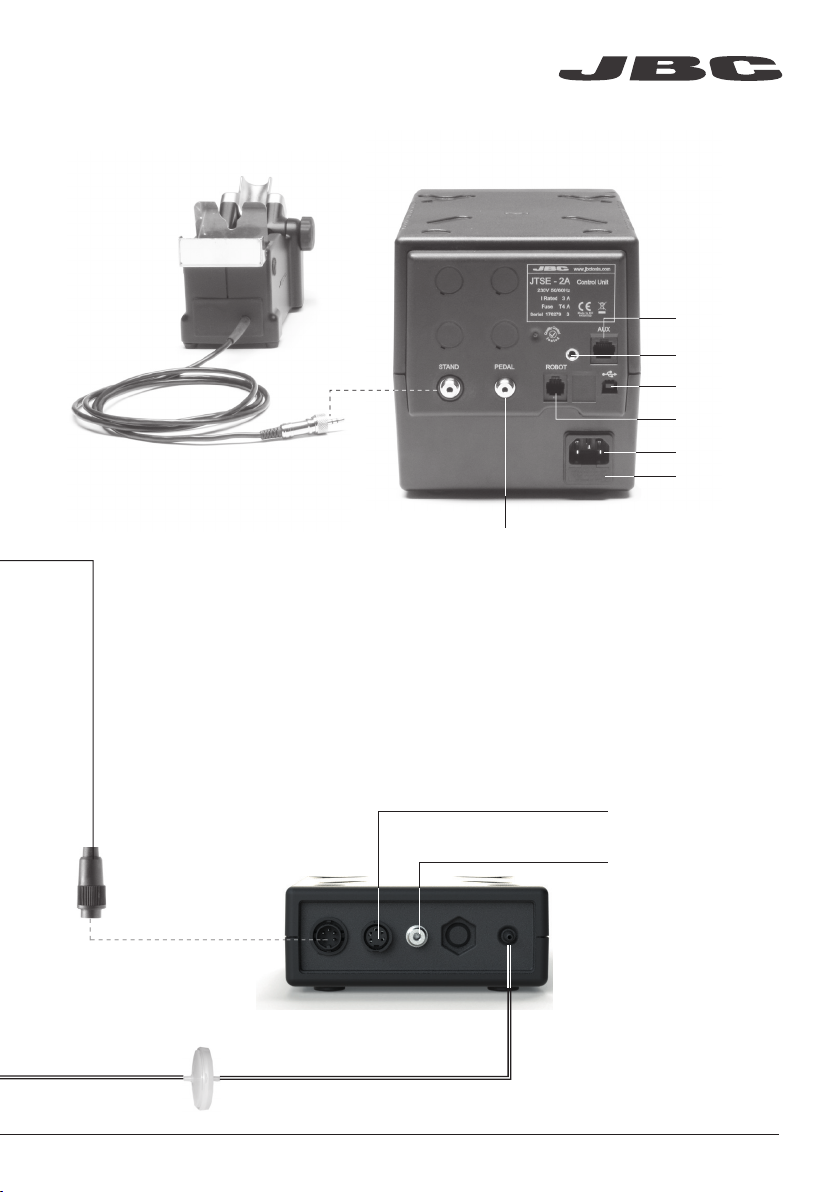

Connections

Work simultaneously with up to 2 tools and join each station port with 1 module + 1 pedal (Peripherals).

Stand Cable

Re f. 001128 3

Equipotential connection

USB-B connector

RJ12 connector for Robot

Power Socket

General

Purpose

Handle

Ref. T245-A

Stand

Ref. AD-SE

Desoldering Iron

Ref. DR560-A

Stand

Ref. DR-SE

6

Page 7

JTSE Connection

Stand

Re f. J T- SE

www.jbctools.com

Auxiliar

connector

Equipotential

connector

USB connector

Robot RS232

connector

Power Socket

Fuse

To Pedal

Ref. P-005* or P-405*

*Not included

Module Cable

Ref. 0 014 874

Suction Filter

Re f. 08 21830

Electric Desoldering Module

Ref. MSE-A

To another peripheral

To Pedal

Ref. P-005* or P-405*

*Not included

7

Page 8

DDE Features

Tilt the display

for easy reading

JTSE Features

USB-A connector2,8” Color TFT screen

Main switch

Thermocouple type K

Ref. PH218

Activates the suction pump

Suction Tube

For tripods and extractors

8

USB-A connector

Main Switch

Heating element

Hot Air button

(On / Off )

Heater Hose set

Re f. J T-T1A (10 0V/12 0V)

JT-T2A (230V )

Page 9

www.jbctools.com

DDE Work Screen

The DDE offers an intuitive user interface which provides quick access to station parameters.

Default PIN: 0105

Status bar

Power

indicator

Displayed if

temperature

levels are

activated

Menu Options

Set the station

parameters

Power

Power

45%

45%

17:14

17:14

T245

T470

ºC

ºC

350

380

Temp. Levels

Temp. Levels

250 350

250 380 400

Set the tool

parameters

380

Port

Port

Tool

in use

1

1

Station

Information

Change

port

Display the hours

worked in each cycle

Station Tools Counters

Consult / modif y the

links of the peripherals

connected to the

station with the por t

they are connected to.

It is possible to

choose the language

from a list.

ResetLanguagePeripherals

Allows you to carry

out an overall station

reset restoring all the

parameters to their

default values.

9

Page 10

Advanced functionalities

It provides detailed graphics of tip temperature and power delivery in real time during

solder joint formation for analysis purposes. This helps you decide how to adjust your

process or which tip to use to obtain the best quality soldering.

Graphics

Designed to avoid thermal shock when soldering Ceramic Chip components like

MLCC, this new and unique feature allows controlling the heating ramp up rate of the

tool to gradually increase the temperature of the

component through all the phases of the soldering process. Up to 25 fully confi gurable

Profi les

JBC Net

Files

soldering profi les can be stored.

The fi rst system to optimize traceability in soldering

- Get greater quality and control in your production

- Manage your whole soldering process remotely in real time

Export graphics

Insert a USB flash drive into the

USB-A connector to save your

soldering process in csv format.

Station update

Download the JBC Update File from

www.jbctools.com/software.html

Update

Insert the USB flash drive with the

file downloadedto the station.

System notifications

The following icons will be displayed on the screen’s status bar.

USB fl ash drive is connected.

Station is controlled by a PC.

Station is controlled by a robot.

10

Station sof tware update.

Press INFO to start the process.

Warning.

Press INFO for failure description.

Er r or.

Press INFO for failure description,

the type of error and how to proceed.

Page 11

MSE Initial Set up

www.jbctools.com

1. After connecting the module, enter the

Peripherals Menu and select the port which

you want to join with the module.

2. Select the module from the list of peripheral

connections. Remember your first connection

is denoted as “a”, the second being “b”, etc.

(e.g. MS _a, M S_b,...).

3. Press Menu or Back to save changes.

Pedal Initial Set up*

1. Enter the Peripherals Menu and select the

port which you want to join to the pedal.

17:14

Peripherals

Pedal PD_a

Module MSE

Port 2-PA

17:14

Peripherals Port 2-DR

Pedal None

Module None

2. Select the pedal from the list (Note that your

first connection is denoted as “a”, the second

being “b”, etc. (e.g. PD_a, PD_b,...).

Peripherals

Pedal PD_a

Module MSE

Module

MSE_a

None

17:14

Port 2-PA

Pedal

PD_a

PD_b

None

3. Set the pedal function according to your work needs:

Select how the pedal

acts: as Sleep,

Extra ctor (hibernation)

or as a module switch.

Select the activating

mode of the pedal

Peripherals Port 2-PA

Pedal PD_a

Function Extractor

Mode released

Minimum time 0 sec

Back

17:14

Set the duration

of the activation

time when pressing

the pedal once**.

For continuous

functioning keep the

pedal pressed.

(pressed/released)

*Ref. P-005 (Not included)

**NB: The same can be applied inversely when continually pressing the pedal and releasing to activate.

11

Page 12

MENU

17:14

?

Port

MENU

17:14

?

Operation

The JBC Most Efficient Soldering System

Our revolutionary technology is able to recover tip temperature extremely quickly. It means the user

can work at a lower temperature and improve the quality of soldering. The tip temperature is further

reduced thanks to the Sleep and Hibernation modes which increase up to 5 times the life of the tip.

3. Hibernation1. Wor k 2. Sleep

Long period

in the stand

When the tool is lifted from

the stand the tip will heat up

to the selected temperature.

17:14

MENU

?

C245-003

ºC

350

Selected 350º

Power

45%

+

Tools Menu:

· Adjust temperature limits and

cartridge.

· Set temperature levels.

Port

3

When the tool is in the stand,

the temperature falls to the

preset Sleep temperature.

Sleep

T

ool in the stand

Actual T

Delay to hibernation: 29:30

Tools Menu:

· Set Sleep temperature.

· Set Sleep delay.

(from 0 to 9 min or no Sleep)

emp. 180º

C

Port

3

Port

3

After longer periods of

inactivity, the power is cut off

and the tool cools down to

room temperature.

Hibernation

Actual Temp. 25ºC

3

Tools Menu:

· Set Hibernation delay.

(from 0 to 60 min or no

hibernation)

12

Page 13

Desoldering process

Use a tip with a larger diameter than the pad to achieve maximum aspiration and thermal efficiency.

www.jbctools.com

1. Placing 2. Rotating

Place the tip over the

lead.

If any solder remains are left on a terminal after desoldering it, resolder it with fresh solder and

repeat the desoldering operation.

If desoldering tips does not provide enough heat to desolder leads from ground planes, consider

using a preheater PCB.

When the solder

melts, gently move

the tip in a circular

motion.

3. Aspirating

Press and hold the

tool button to start the

suction and continue

the movement

completing 3 o 4

circles.

4. Removing

Remove the tip

while maintaining

the suction to make

sure all the solder is

removed from the

joint.

Quick Tip Changer

Save time and change cartridges safely without switching the station off. Be careful, the cartridges

may be hot, when placing them in the storage rack.

1. Removing 2. Inserting 3. Fixing

Place the cartridge in the

extractor and pull the handle

to remove it.

Important: It is essential to

insert the cartridge as far as the

mark for a proper connection.

Place the handle on top

of the new car tridge and

press down.

Mark

D

B

A

Use the holes to fix the

cartridge as follows:

A. For curved C210

B. For C245

C. For straight C210

D. cartridge Storage rack

C

13

Page 14

DR560 Changing Tips

1. Removing

Unscrew the tip using the spanner

supplied.

2. Inserting

Fit the new tip and tighten with the spanner

to make sure it is air tight.

The DR560 uses C560 tips.

Find the model that best suits your soldering needs in www.jbctools.com

Glass Solder Collector Cleaning

1. Removing the lid

Check

internal joint

Check filter

Lid

The lid must be unscrewed with the DR560 in

a vertical position.

3. Inserting the glass solder collector

2. Cleaning

Remove the coil and clean the inside of the

glass solder collector with the cleaning stick.

Check the filter and replace it if it is dirty

or damaged.

The glass solder collector must be inserted

with coil filter in place, positioned between the

2 lines marked.

Then the whole unit must be closed by

screwing the lid.

14

Marks

Page 15

DR560 Maintenance

www.jbctools.com

Tip Care

The intake tube should be periodically cleaned with the largest rod possible.

Important

DO NOT press the vacuum pump button while tinning the desoldering tip, as the fumes given off

by the flux would quickly block the ducts and the air filter.

MSE Changing the pump filters

- Keep the casing clean by using a damp cloth. Periodically check all cable and tube connections.

- Keep filters clean to ensure proper solder suction and replace them when necessary.

Important

Do not use sharp

pointed objects

to open the

suction filter.

Suction filter

Re f. 08 21830

Cotton filters

Ref. 0781046

O Ring

Ref. 0007717

Filter cover

Ref. 0004710

Spare filters

Ref. 0005966

15

Page 16

Tip Cleaner

Improve thermal transfer by cleaning the tip after each solder joint.

Brass wool

Ref. C L6 210

Very ef fective cleaning

method. It leaves a small

layer of solder on the tip to

prevent oxidation bet ween

cleaning and rewetting.

Splashguard

Ref . 0017576

It prevents splashing of

solder particles when

using the brass wool.

Antisplash

Membrane

Ref. 0 0175 74

Prevents splashing

to maintain the

work area clean.

ESD Tip Wiper

Ref. CL0240

A temperature resistant

receptacle lets the

operator remove

excess solder by gentle

tapping or wiping.

Sponge

Ref. S0354

The least harmful

cleaning method. Keep

the sponge damp with

distilled water when

working to avoid tip wear.

Non-slip base

No need to hold the

base while cleaning tips.

Tapping: Wiping:

Tap to remove excess solder. Use the slots to remove remaining particles.

16

Page 17

www.jbctools.com

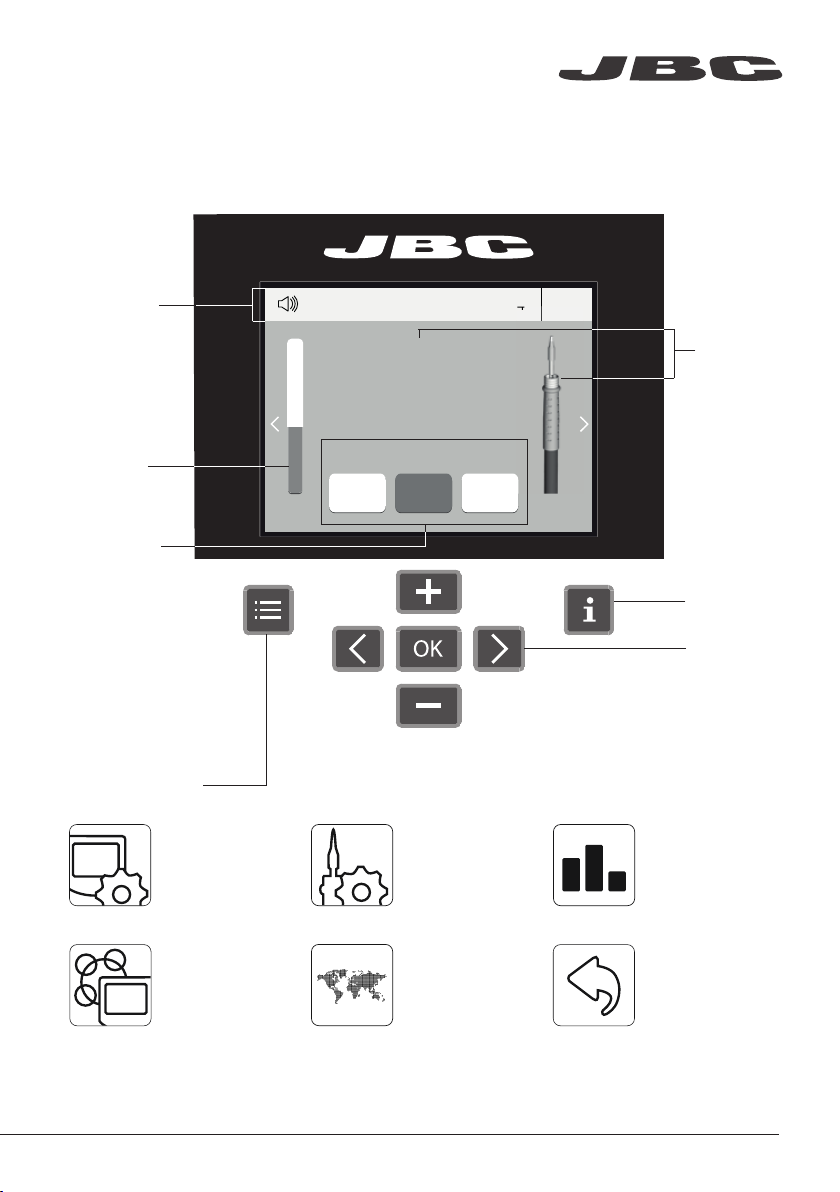

JTSE / TESE Work Screen

The JTSE /TESE offers an intuitive user interface which provides quick access to station pa rameters.

Default PIN: 0105

Status bar

Instant power

supplied to

heater

Current

air

temp.

Air

temp.

selected

Current

Externa l

TC temp.

Menu Options

Set the station

parameters

4m 38s

Hot Air Temp. Air Flow Selec.

ºC

400

400ºC Selected

Power

45%

TC

Temp.

20

Set the tool

parameters

80

ºC

120ºC Selected

17:14

%

Protection

Status

indicator

Selected

Air flow

Selected

External Tc

temp.

Station

Information

Display the hours

worked in each cycle

Station Tools Counters

It is possible to

choose the language

from a list.

ResetLanguage

Allows you to carry

out an overall station

reset restoring all the

parameters to their

default values.

17

Page 18

Point

2/5

Temp

250

ºC

Flow

60

%

Time

2m 30s

3m 18s

Hot Air Temp

240

ºC ºC %

Ext. TC Temp

20

Air Flow

80

3m 18s

Advanced functionalities

To work with profiles it is essential to use the RWB / RWS / RWT rework arms. The

Rework Arms supports the Hot Air Heater maintaining the distance and position to

the component.

Profiles

Profile name

Current

air temp.

Edit Mode

In this mode you can set up or edit as many as 25 profiles of temperature and air flow.

Current

air flow

Current

Externa l

TC temp.

Data for

these points

18

Menu

Options

· Add point

· Delete point

· Load profile

· Save profile

· Exit

Page 19

450

400

350

300

250

150

100

50

200

Power Temp

Graphics

Power (%)

Temperature

JBC Net

Files

Update

www.jbctools.com

By pressing Graphics in the main MENU, temperature and power fi gures in real time

are displayed. This helps you decide which tip to use to obtain the best quality solder

joints.

17:14

Ext. te mp

Externa l

temp.

The fi rst system to optimize traceability in soldering

- Get greater quality and control in your production

- Manage your whole soldering process remotely in real time

Export graphics

Insert a USB flash drive into the USB-A

connector to save your soldering process

in csv format.

Station update

Download the JBC Update File from

www.jbctools.com/software.html

Insert the USB flash drive with the file downloadedto the station.

System notifications

The following icons will be displayed on the screen’s status bar.

USB fl ash drive is connected.

Station is controlled by a PC.

Station is controlled by a robot.

Station sof tware update.

Press INFO to start the process.

Warning.

Press INFO for failure description.

Er r or.

Press INFO for failure description,

the type of error and how to proceed.

19

Page 20

Adjustable Stand

Adjust the tool holder angle to suit your work position.

Operation Modes

1. From the Tool Settings Menu, select the Start mode to activate the tool depending on the task.

Tool button

Press

Press the start/stop button to blow hot air. Set pedal mode (press once or press

2. The tool stops blowing when pressing the start/stop button.

If the stand is connected to the station and for safety it will also stop when returned to the stand.

Pedal

Press

continuously) depending on the task.

P-005* and P-405* pedals are compatible with

JTSE station.

*Not included. See our website.

20

Page 21

Operation

www.jbctools.com

Position the extractor with the

appropriate suction cup and

press the suction button.

2. Heating

Heat the component.

3. Extracting1. Placing

The component lifts off

automatically when the

solder melts.

Protectors & Extractors

For small components (fig. 1 and 2). For large components (fig. 3 and 4).

We recommend using the protector + tripod We recommend using the manual extractors

1 2 3 4

21

Page 22

Pick & Place (not supplied with JT)

This tool helps you place and remove SMDs of any size easily thanks to the suction pump.

Pick & Place

Ref. T260-A

Bent Needles Set

Ref. 0861660

Straight Needles Set

Re f. 090154 6

Operation

Choose the needle and the suction cup that best fits the component and start as follows:

Press the button to

start/stop the suction

Suction cups

1. Suction 2. Release

Maximum working temp: 250º C (482ºF)

Insert the needle with

the appropriate cup

for a correct suction

process.

22

Make sure the needle

does not protrude

from the cup.

Once the suction is

activated, cover the

pen hole with your

finger and lift off the

component.

Lift your finger to

release the component.

Page 23

Accessories

www.jbctools.com

Protectors

* Ref. AxB (mm) AxB (in) * Ref. AxB (mm) AxB (in)

P3353 4,3 x 3 0.1 6 x 0.12 P1249 12 x 23 0.47 x 0.9

P3786 5,2 x 5,2 0.20 x 0.20 44 P4000 12,5 x 12 ,5 0.49 x 0.49

P3352 5,2 x 7,5 0.20 x 0.29 P3354 13, 2 x 13, 2 0.52 x 0.52

P3355 5,2 x 9,5 0.20 x 0.37 P4025 13,5 x 21,5 0.53 x 0.85

P3356 6,2 x 4,2 0.24 x 0.16 48 P2230 15 x 15 0.59 x 0.59

P3785 7, 2 x 7, 2 0.28 x 0.28 60 P4 010 17 x 17 0.67 x 0.67

P3784 8,2 x 8,2 0.32 x 0.32 P4 005 18 x 29 0.71 x 1.14

P4035 9 x 13 0.35 x 0.51 P4030 18,5 x 18 ,5 0.73 x 0.73

P4040 9,5 x 19 0.7 x 0. 74 P1068 18,5 x 24 0.73 x 0.94

P4080 9,5 x 21 9.5 x 0.83 P2685 28,5 x 28,5 1.12 x 1.12

32 P2220 10 x 10 0.39 x 0.39 P4085 31, 5 x 31,5 1. 24 x 1. 24

P4045 10,5 x 21 0.14 x 0.82 P2 672 33 x 46 1. 30 x 1.18

P4090 11 x 16 0.43 x 0.63 P40 02 50 x 50 1.97 x 1.97

24 P2235 12 x 17 0.47 x 0.67 P3357 52,5 x 14 2.06 x 0.55

Extractors

* Ref. AxB (mm) AxB (in) * Ref. AxB (mm) AxB (in)

52 E2052 20 X 20 0.79 x 0 .79 E 40 15 31,5 X 31,5 1.24 x 1.24

64 E2064 20 X 26 0.79 x 1.02 E2084 33 X 33 1. 3 0 x 1.3 0

80 E2184 24 X 24 0.94 x 0.94 E2 100 38 X 38 1.5 0 x 1.50

E2068 27 X 27 1.0 6 x 1.06 E212 4 45 X 45 1.7 7 x 1.77

E4020 28,5 X 28,5 1.12 x 1 .12

Trip ods

Ref. øC (mm) øC (in)

T2050 39 1.5 3

T2250 85 3.35

Manual extractor

Ref. øD (mm) øD (in)

E2190 7 0.27

øD

* Reference Desk

23

Page 24

Using the Thermocouple type K

Connect a TC type K (PH218) to the station and use it as a protection or regulation sensor.

You can define its use mode by means of the “Ext TC mode” option in the “Tool” menu.

You can choose from two work modes:

Regulation: the station regulates the air

temperature automatically to maintain the

External Thermocouple (TC) temperature.

Fix the TC with Kapton Tape (Ref. PH217) as near as possible to the component being worked on.

If Kapton tape is not ESD you must use an ionizer.

IPC* does not recommend exceeding ramp-up rates over 3-4ºC / sec. (5-7ºF / sec) so as to reduce

the risk of thermal stress on the PCB.

Protection: the station cuts the air supply off

when the External Thermocouple (TC)

temperature is reached.

* IPC was founded in the U.S. in 1957 as the Institute for Printed Circuits.

24

Page 25

www.jbctools.com

Quick Nozzle Changer

Changing nozzles quickly and safely.

2

Turn the tool

off and handle with

care. The heating

element and the

nozzle are still hot.

Compatible Nozzles

The JT-TA works with JT nozzles. Find the model that best suits your soldering needs in www.jbctools.com

Straight Bent Flat

Ø Ø A x B

1

* Ref. Shape Ø Size

(mm)ØSize (in)

* JN2020 Straight Ø 8 Ø 0.31

JN8417 Straight Ø 10 Ø 0.4

* JN2015 Bent Ø 4 Ø 0 .16

* J N2 012 Bent Ø 6 Ø 0.24

JN6633 Bent Ø 8 Ø 0.31

JN7637 Flat 10 x 2 0.4 x 0.08

JN7638 Flat 20 x 2 0.8 x 0.08

JN7639 Flat 30 x 2 1.18 x 0.08

In case of a loosely fitting nozzle:

1. Push the nozzle tab inwards with a screwdriver or flat-nosed pliers.

* Included in JT Accessory set (Ref. 0012332)

2. Insert the nozzle into the JT-TA again.

25

Page 26

Replacing the Heating Element

Only perform this operation when the element is cold and the unit is disconnected from the mains.

1. Loosen the screw.

2. Pull the heating element out of the handle.

3. Connect the new heating element, ensuring it is pushed all the way in.

4. Tighten the screw.

Heating Element

Ref. 0014107 (230V)

0014105 (100V / 120V)

Handle

Ref. 0009829

Heating Hose Set

Ref. JT-T1A (100V / 120V)

JT-T2A (230V )

Changing the JT-TA Heater Hose Set

1. Unplug the power cable.

2. Use a spanner to unscrew the nut.

3. Make sure that the new heater tube fits into

the grooves in the socket.

4. Tighten the screw.

26

Page 27

DDE Compatibility

Select the equipment that best suit your soldering or desoldering needs.

Basic working system Peripherals

Control

Unit

DDE-C

Stand Too l

AD-SE

DN-SE

AP-SE AP250 -A C250

PA-SE PA120-A C120

HT- S E HT420-A C420

DS-SE DS360-A C360

DR-SE DR560-A C560

T210 -A C 210

T245 -A C245

T210- NA* C210

T24 5-N A* C245

* The MNE Nitrogen Flow Regulator is required.

** MSE / MVE Desoldering module required.

Cartridge

Range

MSE-A /

MVE-A

MNE-A FSE-A P-005**

www.jbctools.com

MSE Compatibility

Module To ol

MSE-A

DS360-A C360 DS-SE

DR560-A C560 DR-SE

Cartridge

Range

Stand

Hot Air Stations Compatibility

Basic working system Nozzle Peripherals

Control

Unit

JTSE-A

TESE-B

Too l Heating Element Stand JN Series TN Series P-005

JT- A

TE-B 0012374 (100V/120V/230V) TE-SE

0014107 (230V)

0014105 (100V/120V)

Control Units Peripherals

DDE DME P-005

JT- S E

27

Page 28

Maintenance

Before carrying out maintenance or storage, always allow the equipment to cool.

- Clean the station screen with a glass cleaner

or a damp cloth.

- Use a damp cloth to clean the casing and the

tool. Alcohol can only be used to clean the

metal parts.

- Periodically check that the metal parts of the

tool and stand are clean so that the station

can detect the tool status.

- Maintain tip surface clean and tinned prior to

storage in order to avoid tip oxidation. Rusty

and dirty surfaces reduce heat transfer to the

solder joint.

- Periodically check all cables and tubes.

- Replace a blown fuse as follows:

Clean periodically

Fuse

Fuse holder

1. Pull of f the fuse holder and remove the

fuse. If necessary use a tool to lever it off.

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

2. Press the new fuse into the fuse holder

and replace it in the station.

28

Fuse holder

Page 29

www.jbctools.com

Safety

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

- Do not use the units for any purpose other than soldering or rework. Incorrect use may cause fire.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded

before use. When unplugging it, hold the plug, not the wire.

- Do not work on electrically live parts.

- The tool should be placed in the stand when not in use in order to activate the sleep mode.

The soldering tip, the metal part of the tool and the stand may still be hot even when the station

is turned off. Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- Do not cover the ventilation grills. Heat can cause inflamable products to ignite.

- Avoid the contact of flux with skin or eyes to prevent irritation.

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight and also persons with reduced

physical, sensory or mental capabilities or lack of experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance.

- Maintenance must not be carried out by children unless supervised.

29

Page 30

有害物质含量表

产品中有害物质的名称及含量

有害物质

部件名称

铅(Pb) 汞(Hg) 镉(Cd)

烙铁头 O O O O O O

手柄 O O O O O O

电源线 O O O O O O

主机 O O O O O O

电源插座 O O O O O O

保险丝 O O O O O O

主开关 O O O O O O

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

电位连接 X O O O O O

变压器 O O O O O O

线路板 X O O O O O

O 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572 规定的限量要求以下。

X 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572 规定的限量要求。

30

Page 31

www.jbctools.com

Specifications

Complete Rework station with Electric Pump

RMSE-1QE / RMSE-2QE / RMSE-9QE

J TSE-1A 100V - 120V 50/60Hz. Input fuse: 8A. Rated current: 7A

JTSE-2A 230V 50/60Hz. Input fuse: 4A. Rated current: 3A

- Nominal power: 700W

- Temperature selection: Room temp. / 150 - 450 °C (300 - 840 °F)

Cool mode: T off. Used to blow air to room temperatur

- Ambient operating temp.: 10 - 50 ºC (50 - 122 ºF)

- Air flow regulation: 5 - 50 SLPM

- Vacuum: 30% / 228 mmHg / 9 inHg

- Connectors: USB-A / USB-B

RJ12 for RS232 (Robot)

Pedal for P-005

- Control Unit Weight: 1,9 kg (4.2 lb)

- Control Unit Dimensions: 148 x 184 x 140 mm (5.83 x 7.24 x 5.51 in)

DDE-1A 120V 50/60Hz. Input fuse: 4A. Output: 23.5V

DDE-2A 230V 50/60Hz. Input fuse: 2A. Output: 23.5V

DDE-9A 100V 50/60Hz. Input fuse: 5A. Output: 23.5V

- Temperature Range: 90 - 450 °C (190 - 840 ºF)

- Idle Temp. Stability (still air): ±1.5 ºC (±3 ºF)

- Output Peak Power: 150W per tool

- Tip to ground resistance: <2 ohms

- Tip to ground voltage: <2mV RMS

- Ambient Operating Temperature: 10 - 50 ºC (50 - 122 ºF)

- Connectors: USB-A / USB-B / Peripherals connectors

RJ12 for RS-232 (Robot)

- Control Unit Weight: 3,815 kg (8.41 lb)

- Control Unit Dimensions: 148 x 120 x 232 mm (5.83 x 4.72 x 9.13 in)

MSE-A

- Ambient Operating Temperature: 10 - 50 ºC (50 - 122 ºF)

- Vacuum: 75% / 570 mmHg / 22.4 inHg

- Flow rate: 9 SLPM

- Peripheral Weight: 1,2 kg (2.7 lb)

- Peripheral Dimensions: 145 x 55 x 225 mm (5.71 x 2.17 x 8.86 in)

- Connectors Pedal for P-005

- Total Package: 480 x 340 x 380 mm / 15.90 kg

18.9 x 14.6 x 15.0 in / 35.05 lb

Complies with CE standards.

ESD protected housing.

31

Page 32

Warranty

JBC’s 2 year warranty covers this equipment against

all manufacturing defects, including the replacement

of defective parts and labour.

Warrant y does not cover product wear or misuse.

In order for the warranty to be valid, equipment must

be returned, postage paid, to the dealer where it was

purchased.

Get 1 extra year JBC warranty by registering here:

https://www.jbctools.com/productregistration/

within 3 0 days of purchase.

This product should not be thrown in the garbage.

In accordance with the European directive 2012/19/EU, electronic equipment at the end of its life must

be collected and returned to an authorized recycling facility.

www.jbctools.com

0023140-0819

Loading...

Loading...